Mira SILVER, Element Thermostatic Mixer User Manual

1

MIRA SILVER

Installation and User Guide

THERMOSTATIC MIXER

These instructions must be left with the user.

For SPARES, ADVICE

or REPAIRS

Please call us on

0844 571 5000

(UK Only)

2

CONTENTS

Introduction .............................................................................................3

Guarantee ............................................................................................4

Patents and Design Registration ..........................................................4

Safety : Warnings ....................................................................................5

Pack Contents .........................................................................................7

Dimensions .............................................................................................. 9

Specications ........................................................................................ 10

Operating Parameters ........................................................................ 10

Installation Requirements ....................................................................12

Installation .............................................................................................14

General ...............................................................................................14

Installation Methods ...........................................................................15

Exposed Thermostatic Mixer .............................................................. 16

1. Rear Entry Supplies (rising or falling concealed pipework) ............ 16

2. Rising or Falling Supplies ...............................................................18

Built-in Thermostatic Mixer ................................................................. 20

1. Solid Wall or Stud Partition

(Using Securing Brackets - Mounting on Front Face of Wall) ....20

2. Solid Wall or Stud Partition

(Using Rear Fixing Points on the Thermostatic Mixer) ...............23

3. Laminated Panel

(Using Securing Brackets - Mounting on Rear Face of Wall) ..... 25

Control Assembly (Built-in Models) .................................................... 27

Reversed Inlet Supplies ........................................................................ 28

Operation ...............................................................................................30

Commissioning .....................................................................................31

Maximum Temperature Setting .......................................................... 31

Fault Diagnosis ......................................................................................32

Maintenance ...........................................................................................33

General ...............................................................................................33

Spare Parts ............................................................................................36

Accessories ...........................................................................................38

Notes ......................................................................................................39

Customer Service .................................................................................. 40

3

INTRODUCTION

Thank you for purchasing a quality Mira product. To enjoy the full potential of your

new product, please take time to read this guide thoroughly, having done so, keep

it handy for future reference.

The Mira Silver Thermostatic Mixer is a Thermostatic Shower Control with a single

control lever for on/off and temperature control.

There is no adjustable ow control. A 12 L/Min ow regulator is supplied for high

pressure systems to reduce excessive shower force.

The Thermostatic Mixer incorporates a wax capsule temperature sensing unit, which

provides an almost immediate response to changes in pressures or temperature of

the incoming water supplies to maintain the selected temperature. An adjustable

maximum temperature stop is provided which limits the temperature to a safe level.

Inlet Filters are tted to protect the thermostatic cartridge.

Mira Silver Exposed: Thermostatic Mixer for connection to rising, falling or rear

entry pipework, supplied with L10 EV Shower Fittings.

Mira Silver Built-in: Thermostatic Mixer for connection to concealed pipework,

supplied with L10 BIV or BIR Shower Fittings.

Type 2 Valves

This product has been certied as a Type 2 valve under the BUILDCERT TMV2 scheme.

This product also complies with the Water Supply (water ttings) Regulations 1999.

Application

The approved designations for Type 2 Valves are as follows:

Model Designation

Mira Silver HP-S, LP-S

Important! The tting of any ow regulator will invalidate TMV2 compliance due to

the minimum ow rate requirements. Do not t ow regulators in TMV2 applications.

For Type 2 Valves refer to the TMV2 Requirements Manual.

4

If you experience any difculty with the installation or operation of your new

Thermostatic Mixer, please refer to ‘Fault Diagnosis’, before contacting Kohler Mira

Ltd. Our telephone and fax numbers can be found on the back cover of this guide.

Guarantee

For domestic installations, Mira Showers guarantee the Mira Silver Thermostatic

Mixer against any defect in materials or workmanship for a period of ve years from

the date of purchase.

For non-domestic installations, Mira Showers guarantee the Mira Silver

Thermostatic Mixer against any defect in materials or workmanship for a period of

ve years from the date of purchase.

