Page 1

1

Important! This product is suitable for mains fed cold water only.

Installation Guide

Mira Advance ATL

ADJUSTABLE TEMPERATURE LIMIT THERMOSTATIC

9.0 and 9.8 kW

For SPARES, ADVICE

or REPAIRS

Please call us on

0844 571 5000

(UK Only)

Page 2

2

CONTENTS

Shower Models ........................................................................................ 4

Guarantee ............................................................................................4

Patents and Design Registration ..........................................................5

Important Safety Information .................................................................5

Warning ................................................................................................ 5

Caution ................................................................................................. 6

Pack Contents .........................................................................................7

Specications .......................................................................................... 8

Standards and Approvals .....................................................................8

Dimensions ...........................................................................................9

Installation Requirements ......................................................................9

General .................................................................................................9

1. Plumbing ..........................................................................................9

2. Electrical ......................................................................................... 11

Installation .............................................................................................13

Priming the Shower ............................................................................ 14

Mira Advance Shower Models for use with the

Instantmatch by Whale® Digital Pump ................................................16

Electrical Schematic Diagram (Drain Pump) ...................................... 17

Instantmatch by Whale® Digital Pump ................................................18

Wireless Installation ...........................................................................19

Wireless Signal Schematic Diagram .......................................... 19

Drain Pump Registration ............................................................ 20

Drain Pump Test ......................................................................... 20

Registration or Test Failure ........................................................21

Basic Post Installation Checks ...........................................................22

Commissioning .....................................................................................23

Set Maximum Temperature and Commissioning Cycle ......................23

Commissioning Failures ..................................................................... 24

BEAB Care ......................................................................................... 25

Memory Model ....................................................................................25

If you experience any difculty with the installation or operation of your new Electric

Shower, then please refer to 'Fault Diagnosis', before contacting Mira Showers.

Our contact details can be found on the back cover of this guide.

Page 3

3

Fault Diagnosis ......................................................................................25

1. Installer Troubleshooting Guide......................................................26

2. Diagnostic Procedure ..................................................................... 27

BEAB Care In-Service Tests ................................................................. 32

Maintenance ...........................................................................................35

Spare Parts and Accessories ............................................................... 36

Wiring Diagram ...................................................................................... 38

Customer Service .................................................................. Back Cover

Page 4

4

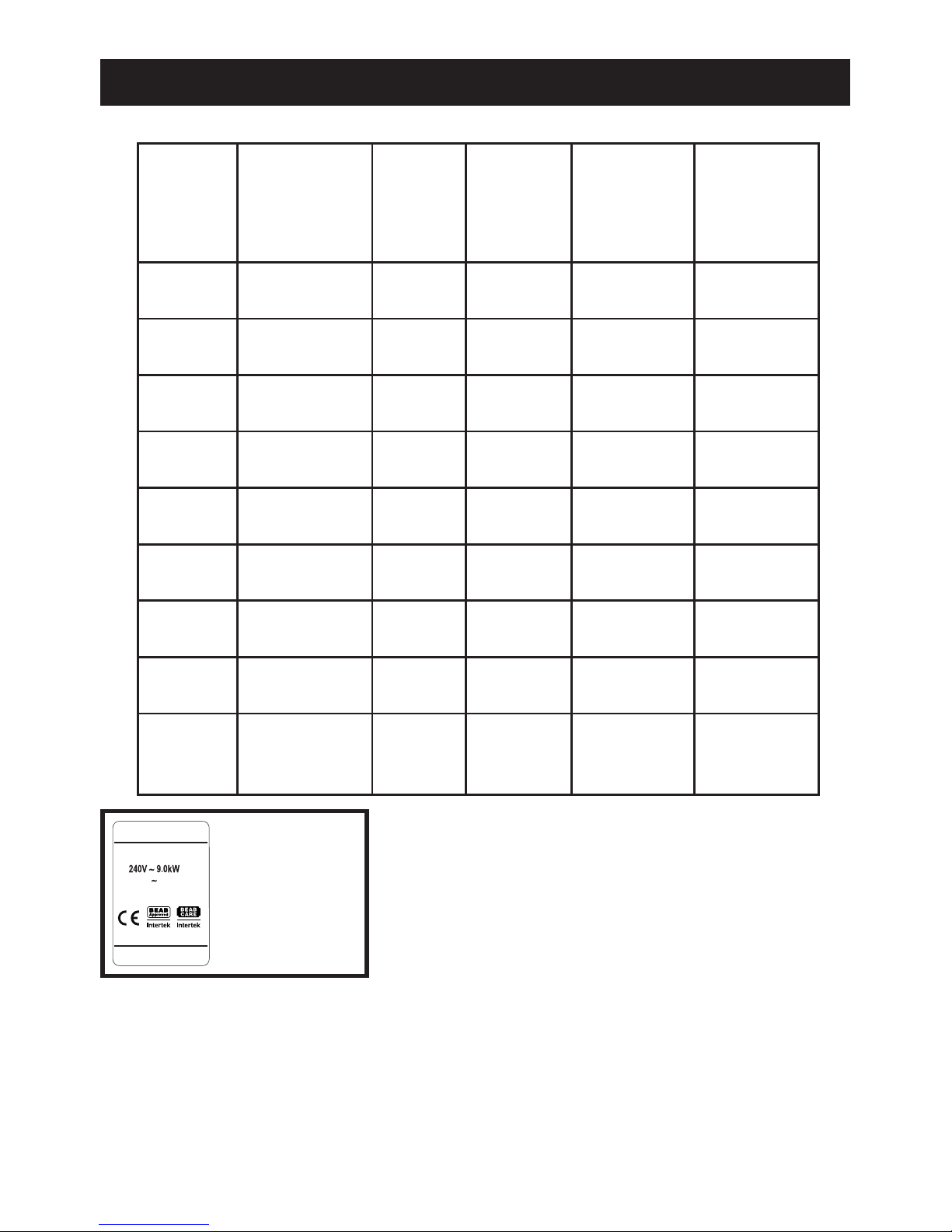

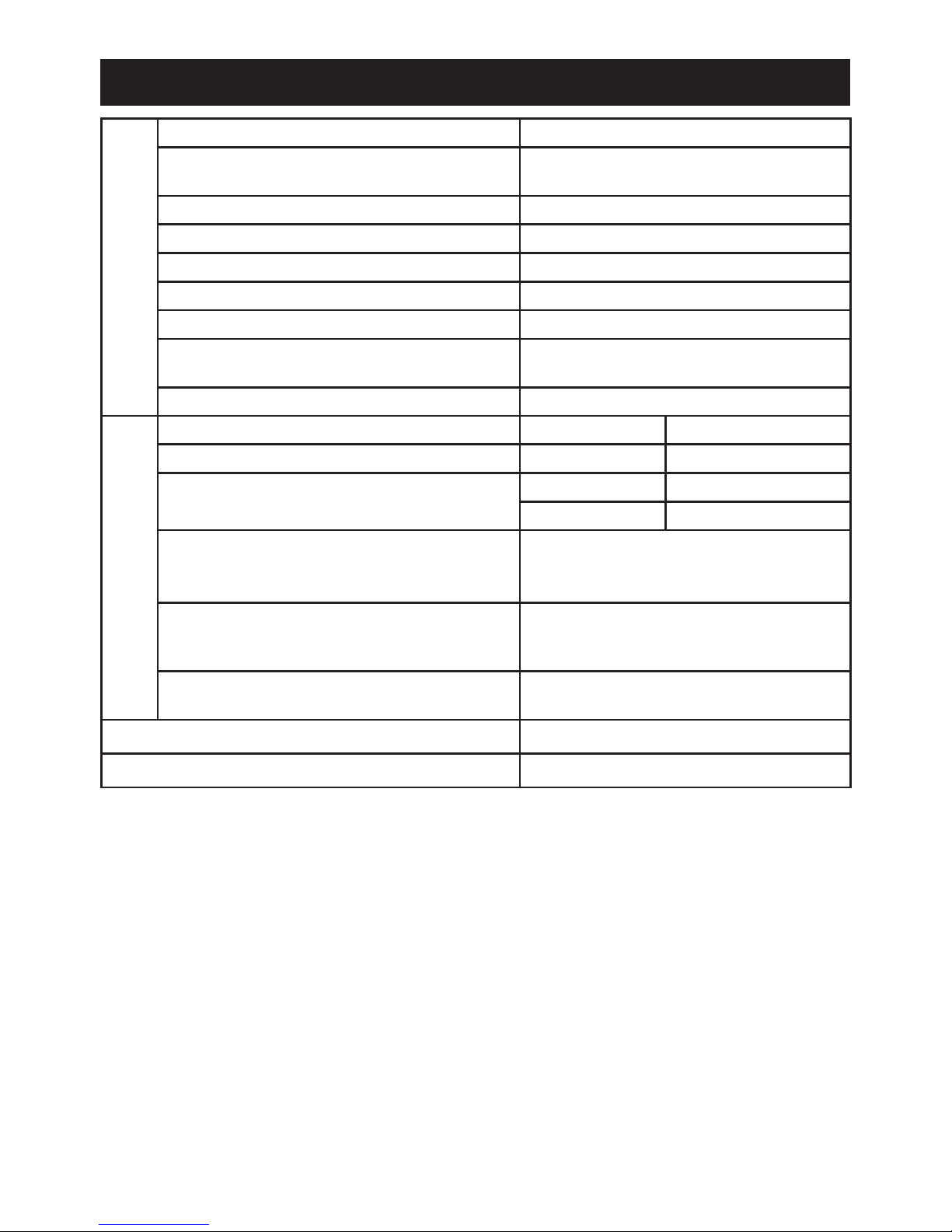

SHOWER MODELS

Mira Advance ATL models covered by this guide

Product

Variant

Adjustable

Temperature

Limit

Memory

Push

Button

Feature

Extended

Lever

Control

Drain

Pump

Compatible

Model No.

