Page 1

PRESSURE BALANCED

Installation and User Guide

SHOWER CONTROL

These instructions are to be left with the user

Page 2

2

CONTENTS

INTRODUCTION .......................................................................................3

Mira 415 Pressure Balanced Shower Control Range...........................3

Product range .......................................................................................3

WARNING! ........................................................................................... 3

Safety ...................................................................................................3

IMPORTANT SAFETY INFORMATION .................................................... 4

Mira 415 Surface Mounted Shower Control .........................................5

Mira 415B Built-in Shower Control .......................................................6

DIMENSIONS ............................................................................................7

SPECIFICATIONS..................................................................................... 8

415 and 415B ....................................................................................... 8

INSTALLATION REQUIREMENTS ...........................................................9

INSTALLATION .......................................................................................13

Mira 415 Surface Mounted Shower Control .......................................13

Back Inlet Supplies ............................................................................. 17

415B Built-in Shower Control .............................................................20

Solid, Dry-lined, Stud Partition or Dry Partition Wall Structures ......... 22

Shower Cubicle or Laminated Panel .................................................. 28

Reversed Outlet Connection ..............................................................31

Reversed Inlet Supplies ....................................................................32

COMMISSIONING ..................................................................................33

Multi-point Gas Water Heaters ........................................................... 33

Combination Boilers ...........................................................................33

Adjustable Maximum Temperature Stop ............................................34

Temperature Override Button Disable ................................................ 36

OPERATION ...........................................................................................37

How the pressure balancing principle operates .................................38

FAULT DIAGNOSIS ................................................................................39

MAINTENANCE ......................................................................................42

‘O’ Seal Renewal ................................................................................ 44

SPARE PARTS ....................................................................................... 46

ACCESSORIES ...................................................................................... 49

NOTES ....................................................................................................50

CUSTOMER SERVICE ...........................................................................52

Page 3

3

Mira 415 Pressure Balanced Shower Control Range

Description

A range of Mira 1/2" pressure balanced shower controls which automatically adjusts

for variations in inlet pressures to maintain a constant outlet temperature provided

the inlet water temperatures remain stable.

The Mira 415 is not a thermostatic shower control and does not sense supply

temperature variations. Therefore, inlet water temperatures especially the hot, should

be relatively constant.

The Mira 415 is suitable for installation with the following packages:-

– Fully modulating multi-point gas water heaters.

– Fully modulating combination boilers.

– Unvented mains pressure systems.

–

Mains pressurised, instantaneous hot water heated from thermal store,

systems.

– Pumped systems.

Showering temperature is adjusted by the shower control. The ow rate is determined

by the supply pressures available at the inlets, and the output rating of the heater

appliance.

Product range

Mira 415: Surface mounted pressure balanced shower control for connection to

exposed pipework, for high pressure applications (1.0 – 5.0 bar).

White/chrome or white/light golden colour models are available.

Mira 415B: Built-in shower control for connection to concealed pipework, for

high pressure applications (1.0 – 5.0 bar). White/chrome or white/

light golden colour models are available.

WARNING!

Products manufactured by us are safe and without risk provided they are installed,

used and maintained in good working order in accordance with our instructions and

recommendations.

Safety

Anyone who may have difculty understanding or operating the controls of any

shower should be attended whilst showering. Particular consideration should be

given to the young, the elderly, the inrm or anyone inexperienced in the correct

operation of the controls.

INTRODUCTION

Page 4

4

IMPORTANT SAFETY INFORMATION

WARNING!

1.1. Products manufactured by us are safe and without risk provided they are

installed, used and maintained in good working order in accordance with our

instructions and recommendations.

Caution!

2.1. Read all of these instructions.

2.2. Retain this guide for later use.

2.3. Pass on this guide in the event of change of ownership of the installation

site.

2.4. Follow all warnings, cautions and instructions contained in this guide.

2.5. The plumbing installation must comply with Water Supply Bye-laws, BS 6700,

Building Regulations or any particular regulations and practices, specied

by the local water company or water undertakers. The installation should be

carried out by a plumber or contractor who is registered, or is a member of, an

association such as:

2.5.1. Institute of Plumbing (IOP), throughout the UK, Tel: 01708 472791.

2.5.2. National Association of Plumbing, Heating and Mechanical Services

Contractors (NAPH & MSC), England and Wales, Tel: 01203 470626.

2.5.3. Scottish and Northern Ireland Plumbing Employers’ Federation

(SNIPEF), Scotland and Northern Ireland, Tel: 0131 225 2255.

2.6. Anyone who may have difculty understanding or operating the controls of any

shower should be attended whilst showering. Particular consideration should

be given to the young, the elderly, the inrm, or anyone inexperienced in the

correct operation of the controls.

Page 5

5

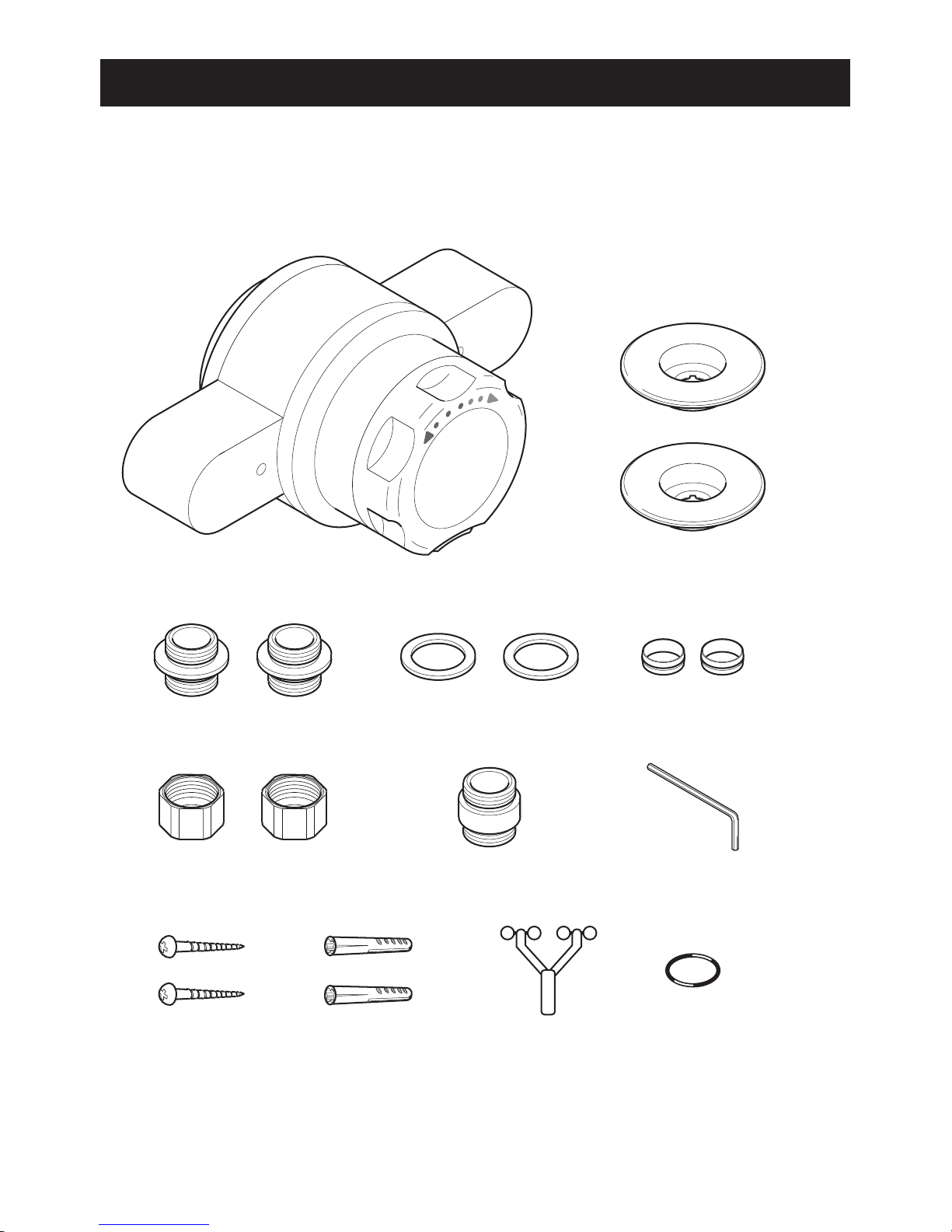

1 x 415 Shower Control

2 x Pipe Concealing Plates

2 x 1/2" BSP Inlet Connector Nipples

2 x Fibre Gaskets

2 x Olives

2 x Compression Nuts

1 x Outlet Nipple

1 x 2.5mm A/F

Hexagon Wrench

2 x 13/4" Fixing Screws

2 x Wallplugs

2 x Concealing Caps

1 x ‘O’ Seal

Tick the appropriate boxes to familiarise yourself with the part names and to

conrm that the parts are included.

Mira 415 Surface Mounted Shower Control

Documentation

1 x Installation, Operation and Maintenance Guide

1 x Customer Support Brochure

PACK CONTENTS CHECKLIST

Page 6

6

1 x 415 Shower Control with

Building-in Shroud

1 x Concealing Plate,

Circular Mounting Bracket

and Foam Seal

1 x Wall Mounting Bracket

3 x Compression Nuts

3 x Olives

2 x M4 x 30mm Screws

2 x No. 8 x 11/4" Fixing Screws

2 x Wallplugs

2 x M4 x 16mm Screws

1 x 2.5mm

A/F Hexagon

Wrench

1 x Outlet Nipple

1 x ‘O’ Seal

Tick the appropriate boxes to familiarise yourself with the part names and to

conrm that the parts are included.

