Page 1

1

MIRA FORM

These instructions are to be left with the user

SHOWER CONTROL

Installation & User Guide

Page 2

2

CONTENTS

Introduction ............................................................................................. 3

Safety:Warnings ...................................................................................... 3

Pack Contents ......................................................................................... 4

Dimensions ............................................................................................. 6

Specifications .......................................................................................... 7

Normal Operating Conditions ................................................................ 7

Pressures and Flow Rates ................................................................... 7

Temperatures ....................................................................................... 9

Installation Requirements .................................................................... 10

Installation ............................................................................................. 13

General .............................................................................................. 13

Reversed Inlet Supplies ..................................................................... 14

Installation: Solid and Dry-lined Walls ................................................ 15

Shower Fittings - Installation .............................................................. 18

Installation: Panel walls ..................................................................... 19

Commissioning ..................................................................................... 22

Operation ............................................................................................... 25

Fault Diagnosis ..................................................................................... 27

Maintenance .......................................................................................... 29

Spare Parts ............................................................................................ 41

Customer Service .................................................................... Back Page

Page 3

3

This Form Thermostatic Shower Control is precision engineered and should give

continued safe and controlled performance, provided:

1. It is installed, commissioned, operated and maintained in accordance with

manufacturers recommendations.

2. Periodic attention is given, when necessary, to maintain the product in good

functional order.

The function of a thermostatic mixing valve is to deliver water consistently at a safe

temperature. In keeping with every other mechanism, it cannot be considered as

functionally infallible and as such, cannot totally replace a supervisor’s vigilance

where that is necessary. Provided it is installed, commissioned, operated and

maintained within manufacturers recommendations, the risk of failure, if not eliminated,

is reduced to the minimum achievable.

The Mira Form Thermostatic mixing valve is specified to meet the highest standards

of safety, comfort and economy as demanded by todays users. The Mira Form is

designed, manufactured and supported in accordance with accredited BS EN ISO

9001:1994 Quality Systems.

This Manual covers all Mira Form Thermostatic mixing valves manufactured from

March 2001.

The Mira Form Shower Valve is a thermostatic shower control with independent selection

for temperature and spray force and is suitable for connection to concealed pipework.

Mira Form Built-in, with 15 mm compression inlet/outlet connections. Supplied hotleft, cold-right but can be reversed.

INTRODUCTION

SAFETY:WARNINGS

If you experience any difficulty with the installation or operation of your new shower

control, then please refer to ‘Fault Diagnosis’, before contacting Kohler Mira Limited.

Our telephone and fax numbers can be found on the back cover of this guide.

Page 4

4

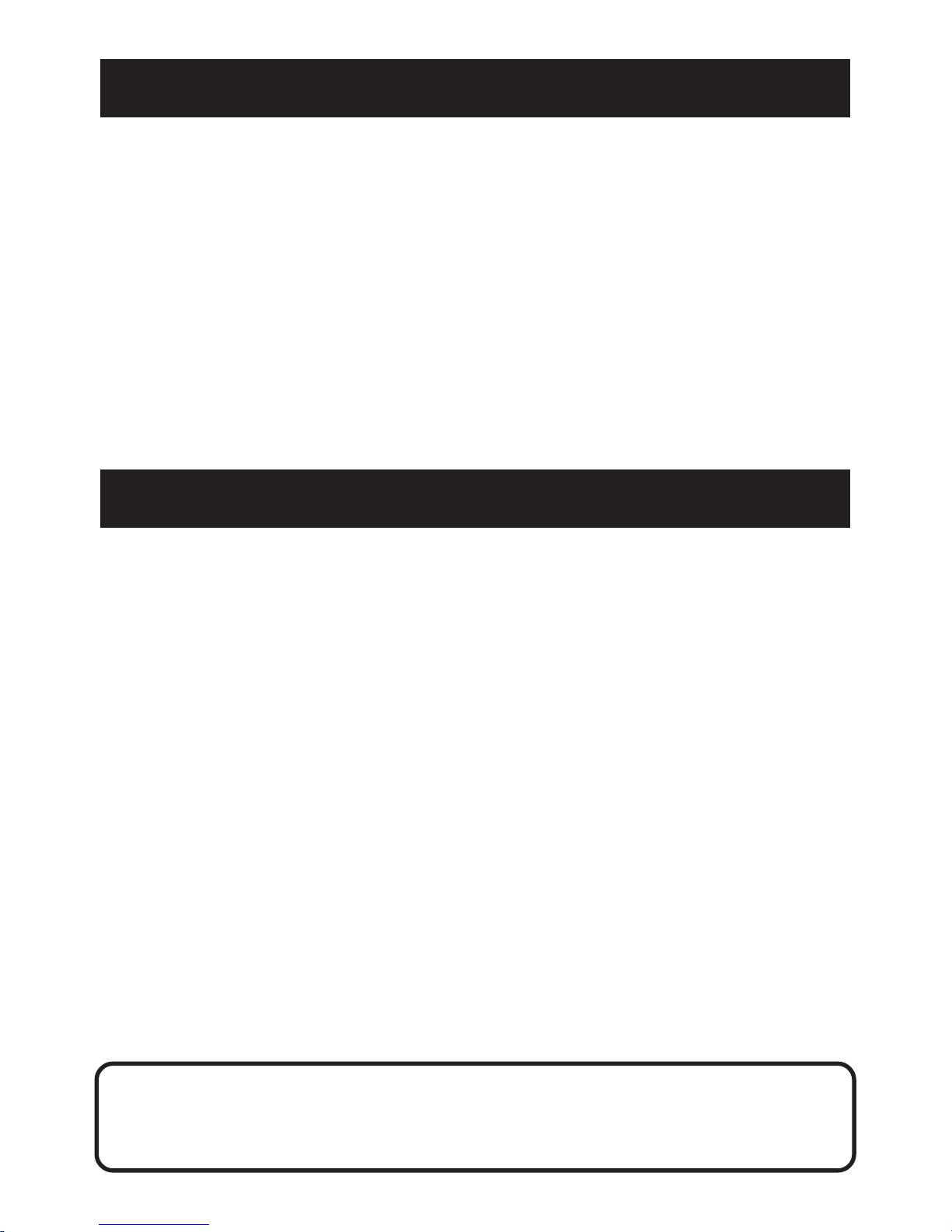

PACK CONTENTS

Tick the appropriate boxes to familiarize yourself with the part names and to

confirm that the parts are included.

Form Mixing Valve

9

1 x Concealing Plate

3 x Compression Nuts

3 x Olives

1 x RAC Elbow

1 x Valve Assembly

(with building-in shroud fitted)

1 x Outer Seal

6 x Wall Plugs

6 x Countersunk

Short Bolts

6 x Countersunk

Fixing Screws

1 x 2.5mm Hexagonal Key

1 x Outlet Support Plate

1 x Wall Clamp Nut (with foam seal)

1 x Right Angled Connector

(RAC)

1 x 3mm Hexagonal Key

1 x Flow Regulator

(with ‘O’ seal)

Page 5

5

Documentation

1 x Installation, Operation and Maintenance Guide

1 x Customer Support Brochure

Form Fittings

2 x Slidebar

Ends

1 x High Capacity

Sprayplate

1 x Clamp Bracket

1 x Outlet Support Plate

(with low capacity sprayplate fitted)

