MIOX RIO, RIO M1, RIO M3, RIO M2, RIO M4 Maintance Manual

...

RIO SERIES ON-SITE GENERATOR

M1-M5 H1-H5

Installation, Operation, and Maintenance

Manual

March 26, 2019

MIOX RIO Series Operators Manual

MIOX maintains a constant product improvement program that may affect design

and/or specifications. The company reserves the right to make these changes without prior notice

or liability. Portions of the MIOX OSGs are covered by U.S. patent.

Customer Service

5601 Balloon Fiesta Parkway NE, Suite A

Albuquerque, NM 87113

Phone: 1.505.343.0090

Toll Free: 1.866.MIOX.HLP (1.866.646.9457)

FAX: 1.505.343.0093

Contact@mioxservice.com

www.MIOX.com

http://www.denora.com/

International distributors and sales agents located worldwide

P/N: 102-00076-G Page 1

MIOX RIO Series Operators Manual

Table of Contents

Introduction ................................................................................................................... 7

Regulatory Compliance ................................................................................................. 7

U. S. Environmental Protection Agency (US EPA) ........................................................... 7

NSF International ..................................................................................................... 7

State Approvals ........................................................................................................ 7

List of Certifications .................................................................................................. 7

Components of the System ........................................................................................... 8

Space Requirements ................................................................................................. 8

Security ................................................................................................................ 10

RIO Series OSG System and Ancillary Components ...................................................... 10

RIO Series OSG System Optional Equipment ............................................................... 11

Installation .................................................................................................................. 12

Recommended Tools for Installation: RIO Series OSG ..................................................... 13

Mechanical Tools .................................................................................................... 13

Plumbing Tools ....................................................................................................... 13

Receiving and Unpacking the RIO Series OSG ................................................................ 14

Securing the Cabinet ............................................................................................... 14

System Description .................................................................................................... 15

Electric Connections Required for Start-Up .................................................................... 16

Electrical Power Connection ...................................................................................... 16

Control System/Rear Panel Connections ..................................................................... 18

Tank Level Inputs ................................................................................................... 19

Auxiliary Relay Connection ....................................................................................... 20

Auxiliary 24V Power Connection ................................................................................ 21

Dilution Air Connection ............................................................................................ 22

Hydrogen/Hardness Connections ............................................................................... 23

Ethernet Connection ................................................................................................ 24

Plumbing Connections Required for Startup ................................................................... 25

Feed Water Connection ............................................................................................ 25

Brine Feed Connection ............................................................................................. 26

Oxidant Discharge .................................................................................................. 27

Drains ................................................................................................................... 28

Brine Generator Installation (Optional) ......................................................................... 29

P/N: 102-00076-G Page 2

MIOX RIO Series Operators Manual

Brine Silos ............................................................................................................. 31

Brine Pressure Boost System Installation (Optional) ........................................................ 32

Oxidant Storage Tank Installation ................................................................................ 32

Ventilation Requirements ......................................................................................... 32

Level Switch Installation .......................................................................................... 36

Pressure Transducer Installation (Optional) ................................................................ 37

Oxidant Tank Lid .................................................................................................... 38

Feed Line Connection/Injection System ...................................................................... 38

Overflow Port ......................................................................................................... 38

Cell Installation and Removal ...................................................................................... 39

Removal ................................................................................................................ 39

Installation ............................................................................................................ 39

Electrical Connections .............................................................................................. 40

Plumbing Connections ............................................................................................. 42

Cell Guard Installation ............................................................................................. 44

Operations ................................................................................................................... 46

Initial Settings and Startup Checks ............................................................................... 46

Electrical Check ...................................................................................................... 46

Initial Salt Filling .................................................................................................... 46

Checks Prior to Startup ............................................................................................ 47

Brine Boost Operation ............................................................................................. 47

Water Softener Operation ........................................................................................ 47

Routine Operations .................................................................................................... 48

Turn On Disconnect Switch ...................................................................................... 48

Push Run/Stop Switch ............................................................................................. 48

Startup Sequence/Operating Window ......................................................................... 49

Brine Boost Pump Commissioning ............................................................................. 50

Operation Controls ..................................................................................................... 50

Modes of Operation ................................................................................................. 50

System Status Lights .............................................................................................. 52

Fault Conditions ..................................................................................................... 53

Water Flow Control Valve Reset Procedure.................................................................. 55

System Shutdown procedure ....................................................................................... 55

General Periodic Maintenance ......................................................................................... 56

Daily Maintenance...................................................................................................... 56

P/N: 102-00076-G Page 3

MIOX RIO Series Operators Manual

Weekly Maintenance .................................................................................................. 57

Monthly Maintenance.................................................................................................. 58

Quarterly Maintenance ............................................................................................... 58

Annual Maintenance ................................................................................................... 58

Electrolytic Cell Replacement ....................................................................................... 59

Storage of Equipment ................................................................................................. 60

Troubleshooting Guide ................................................................................................... 61

Procedures .................................................................................................................. 67

Brine Pump Replacement ............................................................................................ 67

Removing The Old Brine Pump .................................................................................. 67

Installing the New Brine Pump .................................................................................. 68

Rupture Disk Maintenance ........................................................................................... 68

Replacing the Rupture Disk Diaphragm ...................................................................... 68

Rupture Probe Maintenance ...................................................................................... 69

Acid Washing the Cell ................................................................................................. 69

Oxidant Demand Testing ............................................................................................. 70

Chlorine Production Testing ......................................................................................... 74

APPENDICES ................................................................................................................ 78

Appendix A - Water Quality Guidelines .......................................................................... 79

Appendix B – Salt Quality Guidelines ............................................................................ 81

P/N: 102-00076-G Page 4

MIOX RIO Series Operators Manual

ListofFigures

Figure 1 RIO Series On-Site Generator ............................................................................... 8

Figure 2 RIO Series OSG Space Requirements .................................................................... 9

Figure 3 RIO Series OSG Compartments .......................................................................... 15

Figure 4 Rear View of RIO OSG Showing Main Power Conduit .............................................. 16

Figure 5 Incoming Power ............................................................................................... 17

