Page 1

imaging Series

4:2:2 Component

ASD-111i

Guide to Installation and Operation

M293-9900-201

Copyright 2002 Miranda Technologies Inc.

Specifications may be subject to change.

Printed in Canada

August 2002

Analog to Digital

Converter

1i

Miranda

Technologies inc.

3499 Douglas-B.-Floreani

St-Laurent, Québec, Canada H4S 1Y6

Tel. 514-333-1772

Fax. 514-333-9828

www.miranda.com

-11

ASD

Page 2

i

Page 3

WARRANTY POLICIES

Warranty Statement

Miranda Technologies Inc. warrants that the equipment it manufactures shall be free from defects in

material and workmanship for a period of two (2) years from the date of shipment from the factory. If

equipment fails due to such defects, Miranda Technologies Inc. will, at its option, repair or provide a

replacement for the defective part or product. Equipment that fails after the warranty period, has been

operated or installed in a manner other than that specified by Miranda, or has been subjected to abuse or

modification, will be repaired for time and material charges at the Buyer’s expense.

All out-of-warranty repairs are warranted for a period of ninety (90) days from the date of shipment from

the factory.

Miranda Technologies Inc. makes no other warranties, expressed or implied, of merchantability, fitness

for a particular purpose or otherwise. Miranda’s liability for any cause, including breach of contract,

breach of warranty, or negligence, with respect to products sold by it, is limited to repair or replacement

by Miranda, at its sole discretion. In no event shall Miranda Technologies Inc. be liable for any incidental

or consequential damages, including loss of profits.

Effective January 1, 2002

Warranty Exchange Policies

Miranda Technologies Inc. warrants that the equipment it manufactures shall be free from defects in

materials and workmanship for a period of two (2) years from the date of shipment from the factory. If

equipment fails due to such defects, Miranda will provide repair of the failed unit under the terms of the

Miranda warranty.

If the equipment has been proven to be defective on arrival, Miranda will ship a new product in exchange,

usually within 36 hours of factory notification.

If the equipment to be repaired is essential and the customer so requests, Miranda will, at its option,

provide a service replacement or loaner part or product, usually within 36 hours of factory notification,

weekends and holidays excluded.

All warranty exchange or loaner parts or products shall be shipped to the Buyer with a packing list clearly

describing the items and stating the date of shipment. Repaired parts or products will be shipped to the

Buyer with a similar packing list. In the case of exchange, the defective products or parts must be

returned to Miranda within fifteen (15) days from receipt by the customer of the exchange product. In the

case of a loaner, the loaned products or parts must be returned to Miranda within fifteen (15) days from

receipt by the customer of the repaired equipment.

If the equipment is not returned within fifteen (15) days, as described for either exchanges or loans, A

Rental Invoice will be generated. Rental terms will be fifteen (15) percent of the current list price of the

products or parts per month or a fraction thereof. Before returning the equipment to Miranda

Technologies Inc., for any reason, the Buyer must first obtain a Return Authorization Number from

Miranda Technologies Inc. Miranda Technologies Inc will pay freight and insurance charges for the

delivery of the loaner or exchange products or parts. Freight and insurance charges for the return of the

defective product or part will also be paid by Miranda Technologies.

Out-Of-Warranty Repair Policy

Miranda will repair equipment which is out of Warranty. The current pricing structure for this service is

available from the Miranda web site at

at (514) 333-1772. All out-of-warranty repairs are warranted for a period of 90 days from the date of

shipment from the factory. Before returning the equipment to Miranda Technologies Inc., for any reason,

the Buyer must first obtain a Return Authorization Number from Miranda Technologies Inc. In the case of

a product deemed by Miranda to be beyond repair, the customer must purchase a new product at current

retail prices.

The Buyer will pay freight and insurance charges for the return of the defective product or part to the

manufacturer for repair. Miranda Technologies will pay freight and insurance charges for the return of the

repaired product or part to the Buyer.

www.miranda.com

or from Miranda Technical Support Services

ii

Page 4

Out-Of Warranty Equipment Updates and Spare Parts Policy

Miranda Technologies’ current pricing structure for out-of-warranty equipment updates, or the sale of

spare parts, is available from Miranda Technical Support Services at (514) 333-1772.

