Page 1

Parts and Instruction Manual

TRS 14

Total Recovery System

Page 2

This manual is furnished with each new MINUTEMAN TRS 14 . This provides the necessary operating

and preventive maintenance instructions. Operators must read and understand this manual before operating or servicing this machine.

This machine was designed to give you excellent performance and efficiency. For best results and

minimal cost, please follow the general guidelines below:

· Operate the machine with reasonable care.

· Follow the manufacturers suggested maintenance instructions as provided in this booklet.

· Use original Minuteman supplied parts.

TECHNICAL SPECIFICATIONS

Model TRS 14

Model No.

Vac Motor

W ater Lift

Capacity

Flow

Wheels

Casters

Length

Width

Height

TRS14115

3 Stage 1 HP

80” (203cm)

14 gal. (53L)

250psi at nozzle, 1gpm

12” (30.5cm)

5” (13cm)

32” (81cm)

43” (109cm)

25” (63.5cm)

Page 3

Safety Precautions.......................................................................................................1

Grounding Instructions ...............................................................................................1

Safety Labels................................................................................................................ 2

Machine Components.................................................................................................. 2

Tools & Accessories .................................................................................................... 5

Machine Set Up ............................................................................................................ 6

Pre-Operation............................................................................................................6

Set Up .......................................................................................................................6

Operation...................................................................................................................6

Priming ......................................................................................................................6

Draining Recovery Tank .............................................................................................. 7

Machine Maintenance ..................................................................................................7

Daily Maintenance.....................................................................................................7

Weekly Maintenance .................................................................................................7

Storing Machine ........................................................................................................... 8

Troubleshooting ........................................................................................................... 8

Exploded Views..........................................................................................................10

TRS 14 - Base Assembly ........................................................................................10

TRS 14 - Solution Tank Assembly ........................................................................... 11

TRS 14 - Recovery Tank Assembly.........................................................................12

TRS 14 - Bill of Material ..........................................................................................13

Minuteman International Made Simple Commercial Limited Warranty................. 14

Contents

Page 4

Safety Precautions

This machine is intended for commercial use. Use only

recommended cleaning solutions and

accessory tools.

All operators must read, understand and practice the

following safety precautions.

The following safety alerts symbols are used

throughout this manual as indicated in their

description:

WARNING: To warn of hazards or unsafe

practices which could result in severe personal

injury or death.

FOR SAFETY: To identify actions which must be

followed for safe operation of equipment.

The following information signal potentially

dangerous conditions to the operator or equipment:

FOR SAFETY:

1. Do not operate machine:

2. Before operating machine:

3. When using machine:

-Unless trained and authorized.

-Unless operator manual has been read

and understood.

-In flammable or explosive areas.

-Unless cord is properly grounded.

-With damaged cord or plug.

-If not in proper operating condition.

-In outdoor areas.

-In standing water.

-With the use of an extension cord.

-Make sure all safety devices are in

place and operate properly.

-Do not run machine over cord.

-Do not pull machine by plug or cord.

-Do not pull cord around sharp edges or

corners

-Do not unplug by pulling on cord.

-Do not stretch cord.

-Do not handle plug with wet hands.

-Keep cord away from heated surfaces.

-Report machine damage or faulty

operation immediately to your

distributor.

-Follow mixing and handling

instructions on chemical containers.

4. Before leaving or servicing machine:

-Turn off machine.

-Unplug cord from wall outlet.

5. When servicing machine:

-Unplug cord from wall outlet.

-Avoid moving parts.

-Do not wear loose jackets, shirts, or

sleeves.

-Use manufacturer supplied or

approved replacement parts.

WARNING: Hazardous Voltage. Shock or

electrocution can result. Always unplug machine

before servicing.

WARNING: Flammable materials can

cause an explosion or fire. Do not use flammable

materials in tank(s).

WARNING: Flammable materials or

reactive metals can cause an explosion or fire.

Grounding Instructions

Machine must be grounded. This

machine is equipped with a cord having an

equipment-grounding conductor and grounding

plug. The plug must be plugged into an

appropriate outlet that is properly installed in

accordance with all local code and ordinances.

Do not remove ground pin; if missing, replace

plug before use.

Parts an d Instruction Manual

Page 1

Page 5

Safety Labels

The safety labels appear on the machine in various locations. Replace labels if they become damaged

or cannot be read.

