Page 1

1

These instructions must be left with the user

Installation Guide

Mira Sport

7.5, 9.0 & 9.8 kW

Page 2

2

If you experience any difculty with the installation or operation of your new Electric

Shower, please refer to ‘Fault Diagnosis’, before contacting Kohler Mira Ltd. Our

telephone and fax numbers can be found on the back cover of this guide.

CONTENTS

Introduction .............................................................................................3

Guarantee ............................................................................................3

Patents and Design Registration ..........................................................3

Important Safety Information .................................................................4

Pack Contents Checklist ........................................................................5

Wiring Diagram ........................................................................................ 6

Specications .......................................................................................... 7

Plumbing ..............................................................................................7

Electrical ............................................................................................... 7

Dimensions ...........................................................................................7

Installation Requirements ......................................................................8

Plumbing ..............................................................................................8

Electrical ............................................................................................. 10

Installation ............................................................................................. 11

Commissioning .....................................................................................13

User Instructions ................................................................................... 15

User Safety Information ........................................................................ 17

Fault Diagnosis ......................................................................................19

User Maintenance ..................................................................................23

Cleaning .............................................................................................23

De-scaling the Showerhead ...............................................................23

Servicing ................................................................................................24

Inlet Filter - Cleaning/Renewing .........................................................24

Spare Parts ............................................................................................25

Accessories ...........................................................................................27

Customer Service .................................................................................. 28

Page 3

3

INTRODUCTION

Thank you for purchasing a quality Mira product. To enjoy the full potential of your

new product, please take time to read this guide thoroughly. Having done so, keep

it handy for future reference.

The Mira Sport is an electric shower with separate controls for power selection and

temperature/ow adjustment. A unique ow regulator stabilises temperature changes

caused by water pressure uctuations. These can result from taps being turned on

or off or toilets being ushed. Individual lights indicate "POWER" and "LOW FLOW".

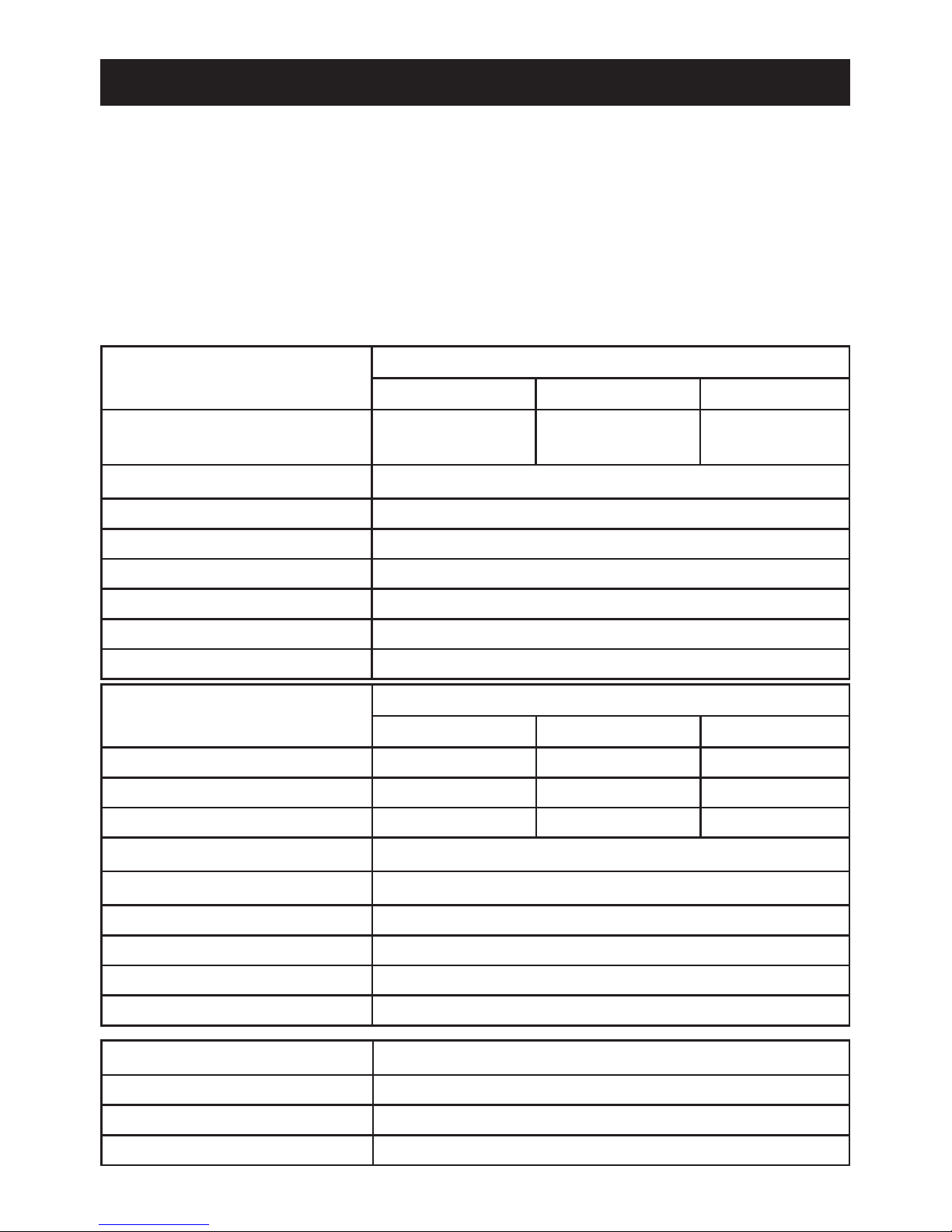

Mira Sport models covered by this guide:

Product Model Number Colour

Mira Sport 7.5 J95A White/Chrome

Mira Sport 9.0 J95B/J95V White/Chrome & Chrome

Mira Sport 9.8 J95C/J95W White/Chrome & Chrome

Guarantee

For domestic installations, Mira Showers guarantee the Mira Sport against any

defect in materials or workmanship for a period of 2 years from the date of purchase

(shower ttings for one year).