For terms and conditions refer to the back cover of this guide.

Recommended Usage

Application

Domestic

ü

Light Commercial

ü

Heavy Commercial

û

Healthcare

û

Patents and Design Registration

Design Registration: 000555768-008, 000555768-009

Patents: GB: 2 291 693, 2 392 225, 2 421 297

Germany: 695 13 455.8

France: 0 694 721 (E)

USA 7 240 850

Patent Applications: GB: 0621637.8

Euro: 1 672 257, 03254070.0

USA: 2006-0124758-A1

5

SAFETY : WARNINGS

This Mira Silver Thermostatic Mixer is precision engineered and should give continued

safe and controlled performance, provided:

1. It is installed, commissioned, operated and maintained in accordance with

manufacturer’s recommendations.

2. Periodic attention is given, when necessary, to maintain the product in good

functional order.

3. Type 2 Valves are only used for applications covered by their approved

designations, refer to the TMV2 Requirements Manual.

Caution!

1. Read all of these instructions.

2. Retain this guide for later use.

3. Pass on this guide in the event of change of ownership of the installation site.

4. Follow all warnings, cautions and instructions contained in this guide.

5. The function of a thermostatic mixing valve is to deliver water consistently at a safe

temperature. In keeping with every other mechanism, it cannot be considered as

functionally infallible and as such, cannot totally replace a supervisor’s vigilance

where that is necessary. Provided it is installed, commissioned, operated and

maintained within manufacturers recommendations, the risk of failure, if not

eliminated, is reduced to the minimum achievable.

6. Anyone who may have difculty understanding or operating the controls of any

shower should be attended whilst showering. Particular consideration should

be given to the young, the elderly, the inrm or anyone inexperienced in the

correct operation of the controls. This shower is not intended for use by persons

(including children) with reduced physical, sensory or mental capabilities, or

lack of experience and knowledge, unless they have been given supervision or

instruction concerning the use of the shower by a person responsible for their

safety.

7. Rapid/Excessive movement of the ow and/or temperature control levers may

result in momentary unstable blend temperatures.

8. Care is required when adjusting ow or temperature, make sure that the

temperature has stabilised. Sunburn or skin conditions can increase your

sensitivity to hot water.

9. Make sure that you fully understand how to operate this shower and make sure

that it is properly maintained in accordance with the instructions given in this

manual.

6

10. The plumbing installation must comply with the requirements of UK Water

Regulations/Bye-laws (Scotland), Building Regulations or any particular

regulations and practices, specied by the local water supplier. The installation

should be carried out by a plumber or contractor who is registered or is

a member of an association such as:

i) Institute of Plumbing (IOP), throughout the UK.

ii) National Association of Plumbing, Heating and Mechanical Services

Contractors (NAPH & MSC), England and Wales.

iii) Scottish and Northern Ireland Plumbing Employers’ Federation

(SNIPEF), Scotland and Northern Ireland.

11. The shower head must be de-scaled regularly. Lack of regular shower head

cleaning will lead to poor performance and cause early failure of the product.

If necessary refer to the Shower Fittings User Guide for more information.

12. When this product has reached the end of its serviceable life, it should be

disposed of in a safe manner, in accordance with current local authority

recycling, or waste disposal policy.