Figure 6 Switch Gear Cover ............................................................................................ 17

Figure 7 Power Routing to Switch Gear ............................................................................ 17

Figure 8 Rear Panel Connections ..................................................................................... 18

Figure 9 Tank Level Connector ........................................................................................ 19

Figure 10 Auxiliary Relay Connector ................................................................................ 20

Figure 11 Auxiliary 24V Power Connector ......................................................................... 21

Figure 12 Dilution Air Connector ..................................................................................... 22

Figure 13 H2/Hardness Connector .................................................................................... 23

Figure 14 Plumbing Enclosure ......................................................................................... 26

Figure 15 Feed Water, Brine, Y-strainer, and Oxidant Union Connections .............................. 27

Figure 16 Float Valve Assembly and Detail ........................................................................ 29

Figure 17 Internal View Float Valve Assembly and Detail .................................................... 30

Figure 18 Brine Pressure Boost System ............................................................................ 32

Figure 19 Oxidant Tank Vents ......................................................................................... 33

Figure 20 Oxidant Storage Tank with Safety Placards ......................................................... 34

Figure 21 Ventilation Requirements ................................................................................. 35

Figure 22 Level Switch Installation .................................................................................. 36

Figure 23 Pressure Transducer Assembly .......................................................................... 37

Figure 24 Cell Lead Connections...................................................................................... 40

Figure 25 Cell Lead and Buss Bar Connection .................................................................... 41

Figure 26 Cell Plumbing Connectons - 1 Module ................................................................ 42

Figure 27 Multiple Module Cell Inlet/Outlet Manifold ........................................................... 43

Figure 28 Cell Guard Pre-Assembly .................................................................................. 44

Figure 29 Location of Socket Head Shoulder Screws – Back ................................................ 45

Figure 30 Location of Socket Head Shoulder Screws - Front ................................................ 45

Figure 31 Display Screen, Run/Stop Switch, and Disconnect Switch ..................................... 48

Figure 32 Main Display Screen ........................................................................................ 49

Figure 33 Switch Gear Panel Components ......................................................................... 65

Figure 34 Interface Board .............................................................................................. 66

Figure 35 Rupture Disk Ruptured Diaphragm .................................................................... 69

Figure 36 Rupture Probe ................................................................................................ 69

P/N: 102-00076-G Page 5

MIOX RIO Series Operators Manual

ListofTables

Table 1 Tank Level Connector Name and Description.......................................................... 19

Table 2 Tank Level Status .............................................................................................. 19

Table 3 Auxiliary Relay Connector Name and Description .................................................... 20

Table 4 Auxiliary 24V Power Connector Name and Description ............................................. 21

Table 5 Dilution Air Connector Name and Description ......................................................... 22

Table 6 Hydrogen/Hardness Connector Name and Description ............................................. 23

Table 7 Ethernet Connector Pin-Out ................................................................................. 24

Table 8 Feed Water Requirements ................................................................................... 25

Table 9 Electrical Connections Per Cell Module .................................................................. 40

Table 10 LED Status Lights............................................................................................. 52

Table 11 Output Testing ................................................................................................ 52

Table 12 Fault Conditions ............................................................................................... 53

Table 13 Perimeter Bolt Torque Specifications ................................................................... 57

Table 14 Switch Gear Panel Components .......................................................................... 65

P/N: 102-00076-G Page 6

MIOX RIO Series Operators Manual

Introduction

This manual is designed to provide installation, operation, and maintenance guidelines to

the water plant operator. Proper maintenance of the system will increase cell life and

system performance. Follow all warnings and precautions when installing, operating, and

maintaining your On-Site Generator (OSG). Should advanced troubleshooting be required

to solve a problem, please contact your MIOX Customer Service provider for further

assistance.

Regulatory Compliance

U. S. Environmental Protection Agency (US EPA)

On-site oxidants are listed as a compliance technology for water disinfection. To be listed

as a compliance technology, the system must be cost effective and achieve compliance with

the regulated maximum contaminant levels (MCLs), and the operator must be capable of

reliably operating the technology. The on-site oxidant category was added to this list in

1997 primarily based on independent research of MIOX technology.

NSF International

MIOX maintains a policy of verification and compliance of MIOX technology for water

applications. The NSF Standard provides the criteria used to evaluate the public health

safety of materials, components, products, or systems that contact drinking water, drinking

water chemicals, or both. For details of specific NSF standards for specific MIOX equipment,

please consult with MIOX. NSF listings are also available through NSF International at (800)

NSF-Mark or their web site at www.nsf.org.

State Approvals

MIOX maintains a policy of obtaining state regulatory approval in all states where MIOX

equipment is installed and operated. MIOX has never been rejected for approval in any

state. For a complete of states currently approving on-site oxidant technology, please

contact MIOX

List of Certifications

EPA Registration Number: 69723-NM-001

P/N: 102-00076-G Page 7

MIOX RIO Series Operators Manual

Components of the System

The RIO Series OSG (Figure 1) must be installed by trained technicians. After installation

and system startup, the units operate automatically and self-diagnose.

