Page 1

POWER RANGE

MIRA LOGIC

SHOWER FITTINGS

Installation & User Guide

These instructions are to be left with the user

1

Page 2

CONTENTS

Introduction.............................................................................................3

Important Safety Information .................................................................3

Pack Contents Checklist ......................................................................... 4

Mira Logic Power Shower Fittings ........................................................4

Dimensions .............................................................................................5

Specifications..........................................................................................6

Installation Requirements ......................................................................7

Installation............................................................................................... 8

Slide Bar and Clamp Bracket ...............................................................8

Handset Installation ........................................................................... 10

Soap Dish Installation ........................................................................ 10

Operation............................................................................................... 11

Changing Spray Settings ................................................................... 11

Clamp Bracket Adjustment ................................................................ 12

Fault Diagnosis ..................................................................................... 13

Maintenance .......................................................................................... 14

Cleaning............................................................................................. 14

Spray Plate - Removal and Installation .............................................. 15

Spares.................................................................................................... 16

Mira Logic Spares List ....................................................................... 16

Mira Logic Spares Diagram ................................................................17

Accessories ........................................................................................... 18

Notes...................................................................................................... 19

Customer Service.................................................................... Back Page

2

Page 3

INTRODUCTION

Thank you for purchasing a quality Mira product. To enjoy the full potential of your new

product, please take time to read this guide thoroughly, having done so, keep it handy

for future reference.

Mira Logic Power Shower Fittings

An adjustable spray handset with four different spray actions (start, champagne,

massage and eco*), supplied complete with flexible hose, clamp bracket assembly,

slide bar, supports, hose retaining ring/gel holder and wall mounted soap dish. Available

in white and white/chrome finish.

* The eco setting reduces the water flow on the start mode to give better economical

use of water, whilst still giving an adequate shower performance. This setting performs

best with pumped and mains pressure unvented systems. On some combination

boiler systems the economy setting will have no effect, and will give the same spray

action as the start setting.

IMPORTANT SAFETY INFORMATION

Warning!

1. Products manufactured by us are safe and without risk provided they are installed,

used and maintained in good working order in accordance with our instructions

and recommendations.

Caution!

1. Read all of these instructions.

2. Retain this guide for later use.

3. Pass on this guide in the event of change of ownership of the installation site.

4. Follow all warnings, cautions and instructions contained in this guide.

5. Anyone who may have difficulty understanding or operating the controls of any

shower should be attended whilst showering. Particular consideration should be

given to the young, the elderly, the infirm, or anyone inexperienced in the correct

operation of the controls.

6. When this product has reached the end of its serviceable life, it should be disposed

of in a safe manner, in accordance with current local authority recycling, or waste

disposal policy.

If you experience any difficulty with the installation or operation of your new shower

fittings, then please refer to "Fault Diagnosis", before contacting Kohler Mira Limited.

Our telephone and fax numbers can be found on the back cover of this guide.