For non-domestic installations, Mira Showers guarantee the Mira Sport against

any defect in materials or workmanship for a period of 1 years from the date of

purchase.

For Terms and Conditions refer to the back cover of this guide.

Patents and Design Registration

Design Registration: 000373543-002-004

Patents: GB: 2 341 667

Ireland: 82835

Patent Applications: UK: 2 427 460, 2 432 201

Ireland: 2006/0462, 2006/0818

Page 4

4

IMPORTANT SAFETY INFORMATION

WARNING - This shower can deliver scalding temperatures if not operated,

installed or maintained in accordance with the instructions, warnings and

cautions contained in this guide and on or inside the appliance.

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK OR INJURY:

1. Installation of this shower must be carried out in accordance with these

instructions by qualied, competent personnel.

2. Isolate the electrical and water supplies before commencing installation. The

electricity must be isolated at the consumer unit and the appropriate circuit

fuse removed, if applicable. Mains connections are exposed when the cover

is removed.

3. DO NOT install the shower in areas with high humidity and temperature (i.e.

steam rooms and saunas).

4. DO NOT install the shower where it may be exposed to freezing conditions.

Ensure that any pipework that could become frozen is properly insulated.

5. DO NOT switch the shower on if there is a possibility that the water in the

shower is frozen.

6. DO NOT switch the shower on if water starts leaking from the shower case.

Isolate the electrical supply to the shower immediately.

7. DO NOT connect the outlet of the shower to any tap, control valve, trigger

handset or showerhead other than those specied for use with this shower.

Only Kohler Mira recommended accessories should be used.

8. The water supplies to this product must be isolated if the product is not to be

used for a long period of time. If the product or pipework is at risk of freezing

during this period they should also be drained of water.

9. DO NOT perform any unspecied modications to the shower or it’s accessories.

When servicing only use Genuine Kohler Mira replacement parts.

10. If the shower is dismantled during installation or servicing then upon completion

the product must be inspected to ensure all electrical connections are tight and

that there are no leaks.

11. Read all installation instructions before installing this shower.

12. Upon completion of the installation, make sure that the user is familiar with the

operation of the shower, and leave this guide with the owner.

Page 5

5

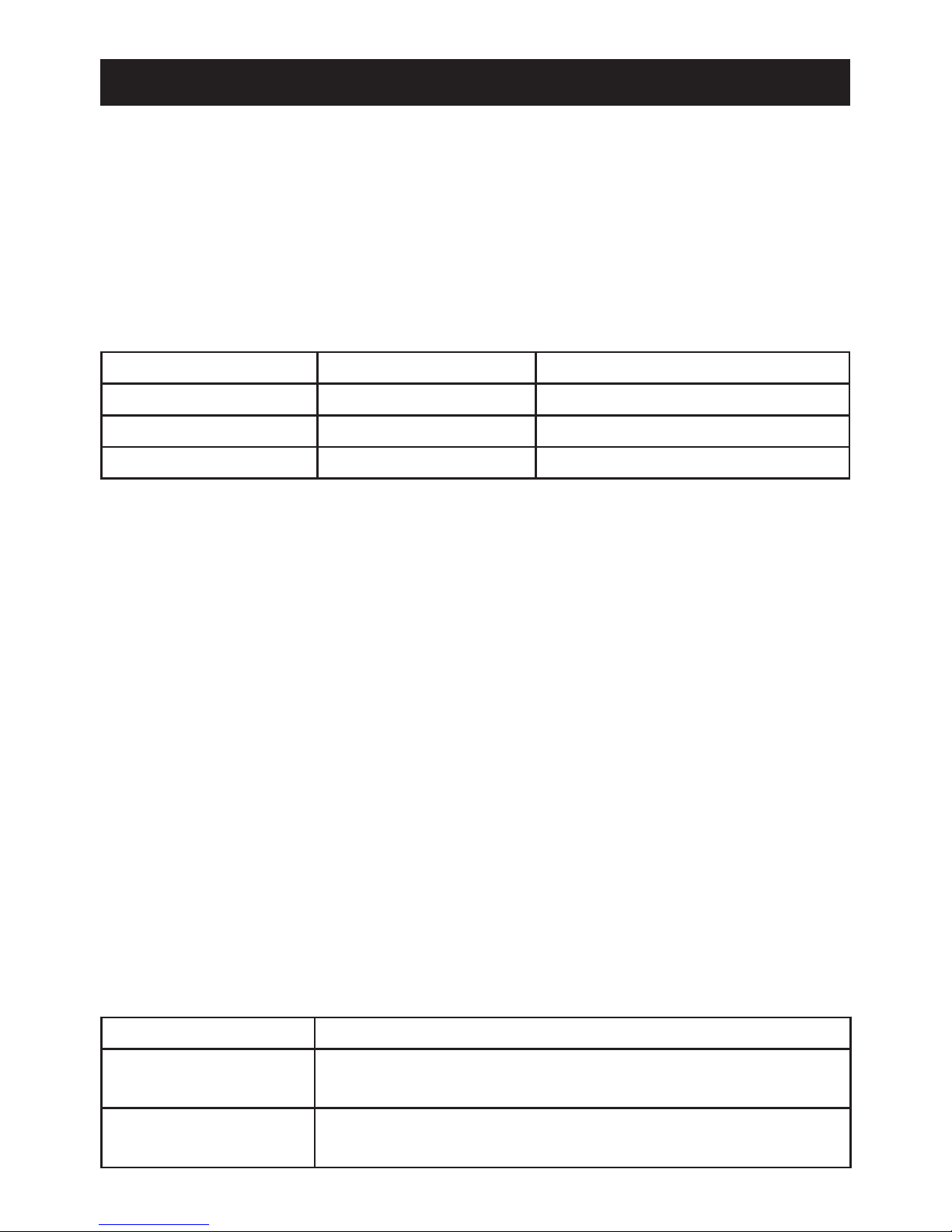

PACK CONTENTS CHECKLIST

Tick the appropriate boxes to familiarize yourself with the part names and to

conrm that the parts are included.