Mira 415B Built-in Shower Control

Documentation

1 x Installation, Operation and Maintenance Guide

1 x Customer Support Brochure

Page 7

7

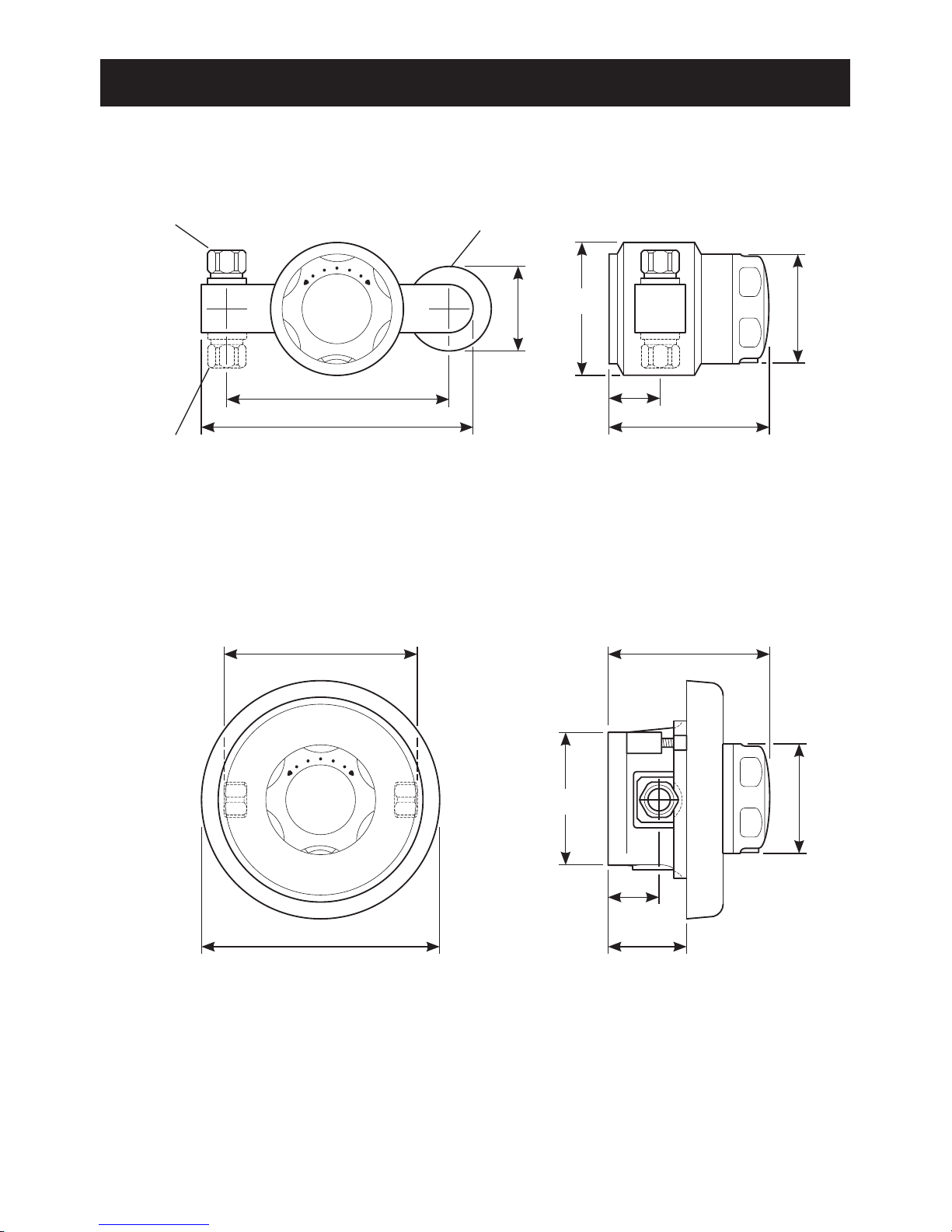

DIMENSIONS

All dimensions are nominal and in millimetres

415B

415

Falling Top Inlet

Supplies

Rising Bottom

Inlet Supplies

Ø153

Ø188.5

Ø56

Back Inlet

Supplies

Ø92

Ø76

Ø35

Ø112

132 A/F

Ø163

57 - 74

35

112

92 A/F

Ø76

Page 8

8

415 and 415B

Pressure Range

Minimum maintained pressure 1 bar

Maximum maintained pressure 5 bar

Maximum static pressure 10 bar

Note! For optimum performance, the initial supply pressures should be nominally

equal.

Temperatures

Maximum hot water temperature 85°C

However, BS6700 recommends that the stored temperature of water should never

exceed 65°C. A stored water temperature of 60°C is considered sufcient to meet

all normal requirements and will minimize the deposition of scale in hard water

areas.

Connections

Inlet

15mm Compression or 1/2'' BSP male (415)

15mm Compression (415B)

Outlet

1/2'' BSP male (415)

15mm Compression or 1/2'' BSP male (415B)

SPECIFICATIONS

Page 9

9

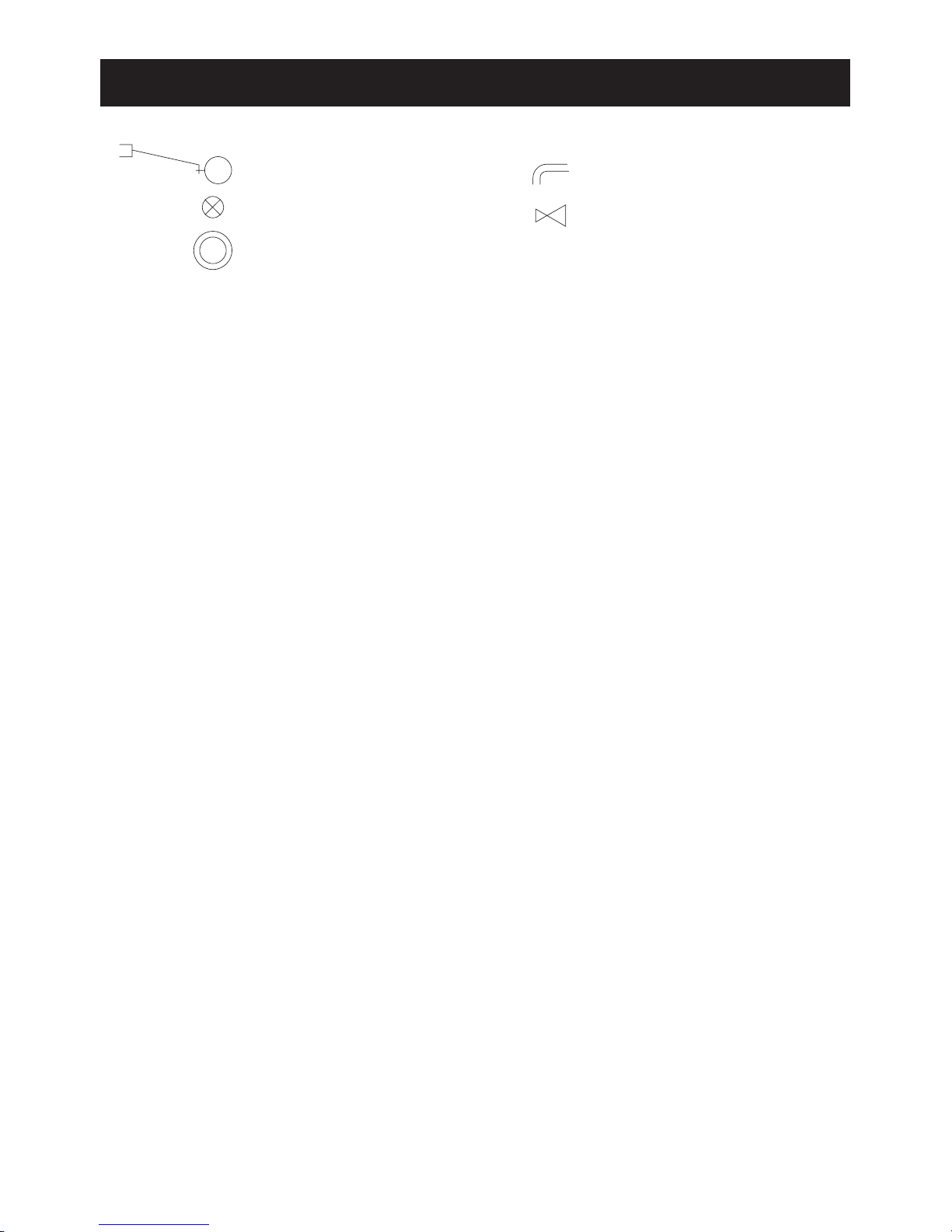

Float operated valve

Isolating valve

Shower control

Warning or overow pipe

Pressure reducing valve

Key to symbols appearing throughout this guide.

1. Layout and sizing of pipework must be such that when other services are used,

pressures at the shower control inlets do not fall below the recommended minimum

(1 bar). The pressure balancing performance is impaired below 1 bar. When tted

with some heater appliances the minimum maintained pressure may be above 1 bar,

refer to the section entitled “Commissioning” - “Multi-point gas water heaters”

or “Combination boilers”.

2. The Mira 415 is not suitable for installation as part of a gravity-fed plumbing system.

i.e. in conjunction with a hot water cylinder and cold water storage cistern.

3. When used with a modulating multi-point or combination boiler above 5 bar

maintained pressure, a pressure reducing valve will be necessary.

4. Supply pipes MUST be ushed to clear debris before connecting the shower control

(Byelaw 55).

5. The installation of in-line strainers are recommended to protect the shower control

from the ingress of water borne debris.

6. Conveniently situated isolating valves must be tted for servicing purposes.

7. No form of outlet ow control should be tted, only Kohler Mira recommended

ttings should be used in the outlet pipework.