3

Page 4

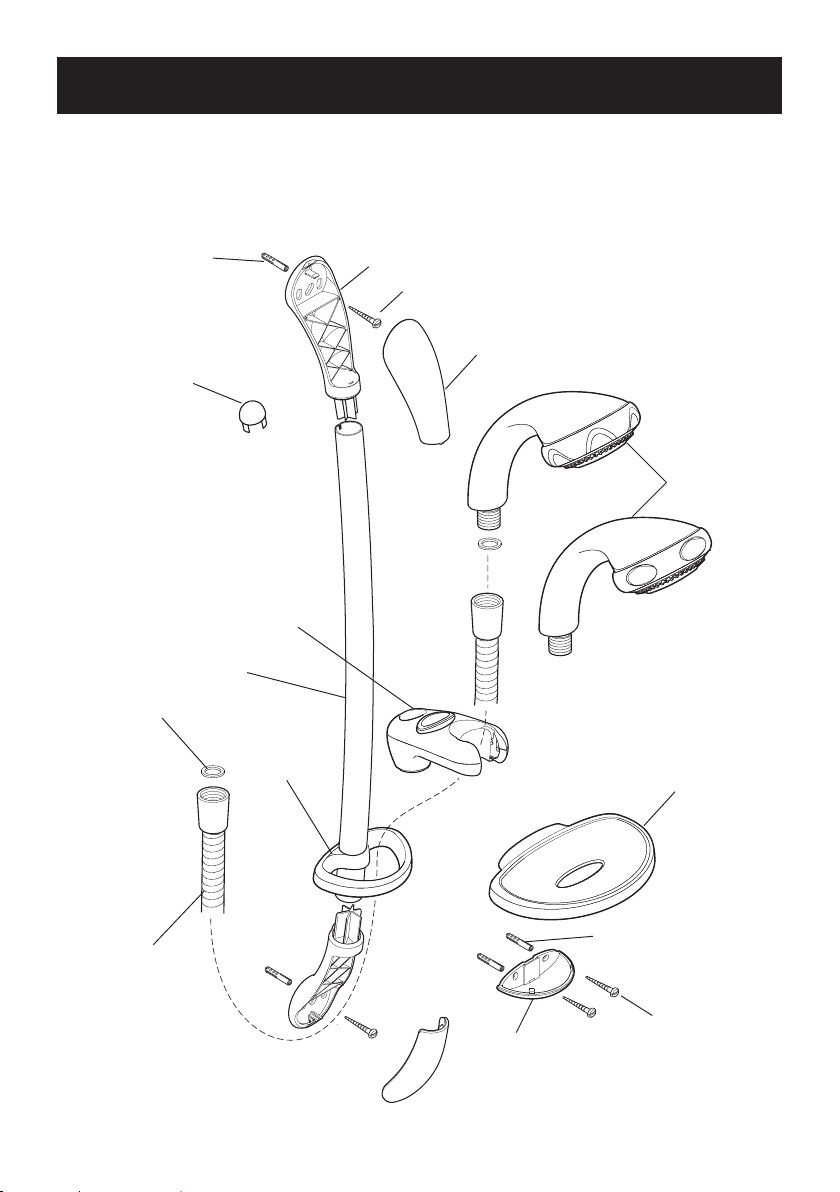

PACK CONTENTS CHECKLIST

Tick the appropriate boxes to familiarize yourself with the part names and to

9

confirm that the parts are included.

Mira Logic Power Shower Fittings

2 x Wall Plugs

1 x Applicator

1 x Clamp Bracket

Assembly

1 x Slide Bar

2 x Hose Seals

1 x Hose

Retaining

Ring

2 x Slide Bar

End Supports

2 x Fixing Screws

2 x Slide Bar

End Caps

OR

1 x Handset

1 x Soap Dish

1 x 1.25 m

Flexible Hose

Documentation

1 x Installation and User Guide

1 x Guarantee Card

4

1 x Soap Dish

Wall Bracket

2 x Soap Dish

Wall Plugs

2 x Soap Dish

Fixing Screws

Page 5

354 mm Max.