1 x Soapdish

1 x Flexible Hose

1 x Slidebar

2 x Hose Seals

2 x Wall Plugs

2 x End Supports

2 x End Plugs

2 x Fixing Screws

Page 6

6

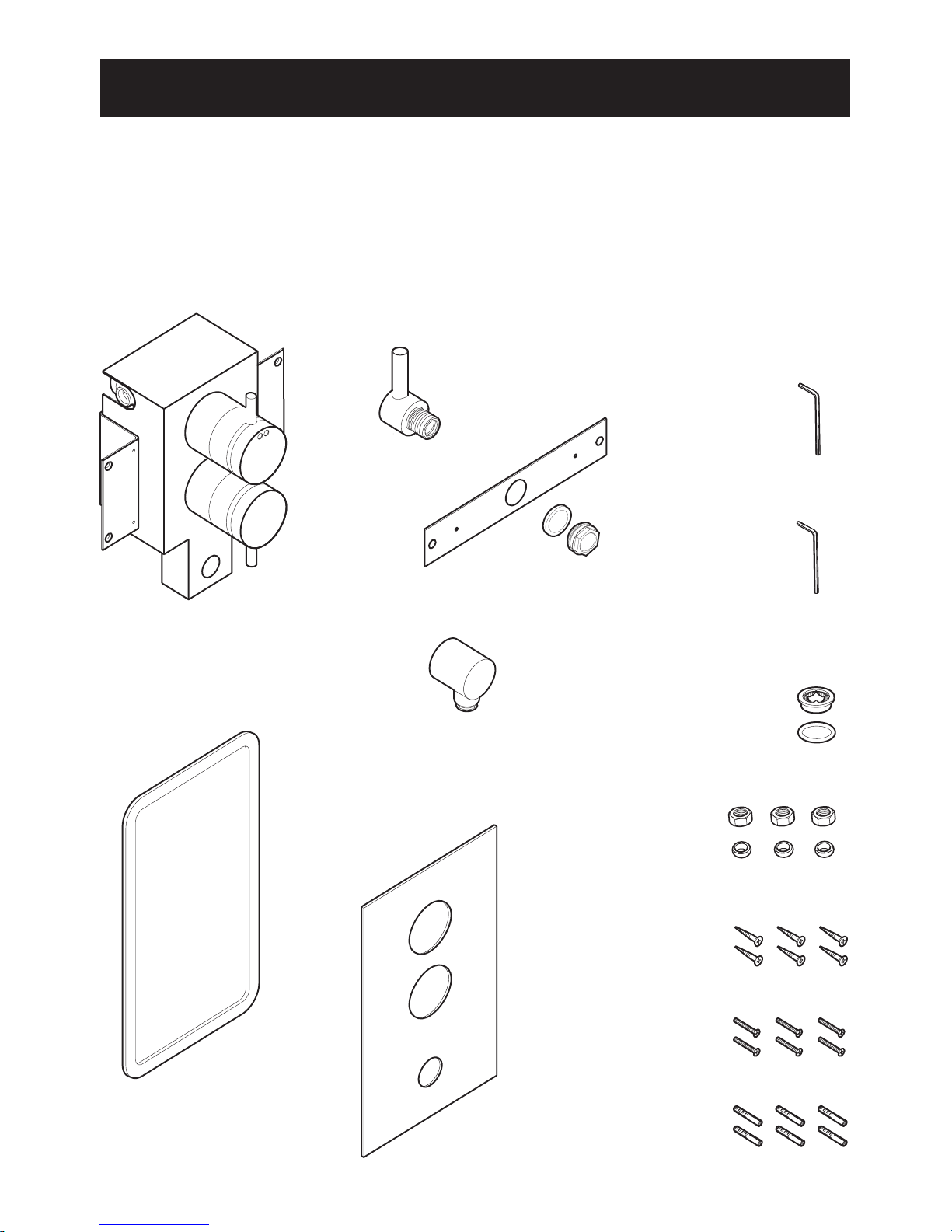

DIMENSIONS

DIMENSIONS

600 mm

283 mm

max.

75 mm

184.5 mm

251 mm

152 mm

310 mm

6-21 mm when

front mounted onto

a solid, stud wall

4-19 mm when

rear mounted onto

a panel wall

100 mm

80 mm

62 mm

Page 7

7

Normal Operating Conditions:

- inlet dynamic pressures nominally balanced to within 10% of each other during

flow.

- a differential of approximately 50 oC between the hot and cold inlet temperatures,

and with differentials of 15-35 oC between the blend setting and either supply.

- daily usage of 1-6 hours.

- installation and usage environment not subject to extremes of temperature,

unauthorised tampering or wilful abuse.

Other Applications

For information on other specific applications or suitability, refer to Kohler Mira Ltd,

for Local Agent.

Disinfection

In applications where system chemical disinfection is practised, chlorine can be used

(calculated chlorine concentration of 50 mg/l (ppm) maximum in water, per one hour

dwell time, at service interval frequency). Such procedures must be conducted strictly

in accordance with the information supplied with the disinfectant and with all relevant

Guidelines/Approved Codes of Practice.

If in any doubt as to the suitability of chemical solutions, refer to Kohler Mira Ltd, or

Local Agent.

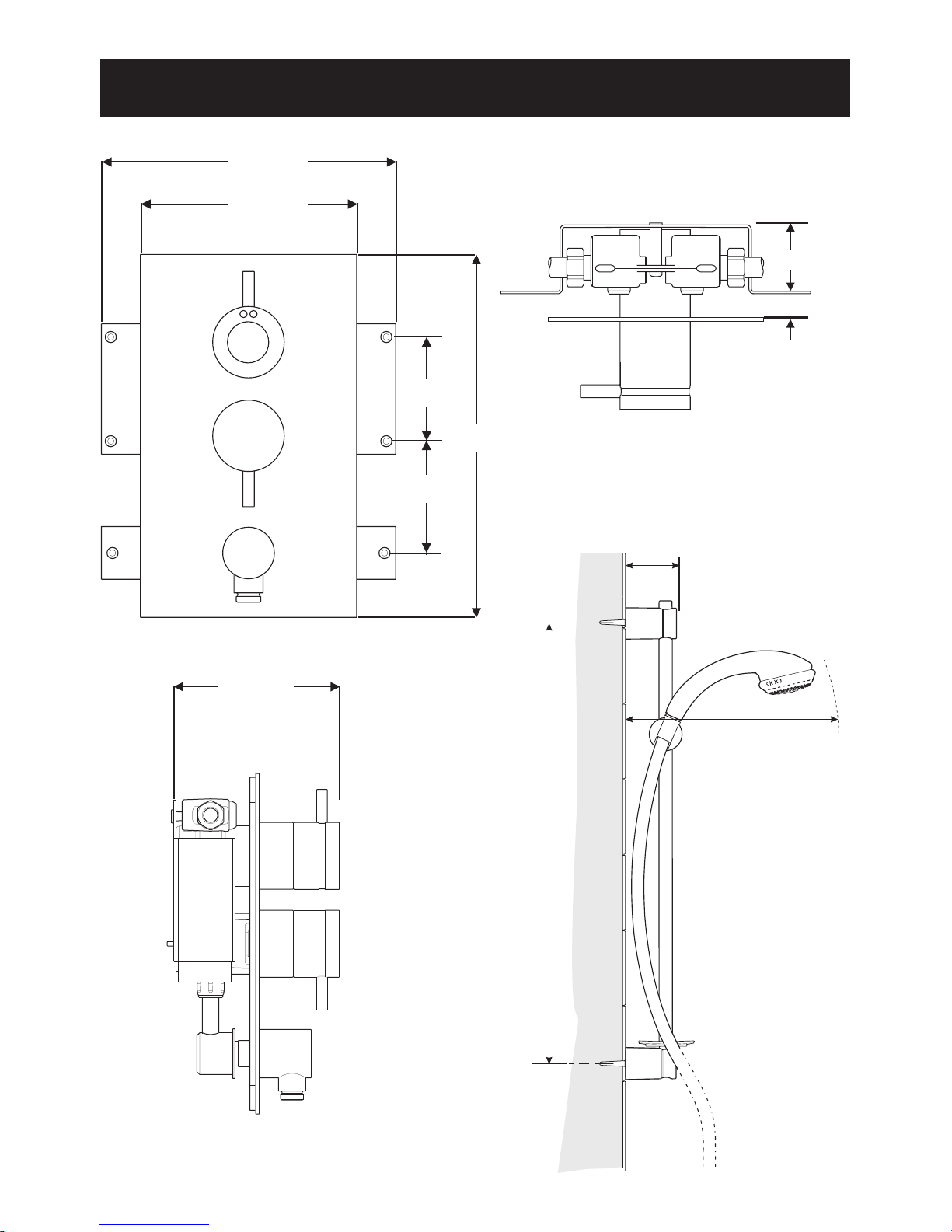

Pressures and Flow Rates

For optimum performance, dynamic supply pressures should be nominally equal.

Recommended Minimum Dynamic Supply Pressure: 0.15 bar (0.2 bar healthcare).

Recommended Minimum Flow Rate: 8 l/min at mid-blend with equal dynamic supply

pressures.

Recommended Maximum Flow Rate: 200 l/min at mid-blend (which equates to

maximum pressure loss of 3.5 bar).

Maximum Pressure Loss Ratio*: should not exceed 10:1, in favour of either supply,

during flow.

Maximum Static Pressure is 10 bar.

Recommended maximum flow velocity in pipelines is 2 metres/second.

* Pressure Loss Ratio is determined by subtracting the resistance of the outlet pipework

and outlet fittings from the dynamic pressures of the hot and cold water at the inlets of

the mixing valve. This is at its extreme when the mixing valve is used at its lowest

flow-rate and when the maximum inequality occurs in the pressure of the hot and cold

water supplies.

SPECIFICATIONS

Page 8

8

The high capacity spray plate should be fitted to the handset when maintained inlet

pressures are above 1 bar .