ELECTROMAGNETIC COMPATIBILITY

- This equipment has been tested for verification of compliance with FCC Part 15,

Subpart B, class A requirements for Digital Devices.

- This equipment complies with the requirements of EN55022 Class A, Electromagnetic

Emissions, En 60555-2 & -3, Disturbance in Supply Systems and EN50082-1,

Electromagnetic Immunity.

How to contact us:

Head Office Miranda Europe Miranda Asia

Miranda Technologies Inc. 222, 226 Rue De Rosny Mita Nexus Bldg. 2F

3499 Douglas-B.-Floreani 93100 Montreuil 1-3-33 Mita, Minato-Ku

St. Laurent (Montreal), Que. H4S 1Y6 France Tokyo, Japan 108-0073

Canada

Tel +1 (514) 333-1772 +33 1 55 86 87 88 +81 3 5730 2988

Fax +1 (514) 333-6914 +33 1 55 86 00 29 +81 3 5730 2973

Toll free: 1-800-224-9828

www.miranda.com

iii

Page 5

Contents

1 ASD-111i 4:2:2 Analog to Digital Converter...........................................................

1

1.1 Introduction.......................................................................................................... 1

1.2 Features............................................................................................................... 1

2 Installation................................................................................................................ 3

2.1 ASD-111i Mechanical Installation........................................................................ 3

2.1.1 imaging Quartet, Quartet-C and Quartet-M Housing Frame......................

3

2.1.2 imaging Symphonie Housing Frame.......................................................... 3

2.1.2 imaging Solo Housing Frame.....................................................................

3

2.2 Rear Panel Label................................................................................................. 4

2.2.1 imaging Quartet/Quartet-C/Quartet-M/Solo Connector Label...................

4

2.2.2 imaging Symphonie Connector Label........................................................ 4

2.3 ASD-111i Electrical Installation............................................................................

5

3 Operation.................................................................................................................. 7

3.1 ASD-111i User Interface...................................................................................... 7

3.2 Line Format Status and Error Detection.............................................................. 8

3.3 Input Signal Format Selection..............................................................................

9

3.4 Automatic Calibration with Error Status............................................................... 9

3.5 Manual Calibration of Gain, Offset and Horizontal Centering..............................

10

3.6 Recalling Default Values......................................................................................

11

3.7 Vertical Ancillary Data Masking........................................................................... 12

3.8 Sync Selection..................................................................................................... 12

3.9 Coring Selection...................................................................................................

12

4 Specifications........................................................................................................... 13