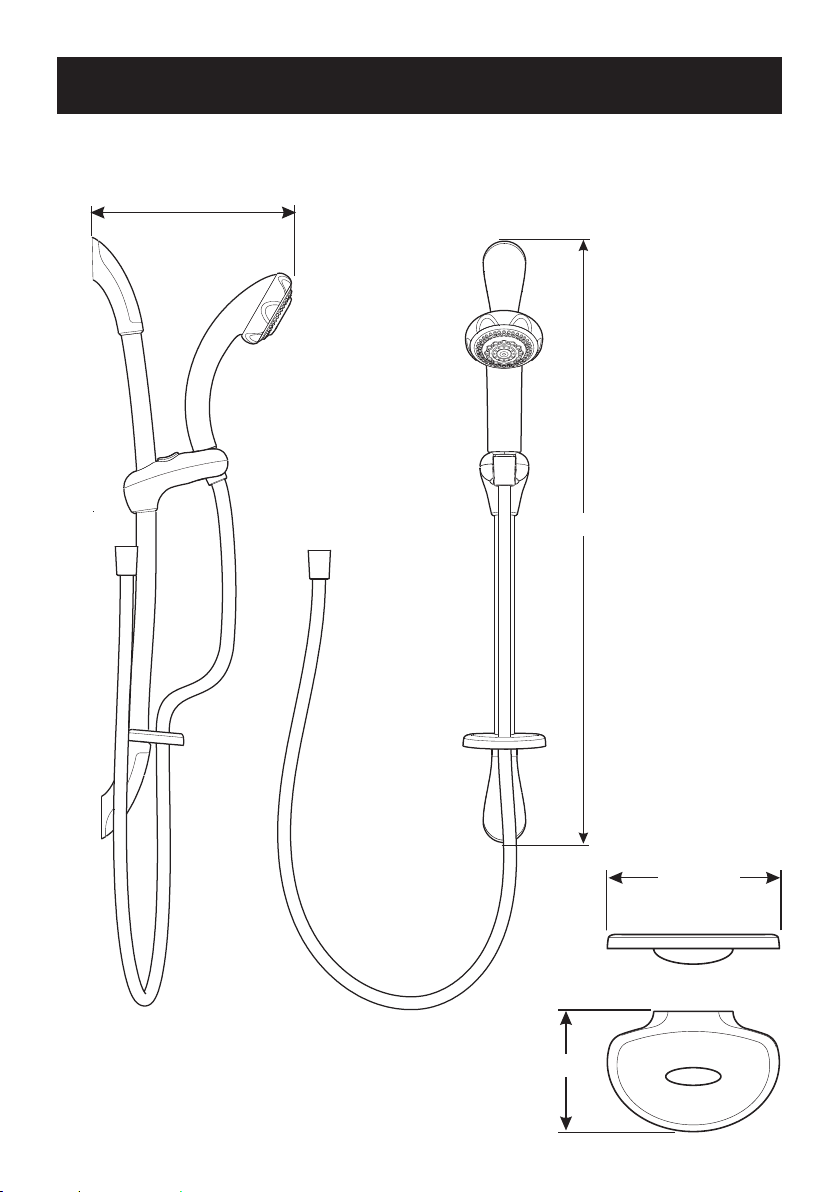

DIMENSIONS

659 mm

156 mm

109 mm

5

Page 6

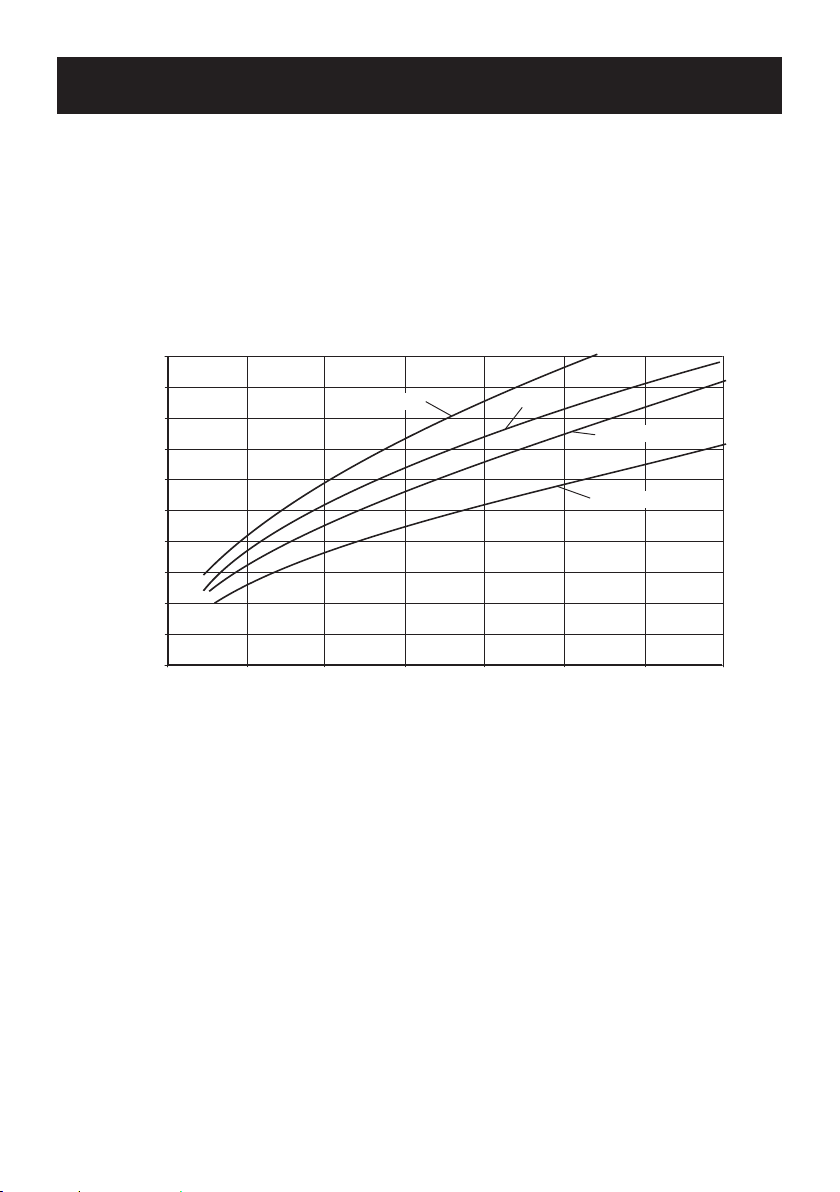

SPECIFICATIONS

Minimum maintained pressure: 0.4 bar

Maximum maintained pressure: 5.0 bar

Warning! Exceeding the stated maximum maintained pressure could result in excessive

spray forces and possible damage to the product.

This is the typical flow performance graph for the Mira Logic power shower fittings

only. There will be an additional pressure loss through the shower control.

20

18

16

14

12

10

8

6

Flow Rate (litres/minute)

4

2

0

0 0.2 0.4 0.6 0.8 1.0 1.2

Start Eco

Massage

Champagne

1.4

Pressure Loss (bar)

Pressure loss = Pressure difference between the inlet and outlet of the fitting.

6

Page 7

INSTALLATION REQUIREMENTS

Installation must be carried out in accordance with these instructions, and must be

conducted by designated, qualified and competent personnel.

1. The hose retaining ring supplied must be used to stop the handset from dropping

below the spill-over level of the bath or shower tray. This will prevent water supply

contamination due to backsiphonage.

2. Installations must comply with UK Water Regulations/ Bye-laws (Scotland), and

Building and Plumbing Regulations in force at the time of installation.

3. When installing the shower fittings in a cubicle, position with the spray pointing

across rather than toward the opening of the cubicle.

4. When installing the shower fittings over a bath, position with the spray pointing

down the centre line of the bath.

5. Avoid layouts where the shower hose will be sharply kinked. This may reduce the

life of the hose.

6 . Do not fit any form of flow control in the shower outlet.

7. Do not use excessive force when making connections.

8. Do not install the fittings in a position where it could become frozen.

9. The minimum pressure required for a satisfactory spray pattern to form, at the

handset or spray head, is 0.1 bar. For a gravity fed shower installation the minimum

head of water required, to accommodate the pressure loss in the pipes and shower

control of a typical installation, is 1.0 metre.

