Mira SDP044T, SDP054T User Manual

1

Installation & User Guide

MIRA ADV ANCE ATL

These instructions are to be left with the user

8.7 AND 9.8 kW

ELECTRIC SHOWER

This product is suitable for mains fed cold water only.

2

CONTENTS

Introduction .............................................................................................3

Important Safety Information .................................................................4

Pack Contents .........................................................................................6

Dimensions ..............................................................................................7

Specifi cations ..........................................................................................8

1. Plumbing ..........................................................................................8

2. Electrical ...........................................................................................8

3. Standards and Approvals .................................................................8

4. Patents .............................................................................................8

Shower Performance ..............................................................................9

Installation Requirements ....................................................................10

1. Plumbing ........................................................................................10

2. Electrical .........................................................................................12

Installation .............................................................................................14

Priming the Mira Advance ATL ...........................................................17

Adjustable Temperature Limit ..............................................................20

Commissioning .....................................................................................21

Operation ...............................................................................................23

1. Using your Mira Advance ATL ....................................................... 23

2. Storing the Memory Presets (Memory Control Model only) ...........25

3. How your Mira Advance ATL Shower Works ..................................26

Fault Diagnosis ......................................................................................28

1. Users Troubleshooting Guide .........................................................28

2. Installers Troubleshooting Guide ....................................................30

Maintenance ...........................................................................................34

Wiring Diagram ......................................................................................40

Spare Parts ............................................................................................42

Accessories ...........................................................................................42

Customer Service ....................................................................Back Page

3

TO THE CUSTOMER...

Mira Advance A TL key features:

•

Designed for safety and comfort.

•

Automatically adjusts to maintain constant temperature.

•

Constantly monitors supply conditions.

Mira Advance ATL models covered by this guide

Product

Variant

8.7 9.8

Adjustable

Temperature

Limit

Memory

Push

Button

Feature

Extended

Lever

Control

Drain

Pump

Compatible

Standard

99 9 8 8 8

Memory

99 9 9 8 8

Flex

99 9 8 9 8

Standard

Extra

98 9 8 8 9

Flex

Extra

98 9 8 9 9

•

The following separate drain kits are required for the "Extra" models:

SDP044T Mira Whale Tray Kit (complete with 50 mm gully)

SDP054T Mira Whale Wet Floor Kit (complete with wet gully for vinyl)

If you experience any diffi culty with the installation or operation of your new Electric

Shower , then please refer to “Fault Diagnosis”, before contacting Kohler Mira Ltd.

Our telephone and fax numbers can be found on the back cover of this guide.

4

IMPORTANT SAFETY INFORMATION

1. Warning!

1.1 Products manufactured by us are safe and without risk provided they are

installed, used and maintained in good working order in accordance with our

instructions and recommendations.

1.2 THIS APPLIANCE MUST BE EARTHED. MAKE SURE SUPPLEMENTARY

BONDING COMPLIES WITH THE "REQUIREMENTS FOR ELECTRICAL

INSTALLATIONS".

In accordance with the current edition of 'The Plugs and Sockets etc. (Safety)

Regulations' in force at the time of installation, this appliance is intended to be

permanently connected to the fi xed electrical wiring of the mains system.

1.3 DO NOT twist the individual cable cores of the live and neutral conductors, as

this will prevent them from entering the terminal block.

1.4 The shower unit must not be fi tted where it may be exposed to freezing

conditions. Make sure that any pipework that could become frozen is properly

insulated.

1.5 DO NOT operate this appliance if it appears to be frozen. Allow the appliance

to thaw and then contact your installer before using again.

1.6 DO NOT operate this appliance if water leaks from the Case. Maintenance may

be required before the appliance can be safely used.

1.7 DO NOT fi t any form of outlet fl ow control as the outlet acts as a vent for the

tank body. Only Mira recommended outlet fi ttings should be used.

1.8 There are no user serviceable components beneath the cover of this appliance.

Only a competent tradesperson should remove the cover.

1.9 If any of the following conditions occur , isolate the electricity and water supplies.

Contact your installer or refer to 'To contact us', on the back page of this

guide.

1.9.1 If the cover is not correctly fi tted and water has entered the appliance

case.

1.9.2 If the case is damaged.

1.9.3 If the appliance begins to make an odd noise, smell or smoke.

1.9.4 If the appliance shows signs of a distinct change in performance,

indicating a need for maintenance.

1.10 Isolate the electrical and water supplies before removing the cover.

1.11 Mains connections are exposed when the cover is removed.

1.12 Refer to the wiring diagram before making any electrical connections.

1.13 Make sure all electrical connections are tight, to prevent overheating.

5

2. Caution!

2.1 Read all of these instructions and retain this guide for later use.

2.2 Pass on this guide in the event of change of ownership of the installation site.

2.3 Follow all warnings, cautions and instructions contained in this guide, and on

or inside the appliance.