q 3 x Wall Plugs

q 1 x Compression Nut

q 3 x Fixing Screws

q 2 x Case Inserts

q 1 x Olive

q 1 x Mira Sport 7.5, 9.0 or 9.8

Documentation

q 1 x Installation Template

q 1 x Installer Checklist

q 1 x Guarantee Card

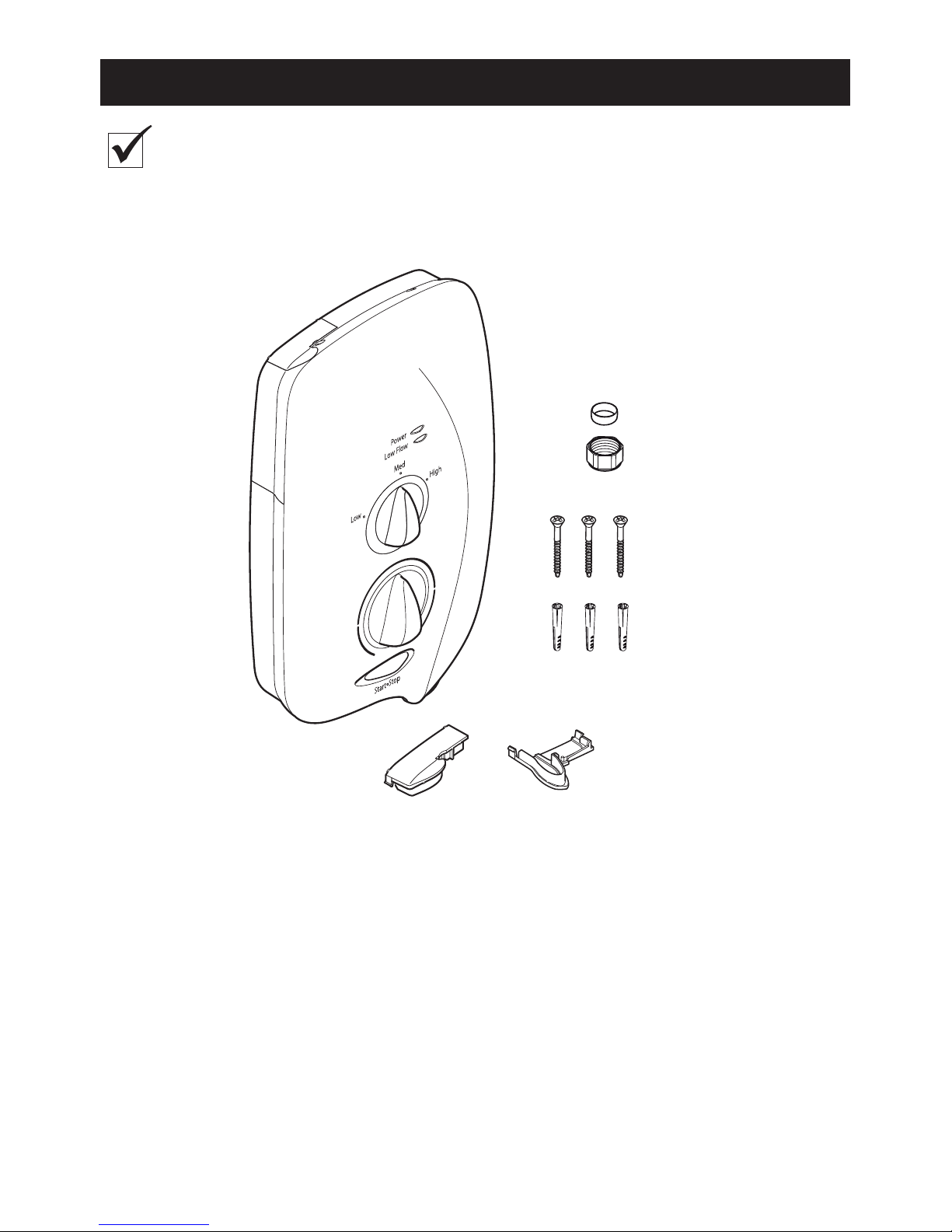

Page 6

6

BROWN

BROWN

BROWN

BROWN

BLACK

BLACK

BLACK

BLUE

BLUE

GREEN

GREEN

BLACK

RED

RED

RED

Thermal Cutout

Dual Disc

L

Solenoid

Valve

Pressure/Power

Selector Switch

Low Flow

Neon

Power On

Neon

N

E

Tank Connection

Inlet Connector

Internal Wiring Diagram

Load

WIRING DIAGRAM

START/STOP

Page 7

7

SPECIFICATIONS

European Conformity Information

Mira Sport range of showers complies with the following European directives:

2006/95/EC Low Voltage Directive, 2004/108/EC EMC Directive.

Mira Sport range of showers are high power appliance and are subject to

conditional connection. If the main electrical supply fuse is rated less than 80

Amps, the local electricity supply company must be contacted to conrm if the

electrical supply is adequate.

Mira Sport range of showers complies with the requirements of the UK’s water

regulations.

Dimensions

Height 340 mm

Width 204 mm

Depth 80 mm

Electrical

Variant

Sport 7.5 Sport 9.0 Sport 9.8

Nominal Power at 230 V ac 6.9 kW 8.3 kW 9.0 kW

Nominal Power at 240 V ac 7.5 kW 9.0 kW 9.8 kW

Recommended MCB Rating 40 A 40 A 45 A

Maximum Supply Cable Size 16 mm²

Recommended RCD Rating 30 mA tripping current

Recommended Isolator Switch 45 A double-pole with 3 mm contact separation

Appliance Sealing Rating IP X4 - Suitable for installation in Zone 1

Maximum Ambient Temperature 30°C

Minimum Ambient Temperature 2°C

Plumbing

Variant

Sport 7.5 Sport 9.0 Sport 9.8

Minimum Dynamic Pressure 70 kPa

(0.7 bar)

70 kPa

(0.7 bar)

70 kPa

(0.7 bar)

Maximum Static Pressure 1000 kPa (10 bar)

Minimum Static Pressure 20 kPa (0.2 bar)

Maximum Inlet Temperature 30°C

Minimum Inlet Temperature 2°C

Inlet Connection 1/2” BSP Male / 15 mm Compression Fitting

Maximum Water Hardness 200 ppm CaCO

3

Outlet Connection 1/2” BSP Male

Page 8

8

Please read the Important Safety Information and specications sections at

the front of this guide, and the requirements detailed in this section before

installing the shower.