For a pump installation the minimum acceptable vertical distance between the

base of the cold water storage cistern and the shower head to operate the pump’s

flow switches, is typically 0.6 m (600 mm).

7

Page 8

INSTALLATION

Note! For dry lined, stud partition, shower cubicle or laminated panel walls the installer

may wish to obtain alternative proprietary cavity fixings. Use of these alternative

fixings is beyond the scope of this guide.

Important! If the Logic slide bar replaces an existing Mira slide bar make sure that

the position of the shower control and the shower fittings provide a minimum of 25 mm

between the handset and bath/tray spill-over level. This is necessary to prevent

back-siphonage. If this is not possible then the new slide bar will have to be

repositioned.

Slide Bar and Clamp Bracket

Read the section: Installation Requirements before proceeding with the installation.

The slide bar should be positioned to one side of the shower control at a convenient

height for all the family. It should be positioned so that the handset discharges down

the centre line of the bath, or across the opening of the shower cubicle. The handset

should be directed away from the shower control.

1. Decide on a suitable position for the

slide bar avoiding buried cables and

pipes. Make sure that when the hose

retaining ring is placed on the lowest

position on the slide bar there is a

minimum of 25 mm between the

handset and bath/tray spill-over level.

This is necessary to prevent

back-siphonage.

2. Important! The slide bar has been

supplied with an applicator fitted to one

end (refer to illustration) to assist the

assembly of the slide bar through the

clamp bracket.

With the clamp bracket button FULLY

depressed carefully ease the slide bar

through the hole in the clamp bracket.

Take care not to dislodge the constant

friction mechanism or the friction pad.

3. Release the clamp bracket button.

Remove the applicator from the slide

bar and store in a safe place for future

use.

4. Slide the hose retaining ring onto the

slide bar below the clamp bracket.