2.4 The electrical installation must comply with the "Requirements for Electrical

Installations" commonly referred to as the IEE Wiring Regulations, or any

particular regulations and practices, specifi ed by the local electricity supply

company in force at the time of installation. The installation should be carried out

by an electrician or contractor who is "Part P" (Building Regulations) registered,

or is a member of, an association such as:

2.4.1 National Inspection Council for Electrical Installation and Contracting

(NICEIC), throughout the UK.

2.4.2 The Electrical Contractors Association (ECA), England and Wales.

2.4.3 The Electrical Contractors Association of Scotland (ECAS).

2.5 This appliance is a high power unit, it is essential to contact your electricity supply

company to ensure that the electricity supply is adequate for the purpose.

2.6 The plumbing installation must comply with the requirements of UK Water

Regulations/Bye-laws (Scotland), Building Regulations or any particular

regulations and practices, specifi ed by the local water company or water

undertakers. The installation should be carried out by a plumber or contractor

who is registered, or is a member of, an association such as:

2.6.1 Institute of Plumbing (IOP), throughout the UK.

2.6.2 National Association of Plumbing, Heating and Mechanical Services

Contractors (NAPH & MSC), England and Wales.

2.6.3 Scottish and Northern Ireland Plumbing Employers’ Federation (SNIPEF),

Scotland and Northern Ireland.

2.7 Anyone who may have diffi culty understanding or operating the controls of any

shower should be attended whilst showering. Particular consideration should

be given to the young, the elderly, the infi rm, or anyone inexperienced in the

correct operation of the controls.

2.8 When this appliance has reached the end of its serviceable life, it should be

disposed of in a safe manner , in accordance with current local authority recycling,

or waste disposal policy.