1.0

2.0

3.0

0

4.0

Flow Rate (litres/minute)

Pressure Loss (bar)

5.0

05 252010 15 30

Economy

Soothe

Start

Force

Mira Form with the high capacity sprayplate fitted to the handset

(Maintained supply pressures are equal and outlet temperature set to mid-blend)

Mira Form Thermostatic Shower with Fittings

Flow Rate / Pressure Loss Graphs

1.0

2.0

3.0

0

4.0

Flow Rate (litres/minute)

Pressure Loss (bar)

5.0

05 252010 15 30

Soothe

Start

Force

Mira Form with the low capacity sprayplate fitted to the handset

(Maintained supply pressures are equal and outlet temperature set to mid-blend)

Economy

Page 9

9

Temperatures

Optimum performance is obtained when temperature differentials of 20°C or more

exist between blend and either supply. Blend control accuracy will begin to diminish

at temperature differentials below 12°C.

Blend Temperature Range: Between ambient cold and approximately 60°C,

according to hot water supply temperature.

Thermostatic Control Range: Approximately 25-60°C.

Optimum Thermostatic Control Range: 30-50°C.

Recommended Minimum Cold Water Supply Temperature: 1°C.

Recommended Maximum Hot Water Supply Temperature: 85°C.

Note! The shower control can accept temporary temperature excursions above 85°C

without damage, however operation at such elevated supply temperatures is not

recommended. For reasons of general safety, hot water storage temperatures should

ideally be maintained at between 60-65°C where serving ablutionary applications.

Minimum temperature differential between hot and outlet temperature: 10°C.

Flow Control

The Mira Form shower control has integral flow control; no other user-operated flow

control should be used with this shower control.

Connections

The shower control inlet connections are 15 mm compression (nuts and olives are

provided).

Hot (H) and Cold (C) inlets are clearly marked for the shower control and must be

connected as described in the INSTALLATION section.

Page 10

10

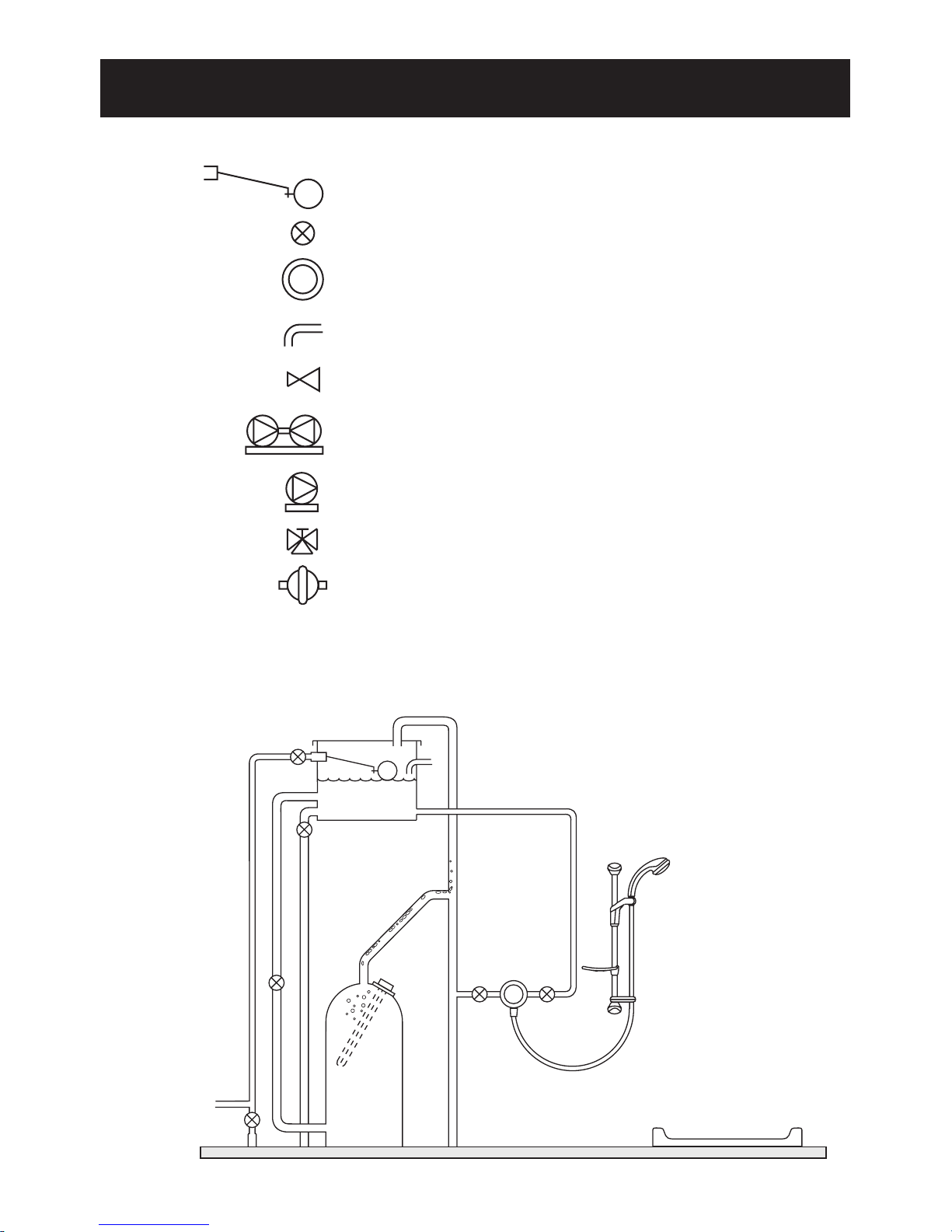

Key to Symbols

INSTALLATION REQUIREMENTS

Gravity Fed Shower - The shower MUST be fed from a cold water cistern and hot

water cylinder providing nominally equal pressure.

Mixing Valve

Twin Impeller Pump

Tempering Valve

Pressure Reducing Valve

Single Impeller Pump

Overflow

Float operated valve

Mini expansion vessel

Isolating Valve

Page 11

11

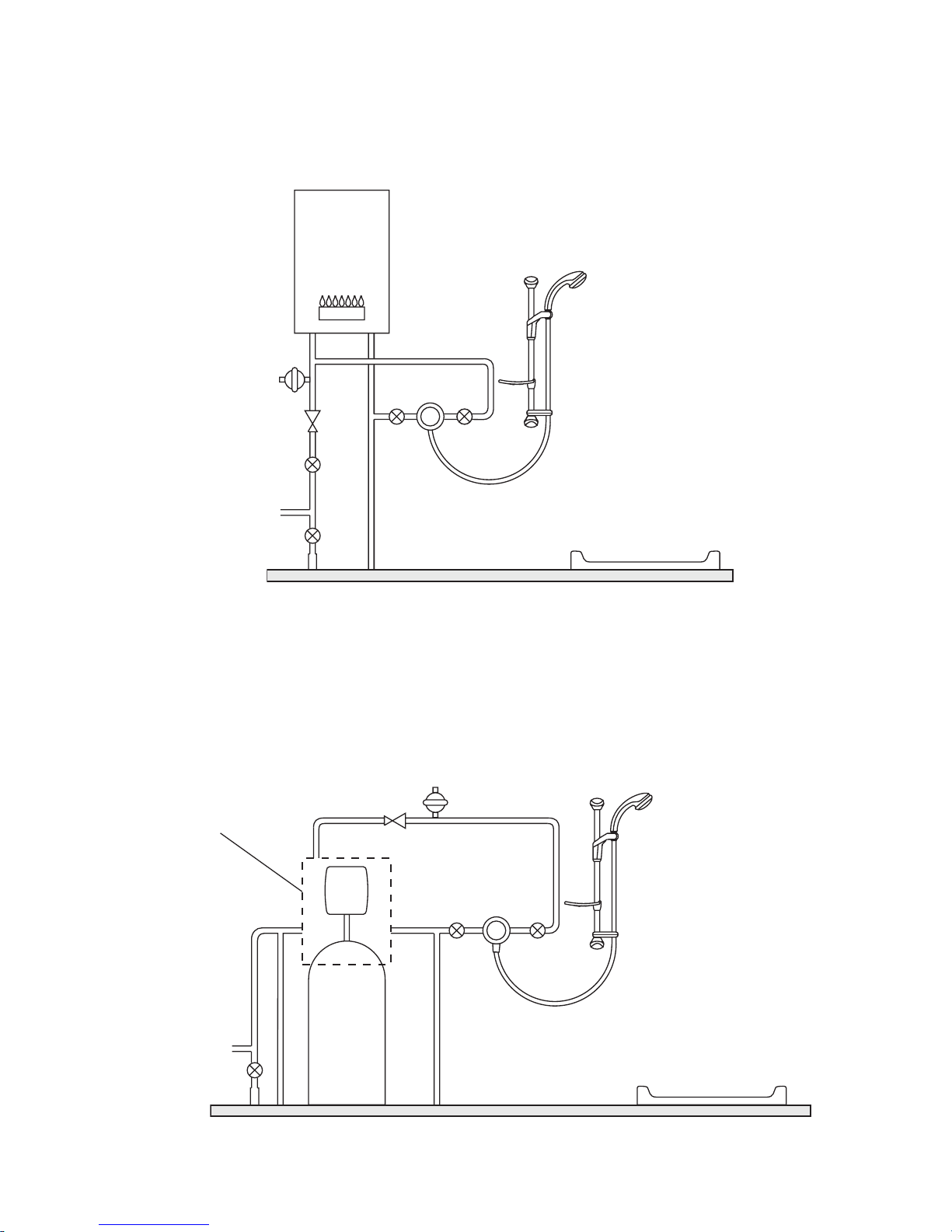

Unvented Mains Pressure Shower - The shower can be installed with a unvented,

stored hot water cylinder. Only “a competent person” as defined by the Building

Regulations may fit this type of system.