WARNING - TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK OR INJURY:

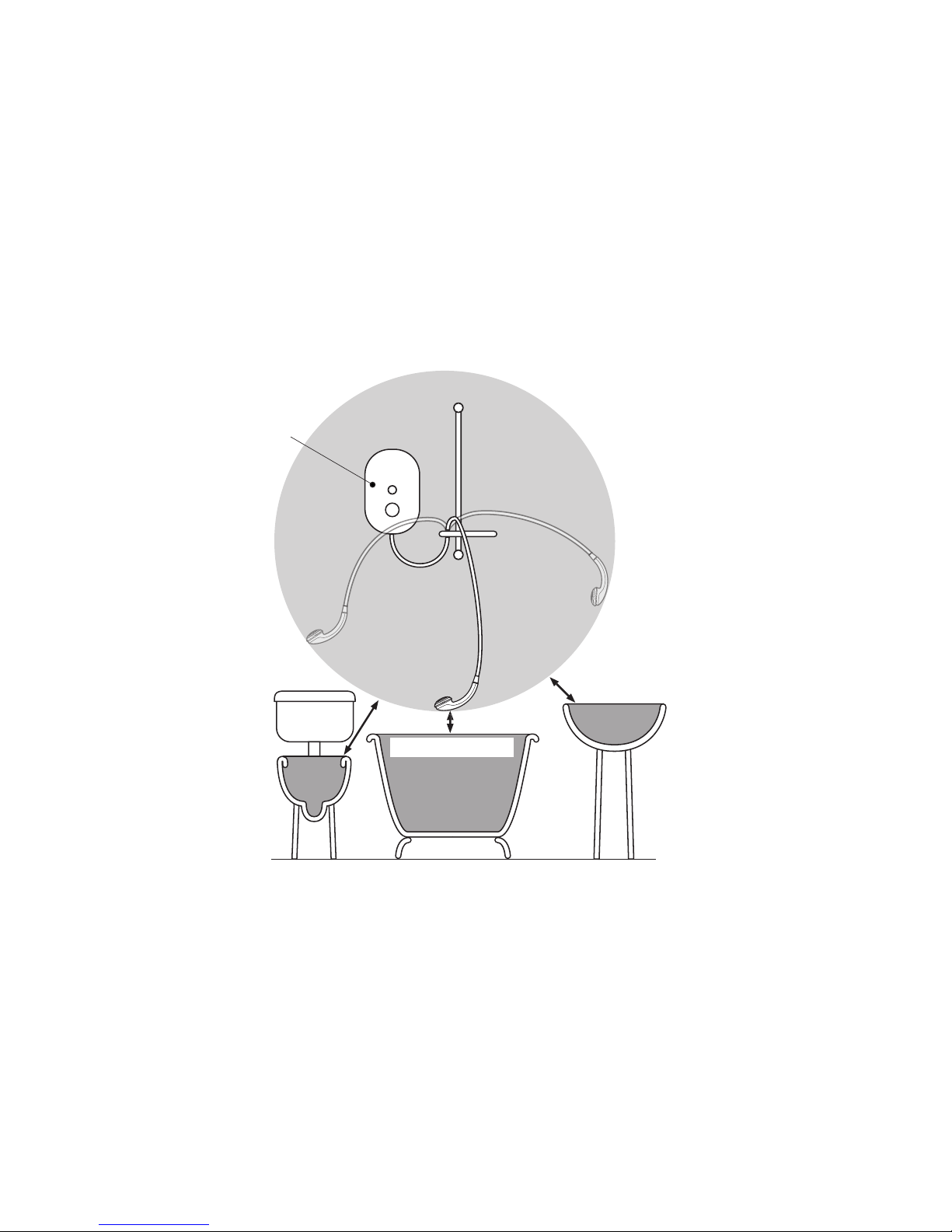

Plumbing

1. The plumbing installation must comply with all national or local water regulations

and all relevant building regulations, or any particular regulation or practice

specied by the local water supply company.

2. Do not install the product in a position in which service access is limited.

3. Decide on a suitable position for the shower (minimum distance of 200 mm from

the ceiling to allow for cover t and removal).

4. The position of the shower and shower ttings must provide a minimum gap of

25 mm between the showerhead and the spill over level of any bath, shower

tray or basin and a minimum gap of 30 mm between the showerhead and the

spill over level of any toilet, bidet or other appliance with a Fluid Category 5

backow risk (see diagram on page 9).

5. The shower is suitable for installation within the shower area and is tted with

a pressure relief valve. It must be positioned over a water catchment area with

the controls at a convenient height for the user.

6. The shower must be tted to a waterproof at and even wall surface.

7. DO NOT t the shower to the wall and tile up to the case.

8. DO NOT seal the gap between the shower and the wall surface.

9. The showerhead should be positioned so that it discharges down the centre

line of the bath or across the opening of a shower cubicle.

10. The showerhead must be directed away from the shower unit, during normal

use the showerhead must not spray directly on to the shower unit.

11. DO NOT apply excessive force to plumbing connections; always provide

mechanical support when making plumbing connections. Any soldered joints

should be made before connecting the shower.

12. This shower is not designed to be plumbed directly from the rear. For rear-entry

supply, add an elbow to the supply pipe and connect as a rising or a falling supply.

13. If pipework and/or electrical cables enter the shower from the rear through a

hole in the wall provision must be made to prevent water ingress back into the

wall structure.

14. Only use the inlet connector supplied with the shower. DO NOT use any other

type of tting.

INSTALLATION REQUIREMENTS

Page 9

9

Hose Retaining Ring tted and shower ttings xed at a suitable height preventing

dirty water backow.