6

Medium

Low

Stop

R

ese

t

Low Pres

sure

Temperature

High

Flow

Medium

Low

Stop

R

es

e

t

Low Pres

sure

Tem perature

High

Flow

Medium

Low

Stop

Stor

e

R

es

e

t

Low P

res

sure

Temperature

High

Flow

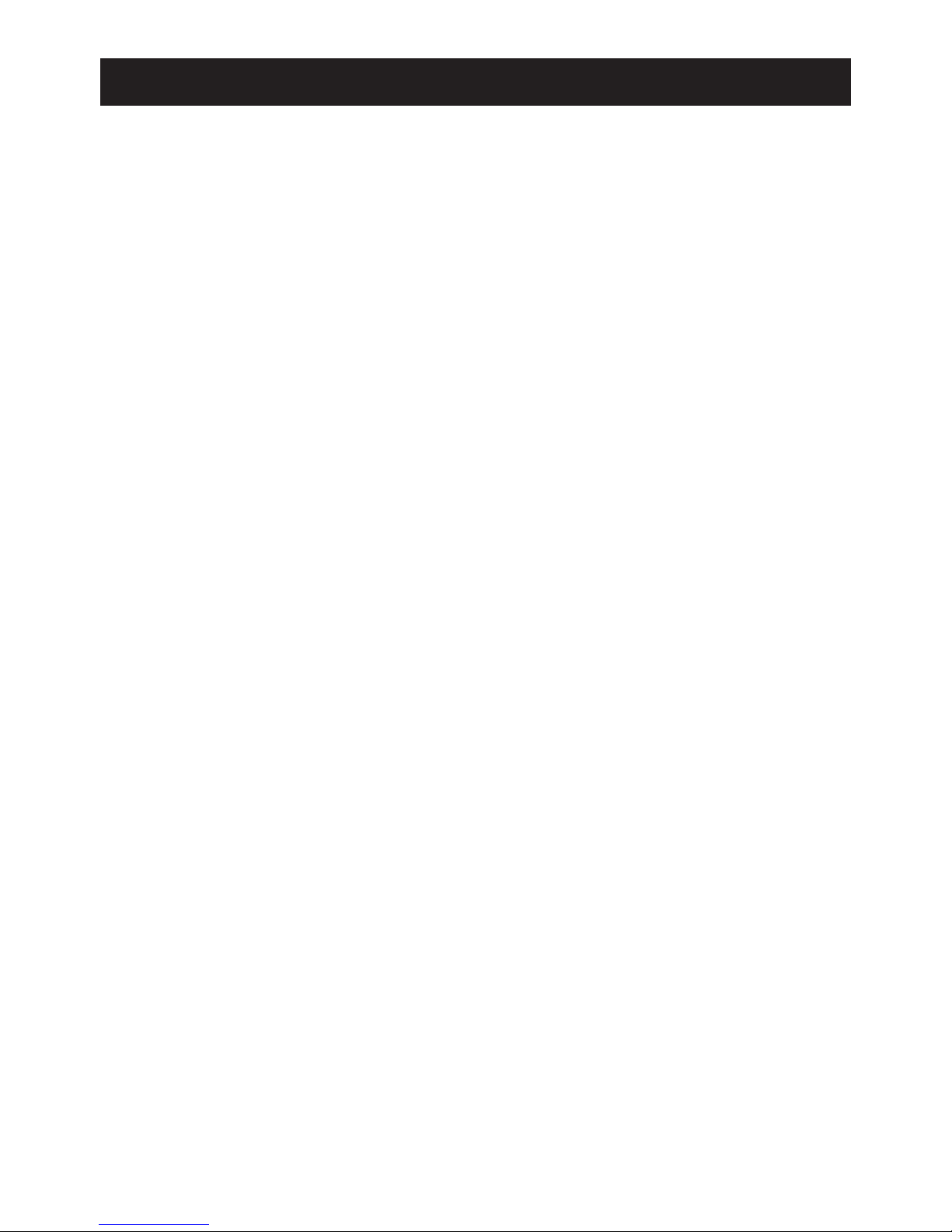

PACK CONTENTS

1 x Installation and User Guide

1 x Installer Checklist

1 x Installation Template

1 x Guarantee Card

1 x Olive 1 x Compression Nut 1 x Tap Connector Adaptor

(for fi tting to existing tap connector)

1 x Mira Advance ATL

Standard or Standard Extra

(Whale Shower Drain Pump

supplied separately)

2 x Wall Screws

2 x Wall Plugs

1 x Earth Sleeve

Or Or

Tick the appropriate boxes to familiarize yourself with the part names and to

confi rm that the parts are included.

1 x Mira Advance ATL

Memory

1 x Mira Advance ATL

Flex or Flex Extra

(Whale Shower Drain Pump

supplied separately)