Figure 1 RIO Series On-Site Generator

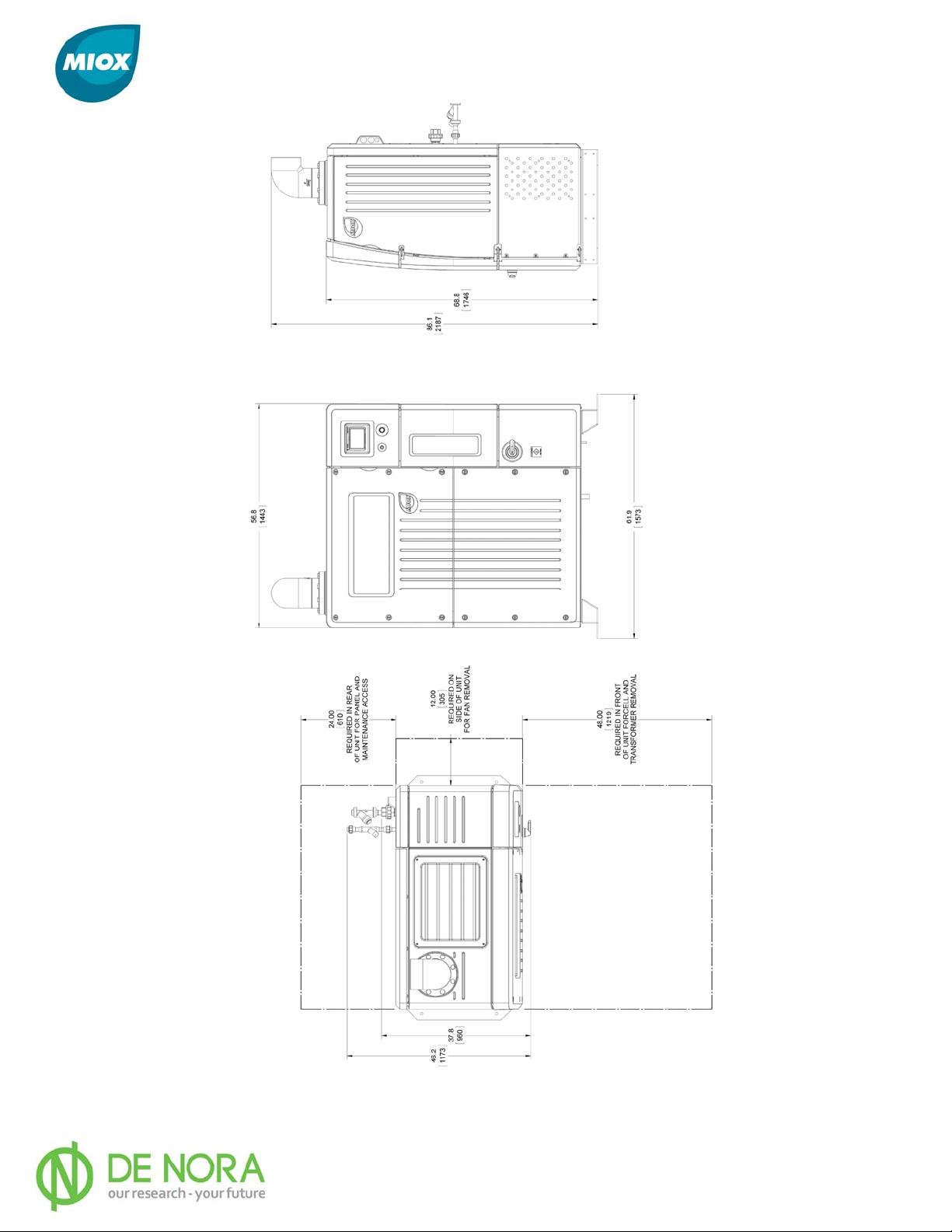

Space Requirements

Appropriate floor-space must be identified to accommodate the OSG enclosure and

sufficient working space clearance (Figure 1-2). The enclosure is 62 in. (1.6 m) wide by 38

in. (1.2 m) deep by 69 in. (1.75 m) high. Front clearance is 48 in. (1.2 m), rear clearance

is 24 in. (0.66 m), and side clearance is 12 in. (0.30 m) from the edge of the feet.

P/N: 102-00076-G Page 8

MIOX RIO Series Operators Manual

Figure 2 RIO Series OSG Space Requirements

P/N: 102-00076-G Page 9

MIOX RIO Series Operators Manual

Note: Additional floor space will be required for an oxidant storage tank, brine generator, water

softener, brine pressure boost system, and depending on the installation, salt storage. Additional

floor space will also be required for the injection system and additional booster pumps

Security

MIOX equipment must be installed in a building or protected structure that provide shelter

from the weather and extreme temperature variances, and which can be locked or

otherwise secured. Physical security is required to ensure that unauthorized persons

cannot access the unit

RIO Series OSG System and Ancillary Components

Electrolytic Cell

The proprietary membrane-less electrolytic cell produces a mixture of oxidants and is

manufactured by MIOX. The RIO Series cell is configured to provide modular cell capacity

depending on the disinfectant requirement. Each MIOX cell module is configured to provide

60 lb/day Free Available Chlorine (FAC), while each HYPO cell module is rated to provide

100 lb/day FAC. Each cell can be configured from a single cell module (60 or 100 lb/day

FAC) up to a 5-module (300 or 500 lb/day FAC) cell.

The electrolytic reaction that takes place within the cell occurs under pressure (5-25 psi, 34172 kPa). The cell is equipped with a rupture disc (pressure relief port) that is designed to

rupture in the event of over-pressurization within the cell.

Water Softener

All MIOX equipment requires soft water. Hard water will cause severe damage to the cell.

Water hardness must be maintained at less than one grain/gallon (17.1 mg/L of CaCo

). The softener resin is recharged with brine from the brine generator. The correct sized

recharge meter disc is determined by water hardness.

Brine Generator

The capacity of brine generators ranges from 500 lb., manually loaded systems, to 160,000

lb. systems, pneumatically loaded from a transport truck. A mechanical float valve assembly

which monitors the brine level is included with the brine generator.

Oxidant Storage Tank

The oxidant storage tank is an integral part of an on-site generator, and is sized to meet the

injection demand at the peak hourly flow. The oxidant tank must be vented directly to the

atmosphere outside the facility.

3

Brine Pressure Boost System

A brine pressure boost system insures that sufficient brine pressure is supplied to the brine

metering pump to maintain optimal cell operation amperage. A separate electrical circuit is

required for the brine boost system.

P/N: 102-00076-G Page 10

MIOX RIO Series Operators Manual

Tubing and Fittings

All tubing and fittings shipped by MIOX meet Schedule 80 specifications. The U.S.

specifications ensure that materials are rated for proper thickness, pressure requirements,

and temperature resistance for the specific application.

RIO Series OSG System Optional Equipment

Heater or Chiller

If the OSG feed water temperature is less than 40°F (5°C) or greater than 95°F (35°C),

damage to the electrolytic cell will occur. A water heater or chiller is recommended to bring

the water temperature into range.

Oxidant Solution Injection System

MIOX can supply injection systems to dose raw water with disinfectant. These systems

come with separate installation and operation instructions.