Gas Heated Shower - The shower MUST be installed with a gas water heater or

combination boiler of a fully modulating design. A modulating boiler is one that the

draw off rate is indirectly controlling the gas flow to the boiler, producing a relatively

constant hot water temperature.

Cold Hot

Safety devices

not shown

for clarity

Hot

Cold

Page 12

12

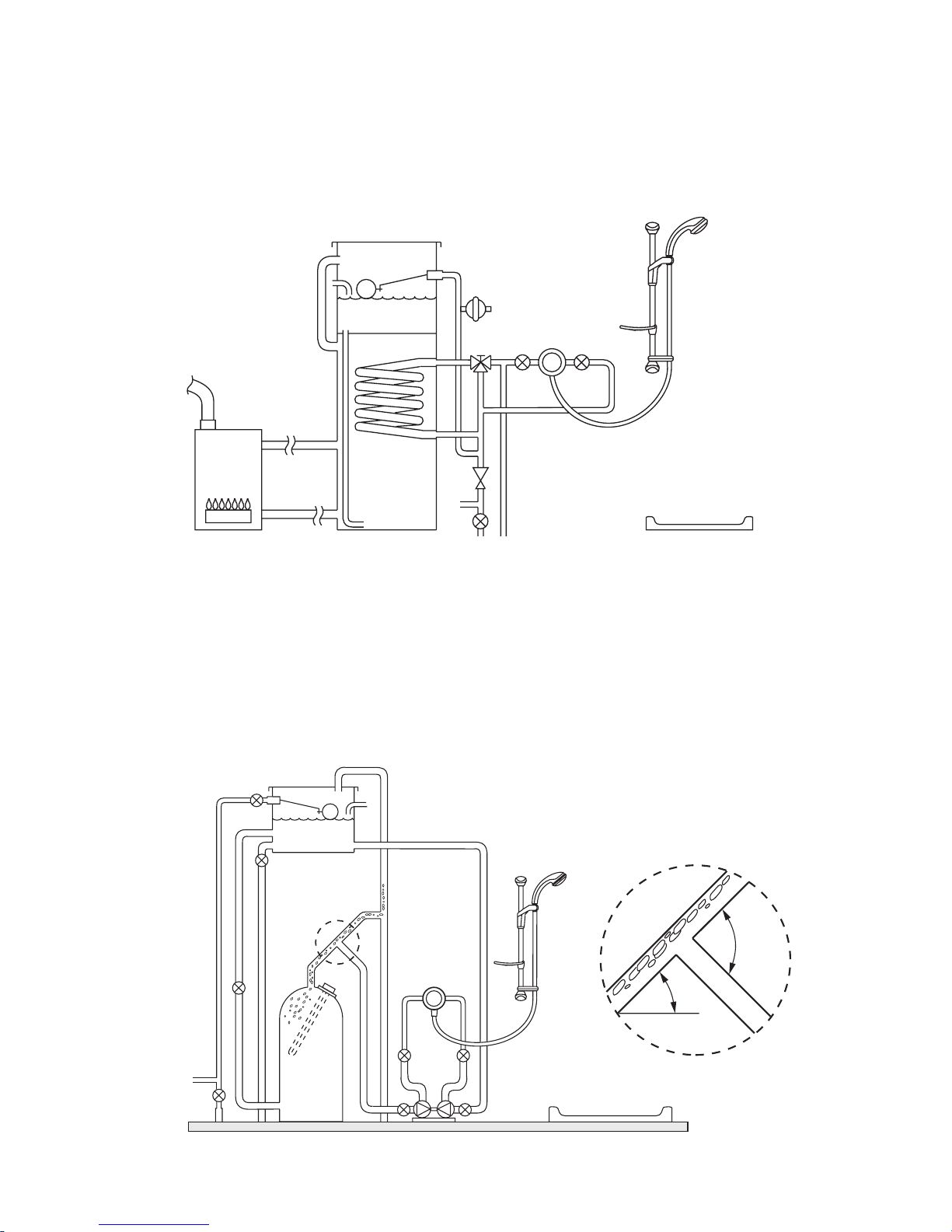

Mains Pressurised Instantaneous Hot Water Shower - The shower installed with

systems of this type is supplied hot water via a tempering valve, this provides relatively

constant hot water and the shower will compensate for temperature changes should

they occur.

Pumped Shower - The shower can be installed with an inlet pump (twin impeller).

The pump must be installed on the floor next to the hot water cylinder. Ensure hot

cylinder vent pipe is arranged as shown to enable air separation.

Cold Hot

Page 13

13

INSTALLATION

General

Installation must be carried out in accordance with these instructions, and must be

conducted by designated, qualified and competent personnel.

1. Before commencing, make sure that the installation conditions comply with the

information given in section: ‘Specifications’.

2. Care must be taken during installation to prevent any risk of injury or damage.

3. The mixing valve should be positioned for easy access during use and

maintenance. All routine maintenance procedures can be conducted with the

mixing valve body in place (except for strainer and checkvalve access). For all

models, allow a minimum 80 mm clearance in front of the temperature control to

enable removal of the serviceable parts during maintenance.

4. The use of supply-line or zone strainers will reduce the need to remove debris at

each mixing valve point. The recommended maximum mesh aperture dimension

for such strainers is 0.5 mm.

5. Pipework must be rigidly supported.

6. Pipework dead-legs should be kept to a minimum. The mixed outlet water piping

should not exceed 2 m and the overall length from the hot water circuit to the

discharge point should not exceed 5 m.

7. Supply pipework layout should be arranged to minimise the effect of other outlet

usage upon the maintained pressures at the mixing valve inlets.

8. Inlet and outlet threaded joint connections should be made with PTFE tape or

liquid sealant. Oil-based, non-setting jointing compounds should not be used.

9. To eliminate pipe debris it is essential that supply pipes are thoroughly flushed

through before connection to the mixing valve.

Page 14

14

Reversed Inlet Supplies

It is essential the inlet supplies correspond with the red and blue markings on the

thermostatic cartridge for the Mira Form to operate correctly. The shower control is

supplied with the inlet connections configured hot-left, cold-right. If the existing hot

and cold pipework makes this configuration inconvenient the cartridge inlets can be

reversed.

The connections can be altered by rotating the thermostatic cartridge through 180°,

before or after installation is complete.

1. If the mixing valve body has already been installed, turn off the supplies to the

mixing valve, and open the flow control. This will release the trapped water pressure

and assist in draining residual water.

2. Remove the knob and cover assemblies. Refer to section: ‘Maintenance,

Removing/Fitting Knob and Concealing Plate Assemblies’.

3. With the removal clip still in place, unscrew the head nut using a 35 mm A/F

wrench; this will begin to draw the thermostatic cartridge out of the body.

Note! Some residual water may be released. Pull the thermostatic cartridge free

of the valve body.

4. Rotate the thermostatic cartridge through 180o and carefully push the cartridge

back into the valve body, checking that the 2 cartridge inlet port seals remain in

place, and locate the cartridge lugs into the body slots.

Note! The red and blue markings on the cartridge will now not correspond with

the body markings, to avoid future confusion remove the red and blue stickers

from the valve body.

5. Carefully align and then tighten the head nut, do not overtighten.

6. Complete the Installation, if appropriate.

7. If the mixing valve body has already been installed, restore hot and cold supplies

and check for any leaks.

8. Refit the knob and cover assemblies; refer to section: ‘Maintenance,

Removing/Fitting Knob and Concealing Plate Assemblies’.