7

5

6

4

7

3

8

2

9

1

1

2

3

4

5

Flow

High

Medium

Temperature

Stop

Low

Reset Low Pressure

5

6

4

7

3

8

2

9

1

Flow

High

Medium

Temperature

Stop

Low

Reset Low Pressure

5

6

4

7

3

8

2

9

1

1

2

3

4

5

Flow

High

Medium

Temperature

Stop

Store

Low

Reset

Low Pressure

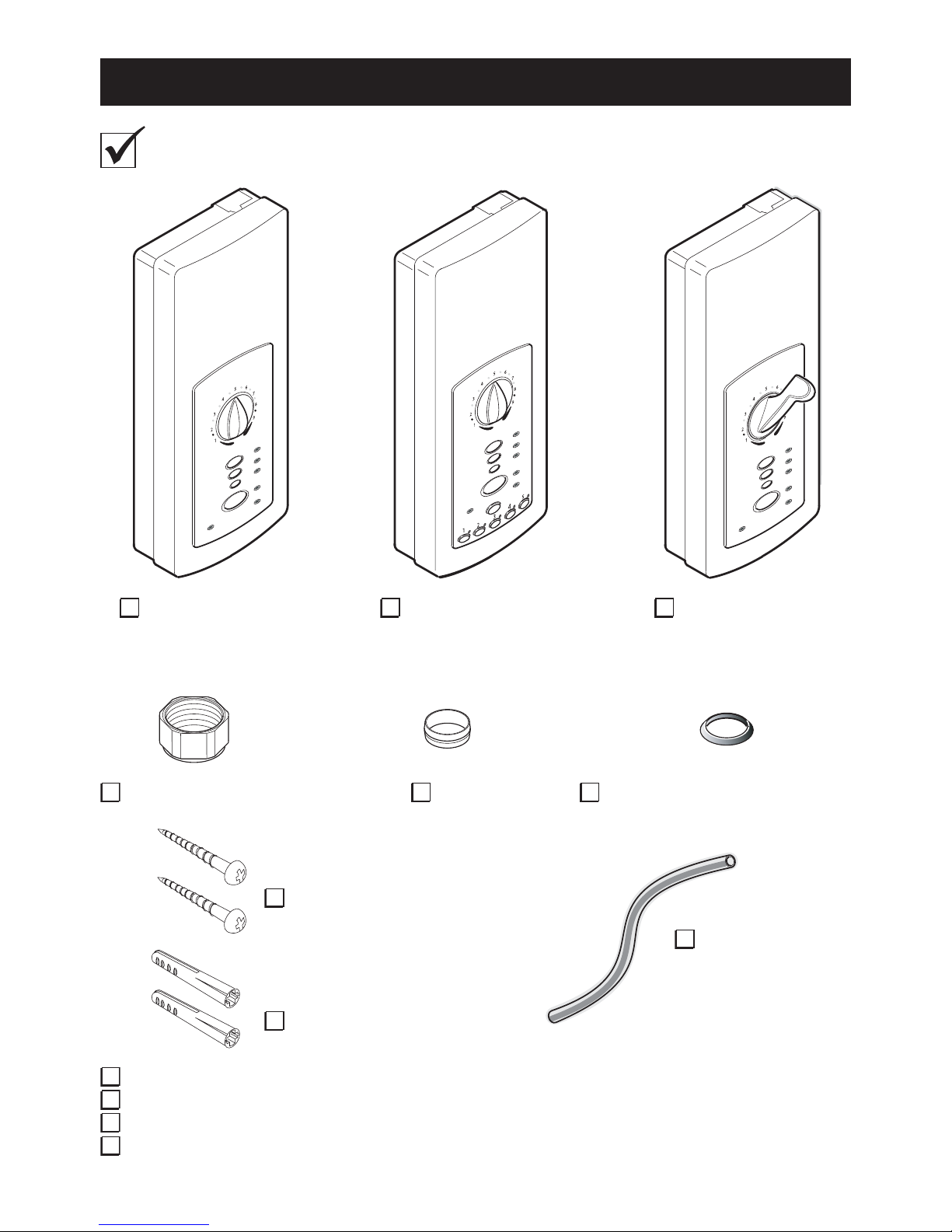

DIMENSIONS

168 mm 168 mm

168 mm

Advance A TL Flex

or Flex Extra

Advance A TL Standard

or Standard Extra

Advance A TL Memory

84.5 mm

68 mm

84.5 mm

68 mm

395 mm395 mm

395 mm

110 mm

68 mm

All dimensions are nominal

8

SUPPLY/SPECIFICATIONS

Plumbing Supply

Supply Source Mains cold water only

Recommended Minimum

Dynamic Pressure*

100 kPa (1.0 bar)

Maximum Static Pressure 1000 kPa (10 bar)

Minimum Static Pressure** 20 kPa (0.2 bar)

Maximum Inlet Temperature 28°C

Minimum Inlet Temperature 2°C

Inlet/Outlet Connections ½" BSP male fitting

Electrical Supply

Nominal Rating at 230 V 8.0 kW 9.0 kW

Nominal Rating at 240 V 8.7 kW 9.8 kW

Supply Fuse/Circuit Breaker

8.7 kW 40 Amps

9.8 kW 45 Amps

Residual Current Device RCD

(Strongly Recommended)

30 mA

Supply Cable

No larger than 16mm²

Note: Refer to current IEE

regulations to determine

minimum cable size.

Isolation Switch

45 Amp Double pole, with

3mm contact separation.

Maximum Ambient T emperature 30°C

Minimum Ambient T emperature 2°C

* Thermostatic performance will be maintained down to 50 kPa (0.5 bar) with reduced flow

performance.

** Static pressure must never fall below 20 kPa (0.2 bar) when other draw offs are in use, e.g. fl ushing

toilet. This is the minimum pressure required to keep the fl ow valve closed.

Standards and Approvals

The Mira Advance ATL complies with the requirements of the BEAB Care Mark

Standard and the relevant directives for CE marking.

Patents and Design Registration

Design Registration: 2 087 315, 2 087 316, D.13322, D.13320

Patents: 2269466, 2270370, 2298478, 2298479, 2298481

9

SHOWER PERFORMANCE

Seasonal changes

affecting water supply

temperature.

Changes of incoming

supply pressure.

Changes of incoming

supply voltage.

Mains cold water draw

off, e.g. toilet, wash

basin etc.

Heat transfer due to

position of mains cold

water pipe.

Changes in Flow Rate

(force of shower).

Temperature remains

constant.

What affects shower performance?

The shower unit's top priority is to keep the desired water temperature constant.

To maintain this temperature, the shower may have to automatically change the

rate of water fl owing through the unit. Any of the following conditions can cause the

shower to change the fl ow rate (force of the shower) in order to keep the temperature

constant. Most changes are minor and will go unnoticed.

hot pipe

mains cold

pipe

E.g.

Positioned next to hot

water pipe.

Routed through heated

area such as loft or

airing cupboard.

10

General Notes

This product works best when supply temperatures and pressures remain

stable and within the product specifi cations, refer to section "Specifi cations".