Water Pressure Boost System

A water pressure boost system can be included to insure minimum water pressure for OSG

operation and support of water softener regeneration. A separate electrical circuit is

required for the water pressure boost system.

P/N: 102-00076-G Page 11

MIOX RIO Series Operators Manual

Installation

Your RIO Series OSG has been factory tested and must be properly installed by technicians

trained by MIOX or its representatives. This chapter describes the procedures for unpacking and

installing the RIO OSG and auxiliary equipment, including all requirements for plumbing and

electrical tie-ins. Specifications and conditions regarding electrical power to the unit, water

quality, water line pressure requirements, and other requirements for installation of your OSG

are discussed.

SAFETY PRECAUTIONS AND WARNINGS

Ensure that the facility and the installation are in conformance with all codes and

standards. Please refer to the MIOX Hydrogen White Paper or your local authority having

jurisdiction for more information. Untrained persons should not attempt to install or

operate MIOX OSGs.

A liquid barrier system is mandatory. Ensure that all hydrogen vent lines slope

towards the oxidant tank.

Ensure that no valves, drop legs, or P-traps are in the hydrogen vent lines. Do NOT cross connect

vent lines.

Ensure that storage tanks are labeled properly.

Disconnect power before working on units. Do not reconnect the power to the switch gear enclosure

until installation is complete.

Do not defeat or tamper with electrical interlocks or lockout mechanisms.

All MIOX units require a good earth ground. A neutral is not a substitute for a proper earth

ground. Electrical wiring to all MIOX units should be performed by a certified electrician.

The circuit feeding the MIOX OSG should be separated from other power devices.

Failure to install unit properly could result in electrical shock.

P/N: 102-00076-G Page 12

MIOX RIO Series Operators Manual

Recommended Tools for Installation: RIO Series OSG

Mechanical Tools

• Forklift, pallet jack, or crane - unload and place equipment

• Hammer - remove crating

• Pry bar - remove crating

• 2-¾” end wrenches or equivalent - connect cell

• Channel locks or equivalent slip joint pliers - tighten plumbing connections

• Phillips screw driver - make main electrical connections

• Small flat screwdriver - connect control relay wiring

• Wire strippers

• Allen wrench set

• Tape measure

Plumbing Tools

• PVC pipe cutter or saw

• PVC pipe reamer - remove burrs from cut pipe

• Glue - use correct type for pipe material

• Primer/cleaner - use correct type for pipe material

• Teflon Ta p e

• Strap wrench

• 12” pipe wrench

Untrained Persons should not attempt to install of operate MIOX equipment.

P/N: 102-00076-G Page 13

MIOX RIO Series Operators Manual

Receiving and Unpacking the RIO Series OSG

Your RIO Series OSG has been carefully packed to avoid shipping and handling damage. The

OSG enclosures are shipped in crated pallets. Brine generator tanks, oxidant tanks, water

softeners, and other ancillary equipment are also shipped on pallets. To safely unpack your OSG,

complete the following steps:

1. Unpack the OSG enclosure - Remove the crate from around the enclosure.

Check the enclosure for any damage that may have occurred during shipping.

2. Unpack Installation Kits - Remove the contents from the brine generator and

oxidant storage tanks. These items include the OSG installation kit, the solution

tank level switch, the softener installation kit, and the solution tank drop tube.

3. Unpa ck the water softener - Remove the water softener towers from their

packaging. Do not turn the softeners over or lay them on their sides as this will

disturb the softening resin and gravel beds inside the softener and affect softener

performance.

4. Unpack all other equipment - Remove any optional components (heaters,

chillers, injection systems, etc.) from their packaging and inspect for damage.

After completing a visual inspection, compare ordered items against what was delivered. Should

you find anything damaged or missing, please contact your MIOX sales agent or MIOX Customer

Service.

Securing the Cabinet

The RIO Series OSG is designed with mounting feet and holes for securing the enclosure to the

floor. While there are no vibrational components that would cause the system to move, good

seismic design practice and building codes in some areas require that the unit be secured to the

floor. Concrete anchors or other suitable hardware is recommended to secure the RIO OSG to

the floor. Consult local seismic codes for site-specific requirements.

P/N: 102-00076-G Page 14

MIOX RIO Series Operators Manual

System Description

The RIO Series OSG is made up of six compartments, Controls, Switch Gear, Power Supply,

Cooling, Plumbing, and Cell (Figure 3).

Cell

Controls

Plumbing

Power Supply

Switch Gear

Figure 3 RIO Series OSG Compartments

P/N: 102-00076-G Page 15

Cooling

MIOX RIO Series Operators Manual

Electric Connections Required for Start-Up

Normal precautions should be taken with regard to electrical components in the

vicinity of a water source.

Electrical Power Connection

The power cable to the OSG is run through the cooling compartment into the switch gear

compartment. The power cable enters the enclosure through the back of the cooling

compartment into conduit (Figure 4 & 5). Remove the switch gear cover by loosening the

screws in each corner (Figure 6) and pull the cable into the switch gear compartment. Route

the power cable to the top of the switch gear and wire the switch gear (Figure 7). Replace

the switch gear cover. Do not Apply power to the system until installation is complete

Conduit

Figure 4 Rear View of RIO OSG Showing Main Power Conduit

P/N: 102-00076-G Page 16

MIOX RIO Series Operators Manual

System Power

Ratings

Power In

4x Screws

Figure 5 Incoming Power Figure 6 Switch Gear Cover

Figure 7 Power Routing to Switch Gear

P/N: 102-00076-G Page 17

MIOX RIO Series Operators Manual

Control System/Rear Panel Connections

The RIO Series OSG features an Allen Bradley Micrologix 1400 PLC to maintain consistent cell

control. The operator interface is an Allen Bradley Panelview Plus 600 Touch screen display.

Connection to site SCADA systems is done directly from OSG controls using the RJ45 cable.

As an optional adder, a Red Lion CSMSTRSX Modular Controller can be used as a protocol

converter which can be configured to match plant communications. The interface can be

configured to support e-mail and SMS notification if the system shuts down for a fault that

requires operator attention.