7

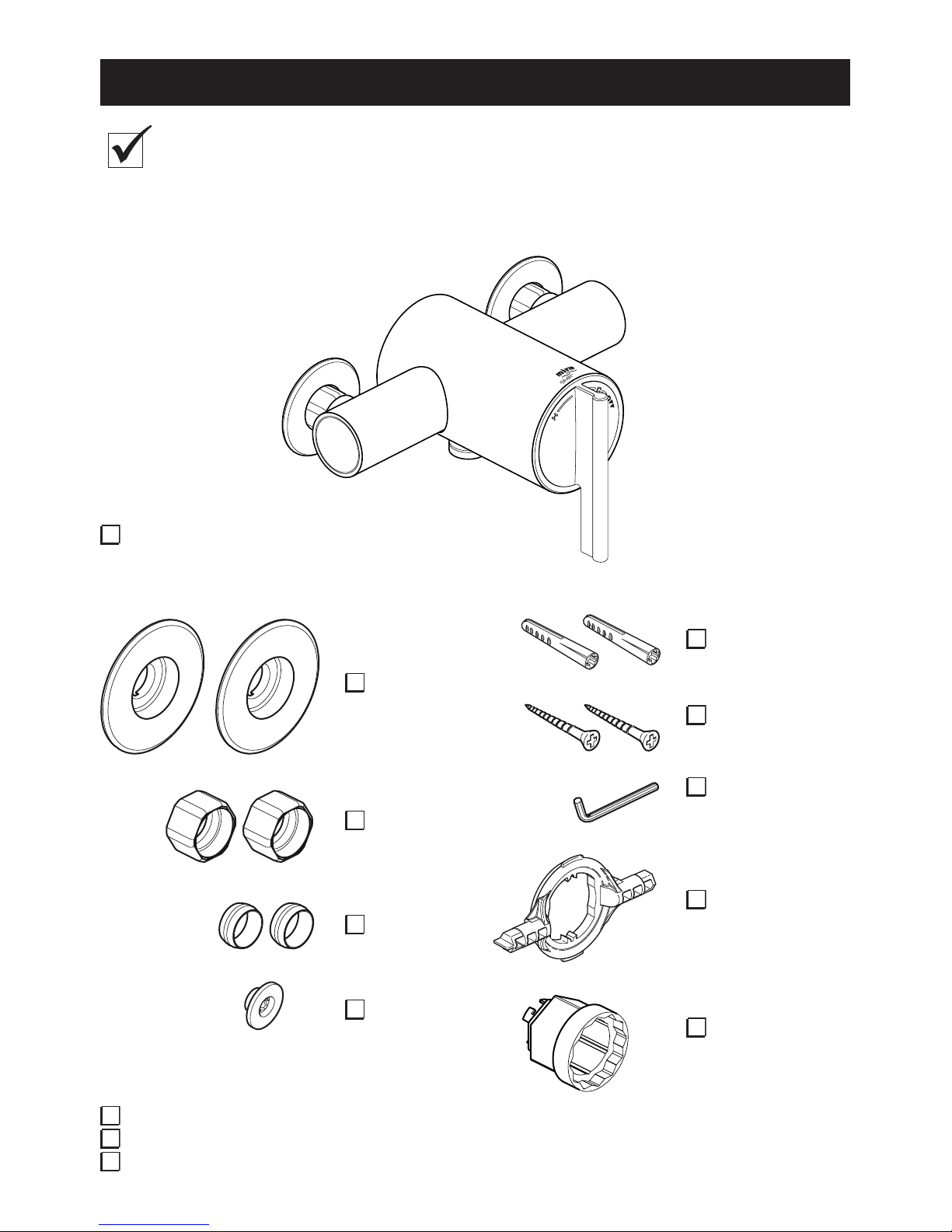

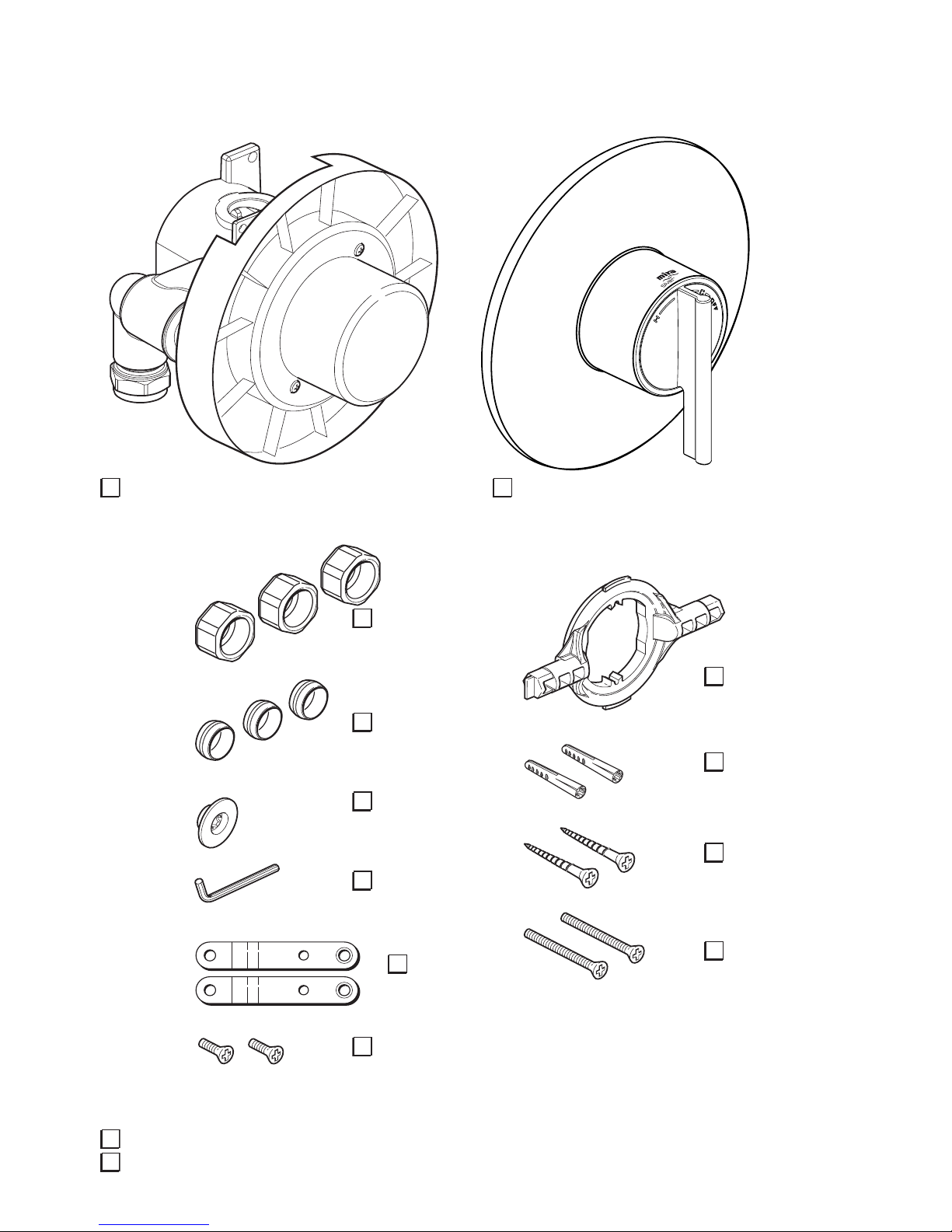

PACK CONTENTS

Tick the appropriate boxes to familiarize yourself with the part names and to

conrm that the parts are included.

1 x Mira Silver Thermostatic Mixer

1 x ‘O’ Key

2 x Olives

2 x Compression

Nuts

2 x Concealing

Plates

1 x 2.5 mm

Hexagon Key

2 x No. 8 x 1 ¼”

Screws

2 x Wall Plugs

Documentation

1 x Guarantee Registration Document

1 x Installation Template

1 x TMV2 Requirements Manual

1 x 12 L/Min

Flow Regulator

Exposed Silver Thermostatic Mixer

1 x Cartridge

Removal Socket

8

Built-in Silver Thermostatic Mixer

Documentation

1 x Guarantee Registration Document

1 x TMV2 Requirements Manual

1 x 2.5 mm

Hexagon Key

2 x No. 8 x 1 ¼”

Screws

2 x Wall Plugs

1 x 12 L/Min

Flow Regulator

3 x Olives

3 x Compression

Nuts

1 x Mira Silver Thermostatic Mixer

(attached to the Building-in Shroud)