9. The maximum temperature may now need resetting, check the outlet water

temperature, and if necessary refer to section ‘Commissioning’.

Page 15

15

1. Decide on a suitable position for the

shower control and fittings. Ideally the

shower should be fitted at a convenient

height for all the family, facing down

the centre-line of the bath or across

the shower cubicle opening.

2. Determine whether the hot or cold water

supplies will connect to the shower

control from the top (falling) or from

the bottom (rising).

3. Remove the control knobs and the

building-in shroud from the valve. Refer

to MAINTENANCE for detailed

instructions on Removing/Fitting

Knob and Concealing Plate

Assemblies. Familiarise yourself with

the hot and cold inlets for the valve.

4. Fit the compression nut and the olive

onto the RAC elbow and fit to the valve.

Before tightening the compression

fitting ensure the pipe is pushed all

the way into the valve outlet and the

elbow outlet is inline with the

control knobs, otherwise the elbow

will fail to line up with the hole in the

concealing plate.

5. Peel off the backing on the adhesive

side of the foam outer seal and fix the

seal in the machined groove on the

back of the concealing plate.

Hot water

inlet falling

or rising

supply

Cold water

inlet falling

or rising

supply

RAC Elbow

15 mm

Compression

Nut and Olive

Foam Outer

Seal

Concealing

Plate

Elbow Outlet

Installation: Solid and Dry-lined Walls

Shower Control - Installation

The Mira Form can be built into solid, dry-lined, stud partition or dry partition wall

structures. All plumbing connections are 15 mm compression.

A building-in shroud is supplied, which can provide a depth reference when chiselling

out the wall surface and protects the shower control during plastering.

Page 16

16

6. Mark the route of the inlet pipework

and the approximate shape of the

recess.

7. Remove the plaster and

brickwork/dry-lining to the required

depth using the building-in shroud as

a reference. The wall mounting bracket

requires a minimum building-in depth

of 60 mm.

The total building-in depth for the

shower control (to the finished wall

surface) can be between 66 mm and

81 mm. This will accommodate a final

thickness of plaster and tiles of

between 6 mm and 21 mm.

8. Mark the position of the wall mounting

bracket outer fixing holes. Drill a

6.0 mm diameter hole at each of the

marked positions and insert the wall

plugs (supplied).

9. Fit the supply pipes into the cut

channels. Flush the hot and cold

water supply pipes thoroughly. The

supplies must be clean and free

from debris before connecting the

shower control. Failure to do so

may result in product malfunction.

60mm 21 mm

max.

6 mm

min.

Outer Fixing

Holes

155mm

260mm

62mm

75mm

Page 17

17

Protective

Cap

Building-in Shroud

Outlet Support

Bracket

Hot and

Cold Inlets

Outlet

10. Fit the valve and connect the supply

pipework. Check the hot and cold

supplies have been connected to the

correct inlets. If necessary the valve

inlets can be reversed, refer to

Reversed Inlet Supplies for further

information.

Note! If the wall screws cannot be

fixed into the wall, fit the building-in

shroud and fill the cavity behind the

mounting bracket with an appropriate

material (e.g. expandible foam).

11. Fit the outlet support bracket over the

RAC elbow and mark the position of

the two fixing holes. Remove the

bracket and drill the two 6.0 mm

diameter fixing holes. Insert the wall

plugs and fit the outlet support bracket

with the fixing screws supplied.

12. Make sure that the protective cap is

fitted to the outlet on the RAC elbow,

and place the building-in shroud over

the valve.

13. Plaster and tile up to the edge of the

building-in shroud. Make sure that the

finished wall surface falls

somewhere between the two lines

marked on the shroud.

14. When the wall surface has been

completed, remove the building-in

shroud and outlet cap. If necessary,

cut the shroud to help removal.

15. Turn on the hot and cold supplies and

check for leaks.

16. Fit the concealing plate and secure with

the control knob and outlet assemblies.

Refer to section: ‘Maintenance,

Removing/Fitting Knob and

Concealing Plate Assemblies.

Page 18

18

Flow Regulator - Installation

For high pressure installations an optional

flow regulator is supplied. Fitting the

regulator will limit the flow to 10 l/min, and

reduce the spray force to a more

comfortable level. The regulator may also

be fitted if water conservation is a concern.

1. Unscrew the outlet nipple from the RAC

with a 12 mm A/F wrench (not

supplied).

2. Fit the flow regulator as illustrated.

Make sure the ‘O’ seals are fitted and

the regulator is the correct way up.

3. Refit the outlet nipple to the RAC.

‘O’ Seal

Outlet

Nipple

‘O’ Seal

Flow

Regulator

Direction of

Waterflow

RAC

Shower Fittings - Installation

1. Drill the two 7.0 mm fixing holes for

the slidebar at 600 mm centres,

avoiding any buried cables or pipes,

and insert the wall plugs.

2. Assemble the clamp bracket

components. Push the plastic slidebar

ends into the slidebar.

3. Push the slidebar through the clamp

bracket assembly and soapdish.

4. Fit the bottom end support loosely to

the wall. Insert the fixing screw into

the countersunk hole of the slide bar

end and through the slidebar support.

5. Place the screw through the top end

support and fully tighten. Fully tighten

the bottom end support.

6. Fit the end support caps over the ends

of the slidebar end supports.

7. Screw the hose onto the handset and

the outlet of the shower control (Make

sure the hose seals are fitted). Do not

overtighten.

8. Place the handset into the slidebar

clamp bracket.

600mm

End Support

Cap

End Support

Fixing Screw

Slidebar End

Clamp

Bracket

Assembly

Soapdish

Slidebar

Note! The clamp bracket is tapered. The handset will only fit properly from one direction.

If necessary turn the end of the clamp bracket until the handset will fit. If the clamp

bracket pivots downwards under the weight of the handset the central securing screw

in the bracket will require tightening to hold the handset in position.

Page 19

19

Installation: Panel walls

The Mira Form can be installed through a laminated panel or shower cubicle from

either the front or the rear of the panel. If fitted from the front the panel must have a

further finishing layer (e.g. plaster and tiles) applied to cover over the wall mounting

plate and fixing screws.

Rear Mounted (4 mm to 19 mm thickness)

To fit the Form shower control to the rear face of the panel, the panel thickness

(including plaster and tiles) must be between 4 mm and 19 mm.

1. Remove the control knobs and

building-in shroud from the valve. Refer

to section: ‘Maintenance,

Removing/Fitting Knob and

Concealing Plate Assemblies. Put

the building-in shroud in the correct

position on the wall and draw around it

with a pencil. Cut out the hole in the

panel.

2. Peel off the backing on the adhesive

side of the foam outer seal and fix the

seal in the machined groove on the

back of the concealing plate.

3. Fit the compression nut and olive onto

the RAC elbow and fit to the valve.

Before tightening the compression

fitting make sure that the pipe is

pushed all the way into the valve

outlet and the elbow outlet is inline

with the control knobs, otherwise

the elbow will fail to line up with the

hole in the concealing plate. Fit the

outlet support bracket to the elbow and

secure with the wall clamp nut.

4. Using the valve as a template, mark

and drill the 6 fixing holes to secure

the mounting bracket and the outlet

support bracket in position. If no further

finishing surface is to be added to the

panel use the six inner fixing holes to

mount the valve. The concealing plate

will cover the fixing screws when fitted.

RAC Elbow

15 mm

Compression

Nut and Olive

Inner

Fixing

Holes

Elbow Outlet

Page 20

20

5. Mount the mixing valve securely onto the rear of the panel, with the fixing screws

supplied.

Note! If access is available it may be preferable to make the initial valve/pipework

connections prior to securing the mixing valve to the panel.

6. Important! Always flush through the hot and cold supplies thoroughly before

connection to the mixing valve.

7. Connect the inlet pipework, checking that the hot and cold supplies have been

piped to the correct inlets. Check that all connections are watertight.

8. To complete installation follow the instructions in section: ‘Installation: solid

and dry lined walls’. Refer to section: ‘Commissioning’ before operating the

shower control.

Laminated Panel

(4 mm - 19 mm thick)

Concealing Plate

Foam Outer Seal

Concealing Plate

Wall Clamp Nut

Outlet Seal

Locknut

and Trim

Control

Knob

Assembly

Use the six inner fixing holes to

mount the valve if no further finishing

surface is to be added to the panel.

Outlet Support

Bracket

Right Angle

Connector

Page 21

21

Front Mounted (maximum thickness 13 mm)

To fit the Form shower control to the front face of a panel, a further finishing layer

(e.g. plaster and tiles) must be applied to the panel to cover over the wall mounting

plate and fixing screws. This finishing layer can be between 6 mm and 21 mm thick.

