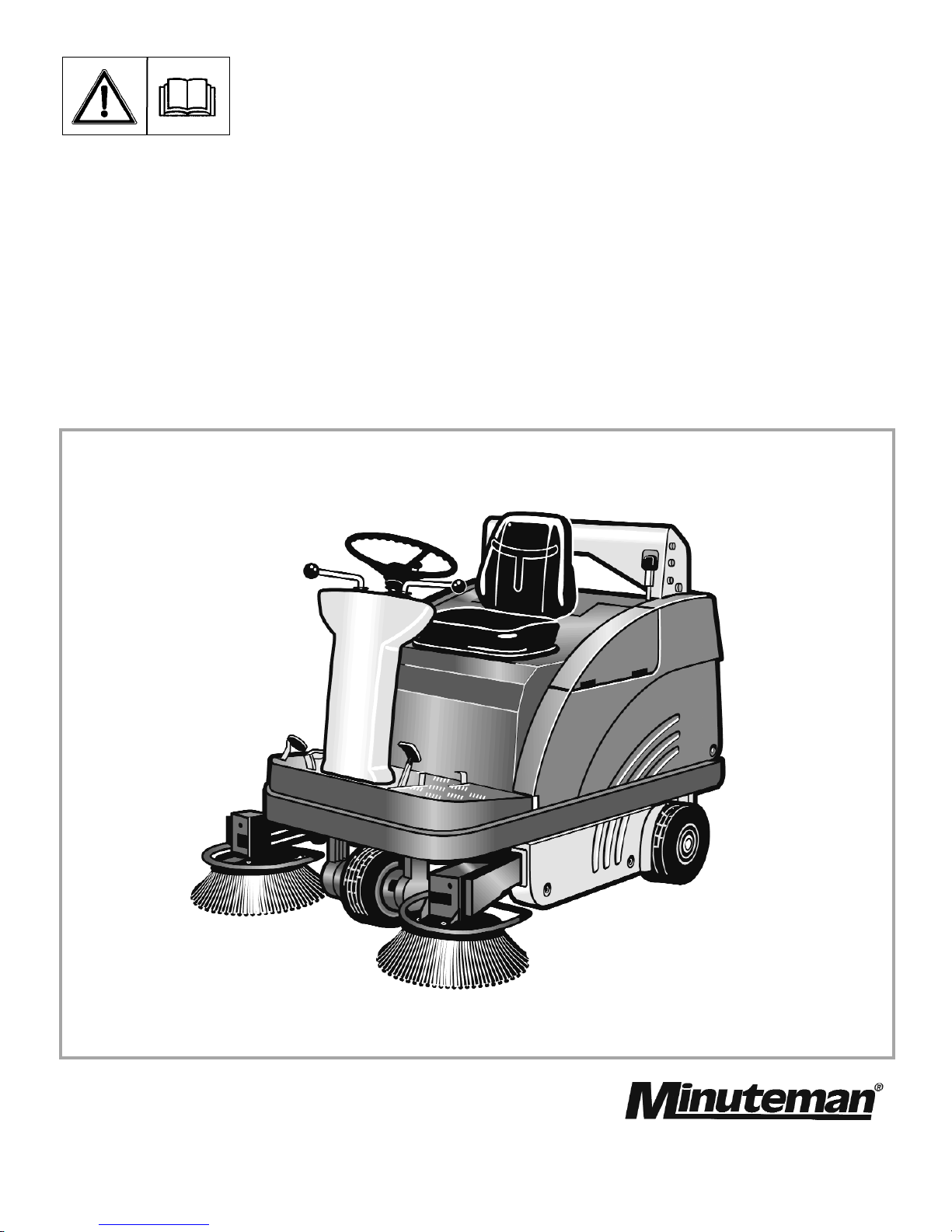

Minuteman SW5X PB40PL, SW5X PB40PH Instruction Manual

SW5X

Model: PB40PL, PB40PH

Instruction Manual

Introduction

Please be advised explicitly that

we cannot accept any legal issues out of the contents of this

manual.

If repair work has to be performed make sure that only genuine spare parts are used; only

genuine spare parts may guarantee a dependable machine.

Valid as of: March 2005

Dear customer,

It is our desire that the good cha-

racteristics of the SW5X should

justify the confidence you demonstrated by making this purchase.

Before first operation of your

SW5X, read these instructions

carefully. The manual provides

valuable information about operation, service and maintenance.

The symbol as used in this manual

identifies items relevant to safety.

Please observe the safety provisions (see chapter 1).

Before first operation of the machine,

read these instructions and safety information carefully and comply with

them.

2

Proper Use

The SW5X sweeper has been

exclusively designed for collecting

dry and moist matter from floor surfaces in e.g. factories, storage buildings, parking ground and pedestrian areas. Using the machine

beyond this scope of application

will be deemed improper use; The

manufacturer cannot be held liable

for consequential damages.

The term of proper use also includes operation, maintenance and

repair work to be performed in compliance with the manufacturer's

specifications.

The SW5X may be used by personnel only that are familiar with the

machine and aware of possible

hazards involved.

The applicable Accident Prevention

Regulations, Road Traffic

Regulations, and aspects of safety

and working medicine in vigour will

have to be complied with.

If modifications to the machine are

made in absence of the manufacturer's prior consent, the latter cannot be held liable for damage resulting from such unauthorized modification.

The machine has not been

designed for collecting

dusts which are detrimental

to health or explosive.

Notes on warranty

The terms of the sales contract apply.

Damages are not subject to warranty

if they are due to non-compliance

with the maintenance and service

provisions. The maintenance work

has to be performed by an authorized

service center and confirmed in the

"Maintenance certificate" which is the

warranty document.

The following is excluded from warranty:

fuses, natural wear, damages caused

by overload, inexpert handling and

unauthorised modification of the

machine. Moreover, any claim for

warranty cannot be accepted if damages at the machine are caused by fitting

parts or accessories without prior

and explicit consent or by non-compliance with the maintenance

instructions.

Inspection

Carefully unpack and inspect your

SW5X for shipping damage. Follow

unpacking instructions on shipping

pallet. Each unit has been tested

and thoroughly inspected before

shipment. Any damage is the responsibility of the delivery carrier who

should be notified immediately.

Proper Use

3

4 Operation . . . . . . . . . . . . . . . . . . . . .19

4.1 Controls . . . . . . . . . . . . . . . . . . . .19

4.2 Control Panel . . . . . . . . . . . . . . . .21

4.3 Empty Dirt Hopper . . . . . . . . . . . .26

4.4 Empty Dirt Hopper

Lift-Up Disposal . . . . . . . . . . . . . .26

4.5 Working with the machine . . . . . . .29

4.5.1 Before Start of Engine . . . . . . . . .29

4.5.2 Start Engine . . . . . . . . . . . . . . . . .29

4.5.3 Stop Engine . . . . . . . . . . . . . . . . .30

4.5.4 Sweep . . . . . . . . . . . . . . . . . . . . . .30

4.5.5 Stop and Park . . . . . . . . . . . . . . . .30

4.5.6 Displace . . . . . . . . . . . . . . . . . . . .31

4.5.7 Transport . . . . . . . . . . . . . . . . . . .32

5 Technical Data . . . . . . . . . . . . . . .32

6 Maintenance/Service . . . . . . . . .37

6.1 Maintenance Instruction . . . . . . . .37

6.2 Mount/Dismount Cylinder Broom .38

6.3 Adjust Sweeping Track . . . . . . . . .38

6.4 Sealing strips for Broom

Compartment . . . . . . . . . . . . . . . .40

6.5 Folding Apron Adjustment . . . . . . .40

6.6 Replace Side Brush . . . . . . . . . . .41

6.7 Dismount Plate Filter . . . . . . . . . .42

6.8 Basic Cleaning of Plate Filter . . . .44

6.9 Engine . . . . . . . . . . . . . . . . . . . . .45

6.9.1 Check Engine Oil Level . . . . . . . .45

6.9.2 Change Engine Oil . . . . . . . . . . . .46

6.9.3 Air Cleaner . . . . . . . . . . . . . . . . . .46

6.10 Hydraulic System . . . . . . . . . . . . .47

6.10.1 Check hydraulic Fluid-Level . . . . .48

6.10.2 Refill Hydraulic fluid . . . . . . . . . . .48

6.10.3 Change Hydraulic Fluid Filter . . . .48

6.10.4 Check and Refill Hydraulic

System Lift-Up Disposal . . . . . . . .49

6.11 V-Belt Drive . . . . . . . . . . . . . . . . . .50

6.11.1 Replace Cylinder Broom V-Belt . .51

6.11.2 Replace Side Brush V-Belt . . . . . .51

6.11.3 Replace Suction Fan V-Belt . . . . .52

6.11.4 Replace Hydraulic Pump V-Belt . .52

6.12 Electric System . . . . . . . . . . . . . . .53

6.13 Maintenance System . . . . . . . . . .54

7 Liquid propellant gas system . .56

8 Spare Parts . . . . . . . . . . . . . . . . .62

Contents

Introduction/Proper Use

Notes on Warranty

Inspection

1 Safty Information . . . . . . . . . . . . .5

1.1 General Safety Information . . . . . . .5

1.2 Safety and Warning Symbols . . . . .6

1.2.1 Generally Applicable Symbols . . . .6

1.3 Labels at the Machine . . . . . . . . . .7

1.4 Operation/Safety Information . . . .10

1.5 Cleaning Informaton . . . . . . . . . . .11

1.6 Maintenance instructon . . . . . . . .12

2 Description . . . . . . . . . . . . . . . . .14

2.1 Functional Descripton . . . . . . . . . .14

2.2 Cylinder Broom . . . . . . . . . . . . . . .15

2.3 Side Brush . . . . . . . . . . . . . . . . . .15

2.4 Filter System/Dust Evacuation . . .15

2.5 Shaking System . . . . . . . . . . . . . .15

2.6 Steering . . . . . . . . . . . . . . . . . . . .15

2.7 Wheels . . . . . . . . . . . . . . . . . . . . .15

2.8 Brake . . . . . . . . . . . . . . . . . . . . . .16

2.9 Travel Drive Assembly . . . . . . . . .16

2.10 Hydraulic System Lift-Up

Disposal . . . . . . . . . . . . . . . . . . . .16

3 First Operation . . . . . . . . . . . . . .17

3.1 General . . . . . . . . . . . . . . . . . . . . .17

3.2 Refill Fuel . . . . . . . . . . . . . . . . . . .17

3.3 Check Engine Oil Level . . . . . . . .18

4

Safety Information

1 Safety Information

1.1 General Safety Information

Apart from the instructions contained

in this manual, the general safety

instructions and accident prevention

regulations, as imposed by law will

have to be complied with. Do not put

the Manual aside without reading it

even if you used similar sweepers

before. Take the time to read them

now and save time later. Machines

with known defects must not be used.

