Page 1

Direct Vent Insert

INSTALLATION

AND

OPERATING

INSTRUCTIONS

SERIES A

DIRECT VENT

FIREPLACE INSERT

f i r e - p a r t s . c o m

WARNING: If the information in this manual is not followed exactly, a fire or

explosion may result causing property damage, personal injury or loss of life.

-- Do not store or use gasoline or other flammable vapors and liquids in the

vicinity of this or any other appliance.

-- WHAT TO DO IF YOU SMELL GAS

- Do not try to light any appliance.

- Do not touch any electrical switch; do not use any phone in your building.

- Immediately call your gas supplier from a neighbour’s phone. Follow the

gas supplier’s instructions.

- If you cannot reach your gas supplier, call the fire department.

--Installation and service must be performed by a qualified installer, service

agency or the gas supplier.

IMPORTANT: THESE INSTRUCTIONS ARE TO REMAIN WITH THE HOMEOWNER

200598-24 DVI-INST # 5055.65

Page 2

Contents

Caution....................................................................................... 3

Safety ......................................................................................... 3

Maintenance............................................................................... 3

Installation ................................................................................. 4

Clearances.................................................................................. 5

Venting ...................................................................................... 6

Rocker Switch............................................................................ 7

Gas Supply................................................................................. 8

Burner Assembly ....................................................................... 8

Brick Panels Installation.......................................................... 10

Levelling Legs ......................................................................... 10

Log Set..................................................................................... 11

Surround Assembly ................................................................. 12

First Fire................................................................................... 13

f i r e - p a r t s . c o m

Operation ................................................................................. 13

Primary Air Adjustment .......................................................... 13

Optional Blower ...................................................................... 15

Replacement Parts ................................................................... 16

Glass Frame Removal.............................................................. 18

Optional Radiant Overlay........................................................ 18

Appendix A.............................................................................. 19

Vent Terminal Kit .............................................................. 19

Vent Terminal Flashing Installation Guide ....................... 20

Optional Blower Kit ........................................................... 21

Louver Kit Installation Guide ............................................ 22

Safety Label........................................................................ 23

2

Page 3

Caution

Maintenance

FOR YOUR SAFETY - Do not install or operate your Pacific

Energy Mirage Direct Vent Gas Insert without first reading

and understanding this manual. Any installation or operational deviation from the following instructions voids the

Pacific Energy Gas Stove Warranty and may prove hazardous.

This appliance and its individual shutoff valve must be

disconnected from gas supply piping system during any

pressure testing of that system at test pressures in excess of 1/

2 psig. (3.5 kPa)

This appliance must be isolated from the gas supply piping

system by closing its individual manual shutoff valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig. (3.5 kPa)

Note: When lit for the first time, the appliance will emit a

slight odour for a couple of hours. This is due to the curing

of paints, sealants and lubricants used in the manufacturing

process. This condition is temporary. Open doors and

windows to ventilate area. Smoke and fumes caused by the

curing process may cause discomfort to some individuals.

f i r e - p a r t s . c o m

Safety

Due to high temperatures, this gas appliance should be

located out of traffic and away from furniture and

draperies.

Children and adults should be alerted to the hazards of

high surface temperature and should stay away to avoid

burns or clothing ignition.

Young children should be carefully supervised when they

are in the same room as the appliance.

Clothing or other flammable material should not be placed

on or near the appliance.

Any grill, panel or door removed for servicing the unit

must be replaced prior to operating. Failure to do so may

create a hazardous condition.

Installation and repair should be done by a qualified

service person. The appliance should be inspected before

use and at least annually by a professional service person.

More frequent cleaning may be required due to excessive

lint from carpeting, bedding material, etc. It is imperative

that control compartments, burners and circulating air

passageways of the appliance be kept clean.

Caution: Turn off gas and electrical power supply and allow

ample time for unit to cool before servicing appliance. It is

recommended that this appliance and venting should be

inspected at least once a year by a qualified service person.

Do not use this heater if any part has been under water.

Immediately call a qualified service technician to inspect the

heater and to replace any part of the control system and any

gas control which has been under water.

Annual Inspection:

a) Clean louvers and air passage ways of excessive lint

buildup from carpeting, bedding material, etc. The flow of

combustion and ventilation air must not be obstructed.

b) Remove glass panel and log set. Inspect logs and burner

assembly for lint and soot buildup. If excessive buildup of

soot is present, have a qualified service person inspect and

adjust unit for proper combustion. Clean logs and burner with

a vacuum cleaner, paying close attention to burner ports.