The laminated panel can be a maximum of 13 mm thick.

Follow the instructions in section: ‘Installation: solid and dry lined walls’ to install

the shower control and fittings. Refer to section: ‘Commissioning’ before operating

the shower control.

Laminated Panel

(maximum thickness 13 mm)

Concealing Plate

Foam Seal

Concealing Plate

Outlet Support

Bracket

Wall Clamp Nut

Outlet Seal

Right Angle

Connector

Locknut

and Trim

Control Knob

Assembly

If the shower is front panel

mounted a further finishing

surface (6 mm to 21 mm thick)

must be applied to the panel.

Page 22

22

COMMISSIONING

Commissioning must be carried out in accordance with these instructions, and

must be conducted by designated, qualified and competent personnel.

Exercising the Thermostat

Thermostatic mixing valves with wax thermostats are inclined to lose their

responsiveness if not used. Valves which have been in storage, installed but not

commissioned, or simply not used for some time should be exercised before setting

the maximum temperature or carrying out any tests.

A simple way to provide this exercise is:

(a) make sure that the hot and cold water are available at the valve inlets, and the

outlet is open.

(b) move the temperature control rapidly from cold to hot and hot back to cold

several times, pausing at each extreme.

Maximum Temperature

The maximum blend temperature obtainable by the user should be limited, to prevent

accidental selection of a temperature that is too hot.

All Mira Thermostatic mixing valves are fully performance tested and the maximum

temperature is preset to approximately 43oC under ideal installation conditions at the

factory.

Site conditions and personal preference may dictate that the maximum temperature

has to be reset following installation.

This shower control is provided with an adjustable temperature control knob, which

allows the user to select the blend temperature between ambient cold up to a preset

maximum.

Maximum Temperature Setting

Check that an adequate supply of hot water is available at the hot inlet of the shower

control.

During resetting, the hot supply to the shower must be as close to the typical maximum

to offset the possibility of any blend shift due to fluctuating supply temperatures.

However, the minimum temperature of the hot water must be at least 12°C above the

desired blend for correct thermostatic operation.

Temperatures should always be recorded using a thermometer with proven accuracy.

Check that both inlet isolating valves are fully open. Turn the temperature knob to

maximum and operate the flow control. Allow the temperature to stabilize and check

the outlet temperature.

- If the outlet temperature is set correctly then refer to Commissioning Checks.

- If adjustment of the temperature is required, carry out the following procedure:

Page 23

23

4. Refit the temperature spindle at the maximum temperature position and secure

with the locking screw.

5. Refit the locknut and temperature knob assemblies.

6. Rotate the temperature knob through its full range of movement to make sure

that the full range of water temperatures can be selected.

3 mm A/F

Hexagonal

Wrench

Temperature

Spindle

Cartridge

Spindle

Lever Cover

and Screw

Inner Bush

Locknut Trim

Locking

Screw

Maximum Temperature Setting

Temperature

Knob

Locknut

Grub

Screw

1. Remove the temperature knob and locknut assemblies. Refer to section:

‘Maintenance, Removing/Fitting Knob and Concealing Plate Assemblies’.

2. Unlock and remove the temperature spindle. Use the 3 mm hexagonal key supplied

to undo the locking screw.

3. Rotate the cartridge spindle until the required maximum blend temperature is

obtained at the discharge point (clockwise = decrease temperature).

When resistance is felt do not use force to turn any further, as this can damage

the internal parts.

Page 24

24

Commissioning Checks

(Temperatures should always be recorded with a thermometer with proven accuracy).

1. Check inlet pipework temperatures for correct function of checkvalves i.e. that

hot water does not cross flow into the cold supply and vice versa.

2. Check that the supply pressures are within the operating pressures for the valve.

3. Make sure that all connections and mixer body are water tight.

4. Exercise the thermostat.

(a) make sure that the hot and cold water are available at the valve inlets, and the

outlet is open.

(b) move the temperature control rapidly from cold to hot and hot back to cold

several times, pausing at each extreme.

5. Adjust the temperature of the mixed water in accordance with the instructions

(refer to Maximum Temperature Settings).

6. Operate the outlet flow control and check:

(a) Flow rate is sufficient for the purpose.

(b) Temperature(s) obtainable are acceptable.

Page 25

25

OPERATION

Turn the temperature lever anticlockwise

for warmer water or clockwise for cooler

water. The preset maximum temperature

can be adjusted as required to suit both

site conditions and the user's comfort. Refer

to section: ‘Commissioning’ for further

information on Maximum Temperature

Setting.

Turn the flow lever anticlockwise until the

desired force of water is obtained.

Note! When the Form shower control is

installed with a fully modulating multipoint

or combination type gas water heater, the

maintained mains water pressure, and

hence the flow, must be sufficient to keep

the heater ignited. Therefore, it is important

to ensure that the flow knob is fully open to

prevent variation in the hot water supply

temperature.

Mira Form Shower Control

The Mira Form shower control has separate controls for temperature and flow.

Page 26

26

Start

Soothe

Force

Economy Setting

Mira Form Fittings

Handset Spray Adjustment

The Mira Form adjustable handset has three different spray actions (start, soothe and

force) and an economy setting.

1. Start Spray

Turn the adjuster ring until the three

dots align with top centre of the

handset. Water will flow from the outer

set of holes.

2. Soothe Spray

Turn the adjuster ring until the two dots

align with top centre of the handset.

Water will flow from the middle set of

holes.

3. Force Spray

Turn the adjuster ring fully

anticlockwise. The single dot will align

with top centre of the handset. Water

will flow from the inner set of holes.

4. Economy Spray Setting

Turn the adjuster ring fully clockwise.

The oval symbol will align with top

centre of the handset. Water will flow

from the outer set of holes and the flow

rate will be reduced.

Page 27

27

FAULT DIAGNOSIS

Symptom

Cause/Rectification

Normal function of thermostatic control when operating

conditions are unsatisfactory;

a. Check strainers and inlet/outlet fittings for flow restriction.

b.Make sure that minimum flow rate is sufficient for supply

conditions.

c. Make sure that dynamic inlet pressures are nominally balanced

and sufficient.

d.Make sure that inlet temperature differentials are sufficient.

e. (Subsequent to rectification of supply conditions) Check

thermostatic performance; renew thermostatic cartridge, if

necessary.

2. Fluctuating

or reduced

flow rate.

3. No flow from

shower

control

outlet.

4. Blend

temperature

drift.

Indicates operating conditions changed.

a. Refer to symptom 2. above.

b. Hot supply temperature fluctuation.

c. Supply pressure fluctuation.

a. Check strainers and inlet/outlet fittings for blockage.

b. Hot or cold supply failure; thermostat holding correct shutdown

function: rectify, and refer to symptom 2.e. above.

c. Flow control cartridge faulty. Check and renew if necessary.

a. Inlet supplies are reversed (refer to section: ‘Installation,

Reversed Inlet Supplies’. Check.

b. No hot water reaching shower control. Check.

c. Check strainers and inlet/outlet fittings for blockage.

d. Refer to symptom 5 below.

e. Installation conditions continuously outside operating

parameters: refer to section: ‘Specifications’, and 2e below.

1. Only hot or

cold water

from outlet.

5. Hot water in

cold supply

or vice

versa.

Indicates checkvalves require maintenance, refer to section:

‘Maintenance’.

6. Maximum

blend

temperature

setting too

hot or too

cool.

a. Indicates incorrect maximum temperature setting; refer to

section: ‘Commissioning’.

b. As symptom 4. above.

c. As symptom 5. above.

Page 28

28

Symptom

Cause/Rectification

7. Water leaking

from shower

control body.

Seal(s) worn or damaged.

a. Obtain service pack and renew all seals.

b. (If leak persists from around temperature spindle) Renew

thermostatic cartridge.

8. Flow knob or

temperature

knob stiff to

operate.

a. Impaired free movement of internal components. Renew the

appropriate cartridge.

b. Supply pressures too high. Fit pressure reducing valve. Refer

to section: ‘Specifications’ for acceptable operating

pressures.

9. Drip from

spray plate

assembly in

the handset.

10. Shower

temperature

changes

when spray

action is

adjusted.

a. A small amount of water may be retained in the shower fitting

after the shower control has been turned off. This may drain

over a few minutes. Change the angle of the handset to vary

the draining time.

b.Flow control cartridge faulty. Check and renew if necessary.

a. Spray plate assembly blocked. To clear the blockage, refer

to section: ‘Maintenance, Spray Plate Cleaning’.

b.Adjusting the spray action significantly changes the flow of

water. Install the high capacity spray plate assembly, refer to

section: ‘Maintenance, Spray Plate - Removal and

Installation’.