Standard

9.0 kW

J97A

Standard

9.8 kW

J97B

Flex

9.0 kW

J97C

Flex

9.8 kW

J97D

Memory

9.0 kW

J97E

Memory

9.8 kW

J97F

Standard

Extra

J97G

Flex

Extra

J97H

Flex

Extra

Wireless

J97P

Guarantee

For domestic installations, Mira Showers guarantee the Mira Advance ATL against

any defect in materials or workmanship for a period of two years from the date of

purchase (shower ttings for one year).

For non-domestic installations, Mira Showers guarantee the Mira Advance ATL against

any defect in materials or workmanship for a period of one year from the date of purchase.

For Terms and Conditions refer to the back cover of this guide.

J97H

32/11

Advance 9.0S ATL Flex Extra

Serial No.

OPEN OUTLET 0 kPa ( 0 BAR )

IPX4

230V 8.3kW

100

– 1000 kPa

Kohler Mira Ltd.

Cheltenham GL52 5EP

The Model No. can be

found on the rating label

located on the rear case.

The 'Extra' models (J97G, J97H and J97P) feature

a dedicated hardwire or wireless connection to a

shower drain pump.

The following shower drain pump kit is compatible

for 'wireless' connection:

SDP134T - Instantmatch by Whale®

Page 5

5

Recommended Usage

Domestic

Light Commercial

Heavy Commercial

Healthcare

Patents and Design Registration

Design Registration: 000738141: 0003, 0006, 0007, 0009

Patents: GB: 2269466, 2270370, 2298478, 2298479, 2298481

IMPORTANT SAFETY INFORMATION

Installation must be carried out in accordance with these instructions, and must be

conducted by designated, qualied and competent personnel.

WARNING!

Follow all warnings, cautions and instructions contained in this guide, and on or

inside the shower.

1. This shower can deliver scalding temperatures if not installed or

maintained in accordance with the instructions, warnings and cautions

contained in this guide and on or inside the appliance.

2. This product is suitable for installation within Zone 1 and is rated IPX4.

3. Isolate the electrical and water supplies before commencing installation. The

electricity must be turned off at the mains and the appropriate circuit fuse

removed, if applicable.

4. Mains connections are exposed when the cover is removed.

5. Refer to the wiring diagram before making any electrical connections.

6. Make sure all electrical connections are tight, to prevent overheating.

7. Make sure that any pipework that could become frozen is properly insulated. The

shower unit must not be tted where it may be exposed to freezing conditions.

8. The water supplies to this product must be isolated if the product is not to be

used for a long period of time. If the product or pipework is at risk of freezing

during this period they should also be drained of water.

9. DO NOT operate this appliance if it is frozen. Isolate the electrical supply and

allow to thaw. Check for leaks before reconnecting the electrical supply.

10. DO NOT install the product in a position in which service access is restricted.

11. If the shower is dismantled during installation or servicing then upon completion

the product must be inspected to ensure there are no leaks.

Page 6

6

12. DO NOT t any form of outlet ow control (e.g. trigger handsets) as the outlet

acts as a vent for the tank body. Only Mira recommended outlet ttings should

be used.

13. This product is not suitable for areas with high humidity (i.e. steam rooms).

14. THIS APPLIANCE MUST BE EARTHED. MAKE SURE SUPPLEMENTARY

BONDING COMPLIES WITH THE ‘REQUIREMENTS FOR ELECTRICAL

INSTALLATIONS’ BS7671. This electric shower is intended to be permanently

connected to the xed electrical wiring of the mains system.

15. This appliance must be provided with means for disconnection that is

incorporated into the xed wiring in accordance with the relevant local wiring

regulations.

16. This appliance is suitable for installation within the shower area. It must be

positioned over a water catchment area with the controls at a convenient height

for the user. The shower tting should be positioned so that it discharges down

the centre line of the bath, or across the opening of a shower cubicle, and must

be directed away from the appliance.

17 DO NOT tile up to the sides of the shower or use sealant around the case (see

section 'Installation Requirements').

CAUTION!

1. Read all of these instructions and retain this guide for later use.

2. The electrical installation must comply to 'BS 7671 (commonly referred to as the

IEE Wiring Regulations) and all relevant building regulations, or any particular

regulation or practice specied by the local electricity supply company.

3. The plumbing installation must comply with all national or local water regulations

and all relevant building regulations, or any particular regulation or practice

specied by the local water company or water undertakers.

4. Switch off the appliance at the electrical isolating switch when not in use. This

is for safety and is recommended with all electrical appliances.

5. This appliance is not suitable for use with any form of electronic timer. The

shower must be shut down in accordance with the instructions contained in

this installation guide, or the separate user guide.

6. Having completed the installation, make sure that the user is familiar with the

operation of the appliance.

7. When this appliance has reached the end of its serviceable life, it should

be disposed of in a safe manner, in accordance with current local authority

recycling, or waste disposal policy.

8. Please pass this guide on in the event of a change of ownership of the installation

site.

Page 7

7

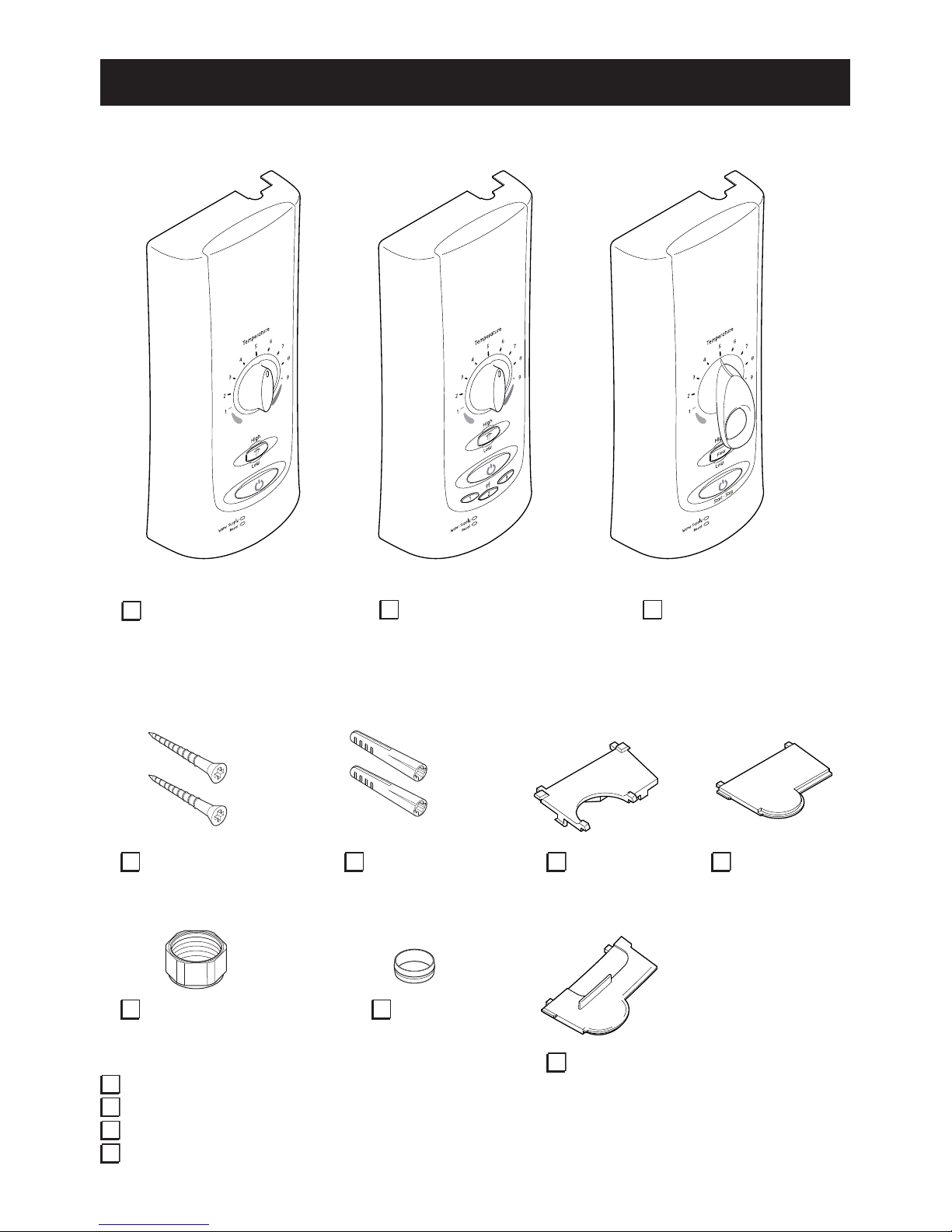

PACK CONTENTS

Tick the appropriate boxes to familiarise yourself with the part names and to conrm

that the parts are included.