Spill-over level

Clamp Bracket

Constant Friction

Mechanism and

Friction Pad

Hose Retaining

Ring

25 mm Minimum

Applicator

Slide Bar

8

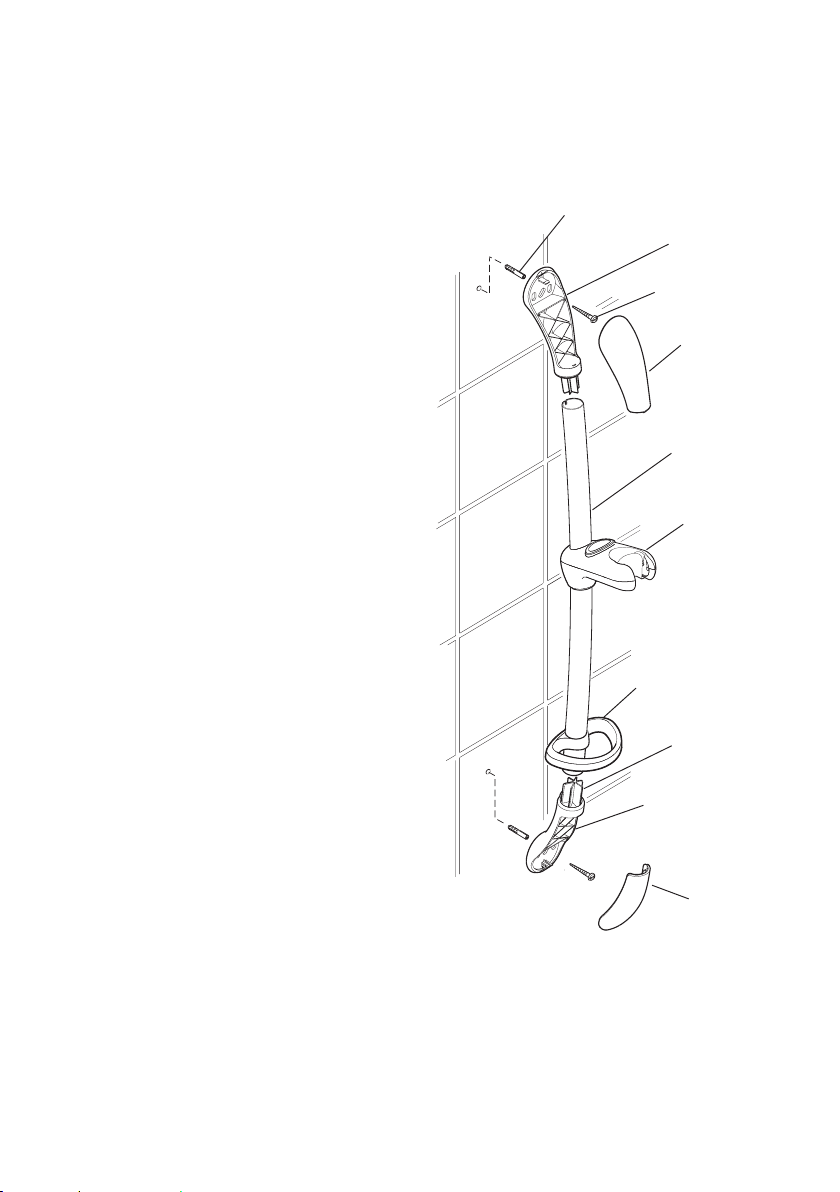

Page 9

5. Make sure that the slots in the slide

bar are aligned with the lugs in the

support and fit the two slide bar

supports to the ends of the slide bar.

Make sure that each support is pushed

firmly home.

Note! If replacing an existing Mira Slide

Bar proceed to instruction 8.

6. Using the assembled slide bar and

supports as a template, mark the

position of the two fixing holes using

the centre slot.

Warning! Make sure that there are no

buried cables or pipes in the wall before

drilling.

7. Drill the two 8 mm holes for the fixing

screws and insert the wall plugs

supplied. (Alternatively use proprietary

cavity fixings for dry lined, stud

partition, shower cubicle or laminated

panel walls).

8. Fix the bottom slide bar support to the

wall using the screw provided. Make

sure that the screw is fully tightened.

9. Loosely screw the top slide bar

support to the wall. Press firmly down

on the top slide bar support and, while

continuing to apply force, fully tighten

the screw.

10. Fit the end caps to the slide bar

supports.