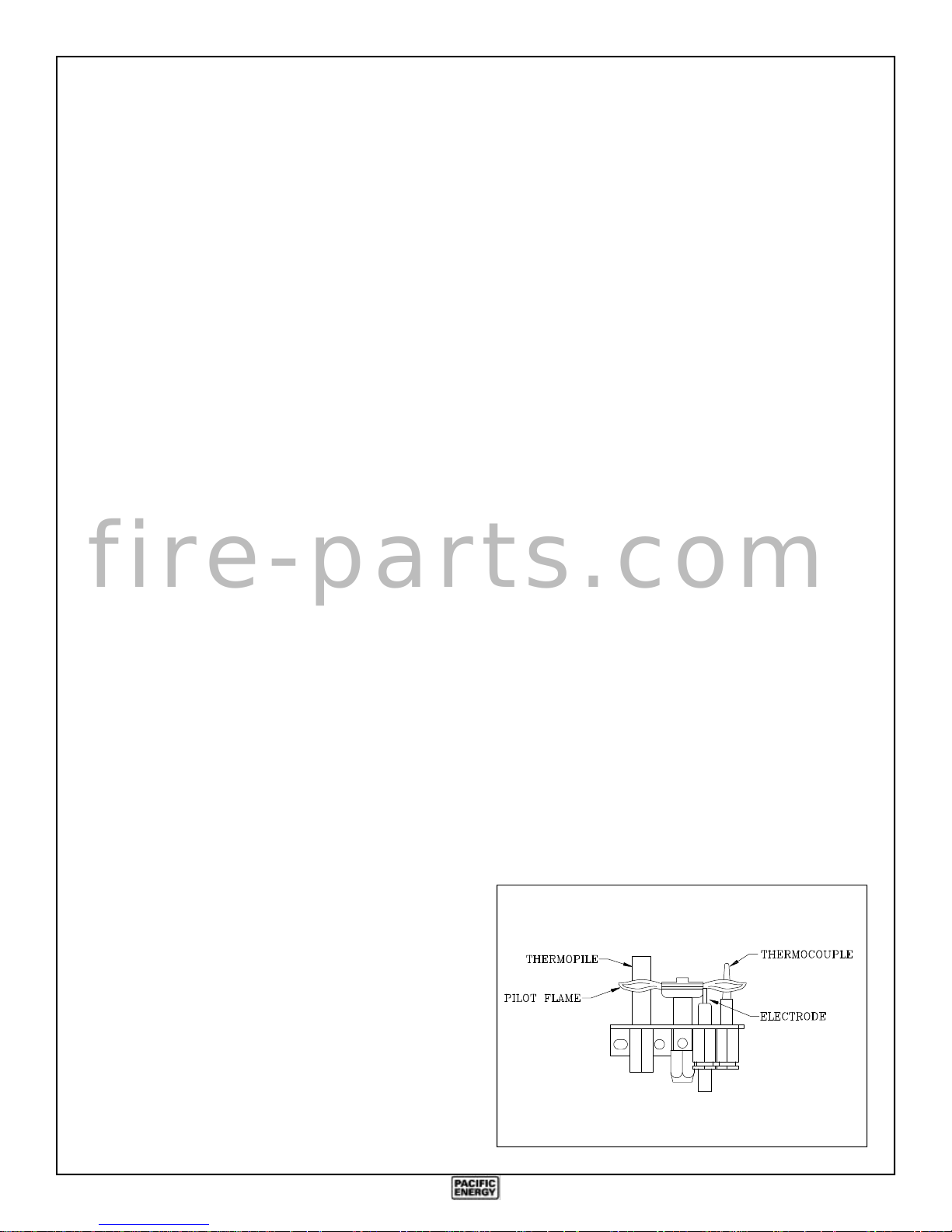

c) Check the pilot system for proper operation. (See Fig.

#1)

d) Check that the chimney flue and its outlet are open and

free from blockage or debris.

e) Check glass panel gasket, replace if necessary.

Note: The appliance area must be kept clear and free from

combustible materials, gasoline and other flammable vapours and liquids.

Periodically:

a) Viewing glass may be cleaned with glass cleaner.

b) Exterior porcelain enamel finish may be cleaned with

soap and water.

Note: Never use abrasives to clean this appliance.

Fig. # 1

It is Pacific Energy’s policy that no responsibility is

assumed by the Company or by any of its employees or

representatives for any damages caused by an inoperable,

inadequate, or unsafe condition which is the result, either

directly or indirectly, of any improper operation or

installation procedures.

3

Page 4

Installation

The Mirage Direct Vent Gas Insert installation and venting

must conform to the current CAN/CGA-B149 installation

code (in Canada) or the National Fuel Gas Code, ANSI

Z223.1 -1988 (in the USA), and approved per local codes.

Only qualified (licensed or trained) personnel should

install this product.

Fig. # 3

Existing Fireplace

(Masonry or Factory Built)

The Mirage Direct Vent Gas Insert is designed to be installed

into a masonry or a factory built zero clearance fireplace. The

masonry fireplace must be built according to the requirements of the standards for chimneys, fireplaces, vents and

solid fuel burning appliances, NFPA 211 (Latest Edition) or

applicable National, Provincial, State or local codes. The

factory built zero clearance fireplace and its chimney must be

certified and meet applicable National, Provincial, State or

local codes.

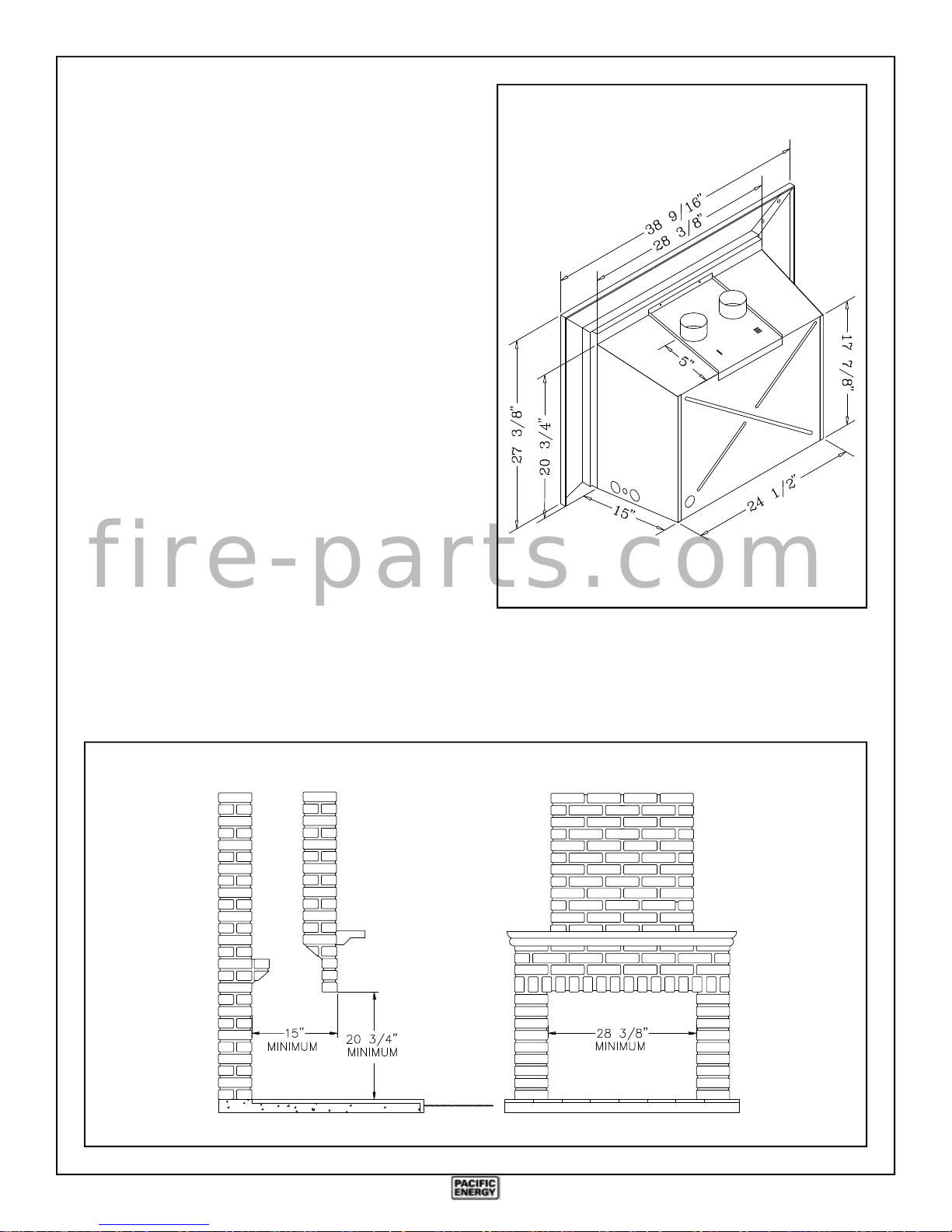

In order to sufficiently accommodate the Mirage Direct Vent

Gas Insert, the minimum size of the fireplace should be 28-3/

f i r e - p a r t s . c o m

8 inches wide, 20-3/4 inches high and 15 inches deep (see

Fig.#2).

The fireplace and its chimney should be swept and inspected.

The existing fireplace damper (if present) should be locked

open or removed completely if the opening is too small for

two - 3" flue liners to pass through.