5 Schematic Diagrams................................................................................................ 15

iv

Page 6

v

Page 7

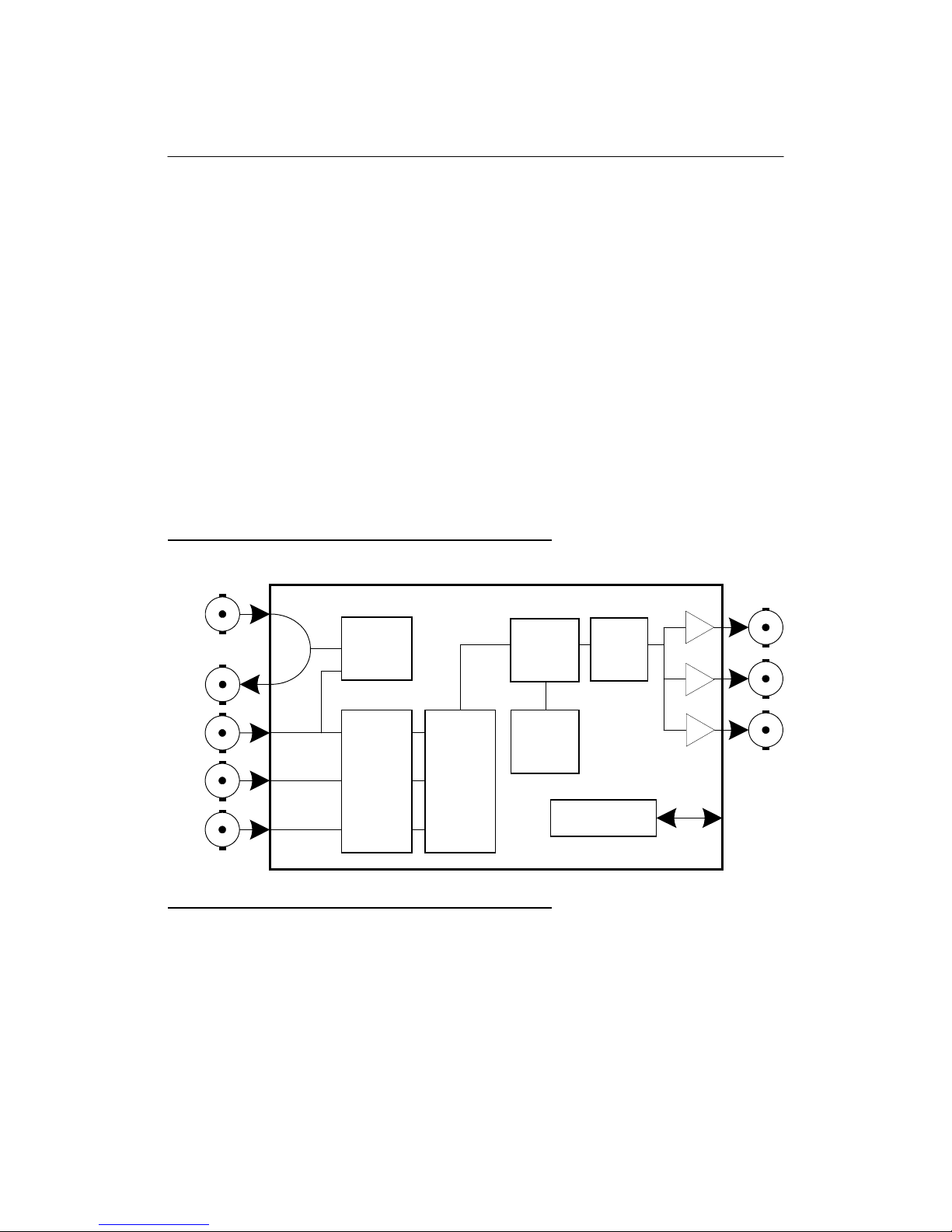

1 ASD-111i 4:2:2 Analog to Digital Converter

1.1 Introduction

The ASD-111i is a high-quality 10-bit analog to digital 4:2:2 video converter. A wide

range of component analog video (CAV) inputs are supported including GBR,

SMPTE/EBU, Betacam, and MII. Its microcontroller-based technology simplifies

switching from one standard to another. As an EDH inserter, the ASD-111i will insert

EDH Check Sum and Flag information into the outgoing serial signal. The ASD-111i's

powerful automatic calibration feature can accommodate a non-standard video or

correct a calibration defect in the incoming video signal. Factory set with 11 different

formats, all user configurations are stored in non-volatile memory for ease of use.

The ASD-111i's digital oversampling offers the best signal quality, while digital

processing eliminates the need for analog adjustments. A total of three 4:2:2 serial

digital video outputs are supplied; all 4:2:2 outputs conform to the SMPTE 259M

standard.

The ASD-111i is a member of the imaging family of digital video cards and therefore

requires the imaging Quartet, Quartet-C or Quartet-M, imaging Solo or imaging

Symphonie housing frame for mounting and power.

Figure 1.1 ASD-111i Functional Block Diagram

REF IN

G/Y

B/B-Y

R/R-Y

Genlock

Color

Space

Converter

ADC

Formatter

Calibration

Generator

1.2 Features

• GBR, SMPTE/EBU, Betacam

and MII analog inputs

• Automatic 525/625 input detection

• Studio reference input with loop-through

• Three 4:2:2 serial digital video outputs

• High-quality 10-bit signal path

• 2X oversampling

&

Test

Microcontroller

EDH

Insertion

REMOTE

CONTROL

1

4:2:2

2

OUT

3

1

Page 8

• Automatic input calibration

• Pre-calibration for 11 formats

• EDH Insertion (as per SMPTE-165M)

• Built-in color bars

• Black on loss of signal

• Horizontal centering adjustment

• External or sync-on-green sync selection

• Masking capability of incoming vertical ancillary data

• Coring function enabled with jumper setting

2

Page 9

2 Installation

2.1 ASD-111i Mechanical Installation

The ASD-111i must be mounted within Quartet, Quartet C, Quartet M,

Symphonie or Solo imaging housing frames in order to provide power to the

card. This section describes how to install the ASD-111i in any of these housing

frames. It is not necessary to switch off the power from these housing frames

when installing the SDM-111i.