8. Installations MUST comply with the Local Water Company or Water Undertakers

Byelaws and BS6700

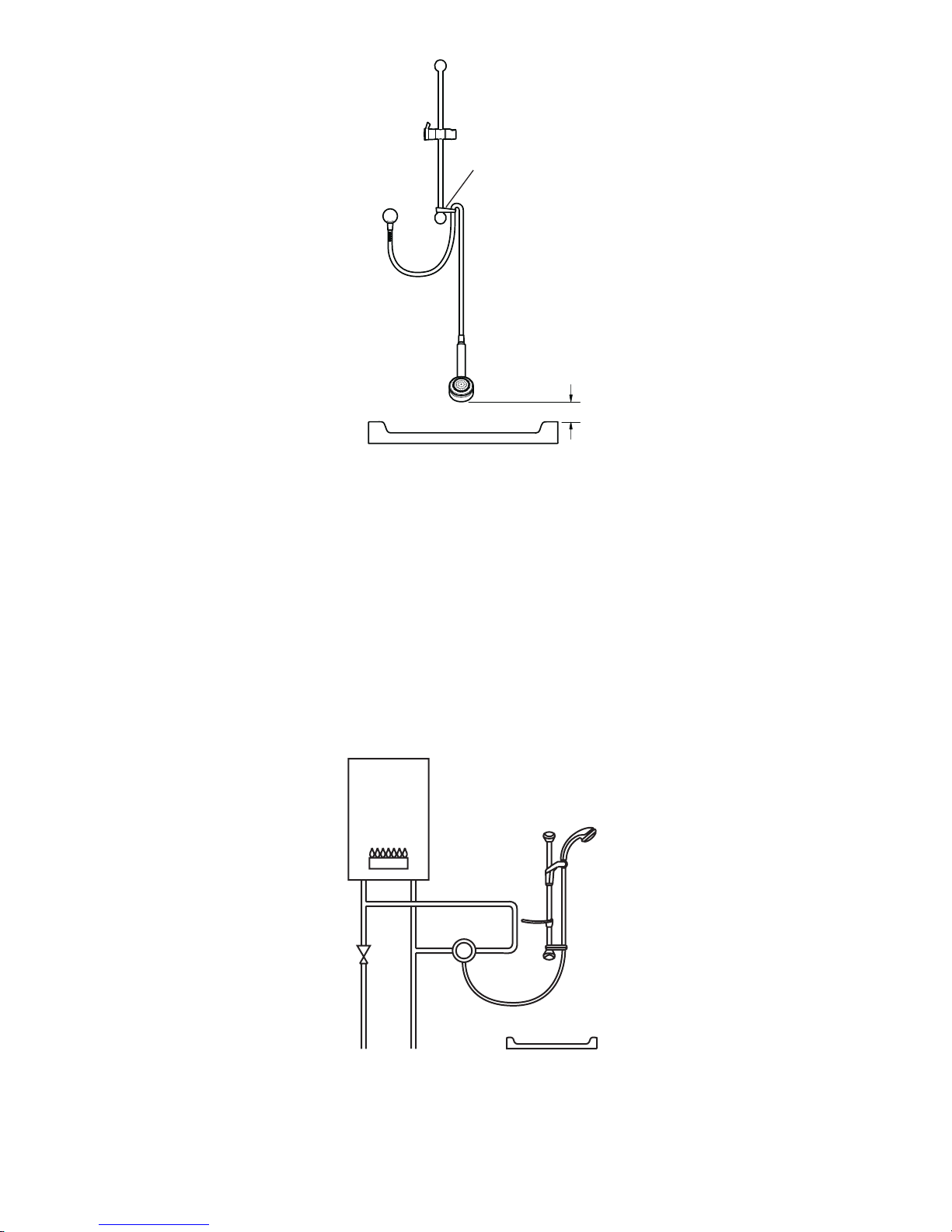

Byelaw 17 – “Shower Hose Connections” requires the handset to be “constrained

by a xed or sliding attachment so that it can only discharge water at a point not

less than 25mm above the spill-over level of the relevant bath, shower tray or other

xed appliance”, refer to Figure 1.

Byelaw 91 - If a product is to be used with a mains fed secondary water heating

device (eg jacketed heater) the system must have a means of accommodating the

expansion of water.

For further information please see “The Mira Shower Guide to the new Model Water

Byelaws”.

If in doubt we recommend that a plumber or contractor who is registered with one

of the following be contacted:-

Institute of Plumbing (I.O.P.) throughout the U.K. Tel: 01708 472791

National Association of Plumbing, Heating and Mechanical Services Contractors

(N.A.P.H. & M.S.C.) England and Wales. Tel: 01203 470626

Scottish and Northern Ireland Plumbing Employers’ Federation (S.N.I.P.E.F)

Scotland and Northern Ireland. Tel: 0131 225 2255

INSTALLATION REQUIREMENTS

Page 10

10

Figure 2

Figure 1

25 mm minimum

Hose Retaining Ring

The following diagrams and text illustrate typical examples of suitable plumbing

systems for the 415 shower control range:-

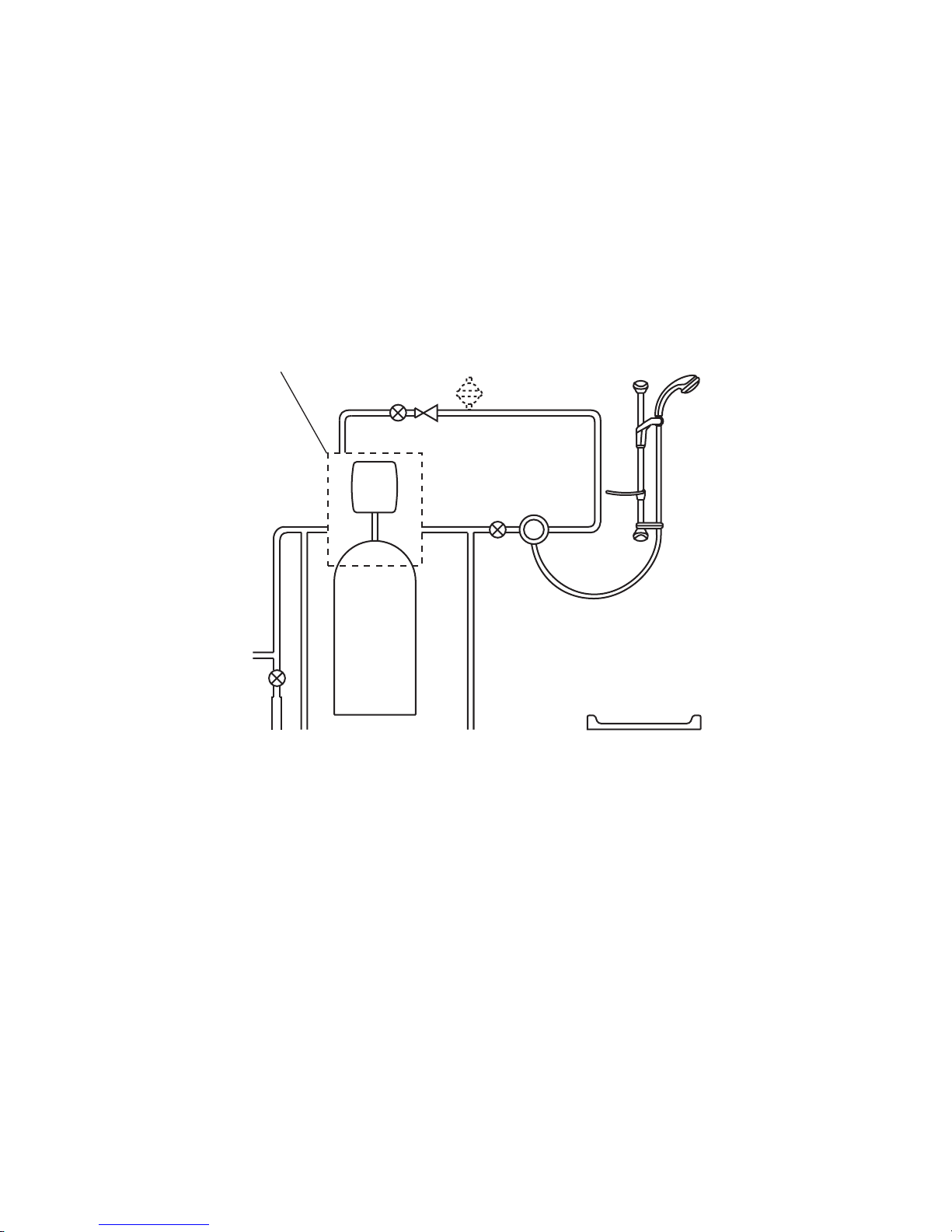

9. Gas heated showers

The shower control MUST be installed with a multi-point gas water heater or

combination boiler of a fully modulating design. A fully modulating multi-point

gas water heater or combination boiler is one in which the water draw-off rate

controls indirectly the gas ow rate to the burner. The concept is to produce

relatively constant hot water output temperatures within the operating limits of

the heating appliance. A pressure reducing valve will be required to ensure that

cold water pressures do not exceed 5 bar maintained, refer to Figure 2.

Page 11

11

10. Unvented mains pressure showers

The shower control can be installed with an unvented, stored hot water cylinder.

Only a “competent person” as dened by “Part G” of “Schedule 1” of the “Building

Regulations”, may t this type of system. For packages with no cold water

take off after the appliance pressure reducing valve, it will be necessary to t

an additional pressure reducing valve, set at the same value as the unvented

package in the position shown dotted, when the mains pressure is over 5 bar,

refer to Figure 3. This does not apply to packages with a cold take off after the

pressure reducing valve.

The supply pressures should be between 1 bar and 5 bar to the Mira 415.