Documentation

1 x Installation Guide

1 x User Guide

1 x Installation Template

1 x Guarantee Registration Document

1 x Olive

1 x Compression Nut

1 x Mira Advance ATL

Standard or Standard Extra

(Instantmatch by Whale®

Pump supplied separately)

Or Or

1 x Mira Advance ATL

Memory

1 x Mira Advance ATL

Flex or Flex Extra

(Instantmatch by Whale®

Pump supplied separately)

1 x Cover

Insert Top

2 x Fixing Screws 2 x Wall Plugs 1 x Cover / Pipe

Insert Top

1 x Cover

Insert Bottom

Page 8

8

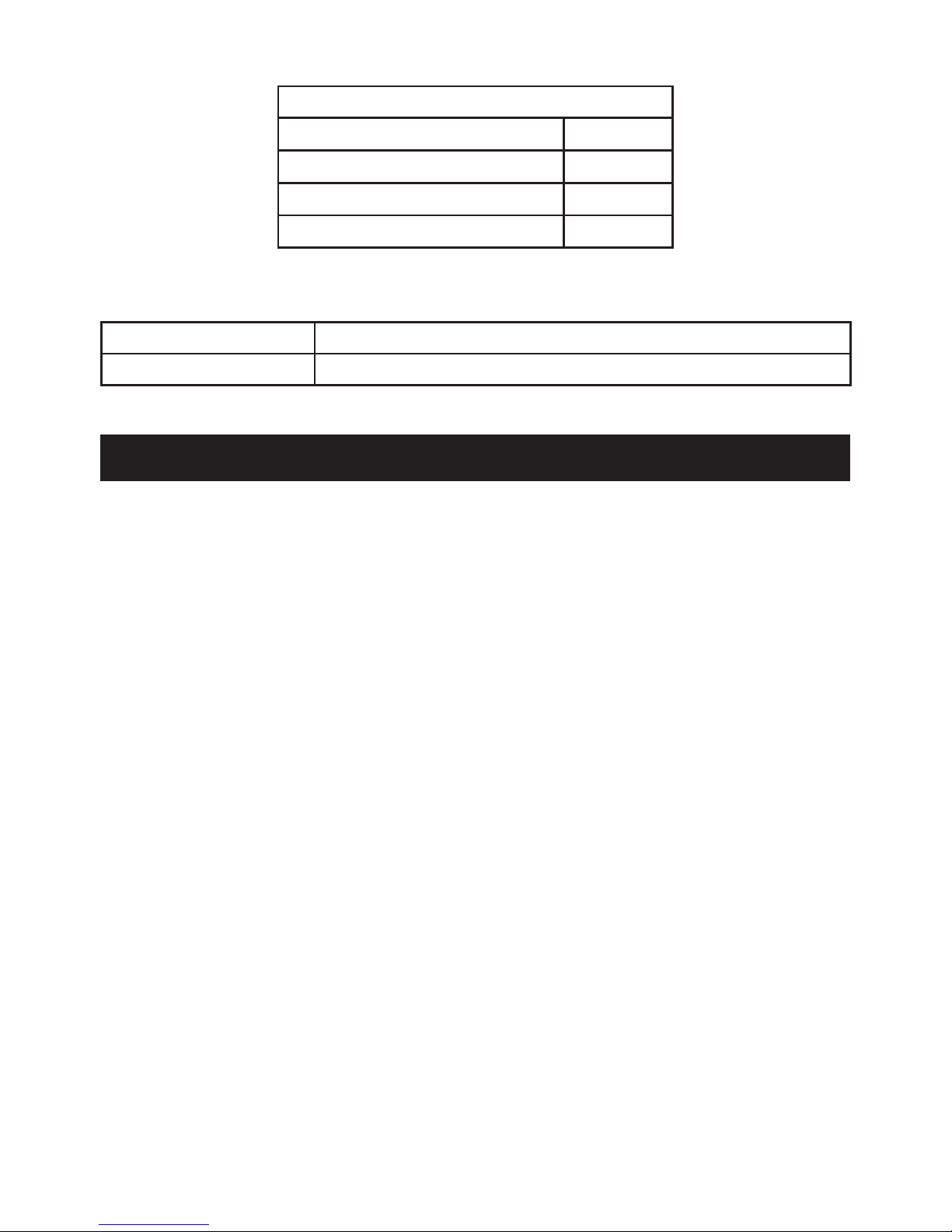

SPECIFICATIONS

Plumbing Supply

Supply Source Mains pressure cold water only

Minimum Dynamic Pressure*

50 kPa (0.5 bar)

(100 kPa (1 bar) BEAB Care)

Maximum Dynamic Pressure 500 kPa (5.0 bar)

Maximum Static Pressure 1000 kPa (10 bar)

Minimum Static Pressure** 20 kPa (0.2 bar)

Maximum Inlet Temperature 30°C (20°C BEAB Care)

Minimum Inlet Temperature 2°C (5°C BEAB Care)

Inlet Connection ½" BSP male & 15 mm compression

tting.

Outlet Connection ½" BSP male fitting

Electrical Supply

Nominal Rating at 230 V 8.3 kW 9.0 kW

Nominal Rating at 240 V 9.0 kW 9.8 kW

Supply Fuse/Circuit Breaker

9.0 kW 40 Amps

9.8 kW 45 Amps

Residual Current Device RCD 30 mA

Supply Cable

No larger than 16 mm²

Note: Refer to current IEE regulations and

BS 7671 to determine minimum cable size.

Isolation Switch

45 Amp Double pole, with 3 mm contact

separation.

Maximum Ambient Temperature 30°C

Minimum Ambient Temperature 2°C

* Recommended dynamic pressure of 100 kPa (1.0 bar) for full ow performance.

** Static pressure must never fall below 20 kPa (0.2 bar) when other draw offs are in use, e.g. ushing

toilet. This is the minimum pressure required to keep the ow valve closed.

Standards and Approvals

The Mira Advance ATL complies with the requirements of the BEAB Care Mark

Standard and the relevant directives for CE marking.

The BEAB Care mark is invalid if the product is not installed and used in accordance

with the manufacturer's specications and instructions.

The Mira Advance ATL Flex Extra Wireless (J97P) is in compliance with the essential

requirements and other relevant provisions of the R&TTE directive 1999/5/EC. A

copy of the declaration of conformity may be obtained by contacting Kohler Mira Ltd

UK customer services department. See back cover for details.