2.1.1 imaging Quartet, Quartet C and Quartet M Housing Frames

To install this card into Quartet, Quartet C or Quartet M follow these steps. For a

closer look at card installation and removal, refer to the housing frame's Guide to

Installation and Operation.

1. Remove the housing frame's front panel by rotating the thumb screws

counter-clockwise. Pull on the handles.

2. Select an empty slot.

3. Carefully place the ASD-111i between a set of card guides and gently push

the card towards the rear of the housing frame until the card's edge

connector is secured to the backplane. Pull lightly on the card verifying that

it does not move.

4. Replace the housing frame's front panel. Make sure to rotate the thumb

screws clockwise in order to secure it to the chassis.

2.1.2 imaging Symphonie Housing Frame

To install this module into Symphonie follow these steps. For a closer look at

module installation and removal, refer to the frame's Guide to Installation and

Operation. You also need to install Symphonie-R-M or –R-C rear module for

complete installation.

1. Remove the front panel door by pulling on the door handles and gently

lowering it.

2. Select an empty compartment.

3. Carefully place the SDM-111i between the module guides and slowly push

the module towards the rear of the frame until the module's edge connector

is secured to its rear module. A light pressure to mate the connectors may

be required. Pull lightly on the module verifying that it does not move.

4. Replace the front panel door.

2.1.3 imaging Solo Housing Frame

To install this card into Solo follow these steps. For a closer look at card

installation and removal, refer to the housing frame's Guide to Installation and

Operation.

1. In order to remove the housing frame's front panel, gently pull on it.

3

Page 10

2. Carefully place the ASD-111i between the card guides and gently push the

card towards the rear of the housing frame until the card's edge connector is

secured to the backplane. Pull lightly on the card verifying that it does not

move.

3. Replace the housing frame's front panel.

2.2 Rear Panel Label

2.2.1 imaging Quartet/Quartet-C/Quartet-M/Solo Connector Label

A connector label has been shipped with your ASD-111i. This label is to be

installed on the housing frame's rear panel in order to identify the ASD-111i external

connectors. To install the label, follow these steps.

1. Remove the screws associated with the ASD-111i connectors.

2. Carefully apply the label to the connectors as shown in Figure 2.1.

3. Replace the screws making sure not to damage the label.

Figure 2.1 ASD-111i rear panel label installation

ASD-111i label

imaging Quartet

or

imaging Solo

(top view)

2.2.2 imaging Symphonie Connector Label

To install the Symphonie label, follow these steps while referring to Figure 2.2.

1. On Symphonie’s rear panel, locate the appropriate connectors.

2. Remove the rear label mounting screws from the rear module.

3. Carefully apply the label to the connectors making sure the label’s text is read

from top to bottom.

4

Page 11

4. Replace the screws making sure not to damage the label.

Figure 2.2 Symphonie rear panel label installation

REF IN

Label

ASD-111i COMPONENT ANALOG VIDEO TO 4:2:2 CONVERTER

G/Y

IN

B/B-Y R/R-Y

1 2 3

4:2:2 OUT

Rear module

2.3 ASD-111i Electrical Installation

When connecting the ASD-111i to external equipment, make sure that all serial

digital connections are point-to-point. For instance, there must be a point-to-point

connection between a 4:2:2 OUT BNC and target equipment. If a T-connector is

used to connect other equipment, the maximum specified cable length is no longer

valid.

5

Page 12

Also, make sure that the cable lengths of the output serial digital cables are a

maximum 250m (850') each. Refer to Figure 2.2 and to the following descriptions for

a complete ASD-111i electrical installation.

Studio reference input with loop-through output

For external synchronization, connect the studio reference signal to the BNC labeled

REF IN. To enable this input make sure the GBR SYNC jumper is in the REF

position. Refer to section 3, Operation.