Fig. # 2

4

Page 5

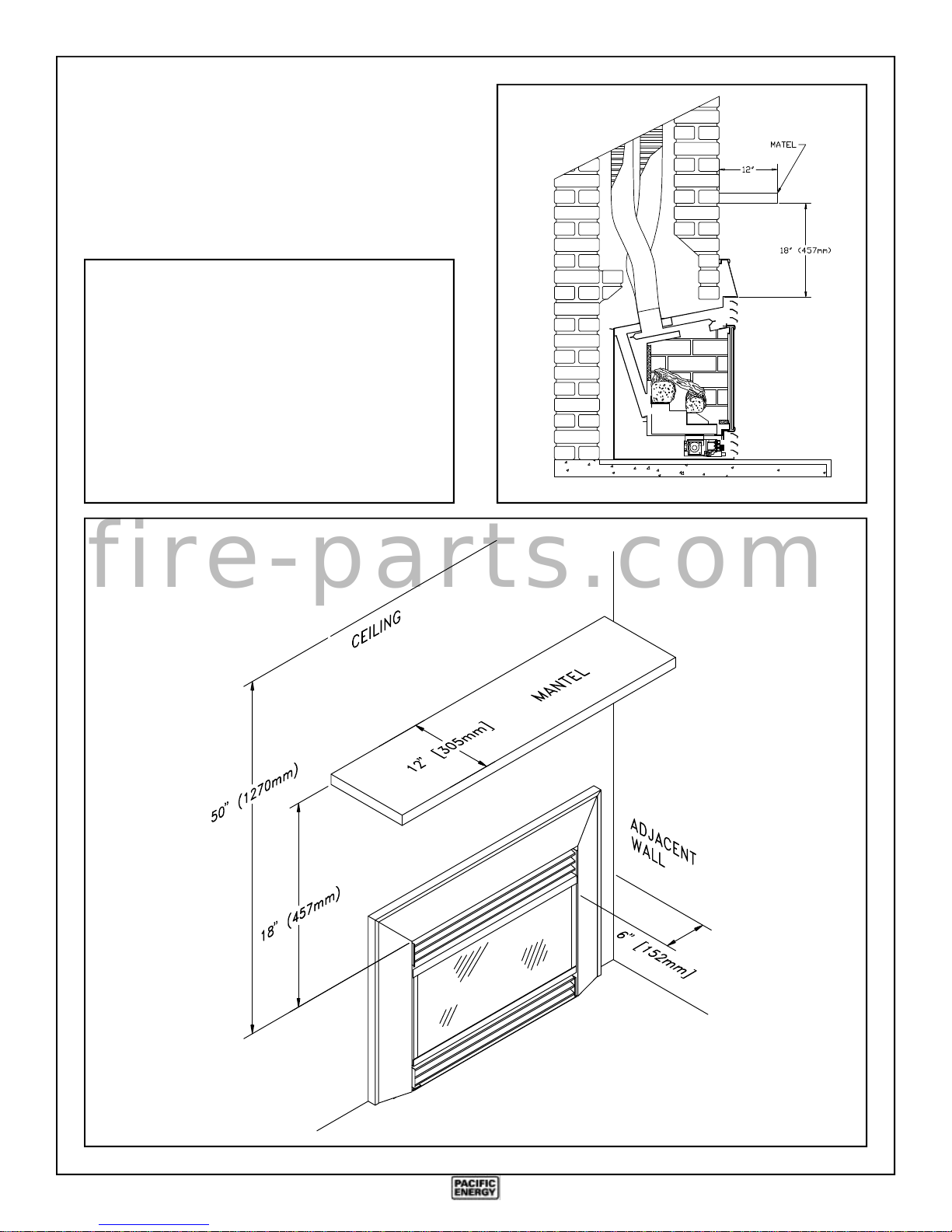

Clearances

The minimum clearances from the appliance to combustible

surfaces are shown on Fig. #4 and #5. Adequate clearances

around air openings and combustion air supplies are required.

MINIMUM CLEARANCES

TO COMBUSTIBLES:

Adjacent sidewall: .......................6.0 in. (152 mm)

Ceiling to appliance:.....................50 in. (1270 mm)

Mantel to appliance:.....................18 in. (457 mm)

Maximum mantel extension: .......12 in. (305 mm)

Mantel top support

to appliance ...................................18 in. (457 mm)

Mantel side support

to appliance .....................................6 in. (150 mm)

Fig. # 4

Fig. # 5

f i r e - p a r t s . c o m

5

Page 6

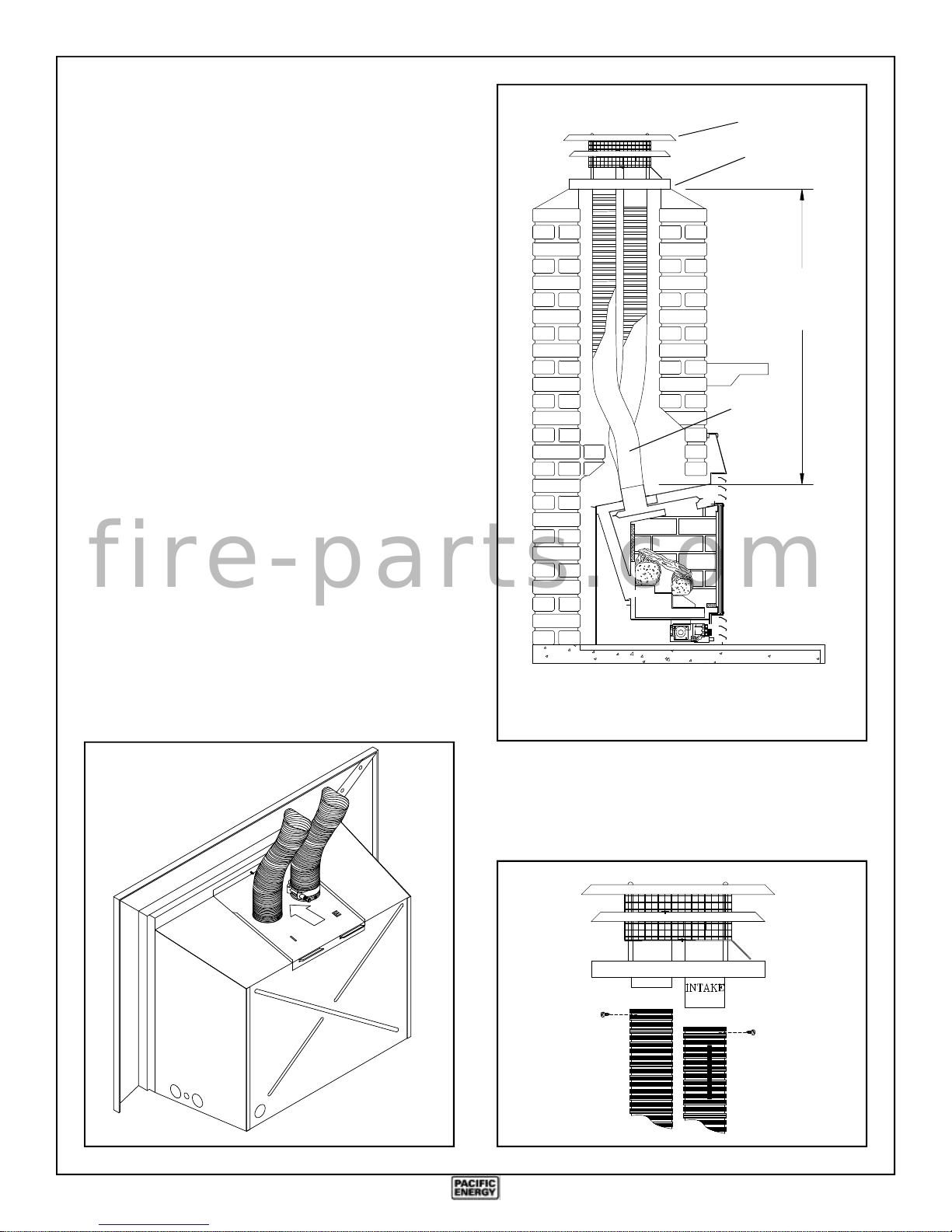

Venting

Fig # 7

Vent Terminal

Caution: Only Flex Liner kit (MIND.FL25) or an approved

gas vent flue liner and a Vent Terminal (MIND.VTTERM)

is approved for use with this appliance.