Note! There will be occasions when the hose retaining ring will not provide a suitable

solution for Fluid Category 3 installations, in these instances an outlet double

checkvalve must be tted, this will increase the required supply pressure typically

by 10kPa (0.1 bar). Double checkvalves tted in the inlet supply to the appliance

cause a pressure build up, which could exceed the maximum static inlet pressure

for the appliance and must not be tted. For Fluid category 5 double checkvalves

are not suitable.

Zone of

Backow Risk

30 mm

Minimum

Toilet or Bidet

FC5

Hand Basin

FC3

Bath or Shower

Tray FC3

Electric

Shower

25 mm

Minimum

25 mm Minimum

15. A full bore/non restrictive servicing valve must be tted in a readily accessible

position adjacent to the shower to facilitate maintenance of the shower.

DO NOT use a valve with a loose washer plate (jumper) as this can lead to a

build up of static pressure.

16. A water treatment device should be installed where the water hardness may

exceed 200 ppm. Malfunctions caused by excessive limescale formation are

not covered by this shower’s guarantee (see back page for details).

17. The installation must not cause the hose to be sharply kinked during normal

use.

18. DO NOT perform the electrical installation until the plumbing has been

completed and checked for leaks.

Page 10

10

Consumer Unit

Double-pole Isolating

Switch

WARNING - TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK OR INJURY:

Electrical

1. The electrical installation must comply with BS 7671 (commonly referred to as

the IEE Wiring Regulations) and all relevant building regulations, or any particular

regulation or practice specied by the local electricity supply company.

2. Ensure that all circuit protection devices, switches and cabling is adequate

for the rated current of the shower and that the rating of the electricity supply

company fuse and the consumer unit are adequate for the additional demand.

3. The shower must be earthed. Ensure any supplementary bonding complies

with the relevant regulations.

4. This shower is intended to be permanently connected to the xed electrical wiring

of the mains system. A separate supply must be provided from the consumer

unit to the shower.

5. DO NOT supply any other electrical equipment including extractor fans or pumps

via this product.

6. This shower must be provided with means for local disconnection that is

incorporated into the xed wiring in accordance with the relevant local wiring

regulations. This must be a double pole switch, which has at least 3 mm contact

separation in each pole. The switch can be a ceiling mounted pull-cord type within

the shower room or a wall mounted switch tted in the applicable zone area.

7. A 30mA Residual Current Device (RCD) is recommended to be tted in the

circuit to the shower.

8. DO NOT apply excessive force to the terminal block.

9. All electrical connections should be checked for tightness to prevent overheating

before switching on the electrical supply.

10. DO NOT switch on the electrical supply until the plumbing has been completed

and checked for leaks.

Plumbing and Electrical Schematic

Page 11

11

INSTALLATION

Read the section “Important Safety Information” rst

Electrical supply is turned

off at the mains.

200 mm minimum gap

from ceiling.

Remove three screws.

INSTALLATION TEMPLATE

Mira Sport

Attention Installer

Caution! Do not drill into

buried cables or pipes.

Drill and plug* the three

holes using template.

Remove cover and

determine supply pipe

position.

For back inlet use soldered

elbow.

Do not trap green wire.

Fix appliance to wall. Flush a minimum of 10

litres through pipework.

* Alternative xings for some wall structures are not supplied.

1. 2.

200 mm

3.

4. 5. 6.

7. 8. 9.

Page 12

12

Connect supply pipe. Do not

overtighten!

Feed cable into Case. Fit Earth

sleeve (not supplied) and strip

insulation.

Do not twist cable cores.

Firmly connect the conductors.

Do not exert strain on the terminal

block.

Make sure wires are clear of all

mounting holes.

Ret the Service Tunnel and Cover.

Make sure they t correctly.

Do not overtighten screws.

Do not use alternative screws to

secure the Cover. This can cause

internal damage to the appliance.

Do not seal around the back of

appliance.

L = BROWN

E = GREEN

N = BLUE

10. 11.

12. 13.

14. 15.

Important! Make sure that the inlet earth

wire is routed as shown. Failure to do so

may cause product malfunction.

Page 13

13

Before carrying out the commissioning procedure install the Shower Fittings,

refer to the Shower Fittings Installation and User Guide.

If you are unsure how an electric shower works, please read through the User

Instructions section before continuing.

COMMISSIONING

Electrical supply is turned

off at the mains.

Turn control to full cold. Turn water supply fully

on.

Check for water leaks. Set control to LOW. Switch on electrical

supply.

Push START button.

COLD

Water will be at full force and

at a cool temperature.

Turn control slowly.

Temperature remains cool

and ow is reduced.

Turn control to full cold. Set control to MEDIUM.

_

+

The temperature will rise

slightly.

0 - 5 secs

5 - 10 secs

1. 2. 3.

4. 5. 6.

7. 8. 9.

10. 11. 12.

Page 14

14

Note! A slight hissing sound may be heard from the Mira Sport during operation.

High mains water pressure and high shower temperatures will affect the tone. This

is quite normal in use.

Set control to HIGH.

_

+

The temperature will rise further.

Adjust temperature as required.

Flow rate will adjust automatically.

Press STOP and isolate power.

The shower will purge water from

its tank for a few seconds.

Residual water may drain over a

few minutes.

5 - 10 secs

0 - 5 secs

13. 14.

15. 16.

17. 18.

Page 15

15

USER INSTRUCTIONS

The warmer the shower, the lower the

ow rate and vice versa.

_

+

COLD

_

+

_

+

Hot water is produced by passing cold

water through a heating tank.

The shower has three heater settings.

How Your Electric Shower Works

Page 16

16

_

+

Water inlet pressure uctuations due to other draw offs (e.g. ushing toilet) will cause

the showering temperature to increase.

*

*

*

_

+

For a cold shower select LOW

For a summer warm shower select MEDIUM

For a winter warm shower select HIGH

Adjust the temperature as required

The ow rate will adjust automatically

The Effect of Seasonal Changes

The Effect of Other Water Devices

Showering temperature

will stabilize to within 6°C

band if other outlets are

opened whilst showering,

providing the minimum

pressure does not fall

below 70 kPa (0.7 bar).

Selected

Showering

Temperature

Example of how shower temperature

stabilizes due to pressure changes.