Page 9

9

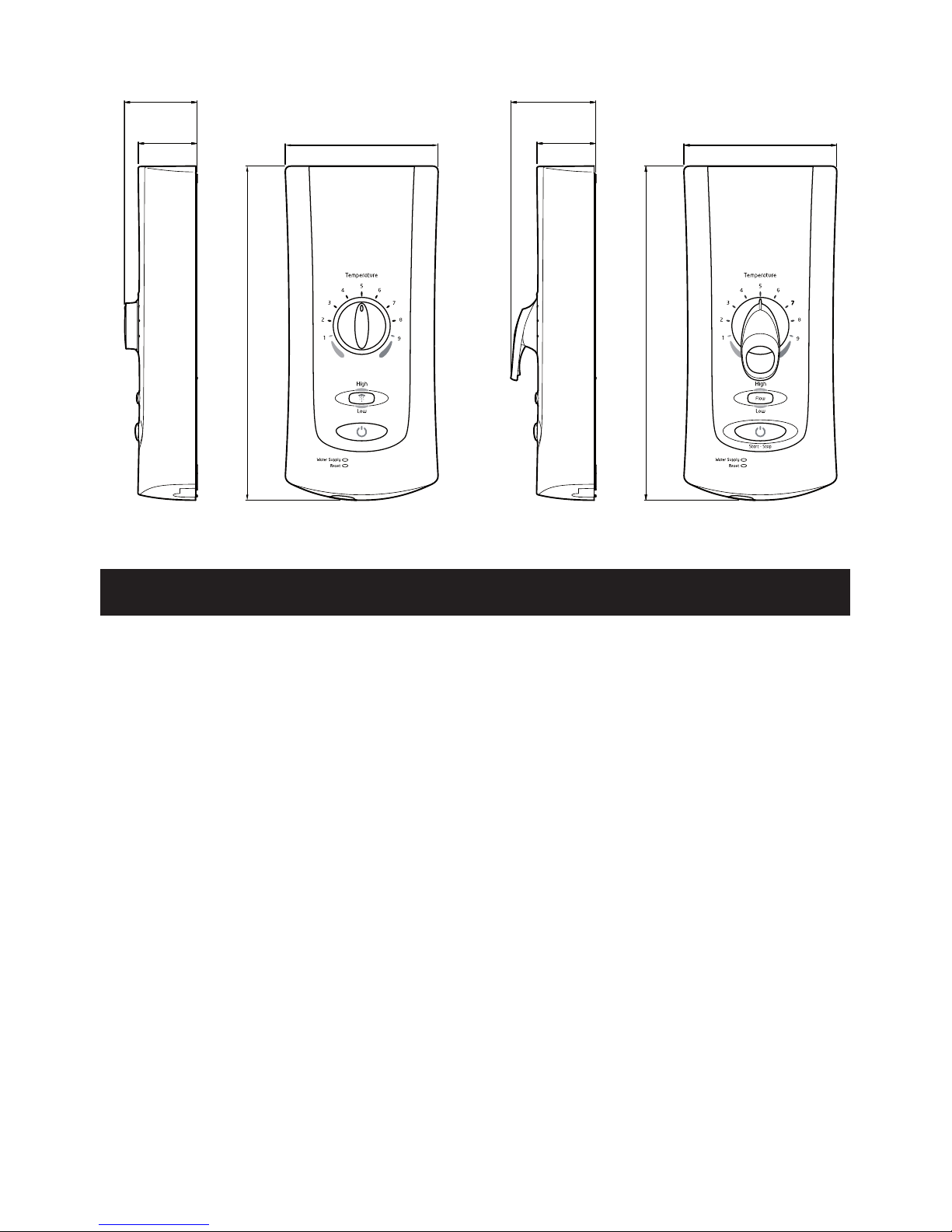

Dimensions

Advance ATL

Standard / Memory

Advance ATL Flex / Flex Extra /

Flex Extra Wireless

403 mm

184 mm

87.5 mm

71 mm

403 mm

184 mm

102 mm

71 mm

INSTALLATION REQUIREMENTS

General

We recommend that the product be brought into the room where it is to be installed

and left to acclimatise to room temperature, this will reduce the possibility of

condensation on electronic components.

The shower works best when water supply conditions are stable and within the

specications, refer to section 'Specications'. If the supply conditions fall outside

the specications, the shower may go into a safe shut down condition.

If pipework and/or electrical cables enter the shower from the rear through a hole in

the wall, provision must be made to prevent water ingress back into the wall structure.

Route cable and pipe supplies via the cut outs moulded in the case and cover.

DO NOT increase the size or cut alternative pipe / cable entry points as water ingress

into the product may occur.

1. Plumbing

Refer to section: 'Important Safety Information' rst.

1.1 Do not use sealing compounds on any pipe ttings or joints.

1.2 To avoid damage to the case when soldered ttings are used, pre-solder the

pipework and ttings before connecting them to the inlet connector assembly.

1.3 Never t the appliance to hot water supplies or to gravity systems of any

description. Only t the product to a mains cold water pipe.

Page 10

10

1.4 Avoid layouts where the shower hose will be sharply kinked. This may reduce

the life of the hose.

1.5 Supply pipework MUST be ushed to clear debris before connecting the

appliance. Debris will reduce the performance of the shower and may damage

the product.

Avoid running the pipework through excessively hot or cold areas such as hot

loft spaces, airing cupboards, or in close proximity to hot water pipes. If this

cannot be avoided, we would recommend insulating the pipes.

1.6 The shower must be tted onto a tiled or sealed nished surface, i.e. on top of

the tiles: [DO NOT tile up to the sides of the shower or use a sealant around the

case.] Failure to do this may cause appliance failure. To ensure the case and

other components are not put under strain during installation always provide

mechanical support when making plumbing connections. Upon completion of

the installation ensure connections and back case are not under any stress

due to misaligned pipework or electrical cables.

1.7 We recommend that a non-restrictive (free owing) isolating valve is tted in

the cold water supply pipe to allow maintenance of the appliance.

1.8 When installed in very hard water areas (above 200 ppm temporary hardness)

your installer may advise the installation of a water treatment device, to reduce

the effects of limescale formation. Any malfunction due to limescale is not

covered by the manufacturer's guarantee. Your local water company will be

able to advise the hardness of water in your area.

Hose Retaining Ring tted and shower ttings xed at a suitable height preventing

dirty water backow.

Zone of

Backow Risk

30 mm

Minimum

Toilet or Bidet

FC5

Hand Basin

FC3

Bath or Shower

Tray FC3

Electric

Shower

25 mm

Minimum

25 mm Minimum

Page 11

11

2. Electrical

Refer to section: 'Important Safety Information' rst.

2.1 In a domestic installation, the rating of the electricity supplier’s fuse and the

consumer unit must be adequate for the additional demand. All Mira Advance

ATL electric showers are high power appliances. Voltage drop due to local

heavy demand will reduce the shower’s performance.

2.2 The appliance must be earthed by connecting the supply-cable earth conductor

to the earth terminal.

Any supplementary bonding and supply cable size must conform to BS 7671.

2.3 As a guide only, and in accordance with BS 7671 we recommend close circuit

protection:

i.e. 9.0 kW = 40 Amp

9.8 kW = 45 Amp

In accordance with BS 7671, a 30 mA Residual Current Device (RCD) MUST

be included in the electrical circuit. This may be part of the consumer unit or a

separate unit.

A separate, permanently connected supply must taken from the consumer

unit to the appliance through a double-pole switch, which has at least 3 mm

contact separation. The switch can be a ceiling mounted pullcord type within

the shower room or a wall mounted switch in the applicable zone area.

2.4 DO NOT exert strain on the terminal block. Make sure that the electrical

connections are tightly screwed down.

2.5 DO NOT turn on the electrical supply until the plumbing has been completed.

2.6 Unless otherwise stated, electrical equipment such as extractor fans, pumps

must not be connected via this product.

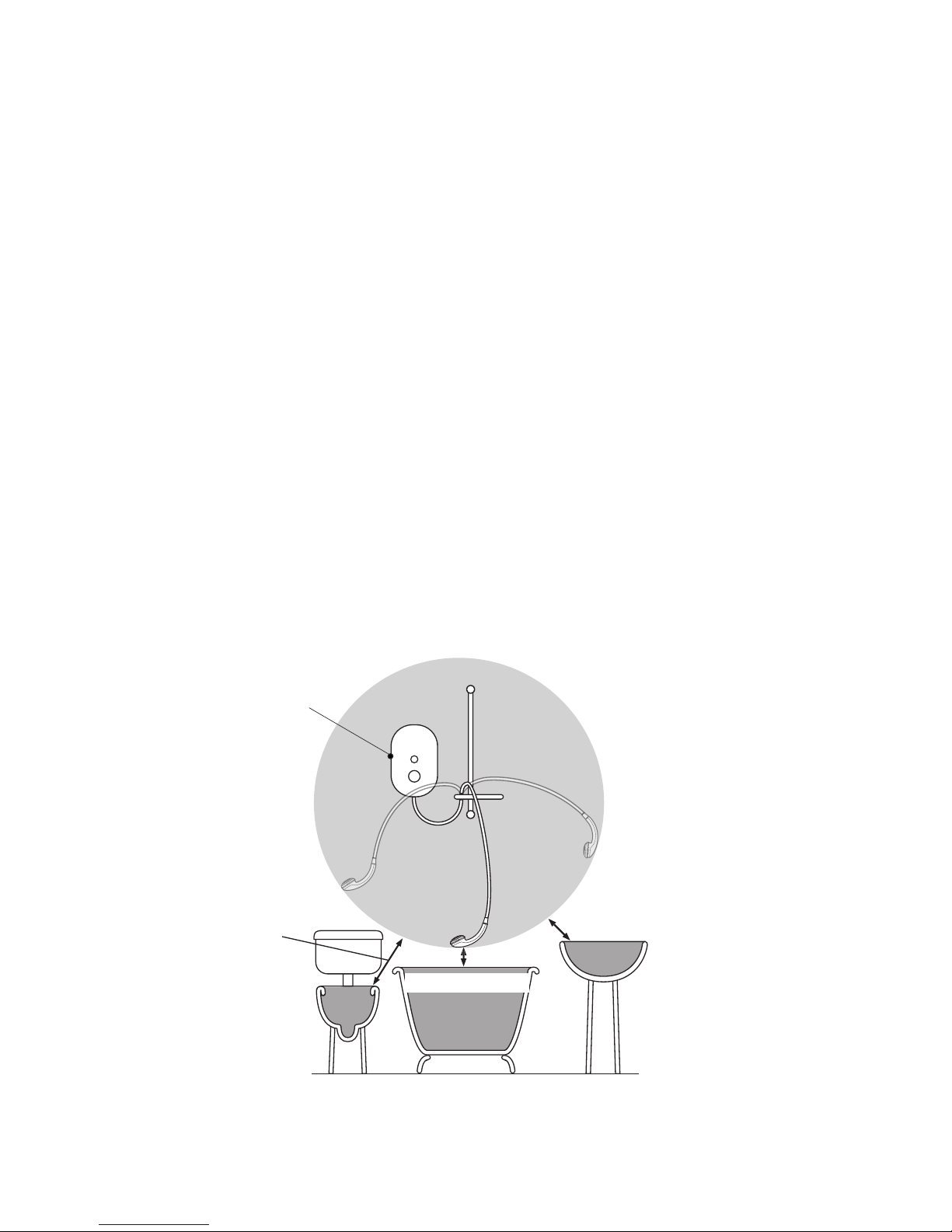

1.9 The position of the shower and shower ttings must provide a minimum gap of

25 mm between the showerhead and the spill over level of any bath, shower

tray or basin and a minimum gap of 30 mm between the showerhead and the

spill over level of any toilet, bidet or other appliance with a Fluid Category 5

backow risk.

