Page 1

Instructions for installing the API CMS-1

The API CMS-1 includes:

2 Bezels with Templates

2 Grilles

4 Long Metal Channels

4 Short Metal Channels

4 Z Brackets

40 Drywall Screws (4 extra)

14 Rubber Cups (2 extra)

8 Wall Anchors

18 Machine Screws (2 extra)

Tools required:

Drywall Cutting Tool

Drill

3/16"(5mm) Drill Bit

Phillips Screwdriver

Hammer

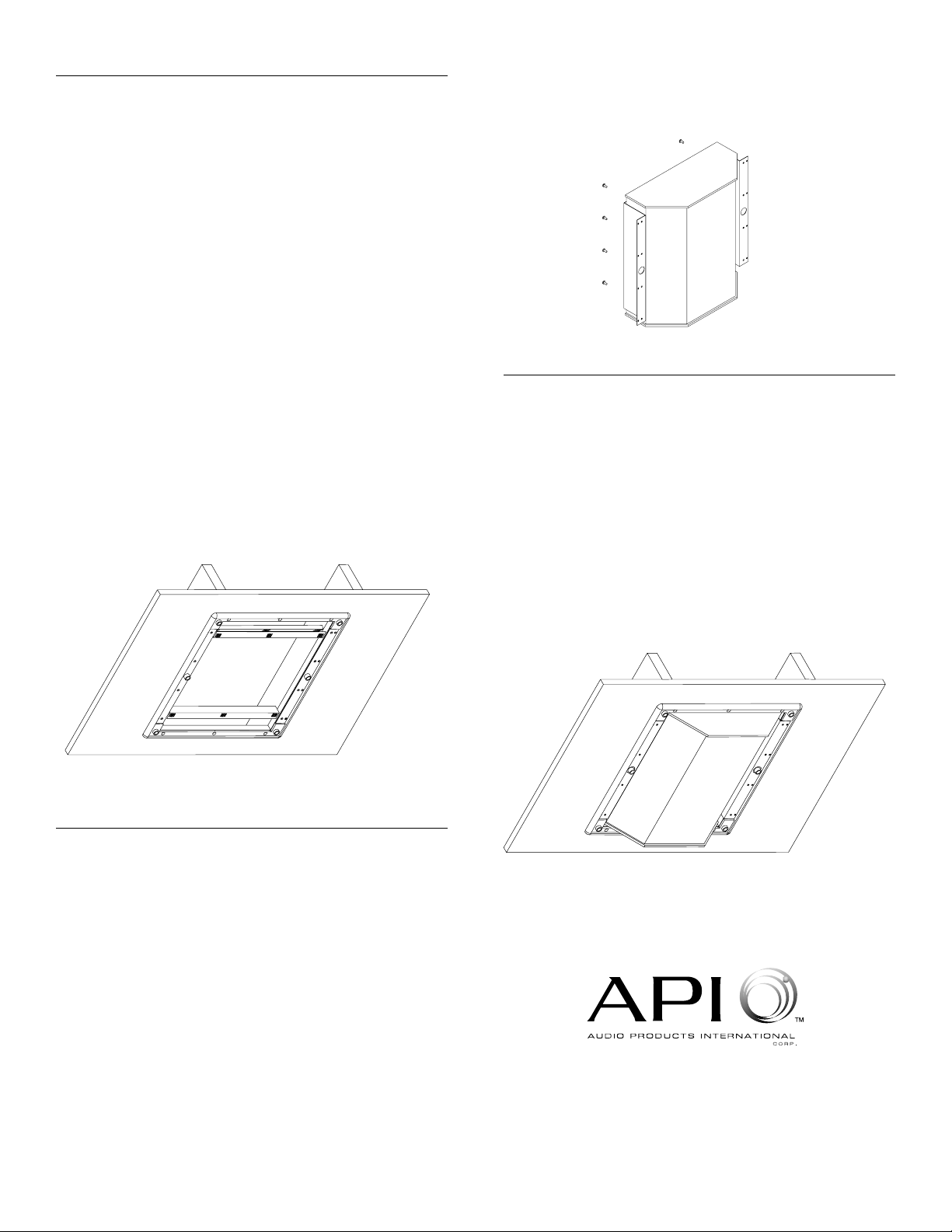

Versatility

Whether integrated into simple drywall or with studs of

any spacing, the proprietary design of the new API CMS-1

provides a sturdy, unyielding custom speaker installation

for any retrofit construction application.

Avoid installing the speaker in front of anything that may

impede its insertion to the wall such as ducts, pipes, or

studs. The use of a stud finder should guarantee a

suitable location.