It will be of essence to make yourself

familiar with all accessories and controls and their functions before you

start working. Avoid the mess of

having to read this book while trying

to run the machine.

Using the machine in areas with

explosion hazard, on public roads

and places is prohibited.

The operator has to use the machine

within its design limits.

Shut the motors down before transporting the machine.

Keep clear of hazard zone!

Before commencing work, the operator has to make sure that the SW5X

and its accessories are in proper and

safe condition.

Warning and instruction labels attached to the machine contain important information about safe operation.

Illegible or lost labels have to be

replaced.

Make sure that all covers

are fitted before starting to

sweep.

Provide for sufficient

ventilation when sweeping

indoors (dust and

combustion gas).

Pinching and shearing hazard. Provide for required

safe distance before lifting

or lowering the dirt hopper.

Shut down the engine before re-fuelling.

Smoking and handling open

flames is prohibited when

filling fuel tanks or when

working at or in the vicinity

of components containing

fuel.

5

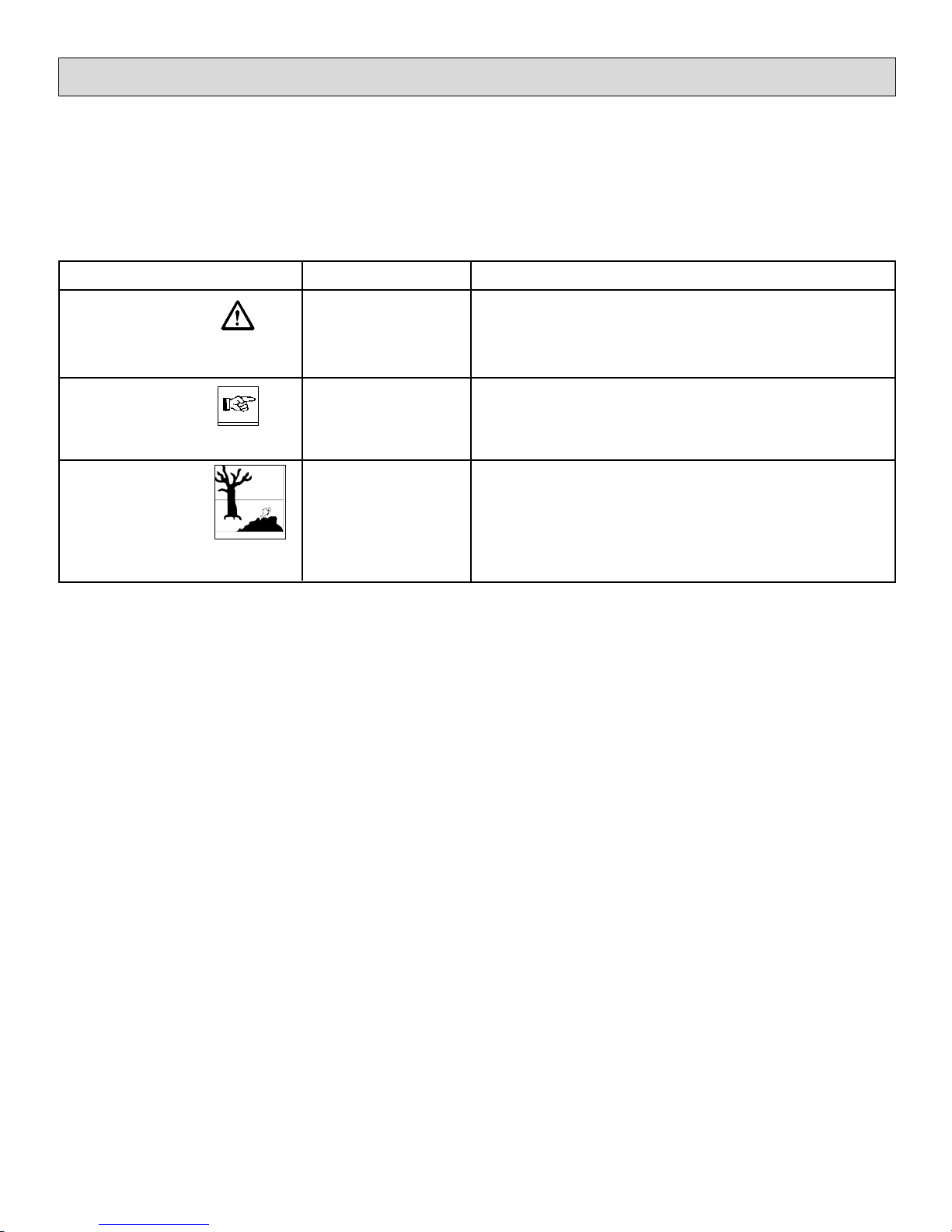

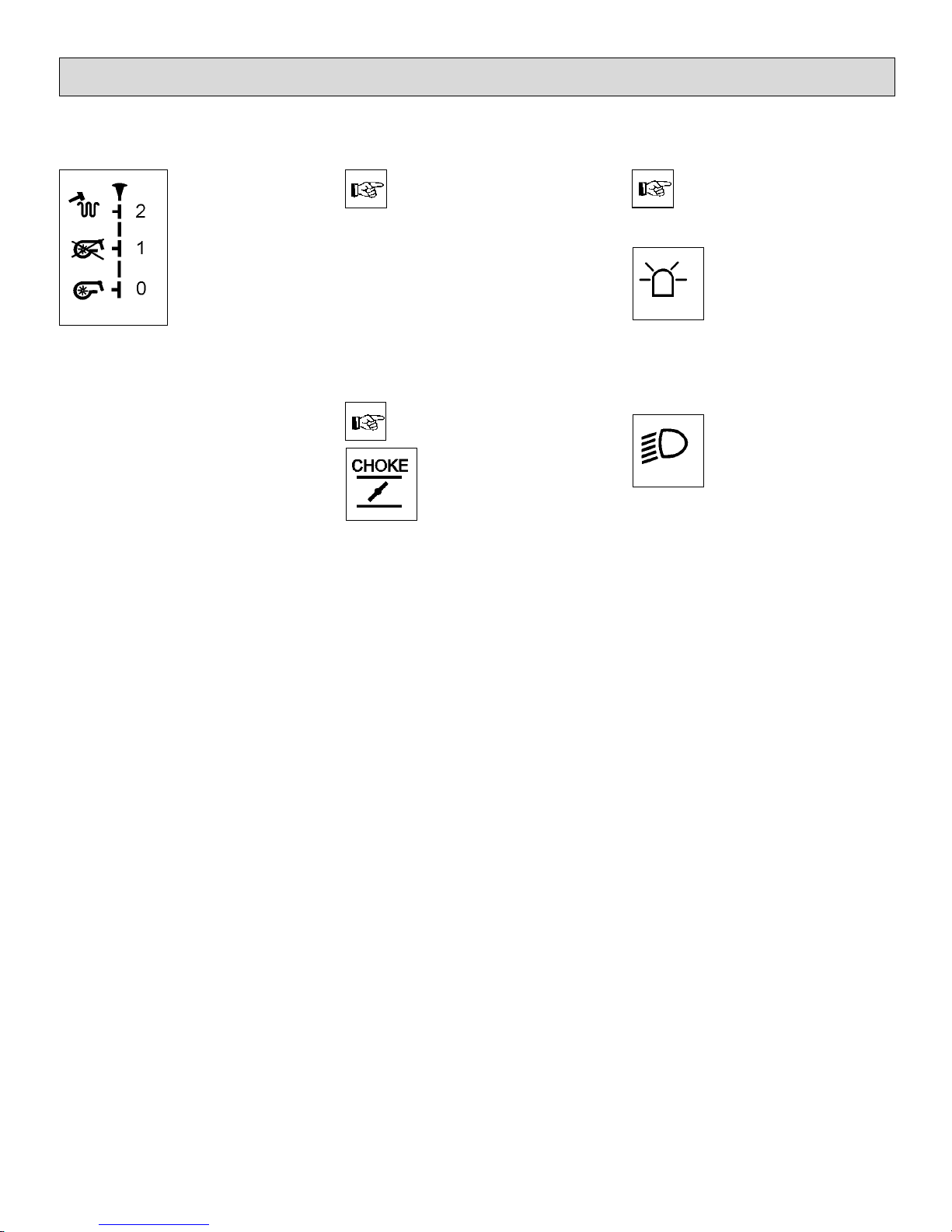

1.2 Safety and Warning Symbols

1.2.1Generally Applicable Symbols

All paragraphs in this manual referring to your personal safety, the safety of your machine and the environment protection are attributed one of

the following warning symbols:

Safety Information

Hazardous for....

persons and

goods

the machine

the environment

Description

dangerous situation

caused by misuse inaccurate adherence of instructions or

prescribed work routine

important information on handling the machine in order to

maintain operability

due to use of substances representing an inherent danger to

health of environment

Symbol

DANGER

CAUTION

Ecological hazard

6

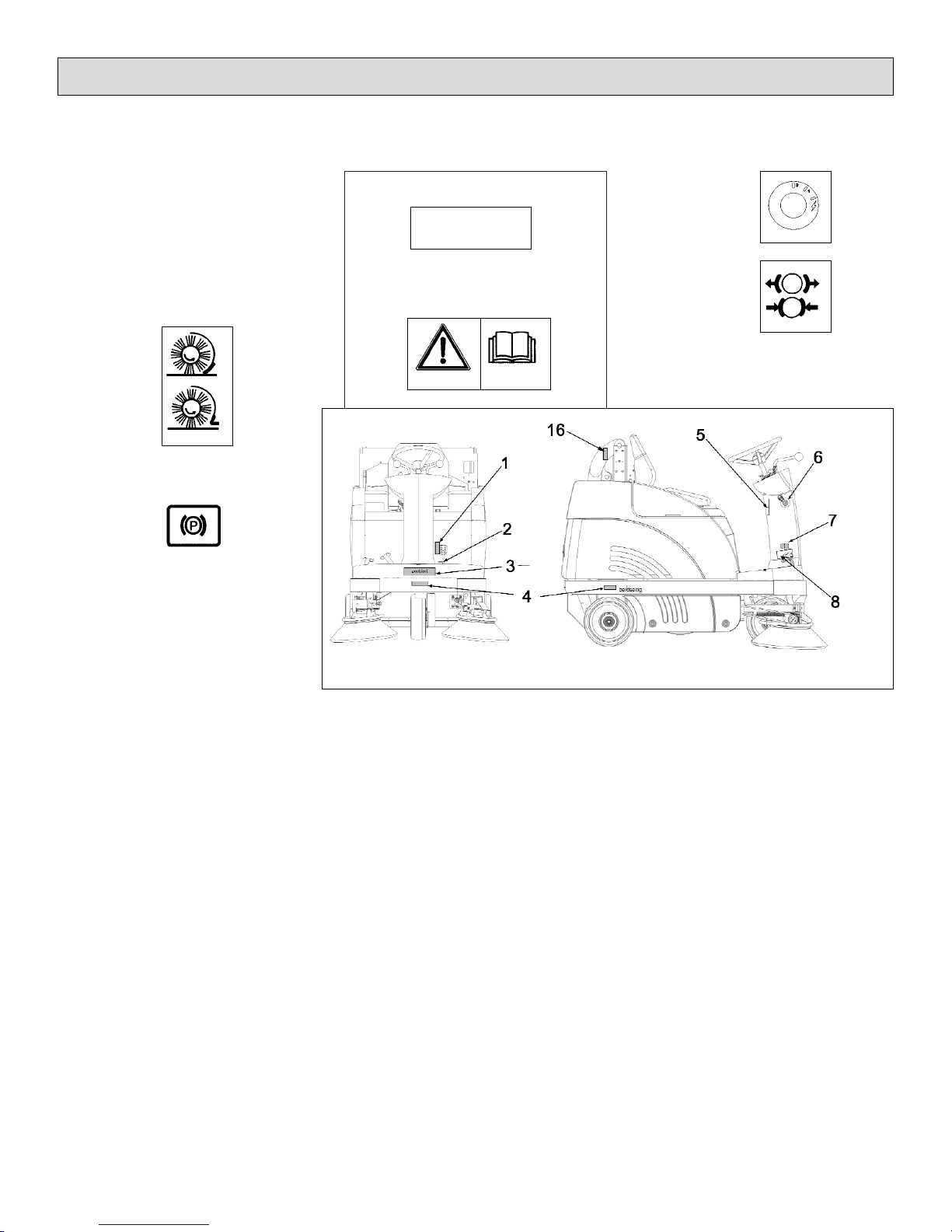

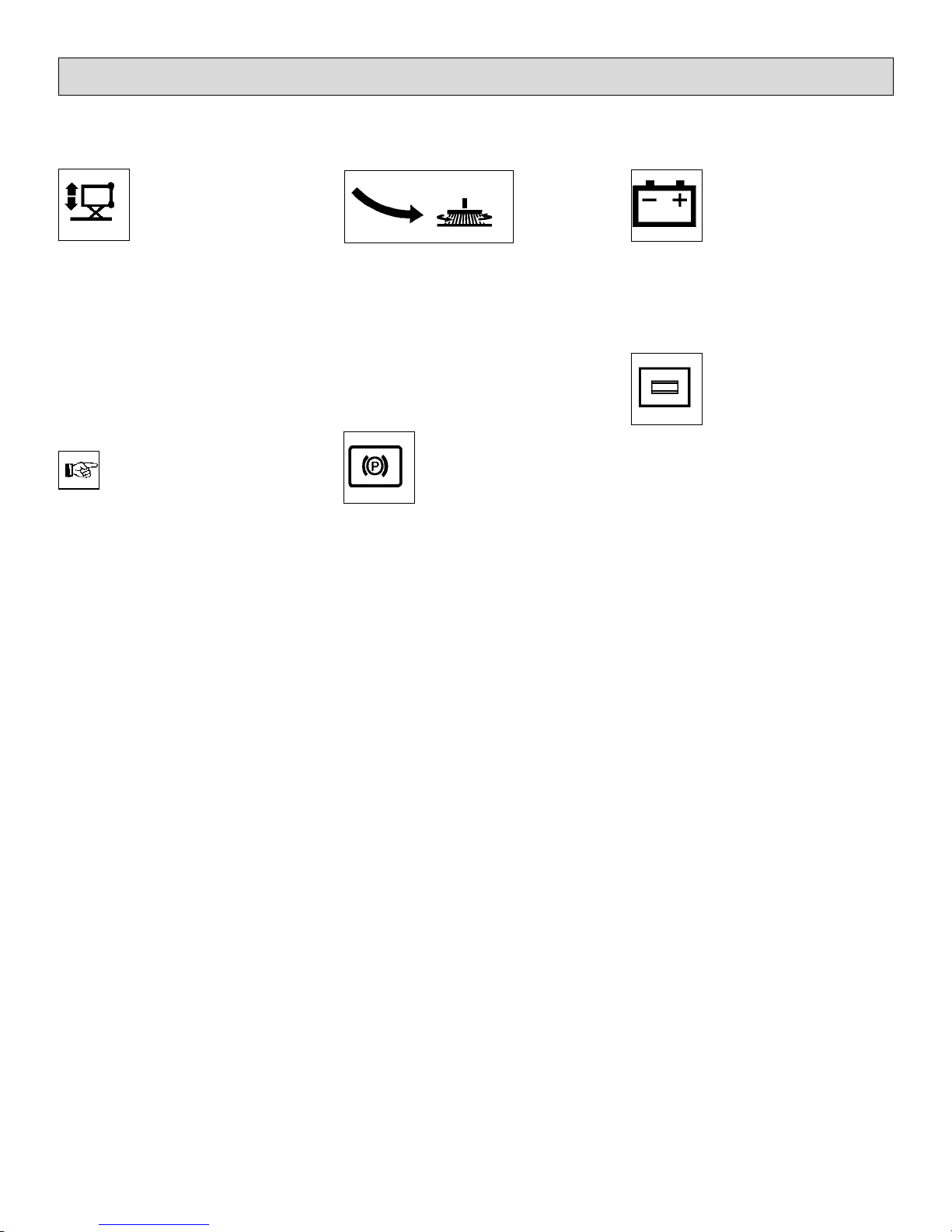

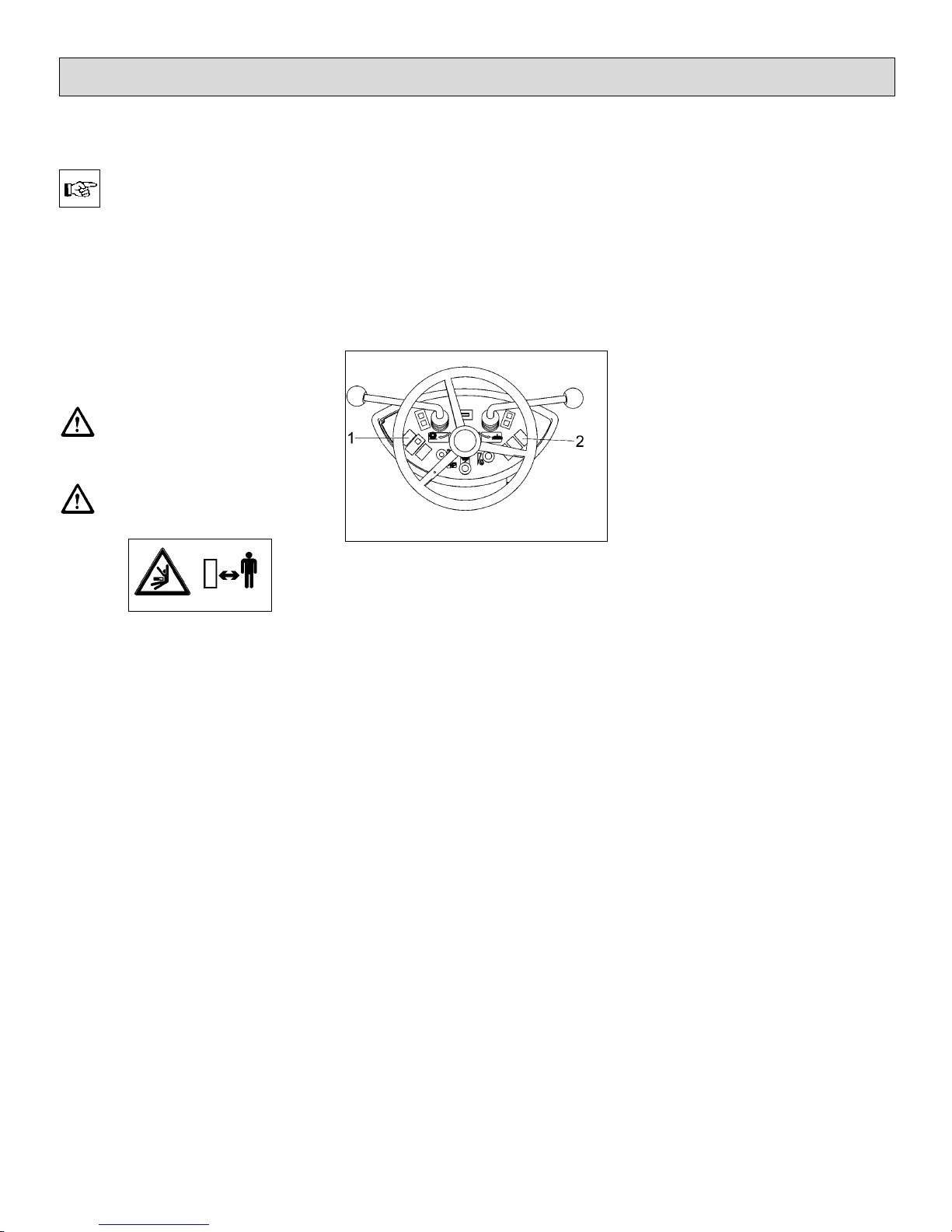

1.3 Labels at the Machine

The following safety and information

signs are legibly attached to the

machine. Missing or illegible stickers