If the supply conditions fall outside the specifi cations, the shower may go into

a safe shut down condition.

1. Plumbing

Refer to section: "Important Safety Information" fi rst.

1.1 Do not use sealing compounds on any pipe fi ttings or joints.

Supply pipework MUST be fl ushed to clear debris before connecting the Mira

Advance ATL. Debris will reduce the performance of the unit.

1.2 Avoid running the pipework through excessively hot or cold areas such as hot

loft spaces, airing cupboards, or in close proximity to hot water pipes. If this

cannot be avoided, we would recommend insulating the pipes.

1.3 Never fi t the unit to hot water supplies or to gravity systems of any description.

Only fi t the product to a mains cold water pipe.

1.4 The Mira Advance A TL is suitable for installation within a shower area and must

be positioned over a water catchment area with the controls at a convenient

height for the user . The shower fi ttings should be positioned so that the handset

discharges down the centre line of the bath, or across the opening of a shower

cubicle, and must be directed away from the Mira Advance ATL.

1.5 The Mira Advance ATL is fi tted with an inlet connector assembly that is designed

to accept water supplies from the top or bottom. The water supply can be fed with

15 mm pipe or 10 mm microbore pipe, suitably adapted for the inlet connector

assembly . If 10 mm microbore is used, then an allowance for increased pressure

loss must be made to make sure that the minimum maintained inlet pressure

of 1 bar is achieved, refer to section: "Specifi cations".

1.6 The Mira Advance A TL must be fi tted onto the fi nished wall surface i.e. on top of

the tiles. Do not block the air ventilation gaps around the sides of the unit, either

by tiling up to the sides of the unit or by using a sealant around the case (Small

pillars moulded on to the back of the case allow air circulation). The appliance

is designed to be ventilated. Failure to do this may cause product failure.

1.7 We recommend that a non-restrictive (free fl owing) isolating valve is fi tted in

the cold water supply pipe to allow maintenance of the Mira Advance ATL. Do

not fi t a valve that has a loose washer plate (jumper) as this can lead to a build

up of static pressures.

1.8 When installed in very hard water areas (above 200 ppm temporary hardness)

your installer may advise the installation of a water treatment device, to reduce

the effects of limescale formation. Malfunction of the Mira Advance ATL due to

excessive limescale formation is not covered by the manufacturer's guarantee.

Your local water company will be able to advise the hardness of water in your

area.