Page 17

17

USER SAFETY INFORMATION

1. Make sure that you fully understand how

to operate this shower before use, read

all operating instructions and retain this

guide for future reference.

2. This shower is not intended for use

by persons (including children) with

reduced physical, sensory or mental

capabilities, or lack of experience and

knowledge, unless they have been given

supervision or instruction concerning

the use of the shower by a person

responsible for their safety.

3. Children should be supervised to ensure

that they do not play with the shower.

4. DO NOT switch the shower on if there is

a possibility that the water in the shower

is frozen.

5. DO NOT switch the shower on if water

leaks from the shower unit. Isolate

the electrical supply to the shower

immediately.

6. DO NOT switch the shower on if

the case appears to be damaged or

incorrectly tted. Isolate the electrical

supply to the shower immediately.

7. Switch off the appliance at electrical

isolating switch when not in use. This is

for safety and is recommended with all

electrical appliances.

8. DO NOT connect the outlet of the

shower to any tap, control valve, trigger

handset or showerhead other than those

specied for use with this shower. Only

Kohler Mira recommended accessories

should be used.

9. Always check the water temperature

before entering the shower. Sunburn

or skin conditions can increase your

WARNING - THIS SHOWER CAN DELIVER SCALDING TEMPERATURES IF

NOT OPERATED, INSTALLED OR MAINTAINED IN ACCORDANCE WITH THE

INSTRUCTIONS, WARNINGS AND CAUTIONS CONTAINED IN THIS GUIDE AND

ON OR INSIDE THE APPLIANCE.

To reduce the risk of re, electric shock or injury:

sensitivity to hot water. Make sure

that you set the shower to a cooler

temperature.

10. DO NOT operate the temperature

control rapidly, allow 10 – 15 seconds for

the temperature to stabilise before use.

11. Care is required if the shower is turned

off and back on during showering as

this may result in unstable temperature.

Ensure temperature has stabilised

before re-using shower.

12. The showerhead must be de-scaled

regularly, refer to the user maintenance

section towards the rear of this guide

for details.

13. The shower hose must be checked

regularly and replaced if damaged, refer

to the user maintenance section towards

the rear of this guide for details.

14. DO NOT store bathroom items on top of

the shower unit (i.e. shampoo or shower

gel containers).

15. The shower must be operated and

maintained in accordance with the

requirements of this guide.

16. If any of the following conditions occur,

isolate the electricity and water supplies

and contact Kohler Mira Customer

Service.

• If the case is damaged or the cover

is not correctly tted and water has

entered the shower case.

• If the shower begins to make an

odd noise, smell or smoke.

• If the shower shows signs of a

distinct change in performance

indicating a need for maintenance.

Page 18

18

A small amount of water may

continue to drain over a few

minutes.

Press STOP button. Shower will

continue to run for a few seconds

before stopping.

_

+

Switch on electrical supply. Press START button.

Set to desired position.

Allow 10-15 seconds for any temperature adjustments to reach the

handset.

_

+

Check water temperature before

entering shower.

Using Your Shower

Read the section “User Safety Information” rst.

1. 2.

3. 4.

6. 7.

5.

Page 19

19

FAULT DIAGNOSIS

The trouble shooting information tabled below gives details on probable causes and

remedies should difculties be encountered whilst the shower is in operation.

Warning! There are no user serviceable components beneath the cover of the

appliance. Only a competent trades person should remove the front cover!

Symptom

Power

Light

Low

Flow

Light

Heater

Low/

Med/

High

Probable Cause Possible Remedy

Appliance

fails to

operate.

OFF

OFF

OFF

OFF

Any

Any

Electrical supply

isolated at double

pole switch.

Fuse blown or

MCB/RCD tripped,

indicating possible

electrical fault.

Switch on electrical

supply via the

pullcord or wall

mounted switch.

Renew the fuse

or reset the MCB/

RCD. If fault

persists, contact

your installer.

Shower

cycles from

hot to cold.

ON

ON

ON

ON

ON

OFF

Med/

High

Med/

High

Med/

High

Handset blocked.

Water pressure

below minimum

required for

appliance

operation.

Temperature dial or

heater setting too

high.

Remove and clean.

Make sure incoming

mains water

stopcock and/or

appliance isolating

valve is fully turned

on.

Turn the heater

selector knob to

medium or turn

the temperature

control until a

cooler temperature

is achieved.

Page 20

20

Symptom

Power

Light

Low

Flow

Light

Heater

Low/

Med/

High

Probable Cause Possible Remedy

Unable to

select a

cool enough

shower.

ON OFF High Due to the rise in

mains water supply

temperature, the

Heater setting may

be too high.

Turn the heater

selector knob to

medium and adjust

the temperature

control until a

suitable temperature

is achieved.

Handset

dripping.

OFF

OFF

OFF

OFF

Any

Any

Insufficient water

supply pressure for

shut off.

Flow Valve faulty.

Min static pressure

to ensure shut off

and prevent dripping

is 20 kPa (0.2 bar).

Note! If other

appliances are

operating, static

pressure may

drop below 20

kPa (0.2 bar).

Contact local water

company. Renew

Flow Valve.

Replace.

Low or no

ow.

ON ON Any Water supply

pipework or inlet

lter restricted by a

blockage or partial

blockage.

Insufficient water

supply pressure/

ow for operation.

Flush supply pipe.

Clean Inlet Filter.

Contact local water

company. Supply

pressure must be a

minimum of 70 kPa

(0.7 bar).

Note! If other

appliances are

operating, pressure

may drop below

70 kPa (0.7 bar).

(cont....)

Page 21

21

Symptom

Power

Light

Low

Flow

Light

Heater

Low/

Med/

High

Probable Cause Possible Remedy

Low or no

ow.

(cont....)

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

Any

Any

Any

Any

Any

Other outlets (e.g.

toilet, garden hose,

washing machine,

etc.) drawing water

while the shower is

being used.

Handset blocked.

Service tunnel or

cover not fitted

correctly causing

Start/Stop button

not to operate.

Flow Valve faulty.

Heater Tank

excessively scaled.