Safety devices have not been shown whithin

dotted line area for clarity of illustration

Figure 3

Page 12

12

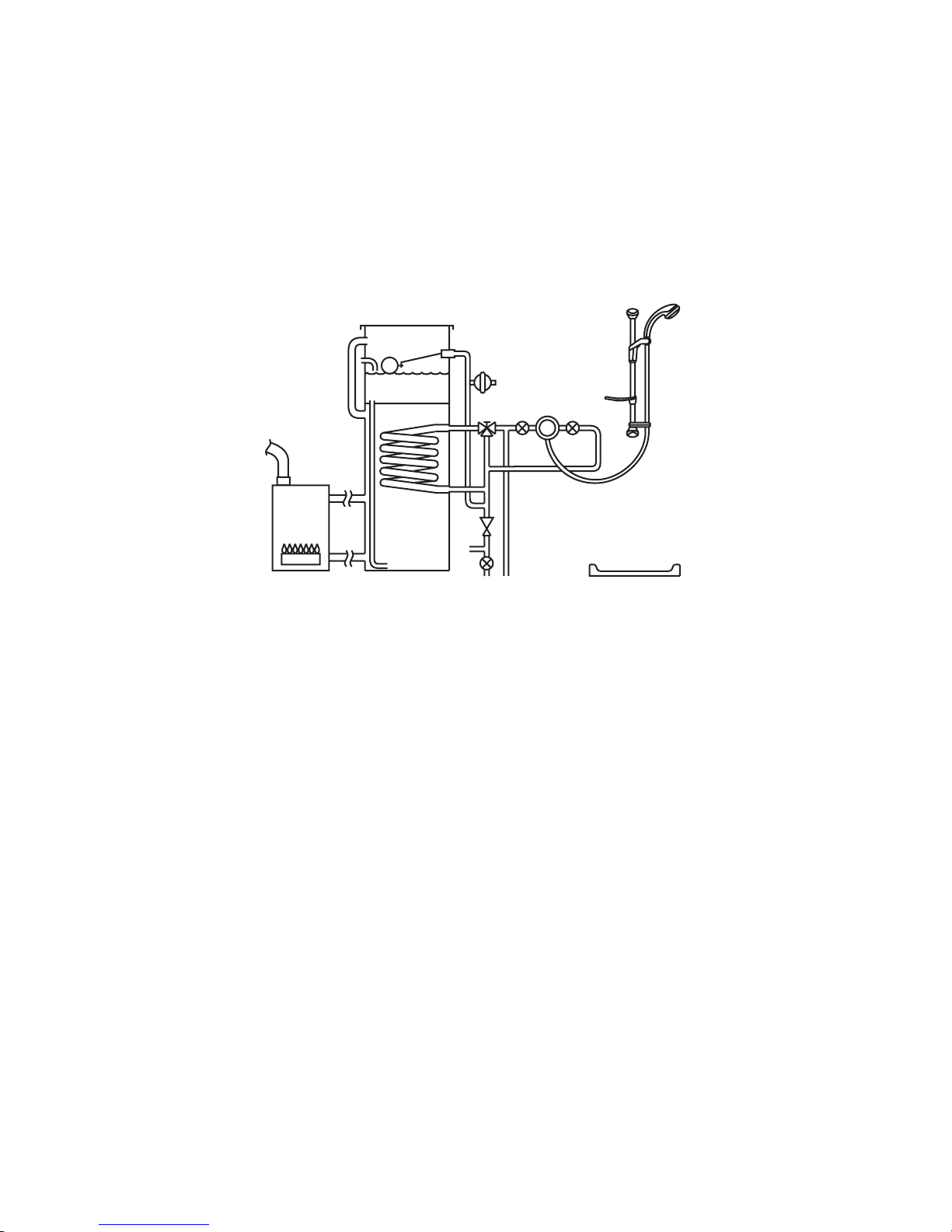

11. Mains pressurised instantaneous hot water, heated from thermal store,

showers

Packages of this type, tted with a tempering valve can be used with the

Mira 415. The tempering valve provides a relatively constant hot water

temperature and the 415 pressure balancing valve compensates for system

pressure variations. The Mira 415 supply pressure range is 1 bar to 5 bar.

For pressures above 5 bar a pressure reducing valve will be required, refer to

Figure 4.

Figure 4

Page 13

13

Mira 415 Surface Mounted Shower Control

Rising or Falling Inlet Supplies

1.1 Determine whether the hot or cold water services will be connected to the shower

control from the top (falling) or from the bottom (rising). Before deciding the

nal positioning of the shower control, please bear in mind the following:-

1.2 Consideration should be given to the requirements of Byelaw 17 with regard to

positioning of the shower control and selected shower ttings. (Not applicable

to rigid shower ttings).

1.3 Determine the position of the outlet in relation to the type of shower tting

used.

e.g. Mira er-s: Select top outlet.

Mira ev-s: Select bottom outlet.

Rising Supplies

Falling Supplies

The Mira 415 is supplied with inlet connections hot left, cold right and bottom

outlet as standard. To change the position of the outlet refer to the section,

“Reversed Outlet Connection”: instructions 1 to 8 inclusive.

Hot Inlet Port

Bottom Outlet

INSTALLATION

Page 14

14

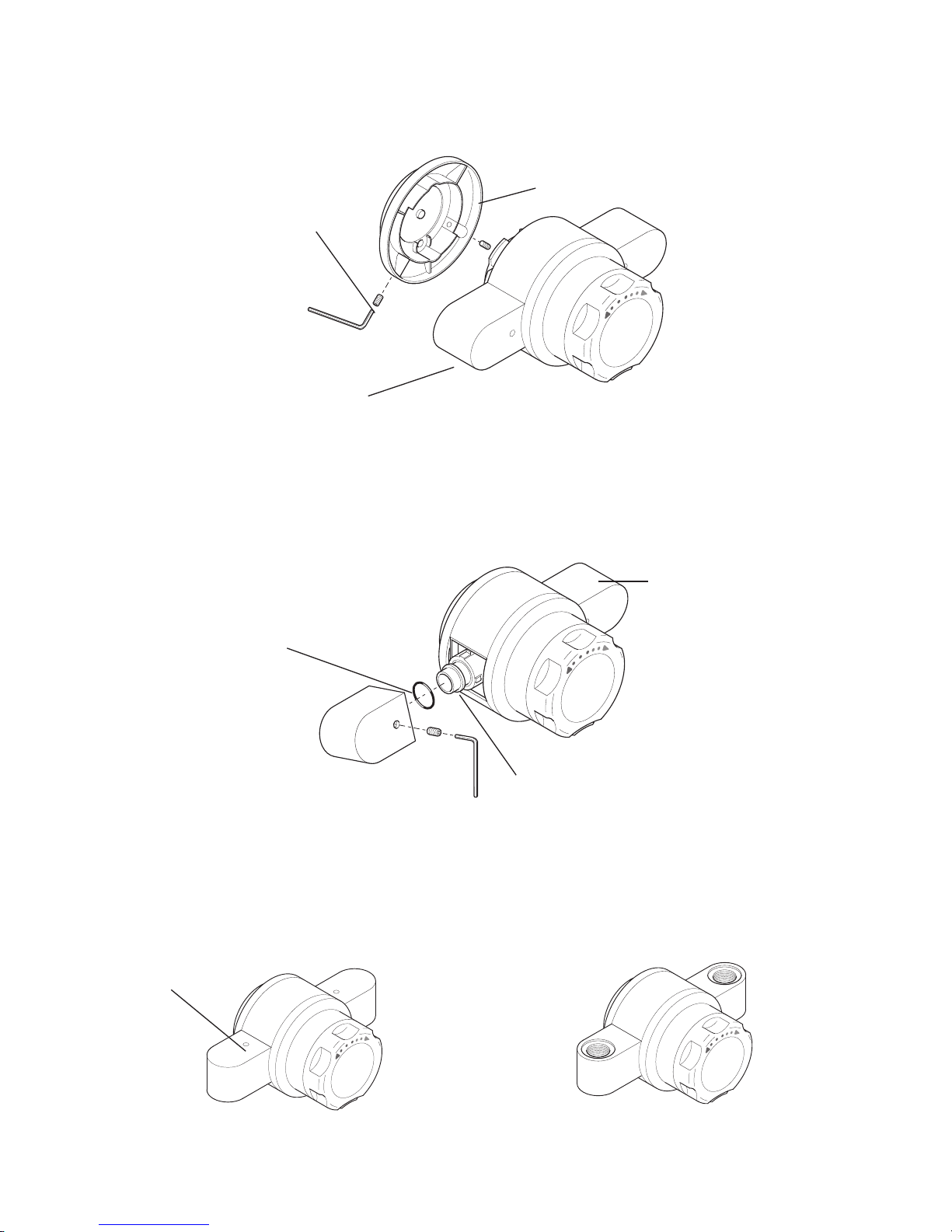

1.4 Remove the backplate by releasing, anti-clockwise, the two recessed grub

screws which retain the backplate against the brass shower control body, using

the 2.5mm A/F hexagon wrench (supplied).

1.6 Drill and suitably plug the two marked xing holes. Secure the backplate to the

wall with the two No. 8 x 13/

4

"

xing screws and wallplugs provided, if suitable,

ensuring that screw head seats into guide ribs.

Note! Screws with larger heads will foul the shower control body.

Guide Ribs

1.7 Thoroughly flush the incoming hot and cold water supplies before final

connection of the shower control (Byelaw 55).

1.5 Mark the nal position on the nished wall surface using the backplate as a

template.

Mark through the backplate the position of the two holes ensuring that they are

vertically aligned.

Backplate

Grub Screw

Page 15

15

1.9 Release, anti-clockwise, the two grub screws that retain the inlet elbows, using

the 2.5mm A/F hexagon wrench (supplied). Ensure that the ‘O’ seal is correctly

located on the smaller diameter shoulder of the brass inlet connector, and not

in the ‘V’ groove.

1.10 Ret the elbows in the required position, i.e. rising or falling supplies, ensuring

that the grub screws locate into the grub screw socket.

Tighten, clockwise, the grub screws and t the two concealing caps into the

hexagon recesses.

Concealing Cap

Rising supplies Falling supplies

1.8 Locate the shower control body onto the backplate and secure by tightening,

clockwise, the two recessed grub screws, using the 2.5mm A/F hexagon wrench

(supplied).

Grub Screw

Backplate

Shower Control Body

Grub Screw Groove

'O' Seal

Inlet Elbow

Page 16

16

1.11.6 Finally, carefully tighten, clockwise, the compression nut using, if

necessary, a cloth to protect the plated surfaces.

1.11.2 Screw in, clockwise, the 1/2" BSP connector nipple ensuring that the

compression taper faces uppermost, using a 12mm A/F hexagon wrench

(not supplied).

1.11.3 Slide, in turn, the compression nut, then the olive, over the hot and cold

inlet pipework. If necessary, sparingly, smear ‘liquid jointing’ on the pipe

end and the outside of the olive.

1.11.4 Insert the hot and cold inlet pipework into the opening of the 1/2" BSP

inlet connector nipple then slide the olive and compression nut into

place.