Note! There will be occasions when the hose retaining ring will not provide a suitable

solution for Fluid Category 3 installations, in these instances an outlet double

checkvalve must be tted, this will increase the required supply pressure typically by

10kPa (0.1 bar). Double checkvalves tted in the inlet supply to the appliance cause

a pressure build up, which affect the maximum static inlet pressure for the appliance

and must not be tted. For Fluid category 5 double checkvalves are not suitable.

1.10 Wall xings are supplied for solid wall structures. For other wall structures such

as panels alternative xings may be required. A minimum of 2 xing screws

must be used.

Page 12

12

Terminal Block

Tank Assembly

Outlet

Connector

Flow Valve

Turbine and

Inlet Sensor

Wire 75 Earth

Inlet Clamp

Splash Guard

Relay Board

Flow Valve

Solenoid

Connector

Lead Socket

Thermal Switch

Element Assembly

Clip (secures

thermal switch)

Outlet

Sensor

Connector Lead

Sockets for the Flow

Valve Turbine and

Inlet Sensor, and

the Tank Assembly

Sensor.

Ribbon Cable

(connect to front Cover).

Flow Valve

Air Bleed

Button

Drain Pump PCB

(Mira Advance 'Extra'

models only)

Mira Advance ATL

Page 13

13

INSTALLATION

Refer to section: 'Important Safety Information' rst.

This installation covers all models of the Mira Advance ATL Thermostatic

shower.

1. Electrical supply

is turned off at the

mains.

2.

Decide on shower position,

leaving adequate space for

maintenance.

(If installation includes an

Instantmatch by Whale®

drain pump, see "Wireless"

section for information

on position of wireless

devices.)

3. Remove cover screw. 5. Turn inlet connector

to suit supply pipe. Do

not trap green wire.

6. Complete any

soldering required

away from appliance.

8. DO NOT flush

through the product

by removing the inlet

filter. Debris may

damage the product

and invalidate the

guarantee

7. Flush a minimum of

10 litres (2 gallons)

through pipework prior

to connection.

10 mm

100 mm

4. Remove cover and

splash guard. Determine

cable and pipe supply

routes via cutouts

moulded in the case

and cover

DO NOT

REMOVE

TO FLUSH

PRODUCT

Page 14

14

9. Caution! Do not drill

into buried cables or

pipes.

10. Use template provided

to mark and drill

required xing holes.

Do not drill through

the plastic case into

the wall. Plaster and

brick dust will damage

internal components.,

Mira Advance ATL

Attention Installer

IMPORTANT! The following key details should be read in

conjunction with the Installation and User Guide.

Optional

Fixing Hole

Required

Fixing Hole

1083677-W7-A

© Kohler Mira Limited, May 2007

Optional

For technical support and general enquires,

spare parts and after sales service contact us on:

Telephone : 0870 241 0888

Fax : 01242 282 595

email : mira_technical@mirashowers.com

Optional

Optional

Leave minimum gap to

install and maintain

Do not install the appliance where it

may become frozen.

Do not drill into buried cables or

pipes.

Avoid dust contamination of the

product by using this template to mark

and drill into the wall. Drill appliance

case separately.

Do not use alternative screws to

secure the cover.

Do not seal any part of the appliance.

Use the correct supply cable

size. Refer to BS 7671.

Leave minimum gap

to remove cover

Required

Fixing Hole

Thoroughly fl ush the

pipework before connecting

to the appliance.

11. Drill holes through

plastic case as

required. Route signal

cable to shower drain

pump (if applicable).

Fix appliance to wall.

Use appropriate

screws and wall plugs

for xing.

14. Connect hose and

showerhead, pointing

into bath or tray.

13. Turn on water supply

and check for leaks.

12. Connect supply pipe.

Do not overtighten.

15. Important! Priming the Shower

Make sure electricity is isolated!

Push down and hold air bleed

button to prime appliance until

water flows from shower head

for a minimum of 10 seconds,

repeat 3 times. Failure to prime

will seriously affect shower

performance!

Carefully dry off water before

connecting / reinstating electricity.

Page 15

15

17. Ret splash guard.

N = BLUE

E = GREEN

L = BROWN

N

L

16. Feed cable into

case. Firmly connect

conductors. DO NOT

exert strain on terminal

block.

20. Do not use alternative

screws to secure

cover. This can cause

internal damage to

appliance. Do not seal

around any part of

appliance.

21. Install shower ttings.

Refer to separate

Installation and User

Guide.

19. Refit cover. Inserts

are provided to nish

top and bottom as

required.

18. Connect ribbon cable

to inside of cover.

Insert

Insert

Page 16

16

Mira Advance Shower Models

for use with the

Instantmatch by Whale® Digital Pump

Standard Extra

J97G*

Instant Match

transformer

Flex Extra

J97H*

Flex Extra Wireless

J97P*

Hardwire alternative with cable

accessory 1.1759.125

(not included)

Hardwire cable

included

For use with the

Whale Instant Match

Pump Wireless

For use with the

Whale Instant Match

Pump Wireless

Instant Match

J97H

32/11

Advance 9.0S ATL Flex Extra

Serial No.

OPEN OUTLET 0 kPa ( 0 BAR )

IPX4

230V 8.3kW

100

– 1000 kPa

Kohler Mira Ltd.

Cheltenham GL52 5EP

* The model number can be

found on the rating label

located on the rear case.

Page 17

17

Electrical Schematic Diagram (Drain Pump)

Optional Outlet

Double Checkvalve

45 Amp Double-pole

Isolating Switch

Mains Fed Cold

Water Supply

Signal Cable

Connector

(Optional)

Consumer Unit

Isolating

Valve

Unswitched

Spur

Instant Match

Transformer

Instantmatch

by Whale®

Pump

Supply cable

Supply cable

Page 18

18

Instantmatch by Whale® Digital Pump

The Mira Advance ATL 'Extra' models can be connected to the Instantmatch by

Whale® Pump. This section describes how to identify and connect the shower to the

drain pump. For full installation instructions of the Instantmatch by Whale® Pump,

see separate guide.

1. Identify the drain pump model using the TYPE number in the table. The

corresponding number is shown on the drain pump transformer.

2. Set the electronic jumper positions of the DRIVER and SIGNAL in the shower

according to the TYPE number of the drain pump

DRIVER SIGNAL

Jumper

location

(Mira Advance Flex Extra Wireless J97P only.)

TYPE

Drain

Pump

Shower

Type Driver Signal

755.171 LK1 Hardwired

755.199 LK1 Hardwired

755.299 LK2 Hardwired

755.349 LK2 Hardwired

755.399 LK2 Hardwired

755.449 LK2 Hardwired

755.549 LK2

Hardwired/

Wireless

R

INSTANT

MATCH

Input: 230Vac ~ 50Hz 800mA

Fuse T5A

Duty Cycle: 30min/60min

This transformer is only for use with:

SDP021T Shower Drainage Pump

Type: 755.549

IP 45 30°C Max

Class II Indoor use

only

F

Jumper Layout - See Instructions

Post installation - To perform any

change to jumper settings, the power

supply must be switched off for

30 seconds prior to the change being made.

Off

Delay

(Seconds)

10

30

Gems Sensor

Venturi Sensor

Mira Advance

Extra Wired

Mira Advance

Extra Wireless

Page 19

19

Maximum for

Wireless Signal

Range = 5 metres

Shower

Bathroom

Drain Pump

to waste

Consumer

Unit

Drain Pump

Transformer

Wireless Installation (Flex Extra Wireless J97P model only)

1. The wireless version of the Instantmatch by Whale® Pump is connected to the

Mira Advance ATL 'Extra' Wireless shower model with a radio signal.

2. For optimum signal strength, site the pump transformer as close to the shower

as possible. See the 'Wireless Signal Schematic Diagram' for shower and

drain pump positions.

3. Metal objects such as steel baths or sinks, cold water storage tanks, hot water

cylinders, foil lined plaster board walls, radiators and even thick brick walls, can

all reduce the operational range of any radio controlled product dramatically.

Interference from other radio signals can also reduce the ability of the shower

and drain pump to register or communicate. These may include; mobile phones,

radio control boiler thermostats, wireless broadband routers, radio control toys,

cordless phones, remote outdoor weather stations etc.

If you encounter difculty registering the drain pump to the shower make sure

all other radio interference is temporarily switched off.

Note! Failure to follow these guidelines can result in poor, intermittent or

complete failure to communicate with the drain pump.

4. Install the drain pump in accordance with the separate installation guide

supplied.