11. Check the slide bar cannot be rotated

or vertically moved. If there is

movement remove the slide bar

assembly from the wall. Check the slide

bar support lugs are properly engaged

with the slots in the slide bar and the

supports are pushed fully onto the slide

bar ends. Refit the slide bar assembly.

12. Refer to sections: Handset Installation

and Soap Dish Installation to

complete the fittings installation.

Wall Plug

Top Slide Bar

Support

Fixing Screw

End Cap

Slide Bar

Clamp

Bracket

Assembly

Hose

Retaining

Ring

Slide Bar

Support Lug

Bottom Slide Bar

Support

End Cap

9

Page 10

Handset Installation

Caution! Do not overtighten the hose.

1. Screw the hose onto the outlet of the

shower control (Make sure that the

hose washer is fitted).

2. Pass the flexible hose through the

hose retaining ring and screw the

remaining end of the hose onto the

handset (Make sure that the hose

washer is fitted).

3. Place the handset in the clamp bracket

assembly.

Handset

Hose

Washer

Clamp

Bracket

Assembly

Hose

Retaining

Ring

Soap Dish Installation

1. Decide on a suitable position for the

soap dish, avoiding any buried cables

and pipes.

2. Place the wall bracket on the wall and

mark the position of the fixing holes.

Warning! Make sure that there are no

buried cables or pipes in the wall before

drilling.

3. Drill the two 8.0 mm fixing holes for

the soap dish at 35 mm centres, and

insert the wall plugs supplied.

4. Screw the wall bracket to the wall.

5. Clip the soap dish onto the wall bracket.

6. This completes the installation of the

Mira Logic power shower fittings.

35 mm

Soap Dish

Wall Plug

Wall Bracket

Fixing Screw

10

Page 11

OPERATION

Changing Spray Settings

The handset has four different spray settings (start, champagne, massage and eco).

1. Eco Setting

Turn the spray plate fully clockwise.

Water will flow from the outer set of

holes and the flow rate will be reduced.

This setting performs best with most

gravity, pumped, and mains pressure

unvented systems. On electric

showers and some combination boiler

systems the economy setting will

have no effect, and will give the same

spray action as the start setting.

2. Start

Turn the spray plate anticlockwise until

it 'clicks' (one click from economy

setting). Water will flow from the outer

set of holes.

3. Champagne

Turn the spray plate anticlockwise until

it 'clicks' (two clicks from economy

setting). Water will flow from the large

diameter holes.

4. Massage

Turn the spray plate anticlockwise until

it 'clicks' (three clicks from economy

setting). Water will flow from the inner

set of holes.

11

Page 12

Clamp Bracket Adjustment

1. Depress the release button and slide

the clamp bracket assembly to the

required position.

2. Move the handset to the required angle.

A friction mechanism within the clamp

bracket assembly will hold the handset

at the desired angle.

Release

Button

Clamp Bracket

Assembly

12

Page 13

FAULT DIAGNOSIS

The trouble shooting information tabled below gives details on what you can do as a

user, should you encounter difficulties with the shower fittings whilst operating the

shower. Before replacing any parts make sure that the underlying cause of the

malfunction has been resolved.

Cause RemedyMalfunction

No flow or low flow

rate from shower

fittings.

Drip from spray plate

assembly in handset.

Spray plate blocked.

Hose blocked or twisted.

Partially closed stop or

servicing valve in supply pipe

work to the shower control.

Head of water below minimum

required.

Problem with shower control.

A small amount of water may

be retained in the shower

fitting after the shower control

has been turned off. This may

drain over a few minutes.

Problem with shower control.

Refer to section:

Maintenance, Cleaning.

Clear blockage or release

twist in hose or renew hose.

Open valve.

Raise cistern or fit Mira pump.

Refer to the shower control

Installation and User Guide.

This is quite normal. Changing

the angle of the shower fitting

may vary the draining time.

Refer to the shower control

Installation and User Guide.

Shower temperature

changes when spray

action is adjusted.

Adjusting the spray action

changes the flow of water.

This may affect some shower

controls and plumbing

installations.

13

To minimise the effect make

sure that the spray plate is

clean. Refer to section:

Maintenance, Cleaning. If

the malfunction persists refer

to the shower control

Installation and User Guide.