Step 1: Installing the Bezel

In the desired location, squarely position the bezel upright

so the wording on the template can be read. If an

electrician has already passed the speaker to this area,

pull the exposed wire through the hole in the middle of the

template marked "Speaker Wire". The in-wall kit and

matching speakers can be positioned in a variety of ways

but this is the suggested manner to maximize dispersion.

For ceiling applications, position the bezel so the longer

sides face the side walls.

Drill a guide hole into the wall through each of the four

corner protruding cylinders of the bezel using a 3/16”

drill bit. Remove the bezel. With a hammer, gently tap a

wall anchor into each of the 4 drilled holes. Attach the

bezel to the wall using four of the provided drywall screws

inserted through the four protruding corner cylinders and

into the drywall anchors. Tighten the screws securely, to

the point of good resistance, but be careful not to overtighten. This step is cosmetic, not structural; the bezel

will be further solidified in proceeding steps. The bezel is

now in place and can be painted.

Step 2: Making the Cuts

Insert a drywall-cutting tool into the 1.5” by 5”

rectangular slot in the template under the API logo and

cut out this area. This provides a useful handle to the

drywall for ease of cutting the next piece and prevents it,

and the speaker wire, from falling into the wall.

Next, insert a drywall-cutting tool into the guide cut

passage between the template and bezel. Cut out this

square, leaving just the bezel, speaker wire, and the open

hole where the speaker will be housed. Cut as flush to the

bezel border as possible to result in a smooth fit for the

metal channels and speaker. If necessary, lightly sand the

edges of the drywall to remove any rough spots. This

provides a smooth surface to allow a flush fit for the

metal channel.

Page 2

Step 3: Installing the Metal Channels

Now the opening is ready to be reinforced with the metal

channels. Each channel has a distinct front and back.

The front is identifiable by larger perforations on the front

portion that slides between the bezel and drywall. The

back is identifiable by the smaller perforations and a flared

bend that allows it to be pliable and opened to

accommodate thicker drywall. The front portion of each

channel will slide between the drywall and bezel; the rear

portion grips the back of the drywall. The perforations

allow the drywall screws easy passage through the

channel. Slide the longer metal channels on the vertical

sides of the opening, the shorter channels on the top and

bottom. If necessary, lightly tap the channels into place

with a hammer to move them as flush as possible to the

drywall.

If a border of the hole happens to be flush to a stud,

it will not allow nor need the application of the metal

channel. The stud will provide all the needed foundation

for the drywall screw to grip and provide a sturdy,

reliable installation.

There are 3 holes located on the top and bottom of the

bezel. Keep the channels flush to the drywall and attach

the bezel to the wall through the pre set holes with

drywall screws. Tighten the screws securely, to the point

of good resistance, but be careful not to over-tighten.

Step 4: Attaching the Z Brackets

The provided Z brackets form the attachment between

the speaker and the in wall bracket.

For Incognita HDT-R installations:

First, remove the 8 screws that hold the Incognita HDT-R

grille to the speaker. Remove the grille.

For Energy Veritas 2.0r:

First, remove the grille. Do not attach the side trims

to the Veritas 2.0r. If they have been attached,

remove them.

For both the Incognita HDT-R and Veritas 2.0r:

The back of the speaker has 8 vertical machine screw

inserts, 4 on each side. The Z brackets' rear portion has

4 predrilled holes positioned to match these screw

inserts. Position the Z bracket so this edge matches

these holes. The front portion of the Z bracket has 4 sets

of two vertical holes and a centered, larger hole.

This portion faces forward, towards the front of the

speaker. Attach the Z bracket with the 4 screws that

were removed from the back of the speaker. Follow this

procedure for both the left and right sides of the speaker.

Step 5: Inserting the Speaker

The speaker can now slide into the pre-cut opening with

the attached Z brackets fitting into the bezel and over the

cylinders located at the middle. If the installation does not

use studs, use the set of 4 vertical screw holes closest to

the speaker. If the installation did not require the metal

channels and uses studs, use the set of 4 vertical screws

holes furthest from the speakers. Attach each side Z

bracket to the bezel with 4 of the provided drywall screws

into the selected set of pre-drilled holes. Tighten the

screws securely, to the point of good resistance, but be

careful not to over-tighten.

Insert the 6 rubber cups into the six protruding cylinders.

Finally, with clean hands, attach the grille into these

cylinders.

Audio Products International Corp.

3641 McNicoll Avenue, Scarborough

Ontario, Canada M1X 1G5

416-321-1800 Fax 416-321-1500

Printed in Canada Part #

Loading...

Loading...