5. Register the drain pump to the shower. See section 'Drain Pump Registration'.

Wireless Signal Schematic Diagram

(for Instantmatch by Whale® Pump)

Page 20

20

Drain Pump Registration (Flex Extra Wireless J97P model only)

The shower must register a wireless signal to the drain pump then establish a

reliable connection. If you encounter difculty registering the shower to the drain

pump, make sure all electronic devices that could be causing signal interference

are temporarily switched off.

Drain Pump Test

1. Set shower temperature to FULL COLD.

2. Shower is OFF.

NO water is owing.

Power/Electric to shower is OFF.

Power/Electric to pump is ON.

ON

RED /

GREEN

OFF

3. Turn Power/Electric to shower ON.

5. Shower temperature to FULL COLD.

ON

Transformer

4. Within 30 seconds push and hold PUMP

SWITCH until 'Beep' from shower and

pump switch power light changes

colour from RED/GREEN to GREEN to

indicate successful registration.

GREEN

Page 21

21

6. Press START/STOP.

Registration or Test Failure

• See 'Wireless Installation' for examples of devices/objects that could be causing

signal interference. Make sure all such devices are temporarily switched off, then

reregister using the instructions below and retest the drain pump.

• Attempt to improve the signal strength by moving the drain pump transformer,

then reregister using the instructions below and retest.

• Shower STARTS, but drain pump is NOT RUNNING.

Solution.....Isolate power and remove shower cover. Check jumper

position inside shower cover is set to WIRELESS.

• Drain pump STARTS, but shower is NOT RUNNING.

Solution.....Shut down shower and drain pump and reregister using the instructions

below.

1. Power to shower OFF.

2. Push and hold PUMP SWITCH until light goes from GREEN to RED/GREEN.

3. Within 30 seconds turn power to shower ON.

4. Beep from shower.

5. PUMP SWITCH light changes to GREEN.

6. Turn on shower to conrm shower and pump are operating together.

8. Pump will START. Any delay will depend upon

the plumbing layout, but pump should start within

10 SECONDS.

9 . Pump and shower work normally.

A test failure is indicated by the following:

• Shower and pump stop.

• 1 beep and all lights ash 6 times.

R

7. Shower will START.

Page 22

22

Basic Post Installation Checks

1. Turn on electrical

supply.

3. Temperature to full

cold.

4. Start shower to test for

water ow. If a shower

drain pump is tted, it

should also start.

5. If there is no water

after 5 seconds, make

sure that appliance

has been primed.

5 secs

2. Power to appliance,

check Start/Stop for

blue light.

6. Push Start/Stop to

turn off appliance.

Pulsing light and

"beep" indicates that

appliance is shutting

down.

7. Appliance will purge water from

heater tank for a few seconds.

Important! DO NOT isolate power

until water has stopped.

Go to section: "Commissioning".

Page 23

23

COMMISSIONING

On initial installation, the appliance needs to 'learn' about the site conditions and

does so during the commissioning cycle.

Once set, the shower constantly updates it's memory with information about the site

conditions to deliver the best performance.

DO NOT commission the appliance if water leaks from the unit.

Set Maximum Temperature and Commissioning Cycle

1. Shower is OFF.

Water has STOPPED owing.

Power/Electric is OFF.

3. Turn Power/Electric ON.

Within 30 seconds push and hold FLOW & START/STOP

together.

OFF

ON

2. Set Maximum Temperature

Turn the dial to the desired position in the

table. This will set the maximum temperature

for showering.

When showering, the set maximum

temperature is reached when the dial is

turned to number '9'.

(See also section: "BEAB Care".)

Record the Maximum Temperature setting

on the BEAB Care In-Service Test Record

(separate form supplied) if applicable to the

installation.

B

E

A

B

C

a

r

e

R

a

n

g

e

1

-

5

No.

Max.

Temp

°C

1 37

2 38

3 39

4 40

5 41

6 42

7 45

8 48

BEAB CARE

Page 24

24

1st Beep (LONG) - Release START/STOP.

2nd Beep (SHORT) - Release FLOW.

4.

5. HIGH FLOW LIGHT FLASHES

This indicates shower is commissioning correctly.

Water ows for approximately 1 minute 20 seconds.

In some cases the cycle can take up to 3 minutes.

Allow shower to stop automatically.

IMPORTANT! DO NOT INTERRUPT THE CYCLE!

6. Push START/STOP to turn shower ON.

Check that maximum temperature is

acceptable to the user.

COMMISSIONING FAILURES

(the commissioning cycle was stopped due to an error)

No ashing FLOW LIGHT... solution ...Restart the commissioning cycle.

No water after 5 seconds... solution ...Reprime the shower. (See "Installation".)

WATER SUPPLY or

RESET light is on................ solution ...Reprime the shower. (See "Installation".)

_

+

7. Push START/STOP to turn shower OFF.

Wait until water has stopped flowing

BEFORE turning Power/Electric OFF.

8. Residual water may drain over a few

minutes.

OFF

Page 25

25

BEAB Care

If the shower's maximum temperature is set to 41 °C or cooler, there is a clear triple

beep tone and single pulse of the Start/Stop light every time the double pole switch

is turned on. This is to indicate that the appliance is in a 'BEAB Care' compliant

mode. If recommissioning is required whilst in this mode, wait until 3 beeps have

passed before starting the commissioning cycle.

Memory Model

If the maximum temperature is adjusted after it has been stored in one or more of

the memory buttons (refer to section: 'Operation, Storing the Memory Presets'

in the 'Mira Advance ATL User Guide'), then the showering temperature cannot

exceed the new maximum setting.

E.g.

Memory 1

stored at 45°C

Maximum

temperature

adjusted to 40°C

Memory 1

automatically

cannot exceed

40°C

Maximum

temperature now

adjusted to 48°C

Memory 1 now

back to original

stored temperature

of 45°C

40°C

48°C

x3

Page 26

26

FAULT DIAGNOSIS

1. Installer Troubleshooting Guide

Refer to section: 'Important Safety Information' rst and refer also to 'User Trouble

Shooting Guide'.

The following troubleshooting solutions may require the removal of the cover of the

shower. The cover should only be removed by a competent tradesperson and when

doing so they should be aware of the following:

• Isolate the electrical and water supplies before initially removing the

cover.

• Make sure Ribbon Cable is disconnected when removing the front

cover and reconnect when maintenance is complete.

• Mains connections are exposed when the cover is removed.

• Refer to wiring diagram before making any electrical connections.

• Make sure all electrical connections are tight to prevent arcing/

overheating.

• Make sure all plumbing connections are watertight.

When following these instructions, it is sometimes necessary to examine the

appliance with the electrical and water supplies turned on. It is therefore essential

that the appropriate safe working practices are followed in accordance with the

current Health and Safety Legislation.

If conducting a continuity check using a multimeter, make sure the electrical supply

is ISOLATED.

Page 27

27

2. DIAGNOSTIC PROCEDURE

1. Ensure the shower pullcord / isolator switch is in the OFF position, then turn

ON the pullcord / isolator switch.

2. If the unit ‘Beeps’ & the Start / Stop button is ashing WAIT for 20 SECONDS

until the button stops ashing.

NOTE! If the Start / Stop button continues to ash & no beep was heard

upon start up, refer to ERROR CODE 16 on the fault code sheet.

3. Start the shower & observe light fault indication (if any) & refer to Error Code

Sheet to determine failure and rectify.

NOTE! If the shower operates normally run the unit for at least 5 minutes

at showering temperature & ensure the temperature remains stable.

4. Turn the shower off at the Start / Stop Button & observe ‘phased shutdown’.

DO NOT isolate the power at the pullcord / isolator switch until the water ow

stops.

5. Turn off the power at the pullcord / isolator switch, then turn the power back

on and commission the shower.

6. Run the shower for at least 5 minutes.

7. Show the user the correct start / stop procedure and general operation of the

shower. Advise user that isolating the shower before the ow has stopped

may damage the shower.

For the fault codes 0 to 14 and 18, the reset light will be on or ashing. This will

require the shower to be turned off at the pullcord / isolator switch to reset

the unit. When the pullcord / isolation switch is turned back on the shower

may beep and the Start / Stop button may ash. If this occurs go back to

action number 2 and re-follow the Diagnostic Procedure.

Page 28

28

Advance Error Codes / Display, Causes and Rectication

All fault codes will require the shower to be turned off at the pullcord / isolator switch to reset the

unit. When the pullcord / isolation switch is turned back on the shower may beep and the Start

/ Stop button may ash. If this occurs go back to action number 2 and re-follow the Diagnostic

Procedure

Error Code Indicator Display Possible Cause/Rectication

A

OR

Problem with water supply, unit still operates.

1. Check all isolator valves are fully open.

2. Clean / replace filter, refer to section:

'Maintenance'.

3. Blocked Hose / showerhead.

4. Check Inlet Temperature not too high.

0

An unidentied error has occurred.

1. Replace Control PCB / Cover.

1

Incoming ow too low for appliance to operate

safely.

1. Check all plumbing isolator valves to the

shower are turned fully on

2. Reset - Commission the shower.

3. Blocked or partially blocked lter, hose or

showerhead .