When the REF IN BNC is in use, its loop-through output should be 75 ohm

terminated if it is not being used.

CAV inputs

Supported CAV input formats include GBR, SMPTE/EBU, Betacam, and MII. After

installing the CAV inputs make sure to program the ASD-111i for the appropriate

input format. Refer to section 3, Operation.

4:2:2 Serial digital video outputs

4:2:2 Serial digital component video signals are provided on the BNC connectors

labeled 4:2:2 OUT (1 to 3). These output signals conform to the SMPTE 259M

standard.

Figure 2.2 ASD-111i connections

ASD-111i COMPONENT ANALOG VIDEO TO 4:2:2 CONVERTER

REF IN

ASD-111i Back (Symphonie-R-C, Quartet and Quartet-C and Solo)

ASD-111i COMPONENT ANALOG VIDEO TO 4:2:2 CONVERTER

G/Y B/B-Y R/R-Y

REF IN

G/Y B/B-Y R/R-Y

IN

IN 4:2:2 OUT

ASD-111i Back (Symphonie-R-M, Quartet-M)

1 2 3

4:2:2 OUT

1 2

3

6

Page 13

3 Operation

3.1 ASD-111i User Interface

Figure 3.1 outlines the ASD-111i's user interface situated at the front end of the card.

The interface components include, from left to right:

• Line format status and error detection.

• Input signal format selection.

• Automatic calibration with error status.

• Manual calibration of gain, offset, and horizontal centering.

Location of the ASD-111i's jumpers on the card are indicated by figure 3.2. The

jumpers are:

• Vertical ancillary data masking jumper.

• Sync selection jumper.

• Coring selection jumper.

For operating information on the above functions, refer to the rest of this section.

Figure 3.1 Front panel interface

525 625 ERR

green

yellow

red

FORMAT

INPUT

GBR

BETA

SETUP

MIISMPTE

ASD-111i COMPONENT ANALOG VIDEO TO 4:2:2 CONVERTER

CALIB

ERR

TEST

MANUAL CALIBRATION

7

SELECT

Y

Y

B-Y

R-Y

OFST

GAIN

GAIN

GAINHCENTER

Page 14

Figure 3.2 Jumpers location

ASD-111i COMPONENT ANALOG VIDEO TO 4:2:2 CONVERTER

H

3.2 Line Format Status and Error Detection

The following indicators provide information on the ASD-111i's line format status.

Refer to Figure 3.1 for the correct indicator location.

• 525

This LED lights up to indicate the ASD-111i has detected a CAV input with a 525

line format.

• 625

This LED lights up to indicate the ASD-111i has detected a CAV input with a 625

line format.

• ERR

This LED lights up to indicate that no sync is being detected. During this time,

the corresponding 525 or 625 line format LED indicates the last valid format. At

all times, make sure that all CAV input signals are firmly installed and that source

equipment is functional. Also, depending on your installation, make sure the

ASD-111i is properly configured for external or sync-on-green synchronization.

8

Page 15

3.3 Input Signal Format Selection

The ASD-111i must be informed on the type of CAV input installed. The choices of

CAV inputs, as they successively appear when scrolled through, is shown in Figure

3.3 below. In order to program the appropriate format, use the FORMAT push-button

to scroll through the choices of CAV inputs. In more detail, follow these steps.

1. The current CAV format programmed for the ASD-111i is indicated by the status

of its corresponding LED. The list of LEDs are GBR, SMPTE, BETA, MII and

SETUP. Press the FORMAT push-button to select the next available CAV

format. Use Figure 3.3 as a guide.

2. After each key press, a new CAV format with or without setup is selected. If, for

instance, the SMPTE/EBU format is selected and FORMAT is pressed, then the

BETA LED will turn on and the ASD-111i will be programmed to receive a

Betacam signal without setup. One more key-press will program the ASD-111i

for Betacam with setup. When a format with setup is chosen, the yellow SETUP

LED will turn on.

3. Whenever power is removed from the ASD-111i, the CAV format programmed

prior to the removal of power is recorded. This recorded CAV format is used

when the ASD-111i is re-powered.