Turn off other

appliances whilst

shower is in use.

Remove and clean.

Check case inserts

are cut and fitted

correctly. Check

services (electrical

or plumbing) are

not interfering with

location of service

tunnel or cover.

Replace.

Replace. In hard

water areas consider

the use of a water

softener.

Operation of

Temperature

Control

has little or

no effect

on water

temperature.

ON

ON

ON

ON

ON

OFF

OFF

OFF

Med/

High

Med/

High

Med/

High

Med/

High

Handset or Inlet

Filter blocked.

Flow Valve faulty.

Heater Tank failure.

Microswitch failure.

Remove and clean.

Replace.

Replace.

Replace.

Page 22

22

Symptom

Power

Light

Low

Flow

Light

Heater

Low/

Med/

High

Probable Cause Possible Remedy

No change in

temperature

between Low/

Medium/High

setting.

ON

ON

ON

OFF

Any

Any

Insufficient mains

water pressure.

Possible failure

of flow valve,

microswitch, or

heater tank.

Contact local water

company.

Use a suitable

continuity device to

check the continuity

of the microswitch

or heater tank and

replace parts as

necessary.

Water will not

turn off.

ON

ON

OFF

ON

Any

Any

Flow valve, solenoid,

or Start/Stop switch

faulty.

Supply pressure

below 20 kPa

(0.2 bar).

Replace as

necessary.

Contact local water

company. Check

mains water static

pressure.

Appliance

fails to

produce

hot water

when set

on Medium/

High Heater

Setting.

ON

ON

ON

ON

OFF

OFF

Med/

High

Med/

High

Med/

High

Insufficient water

supply.

Possible failure of

the microswitch or

thermal switch.

Heater tank failure.

Contact local water

company.

Use a suitable

continuity device to

check the continuity

of the microswitch

or heater tank and

replace parts as

necessary.

Replace.

Page 23

23

USER MAINTENANCE

There are no user serviceable

parts inside the shower. Only

qualified, competent personnel

should remove the front cover,

mains connections are exposed

when the cover is removed.

Switch the shower off at the isolator

switch before performing any user

maintenance or before cleaning

the shower.

DO NOT allow young children

to perform user maintenance

including cleaning of the shower.

Use your thumb or a

soft cloth to wipe any

limescale from the

soft nozzles

DO NOT use the showerhead to

clean the shower.

If the shower is not to be used for

a long period, the electrical supply

and water supply to the shower

should be isolated. If the shower

or pipework is at risk of freezing

during this period a qualified,

competent person should drain

them of water.

Unscrew the hose from

the showerhead and

the shower outlet.

Inspect the hose.

Cleaning

Many household cleaners contain abrasives and chemical substances, and should not

be used for cleaning plated or plastic ttings. These nishes should be cleaned with

a mild washing up detergent or soap solution, and then wiped dry using a soft cloth.

WARNING - TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK OR INJURY:

De-scaling the Showerhead

Important! Keeping the showerhead

clean and free from limescale will ensure

that your shower and showerhead

continue to perform to their maximum.

A blocked showerhead can restrict the

flow rate and may cause damage to

your shower

Inspecting the hose.

Important! The shower hose should

be inspected periodically for damage

or internal collapse, internal collapse

can restrict the flow rate from the

showerhead and may cause damage to

the shower. Remove the shower hose

from the shower, inspect and replace the

hose if necessary.

Page 24

24

Make sure that the electrical supply

is turned off at the mains and that the

water supply is fully turned off.

Remove the three screws and the

cover.

Inlet Filter - Cleaning/Renewing

Read the section “Important Safety Information” rst

Cover

Cover Retaining

Screw

Hold a wrench across the ats of the

metal connector. Unscrew the lter

using another wrench as shown. Clean

or renew the Filter as necessary. Ret

in reverse order making sure the Filter

is screwed fully home.

Do not overtighten! Make sure

plumbing connections are sealed

before restoring electricity supply.

Refit the cover making sure it is

correctly located. Do not overtighten

the screws.

Filter

SERVICING

WARNING

There are no user serviceable parts inside the shower.

Servicing of the shower must only be carried out by qualied, competent

personnel following the instructions provided in this guide and those provided

with any spare part.

Before replacing any parts, ensure that the underlying cause of the malfunction

has been resolved.

Page 25

25

SPARE PARTS

405.58 Inlet Connector Assembly

406.27 Inlet Filter (with 'O' seal tted)

416.38 Clamp Bracket (Inlet)

416.41 Thermal Switch

416.48 Latching Switch

416.51 Solenoid Coil

872.01 Microswitch N/O - 2 pin

872.28 Microswitch C/O - 3 pin

1563.500 Heater Tank 7.5 kW 240 V AC (6.85 kW 230 V AC)

1563.502 Heater Tank 9.0 kW 240 V AC (8.2 kW 230 V AC)

1563.504 Heater Tank 9.8 kW (9.0 kW 230 V AC)

1563.507 Flow Valve Assembly

1563.509 Switching Assembly

1563.511 Cover Assembly

1563.513 Screw Pack - components identied 'A'

1563.514 Low Flow Neon Assembly

1563.515 Power On Neon Assembly

1563.516 Outlet Connector

1563.517 Service Tunnel

1563.518 Component Pack - components identied 'B'

1563.519 Terminal Block Assembly 9.8 kW 240 V AC (9.0 kW 230 V AC) only

1563.520 Wire Pack (not shown)

1563.522 Cover Seal (not shown)

1695.017 Cover Assembly (Chrome)

1695.018 Service Tunnel (Chrome)

1695.019 Component Pack (Chrome) Not Shown

1695.026 Case Insert Chrome Top (Not Shown)

1695.027 Case Insert Chrome Bottom (Not Shown)

Note! Case inserts 1695.026 and 1695.027 adapted for chrome variants with top

or bottom service entry points are available on request.

Page 26

26

416.41

1563.502

1563.500

1563.504

1563.511

416.48

416.51

1563.514

1563.515

416.38

406.27

405.58

1563.517

1563.516

A

A

A

B

B

B

B

B

B

B

B

B

1563.507

1563.519

1563.509

872.28

872.01

Important! Push-t connectors must be assembled

back to back onto terminals of micro-switches.