have to be replaced.

Folding apron (1)

Parking brake (2)

Nameplate front (3)

Inflation pressure (4)

Read and observe operator's

Manual (5)

Ignition lock (6)

Brake (7)

Noise power level (8)

91 dB (A)

Safety Information

Fig.1

90 PSI

7

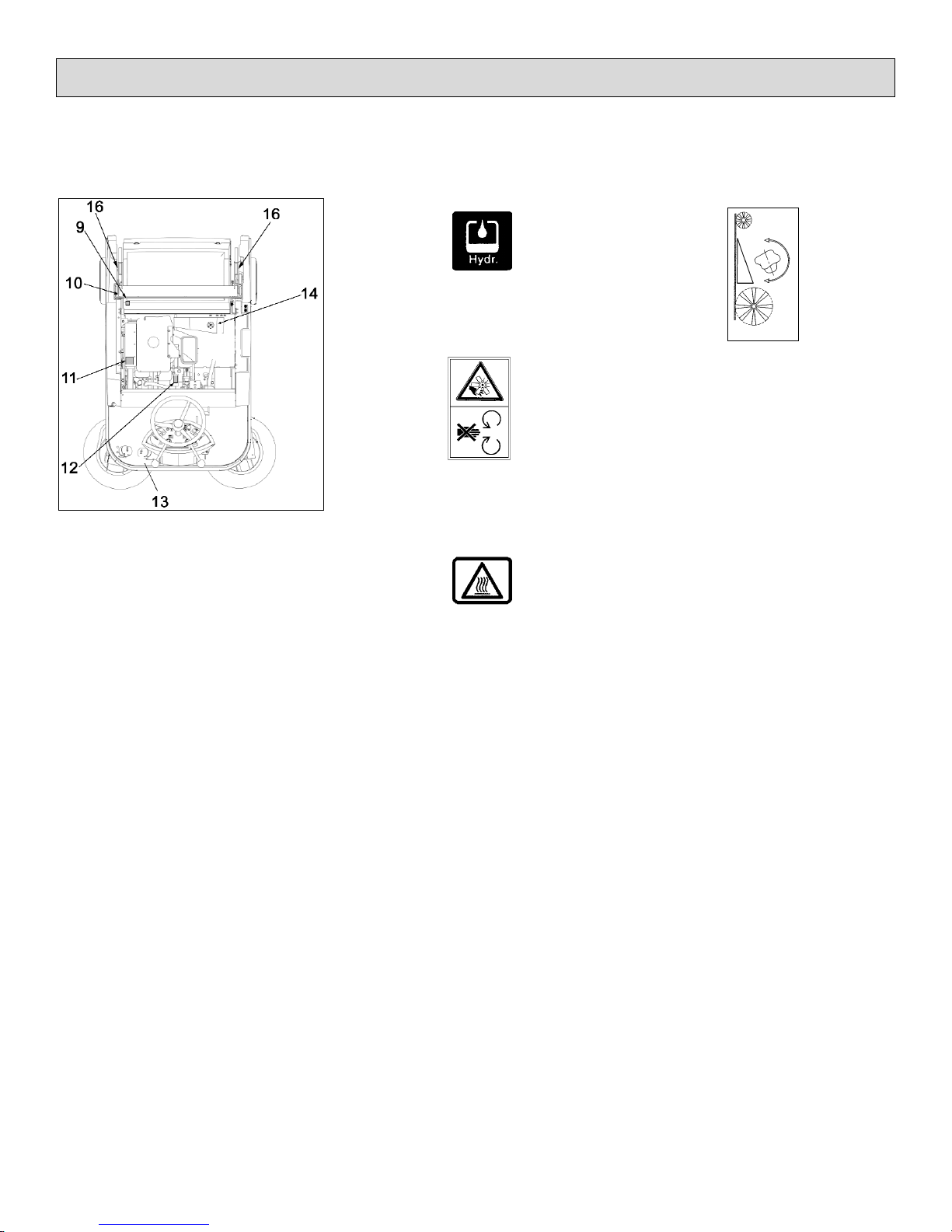

1.3 Labels at the Machine

Fig. 2 Safety and information

signs

Hydraulic fluid (9)

Rotating parts (10)

Burning surface (11)

Cylinder broom wearing take-up (12)

Nameplate (13)

Safety Information

8

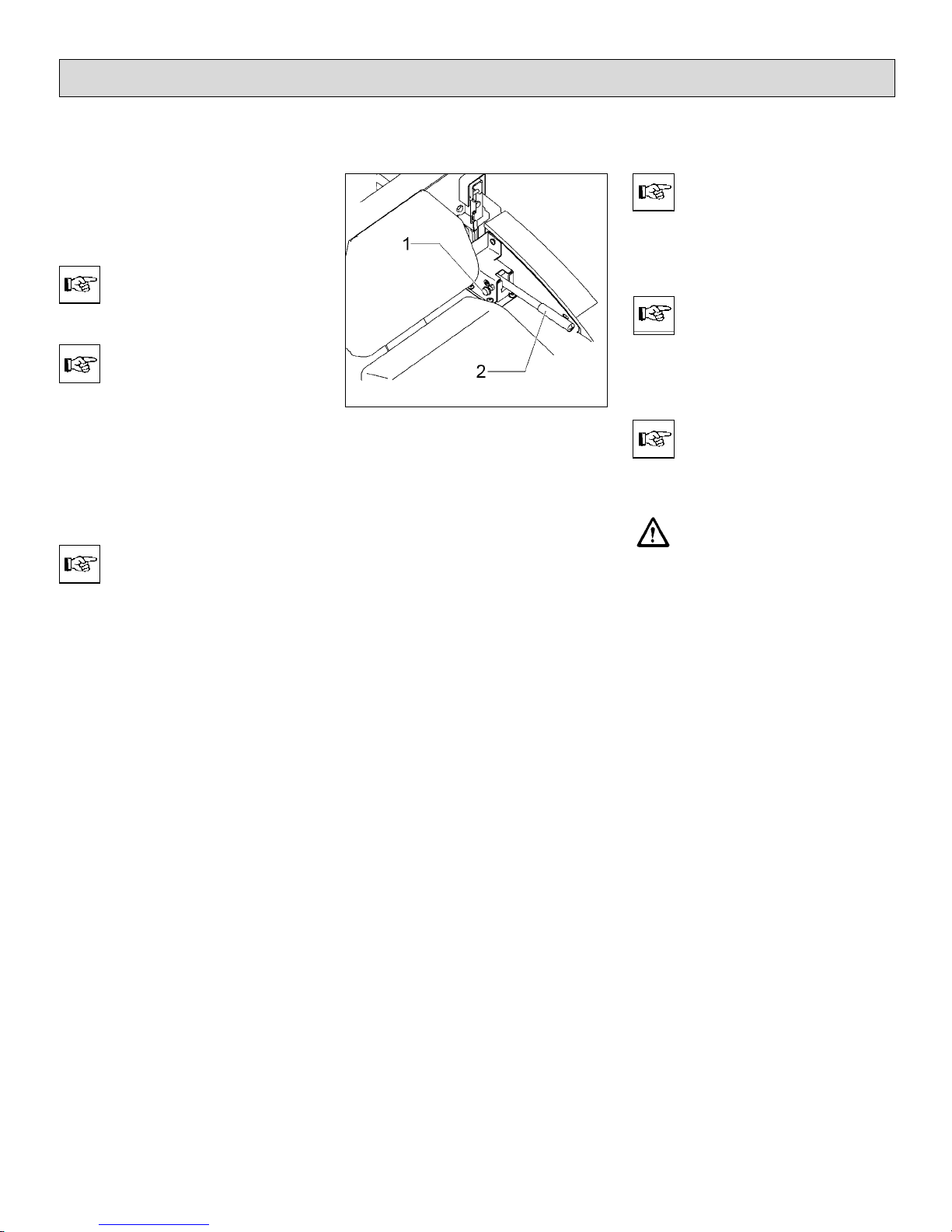

1.3 Labels at the Machine

High-pressure cleaner (14)

Do not clean by means of

high pressure cleaner or

vapour jet.