WARNING: Flammable materials can cause an explosion or fire. Do not use flammable

materials in tank(s). Flammable materials or reactive metals can cause

explosion or fire.

WARNING LABEL- Located on back. Label warns operator of safe practices of equipment

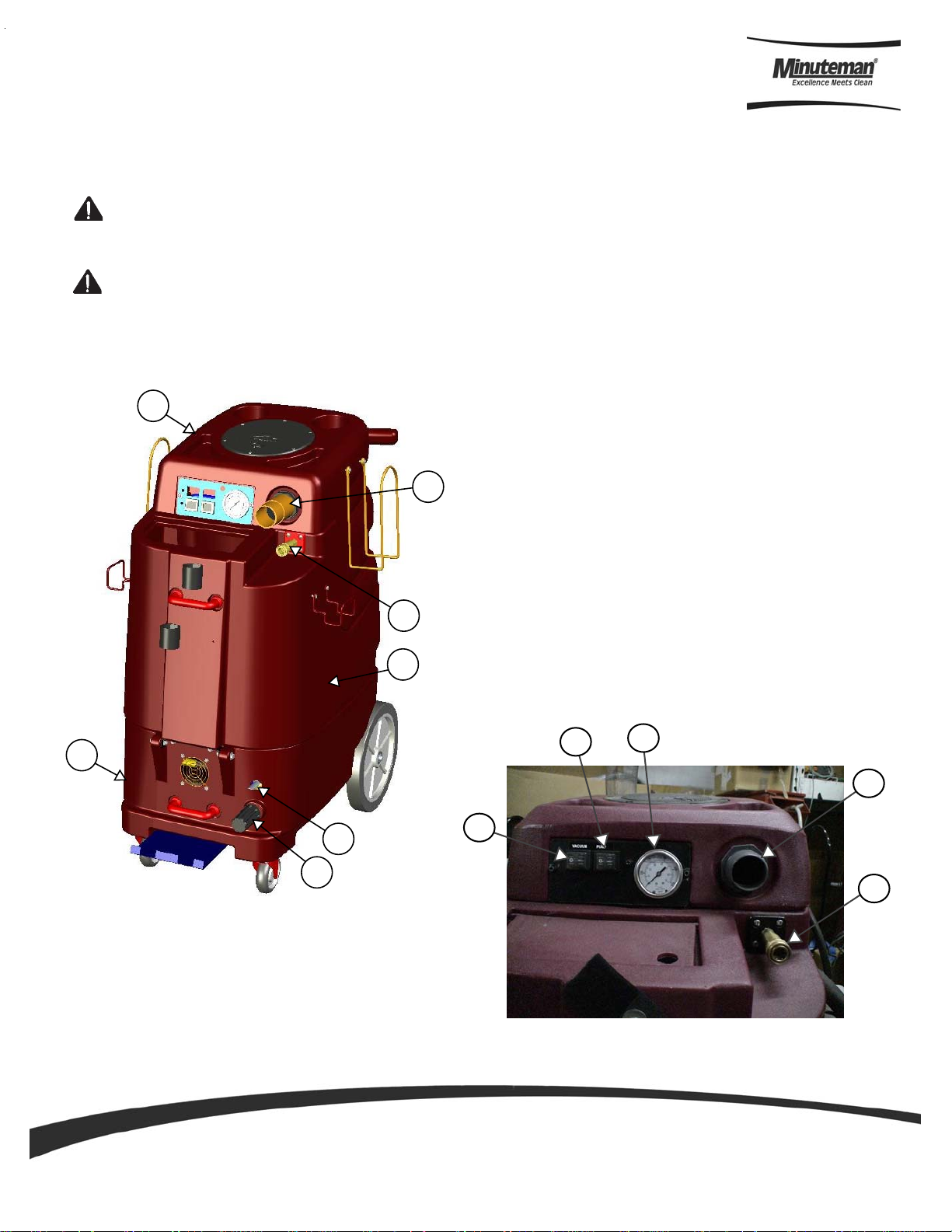

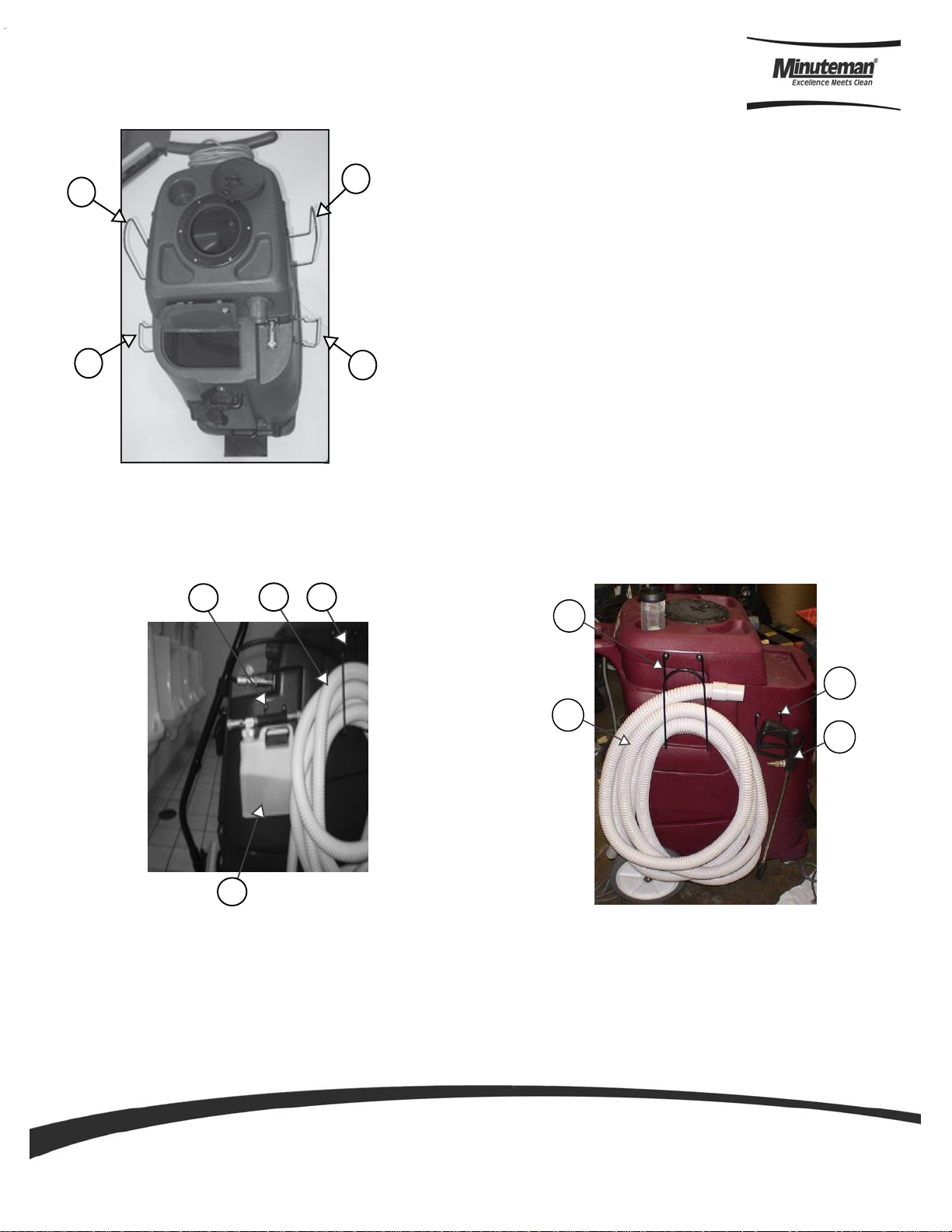

Machine Components

A

A RECOVERY TANK

B

C

D

B VACUUM HOSE CONNECTOR

C SOLUTION HOSE CONNECTOR

D SOLUTION T ANK

E MOTOR HOUSING/BASE

F PRIME VALVE

G PRESSURE REGULATOR

H PESSURE GAUGE

I PUMP SWITCH

J VACUUM SWITCH

E

Parts an d Instruction Manual

G

I

F

J

H

B

C

Page 2

Page 6

Machine Components

A

C

The unit is equipped

with 4 wire brackets

two small and two large

B

A RIGHT HAND LARGE BRACKET

B LEFT HAND LARGE BRACKET

C RIGHT HAND SMALL BRACKET

D LEFT HAND SMALL BRACKET

E RECOVERY HOSE

F CHEMICAL PROPORTIONING TANK

G BLOWER HOSE

D

H PRESSURE GUN

D

E

B

F

Left hand side large

bracket will hold the

recovery hose. Small

bracket holds chemical

proportioning tank.