INSTALLATION REQUIREMENTS

11

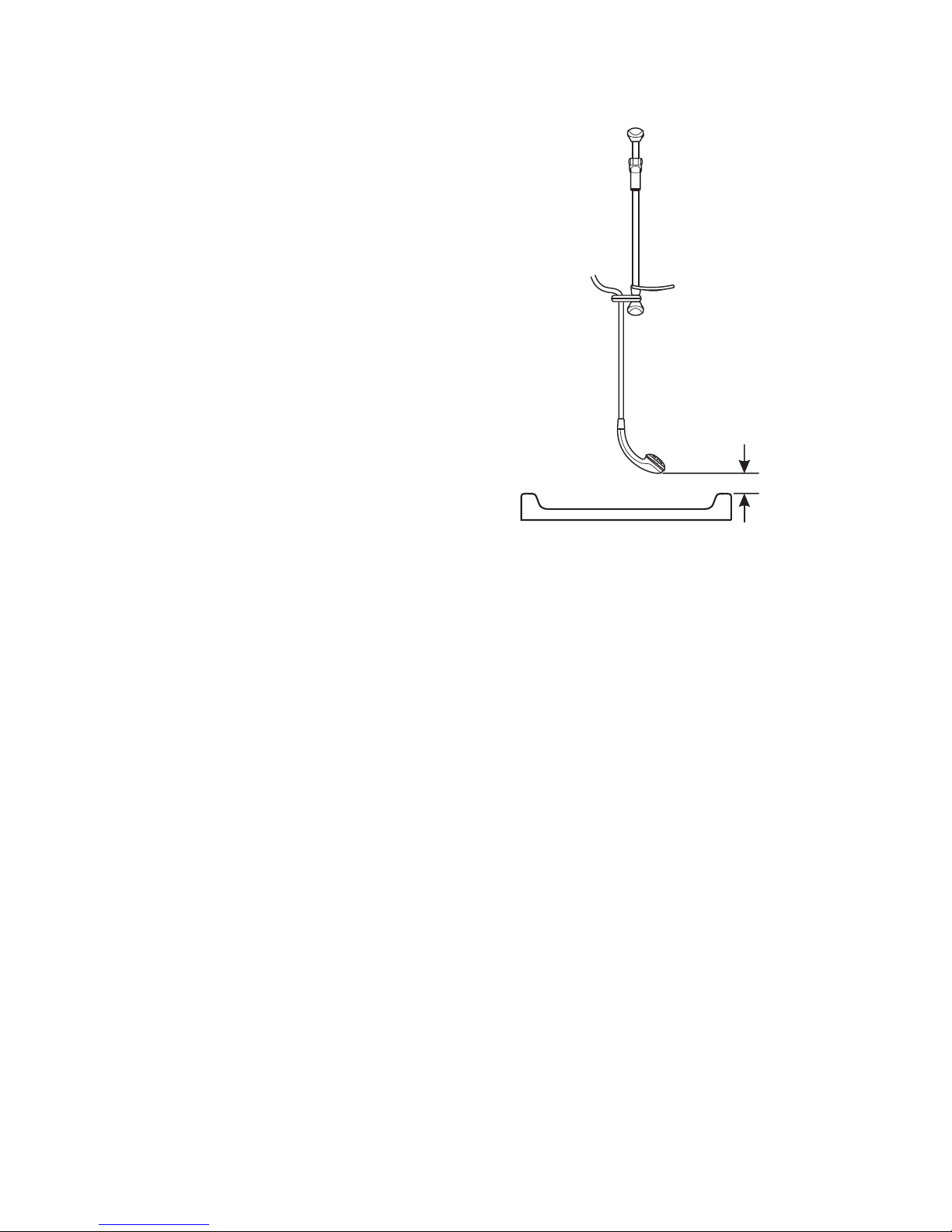

1.9 The hose should be fi tted through the hose retaining ring to prevent the handset

from dropping below the spill-over level of the bath or shower , which could lead

to contamination from backsiphonage.

The hose retaining ring should meet

the majority of user requirements

for shower installations with fl exible

outlet fi ttings. However, there will be

occasions when the hose retaining

ring will not provide a suitable solution.

In these instances an outlet double

checkvalve, e.g. the Mira DCVH, must be fi tted, refer to section:

"Accessories". The inclusion of the

Mira DCV -H will increase the required

supply pressure typically by 10 kPa

(0.1 bar).

Caution! Double checkvalves, fi tted

in the inlet supply to the appliance,

cause a pressure buildup, which could

exceed the maximum static inlet pressure for the appliance.

1.10 Avoid layouts where the shower hose will be sharply kinked. This may reduce

the life of the hose.

Spill-over

Level

25 mm

minimum

12

2. Electrical

Refer to section: "Important Safety Information" fi rst.

2.1 In a domestic installation, the rating of the electricity supplier ’s fuse and the

consumer unit must be adequate for the additional demand. All Mira Advance

ATL electric showers are high power units, therefore it is essential to contact

your electricity supplier to make sure that the supply is adequate for the

product. Voltage drop due to local heavy demand will reduce the shower’s

performance.

2.2 The Mira Advance ATL must be earthed by connecting the supply-cable earth

conductor to the earth terminal.

Supplementary bonding: Within the bathroom or shower room, all accessible

conductive parts of electrical equipment and extraneous conductive parts (metal

parts) that are likely to introduce earth potential, must be electrically bonded to

earth using a minimum cable size of 4.0 mm

2

if the cable is not mechanically

protected, (2.5 mm

2

if mechanically protected).

2.3 The minimum required supply cable size must conform to BS 7671.

2.4 As a guide only, and in accordance with BS 7671 we recommend close circuit

protection:

i.e. 8.7 kW = 40 Amp

9.8 kW = 45 Amp

It is strongly recommended that a 30 mA Residual Current Device (RCD) is

included in the electrical circuit. This may be part of the consumer unit or a

separate unit.

A separate, permanently connected supply is taken from the consumer unit to

the appliance through a double-pole switch, which has at least 3 mm contact

separation. The switch can be a ceiling mounted pullcord type within the shower

room or a wall mounted switch in an adjacent room.

2.5 DO NOT twist the individual cable cores of either the live or neutral conductors,

as this will prevent them from entering the terminal block.

2.6 DO NOT exert strain on the terminal block. Make sure that the electrical

connections are tightly screwed down.