Pinching hazard (16)

(Lifted-Up Disposal)

Safety Information

9

1.4 Operation/Safety

Information

Vacuum sweepers may be run by

qualified personnel only; such personnel will have to have evidenced

their qualification for running the

machine to the owner or his authorized representative; operators explicitly will have to be instructed by the

owner or his authorized representative to use the machine.

The machine may be used

for cleaning such surfaces

approved by the owner or

this authorised representative for operation of vacu

um sweepers.

Before starting the engine,

switch off all drives

Transporting persons on the machine

is prohibited. Ride-on machine types

are to be started with the driver being

seated.

Never leave the machine unattended

before the motors are off and the machine is protected against unintended

movements.

To prevent the machine from unauthorized use, pull the control key to block

all drives.

Shut down the motors before transport of the machine. The driver has to

take account of local conditions and

when operating the sweeper he has

to watch out for other persons, especially children.

Do not open hood or

fairings with the machine

running.

This machine must not be

used as dust-evacuating

machine with dust filter insert (separator) to collect

dusts which are hazardous

to health.

Compared to four-wheeled

vehicles, driving stability of

three-wheeled vehicles is

reduced. We thus recommend:

- do not negotiate curves at

high speed.

- do not turn at slopes but

on level ground only

- ride up- or downhill

straight.

Safety Information

10

11

Safety Information

Warning and instruction labels attached to the machine contain important information about safe operation

Provide for sufficient ventilation when sweeping indoors (dust and combustion

gas).

Proceed to filter shaking only if the dirt hopper is in closed position.

1.5 Cleaning Information

The machine is splash-proof (IPX3).

Do not clean the SW5X by

means of high pressure cleaner or vapour jet.

Proceed to cleaning of the

dirt hopper in regular intervals to preclude formation of

bacterial deposits.

1.6 Maintenance Instructions

A good approach to prevention of

accidents is proper maintenance of

the machine.

Before proceeding to repair or maintenance work remove the key.

Use appropriate tools for maintenance, service, setting etc.

As far as aspects of safety are concerned, spare parts will have to be at

least of the same quality as the genuine spare parts.

Switch off the motors before maintaining the machine

or replacing parts of it. Turn

off the machine and pull the

key.

Check hydraulic hoses and

lines for leakage or damages in regular intervals. Replace defective hoses and

lines immediately.

Before changing wheels

protect the machine against

rolling by placing wedges.

Proceed to wheel changing

when the machine is on level and solid ground.

Do not repair the pneumatic

tires mounted to the machine yourself. Dismount the

wheel and take it to repair to

a tire workshop.

Use of other than the cylinder brooms and side brushes approved by the manufacturer is not acceptable

(see technical data) since

use of other cylinder

brooms and side brushes

may affect your safety.

When handling lubricating agents, the applicable regulations for

protection of the environment and prevention of fire have to be

complied with. Provide

for disposal of used oil

and grease in accordance with the provisions imposed by law.

Collect cleaning

agents, oil, fuel oil, grease etc. and provide for

adequate disposal. Wipe away spilled substances.

Safety Information

12

Before commencing any

work on the electric system

disconnect battery (neg. lead) of the SW5X and pull the

ignition key.

Do not keep batteries dsicharged for a longer period;

always recharge them as

soon as possible.

Top with distilled water only. Never refill battery acid

in battery cells of perfect

condition.

Keep batteries dry and clean and clear of soiling such

as e.g. metallic dust to avoid leakage current.

Do not place metal objects

or tools onto batteries.

Short-circuit and deflagration hazard.

Spilled (straight) battery

acid must not get into the

sewage system before having been neutralised. Comply with the regulations imposed by law and observe

local provisions.

Battery acid is highly

caustic (keep clear of

children).

When checking the battery

acid level, wear safety glasses. If acid splashes get into the eyes rinse with clear

water for 15 minutes and

contact a doctor immediately.

Use appropriate protective

means (e.g. protective gloves or finger-stalls) when

handling battery acid.

Do not use open flames

(explosion hazard).

Safety Information

13

2 Description

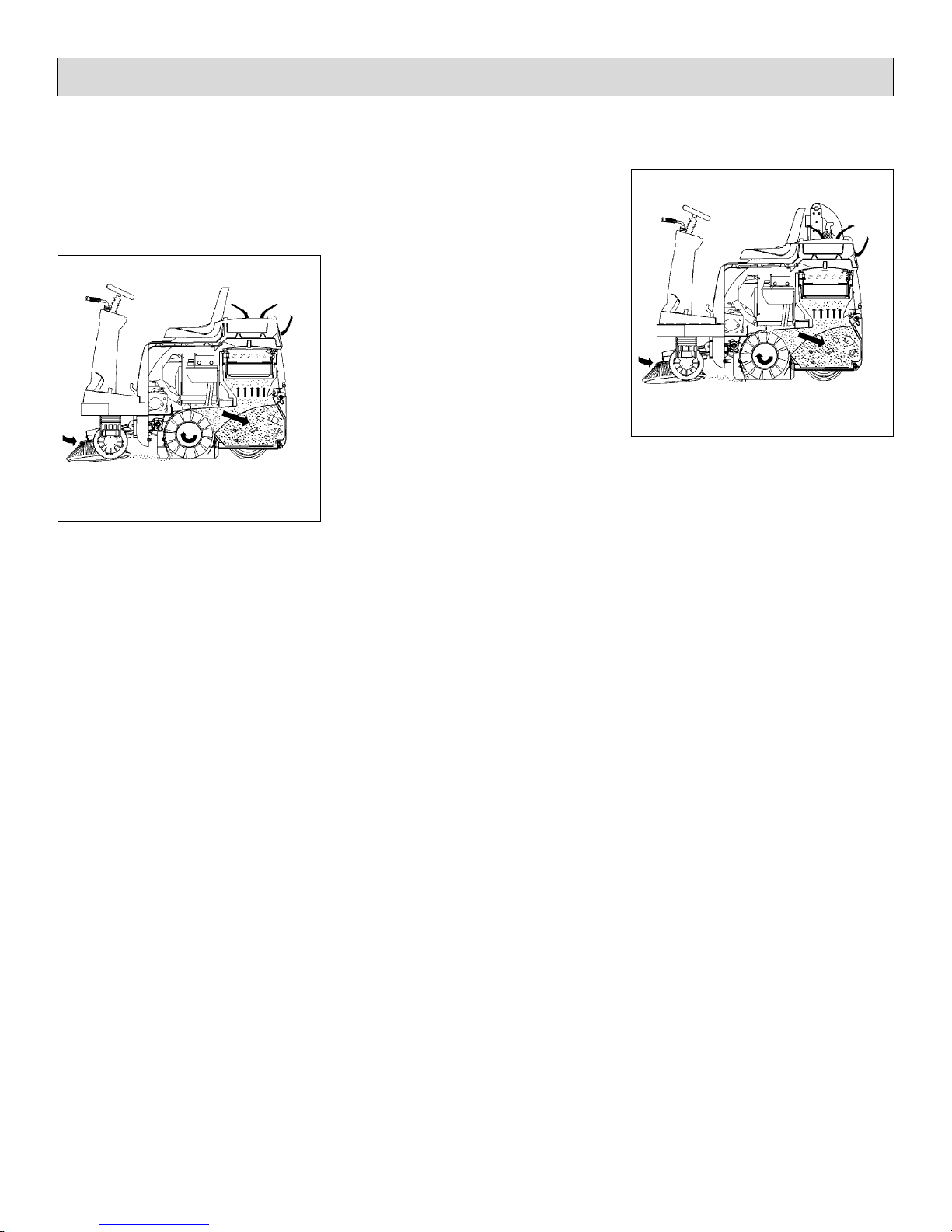

2.1 Functional Description

Principle

The side brush is used to collect dirt

at borders and to enlarge the working

width as well as to increase the area

performance on large surfaces.

The cylinder broom casts the debris

overhead into the dirt hopper. The collected fine dust is evacuated by the

suction fan and separated by a filter

system. The air returned into the environment is clean.

Dirt disposal at the SW5X is realized

via two dirt hoppers (2x30 litres)

which are to be emptied manually.

Dirt disposal at the SW5X (Lift-Up

Disposal) is realized via lift-up disposal (lift-up height > 1350mm) directly

into standard waste containers.