A

C

G

H

Right hand side large

bracket will hold the blower

hose. Right hand side small

bracket will hold the

pressure gun.

Parts an d Instruction Manual

Page 3

Page 7

Blower Attachment

Dryer assembly

The TRS 14 comes with a blower attachment.

This attachment hooks to the blower hose and

is designed to be used as a dryer. This works

by utilizing the vacuum motor exhaust at the rear

of the machine.

Blower Hose

Vacuum Motor Exhaust

Clam Shell Design

Disconnect the two latches in the back of the unit

and rotate the top half of the machine forward

then disconnect the vac hose. This will allow

access to all motors and electronics. This

machine is very easy to service.

Parts an d Instruction Manual

Page 4

Page 8

Tools & Accessories

121092 - TRS 14 Tool Assembly Complete

121089 - 1-1/2” Curved Telescopic Wand

121086 - 1-1/2” Gulper Tool

121090 - Scrub & Vac Tool

121091 - 1-1/2” Vac Hose Assy 25 FT.

121082 - Faucet Fill Hose Assy

121101 - Blower Attachment

121097 - Slimline Injection Sprayer

Parts an d Instruction Manual

Page 5

Page 9

Machine Set Up

Pre-Operation

1. Vacuum and remove all debris.

2. Perform MACHINE SETUP procedures.

3. Inspect power cord for damage.

Set Up

1. Carefully check carton for signs of damage.

Report damage at once to freight carrier.

The machine is shipped fully assembled

and is ready for use.

2. Open lid of solution tank. Fill solution tank

with water or approved cleaning agent.

WARNING: Flammable materials can

cause an explosion or fire. Do not use flammable

solutions or materials in tank(s).

FOR SAFETY: When using machine, follow

mixing and handling instructions on chemical

containers.

Operation

1. Turn pump switch to “Hi Pressure” setting.

2. Step lightly on Power Prime for 30 seconds to prime

pump completely. Use regulator adjustment to set pump

at desired pressure on gauge.

3. Hook up your auto fill and pump out hoses to the

appropriate connections on the back of the machine.

4. Switch on Pump-Out pump. NOTE: Pump will not begin

to operate until tank is partially filled. The pump out is

controlled by a sensor in the tank. MAKE SURE YOUR

PUMP OUT HOSE IS SECURED TO A DRAIN.

5. Attach Auto Fill hose to a water inlet, such as a sink or a

garden hose. Turn on the water at medium to medium

low pressure. Monitor solution tank as it fills for the first

time, to ensure that the Auto Fill shuts off correctly.

ATTENTION: If using powdered cleaning

chemicals, mix prior to adding.

3. Attach solution hose. (Located front of

machine.)

NOTE: Make sure the quick

disconnects snap together firmly. As

you do this, always inspect hoses for

cracks or fraying. Do not use if hoses

are damaged.

4. Attach other end of solution hose to wand.

5. Attach vacuum hose to recovery tank.

6. Locate a 20 Amp dedicated power circuit, and

plug the machine cord in. The outlets must

be properly grounded. Plugging into an

ungrounded or improper outlet can result in

equipment damage, fire, and/or harm to the

operator. NEVER DISABLE THE

GROUND PIN, AS SERIOUS PROBLEMS CAN

RESULT!

6. Switch on both Vacuum 1 and Vacuum 2

7. Begin cleaning. As you clean, monitor your tank levels.

The clean water tank should never be run empty, and the

dirty water tank should never be run full.

Priming

To prime the TRS simply connect all the solution hoses

i.e. chemical metering, spray gun. Then turn on the pump

switch and push down on the priming lever. At this point

the TRS will reach its operating pressure.

FOR SAFETY: Do not operate machine unless

cord is properly grounded.

FOR SAFETY: Do not operate machine with

the use of an extension cord.

Parts an d Instruction Manual

Page 6

Page 10

WARNING: Flammable materials or

reactive metals can cause an explosion or fire.

Do not pick up.