In addition to providing internal control of the OSG, the RIO Series control system provides

connectivity to various external inputs and outputs (Figure 8).

A Modbus/Ethernet IP is built in PLC as a standard. For other communication options

available, contact MIOX.

Figure 8 Rear Panel Connections

P/N: 102-00076-G Page 18

MIOX RIO Series Operators Manual

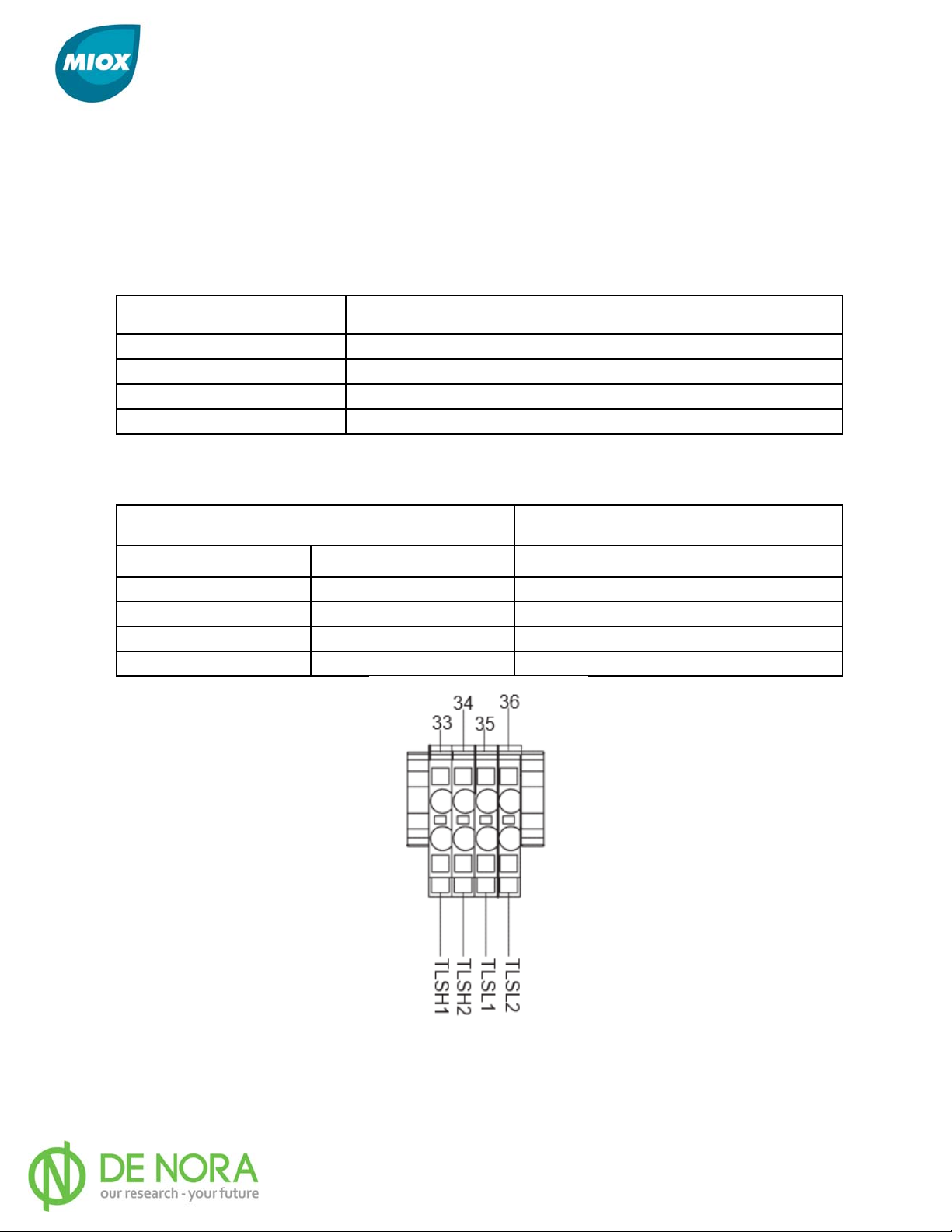

Tank Level Inputs

The tank level connector provides field connection points for external floats, the dry contact

outputs on a tank level controller, or the dry contact outputs of a plant PLC or other control

device. Tables 1 and 2 provide descriptions for each terminal.