Description

Fig.3

Fig.4

14

2.2 Cylinder Broom

The cylinder broom is equipped with

12 rows of bristles arranged in

V-shape.

The cylinder broom width amounts to

27.6 in. (700mm) and its diameter to

13.6 in. (345mm).

2.3 Side Brush

At the standard version, the side

brush is located at the front right of

the machine. The operator lifts and lowers it by hand lever.

The side brush has a light inclination.

The swinging area of the side brush

arm is limited by stop screws.

The side brush is driven by V-belt.

For special application, fitting of a

second side brush at the left is possible.

2.4 Filter System / Dust

Evacuation

The filter system is located in the filter case above the dirt hopper. The

suction fan transports the fine dust

raised by the cylinder broom to the

plate filter where it is separated. The

fine dusts sets at the outsides of the

filter blades.

In case of heavy dust development, check and clean

the plate filter at regular

intervals.

2.5 Shaking System

Due to normal working vibration the

set dust partly falls off into the dirt

hoper. To ensure working in a dustfree environment, however, actuate

the shaking system regularly, or after

request by the pilot lamp at the latest.

2.6 Steering

Steering is controlled mechanically

from steering wheel to front wheel via

chain. This chain is to be re-adjusted

as required.

2.7 Wheels

Pneumatic tyres with hose, size.

4.00 - 4 6PR

Inflation pressure: 90 PSI (6 bar)

Solid rubber tyres (Option)

Description

15

2.8 Brake

The SW5X is equipped with a service

brake.

This brake has been constructed as

shoe brake and equally serves as

parking brake.

It is located in the rear wheels and is

actuated via cables.

A special adjustment screw is situated at the right-hand rear wheel.

Any work at the braking

system has to be executed

by qualified persons in a

qualified workshop only.

2.9 Traction Drive Assembly

The SW5X is equipped with a hydrostatic drive assembly which is driven

by the combustion engine via pump.

2.10 Hydraulic System

Lift-Up Disposal

The hydraulic system comprises a

compact unit (hydraulic pump with

hydraulic tank), the hydraulic hoses

and a hydraulic cylinder.

Hydraulic fluid: Mobiloil DTE 15 M

The named hydraulic fluid has been

filled in the hydraulic system in the

factory.

Filling of hydraulic tank: 0.2 gal. (0.76

litre)

Description

16

3 First Operation

The SW5X has been extensively

tested and submitted to a functional

check before delivery.

Only qualified personnel of your local

contract dealer are allowed to proceed to first operation. After shipping

of the machine, we advise your contract dealer. He will contact you to

make a date for briefing lessons.

3.1 General

Smoking and handling open

flames is prohibited when

filling fuel tanks or when

working at or in the vicinity

of components containing

fuel.

Do not use the SW5X at ambient temperatures of more

than 104°F (40°C).

Do not start the machine at

temperatures of 5°F (-15°C)

or less.

Liquid propellant gas

system: refer to LPG operating instructions.

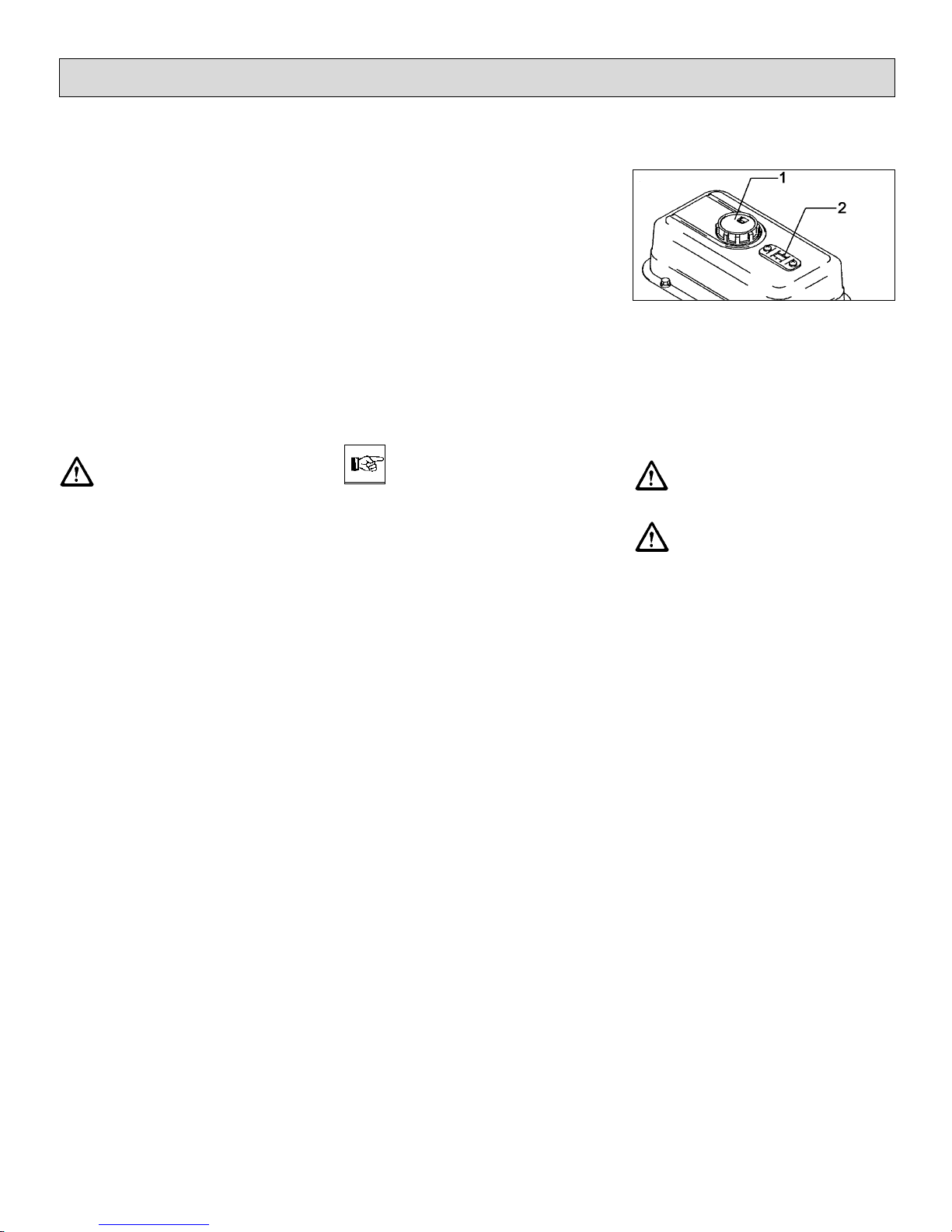

3.2 Refill Fuel

The fuel tank is located under the foldable seat hood.

Use clean fuel oil only. Store fuel in approved and closed reservoirs only.

- Turn engine off

- Secure machine by engaging the

parking brake.

- Pull ignition key.

- Fold back seat hood.

Fuel tank

- Check filling level at the filling level

indicator (Fig. 5/2).

- Remove tank lid (Fig. 5/1) before

filling.

Turn engine off before filling

fuel.

Smoking and handling open

flames is prohibited when

filling fuel tanks or when

working at or in the vicinity

of components containing

fuel.