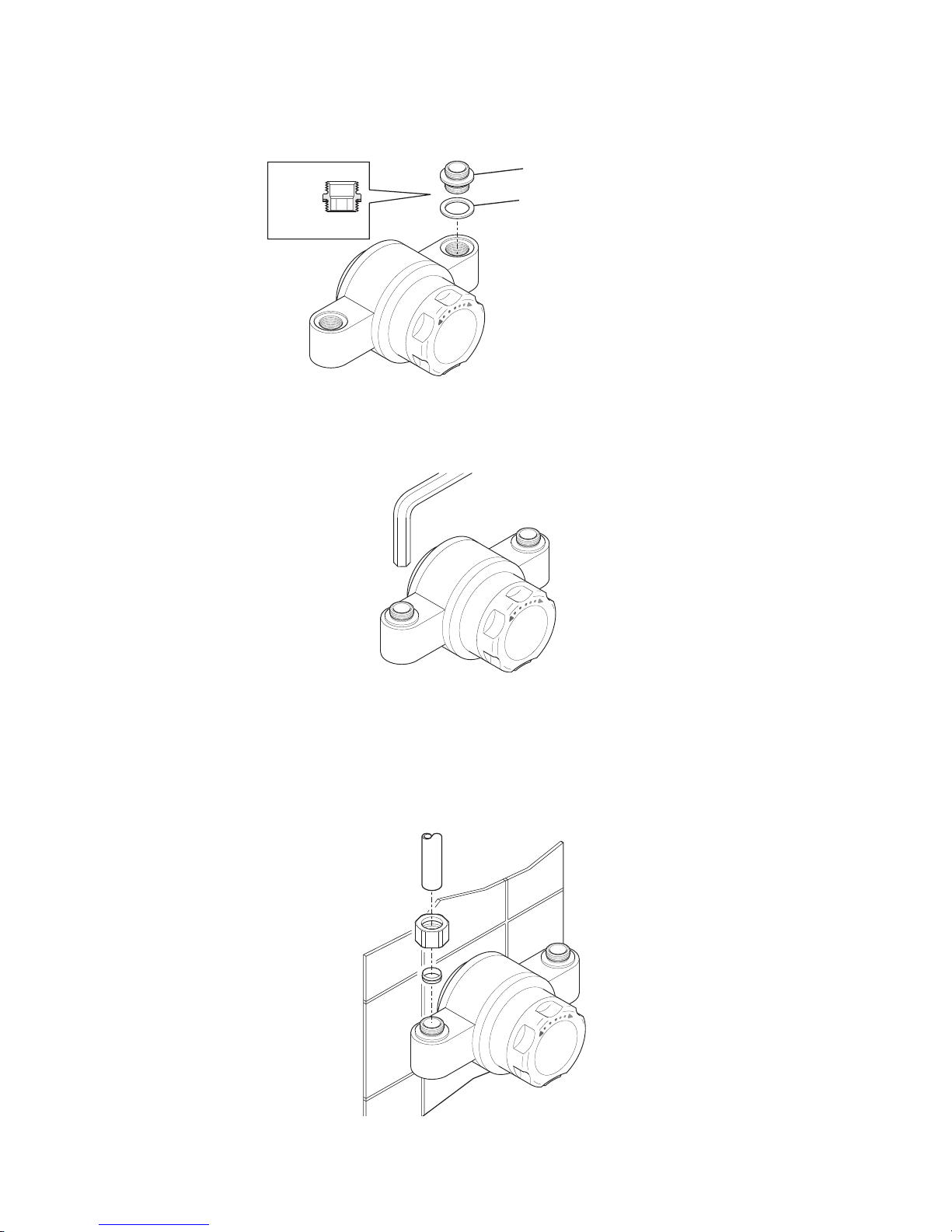

Connector Nipple

Fibre Gasket

1.11 Assemble the components of the inlet connector compression ttings in the

following sequence for each inlet:-

1.11.1 Place the bre gasket against the shoulder of the 1/2" BSP inlet connector

nipple.

Page 17

17

1.12 Fit the ‘O’ Seal to the tapered end of the outlet nipple and screw it into the

shower control outlet using a 12mm A/F hexagon wrench (not supplied). This

will leave the at face for connection of the shower hose.

This completes the installation of the Mira 415 for connection to “Rising and falling

inlet supplies”.

Back Inlet Supplies

1. Follow the shower control installation procedure as for “Rising and falling

inlet supplies”: instructions 1 to 4 inclusive.

2. Using a spirit level, mark the route of incoming hot and cold water supply pipes

at a distance of 153 mm centres.

Page 18

18

3. Remove the plaster and brickwork to the required depth to conceal the supply

pipework. Your attention is drawn to the requirements of Byelaw 58 with regard

to “Accessibility of Pipes and Pipe Fittings.

Note! Depth must be sufcient to prevent pipe concealing plates fouling on

the plumbing elbows.

4. Install the hot and cold water supply pipework ensuring that the pipe ends

emerge from the wall surface at 153mm centres, and project from the nished

wall surface by 13mm. Allow for two circular recesses measuring 32mm

diameter x 10mm depth, to accept the two pipework concealing plates.

13mm from Finished

Wall Surface

Backplate

Concealing Plate

Circular Recess

153mm

Page 19

19

5. Make good the wall surface. Fit the pipework concealing plates over the hot

and cold water supply pipework.

6. Fit the gaskets to the 1/2" BSP connector nipples and screw in the nipples with the

tapered ends outermost to accept the compression ttings. Tighten the 1/2" BSP

connector nipples fully with a 12mm A/F hexagon wrench (not supplied).

7. Thoroughlyushtheincominghotandcoldwatersupplypipesbefore

connecting the shower control (Byelaw 55). Failure to do so may result in a

product malfunction.

8. Slip the compression nuts and olives over the supply pipes.

9. Locate the shower control body onto the backplate and inlet supply pipework,

then secure by tightening, clockwise, the two recessed grub screws, using the

2.5 mm A/F hexagon wrench (supplied).

10. Tighten the compression nuts, using if necessary, a cloth to protect the plated

surfaces.

11. Turn on the water supplies and check for any leaks!

Connector Nipple

Fibre Gasket

Page 20

20

12. Fit the ‘O’ Seal to the tapered end of the outlet nipple and screw it into the

shower control outlet using a 12mm A/F hexagon wrench (not supplied). This

will leave the at face for connection of the shower hose.

13. This completes the installation of the Mira 415 for “Rising and falling back inlet

supplies”.

Connector Nipple

'O' Seal

415B Built-in Shower Control

The built-in shower control incorporates an integral wall mounting bracket assembly

which can be used to install the shower into a solid, dry-lined, stud partition or dry

partition wall structure, shower cubicle or laminated panel. Installers may wish to

consider other options such as fabricating rear supports using wooden noggins,

however, these methods of xing are beyond the scope of this guide.

Page 21

21

The building-in depth for the integral wall mounting bracket assembly is 58mm. The

building-in depth for the shower control (to the nished wall surface) is between 64

and 81mm. The building-in depth calculation must include the nal thickness of

plaster and tiles. This dimension determines how much of the control knob will be

visible through the concealing plate when the installation is completed.

230

134

110

146

214

53

43

67

92 A/F

12

38

Wall Mounting

Bracket

Backplate

Ø101

A building-in shroud is supplied, which protects the shower control during plastering

and provides a reference for the building-in depth when chasing out the wall

surface.

Outlet Port

Hot Inlet Port

Shower Control

Building-in Shroud

Raised Portion

The built-in shower control has 1/2" BSP male inlets and is supplied with 15mm

compression ttings. The outlet has a 1/2" BSP tapping and supplied with a nipple

terminating in a 1/2" BSP male or 15mm compression tting.

Page 22

22

Solid, Dry-lined, Stud Partition or Dry Partition Wall Structures

1. Determine whether the hot or cold water services will be connected to the

shower control from the top (falling) or from the bottom (rising).

2. Remove the plastic building-in shroud. The two M5 x 50mm building-in shroud

retaining screws should be screwed temporarily into the base of the shower

control for use later.

3. Familiarise yourself with the hot and cold water inlet ports and outlet port. They

can be identied as follows:-

The 415B is supplied with inlet connections Hot left, cold right and top outlet

as standard.

To change the position of the outlet refer to the section, “Reversed Outlet

Connection”: instructions 1 to 8 inclusive.

4. Determine the route for the incoming hot and cold water supply pipework. The

outlet pipework to a exible shower tting is best positioned to emerge above

and to one side of the shower control to allow the exible hose to drape around

the underside of the shower preventing the hose from interfering with the knob

(refer to diagram).

5. Ma rk th e wall su rfa ce for an open ing me asu rin g app rox ima tel y

245mm x 125mm.

Page 23

23

Mark the route of the incoming and outgoing pipework services.

Using the building-in shroud as a guide remove the plaster and brickwork/dry-

lining to the required depth of concealment.

NOTE! The depth of concealment must be such that the nal wall surface (e.g.

plaster and tiles etc.) nishes on the raised portion of the plastic building-in

shroud.

6. Mark the nal position in the wall chase of the two larger outer diameter xing

holes in the anges of the wall mounting bracket. This bracket must be xed

at 45°.

7. Drill and suitably plug the two marked xing holes.

8. Thoroughlyushtheincominghotandcoldwatersupplypipesbefore

connecting the shower control (Byelaw 55).

Page 24

24

9. Fix the shower control to the wall mounting bracket using the two M4 x 16mm

screws provided.

Shower Control

Wall Mounting Bracket

10. Install the shower control into the wall chase, aligning the two ange holes of

the wall mounting bracket assembly with the pre-drilled xing holes.

Secure the shower control with the two No. 8 x 11/4" xing screws supplied, if

suitable.

Page 25

25

11. Make the connections to the incoming hot and cold water supply pipes in the

following sequence for each port:-

11.1 Slide the compression nut, then the olive, over the pipe end. If necessary,

sparingly smear liquid jointing on the pipe end and the outside of the

olive.

11.2 Insert pipe end into the opening of the inlet connector then slide the

olive and compression nut into place.

11.3 Finally, carefully tighten, clockwise, the components.

12. Make the connection to the outlet pipe in the following sequence:-

12.1 Place the ‘O’ seal on to the nipple as shown. Locate the hexagon

towards the shower control outlet port. Screw in clockwise the nipple

using a 12mm A/F hexagon wrench (not supplied).

12.2 Slide the compression nut, then the olive, over the pipe end. If necessary,

sparingly, smear liquid jointing on the pipe end.

12.3 Insert pipe end into the opening of the outlet nipple then slide the olive

and compression nut into place.

12.4 Finally, carefully tighten, clockwise, the components.

12.5 Turn on the water supplies and check the pipework for any leaks!

Page 26

26

13. Ret the plastic building-in shroud over the shower control and secure with the

two M5 x 50mm shroud retaining screws, removed in instruction 2.