1. Work away from outlet and power cord to

prevent cord damage.

2. Use a recommended foam control solution in

the recovery tank to prevent vacuum motor

damage. Periodically check for excessive foam

buildup in solution tank.

3. To clean heavily soiled areas, repeat cleaning

path from different direction.

4. When ball float shuts off vacuum, it is time to

empty the dirty water from the recovery tank,

and refill solution tank.

NOTE: When cleaning upholstery, always

check cleaning instructions sewn in furniture

by manufacturer

5. After cleaning, relieve water pressure from tool

before disconnecting hose. Squeeze trigger for

five seconds after turning main power switch off.

Draining Recovery Tank

FOR SAFETY: When servicing

machine, unplug cord from wall outlet.

1. Turn machine off and unplug power

cord.

2. Remove solution & vacuum hose

3. Lift up drain valve lever to empty

solution tank.

Machine Maintenance

To keep machine in good working condition, simply

follow machine’s daily and weekly maintenance

procedures.

FOR SAFETY: When servicing machine, unplug

cord from wall outlet.

Parts-Washing Solutions:

Water-Based (Aqueous) Biodegradable Solutions—

These alkaline solutions wash away both organic soils

(including grease, oil, and soft carbon) and inorganic soils

(such as epoxy , hard-water residue, corrosion, oxides, paint,

plating salts, and rust). For faster cleaning action, heat

cleaners up to 140° F. Rinse with water. Dilute general

purpose formula with four to nine parts of water . Nonferrous

metals formula is formulated for aluminum and other

nonferrous metals. Mix three to eight ounces of this powder

per gallon of water.

Maintenance

DAILY:

1. Empty and rinse out recovery tank thoroughly.

2. Wipe off power cord and check for damage, replace if

necessary. Coil cord neatly after use.

3. Clean machine with an all purpose cleaner and damp

cloth.

Weekly Maintenance

(EVERY 20 HOURS OF OPERATION)

1. Flush solution system with a system maintainer to

dissolve normal chemical buildup.

a. Pour 7.5L (2 gal) of hot water 60°C (140°F)

into solution tank. Add system maintainer

according to mixing instructions on bottle

FOR SAFETY: When using machine,

follow mixing and handling instructions on

chemical containers.

b. Operate machine for one minute.

c. Shut off machine and allow

remaining solution to break down

chemical buildup overnight.

d. Next day, spray out remaining

solution and flush system with

11L (3gal) of clean water.

2. Inspect vacuum hoses for holes and loose cuffs.

3. Inspect spray pattern for clogging. If clogged,

remove spray tips and soak them in a

recommended liquid neutralizer for up to six

hours. To remove spray tip, twist spray tip body

counter-clockwise. Do not use pointed objects to

unplug tips, damage will occur.

4. Lubricate wheels with water resistant oil.

5. Inspect machine for water leaks and loose

hardware.

6. Remove float shut-off screen from recovery

tank and clean.

Parts an d Instruction Manual

Page 7

Page 11

Storing Machine

1. Before storing machine, be certain to completely drain

and

rinse tanks of all water and solution.

2. Drain and dry the vacuum hose as well, using the drain

hose provided

3. Store machine in a dry area in the upright position.

4. Open recovery tank cover to promote air circulation

Troubleshooting

SYMPTOM: UNIT WILL NOT TURN ON:

PROBLEM: Not plugged in.

SOLUTION: Plug machine in proper outlet.

PROBLEM: Circuit breaker has popped.

SOLUTION: Reset circuit breaker. Make sure no other items are running on the same circuit as

machine. Outlet must be a 15-amp circuit.

PROBLEM: Wire from power cord has become disconnected from terminal block.

SOLUTION: Reattach wire to terminal block.

SYMPTOM: PUMP IS NOT RUNNING PROPERLY:

PROBLEM: Quick disconnects are not completely locked together.

SOLUTION: Snap quick disconnects firmly together.

PROBLEM: The solution tank is empty.

SOLUTION: Fill the solution tank up with a premixed detergent.

PROBLEM: Jet on tool is clogged.

SOLUTION: Clean jet with soft wire brush or remove jet and flush clean.

PROBLEM: Filters are clogged.

SOLUTION: Remove filters and rinse clean with water.

PROBLEM: Brass check valve is stuck.