Table 1 Tank Level Connector Name and Description

Connection Name

TLSL1 Lower tank level input 24VDC-CLOSED 0VDC-OPEN

TLSL2 +24VDC source of lower tank level input

TLSH1 Upper tank level input 24VDC-CLOSED 0VDC-OPEN

TLSH2 +24VDC source of upper tank level input

Table 2 Tank Level Status

INPUT STA

Lower Level Input

Closed Closed Tank is empty - Turn ON

Open Open Tank is full - Turn OFF

Open Closed Stand-by - Stays Off or ON

Closed Open Fault Condition - Turn OFF

TES

Upper Level Input

Signal

Description

SYSTEM

System Action

Figure 9 Tank Level Connector

P/N: 102-00076-G Page 19

MIOX RIO Series Operators Manual

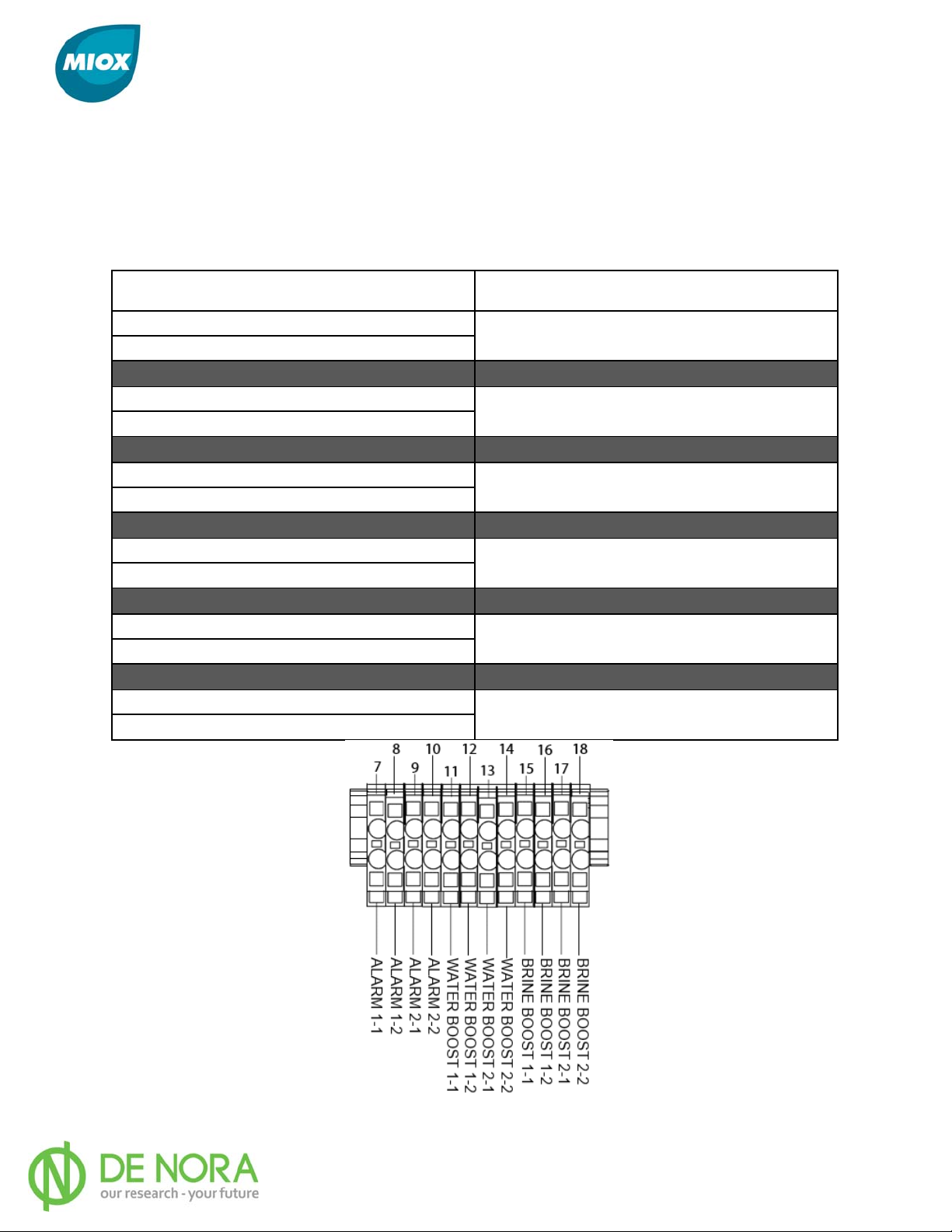

Auxiliary Relay Connection

The auxiliary relay connector provides field connection points for three auxiliary relays,

alarm, brine boost, and water boost. Each relay has two sets of normally open contacts. The

contacts are rated for 277 VAC at 30 Amps or 28VDC at 20 Amps. Table 3 provides the

description for each connection.

Table 3 Auxiliary Relay Connector Name and Description

Connection Name

Alarm 1-1

Alarm 1-2

Alarm 2-1

Alarm 2-2

Water Boost 1-1

Water Boost 1-2

Water Boost 2-1

Water Boost 2-2

Brine Boost 1-2

Brine Boost 2-2

Brine Boost 1-2

Brine Boost 2-2

Description

Contacts close when system shuts down

for a hard fault

Contacts close when system shuts down

for a hard fault

Contacts close when system starts up

(running)

Contacts close when system starts up

(running)

Contacts close when system starts up

(running)

Contacts close when system starts up

(running)