Page 14

MAINTENANCE

Cleaning

Many household cleaners contain abrasives and chemical substances, and should

not be used for cleaning plated or plastic fittings. These finishes should be cleaned

with a mild washing up detergent or soap solution, and then wiped dry using a soft

cloth.

Spray Plate Assembly - External

1. Use your thumb or a soft cloth to wipe

any limescale from the soft rubber

nozzles and the front face of the spray

plate assembly.

Spray Plate Assembly - Internal

1. Remove the spray plate assembly.

Refer to section: Maintenance:, Spray

Plate - Removal and Installation.

2. Remove the massage turbine and the

nozzle ring retainer.

3. Clean all the components with a stiff

brush. If necessary use a plastic kettle

descalent in accordance with the

manufacturer's instructions. Flush

thoroughly with water before the

shower is used.

4. If necessary replace the 'O' seals.

Refer to section: Spare Parts.

5. Refit the components in reverse order.

Make sure that the 'O' seals, the

massage turbine and the nozzle ring

retainer are fitted correctly. Refer to

section: Maintenance, Spray Plate -

Removal and Installation.

14

OR

Handset Body

Assembly

Nozzle Ring

Retainer

Massage

Turbine

'O' Seals

Spray Plate

Assembly

Adjuster Ring

Page 15

Spray Plate - Removal and Installation

Spray Plate Removal

1. Turn the adjuster ring fully

anticlockwise to the massage spray

setting.

2. Unclip and remove the adjuster ring.

3. Unscrew the spray plate assembly in

an anticlockwise direction. The 'O'

seals will provide some resistance.

4. Remove the massage turbine and the

nozzle ring retainer.

Spray Plate Installation

1. Make sure that the four 'O' seals,

massage turbine and nozzle ring

retainer are all correctly fitted.

2. Turn the flow divertor fully clockwise.

3. Carefully screw the spray plate

assembly on to the flow divertor

4. Align the inner teeth on the adjuster

ring with the teeth on the handset flow

divertor. Clip the adjuster ring into

position.

'O' Seal

Nozzle Ring

Retainer

Handset Body

Assembly

Nozzle Ring

Retainer

Massage

Turbine

Spray Plate

Assembly

Adjuster Ring

Spray Plate

Assembly

'O' Seal

Massage

Turbine

'O' Seal

'O' Seal

Flow

Divertor

15

Teeth

Spray Plate

Assembly

Adjuster Ring

Inner Teeth

Page 16

SPARES

Mira Logic Spares List

450.01 Hose 1.25 m - chrome

450.02 Hose 1.25 m - white

450.03 Adjuster Ring (for fittings supplied with Mira Event XS)

450.04 Handset Assembly - white (for fittings supplied with Mira Event XS)

450.07 Slide Bar Support Assembly

450.08 Service Pack 'O' seals- components identified 'A'

450.09 Slide Bar - stainless steel

450.10 Slide Bar - white

450.11 Hose Retaining Ring

450.12 Soap Dish Pack

450.13 Adjuster Ring (for fittings supplied with Mira Extreme)

450.14 Spray Plate Pack - components identified 'B'

450.15 Handset Assembly - white (for fittings supplied with Mira Extreme)

450.17 Slide Bar Wall Fixing Pack- components identified 'C'

632.73 Hose Washer

1594.050 Clamp Bracket Assembly - white

1594.054 Clamp Bracket Assembly (for fittings supplied with Mira Event XS /

Sport)

16

Page 17

Mira Logic Spares Diagram

C

C

450.09

450.10

450.04

450.15

A, B

B

1594.050

1594.054

632.73

450.01

450.02

C

B

B

450.13

OR

450.03

450.11

450.07

450.12

C

17

Page 18

ACCESSORIES

DCV-H: An outlet double check valve, designed to prevent the backflow or

back-siphonage of potentially contaminated water, through shower controls which are

fitted with a flexible hose as part of the outlet shower fitting. The inclusion of the Mira

DCV-H will increase the required supply pressure typically by 0.1 bar. Available as an

optional accessory from Customer Services.

DCV-H Outlet Double Check Valve

(Part no 110.55)

9 litre/minute Flow Regulator: Designed to limit the flow rate for the Mira Logic

fittings in high pressure installations. Contact Customer Services for the flow regulator

options for bir fittings.