4. A section of the supply pipe may be frozen

(thaw). (Advise customer of incorrect

installation)

5. Replace Flow Valve.

6. Replace Thermal Switch.

7. Replace Heater Tank.

2

Internal electrical supply problem.

1. Replace Relay Board.

2. Replace Control PCB / Cover.

3. Replace Thermal Switch.

3

4

Appliance has been incorrectly shut down.

1. Replace Relay Board & Control PCB /

Cover TOGETHER.

Advise the user on correct start/stop procedure

and general operation of the shower, refer to

User Guide.

Page 29

29

5

Incoming water temperature too high.

1. Check inlet water temperature is not too

high. (E.g. pipework runs alongside hot

pipe).

2. Replace Flow Valve.

3. Replace Control PCB / Cover.

4. If the unit is an 'Extra' or 'Flex Extra' model,

replace the Drain Pump PCB.

6

Flow Valve Assembly is disconnected or faulty.

1. Check all internal cable connections.

2. The shower or a section of the supply pipe

may be frozen.

3. Replace Flow Valve.

4. Replace Control PCB / Cover.

7

False ow reading.

1. Replace Flow Valve.

8

Safety relay failure.

1. Check relay contacts. (Debris on contacts

or welded closed)

2. Check Ribbon Cable Connection.

3. Replace Relay Board.

4. Replace Control PCB / Cover.

5. Replace Thermal Switch.

9

10

Internal Electrical Supply problem / Faulty

Control PCB or Relay Board. Appliance has been

incorrectly shut down.

1. Push bleed button to ush the heater tank.

2. Replace Relay Board & Control PCB /

Cover TOGETHER.

Advise the user on correct start/stop procedure

and general operation of the shower, refer to

User Guide.

11

Outlet Sensor faulty or disconnected from Relay

Board or faulty Control PCB.

1. Check Outlet Sensor connection to the

Relay Board.

2. Check Ribbon Cable Connection.

3. Replace Control PCB / Cover.

4. Replace Relay Board.

5. Replace Heater Tank.

Page 30

30

12

Unsafe hot water detected.

1. Unit incorrectly shut down causing hot

water to trip the max temp limit, this would

be following ERROR 17.

2. Hot water in the heater tank, bleed via the

blue button.

3. Check Outlet Sensor connection to the

Relay Board.

4. Check Ribbon Cable Connection.

5. Replace Control PCB / Cover.

6. Replace Relay Board.

7. Replace Heater Tank.

Advise the user on correct start/stop procedure

and general operation of the shower, refer to

User Guide.

13

This failure only occurs during commissioning.

1. Check operation of relays / replace Relay

Board if necessary.

2. Replace Flow valve.

3. Replace Control PCB / Cover.

4. Replace Heater Tank.

14

Error lights when unit is re-started.

This error occurs when the shower has been

incorrectly shutdown and the unit senses

over temperature (refer to ERROR 17).

Advise the user on correct start/stop procedure

and general operation of the shower, refer to

User Guide.

15

Unit fails to start.

1. Replace Relay Board and Control PCB /

Cover TOGETHER.

16

High & Low or Start / Stop lights pulsing rapidly.

1. Associated Button stuck / Replace Control

PCB / Cover.

17

Start / Stop Lights Pulsing Slowly

1. If a 2 second beep and the Start / Stop

button is pulsing SLOWLY = Appliance

has been incorrectly shut down. Refer to

Diagnostic Procedure action number 2.

Product can still be operated safely. Flashing light

will stop after 20 seconds.

Advise the user on correct start/stop procedure

and general operation of the shower, refer to

User Guide.

Lights ashing in

peculiar ways.

Page 31

31

For drain pump only: Advance 'Extra' models

18

Drain Pump not communicating with Shower.

1. Check power to Drain Pump.

2. Check connection between Drain Pump

and Shower. If wireless, reregister the

signal and retest using the procedure in

this guide, see 'Drain Pump Registration'.

3. Wireless Channels.

It may be necessary to alter the shower's

wireless frequency to avoid radio

interference which can prevent the Drain

Pump from operating correctly.

There are 3 channels which can be

selected individually using 1-3 on the

temperature control.

Default frequency is position 1

a. Turn shower off and isolate electric/

power.

b. Choose channel number 2 or 3 with the

temperature control.

c. Repeat steps 2-4 of the Drain Pump

Registration instructions found in this

guide.

If more than one shower and pump

combination are operating in close

proximity to each other, make sure that

each shower is set to a different channel.

4. Contact Customer Service.

Unattended Operation

The appliance has a built in ‘Shower Stop’ timer to protect from accidental unattended operation. This

feature automatically switches the shower off after 40 minutes of continuous use. Normal operation is

restored by re-selecting the Start/Stop button.

C

H

A

N

N

E

L

S

1

-

3

W

I

R

E

L

E

S

S

Shower stops

Drain Pump stops

1 beep and all lights

ash 6 times

Page 32

32

BEAB CARE IN-SERVICE TESTS

The following procedure applies to products operated and maintained within the BEAB Care

requirements. This procedure should be conducted by designated, qualied and competent

personnel only.

To maintain the validity of the BEAB Care mark, regular inspections of the installation and

appliance should be carried out. The purpose of the in-service tests is to monitor and record

the performance of the shower. Any deterioration in performance can indicate the need for

maintenance work on the appliance and/or the water supplies.

Frequency of Inspections

Upon the initial installation of the shower and after any major repair work (e.g. Renewing

the Flow Valve or Heater Tank etc...), the in-service tests must be performed and the results

recorded on the BEAB Care In-Service Test Record to provide a reference point for future

inspections. (The BEAB Care In-Service Test Record is on page 34 and 35).

The shower should be inspected again within 6 to 8 weeks after installation or any major repair.

If there is no signicant change in the outlet water temperature greater than ±1 ºC between

the two inspections, the in-service test frequency may be reduced but must not exceed 12

months between any two inspections.

Equipment Required

The following equipment or suitable equivalent will be required in order for the tests to be

performed:

Digital Multimeter (crocodile clip probes are recommended)

100 mm diameter plastic funnel

Digital liquid thermometer accurate to 0.1 ºC

2 - 22 l/min ow measure cup

Cup or container suitable for catching water

BEAB Care In-Service Test Record

Installation Address:

Location of Shower:

Maximum Temperature Setting:

(maximum of 41 ºC for showering)

Installed by:

Please record all test results on this form, including details of all measurement equipment used. This form is available to download at www.mirashowers.co.uk.

1178847-W9-B © Kohler Mira Limited, August 2011

Date:

Not Operating Normal Operation Restricted Supply

Date /

Signature

Terminal

Block

Voltage

(V)

Inlet

Water

Temp.

(ºC)

Inlet

Filter

Cleaned

Terminal

Block

Voltage

(V)

Outlet

Water

Temp.

(ºC)

Flow

Rate

(l/min)

Outlet

Water

Temp.

(ºC)

Flow

Rate

(l/min)

Equipment Details

(make, model, serial number, calibration date etc...)

Page 33

33

1. Run the shower with the temperature control set to full cold and the ow set to high for 2 - 3 minutes

and then stop the shower. Isolate the electrical and water supplies.

2. For falling supplies, remove the inlet lter (see Maintenance) and use a cup or suitable container

to catch a small quantity of water that will ow from the inlet connector as the lter is removed.

Measure the temperature of the water that is collected.

3. For rising supplies, remove the inlet lter (see Maintenance) and use a suitable probe to measure

the temperature of the water inside the inlet connector.

4. The temperature of the water must be within the range of 5 - 20 ºC, record the temperature on the

test record.

5. Clean and if necessary renew the inlet lter. Ret the inlet lter (See Maintenance.)

6. Switch on the electrical supply to the shower and measure the voltage at the terminal block. The

voltage must be in the range 230V ±10%. Isolate the electrical supply and record the voltage on

the test record.

7. Turn on the water supply and check for leaks. Reprime the shower (see Installation - Priming the

Shower).Remove the showerhead from the hose. Position the end of the hose to allow water to drain

safely when the shower is running, if necessary secure the hose in this position.

8. WARNING, LIVE ELECTRICAL WIRES ARE EXPOSED WHILE SHOWER IS RUNNING!

Connect the ribbon cable to the cover. Switch on the electrical supply to the shower and run the

shower with the temperature control turned to full hot and the ow set to high. Measure the supply

voltage at the terminal block (this may require a second person to assist). Stop the shower, isolate

the electrical supply and record the voltage on the test record.

(If the ribbon cable becomes disconnected the shower will assume a failure has occurred and stop

automatically. Isolate the electrical supply, reconnect the ribbon cable and restart this section of

the test.)

9. Ret the cover and screws. Ret the showerhead to the hose and reattach to the slidebar or

showerhead holder. Switch on the electrical supply to the shower.

10. Run the shower with the temperature set to full hot and the ow set to high. Using the plastic funnel,

catch all the water owing from the showerhead and measure the temperature of the water owing

from the funnel. The temperature must be no more than 2 ºC above the maximum temperature

setting. Record the temperature on the test record. Using the ow measure cup, measure the rate

of water ow from the funnel and record the result on the test record.