A minimum air gap of 4 mm must be maintained

between the connectors after assembly.

4 mm MINIMUM

1695.017

1695.018

Page 27

27

ACCESSORIES

Genuine Mira accessories can be purchased direct from Customers Services (our contact details can

be found on the back cover of this guide) or from approved stockists or merchants.

Everclear Showerhead

White - 2.1616.030

Chrome - 2.1616.031

Mira's new Everclear range has

been specially designed for hard

water areas and reduces the risk

of lime scale build up.

Shower Seat

White - 2.1536.128

White/Chrome - 2.1536.129

For use in or out of the showering

area. Folds up when not in use.

Maximum User Weight - 127 kg

(20 stone) Note! Must be installed

onto a solid wall.

Premium Shower Seat

White/Chrome - 2.1731.001

Grey/Chrome - 2.1731.002

Stylish, slim-line and robust

shower seat for use in or outside

of the shower area. Folds up when

not in use. Maximum User Weight

- 150 kg (23.5 stone) Note! Must

be installed onto a solid wall.

Logic Showerhead Holder

White - 2.1605.149

White/Chrome - 2.1605.150

An alternative to the traditional

slide bar. Often a useful addition

when positioned for the smaller

members of the family.

Outlet Double Check Valve

(DCV-H)

Chrome - 1.0.110.55.1

An outlet double check valve,

designed to prevent the back ow

or back-siphonage of potentially

contaminated water, through

shower controls which are tted

with a exible shower hose as part

of the outlet shower tting.

Mira Standard Grab Bars

300 mm - 2.1605.070

450 mm - 2.1605.071

600 mm - 2.1605.072

Premium grade, highly polished,

stainless steel grab bars.

Note! Must be installed onto a

solid wall.

Page 28

28

Guarantee

Your product has the benefit of our manufacturer’s

guarantee which starts from the date of purchase.

To activate this guarantee, please return your completed

registration card, visit our website or free phone 0800

0731248 within 30 days of purchase (UK only).

Within the guarantee period we will resolve defects in

materials or workmanship, free of charge, by repairing or

replacing parts or product as we may choose.

This guarantee is in addition to your statutory rights

and is subject to the following conditions:

● The guarantee applies solely to the original installation

under normal use and to the original purchaser only.

The product must be installed and maintained in

accordance with the instructions given in this user

guide.

● Servicing must only be undertaken by us or our

appointed representative. Note! if a service visit

is required the product must be fully installed and

connected to services.

● Repair under this guarantee does not extend the original

expiry date. The guarantee on any replacement parts

or product ends at the original expiry date.

● For shower fi ttings or consumable items we reserve

the right to supply replacement parts only.

The guarantee does not cover:

● Call out charges for non product faults (such as

damage or performance issues arising from incorrect

installation, improper use, lack of maintenance, build up

of limescale, f rost damage, corrosion, system debris or

blocked fi lters) or where no fault has been found with

the product.

● Water or electrical supply, waste and isolation issues.

● Compensation for loss of use of the product or

consequential loss of any kind.

● Damage or defects caused if the product is repaired

or modifi ed by persons not authorised by us or our

appointed representative.

● Routine maintenance or replacement parts to comply

with the requirements of the TMV 2 or TMV 3 healthcare

schemes.

● Accidental or wilful damage.

● Products purchased ex-showroom display.

What to do if something goes wrong

If your product does not function correctly when you fi rst

use it, contact your installer to check that it is installed

and commissioned in accordance with the instructions in

this manual.

If this does not resolve the issue, contact

our Customer

Services Team who will offer you or your installer help

and advice.

If you experience problems, check in this manual to see if

simple home maintenance is required. If you require further

assistance call our Customer Services Team.

Extended Guarantees

A selection of protection plans are available that

enable you to cover repair bills for the life of your policy

(excludes Eire). Ring 01922 471763 for more details.

Helpdesk Service

Our Customer Services Team is comprehensively trained

and can offer help and advice, spare parts, accessories or

a service visit.

We will need you to have your model name or number,

power rating (if applicable) and date of purchase. As part of

our quality and training programme calls may be recorded

or monitored.

Mira Showers Website

(www.mirashowers.co.uk)

From our website you can register your guarantee,

download additional user guides, diagnose faults, purchase

our full range of accessories and popular spares, refer to

our FAQ’s and request a service visit.

Spares and Accessories

We maintain extensive stocks of genuine spares and

accessories and aim to provide support throughout the

product’s expected life.

Payment can be made by phone at time of order using

most major Credit or Debit cards and we aim to despatch

orders within 2 working days. Items purchased from us are

guaranteed for 12 months from date of purchase. For safety

reasons spares exposed to mains voltages should only be

fi tted by competent persons.

Returns – items can be returned within one month of date

of purchase, providing that they are in good condition and

the packaging is unopened. If you wish to return any items

please notify us in writing within seven days of receipt.

Service / Repairs

Our nationwide team of Service Technicians can carry out

service or repair work to your product within the guarantee

period and beyond. You have the assurance of a fully trained

Technician, genuine spare parts and a 12 month guarantee

on any chargeable work done.

Payment should be made directly to the Service Technician

who will accept most major Credit or Debit cards.

To Contact Us

UK

Telephone: 0844 571 5000

E-mail - Visit www.mirashowers.co.uk/contactus

Fax: 01242 282595

By Post: Mira Customer Services Dept, Cromwell Road,

Cheltenham, Gloucestershire, GL52 5EP

Eire

Telephone: 01 459 1344

E-mail: sales@modernplant.ie

Fax: Dublin 01 459 2329

By Post: Modern Plant Ltd (Dublin),

Otter House, Naas Road, Clondalkin, Dublin 22

Mira is a registered trade mark of

Kohler Mira Limited.

The company reserves the right to alter

product specifi cations without notice.

FM 14648

1060737-W2-G (1563) (J95A/B/C/V/W) © Kohler Mira Limited, January 2012

CUSTOMER SERVICE

Loading...

Loading...