Page 29

29

MAINTENANCE

General

1. The maintenance of this product must be carried out in accordance with instructions

given in this Manual, and must be conducted by designated, qualified and

competent personnel.

2. Mira products are precision-engineered and should give continued superior and

safe performance, provided:

- They are installed, commissioned, operated and maintained in accordance

with the recommendations stated in this Product Manual.

- Periodic attention is given as necessary to maintain the product and its associated

installation components in good functional order. Guidelines are given below.

3. The use of main supply-line or zone strainers (recommended maximum mesh

aperture dimension is 0.5 mm) will reduce the need to remove debris at each

mixing valve point.

The designed minimum service life of all cartridges used in Mira products is 5 years

providing the Mira Form is operated with the recommended operating conditions and

within the recommended operating parameters. However, when supply conditions

and/or usage patterns do not conform to the recommended operating parameters

and/or the recommended operating conditions, the cartridge and other critical parts

may need to be replaced more frequently (‘recommended operating conditions’ and

‘recommended parameters’ are defined in section: ‘Specifications’ under the headings

of ‘Normal Operating Conditions’ and ‘Operating Parameters’).

Page 30

30

Maintenance Procedures

Maintenance must be carried out in accordance with these instructions, and must be

conducted by designated, qualified and competent personnel.

This mixing valve is designed for minimal maintenance under conditions of normal

use.

External surfaces may be wiped clean with a soft cloth, and if necessary, a mild

washing-up type detergent or soap solution can be used.

Warning! Many household and industrial cleaning products contain mild abrasives

and chemical concentrates, and should not be used on polished, chromed or plastic

surfaces.

Should an internal malfunction occur then this will probably require replacement of

parts.

Components are precision-made, so care must be taken while servicing to avoid

damage.

When ordering spare parts, please state product type, i.e. Mira Form, and identify

part name and number (refer to section: ‘Spare Parts’). A Seal pack is available,

containing all the seals that may be necessary for renewal during maintenance or

servicing.

Lubricant

Important! All seals are pre-lubricated. If you need to lubricate the seals, use only a

small amount of silicone-only based lubricants on this product. Do not use oil-based

or other lubricant types as these may cause rapid deterioration of seals.

Page 31

31

Removing/Fitting Knob and Concealing Plate Assemblies

Temperature

Knob

Locknut

Trim

Inner

Bush

Locknut

Lever

Cover

Lever

Screw

Grub

Screw

Flow Knob

Removing the Knob Assembly

1. Rotate the flow knob fully clockwise

and the temperature knob fully

anticlockwise.

2. Unscrew the lever cover anticlockwise.

3. Unscrew the lever screw,

anticlockwise, and remove the

temperature/flow knob.

4. Unscrew the grub screw using the

2.5 mm hexagonal key and remove the

inner bush.

5. Lift off the locknut trim and unscrew

the locknut in an anticlockwise

direction.

Foam Outlet

Seal

Wall Clamp

Nut

RAC

Concealing

Plate

Grub Screw

1. Remove both flow and temperature

knob assemblies. Refer to Removing

the Knob Assembly for instructions.

2. Unscrew the grub screw, securing the

RAC, using the 2.5 mm hexagonal key

provided. Remove the RAC.

3. Unscrew and remove the wall clamp

nut, then remove the outer seal and

concealing plate.

Removing the Concealing Plate Assembly

Page 32

32

Fitting the Knob Assembly

1. Screw the locknut onto the headnut

until it firmly locks the concealing plate

in place. Make sure that the ‘O’ seal

is fitted to the locknut for a watertight

seal between the locknut and

concealing plate.

Note! Do not overtighten the locknuts

or the concealing plate will deform.

2. Refit the locknut trim. Make sure that

the trim is fitted the correct way round

(see illustration).

3. Fit the control knob inner bush so the

securing grub screw aligns with the

spindle flat. Tighten the grub screw

with the 2.5 mm hexagonal key

provided. Make sure that the inner bush

‘O’ seal is fitted for a watertight seal

between the inner bush and the

locknut.

4. Rotate the inner bush fully clockwise

for the flow control or fully

anticlockwise for the temperature

control. Refit the control knobs (see

illustration) and secure with the lever

screw and the lever cover.

Note! The lever screw needs to be

secured with a spanner. Do not

overtighten the lever screw as product

damage may occur.

Note! If the control knobs are

incorrectly fitted the levers may foul

against each other when in use.

5. Check the control knobs can be rotated

fully and the full flow and temperature

range can be selected.

Headnut

Fit the locknut

trim with the flat

facing outwards

from the valve

Inner

Bush

Locknut

Trim

‘O’ Seal

‘O’ Seal

Locknut

Grub Screw

Temperature

Knob

Lever Cover

and Screw

Spindle

Concealing

Plate

Refit the temperature

knob in the maximum

temperature position

Refit the flow knob in

the off position

Refitting Control Knobs

Page 33

33

Fitting the Concealing Plate Assembly

1. Fit the concealing plate to the valve

and secure with the temperature and

control knobs. Refer to section:

‘Maintenance, Fitting the Knob

Assembly’ for detailed instructions.

Note! If the wall surface or tiling is

uneven, the foam outer seal on the

concealing plate may need

supplementing with silicone sealant to

ensure a watertight seal.

2. Fit the wall clamp nut. Make sure that

the foam outlet seal is fitted between

the wall clamp nut to create a watertight

seal between the nut and the

concealing plate.

3. Fit the RAC to the wall clamp nut and

secure with the grubscrew. Make sure

that the ‘O’ seal is fitted to the wall

clamp nut.

4. Check that the control knobs rotate

fully and that the temperature and flow

controls operate correctly.

Wall Clamp

Nut

RAC

‘O’ Seal

Concealing

Plate

Foam

Outlet

Seal

Grub Screw

Page 34

34

Maintenance Procedure - Thermostatic Cartridge

Removal

1. Turn off the supplies to the shower control. Open the flow control to release the

trapped water pressure and assist the draining of residual water.

2. Remove the temperature and flow knob assemblies, using the 2.5 mm A/F

hexagonal wrench (supplied). Remove the concealing plate, seals and support

bracket. Do not remove the temperature spindle.

3. With the removal clip still in place, unscrew the head nut using a 35 mm A/F

wrench. This will release the body shroud and also begin to draw the thermostatic

cartridge out of the shower control body.

Caution! Some residual water may be released.

4. Note which inlet aligns with the hot (marked H and coloured red) lug on cartridge.

5. Pull the thermostatic cartridge free of the shower control body.

Cleaning/Renewal of Parts

6. The interior surface of the shower control body must be clean before refitting the

cartridge. If scale or deposition is present, clean (without thermostatic, flow

and checkvalve cartridges fitted) using a mild proprietary inhibited scale solvent,

e.g. domestic kettle descalent. After descaling, rinse the body thoroughly in

clean water before refitting cartridges.

Note! The body interior must be cleaned carefully and not damaged in any way.

Do not use any abrasive material.

7. Cartridges may only be cleaned by flushing through under a jet of clean water to

remove lodged particles. Do not descale. Cartridges are not serviceable, and

must not be dismantled.

Cartridges cannot be tested individually, service condition should be assessed

as part of the performance check; refer to Commissioning Checks.

8. When renewing the thermostatic cartridge, retain the temperature spindle, removal

clip and head nut off the displaced unit and refit.

9. Examine all accessible seals for signs of deformation or damage, and renew as

necessary, taking care not to damage seal grooves (a Service Pack is available,

containing all seals and strainer screens that may be necessary for renewal

during maintenance or servicing).

10. Lightly coat all rubber seals with a silicone-only based lubricant to assist

reassembling (see lubricants).

Page 35

35

Maintenance Procedure- Flow Cartridge

Removal

1. Turn off the water supplies to the shower control. Open the flow control to release

the trapped water pressure and assist the draining of residual water.

2. Remove the lever knob and concealing plate assemblies; Refer to section:

‘Maintenance, Removing/Fitting Knob and Concealing Plate Assemblies’.

3. Remove the flow spindle, the headnut and the splined adaptor.

4. Unscrew the flow cartridge anticlockwise and remove.

Warning! Some residual water may be released.

Reassembly

11. Identify which is the hot inlet to the shower control body, and align the thermostatic

cartridge accordingly. Carefully push the thermostatic cartridge back into the

body, checking that the 2 cartridge inlet port seals remain in place, and locate

the cartridge lugs into body slots.

12. Carefully align and then tighten the head nut; do not overtighten (max. Torque

2.5 Nm (1.85 lbf ft)). Fit the removal clip to the head nut.

13. Turn the flow control to the off position and restore hot and cold supplies. Check

for any leaks.