14. Plaster and tile up to the tapered sides of the plastic building-in shroud and,

when set remove the shroud. The two M5 shroud retaining screws should be

screwed temporarily into the base of the shower control for use later. Your

attention is drawn to the requirements of Byelaw 58 with regard to “Accessibility

of Pipes and Pipe Fittings”.

15. Fit the foam seal over the reverse side of the circular mounting bracket.

Page 27

27

16. Fix the circular mounting bracket to the shower control body using the two

M5 x 50mm screws used to retain the plastic building-in shroud.

NOTE! The bracket has been designed with semi-circular knock outs which

may need to be relieved to accommodate the supply pipework under minimum

building-in depth conditions.

17. Push the concealing plate rmly over the circular mounting bracket until it

locates on the four clips.

18. This completes the installation of the Mira 415B for installation into “Solid,

dry-lined, stud partition or dry partition wall structures”.

Page 28

28

Shower Cubicle or Laminated Panel

The built-in shower control incorporates an integral wall mounting bracket assembly

which can be used to install the shower into the front or back face of a shower cubicle

or laminated panel.

230

134

110

146

214

53

43

67

92 A/F

12

38

Wall Mounting

Bracket

Backplate

Ø101

Installation on to the front face of a shower cubicle or laminated panel

Depending on the structure of the shower cubicle or laminated panel it may be

possible to conceal the anges of the integral wall mounting bracket assembly into

the front face of the wall surface then cover over the xings with plaster and tiles.

The building-in depth for the integral wall mounting bracket assembly is 58mm.

The thickness of plaster and tiles which conceal the integral wall mounting bracket

assembly anges must be between 6 and 23mm.

1. Follow the shower control installation procedure as for “Solid, dry-lined, stud

partition or dry partition wall structures”: instructions 1 to 4 inclusive.

2. Cut a circular hole in the panel measuring 145mm in diameter.

Page 29

29

3. Follow the shower control installation procedure as for “Solid, dry-lined, stud

partition or dry partition wall structures”: instructions 6 to 17 inclusive to

complete the installation.

230

134

110

146

214

53

43

67

92 A/F

12

38

Wall Mounting

Bracket

Backplate

Ø101

Installation on to the Back Face of a Shower Cubicle or Laminated Panel

The building-in depth for the integral wall mounting bracket assembly is 58mm. The

integral wall mounting bracket assembly can be used to install the shower control

into a shower cubicle or laminated panel of between 4 and 21mm. The building-in

depth calculation must include for the nal thickness of plaster and tiles.

1. Follow the shower control installation procedure as for “Solid, dry-lined, stud

partition or dry partition wall structures”: instructions 1 to 4 inclusive.

2. Cut a circular hole in the panel measuring 124mm in diameter.

3. Using the wall mounting bracket as a template, mark the position of the two

smaller diameter xing holes on the anges of the bracket. These should be

at an angle of 45°.

Page 30

30

4. Drill the two xing holes.

5. Fix the shower control to the wall mounting bracket using the two M4 x 16mm

screws provided.

6. Feed the shower control through the opening in the panel and x to the panel

with the two M4 x 30mm xing screws.

7. Follow the shower control installation procedure as for “Solid, dry-lined, stud

partition or dry partition wall structures”: instructions 11 to 17 inclusive to

complete the installation.

Page 31

31

Reversed Outlet Connection

Mira 415 shower controls are supplied with inlet connections hot left, cold right

and bottom outlet. The 415B is supplied with inlet connections hot left, cold right

and top outlet as standard.

To reverse the outlet position proceed as follows:-

1. Rotate the shower control body through 180o. Install the shower control.

2. Prise off concealing cap, remove control knob retaining screw/plastic

temperature override stop and control knob.

3. Remove the hub tted to the spindle. Rotate the spindle one full turn (360o)

and ret the hub.

4. Remove the adjustable temperature stop and turn over. Make sure that the

Max oC with indentations side is uppermost. Adjust the maximum temperature

stop (refer to COMMISSIONING).

5. Ret the control knob, (with the override button at the bottom), control knob

retaining screw/plastic override stop and concealing cap.

Turn the knob fully clockwise to the shut off position.

6. This completes the procedure for “Reversed Outlet Connection”.

Cover Shroud

Cover Shroud

Retaining Screws

Concealing Cap

Adjustable

Temperature Stop

Hub

Control Knob

Plastic Override Stop

Control Knob

Retaining Screw

The hub has a at

as shown. This

matches with the

at on the spindle

Spindle

Page 32

32

Reversed Inlet Supplies

Mira 415 shower controls are supplied with inlet connections hot left, cold right

and bottom outlet. The 415B is supplied with inlet connections hot left, cold right

and top outlet as standard.

Both shower controls are tted with a single sequential control knob. The shower

control is turned off by turning the control knob fully clockwise. The correct sequence

of operation is anti-clockwise movement of the control knob followed by: Cold

Warm Hot water. If the sequence is: Hot Warm Cold water, then the hot

and cold water supplies have been reversed.

To correct reversed hot and cold inlet supplies proceed as follows:-

1. Prise off concealing cap, remove control knob retaining screw/plastic

temperature override stop and control knob.

2. Remove the hub. Turn the spindle one full turn (360o). Ret the hub.

3. Ret the control knob, (with the override button at the bottom), control knob

retaining screw/plastic override stop and concealing cap.

4. Ch eck th e maxim um tem per atu re. Ad jus t if ne ces sar y (ref e r to

COMMISSIONING).

5. Turn the knob fully clockwise to the shut off position.

6. This completes the procedure for "Reversed Inlet Supplies".

Control knob

Cover Shroud

Retaining Screws

Cover Shroud

Hub

Plastic Override

Stop

Concealing Cap

Control Knob

Retaining Screw

Page 33

33

All heater appliances must have a fully modulating heat output for the domestic

hot water, to provide a constant temperature of hot water to the Mira 415 shower

control.

Multi-point Gas Water Heaters

These notes are based on a heater with an effective output power of 23.5kW. Heaters

with higher or lower effective output powers will proportionally affect the following

information.

The Mira 415 range does not compensate for water temperature changes.

1 Use the heater appliance on a “high” or “winter” setting only.

2 A minimum maintained water supply pressure of 1.5 bar is required. This allows

for a 0.5 bar pressure loss in the heater

3 The maintained water supply pressure should not exceed 5 bar. A pressure

reducing valve will be needed for pressures over 5 bar to improve the system

operation. It should be installed to reduce both the cold feed pressure to the

heater and the cold feed pressure to the Mira 415 to approximately 3.5 bar.

Additional benets may be obtained by tting the pressure reducing valve after

the premises internal stop valve, drain valve and if tted, outside tap. The valve

should be correctly sized for the duty.

4 If the minimum modulating output of the heater appliance exceeds 14kW with a

reducing hot ow rate, then the maintained minimum supply pressure will need

to be increased. This is to keep the ow rate through the heater sufciently high

in order to ensure that the gas ame stays ignited. An extinguished ame will

produce a cold shower after a short period of time.

Combination Boilers

1 This information is based on a heater appliance tted with an internal ow

regulator rated at 10 l/min hot water.

2 Use the heater appliance on a “high” or “winter” setting only.

3 Should it not be possible to get a hot enough shower it may be necessary to

t a 9 l/min ow regulator (available from Mira Customer Services) between

the shower control and hose to further reduce the ow. The “top hat” regulator

should t into the hose recess such that the black ‘O’ seal is visible before

attaching the hose to the shower control.

4 A minimum maintained water supply pressure of 1.5 bar is required. This allows

for a 0.5 bar pressure loss in the heater.

COMMISSIONING

Page 34

34

5 The maintained water supply pressure should not exceed 5 bar. A pressure

reducing valve will be needed for pressures over 5 bar to improve the system

operation. It should be installed to reduce both the cold feed pressure to the

heater appliance and the cold feed pressure to the Mira 415 to approximately

3.5 bar.

Additional benets may be obtained by tting the water pressure reducing valve

after the premises internal stop valve, drain valve and if tted, outside tap. The

valve should be correctly sized for the duty.

6 The minimum maintained water supply pressure will need to be raised if the

minimum heater output power is greater than 7.5 kW on a reducing ow with

a hot temperature of 62.5 °C.