11. Run the shower set to full hot and the ow set to high. Slowly restrict the water supply to the shower

by closing the isolating valve gradually until the shower shuts down due to the reduced ow. Switch

off the electrical supply and open the isolating valve by a small amount. Remove the cover and

hold down the air bleed button (see Installation - Priming the Shower) to expel all hot water from

the tank.

12. Ret the cover and switch on the electrical supply to the shower. Run the shower for 2 - 3 minutes

at full hot and high ow to make sure that it will operate continuously, then measure the water

temperature and rate of ow as described in test 10 and record the results on the test record. The

temperature must be no more than 2 ºC above the maximum temperature setting. If the shower will

not run continuously for at least 2 minutes and shuts down due to a temperature or ow error, then

reset the shower and reprime to again expel all hot water. Open the isolating valve by a further small

amount and attempt a retest. Always have the cover tted when running the shower during

this test. When a successful test has been performed and recorded, open the isolating valve fully

and set the temperature to mid blend. Stop the shower and isolate the electrical supply. Secure the

cover with the screws.

If the normal operation outlet water temperature has changed by more than 1 ºC since the previous

inspection, or if either of the outlet water temperature measurements are more than 2 ºC above the

maximum temperature setting, the shower showerhead, hose and inlet lter should be checked for

blockages and cleaned and descaled or if required renewed. Checks should be performed to conrm

that any check valves or other backow prevention devices are working correctly and that any isolating

valves in the supply pipework are fully open. The shower should be recommissioned at the relevant

maximum temperature setting and retested. If the temperatures are not able to be brought in line with

these requirements, the shower must not be used.

Page 34

34

BEAB Care In-Service Test Record

Installation Address:

Location of Shower:

Maximum Temperature Setting:

(maximum of 41 ºC for showering)

Installed by:

Please record all test results on this form, including details of all measurement equipment used. This form is available to download at www.mirashowers.co.uk.

Date:

Not Operating Normal Operation Restricted Supply

Date /

Signature

Terminal

Block

Voltage

(V)

Inlet

Water

Temp.

(ºC)

Inlet

Filter

Cleaned

Terminal

Block

Voltage

(V)

Outlet

Water

Temp.

(ºC)

Flow

Rate

(l/min)

Outlet

Water

Temp.

(ºC)

Flow

Rate

(l/min)

Equipment Details

(make, model, serial number, calibration date etc...)

Page 35

35

MAINTENANCE

Tradesperson Maintenance - Inlet Filter Cleaning/Replacing

Read the section 'Important Safety Information' rst.

1. Electrical and water supplies to

appliance are turned off.

2. Remove cover screw, cover and

splash guard. Disconnect ribbon

cable from cover

3. Hold a spanner or other suitable grips

across ats of the metal connector.

Unscrew lter using another spanner

as shown. Clean or replace lter as

necessary. Ret lter making sure

it is screwed fully home. Do not

overtighten.

4. Make sure all plumbing connections

are sealed before restoring water

supply. Re-prime appliance (refer

to 'Installation') before restoring

electricity supply. Ret splash guard,

ribbon cable and cover.

Page 36

36

SPARE PARTS AND ACCESSORIES

416.38 Clamp Bracket

1643.100 Thermal Switch.

1643.101 Tank Assembly 9 kW/230 V 9.8 kW/240 V (earth wire not included).

1643.102 Tank Assembly 8.2 kW/230 V 9 kW/240 V (earth wire not included).

1643.103 Terminal Block/Earth Wire/Neutral Wire.

1643.104 Relay Board (including screws).

1643.105 Top and Bottom Cover Inserts (white).

1643.112 Drain Pump PCB - Extra models only.

1643.113 Component Pack (components identied 'B').

1643.114 Splash Guard.

1643.144 Top and Bottom Cover Inserts (grey).

1643.148 Seal Pack (components identied 'A').

1643.149 Flow Valve Assembly (components identied 'C').

1643.251 Cover and PCB Assembly (Standard)

1643.252 Cover and PCB Assembly (Flex)

1643.255 Cover and PCB Assembly (Memory)

1643.262 Cover and PCB Assembly (Flex Extra Wireless)

1829.062 Filter Assembly

1829.063 Inlet Connector.

Warning! If the wiring layout is changed or amended, the product functionality and

safety may be affected.

Warning! In the interests of safety, spares requiring exposure to mains voltage

should only be tted by competent persons.

Drain Pump Cable

1.1759.125

A cable to connect the Mira Advance

to the Instantmatch by Whale®

Pump. Includes tting instructions.

Suitable for the following models:

Mira Advance Standard Extra.

Mira Advance Flex Extra

Mira Advance Flex Extra Wireless.

Accessories

Page 37

37

B

1829.062

1643.100

1643.101

1643.102

1643.103

1643.104

1643.105

1643.144

1643.105

1643.144

1643.251

1643.252

1643.255

1643.262

1643.112

B

B

B

B

1643.114

C

A,C

416.38

A,C

1829.063

Page 38

38

WIRING DIAGRAM

Relay

Board

N

Inlet Sensor

Red

Brown

Solenoid Valve

230/240 V

AC Only

Brown

Double Pole Switch

45A Break Capacity

3 mm Contact Separation

L

E

Control Board

CN8

Green/Y

Terminal

Block

Outlet

Temperature

Sensor

One Shot

Thermal Switch

Blue

Heater Tank

Plumbing

Connectors

Outlet

Inlet

Pump Driver

Board

(Fitted to Standard Extra and Flex Extra models only.)

(Fitted to Standard Extra and Flex Extra models only.)

CN7

CN4

CN6

CN2

CN3

CN3

CN1

CN1

CN10

CN3

CN4

CN12

CN11

Blue

Radio

PCB

Page 39

39

NOTES

Page 40

40

1170168-W2-D (1643) (J97A-H, J97P) © Kohler Mira Limited, May 2013

Mira is a registered trade mark of

Kohler Mira Limited.

The company reserves the right to alter

product specifi cations without notice.

FM 14648

Guarantee

Your product has the benefit of our manufacturer’s

guarantee which starts from the date of purchase.

To activate this guarantee, please return your completed

registration card, visit our website or free phone 0800

0731248 within 30 days of purchase (UK only).

Within the guarantee period we will resolve defects in

materials or workmanship, free of charge, by repairing or

replacing parts or product as we may choose.

This guarantee is in addition to your statutory rights

and is subject to the following conditions:

● The guarantee applies solely to the original installation

under normal use and to the original purchaser only.

The product must be installed and maintained in

accordance with the instructions given in this user

guide.

● Servicing must only be undertaken by us or our

appointed representative. Note! if a service visit

is required the product must be fully installed and

connected to services.

● Repair under this guarantee does not extend the original

expiry date. The guarantee on any replacement

parts or product ends at the original expiry date.

● For shower fi ttings or consumable items we reserve

the right to supply replacement parts only.

The guarantee does not cover:

● Call out charges for non product faults (such as

damage or performance issues arising from incorrect

installation, improper use, inappropriate cleaning,

lack of maintenance, build up of limescale, frost

damage, corrosion, system debris or blocked fi lters)

or where no fault has been found with the product.

● Water or electrical supply, waste and isolation issues.

● Compensation for loss of use of the product or

consequential loss of any kind.

● Damage or defects caused if the product is repaired

or modifi ed by persons not authorised by us or our

appointed representative.

● Routine maintenance or replacement parts to

comply with the requirements of the TMV 2 or TMV

3 healthcare schemes.

● Accidental or wilful damage.

● Products purchased ex-showroom display.

What to do if something goes wrong

If your product does not work correctly refer to this

manual for fault diagnosis and check that it is installed

and commissioned in accordance with our instructions.

If this does not resolve the issue, contact us for help

and advice.

Extended Guarantees

A selection of protection plans are available that

enable you to cover repair bills (excludes Eire). Ring

01922 471763 for more details.

01 531 9337

Mira Customer Services Dept, Cromwell

Road, Cheltenham, Gloucestershire, GL52

5EP

Helpdesk Service - Ring our Customer

Services Team for product advice, to purchase

spare parts or accessories or to set up service

visit. Yo u can contact us via phone or e-mail,

details below. Please provide your model

name, power rating (if applicable) and date

of purchase.

Mira Showers Website (www.mirashowers.

co.uk)

Visit our website to register your guarantee,

download user guides, diagnose faults,

purchase our full range of accessories and

popular spares, or request a service visit.

Spares and Accessories - We hold the largest

stocks of genuine Mira spares and accessories.

Contact us for a price or visit our website to

purchase items from our accessory range and

popular spares

.

Service/Repairs - No one knows our products

better than our nationwide team of Service

Technicians. We can carry out service or repair

work to your product both during and after the

guarantee period. Ask about our fi xed price

service repairs.

To Contact Us: UK

CUSTOMER SERVICE

E-mail: Visit www.mirashowers.co.uk/

contactus

To Contact Us: Eire Only

0844 571 5000

Fax: 01 242 282595

E-mail: CustomerServiceEire@

mirashowers.com

Loading...

Loading...