First Operation

Fig.5

17

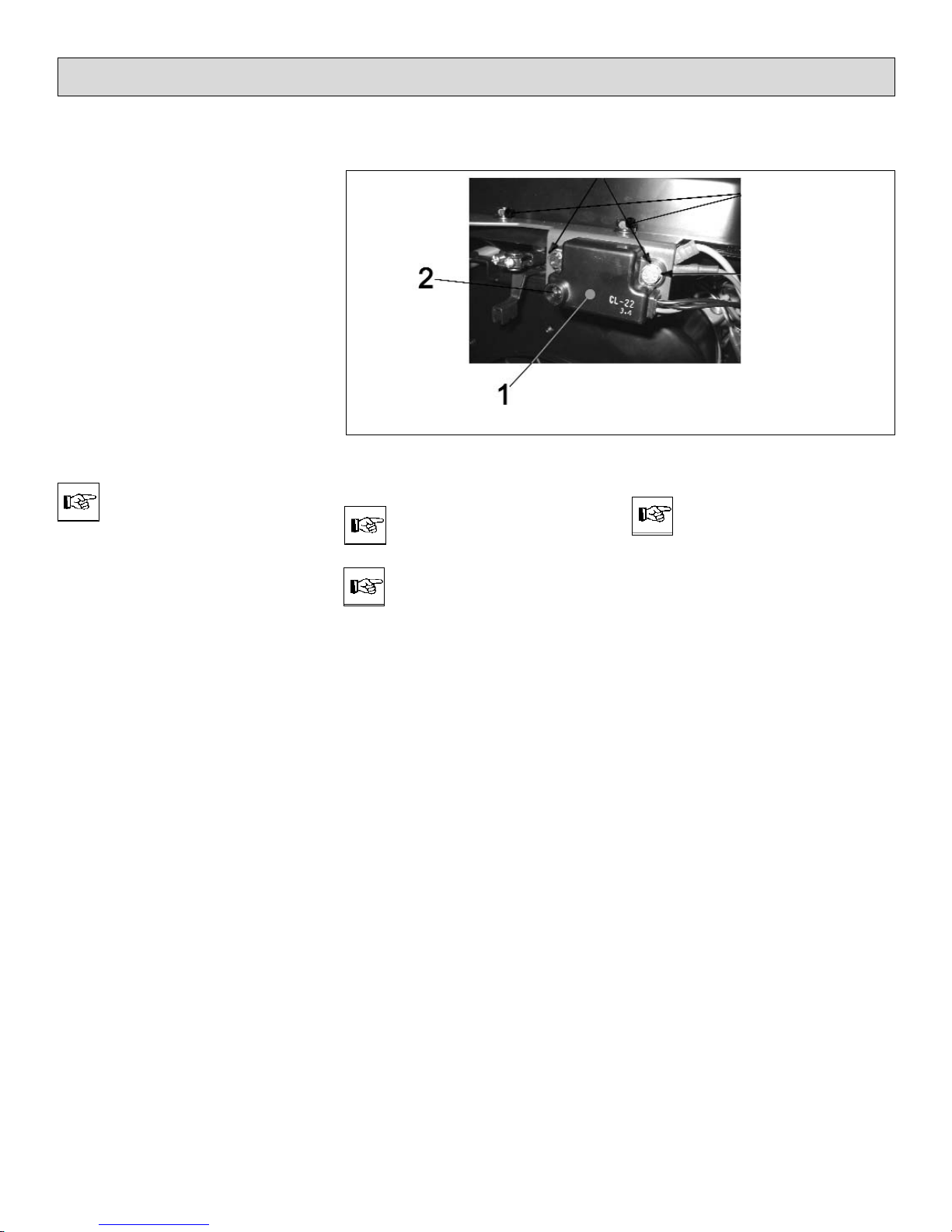

3.3 Check Engine Oil Level

- Engine oil has been filled in the factory.

- For safety reasons, check the engine oil level (refer to paragraph

6.9.2, Fig. 23/2)

- In order to protect the engine, it is

switched off or cannot be started if

engine oil level is insufficient.

This function is controlled by a low

oil level switch (Fig. 0/1) at the engine. A red pilot lamp (Fig. 0/2) is situated at this switch and lights simultaneously in case of insufficient

oil level.

Before the machine is operable again, refill oil until

the prescribed level is attained.

Engine Oil Level

Use clean oil only for

refilling.

Do not use used oil.

Store oil in approved and

closed reservoirs only.

First Operation

Fig.0

18

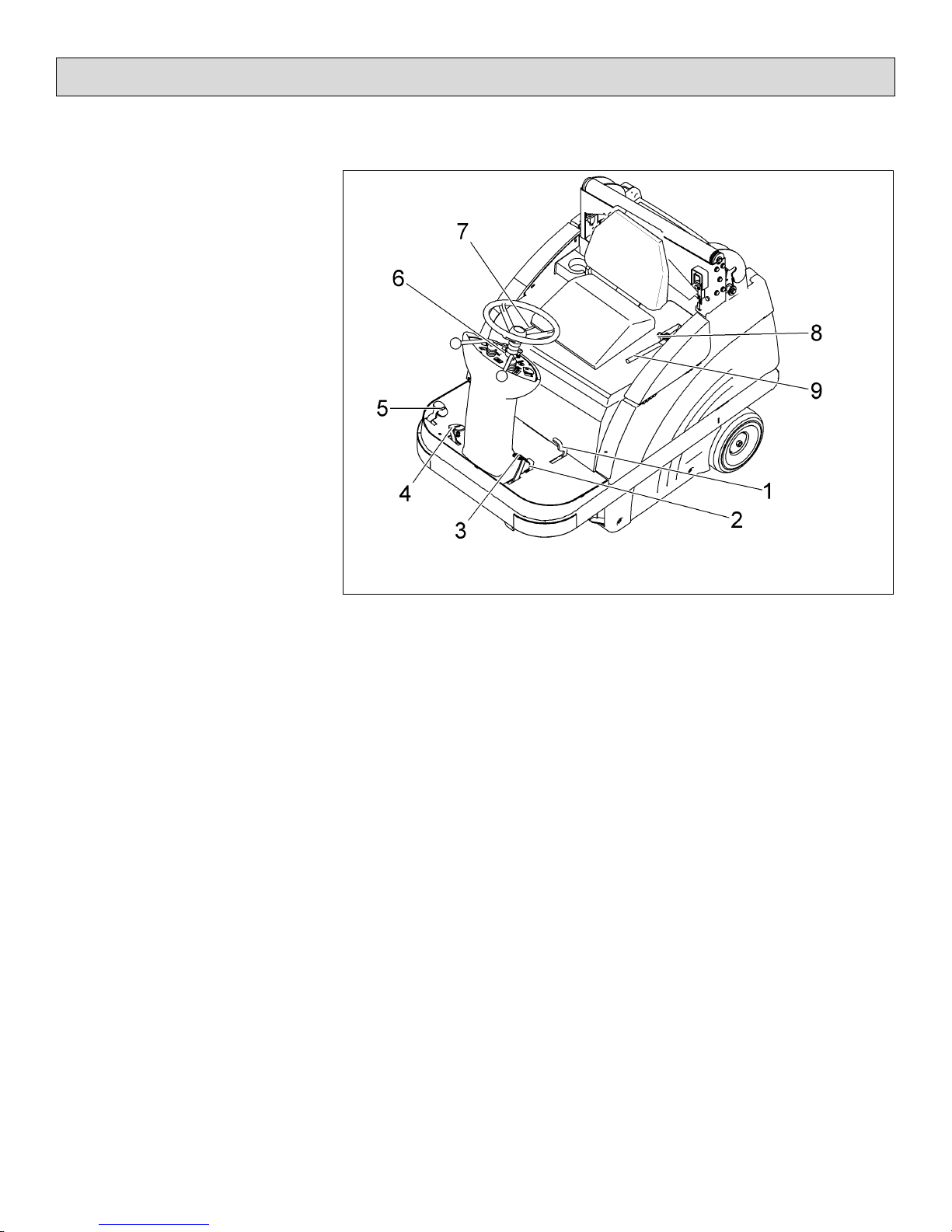

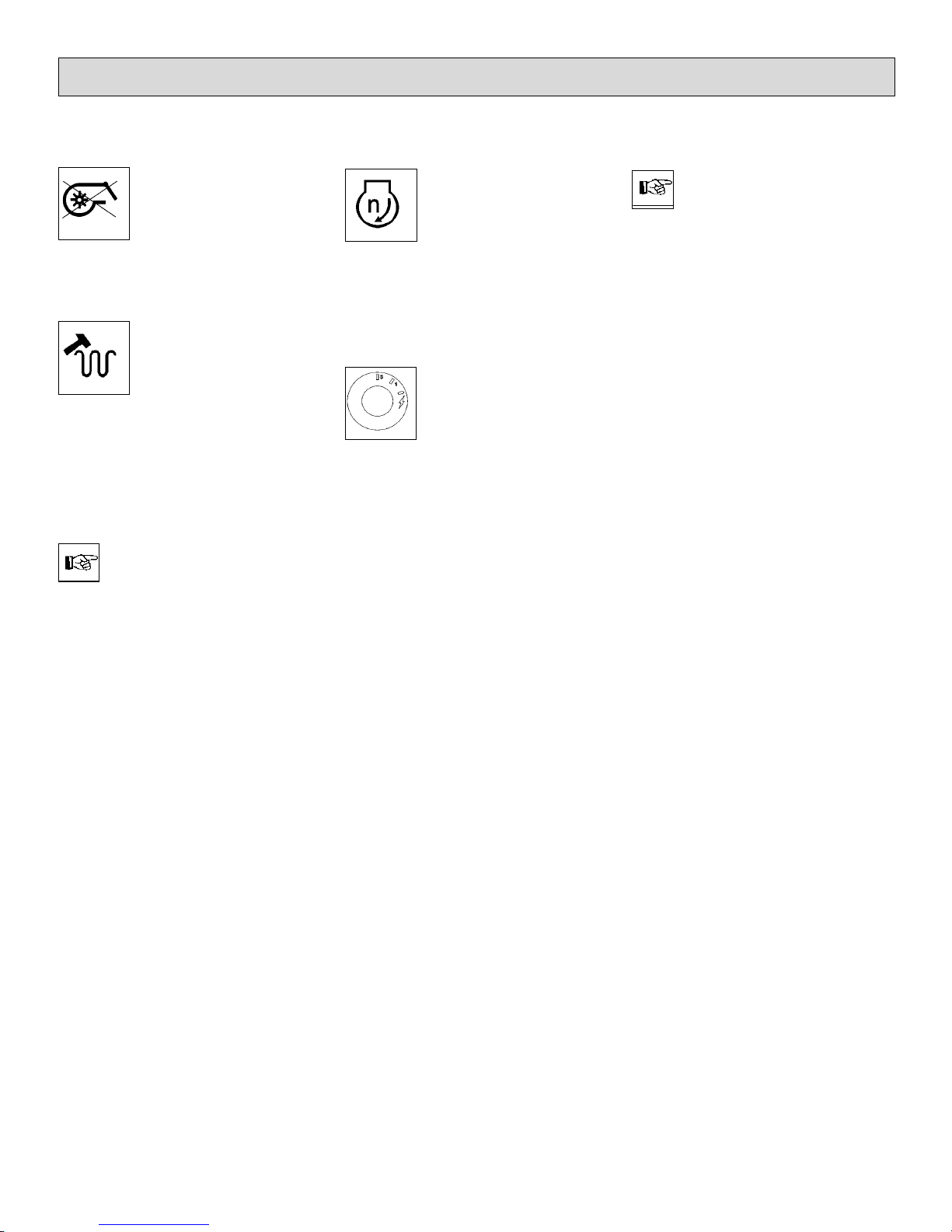

4 Operation

4.1 Controls

1 Actuator for folding apron

2 Service brake lock

3 Service brake/parking brake pedal

4 Drive pedal, reverse

5 Drive pedal, forward

6 Control panel

7 Seat adjustment

8 Safety knob, lock for release of

swinging dirt hopper function

(Lift-Up Disposal)

9 Release lever for swinging dirt

hopper function (Lift-Up Disposal)

Operation

Fig.6

19

1 Actuator for folding apron

to open and close the folding apron

for collecting coarse dirt.