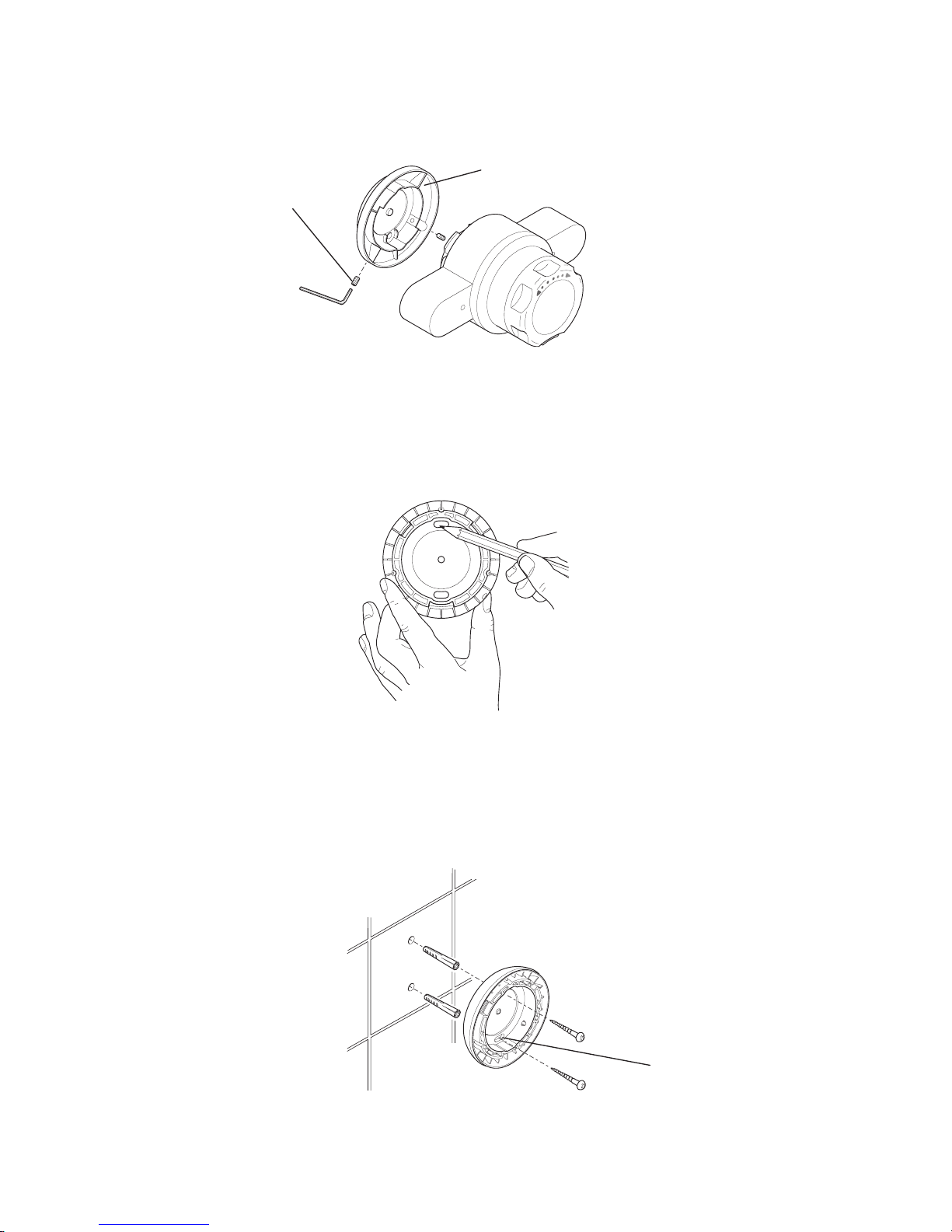

Adjustable Maximum Temperature Stop

Mira 415 shower controls are fully performance tested. The adjustable maximum

temperature (maximum angular movement prior to override) has been preset under

ideal installation conditions at the factory. Site conditions and personal preference

may dictate that the maximum temperature needs to be reset.

To reset the adjustable maximum temperature stop ensure that an adequate supply

of hot water is available in excess of that required from the shower control. Turn the

control knob fully anti-clockwise. Check the temperature at the discharge point (allow

hot water to reach the shower). If incorrect, adjust the temperature as follows:

1. Turn the control knob anti-clockwise until the desired maximum temperature

is achieved. It may be necessary to press the override button and continue to

rotate anti-clockwise, past the preset maximum temperature setting. Note the

nal position of the button, e.g. 11 O’ clock.

2. Turn the control knob fully off.

3. Remove the concealing cap.

4. Remove the control knob retaining screw/plastic temperature override stop and

pull off the control knob.

5. Locate the adjustable temperature stop (identied by a part number and a

“MAX °C” symbol or a “MAX °C” symbol and component indentations).

Note! Ensure that the original face identied, is uppermost after adjustment.

6. With reference to the diagrams, carefully remove the adjustable temperature

stop. Reposition the stop so that the “MAX °C” symbol is aligned with the noted

button position, e.g. 11 O’ clock.

Page 35

35

7. To check the desired maximum temperature setting has been correctly set, ret

the hub and control knob, turn fully anticlockwise and check the temperature

of the water at the outlet. If still incorrect:

To increase the temp er atu re, reposi tion the stop one se rr ati on

anticlockwise.

To decrease the temperature, reposition the stop one serration clockwise.

Repeat the check as necessary.

Cover Shroud

Cover Shroud

Retaining Screws

Concealing Cap

Control Knob

Plastic Override

Stop

Control Knob

Retaining Screw

Adjustable

Temperature Stop

Temperature Override Button

Indentations

Adjustable Temperature Stop

8. Ret the control knob (with the override button at the bottom), control knob

retaining screw/plastic override stop and concealing cap. Please make sure

the plastic override stop is correctly seated.

This completes the procedure for “Commissioning: Maximum temperature

setting”.

Page 36

36

Temperature Override Button Disable

The Mira 415 incorporates a safety feature which prevents the temperature

override button from being depressed, enabling the user to access a higher shower

temperature. The shower control is despatched from the factory with the button in

the “enabled” position. The following sequence will allow the installer to “disable”

the temperature override button if required.

1. Ensure the shower control is turned off.

Remove the concealing cap.

2. Locate the plastic temperature override stop.

3. Pull out the temperature override stop and reposition it in the slot adjacent to

the red temperature override button.

4. Reversing the above procedure will “enable” the temperature override button

movement.

Page 37

37

Mira 415 shower controls have a single sequential control knob. The shower control

is turned on by turning the control knob anti-clockwise. The shower control is turned

OFF by turning the control knob clockwise. When the control knob is turned ON

(anti-clockwise) the sequence is;

Cold water Warm water Preset maximum temperature.

A fuller description is as follows:-

1. Initial anti-clockwise movement turns the water on at full ow of cold water,

further anti-clockwise movement increases the temperature. The ow rate

is determined by the supply pressures at the inlets of the shower control,

or by the effective output power of the heater appliance. Flow rates for gas

heater appliances can vary typically between 8 l/min (winter) and 15 l/min

(summer).

2. The control knob incorporates a red override button, which allows movement

beyond the adjustable maximum adjustable temperature stop. When the

adjustable maximum temperature stop is reached, the override button can be

pressed allowing the control knob to rotate further. This facility is used when

the initial hot water supply temperature has fallen due to increased demand or

when a hotter shower is required. The override mechanism is self cancelling

when the knob is returned to the off position.

3. For safety reasons this product is tted with a adjustable maximum temperature

stop. This setting must be checked and adjusted as necessary to suit both site

conditions and user’s comfort. Refer to the section “Adjustable maximum

temperature setting” for further details.

OPERATION

Page 38

38

How the pressure balancing principle operates

Mira 415 pressure balanced shower controls automatically adjust for variations in

inlet pressures to maintain a constant outlet temperature provided the inlet water

temperatures remain stable.

The Mira 415 is not a thermostatic shower control and does not sense supply

temperature variations. Therefore, inlet water temperatures especially the hot, should

be relatively constant.

Equal Hot and Cold Pressure

The diaphragm is in the centre.

Low Hot and High Cold Pressure

Diaphragm deects towards hot inlet

and restricts cold entry.

Cold Water Pressure Loss

Diaphragm moves to close hot inlet.

High Hot and Low Cold Pressure

Diaphragm deects towards cold inlet

and restricts hot entry.

Page 39

39

Mira 415 shower controls are fully performance tested after assembly. In the unlikely

event that you experience problems with your shower, the following procedure will

enable you to undertake basic fault nding before contacting the person responsible

for installing your shower.

Key for applicability column

A - Gas heated showers.

B - Unvented mains pressure showers.

C - Mains pressurised, instantaneous hot water, heated from thermal store

showers.

Shower insufciently

hot.

Wide temperature

uctuations from

shower when no other

draw-off is being made.

(a) Maximum

temperature incorrectly

set

Reset adjustable

maximum temperature.

(b) Heater not set on

maximum hot

(c) Flow rate still too

high.

Consult heater

manufacturers water

output instructions.

Fit 9 l/min ow

regulator between

shower control and

hose.

Supply temperature

variations to shower,

especially hot water,

caused by the heater

appliance cycling

on and off, due to

insufcient ow rate,

insufcient water

pressure or heater not

fully modulating.

(a) Increase supply

pipe sizes to premises.

(b) Adjust heater

throttle valve to

increase ow and

prevent heater cycling.

(c) Contact your

installer.

(d) See also “Shower

insufciently hot”.

RemedyMalfunction Cause A B C

FAULT DIAGNOSIS

Page 40

40

RemedyMalfunction Cause A B C

Shower pattern

collapses when

another hot tap is

turned on.

(a) Property water

supply pipe partially

blocked or undersized.

Reduce the

simultaneous demand.

Shower pattern

collapses when

anothercold tap is

turned on.

Shower control

operating sequence

is “off, hot, cool”.

Shower insufciently

hot without pressing

red button and

rotating further.

Shower control

"drums" whilst in

use.

Shower control

"thumps" when

another tap is

suddenly turned off.

The heater is not

capable of supplying

several outlets at the

same time.

(b) Property stop or

servicing valve not fully

open.

(c) Insufcient mains

cold water pressure

Hot and cold water

supplies have been

connected in reverse.

Adjustable maximum

temperature incorrectly

set.

Supply pressure

in excess of 5 bar

maintained.

Inlet check valve faulty.

Contact the Water

Undertakers or your

installer.

Contact the Water

Undertakers or your

installer.

Refer to the

section “Reversed

Connections”appearing

earlier in this guide.

Refer to the section

“Adjustable maximum

temperature setting”

appearing earlier in this

guide.

Fit pressure reducing

valve. Refer to the

section “Installation

Notes”.

(a) Remove cartridge

and if possible clear

obstruction in check

valve

(b) Renew cartridge.

Open valve.

Page 41

41

RemedyMalfunction Cause A B C

(a) Heater appliance

not igniting.

Shower force too

strong.

Insufcient mains

pressure.

Fit 9 l/m ow

regulator.

Open valve.

Wait until reheated.

Refer to “Wide

temperature

uctuations”.

Wait for hot water to

reheat.

Renew cartridge

Ret hub. Refer to

the section “Cartridge

renewal”.

Renew ‘O’ seals with

Service Pack.

High pressure

supplies.

(b) Property stop hot

or cold isolating valve

not fully open.

(c) Hot water run out.

(a) Insufcient ow

rate.

(b) Hot water supply

temperature dropped.

(a) Pipework not

ushed before

connecting shower

control. (Internal ‘O’

seals damaged).

(b) Hub incorrectly

tted when renewing

cartridge.

(c) External ‘O’ seals

damaged.

No hot water available

Shower starts warm

and then runs cool.

Shower control cannot

be shut off.

No ow or low ow

from shower head.

(a) Supply stop valve

turned down or off.

(b) Hose or handset

blocked.

(c) Spray plate

blocked.

Turn on.

Clear blockage renew

hose or handset.

Remove and clean.

Page 42

42

Mira products are precision engineered to provide satisfactory performance provided

they are installed and operated in accordance with our recommendations contained

in this guide.