9 Litre/minute Flow Regulator

(Part no. 146.84)

18

Page 19

NOTES

19

Page 20

CUSTOMER SERVICE

Guarantee of Quality

Mira Showers guarantee your product against any defect in

materials or workmanship for the period shown in the

Guarantee Registration Document included with your shower.

Alternatively, to confirm the applicable guarantee period

please contact Customer Services.

To validate the guarantee, please return your completed

registration card.

Within the guarantee period we will resolve defects, free of

charge, by repairing or replacing parts or modules as we

may choose.

To be free of charge, service work must only be undertaken

by Mira Showers or our approved agents in Northern Ireland

and Republic of Ireland.

Service under this guarantee does not affect the expiry

date. The guarantee on any exchanged parts or product

ends when the normal product guarantee period expires.

Not covered by this guarantee:

Damage or defects arising from incorrect installation,

improper use or lack of maintenance, including build-up of

limescale.

Damage or defects if the product is taken apart, repaired or

modified by any person not authorised by Mira Showers or

our approved agents.

This guarantee is in addition to your statutory and other

legal rights.

Before using your shower

Please take the time to read and understand the operating

and safety instructions detailed in this manual.

What to do if something goes wrong

If when you first use your shower it doesn’t function correctly,

first contact your installer to check that installation and

commissioning are satisfactory and in accordance with the

instructions in this manual. We are on-hand to offer you or

your installer any advice you may need.

Should this not resolve the difficulty, simply contact our

Customer Services who will give every assistance, and if

necessary arrange for our service engineer to visit.

If later the performance of your shower declines, consult

this manual to see whether simple home maintenance is

required. Please call our Customer Services to talk the

difficulty through, request service under guarantee if

applicable, or take advantage of our comprehensive AfterSales service.

As part of our quality and training programme calls may be

recorded or monitored.

Our Customer Services Team is comprehensively trained

to provide every assistance you may need: help and advice,

spare parts or a service visit.

Spare Parts

We maintain an extensive stock of spares, and aim to have

functional parts available for ten years from the date of final

manufacture of the product.

Spares can be purchased from approved stockists or

merchants (locations on request) or direct from Customer

Services.

Spares direct will normally be despatched within two working

days. Payment can be made by Visa or Mastercard at the

time of ordering. Should payment by cheque be preferred a

pro-forma invoice will be sent.

Note! In the interests of safety, spares requiring exposure

to mains voltages can only be sent to competent persons.

Service

Our Service Force is available to provide a quality service

at a reasonable cost. You will have the assurance of a Mira

trained engineer/agent, genuine Mira spares – and a 12

month guarantee on the repair.

Payment should be made directly to the Service Engineer/

Agent, using Visa, Mastercard or a cheque supported by a

banker’s card.

To contact us

England, Scotland & Wales

Mira Showers Customer Services

Telephone: 0870 241 0888

8:30 am to 5:00 pm Working days (4:30 pm Friday)

8:30 am to 12.30 pm Saturday

E-mail: technical@mirashowers.com

Fax: 01242 282595

By Post: Cromwell Road

Cheltenham

Gloucestershire

GL52 5EP

Northern Ireland

Wm H Leech & Son Ltd

Telephone: 028 9044 9257 – Mon to Fri 9 am-5pm

Fax: 028 9044 9234 – 24 hours

Post: Maryland Industrial Estate

Ballygowan Road

Moneyreagh, Co Down

BT23 6BL

Republic of Ireland

Modern Plant Ltd

Telephone: 01 4591344 – Mon to Fri 9am to 5pm

Fax: Dublin 01 4592329 – 24 hours

Post: Otter House

Naas Road

Clondalkin

Dublin 22

Mira Showers

Kohler Mira Ltd

Cromwell Road,

Cheltenham GL52 5EP.

P3820/4 (L94C) © Kohler Mira Limited, July 2005

Mira is a registered trade mark of

Kohler Mira Limited.

The company reserves the right to alter

product specifications without notice.

www.mirashowers.com

20

Page 21

Check out our full range of Showers

Electric Showers

Digital Showers

Mixer Showers

Power Showers

Smart Showers

Shower Towers

From Top Shower Brands

Mira Showers

Aqualisa Showers

Triton Showers

Gainsborough Showers

Shower Pumps can upgrade your showering experience even more

Stuart Turner Shower Pumps

Salamander Shower Pumps

Grundfos Shower Pumps

Loading...

Loading...