14. Refit the plate and lever assemblies; refer to section: ‘Maintenance,

Removing/Fitting Knob and Concealing Plate Assemblies’.

15. The maximum temperature will now need resetting; refer to section:

‘Commissioning’.

Thermostatic Cartridge Removal

M4 Locking

Screw

Temperature

Knob

Assembly

Removal Clip

Temperature

Spindle

Head Nut

Inlet Port Seals

Thermostatic

Cartridge

Assembly

Grub Screw

Locknut Trim

Lever Cap

Locknut

Lever Screw

Temperature Knob

Inner Bush

Page 36

36

Flow Cartridge Removal

Flow Spindle

Splined Adaptor

Flow Cartridge

Headnut

Cleaning/Renewal of Parts

5. The inner surface of the shower control body must be clean before refitting the

cartridge. If scale or deposition is present, clean (without thermostatic, flow

and checkvalve cartridges fitted) using a mild proprietary inhibited scale solvent,

e.g. domestic kettle descalent. After descaling, rinse the body thoroughly in

clean water before refitting the cartridge.

Note! The shower control body must be cleaned carefully and not damaged in

any way. Do not use any abrasive material.

6. Clean the cartridge by flushing through under a jet of clean water to remove

lodged particles. Do not descale. Cartridges are not serviceable, and must

not be dismantled.

Cartridges cannot be tested individually, service condition should be assessed

as part of the performance check, refer to section: ‘Commissioning,

Commissioning Checks’.

7. Examine accessible 'O' seals for signs of deformation or damage, and if necessary

renew the cartridge.

8. Lightly coat all seals with a silicone-only based lubricant to assist reassembling.

Reassembly

9. Check that the flow cartridge seals are in place. Align and screw the cartridge

into place.

10. Fit the splined adaptor, the headnut and the flow spindle.

11. Turn the flow control to the off position (Rotate the flow control fully clockwise).

Restore hot and cold supplies and check for leaks.

12. Refit the lever knob and concealing plate assemblies; Refer to section:

‘Maintenance, Removing/Fitting Knob and Concealing Plate Assemblies’.

Page 37

37

Checkvalve Cartridges - Cleaning/Renewal of Parts

Hot water entering the cold supply, or vice versa, indicates the checkvalve cartridge

needs immediate attention.

1. Turn off the supplies to the shower control. Open the flow control to release the

trapped water pressure and assist draining the residual water.

2. Remove the control knob and concealing plate assemblies, Refer to section:

‘Maintenance, Removing/Fitting Knob and Concealing Plate Assemblies’.

3. Undo the cartridge head using a 12 mm A/F wrench and pull the whole cartridge

free from the valve body.

Caution! Some water may be released at

this point.

4. The checkvalve cartridge assemblies may

be cleaned by removing the rubber retainers

and inlet strainers, and flushing through under

a jet of water to remove lodged particles.

Do not descale. Check if the checkvalve

cartridge operates correctly. If the cartridge

is damaged or fails to operate correctly

renew.

5. Lightly wipe external seals and threads with

a silicone-only based lubricant to aid

refitting.

6. Refit cartridges, strainers and retainers. Do not overtighten the cartridge heads

when refitting.

7. Turn the flow control fully clockwise to the off position. Restore the water supplies,

and check for leaks.

8. Follow the steps outlined in section: ‘Maintenance, Removing/Fitting Knob

and Concealing Plate Assemblies’ to reassemble the shower control.

Checkvalve

Cartridges

Cartridge Location

Cartridge

Head

Rubber

Retainer

Strainer

Checkvalve

Cartridge

Checkvalve Cartridges

Page 38

38

Inlet Strainers - Cleaning/Renewal of Parts

Blockage of the inlet strainer screens can lead to poor flow performance and reduced

temperature control. It is essential that the inlet strainer screens are periodically

cleaned or, if necessary, renewed as part of a preventative maintenance programme.

A Strainer pack is available for the Mira Form, containing 2 strainer screens and 2

retainers.

1. Turn off the supplies to the shower control. Open the flow control to release the

trapped water pressure and assist draining the residual water.

2. The strainers are located at the inlet of each checkvalve cartridge. Remove the

cartridges to allow access.

3. Carefully remove the strainers.

4. Clean under a jet of water, or renew if damaged.

5. Refit cartridges, strainers and retainers. Do not overtighten the cartridge heads

when refitting.

6. Turn the flow control fully clockwise to the off position. Restore the water supplies,

and check for leaks.

7. Follow the steps outlined in section: ‘Maintenance, Removing/Fitting Knob

and Concealing Plate Assemblies’ to reassemble the shower control.

Cartridge

Head

Rubber

Retainer

Strainer

Checkvalve

Cartridge

Inlet Strainers

Page 39

39

Removal

1. Turn the adjuster ring fully

anticlockwise.

2. Unclip and remove the adjuster ring.

3. Unscrew the spray plate in an

anti-clockwise direction. The 'O' seals

will provide some resistance.

Installation

4. Make sure that the four 'O' seals are

located correctly.

5. Turn the flow divertor fully clockwise.

Caution! Do not over tighten the spray

plate.

6. Carefully screw the spray plate

assembly on to the flow divertor. The

'O' seals will resist the rotation of the

spray plate. There should be a gap

between the edge of the spray plate

assembly and the flow divertor.

7. Make sure that the green bar on the

adjuster ring is uppermost and align

the inner teeth on the adjuster ring with

the teeth on the handset flow divertor.

Clip the adjuster ring into position.

Handset Body

Assembly

Spray Plate

Assembly

'O' Seal

'O' Seal

Adjuster Ring

Spray Plate

Assembly

Flow Divertor

'O' Seal

'O' Seal

Spray Plate

Assembly

Inner Teeth

Teeth

Shower Fittings

Spray Plate Assembly - Removal and Installation

Adjuster Ring

Page 40

40

Sprayplate Cleaning

Sprayplate External Assembly

1. Use your thumb or a soft cloth to wipe any

limescale from the soft triangular nozzles

and the front face of the spray plate

assembly.

Sprayplate Internal Assembly

2. Remove the spray plate assembly. Refer to

section: ‘Maintenance, Spray plate

assembly - removal and installation’.

3. Remove the 'O' seals.

4. Clean all the components with a stiff brush.

If necessary use a plastic kettle descalent

in accordance with the manufacturer's

instructions.

5. Refit the components in reverse order.

6. Install the spray plate assembly. Refer to

section: ‘Maintenance, Spray plate

assembly - removal and installation’.

'O' Seals

Spray Plate

Page 41

41

SPARE PARTS

Shower Fittings Spare Parts List

126.65 Slidebar Ends

411.37 Service Pack 'O' Seals - components identified 'A'

413.22 Adjuster Ring - satin chrome

413.58 Handset Body Assembly - chrome

413.60 Spray Plate Assembly - High capacity - dark grey

413.61 Spray Plate Assembly - Low capacity - dark grey

449.01 Clamp Bracket Assembly

449.02 Slidebar

449.03 Slidebar Wall Fixing Assembly

449.04 Soapdish

449.05 Hose

632.73 Hose Seal (x2)

449.03

632.73

126.65

449.02

449.04

449.05

449.01

413.22

413.60

413.61

A

413.58

Page 42

42

Shower Control Spare Parts List

147.67 Outlet Checkvalve Assembly

407.26 Cartridge Removal Clip

427.32 Inlet Checkvalve Assembly

427.33 Filter

427.48 Seal Pack - components identified 'A'

427.50 Compression Nut and Olive Pack

441.54 Spindle Extension

441.55 Headnut

441.56 Flow Cartridge Assembly

441.57 Valve Mounting Bracket

441.58 Screw Pack (not illustrated)

441.59 Wall Mounting Bracket

441.75 Valve Body

441.90 Concealing Plate Seal Pack - components identified 'B'

441.91 Concealing Plate

441.92 Locknut Assembly

441.93 Temperature Lever Assembly

441.94 Flow Lever Assembly

441.95 RAC Shroud

441.96 RAC Elbow Assembly - components identified 'C'

441.97 RAC Wall Clamp

441.98 10 L/Min Flow Regulator

1598 030 Thermostatic Cartridge

Page 43

43

441.57

C

441.75

441.93

441.94

441.91

441.92

B

441.95

147.67

441.98

441.59

427.32

427.33

427.50

A

407.26

441.54

1598 030

A

441.55

441.56

C

C

C

C

B

B

441.97

B

Page 44

7

-

#

5

P3704/3 © Kohler Mira Limited, October 2005

CUSTOMER SERVICE

Loading...

Loading...