1 x Control Assembly

2 x M5 x 40 mm

Screws

2 x Securing

Brackets

1 x ‘O’ Key

2 x Bracket

Securing Screws

9

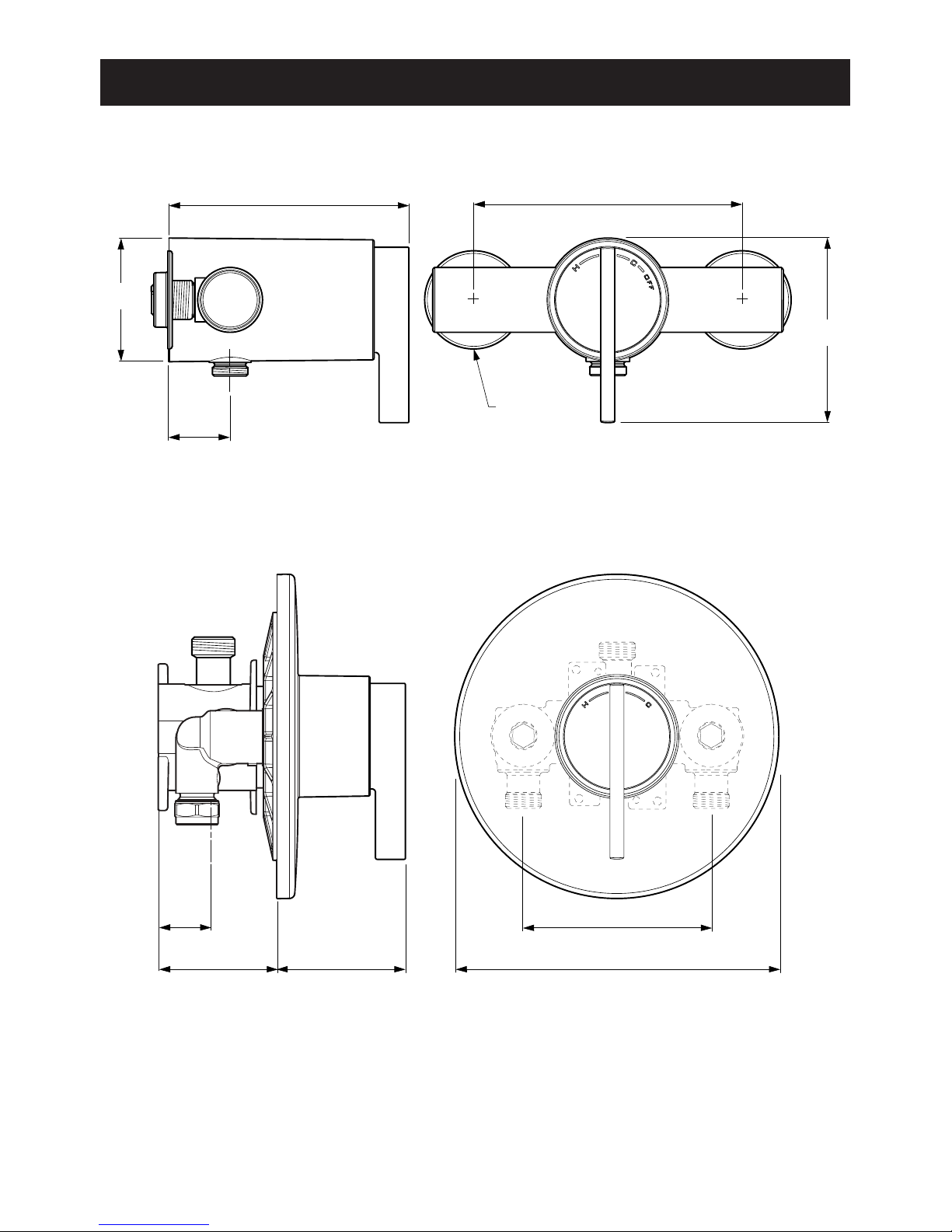

DIMENSIONS

153137

Ø70

35

Ø56

105

20

67 - 85

Building-in Depth

72 Ø183

108

All dimensions in mm.