SOLUTION: Replace with new check valve.

PROBLEM: Pump wire has become disconnected.

SOLUTION: Reconnect wire.

PROBLEM: Switch on switch plate is bad.

SOLUTION: Replace switch.

PROBLEM: Pump motor brushes are worn out.

SOLUTION: Replace pump.

Parts an d Instruction Manual

Page 8

Page 12

SYMPTOM: VACUUM MOTOR IS NOT WORKING PROPERLY:

PROBLEM: Hose not connected tightly to upholstery tool or machine.

SOLUTION: Connect hose tightly.

PROBLEM: Drain valve is not shut completely.

SOLUTION: Close drain valve completely.

PROBLEM: Vacuum tank lid is not on tightly.

SOLUTION: Secure the vacuum tank tightly.

PROBLEM: Ball float is shut off.

SOLUTION: Empty the vacuum tank of all wastewater.

PROBLEM: Water is coming out of vacuum motor.

SOLUTION: Use a low foaming detergent.

PROBLEM: Floor wand is clogged with hair, carpet fibers and or debris.

SOLUTION: Clean floor wand.

PROBLEM: Ball float is not installed correctly.

SOLUTION: Make sure that ball float is firmly installed on the elbow.

Parts an d Instruction Manual

Page 9

Page 13

Exploded Views

TRS 14 - Base Assembly

Parts an d Instruction Manual

Page 10

Page 14

TRS 14 - Solution T ank Assembly

Parts an d Instruction Manual

Page 11

Page 15

TRS 14 - Recovery T ank Assembly

Parts an d Instruction Manual

Page 12

Page 16

TRS 14 - Bill of Material

Bill Of Material - TRS 14

1 12120 3 8 s c rew, #10 x 5/8" hex he ad, zi nc 50 12 1017 1 elbo w, brass , 90 de g, 1/ 2" barb x 3 / 8" m pt

2 12106 1 2 guard, c o oli ng fan, wire 51 12 1016 1 adap t er, b ras s, 1/2 " barb x 3/ 8" fs w, bal l end

3 12112 3 2 handle , breez e 52 12 1190 1 s ol hos e , 1/ 2" kuri 100 ps i

4 12118 2 12 bolt , 1/ 4-2 0 x 1/ 2" serrat ed h ex flan ge, zi nc 53 12 1104 1 filte r, c up, i n-lin e

5 12120 4 1 plat e, wan d m o unt 54 12 1212 1 s ol hos e , 1/ 2" kuri 100 ps i

6 12115 4 5 bolt , 1/ 4-20 x 1/ 2" h ex h ead, z i nc 55 12 1041 6 washer, bun a 1-1/ 8" o d x 3/ 16" i d

7 12117 5 12 bolt , 1/ 4-2 0 x 1" hex head, s/ s 56 12 1158 8 washer, 1/ 4" i d x 1 " od, flat, s/ s

8 12112 8 2 c ast er, 4" 57 12 1127 2 hang er, w ire for inject ion b ot t le

9 12115 7 20 washe r, 1/4 " flat , s / s 58 12 1161 2 nut , he x , 1/ 4-20 s/ s

10 12116 2 16 nut, lock, 1/4 -20, ny l on in s e rt 59 12 1160 4 washer, 1/ 4" l oc k, s / s

11 12116 7 4 was he r, axle, cut 1 / 2" id 60 12 1155 2 bolt , 1 / 4-20 x 1 -1/4 " h ex hea d

12 12105 9 2 wheel , 12 " 61 12 1004 1 qd, brass, 1/4" f

13 12111 6 1 ax l e, 1/ 2 " x 21 " , B reeze, M -s eri es 62 12101 0 2 adapt er, b rass, ex tend er, 1/4" m pt x 1/ 4" fpt, h ex

14 12105 2 2 c ap, ax l e, 1/2" 6 3 121122 1 plate , m o unti ng, Q D

15 12103 7 1 gas ket , i nle t , 1. 80" i . d. 64 12 1103 1 s ol hos e , 45 " x 1/ 4" , (OAL), m x m, for S ing le Jet wa nds

16 12105 6 1 fitt ing, i nle t , pvc, 1-1/ 2 ", g ray 65 12 1206 1 s ol ta nk , m s e ries