Figure 3.3 CAV format selection

Æ

525:

625:

GBRÆGBR w. setupÆSMPTEÆBETAÆBETA w. setupÆMIIÆMII w. setup

Æ

GBRÆSMPTEÆBETAÆMII

3.4 Automatic Calibration with Error Status

The automatic calibration function adjusts the gain and offset levels of the input CAV

signals in order to conform the output 4:2:2 serial digital signal to the SMPTE 259M

standard.

The ASD-111i executes automatic calibration by searching distinct areas in the video

signal for proper sampling. For this reason, it is highly recommended that a 75%,

100%, or SMPTE color bars test pattern be installed whenever performing automatic

calibration. Follow these in order to execute automatic calibration.

1. Install a 75%, 100%, or SMPTE color bars test pattern in the required video

format. If these test patterns are not available, ensure that the input signal has

yellow, cyan, and black situated in the zones as indicated in Figure 3.3.

2. Use the FORMAT push-button to select the video format being processed.

9

Page 16

3. Depress the CALIB. push-button for more than 2 seconds in order to execute

automatic calibration. For several seconds, the ASD-111i will attempt to conform

the output 4:2:2 signal to the SMPTE 259M standard. During this time, the ERR

calibration LED will flicker. The flickering will stop automatically after a complete

and successful calibration. Both offset and gain levels for the current format are

automatically stored.

4. If a particular parameter of the signal could not be calibrated, it will be indicated

by the ERR LED and the manual calibration LEDs. For example, if automatic

calibration failed to properly adjust Y gain, then the Y GAIN LED will be lit. Press

any push-button in order to cancel automatic calibration. No offset or gain levels

for the current format are stored.

Figure 3.3 Input signal sampling zones required during automatic calibration

White Yellow Cyan Green Magenta Red Blue Black

Y gain and B-Y gain

sampling zone

R-Y gain sampling zone

Y OFST (in setup format)

sampling zone

Y OFST (in non-setup format), B-Y OFST, and R-Y OFST sampled during blanking

3.5 Manual Calibration of Gain, Offset and Horizontal Centering

The manual calibration interface consists of the SELECT, +,

Y GAIN, Y OFST, B-Y GAIN, R-Y GAIN, and H CENTER LEDs. The list of

adjustable parameters include G/Y offset, gain for G/Y, B/B-Y, and R/R-Y, and

horizontal centering. When a parameter is selected, its corresponding LED lights up.

After manual calibration is enabled, a 1 minute delay with no push-button selection

will automatically disable manual calibration. However, any changes made are

stored.

To manually calibrate the ASD-111i refer to the following steps.

- push-buttons and the

10

Page 17

1. Make sure the ASD-111i is programmed for the type of input CAV signal being

processed. Use the FORMAT push-button to make any modifications. Refer to

the note following this procedure.

2. Depress the SELECT push-button. The Y GAIN, B-Y GAIN and R-Y GAIN LEDs

light up. Using the +/- push-buttons, a grouped gain calibration can be

performed.

3. Depress the SELECT push-button. The Y GAIN, B-Y GAIN and R-Y GAIN LEDs

turns off and the Y GAIN LED lights up. The +/- push-buttons may now be used

to adjust the output G/Y gain.

5. Depress the SELECT push-button. The Y GAIN LED turns off and the Y OFST

LED lights up. The +/- push-buttons may now be used to adjust the output G/Y

offset.

6. Depress the SELECT push-button. The Y OFST LED turns off and the B-Y

GAIN LED lights up. The +/- push-buttons may now be used to adjust the output

B/B-Y gain.

5. Depress the SELECT push-button. The B-Y GAIN LED turns off and the R-Y

GAIN LED lights up. The +/- push-buttons may now be used to adjust the output

R/R-Y gain.

6. The next parameter to be adjusted is horizontal centering. Horizontal centering

is the timing difference between the active video and the horizontal sync.

Depress the SELECT push-button. The R-Y GAIN LED turns off and the H

CENTER LED lights up. Use the +/- push-buttons to adjust the horizontal

centering which has an adjustment range of -8 to +6 pixels by steps of

approximately 1 ns. Alternatively, depressing and holding the FORMAT pushbutton while using the +/- push-buttons allows to make steps of 1/2 pixel.