Figure 10 Auxiliary Relay Connector

P/N: 102-00076-G Page 20

MIOX RIO Series Operators Manual

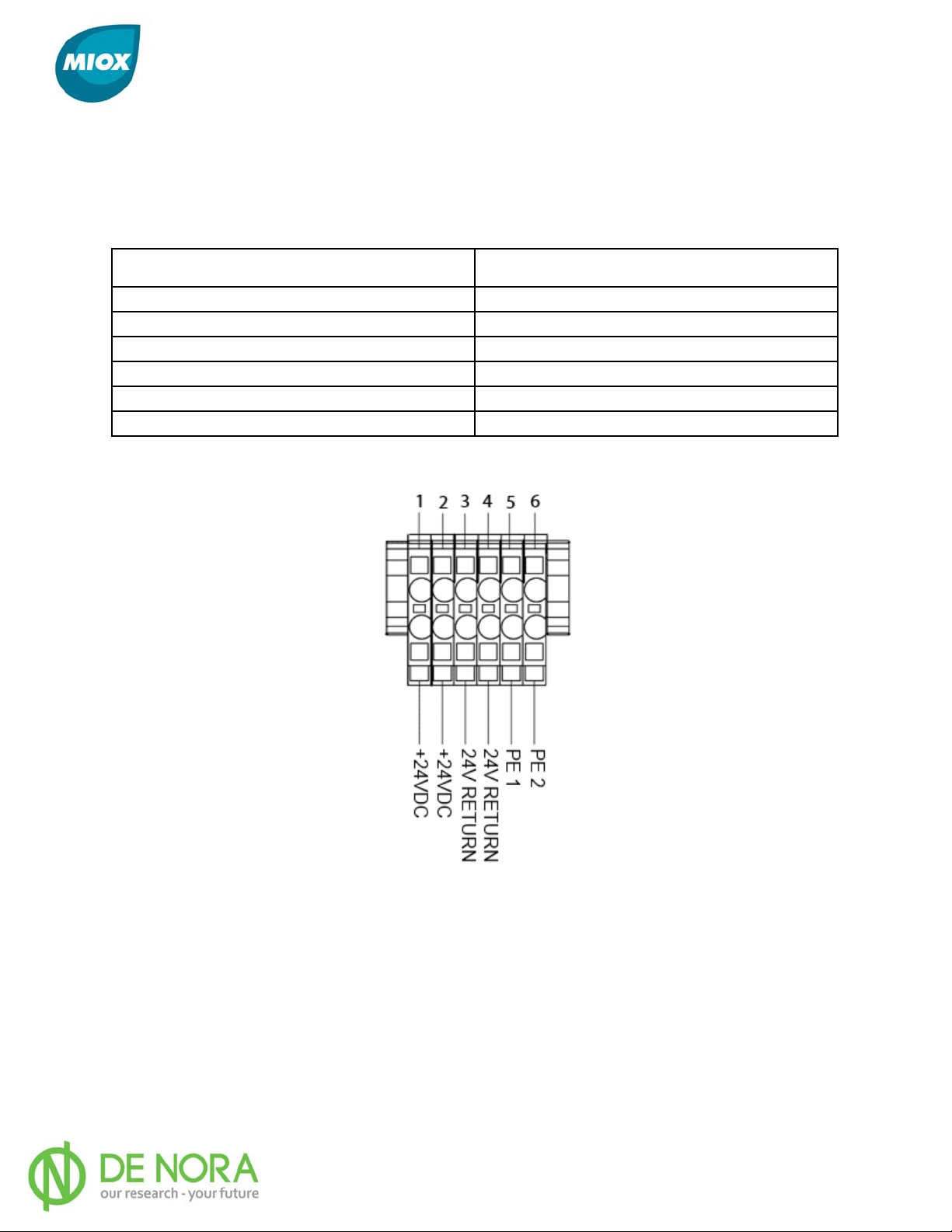

Auxiliary 24V Power Connection

The auxiliary power connector provides field connection points to provide 24V power to the

auxiliary relays. Current is limited to 1 AMP and is fused internally. Table 4 provides the

description for each terminal

Table 4 Auxiliary 24V Power Connector Name and Description

Connection Name

Description

+24VDC +24 volts DC power

+24VDC +24 volts DC power

24V Return Return connection for 24VDC power

24V Return Return connection for 24VDC power

PE1 Physical Earth connection

PE2 Physical Earth connection

Figure 11 Auxiliary 24V Power Connector

P/N: 102-00076-G Page 21

MIOX RIO Series Operators Manual

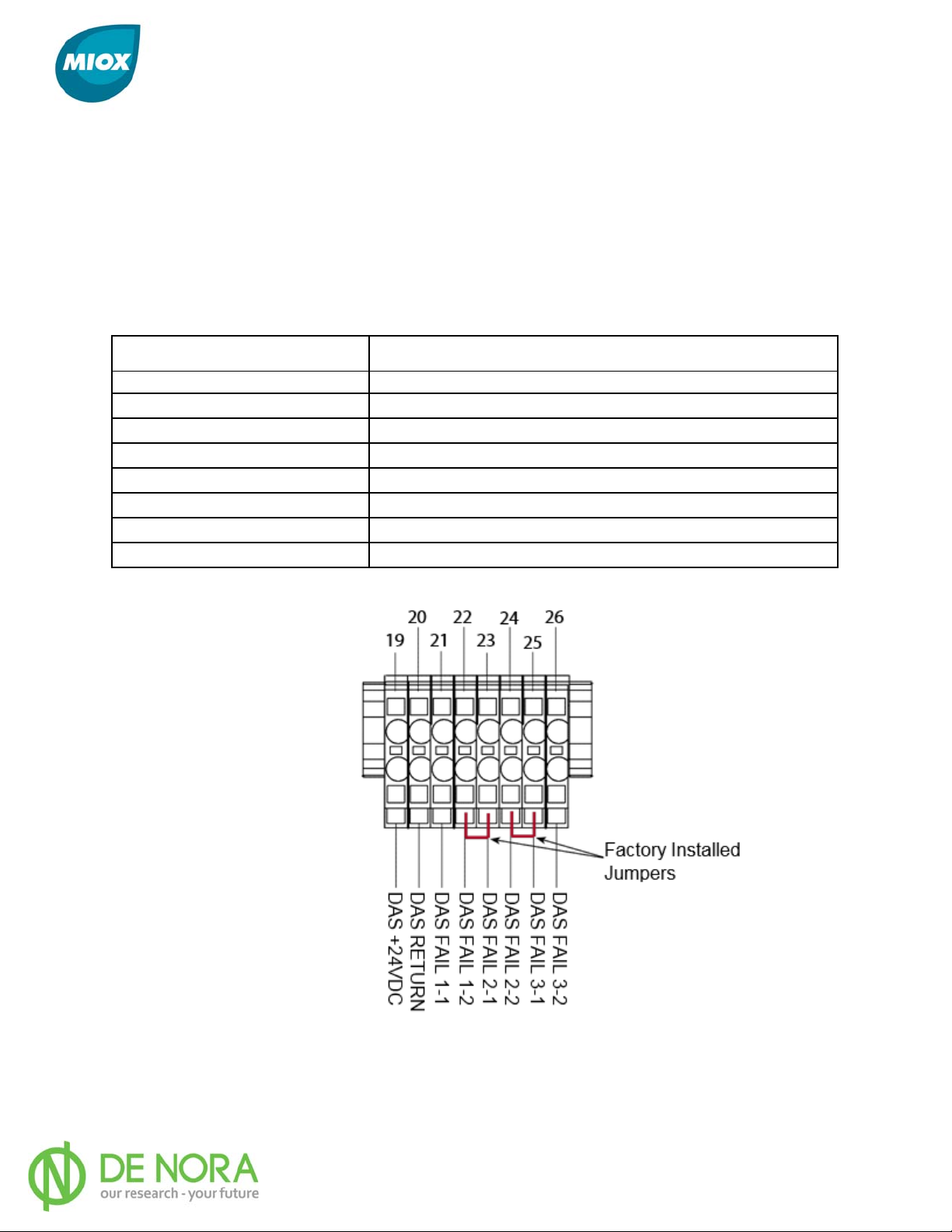

Dilution Air Connection

The dilution air connector provides field connection points for an auxiliary dilution air system

and/ or associated external dilution air system sensors. The connections supported include a

MIOX external dilution air enable, MIOX external dilution air system failure input, and two

other failure inputs. The failure inputs can be connected to either external differential

pressure switches or an external flow switch with dry contacts. Pins 19 and 20 (Figure 12)

should be wired to the Dilution Air Panel Relay to turn on the auxiliary panel. Table 5

provides the description for each terminal.