Exposed Silver Thermostatic Mixer

Built-in Silver Thermostatic Mixer

10

Operating Parameters

For Type 2 Valves, the supply conditions specied in the TMV2 Requirements Manual

take precedence over the operating parameters which follow.

Pressures

Maximum Static Pressure: 10 Bar.

Maximum Maintained Pressure: 5 Bar.

Minimum Maintained Pressure (Gas Water Heater): 1.0 Bar.

(for optimum performance supplies should be nominally equal).

Minimum Maintained Pressure (Gravity System): 0.1 Bar.

(0.1 bar = 1 Metre head from base of cold tank to the outlet of the shower handset).

Note! For combination type boilers it may be necessary to t the ow regulator

(supplied) to restrict the ow through the boiler to ensure it produces a sufciently

hot water temperature.

Important! The tting of ow regulators will invalidate any TMV2 compliance due to the

minimum ow rate requirements. Do not t the ow regulator in TMV2 applications.

Temperatures

Factory Pre-set (Blend) Shower: 43°C.

Optimum Thermostatic Control Range: 35°C - 45°C.

(Achieved with supplies of 15°C cold, 65°C hot and nominally equal pressures).

Recommended Hot Supply: 60°C - 65°C.

Note! The Mixing Valve can operate at temperatures up to 85°C for short periods

without damage. However for safety reasons it is recommended that the maximum

hot water temperature is limited to 65°C.

Minimum Differential between Hot Supply and Outlet Temperature: 10°C.

Cold Water Range: 5°C - 25°C.

Thermostatic Shut-down

For safety the Thermostat will shut off the Hot Supply Within 2 Seconds if the Cold

Supply Fails.

(Achieved only if the hot supply temperature is greater than 10°C above the set

blend temperature).

Connections

Exposed Mixer:

Inlets: 15 mm Compression, Hot - Left, Cold - Right.

Outlet: ½” BSP Flat Face, Bottom - Outlet.

Built-in Mixer:

Inlets: 15 mm Compression, Hot - Left, Cold - Right.

Outlet: 15 mm Compression, Top - Outlet.

If reversed inlets are required refer to section: ‘Reversed Inlet Supplies’.

SPECIFICATIONS

11

Flow Rates

Typical Flow Rates on Low Pressure Systems (0.1 Bar to 1 Bar) - Mira Silver with

L10 Adjustable Fittings or Rigid Head:

Typical Flow Rates on High Pressure Systems (1 Bar to 5 Bar, with 12 Litre/Min Flow

Regulator tted in shower control outlet) - Mira Silver with L10 Adjustable Fittings

or Rigid Head:

Flow Regulator Installation

Flow regulators are supplied with this product and should be tted in high pressure

systems to either;

1. Reduce Excessive Force & Flow Rate

2. Reduce Noise through the mixer due to high or unequal pressures

3. Stabilise incoming supply temperatures

Important! The tting of any ow regulator will invalidate TMV2 compliance due to

the minimum ow rate requirements. Do not t ow regulators in TMV2 applications.