2.7 DO NOT turn on the electrical supply until the plumbing has been completed.

13

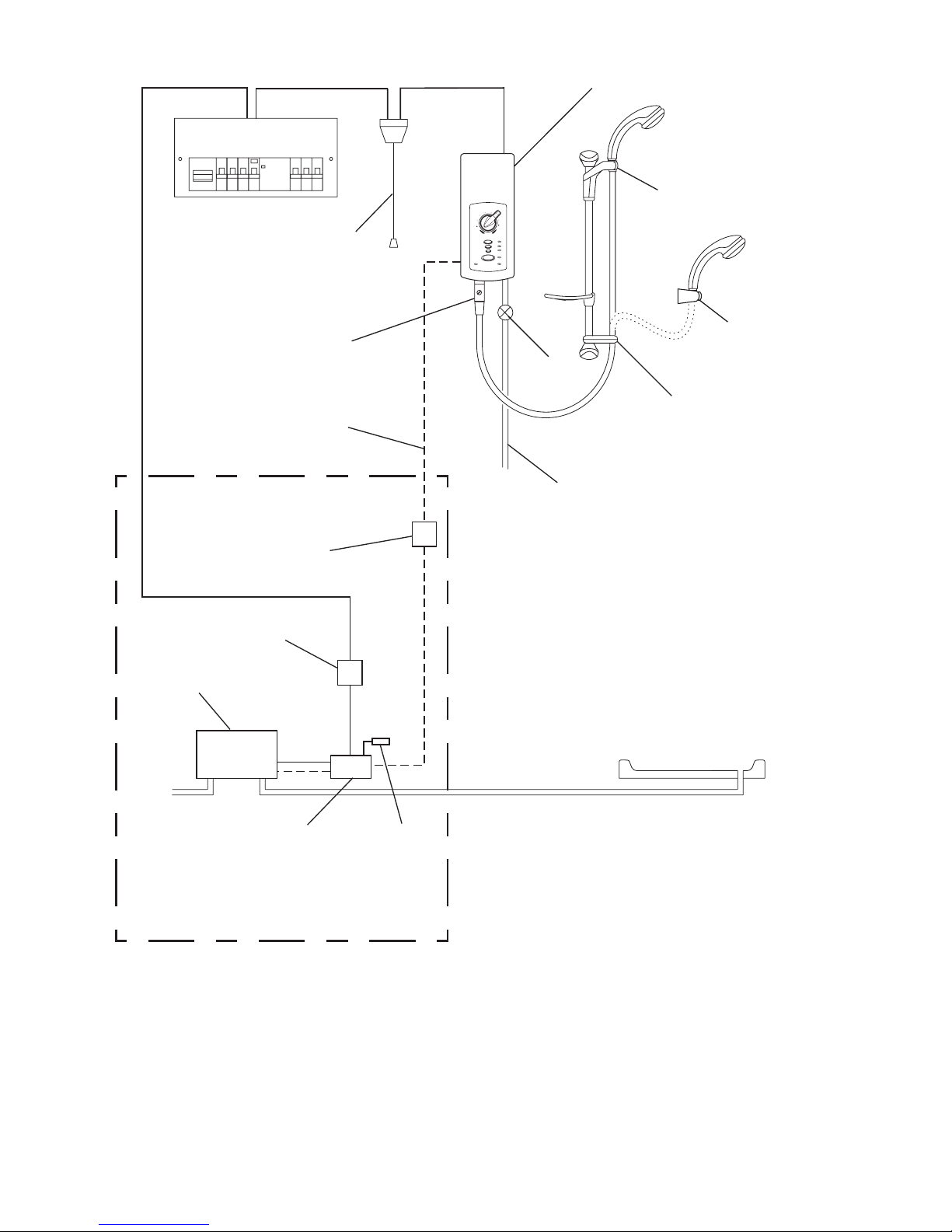

Plumbing and Electrical Schematic Diagram

5

4

7

3

8

2

9

1

L

ow

P

re

s

s

u

r

e

Hig

h

Medium

L

ow

S

to

p

Tem

p

e

r

a

t

u

r

e

S

e

r

v

ic

e

Flow

Mira Advance A TL

Optional Outlet

Double Checkvalve

45 A Double-pole

Isolating Switch

Hose

Retaining

Ring

Mains-fed Cold

Water Supply

Clamp

Bracket

RF2 Handset

Holder

Consumer Unit

Isolating

Valve

Terminal Block

Switched

Spur

Transformer/

Controller

Shower

Drain Pump

Standard Extra & Flex Extra

models only

Signal Cable

Push Button

Override Switch

14

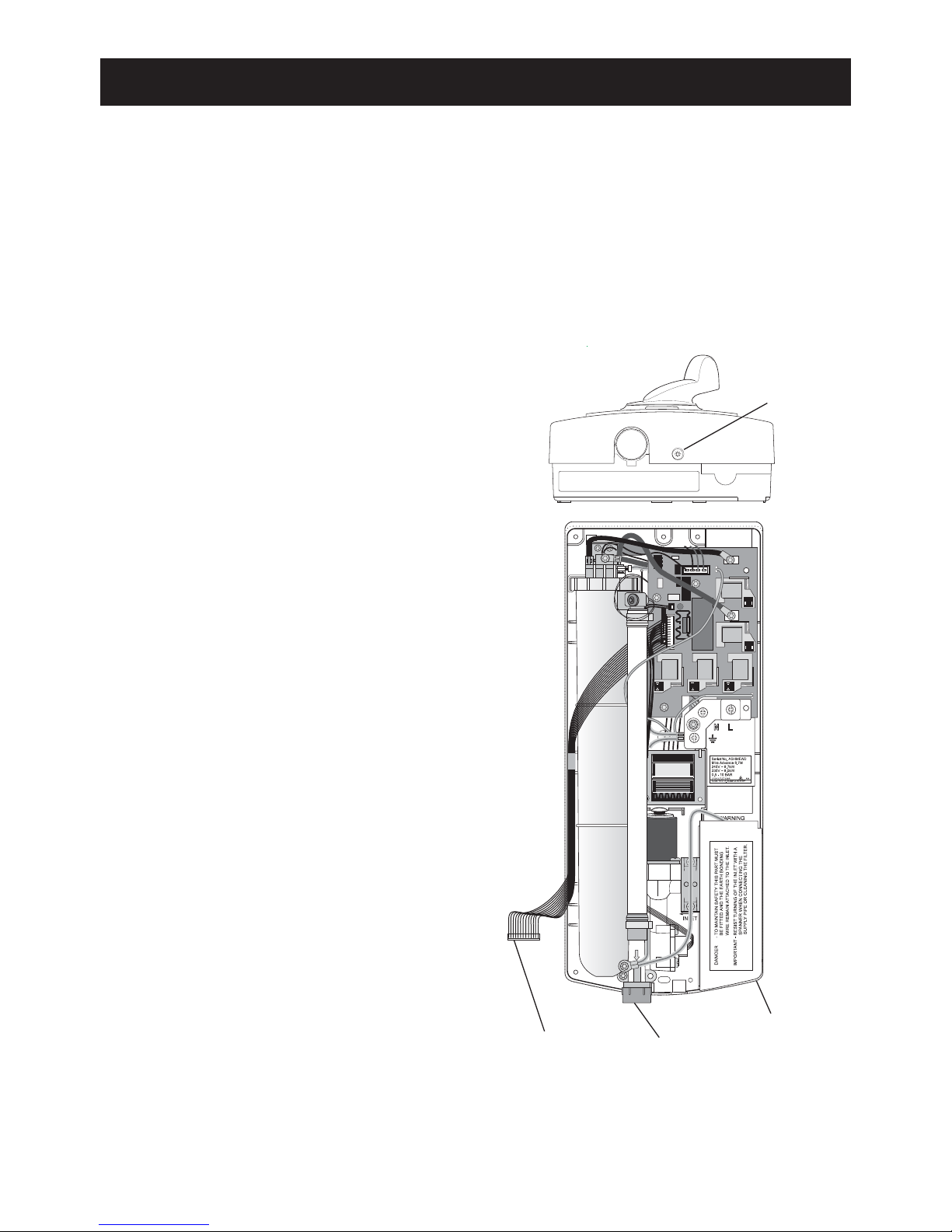

INSTALLATION

Plumbing Connection

1.1 Unscrew the Case Securing Screw

and carefully pull the bottom of the

Cover outwards and upwards off the

Case.

1.2 Remove the Inlet Shield, located over

the Inlet Connector Assembly.

1.3 When deciding the position of the

Mira Advance ATL on the wall, allow

100 mm minimum clearance to

the right hand side of the case, to

provide unrestricted access to the

inlet connector, for installation and

maintenance. Allow 10 mm minimum

clearance from the top of the case to

allow the cover to be removed.

1.4 Determine whether the cold water

and cable supplies will be top (falling),

bottom (rising), or rear inlet to the

Mira Advance A TL. Provision must be

made for routing the signal cable from

the appliance to the Shower Drain

pump (up to 2 m), this applies to the

Standard Extra and Flex Extra models

only.

Note! Rear inlet must allow access to

the water supply pipe fi ttings.

Refer to section: "Important Safety Information" fi rst.

This installation covers all models of the Mira Advance ATL Thermostatic

shower.

Warning! Isolate the electrical and water supplies before proceeding with the

installation of the Mira Advance ATL. The electricity supply must be turned off at the

mains and the appropriate circuit fuse removed, if applicable.

Note! Bottom inlet is illustrated for clarity in these instructions.

Case Securing

Screw

13-Way

Multi-Connector

Inlet Shield

Transit

Sealing Cap

(outlet)

Loading...

Loading...