17 12116 9 8 nut, kep, #10-32 zinc 66 12 1012 1 filte r, s t raine r, 1/ 2"

18 12116 5 27 sc re w, 10-32 x 1/ 2 phi l pan 67 12 1173 2 washer, 11/ 16"id x 1-1/ 2" od x . 075, s/ s

19 12112 4 2 lat c h, front breeze 68 12 1019 1 bus h ing , bras s , 1 / 2" m p t x 3/ 8" fpt, hex

20 12103 1 1 power c ord , ex t , 50', 14/ 3 gry, UL 69 12102 0 1 nippl e, bras s, 3/ 8" x c l os e

21 12116 3 1 nut, l oc k, 1/ 2 " st ee l 70 12 1159 4 washer, 9/ 16"id x 1" od , flat , s / s

22 12105 3 1 fitt ing, st rain relief, c ord 71 12 1005 3 elbo w, brass , 90 de g, 1/ 4"m pt x 1/ 4 " fpt

23 12120 5 1 bas e, m seri es 72 121068 1 brac ket , front hing e, sp/ fb

24 12121 1 1 m anifold, sing le vac 73 12 1202 2 bol t, 1 / 4-20 x 1 -1/2 " hex hea d, s / s

25 12118 1 4 bolt , 1/ 4-20 x 3/ 4" serrat ed h ex flange, zinc 74 12 1129 2 velcro s t rap, k l een s afe

26 12111 7 1 plat e, s i ngl e m a nifold, 6. 5 " x 9" 75 12 1067 2 hang er, w ire form ed, hose

27 12119 2 1 vac hos e, 2" , wi re reinforc ed 76 12 1200 1 gas ket , 2 " i nle t polyet hy l ene , 3" O D 2. 35 " ID

28 12103 8 1 gas ket , vacuu m mot or 77 12 1137 1 adap t or, p vc 2, fm s l x fm t

29 12112 5 3 vac s uppo rt , 3 s t ag e, 4-1/ 16 " 78 121135 1 pipe , pvc, 2"

30 12102 1 1 vac m ot or, 3 st age, 1 15V , t a ngent i al 79 12 1077 1 elbo w, 2" float

31 12105 1 3 c la m p, h os e , 2-1/ 4 DIA 80 12106 9 1 float , 2" , ball s t y l e

32 12121 3 1 vac hos e, 2" , wi re reinforc ed 81 12 1207 1 vac tan k , m s eries

33 12121 4 1 pipe, pvc, 1-1/ 2" 82 12 1174 6 s crew, #8 x 5/ 8 phi l oval, s / s

34 12105 8 1 adapt er, pvc, 1- 1/ 2" fms x fmpt 83 12 1044 1 li d, vac t an k , bl ac k, 7"

35 12119 5 2 hos e, 3/ 8 " x 10 " , (OA L ), f x fsw , surge , 1600psi 84 12104 5 1 gas ket , 7 ", vac li d

36 12101 4 1 elbow , bra s s , 9 0 deg, 1 / 4" m pt x 1/ 4" m p t 85 12 1194 1 elbo w, inl et ass embly 2"

37 12119 9 2 elbow , bra s s , 9 0 deg, 3 / 8" m pt x 1/ 4" m pt 86 12 1054 1 valve, drai n, 1-1/ 2"

38 12111 0 1 pum p, 45 0 psi, 115V 87 12 1114 1 gas ket , 2 " i nle t

39 12101 8 2 elbow , bra s s , 9 0 deg, 3 / 8" m pt x 3/ 8" fmp t 88 12 1007 1 nipp le, b ras s , 1/ 4 " x c l os e

40 12100 9 2 adapt er, brass , 1/ 4" barb x 1 / 4" m p t 89 12 1138 2 inl et , 2"

41 12113 1 1 valve, prime , high p res sure 90 12 1121 1 c uff, 2 x 1 . 5" c rus h proof

42 12111 1 1 regulat o r, 45 0 psi 91 12 1119 2 B rac ket , L 0 70-036

43 12106 4 8 c la m p, h os e , 5/ 16-29 /32 92 12112 6 1 c uff, 2"

44 12121 5 1 s ol hos e, 1/ 4 " k uri 150psi 93 12 1102 1 s ol hos e , 1/ 4" x 39" , (OAL), f x fs w, 30 00p s i