12

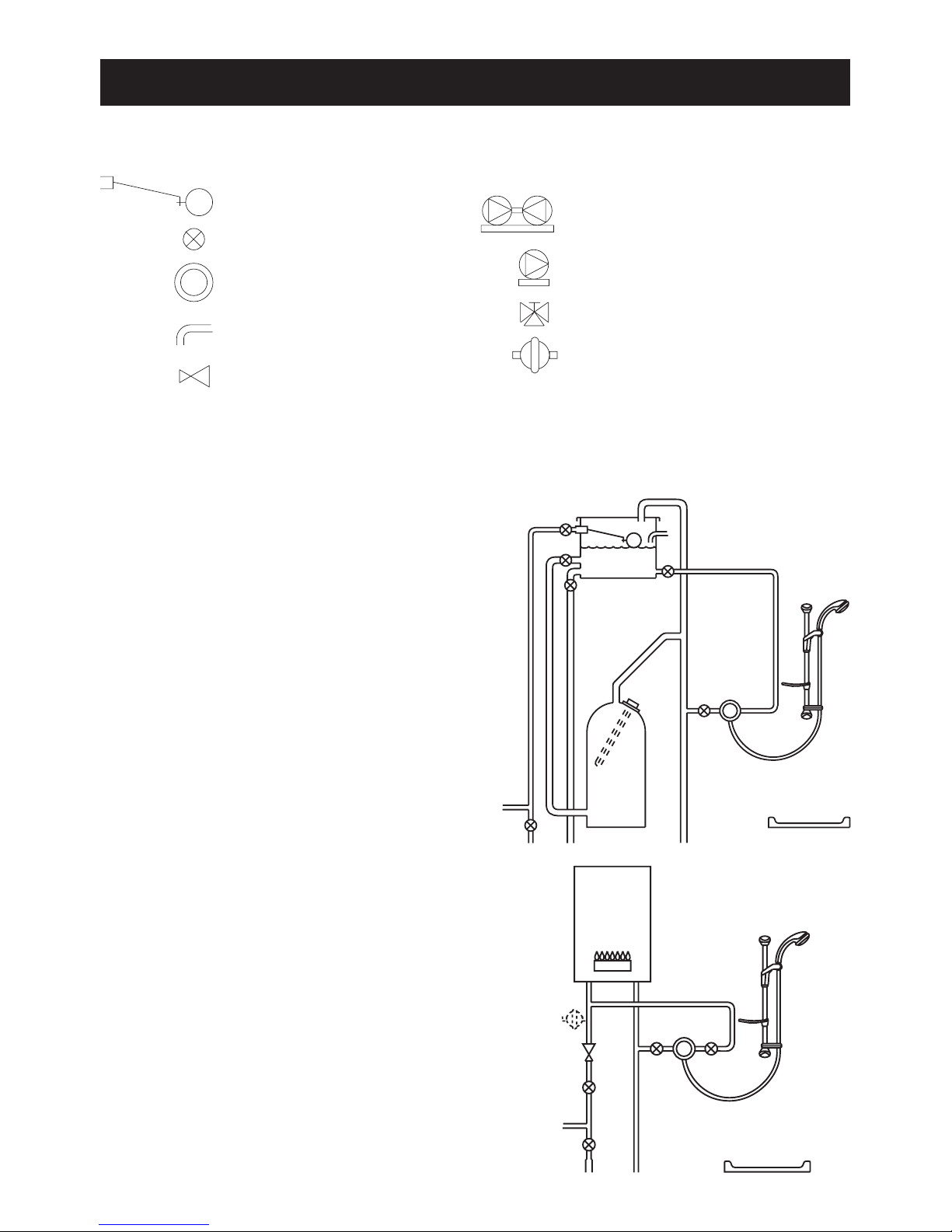

INSTALLATION REQUIREMENTS

Isolating Valve

Thermostatic Mixer

Overow Indicator

Pressure Reducing Valve

Float Valve

Twin Impeller Pump

Single Impeller Pump

Tempering Valve

Mini Expansion Vessel

Key to Symbols

The Mira Silver Thermostatic Mixer is compatible with the following systems:

Gravity fed system

The Thermostatic Mixer MUST be fed from

a cold water cistern and hot water cylinder

providing nominally equal pressure.

Gas heated system

The Thermostatic Mixer MUST be installed

with a gas water heater or combination

boiler of a fully modulating design.

Note! We recommend the use of a

12 L/Min Outlet Flow Regulator (supplied).

However, it is possible following the

installation of the Flow Regulator that the

ow rate is reduced too much for the boiler

to ignite. If this is the case remove the ow

regulator.

Loading...

Loading...