7. Depress the SELECT push-button once again in order to store the new changes

and to disable manual calibration.

Note: You cannot adjust the Y GAIN for a format with setup if you do not have a

75%, 100%, or SMPTE color bars input CAV signal. This is due to the

fact that during manual calibration of the Y GAIN an automatic black level

correction is performed and therefore requires a signal with the correct

sampling zones. Refer to Figure 3.3. However, this constraint is not

applied when a non-setup format is employed because the automatic Y

OFST correction samples in the blanking region.

3.6 Recalling Default Values

In order to recall default values of the current video format make sure you are out of

manual calibration mode. Then, simultaneously press the +/- push-buttons. This

action will erase any changes made to the parameters by the user and recall the

default factory-set parameters. However, this procedure does not recall the H

CENTER parameter.

11

Page 18

In order to recall the default value of the H CENTER, you must enable manual

calibration by depressing the SELECT push-button until the the H CENTER LED

lights up. Finally, depress the +/- push-buttons simultaneously. This action will

erase any changes made to the the H CENTER parameter by the user.

3.7 Vertical Ancillary Data Masking

Any vertical ancillary data found on the CAV input signal lines listed in Table 3.2 may

be masked by the V ANC jumper. Perform the following steps in order to mask

vertical ancillary data or to allow it to pass through the ASD-111i.

1. Locate the V ANC jumper situated on the left side of the ASD-111i (refer to figure

3.2 for location).

2. To buffer through any vertical ancillary data set the jumper in the ON position. To

mask vertical ancillary data set the jumper in the OFF position.

Table 3.2 Masked video lines for 525 and 625 line formats

Masked Lines

525 Line

format

625 Line

format

10 to 19 and 273 to

281

6 to 22 and 319 to

335

3.8 Sync Selection

The ASD-111i can be synchronized to external equipment using an external

reference signal or sync information on the G/Y CAV input. In order to select

between the two modes of synchronization, refer to the following steps.

1. Locate the SYNC jumper (LK1) situated at the top right corner of the module

(refer to figure 3.2 for location).

2. If you are planning to use the studio reference signal to synchronize the ASD111i, set the jumper in the REF position. Make sure the studio reference signal

is connected to the REF IN connector on the rear panel.

3. In order to synchronize the ASD-111i to the G/Y CAV input signal set the jumper

to the G position. Make sure the G/Y input signal contains sync information.

3.9 Coring Selection

Coring reassigns any digital data points situated about the blanking level of the B/B-Y

and R/R-Y inputs, which do not have exact blanking levels, to true blanking levels.

This prevents any unwanted color modulation throughout the video signal during

reconstruction of the 4:2:2 output into NTSC or PAL.

12

Page 19

1. Locate the CORING jumper (LK2) situated on the left side of the ASD-111i (refer

to figure 3.2 for location).

2. To enable the coring function set the jumper in the ON position. In order to

remove the coring effect, set the jumper in the OFF position.

4 Specifications

Input

Signal: G/Y, B/B-Y, R/R-Y: 0.7 Vp-p nominal or 1.0 Vp-p nominal

with sync

Return loss: > 35 dB up to 5.75 MHz

Ext. ref: SMPTE 170M/PAL ITU 624-4 or 2 Vp-p/4 Vp-p

composite sync with passive loop-through

Return loss: > 35 dB up to 5.75 MHz

Output

Signal (3): 4:2:2 SMPTE 259M-C (270 Mbps)

Return loss: > 15 dB up to 270 MHz

Jitter (wideband) < 0.2 UI

Processing Performance

Quantization: 10 bits

Sampling: 27 MHz (2X oversampling)

Frequency response: ±0.1 dB to 5.5 MHz and +0/-0.15 dB from 5.5 to 5.75 MHz

Noise (unweighted): < -61 dB to 5.75 MHz

Processing delay: 2.7 µs

Horizontal centering: -8 pixels/+6 pixels by steps of 1 ns

Processing delay: 3.3 µs

Test signal: 100% color bars

Power: 14 W

Operating temperature range: 0 ºC to 40 ºC

13

Page 20

14

Page 21

5 Schematic DIagrams

15

Loading...

Loading...