Also approved for use is Simpson Dura-Vent GS

termination kits, both Standard Vertical Termination cap

(#980) and the Extended Vertical Termination cap (#930)

in conjunction with the 3" Co-Linear Termination kit

(#923GK).

No other venting system or components may be used.

1) Measure chimney height and cut flex liner as required.

Mark one of the pipes with a stripe to identify combustion

air intake pipe from flue outlet pipe.

2) Attach marked flex liner pipe to the intake side (longer

collar) of vent terminal. Seal and secure with sealant and

screws provided. Attach the other pipe to the outlet side

of vent terminal. Seal and secure with sealant and screws

provided.

3) Insert both flex liners from top of the chimney, down

through the damper opening.

4) The vent terminal is sized to fit most typical chimneys.

Before attaching vent terminal to top of chimney, apply a

bead of caulking to top of clay liner. Slip vent terminal

over liner and secure in place with lateral retaining bolts.

f i r e - p a r t s . c o m

5) For larger chimneys, an optional flashing is available

which may be cut and fitted to suit. The flashing attaches

to the underside of the terminal with four nuts provided.

Caulk the flashing in place to seal any gaps.

Seal

Min. ........ 8' (2.4m)

Max. .......36' (10.9m)

3" Flex

Liner

The vent terminal must be sealed in place to prevent water

from entering the existing chimney.

Fig # 6

Note: The vent must be a minimum 8' long and

must not exceed a total lenght of 36'.

6) Remove the screw located above the top louver which

retains the vent connector plate on the appliance. Attach

ends of the flex liners to the collars on top of the connector

plate.

Fig # 8

6

Page 7

Make sure the marked inlet pipe is attached to the inlet side

Fig # 9

(marked "I"), and the unmarked pipe is attached to the

outlet side (marked "E") of the connector plate.

7) Seal and secure inlet pipe with sealant and screws provided.

8) Slip the 3 1/2" pipe clamp loosely over the end of the flex

flue pipe. Slide the pipe over the collar (marked "E") of

the vent connector plate and clamp tightly in place.

Secure in place with screws provided. No additional seal

is required.

9) Position vent connector plate over top of unit as the Insert

is pushed into the fireplace. Clip connector plate at the

back of the unit, tip down into position and attach in place

with screw previously removed. Leave the Insert extending a couple of inches out of the fireplace temporarily to

allow for proper surround placement.

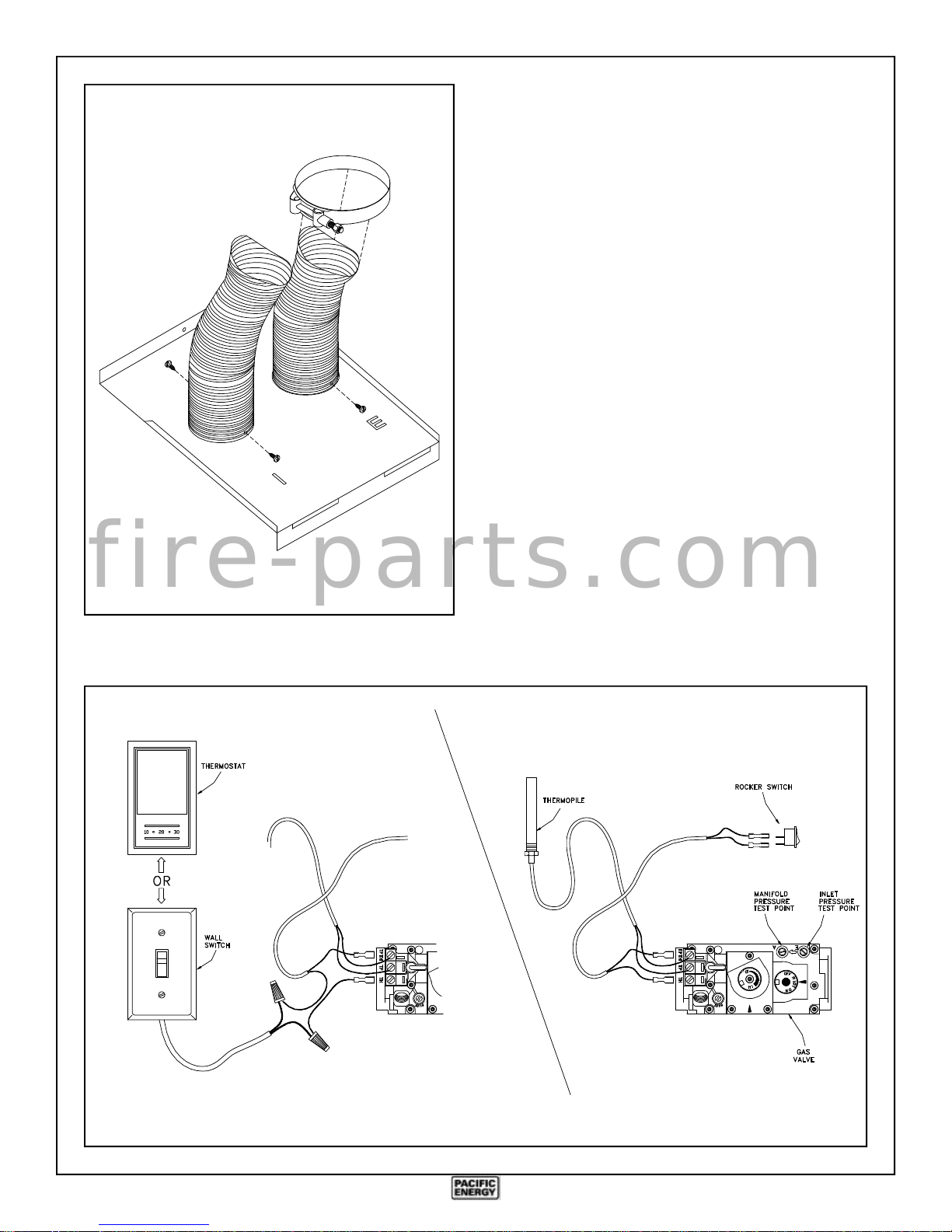

Rocker Switch

No electrical connection is required for the gas system operation. The self generating pilot provides current for the

optional remote wall switch.

The installation of a wall switch allows for manual remote

operation of fireplace, and automatic operation with a wall

f i r e - p a r t s . c o m

thermostat. Use a switch or thermostat rated for millivolts.