The shower control is designed for the minimum of maintenance in normal domestic

use. If a malfunction occurs then this will probably necessitate a complete cartridge

replacement.

The cartridge contains no internally serviceable parts.

When installed in very hard water areas (above 200 p.p.m. temporary hardness)

your installer may advise the installation of a water treatment device to reduce the

effects of limescale formation in the heating appliance and spray plates.

You may, if you wish, choose to engage the services of a Mira Service Engineer or

Agent the terms of which are outlined on the back page of this guide.

WARNING! – Cleaning

Many household cleaners contain abrasives and chemical substances and should

not be used for cleaning plated or plastic ttings. These nishes should be cleaned

using a mild washing up detergent or soap solution, and then wiped dry using a

soft cloth.

Light golden colour nish is softer than chromium nish and its abrasive resistance

much less. When cleaning or using tools during maintenance extra care must be

taken.

Component Interchangeability

Some parts of the latest Mira 415 are not interchangeable with earlier models of

the Mira range.

Cartridge Renewal

Should the cartridge require renewal then the following procedure should be

followed:-

Important - use only silicone based lubricants when re-assembling.

1. Isolate water supplies and turn on shower hose to relieve pressure.

Prise off concealing cap, remove control knob retaining screw/plastic override

stop and control knob.

2. Remove the two shroud retaining screws, cover shroud and adjustable

temperature stop.

Please ensure that the orginal face of the adjustable temperature stop is visible

after adjustment.

Remove the hub.

MAINTENANCE

Page 43

43

3. Undo the four cover retaining screws and remove cover. (A quantity of water

will be discharged).

4. Pull the pressure balancing cartridge from the shower control body.

Cover Shroud

Cover Shroud

Retaining Screws

Cartridge

Concealing Cap

Cover

Hub

Cover Retaining Screws

Control Knob

Plastic Override Stop

Control Knob

Retaining Screw

Adjustable Temperature Stop

Plastic Pins

Cover 'O' Seal

Retaining Bush

'O' Seal

'O' Seal

'O' Seal

5. The new cartridge is marked “H” for Hot, “C” for Cold.

6. Identify which is the hot inlet of the shower control and t the cartridge

accordingly.

Ensure that the two cartridge inlet seals are correctly located.

7. Fit the cartridge into the cover. Make sure that the arrow on the end face of the

cartridge points to the letter "C" (refer to diagram).

Note the one-way cartridge location feature in the cover.

8. Push the cartridge back fully into shower control body. Ensure the two plastic

pins locate in the brass body recess before securing cover with cover retaining

screws.

9. Ensure that the cover “O” seal is correctly located into the cover.

10, Ret the cover and secure with the four cover retaining screws. Make sure that

the at on the spindle is lowermost (refer to diagram).

11. Apply adequate pressure to engage the hub onto the spindle.

Page 44

44

12. Turn on water supplies, check for any leaks.

13. Temporarily t the control knob (with the override button at the bottom). Rotate

the control knob anti-clockwise until the desired temperature is achieved. Note

the nal position of the override button. e.g. 11 O’ clock. Rotate the control knob

to the “off” position.

14. The maximum temperature will now require to be reset following the procedure

“Adjustable Maximum Temperature Setting”.

Arrow

Flat On Spindle

H

C

End View Of Cartridge

‘O’ Seal Renewal

Should the ‘O’ seals require renewing then the following procedure should be

followed:-

Important - use only silicone based lubricants when re-assembling.

1. Follow the procedure detailed in the section “Cartridge renewal”: instructions

1 to 4 to dismantle the shower control.

2. Check the ‘O’ seals on the cartridge hot and cold inlets for any signs of damage

and renew if necessary.

3. Push the cartridge fully into the shower control body. Ensure the two plastic

pins locate in the brass body recess.

Page 45

45

4. Check the cartridge spindle ‘O’ seal (tted in the cover) for signs of damage and

renew if necessary. Fit the spindle ‘O’ seal and retaining bush into the cover.

5. Check the cover ‘O’ seal for signs of damage and renew if necessary.

6. Follow the procedure detailed in the section “Cartridge renewal”: instructions

9 to 15 to re-assemble the shower control.

Cartridge

Cover

Cover Retaining Screws

Plastic Pins

Cover 'O' Seal

Retaining Bush

'O' Seal

'O' Seal

'O' Seal

Page 46

46

SPARE PARTS

004 73 Body

004 74 Body – (415B)

012 12 Cover

410 55 Concealing Plate – light golden

410 54 Concealing Plate – chrome

079 83 Body Shroud – chrome

079 88 Body Shroud – light golden

079 84 Cover Shroud

107 94 Name Plate

119 85 Wall Mounting Bracket (415B)

280 07 Inlet Compression Fitting - chrome

280 15 Inlet Compression Fitting - light golden

553 35 Outlet Nipple Assy – chrome

553 54 Outlet Nipple Assy – light golden

555 67 Outlet Nipple – (415B)

575 12 2.5mm Hexagon Wrench

802 27 Inlet Elbow Assembly – chrome

802 33 Inlet Elbow Assembly – light golden

807 28 Backplate Assembly – (415B) - components identied 'A'

807 33 Backplate Assembly

902 55 Cartridge Assembly

916 94 Control Knob Assembly

932 04 Inlet CompressionFitting (415B)

932 25 Hub Pack

936 22 Seal Pack - components identied 'B'

937 59 Screw Pack (415B) - components identied 'C'

Page 47

47

575 12

807 33

280 07

280 15

079 83

079 88

553 35

553 54

802 33

902 55

012 12

802 27

107 94

916 94

079 84

004 73

B

B

932 25

B

B

B

B

B

B

415

Page 48

48

415B

107 94

916 94

079 84

119 85 807 28

555 67

932 04

004 74

012 12

902 55

410 55

410 54

B

B

B

932 25

B

B

B

B

C

C

A

C

A

Page 49

49

ACCESSORIES

DCV-H: An outlet double check valve, requiring a minimum inlet supply pressure

of 0.5 bar, which has been designed to prevent the backow or backsiphonage of

potentially contaminated water, through shower controls which are tted with a exible

hose as part of the outlet shower tting. Its correct tting will ensure compliance with

Byelaw 17. Available as an optional accessory from your Mira stockists.

DCV-H Outlet double check valve

Page 50

50

NOTES

Page 51

51

NOTES

Page 52

52

P2742/7 © Kohler Mira Limited, December 2007

Guarantee of Quality

Mira Showers guarantee your product against any defect

in materials or workmanship for the period shown in the

Guarantee Registration Document included with your

shower.

A

lternatively, to confi rm the applicable guarantee period

please contact Customer Services.

To validate the guarantee, please return your completed

registration card.

Within the guarantee period we will resolve defects, free

of charge, by repairing or replacing parts or modules as

we may choose.

To be free of charge, service work must only be undertaken

by Mira Showers or our approved agents.

Service under this guarantee does not affect the expiry

date.

The guarantee on any exchanged parts or product ends

when the normal product guarantee period expires.

Not covered by this guarantee:

Damage or defects arising from incorrect installation,

improper use or lack of maintenance, including build-up

of limescale.

Damage or defects if the product is taken apart, repaired or

modifi ed by any persons not authorised by Mira Showers

or our approved agents.

This guarantee is in addition to your statutory and other

legal rights.

What to do if something goes wrong

If when you first use your shower, it doesn’t function

correctly, fi rst contact your installer to check that installation

and commissioning are satisfactory and in accordance with

the instructions in this manual. We are on hand to offer you

or your installer any advice you may need.

Should this not resolve the diffi culty, simply contact our

Customer Services Te am who will give every assistance

and, if necessary, arrange for our service engineer to

visit. If the performance of your shower declines, consult

this manual to see whether simple home maintenance is

required. Please call our Customer Services Te am to talk

the diffi culty through, request a service under guarantee

if applicable, or take advantage of our comprehensive

A

fter-Sales service.

A

s part of our quality and training programme calls may be

recorded or monitored.

Our Customer Services Team is comprehensively trained to

provide every assistance you may need: help and advice,

spare parts or a service visit.

Spare Parts

We maintain an extensive stock of spares and aim to provide

support throughout the product’s expected life.

Spares can be purchased from approved stockists or

merchants (locations on request) or direct from Customer

Services.

Spares direct will normally be despatched within two working

days. Payment can be made by Visa or MasterCard at the

time of ordering. Should payment by cheque be preferred,

a pro-forma invoice will be sent.

All spares are guaranteed for 12 months from date of

purchase. Spares that have been supplied directly from us

can be returned within one month from date of purchase,

providing that they are in good order and the packaging

is unopened.

Note! Returned spares will be subject to a 15% restocking

charge and authorisation must be obtained before return.

Please contact our Customer Services Team.

Note! In the interests of safety, spares requiring exposure

to mains voltages can only be sent to competent persons.

Service

Our Service Force is available to provide a quality service

at a reasonable cost. You will have the assurance of a Mira

trained engineer/agent, genuine Mira spare parts and a

12 month guarantee on the repair.

Payment should be made directly to the engineer/agent

using Visa, MasterCard or a cheque supported by a

banker’s card.

To Contact Us

England, Scotland, Wales and Northern Ireland

Mira Showers Customer Services

Te lephone: 0870 241 0888, Mon to Fri 8:00 am - 5:30 pm

Sat 8:30 am - 3:30 pm

E-mail: technical@mirashowers.com

Fax: 01242 282595

By Post: Cromwell Road, Cheltenham,

Gloucestershire, GL52 5EP

Eire

Modern Plant Ltd (Dublin)

Te lephone: 01 459 1344, Mon to Fri 9:00 am - 5:00 pm

E-mail: sales@modernplant.ie

Fax: Dublin 01 459 2329

Post: Otter House, Naas Road,

Clondalkin, Dublin 22

Modern Plant (Cork)

Te lephone: 021 496 8755, Mon to Fri 9:00 am - 5:00 pm

E-mail: cork@modernplant.ie

Fax: 021 496 8607

Post: Tramore Road, Cork

Mira is a registered trade mark of

Kohler Mira Limited.

The company reserves the right to alter

product specifi cations without notice.

www.mirashowers.com

CUSTOMER SERVICE

Loading...

Loading...