Table 5 Dilution Air Connector Name and Description

Connection Name

DAE +24 VDC

DAE Return Return for enable

DAS Fail 1-1 Failure Input 1; 24VDC OK - 0 VDC FAIL

DAS Fail 1-2 +24VDC source of Failure Input 1

DAS Fail 2-1 Failure Input 2; 24VDC OK - 0 VDC FAIL

DAS Fail 2-2 +24VDC source of Failure Input 2

DAS Fail 3-1 Failure Input 3; 24VDC OK - 0 VDC FAIL

DAS Fail 3-2 +24VDC source of Failure Input 3

+24VDC enable signal for MIOX external dilution air

Description

system

Figure 12 Dilution Air Connector

P/N: 102-00076-G Page 22

MIOX RIO Series Operators Manual

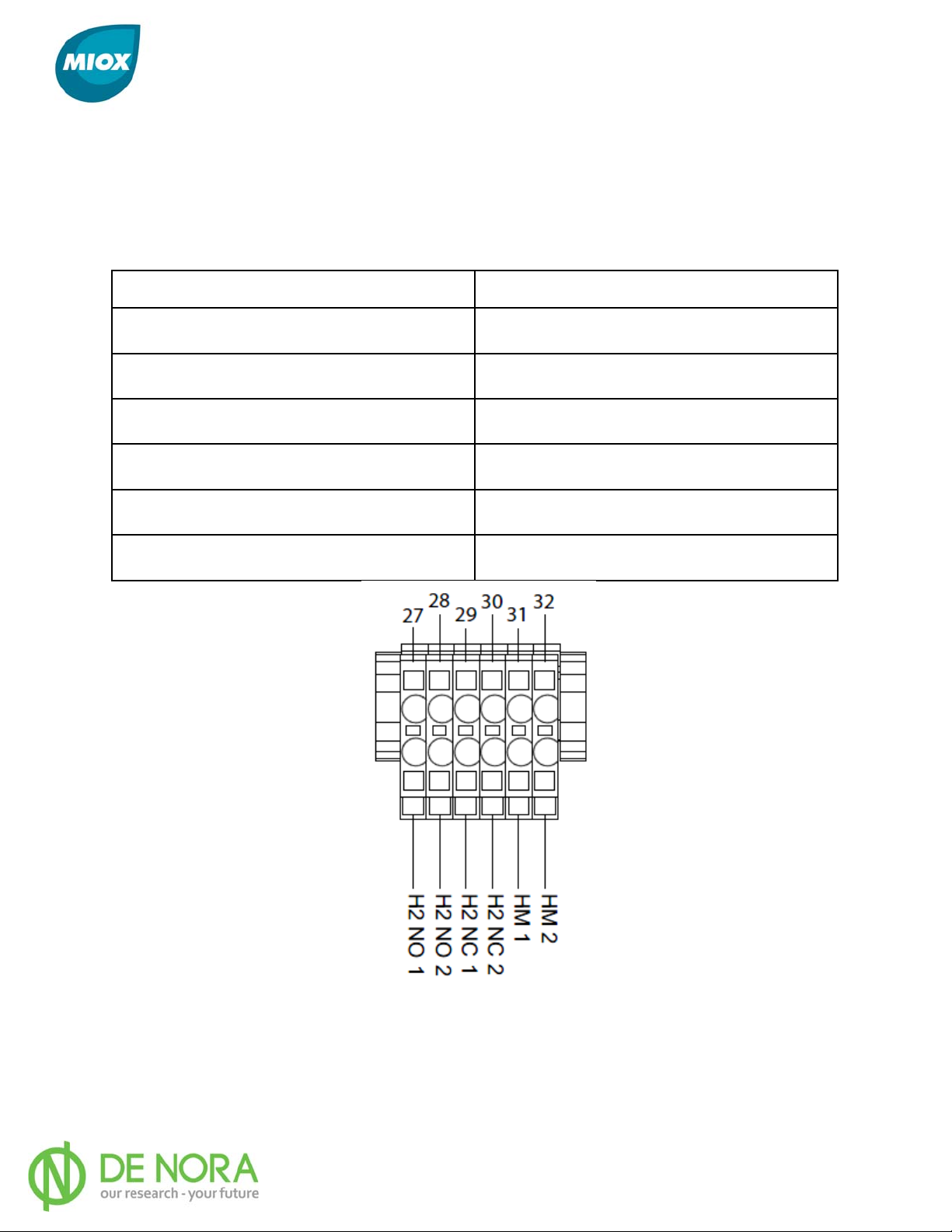

Hydrogen/Hardness Connections

The Hydrogen/Hardness connector provides field connection points for an external hydrogen

monitor and/or an external hardness monitor. The hydrogen monitor inputs require both

normally closed and normally open dry contacts. The hardness monitor input only requires

normally closed dry contacts. Table 6 provides the description for each terminal.

Table 6 Hydrogen/Hardness Connector Name and Description

Connection Name

H2NO1

H2NO2

H2NC1

H2NC2

HM1

HM2

Description

Normally open input; OPEN = OK,

CLOSED =

Normally open input; OPEN = OK,

CLOSED =

Normally closed input; CLOSED = OK,

OPEN

Normally closed input; CLOSED = OK,

OPEN

Hardness monitor input; 24VDC = OK,

+24VDC source of hardness monitor input

FAIL (Safety Relay)

FAIL (Safety Relay)

=

FAIL (Safety Relay)

=

FAIL (Safety Relay)

0 VDC =

FAIL

Figure 13 H2/Hardness Connector

P/N: 102-00076-G Page 23

MIOX RIO Series Operators Manual

Ethernet Connection

The Ethernet connector provides connection to site SCADA systems. Table 7 provides the

pin-out for the connector.

Table 7 Ethernet Connector Pin-Out

Pin

Pin Name

1

2

3 Rx+

4 not used

5 not used

6 Rx-

7 not used

8 not used

Tx+

Tx-

P/N: 102-00076-G Page 24

Loading...

Loading...