Position the wall switch or thermostat so that a maximum of

25 feet of wiring from the switch to the fireplace is used. Use

18/2 thermostat wire. Connect the wall switch to the valve as

shown in Fig. #10.

Fig # 10

Optional Wall Switch or Thermostat

Rocker Switch

7

Page 8

Gas Supply

Burner Assembly

Caution: The gas line should be installed by a qualified

service person in accordance with all building codes. Consult

local and/or national building codes before altering the fireplace.

The Mirage Direct Vent Gas Insert comes equipped with a

flexible connector with a 3/8" N.P.T. Male inlet for easy gas

connection. This connector is attached to the control valve

under the burner assembly and may exit the gas Insert at the

bottom left front or left rear. (Fig. #11)

Proper gas line diameter must be used to assure proper

operation. A pressure test port (1/8 inch N.P.T. plugged

tapping) must be provided for checking gas pressure. This

port must be located immediately upstream of the gas supply

connection to the appliance.

Correct gas pressure requirement:

Natural Gas Propane

Min. Pressure 5.0" wc 11.0" wc

(For purpose of input adjustment)

f i r e - p a r t s . c o m

Max. Pressure 10.5" wc 13.0" wc

The glass frame must be removed to install the burner into the

firebox. The glass frame is held in place by two over-center

latches located under the firebox.

1) Fold down the bottom louver, if installed, to access the

over-center latch. Disengage the latches by pulling each

lever down and forward.

2) Grasp the sides of the frame and swing the bottom out to

clear. Lift it up and forward to disengage from the top and

place in a safe place to avoid damage.

3) Remove the wrapped logs and brick panels and set aside,

taking care not to damage them.

4) Remove burner assembly from the carton and inspect.

Remove the two wing nuts contained in the plastic bag in

the carton.

Manifold Pressure 3.8" wc 11.0" wc

Fig # 11

Optional Blower

Cord Exit

Wire Harness

Gas Inlet

Exit

Rear Knockout

5) Bend the flexible inlet connector so that the line extends

straight from the control valve. While placing the burner

into the firebox, feed the flex gas inlet pipe through the

front plastic bushing located in the casing side. The flex

inlet pipe should extend out of the casing side, through the

plastic bushing.

A knockout is provided at the right rear of the appliance as an

alternate exit for the flexible connector. To use this inlet,

remove the knockout from the rear of the appliance. (Fig.

#11) Remove the plastic bushing installed in the side and

reinstall into the hole at the rear of the appliance.

6) Angle the burner assembly slightly forward, and place

inside the firebox. Be sure to align the two studs on the

side of the burner with the holes provided in the firebox

bottom side ledges. (Fig. #12)

8

Page 9

7) Once positioned inside the firebox and

properly seated on the ledge, push the

burner assembly back and secure in

place with wing nuts provided. (Fig.

#12)

8) Fasten rear burner bracket to firebox

back with screws provided. (Fig. # 13)

9) Connect the wire harness from the

rocker switch to the control valve terminal marked "TH" and "TH TP".

(Fig. #12) Feed the wire through the

smaller plastic bushing located next to

the gas inlet hole in the side casing.

(Fig. #11)

10)Place the self-adhesive label into the

blank box provided on the rating label

to designate the type of gas the appliance is connected to.

Fig # 13

f i r e - p a r t s . c o m

Fig # 12

Wing Nut

9

Page 10

Brick Panels Installation

Levelling Legs

The panels for the firebox are shipped in a separate cardboard

box located inside the appliance. Carefully remove the panels

from the box and install them as follows:

1) Insert the right side panel into the firebox. Push the panel

completely to the rear so that it clears the window frame,

and then bring it forward slightly so that it tucks in behind

the window frame and allows room for the thickness of the

rear panel to come behind it.

2) Install the rear panel by tipping it back and into the space

between the baffle and the back of the firebox and so that

it sits on the ledge provided. Shift the rear panel temporarily to the right so that it tucks in behind the right side

panel, leaving room for the left panel to pass by it.

3) Similarly to installing the right panel, push the left panel

all the way to the rear to clear the window frame and then

pull it forward so that it tucks in behind the window frame.

4) Center the rear panel and then adjust the side panels by

pushing them back against the rear panel.

Levelling legs are provided with the appliance as a convenient means for levelling the appliance when it is installed on

an irregular surface. The legs (3" long threaded bolts) are

supplied in a separate parts bag inside the appliance. Nuts

welded to the base, near the back of the appliance locate the

levelling legs. The legs thread into the nuts and protrude out

the bottom, raising the rear of the appliance until it is level

with the front.