45 12121 6 1 s ol hos e, 1/ 4 " k uri 150psi 94 12 1201 1 gaug e, pres sure, 2000 P SI

46 12119 7 2 adapt er, brass , 1/ 4" s w ba rb x 1/ 4" fpt , w/ gask e t 95 12 1028 2 s w it c h, roc ker, 2 posi ti on

47 12119 8 2 plug, bra s s , 3/ 8" mpt , he x 96 12 1176 2 s crew, #10-32 x 1/ 2" SHCS, all oy

48 12100 6 1 bus hi ng, brass , 3/ 8" mpt x 1 / 4" 9 7 121072 2 was her, #8 flat, s / s

49 12100 8 2 nippl e, brass , 1/ 4" m , h ex 98 12 1118 1 plat e , s wit ch, sp, 4 hol e w /gau ge

Item Part No. Qty. Description Item P a rt No. Qty. Description

Parts an d Instruction Manual

Page 13

Page 17

Minuteman International Made Simple Commercial Limited Warranty

Minuteman International, Inc. warrants to the original purchaser/user that the product is free from defects in

workmanship and materials under normal use. M inuteman will, at its option, repair or repl ace without charge, parts

that fail under normal use and service when operated and maintained in accordance with the applicable operation and

instruction manuals. All warranty claims must be submitted through and approved by factory authorized repair

stations.

This warranty does not apply to normal wear, or to items whose life is dependent on their use and care, such as belts,

cords, switches, hoses, rubber parts, electrical motor components or adjustments. Parts not manufactured by

Minuteman are cover ed by and subject to the warranties and/or guarantees of their manufact urers. Please contact

Minuteman for procedures in warranty claims against these manufacturers.

Special warning to purchaser -- Use of replacement filters and/or prefilters not manufactur ed by Minuteman or its

designated licensees, will void all warranties expressed or implied. A potential health hazard exits without original

equipment replacem ent .

All warranted items become the sole property of Minut eman or its original manufacturer, whicheve r the case ma y be.

Minuteman disclaims any implied warranty, including the warranty of merchantability and the warranty of fitness for a

particular purpose. Minuteman assumes no res ponsibility for any special, incidental or consequential damages.

This limited warranty is applicable only in the U.S.A. and Canada, and is extended only to the original user/purchaser

of this product. Customers outside the U.S.A. and Canada should contact their local distributor for export warranty

policies. Minuteman is not responsible for costs or repairs performed by persons other than those specifically

authorized by Minut eman. This war ranty does not apply to damage from transportation, alterations by unauthorized

persons, misuse or abuse of the equipment, use of non-compatible chemicals, or damage to property, or loss of

income due to malfunct io ns of th e product.

If a difficulty develops with this machine, you should contact the dealer from whom it was purchased.

This warranty gives you specific legal rights, and you may have other rights which vary from state to state. Some

states do not allow the exclusion or limitation of special, inci dental or consequential damages, or limitations on how

long an implied warr anty lasts, so the above exclusions and limitations may not apply to you.

Cord Electric Group………. Three years parts, two years labor, ninet y days travel (Not to exceed tw o hours)

Exceptions………. Port-A-Scrub, one year parts, six months labor

MPV 13, one year parts

MPV 14 and 18, two years parts, one y ear labo r

RapidAir blower, one year parts, one year labo r

Explosion-Proof Vacuum, one year parts, one year labor

Pneumatic Vacuums, three years parts, one year labor

EX 12 and EX12H, one year parts, one year labor

Battery Op er ated Group ….. Three years parts, two years labor, ninety days travel

(Not to exceed two hours)

Exceptions……Sweepers, one year parts, one year labor, ninety days travel

(Not to exceed two hours )

Internal Combustion Group….One year parts , one year labor, ninety day travel

(Not to exceed two hours)

Replac ement Parts……………..Ninety days

Batteries………………………….0-3 months replac em ent, 4-12 months pro-rate

Polypropylene Plastic Tanks…Ten years, no additional labor

111 South Rohlwin g Ro ad · Addison, Illi nois 60101 USA

Phone 630- 627-6900 · Fax 630- 627-1130

E-Mail, www.minutemanintl.com

A Member of the Hako Group

985014

REV A 08/07

Loading...

Loading...