f i r e - p a r t s . c o m

Fig # 14

10

Page 11

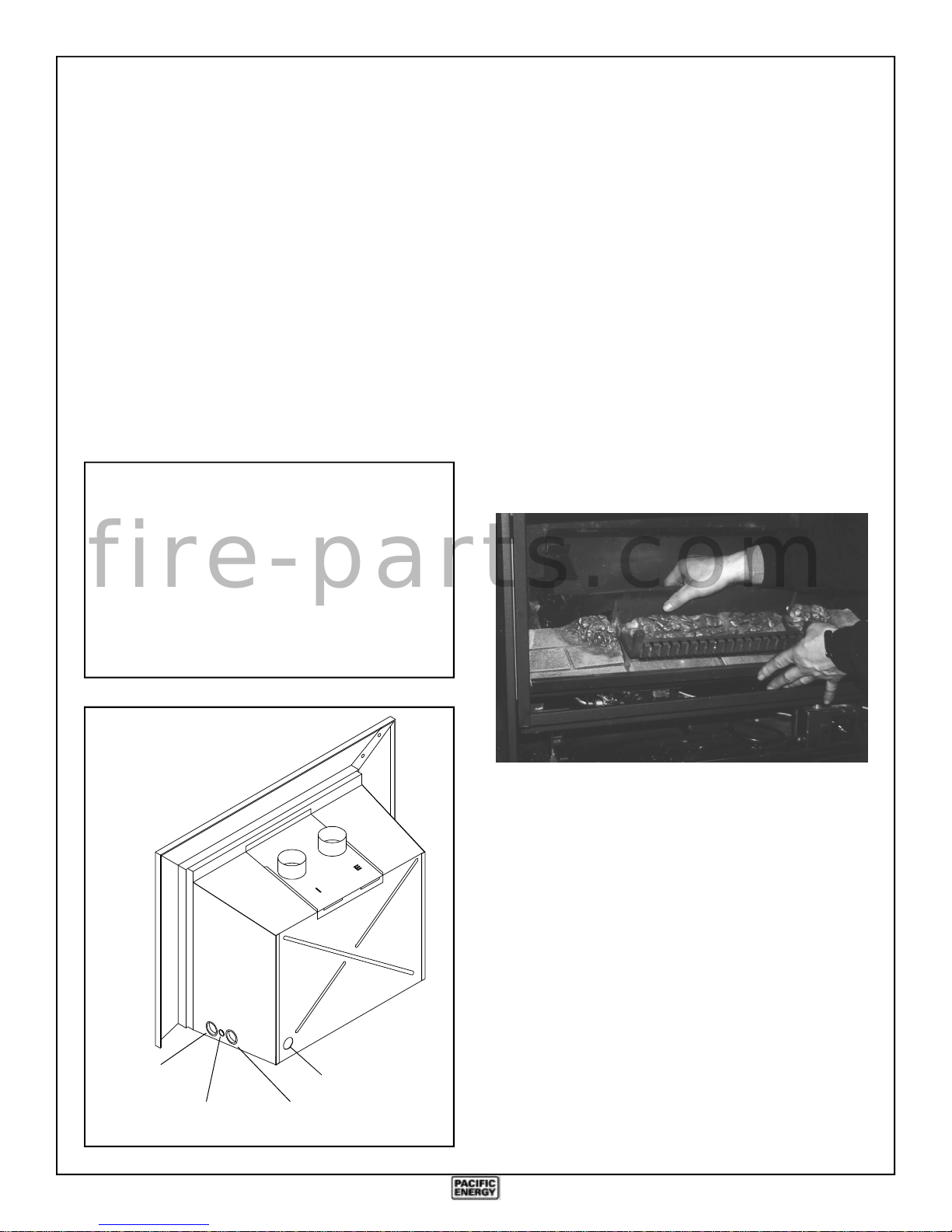

Log Set

The Ceramic logs are durable and long lasting when installed

properly. However, they are delicate and may be damaged

easily if not handled with care. Unpack and inspect log set.

There should be a total of 4 logs as shown in Fig. # 16. All gas

and venting connections should be made before installing log

set.

Log Assembly: (Fig. # 15)

Fig. #16

Back Log

1) Place the rear log in position at the back of the firebox,

centered between the brackets, with flat side facing rear

and the bark side facing forward.

2) Place the front log over the two pins just in front of the rear

burner onto the tabs located at the front of burner

assembly. The log is notched to fit over the pilot.

3) The top left "Y" log bridges across front and rear log. The

log should be properly seated over pin in the front log and

nested in the left relief of the rear log.

4) The top right log also bridges across the front and rear log.

The log should be properly seated over the pin in the front

log and nested in the right relief of the rear log.

Note: Improper placement of logs may cause sooting on

internal parts and glass.

f i r e - p a r t s . c o m

Fig # 15

Left "Y" Log

Back Log

Front Log

Top Left "Y" Log

Top Right Log

Right Log

Front

Log

11

Page 12

Surround Assembly

1) Lay Parts A, B, and C face down on a flat, non-marking

surface. (Fig. #17) Fasten together with spring clips

through holes at points "D". (Fig. #20)

2) Lift the surround assembly to the upright position and

make sure the front face is even at the joint.

3) Assemble the three brass trim pieces using the enclosed

hardware. Slide Part F into the back corners of the brass

trim and tighten screws. Ensure the mitred corners fit

tightly and evenly. (Fig. # 18)

4) Slide the assembled brass trim over the surround from the

top. (Fig. # 17)

5) Tighten the retaining screws at the bottom of each brass

trim side. (Fig. # 21)

Fig. # 17

Fig. # 18

6) Connect the wire from the gas control valve to the on/off

rocker switch in the brass trim. (Fig. # 19)

7) Slide pre-assembled surround on to Insert. Do not lift the

assembly by grasping the brass trim. The surround is

held in place by screws (2 each side), just inside the casing

near the top and bottom. Push surround back until snug

and even with front face of Insert. Fasten in place.

Fig. # 20

Fig. # 19

f i r e - p a r t s . c o m

8) Push the entire appliance back until the surround is in

contact with the fireplace.

Fig. # 21

12

Page 13

First Fire

Primary Air Adjustment

When lit for the first time, the appliance will emit a slight

odour for a couple of hours. This is due to the curing of paints,

sealants and lubricants used in the manufacturing process.

This condition is temporary. Open doors and windows to

ventilate area. Smoke and fumes caused by the curing process

may cause discomfort to some individuals.

Operation

The Mirage Gas Insert comes equipped with an "ON-OFF"

Rocker switch. This switch is conveniently located near the

upper right hand corner of the surround

Once a pilot light has been established, and the gas control

knob turned to the "ON" position, the burner may be turned

on or off simply with the switch. An optional wall thermostat

may be installed to operate the burner automatically.

Fig. # 22

This appliance is provided with primary air adjustment,

which affects flame heights and flame quality of the front and

back burners by controlling the air shutter opening. This

adjustment is preset at the factory for the best flame appearance for most installations. However, adjustment is available

to compensate for varying field conditions, such as vent

system height or altitude, that may affect flame appearance.

The adjustment rods are accessible just to the left of the valve,

in behind the bottom louver, as shown in Fig. #23. Separate

front and back adjusters are provided; the left rod adjusts the

rear burner and the right adjuster controls the front burner.

Pulling the left rod forward closes the rear shutter and

increases the rear flame height. Pushing the right rod upwards

closes the front shutter and increases flame height of the front

burner.

Fig. # 23

f i r e - p a r t s . c o m

Manual HI-LO Burner Control Knob

Manual HI-LO Flame Adjustment: (Fig #22)

The HI-LO burner control knob can be rotated in both

directions, providing infinite control of gas flow rate to the

burner and therefore greater comfort control. The HI setting

provides a maximum gas input, and rotating the knob clockwise toward the LO setting will reduce the gas input to a

minimum setting.

Wall Thermostat (optional):

Set the wall thermostat to a comfortable temperature. Turn

the HI-LO burner control knob to a desired setting. As heat

is required, the Mirage Gas Insert will turn on or off automatically, as needed.

Extend Shutdown:

To shutdown the appliance including the pilot, partially

depress and turn gas control knob clockwise past “PILOT” to

the “OFF” position. DO NOT FORCE.

NOTE: The SIT control has an interlock device which does

not allow the pilot to be lit when the appliance is at operating

temperature. Let the appliance cool down (approx. 60 sec.)

before attempting to relight the pilot. DO NOT use force to

rotate the control knob.

To Adjust: (See Fig. # 23)

1) Fold down bottom front louver.

2) Pull or push on adjustment rods to adjust flame.

3) Close bottom front louver.

Caution: Proper air shutter setting is a must. The flame

should not impinge on the top of the firebox. It should

NEVER be set to create sooting on internal parts and glass.

Open air shutter gradually until sooting stops.

Fig. # 24

13

Page 14

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING: If you do not follow these

instructions exactly, a fire or explosion

may result causing property damage,

personal injury or loss of life.

A. This appliance has a pilot which must be lighted by

hand. When lighting the pilot, follow these instructions exactly.

B. BEFORE LIGHTING smell all around the appliance

area for gas. Be sure to smell next to the floor

because some gas is heavier than air and will

settle on the floor.

WHAT TO DO IF YOU SMELL GAS:

- Do not try to light any appliance.

- Do not touch any electric switch; do not use any

phone in your building.

- Immediately call your gas supplier from a neighbour's phone. Follow the gas supplier's instructions.

- If you cannot reach your gas supplier, call the fire

department.

C. Use only your hand to push in or turn the gas control

knob. Never use tools. If the knob will not push in

or turn by hand, don't try to repair it, call a qualified

service technician. Force or attempted repair may

result in a fire or explosion.

D. Do not use this appliance if any part has been under

water. Immediately call a qualified service technician to inspect the appliance & to replace any part

of the control system & any gas control which has

been under water.

LIGHTING INSTRUCTIONS

1. STOP! Read the safety information above on

this label.

2. Set wall thermostat to lowest setting, if applicable.

3. Turn off all electric power to the appliance.

4. Open the bottom grill to access the controls.

5. Partially depress and turn gas control knob

clockwise past "Pilot" to "Off" position.

Note: Knob cannot be turned

from "Pilot" to "Off" unless

knob is pushed in slightly.

Do not force.

6. Allow sufficient length of

f i r e - p a r t s . c o m

time (minimum 5 minutes)

for any gas in the combustion chamber to

escape. If you still smell gas, STOP! Follow "B"

in the safety information above on this label. If

you don't smell gas, go to the next step.

7. Turn gas control knob back to "Pilot" position.

8. Depress gas control knob fully and hold while

GAS KNOB

you ignite pilot with the push button igniter. Once

the pilot ignites, continue depressing knob for

approximately 5 seconds (30 seconds if equipped

with a Robertshaw control valve). If pilot does not

stay lit, repeat steps 6 through 8, allowing a

longer period before releasing gas control dial.

- If gas control knob does not pop up when

released, stop and immediately call your service

technician or gas supplier.

- If the pilot will not stay lit after several tries, turn

the gas control knob to "Off" and call your

service technician or gas supplier.

9. Turn gas control knob counter-clockwise to

"On" position.

10. Turn HI-LO burner control knob to desired

setting.

11. Close bottom grill and turn on the burner switch

12. Turn on all electric power to the appliance.

13. Set thermostat to desired setting, if applicable.

Note: Sufficient time must be allowed for air to

escape from lines if the unit is being lit for the

first time.

TO TURN OFF GAS TO APPLIANCE

1. Set wall thermostat to lowest setting, if applicable.

2. Turn off all electric power to the appliance if

service is to be performed.

3. Push in gas control knob slightly and turn

clockwise to "Off". Do not force.

14

Page 15

Optional Blower

Electrical Supply:

Circulating air blower electrical rating: 115V, 60

Hz, 80 watts. (Fig #25) For your protection against

shock hazard, use only a properly grounded outlet

that will accept a three-pronged plug. Do not cut or

remove the grounding prong.

Consult local codes or, in the absence of local

codes, with the current CSA C22.1 Canadian Electrical Code and in the USA with the National

Electrical Code, ANSI/NFPA 70 (latest Edition).

Installation:

The blower kit must be installed before the burner

assembly is in place. Unpack and inspect blower

kit.

1) Position the blower onto studs located at the

rear of the appliance and secure in place with

wing nuts provided. (Fig. #26)

2) Place the speed control junction box temporarily in the right front corner of the appliance. The

junction box attaches to the underside of the

burner assembly, once in place. (Fig. #27)

3) Feed the power cord out through the plastic

grommet on the side of the appliance.

f i r e - p a r t s . c o m

Fig. # 26

Fig. # 27

Optional Blower

Studs

Fig. # 25

Rocker

Switch

Speed

Control

Snap Disc

Switch

115 Volts

60 Hz

0.5 Amperes

Blower

G (green)

L1 (white)

L2 (black)

Operation:

The circulating air blower is thermostatically controlled to

turn on automatically once the unit is at operating temperature. A few minutes after the appliance is lit, with the variable

speed control set at a desired setting, the blower will automatically turn on. The blower will automatically turn off a

few minutes after the appliance is shut down.

The blower may also be operated manually. Push the rocker

switch to manual position and the blower will operate independent of the burner provided the variable speed control is

set.

15

Page 16

Replacement Parts

Fig. # 28

(WHEN ORDERING, INCLUDE PART NUMBER WITH DESCRIPTION)

ITEM DESCRIPTION PART NO. ITEM DESCRIPTION PART NO.

1 .......... Main Body....................................... MIND.1800

2 .......... Baffle ............................................... MIND.1834

3 .......... Burner Assembly .....................MIND.NAT/PRO

4 .......... Glass Panel .....................................MINC.50342

5 .......... Glass Frame ..................................... MIND.1820

6 .......... Front Trim Set (2 pcs.) .................... MIND.1888

7 .......... Louver Assembly, Bottom .......... MIND.1879_ _

8 .......... Louver Assembly, Top ............... MIND.1883_ _

9 .......... Burner Panel, Right ..................... MIND.509825

10 ........ Burner Panel, Front ..................... MIND.509823

11 ........ Burner Panel, Left ....................... MIND.509824

12 ........ Rear Ember Panel ........................ MIND.509821

13 ........ Brick Panel, Left.......................... MIND.509772

14 ........ Brick Panel, Back ........................ MIND.509773

All parts may be ordered from your nearest Pacific Energy dealer. Contact Pacific Energy for the location of the dealer nearest

f i r e - p a r t s . c o m

you.

When ordering Surrounds and Louvers, please specify the appropriate finish code. Codes are as follows:

Porcelain Finish Black .......................... BK Paint Finish Metallic Black............ MB

Blue............................. BE

Green.......................... GN Plated Finish Gold ........................... GD

Ivory.............................IY

Red ............................. RD

15 ........ Brick Panel, Right ....................... MIND.509771

16 ........ Surround Trim, Left ......................... MINC.1664

17 ........ Surround Trim, Top........................ MINC.16641

18 ........ Surround Trim, Right .....................MINC.16642

19 ........ Surround Side, Left .....................MINC.1658_ _

20 ........ Surround Top...............................MINC.1659_ _

21 ........ Surround Side, Right ...................MINC.1660_ _

22 ........ Vent Connector Plate....................... MIND.1823

............ Log, Front (not shown) ...........................5098.91

............ Log, Back (not shown) ........................... 5098.92

............ Log, Top Left "Y" (not shown) .............. 5098.93

............ Log, Top Right (not shown) ................... 5098.94

............ Window Gasket Kit (not shown) ....MINC.50671

-notes-

16

Page 17

Fig. # 28

f i r e - p a r t s . c o m

17

Page 18

Glass Frame Removal

Optional Radiant Overlay

The glass frame is designed with quick release catches for

easy removal. The frame is held in place by two over-center

latches located under the firebox. Remove the window glass

as follows:

1) Fold down the bottom louver, if installed, to access the

over-center latches. Disengage the latches by pulling

each lever down and forward. (Fig. #29)

2) Grasp the sides of the frame and swing the bottom out to

clear. Lift up and then forward to disengage from the top.

Installation is the reverse of removal. During installation

ensure that the tabs on the top of the unit engage the corresponding slots in the glass frame. (Fig. #30)

Fig. # 29

Latch

The optional Radiant Overlay may be installed at any time.

Unpack and inspect all parts. Install Overlay as follows:

1) Remove the glass frame as outlined above. Place face up

on a flat, stable surface to avoid damage.

2) Remove screws retaining front trim and set trim aside.

3) Position Radiant Overlay over top of frame.

4) Replace trim and screws.

5) Reinstall complete assembly onto appliance. During

installation ensure that the tabs on the top of the unit

engage the corresponding slots in the glass frame.

f i r e - p a r t s . c o m

18

Fig. # 30

Frame Tabs

Page 19

Appendix A

Vent Terminal Kit

Vent Terminal MIND.VTTERM

Direct Vent Insert

This vent kit is for use with the model MIRAGE DVI, Series A gas insert only. Please refer to the

Installation Instructions provided with the appliance for proper installation.

This box contains:

1 .......Vent Terminal

f i r e - p a r t s . c o m

4 .......#10 x 5/8" TEKS Screws

6 .......#10 x 1 1/2" Machine Screws

170298

19

Page 20

Vent Terminal Flashing

Installation Guide

Direct Vent Insert

This kit contains:

1 ..... Vent Terminal Flashing

4 ..... #8 x 1" Sheet Metal Screws

Installation:

1. Attach the vent terminal to the flashing

f i r e - p a r t s . c o m

using the 4 screws provided.

Vent Terminal MIND.FLASH

2. Attach the flashing to the chimney, by first

notching and then bending the excess

portion of the flashing downwards to suit

the installation.

170298

20

Page 21

Optional Blower Kit

Direct Vent Insert

This kit contains:

1 .......Blower assembly (including blower,

control box, and power cord)

f i r e - p a r t s . c o m

MIND.BLOW

2 .......Wing nuts

2 .......#8 x 1/2 Sheet metal screws

(black in color)

Installation:

Please see instruction manual

170298

21

Page 22

Gas Insert

This kit contains:

1 .......Top Louver (Black or Gold)

1 .......Bottom Louver (Black or Gold)

4 .......#8 x 1/2" sheet metal screws

(black in color)

Louver Kit

Installation Guide

Black Louver MINC.BKLVR

Gold Louver MINC.GDLVR

f i r e - p a r t s . c o m

Installation

Unpack and inspect all parts. A flathead or a

#2 Robertson screwdriver is required to

install the louvers.

1) Fasten top louver to the top casing with

the screws provided. (see Fig. #1)

2) Fasten bottom louver to the hinge

brackets at the bottom of the appliance.

(see Fig. # 2)

Fig. # 2

Fig. # 1

170298

22

Page 23

Safety Label

WH-

LISTED GRAVITY DIRECT VENT WALL FURNACE /

RADIATEUR MURAL A ÉVACUATION DIRECTE PAR

GRAVITE

REPORT NO.

476-1302

(OCT. 96)

ANS Z21.44 -1995 Direct Vent Wall Furn., CAN1-2.19 -M81 Direct Vent

Wall Furnace, CAN/CGA-2.17 -M91 Gas-Fired Applainces For Use At

High Altitudes, CGA I.R. #41 - 1991 and #55 Rev.1 - 1995

MODEL / MODELE: MIRAGE - DIRECT VENT INSERT

SERIES / SERIE: A

VENTED CIRCULATOR OPTIONAL FAN / CIRCULATEUR

VENTILE VENTILATEUR OPTIONNELLES

CERTIFIED FOR CANADA AND U.S.A. / CERTIFIÉ POUR CANADA ET U.S.A.

WH-

FOR USE WITH/ NATURAL GAS/ LP-GAS/

EN CASE D’EMPLOI AVEC: DU GAZ NATUREL DU GAZ LP

Minimum supply pressure / Pression minimum d’alimentation: 5.0 in/wc / 5.0 po/c.e. 11.0 in/wc / 11.0 po/c.e.

(For the purpose of input adjustment / dans le but de regler l’alimenation) (1.25 kPa) (2.74 kPa)

Manifold pressure / Pression de la tuyauterie: 3.8 in/wc / 3.8 po/c.e. 11.0 in/wc / 11.0 po/c.e.

Orifice Size / Diametre de l’injectuer: Front: # 54 DMS # 64 DMS

f i r e - p a r t s . c o m

Input BTU/hr (kW) / Puissance à l'entrée BTU/h (kW) : Max.: 30,000 (8.8) Max.: 27,000 (7.9)

Output BTU/hr (kW) / Puissance fourmie BTU/h (kW)

Optional components: Fan Kit (MIND.BLOW) / Éléments facultatifs: Ventilateur (MIND.BLOW)

Blower electrical rating: 115v, 60hz, 0.5 A / Normes electriques du ventilateur: 115v, 60hz, 0.5 A

This appliance equipped for altitudes 0-4500 ft. (0-1370 m) / Cet unite est concu pour des altitudes variant entre 0- 4500

pieds (0-1370 m)

WARNING: Improper installation, adjustment, alteration, service or maintenance can cause property damage, personal

injury or loss of life. Refer to the owner’s information manual provided with this appliance. Installation and service must

be performed by a qualified installer, service agency or the gas supplier.

This appliance must be installed in accordance with local codes, if any; if not, follow the current CAN/CGA-B149 (Canada)

or ANSI Z223.1 (USA). Cet appareil diot etre installe conformement aux exigences des codes locaux. S’il n’existe aucun

code local, se conformer a la norme CAN/CGA-B149 en vigueur.

Left and Right side are determined when facing the front of the appliance.

Les cotes droit et gauche se determinent en se mettant devant l’appareil et en lui faisant face.

INSTALL IN SOLID FUEL BURNING FIREPLACE / N'INSTALLER QUE DANS UN FOYER NON COMBUSTIBLE

Only for direct discharge without duct connection. Pour sortie d'échappement directe sans gaine de distribution

seulement. Install with listed gas vent liner / Installez avec manchon intérieur de gaz apprové.

MINIMUM CLEARANCES TO COMBUSTIBLES / DEGAGEMENT DES MATIERES INFLAMMABLES

Adjacent Sidewall to Appliance / Mur du côté adjacent à l'Appareil : 6 in. / 6 po. (152 mm)

Ceiling to Appliance / Plafond à l'Appareil: 50 in. / 50 po. (1270 mm)

Mantel to Appliance / Du manteau à l'Appareil ;

Mantel Top Support to Appliance (Max. 12 in. Extension)

Mantel Side Supports to Appliance

12 in. Max. Mantel Extension / Extension max. du manteau de 12 po.: 18 in. / 18 po. (457 mm)

/ Supports du manteau à l'Appareil (Max. 12 po. Extension) : 18 in. / 18 po. (457 mm)

/ Supports du manteau à l'Appareil : 6 in. / 6 po. (152 mm)

- Fan On / Ventilateur ouvert 23,550 (6.9) 22,275 (6.5)

- Fan Off / Ventilateur position fermé 21,900 (6.4) 20,840 (6.1)

Back: # 45 DMS 3/64" (1.19 mm)

(.95 kPa) (2.74 kPa)

Min.: 15,000 (4.4) Min.: 13,500 (4.0)

PACIFIC ENERGY FIREPLACE PRODUCTS LTD.

Duncan, British Columbia, Canada

160498 5050.72 1-DVIA1

MADE IN CANADA / FABRIQUÉ AU CANADA

DO NOT REMOVE OR

COVER THIS LABEL

23

Page 24

f i r e - p a r t s . c o m

Pacific Energy Fireplace Products Ltd.

Box 1060, Duncan, B.C. V9L 3Y2

Phone: 250-748-1184

Web site: http://www.pacificenergy.bc.ca

Printed in Canada

Loading...

Loading...