2 Service brake/parking brake lock

to lock the service brake/parking

brake. If locked, the service brake

works as parking brake. Release

the lock by depressing the service

brake pedal (3).

3 Service brake/parking brake pe-

dal

to actuate the service brake at the

rear wheels. Before leaving the machine unattended, engage the service brake and lock.

4 Drive pedal, reverse

to change direction to reverse ride

with continuous regulation of riding

speed at the same time. If the driver releases the pedal it returns to

initial position and the machine

slows down to standstill.

5 Drive pedal, forward

to change direction to forward ride

with continuous regulation of riding

speed at the same time. If the driver releases the pedal it returns to

initial position and the machine

slows down to standstill.

6 Control panel

Refer to chapter "Control panel"

7 Seat adjustment

to adjust the seat position to drivers

of different height.

Adjust the seat so as to allow the

driver being comfortably seated and

attaining all elements required for

operation.

- Adjust seat lengthwise: push lever

slightly to the right and displace seat forwards or backwards to the required position. Then let the lever

catch again.

8 Safety knob, lock for release of

swinging dirt hopper function

to release the lever for swinging dirt

hopper function.

9 Release lever for swinging dirt

hopper function

to swing the dirt hopper

Operation

20

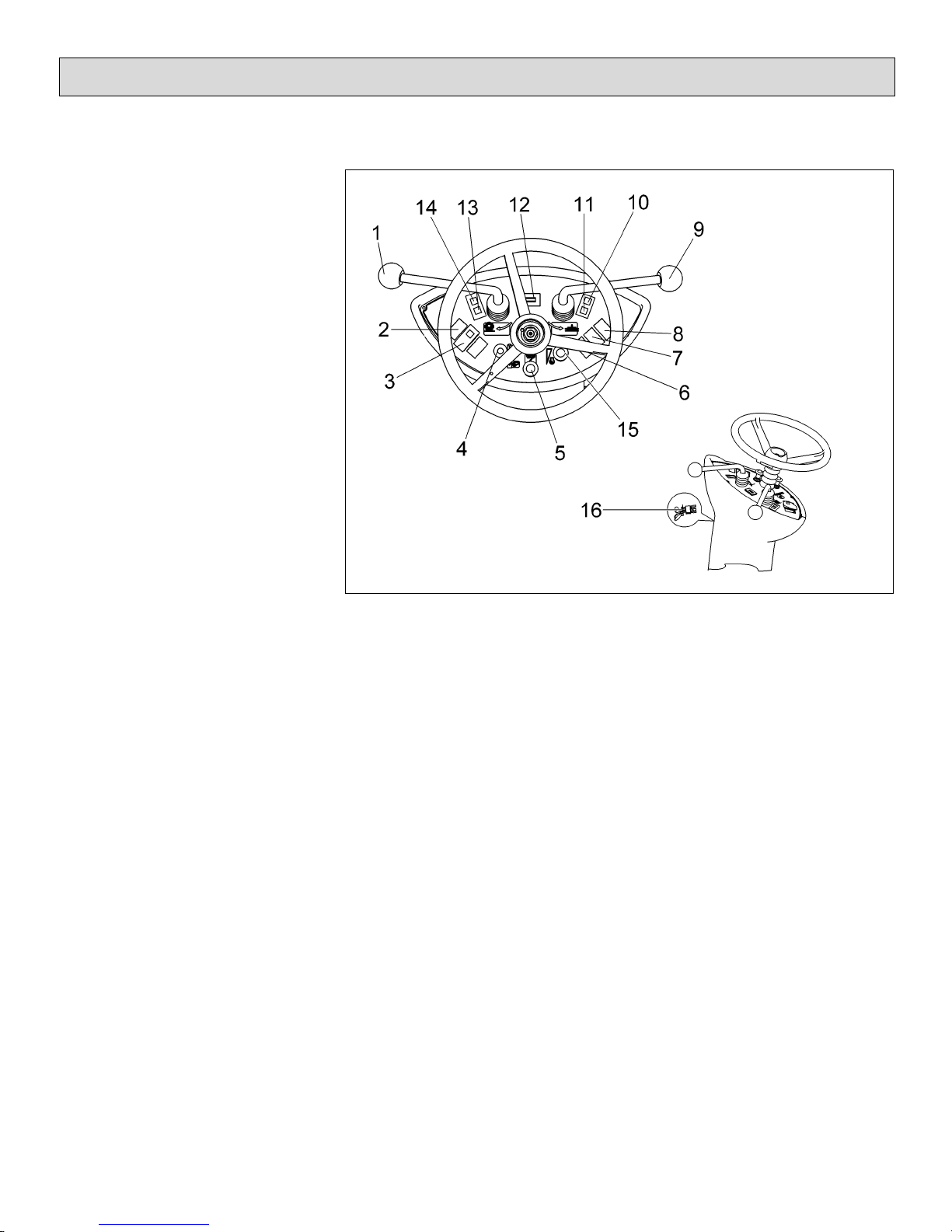

4.2 Control Panel

1 Cylinder broom lever

2 Release of lifted-up disposal func-

tion

3 Horn

4 Suction fan/shaking system knob

5 Choke flap knob

6 Flashlight (option)

7 Lighting (option)

8 Lift and lower (Lift-Up Disposal)

9 Side brush lever

10 Pilot lamp, parking brake

11 Battery charge status indicator

12 Hourmeter

13 Pilot lamp, fan

14 Pilot lamp, shaking system

15 Engine speed regulation knob

16 Ignition switch

Operation

Fig.7

21

1 Cylinder broom lever

to lift and lower as well as to

switch on and off the cylinder

broom and the side brush.

- Lower cylinder broom as well as

switch on cylinder broom and side

brush

= push lever

- Lift cylinder broom as well as switch

off cylinder broom and side brush

= pull lever

2 Release for lifted-up disposal

function

to release the lifted-up disposal

function for lowering of lifting.

Has to be actuated before

pressing the key for

lifting/lowering lifted-up disposal function. Hold the key

during lifting/lowering.

Before changing lifting to

lowering or vice versa, the

"Release Lifted-Up Disposal" key has to be released

once and pressed again

3 Horn

An acoustic signal sounds upon

actuation of this button.

Operation

22

4 Suction fan/shaking system

knob

Knob position (from bottom to top):

Pos. 0 Activated vacuuming function

(close flap before sweeping

dry surfaces or collecting

dry dirt).

Pos. 1 Deactivated vacuuming

function (open flap before

sweeping wet surfaces and

collecting wet dirt).

Pos. 2 Shaking system ON (pull

knob to stop and then

release)

After jolting, the knob is to

be kept in position 1 for about 10 seconds.

Reduce engine speed to id-

ling in order to optimize the

cleaning result in case of

heavy fine dust load.

If the yellow pilot lamp (Fig. 7/13)

lights, actuate the shaking system

(position 2).

In this position, the shaking system is

operable and proceeds to jolting in 7

repeated intervals.

Do not hold the knob in

position 2!

5 Choke flap knob

to actuate the choke flap (cold

start)

- Knob down - choke not actuated

- Knob pulled up - choke actuated

for cold start.

If the engine has already attained temperature, do not

actuate the choke flap and

start with full throttle.

6 Flashlight (option)

to switch the flashlight ON/OFF.

7 Lighting (option)

to switch the driving headlight

ON/OFF.

Operation

23

8 Lift and lower (lifted-up dispo-

sal)

to lift and lower the dirt hopper.

Lift the dirt hopper by pressing the

key until the desired height for lifting-out is attained.

When lowering the dirt hopper make sure to hold the key pressed

until the hopper has contact with

the frame.

Actuate release key for lifted-up disposal and hold

before lifting or lowering.

9 Side brush lever

to lift and lower the side brush.

- Lower side brush

= push lever

- Lift side brush

= pull lever

10 Pilot lamp, parking brake (red)

lights upon actuation of the parking brake Extinguishes upon

release of the parking brake.

11 Battery charge status indicator

(red)

lights upon actuation of the ignition

switch and has to extinguish as

the engine fires.

12 Hourmeter

indicates the operating hours. The

counter works only if the driver is

seated and the ignition is ON.

Operation

24

13 Pilot lamp, suction fan (orange)

lights if the suction fan is not activated.

14 Pilot lamp, shaking system (yel-

low)

Proceed to jolting of the filter

system upon lighting of this pilot

lamp by actuating the knob

(Fig.7/5).

The pilot lamp flashes during the shaking procedure

and extinguishes after filter

has been cleaned. Jolting is

effectuated in 7 intervals.

15 Engine speed regulation knob

to adjust the engine speed. Service speed is attained by pulling

the knob up.

16 Ignition switch

to switch ignition on and off, to

start and stop engine and to secure it against unauthorised use.

For safety reasons, the

SW5X has been equipped

with a seat contact switch.

Starting the engine is possible only after the driver

has taken place on the seat.

If seat contact is interrupted

while the engine is running,

the combustion engine of

the SW5X has to be re-started.

Operation

25

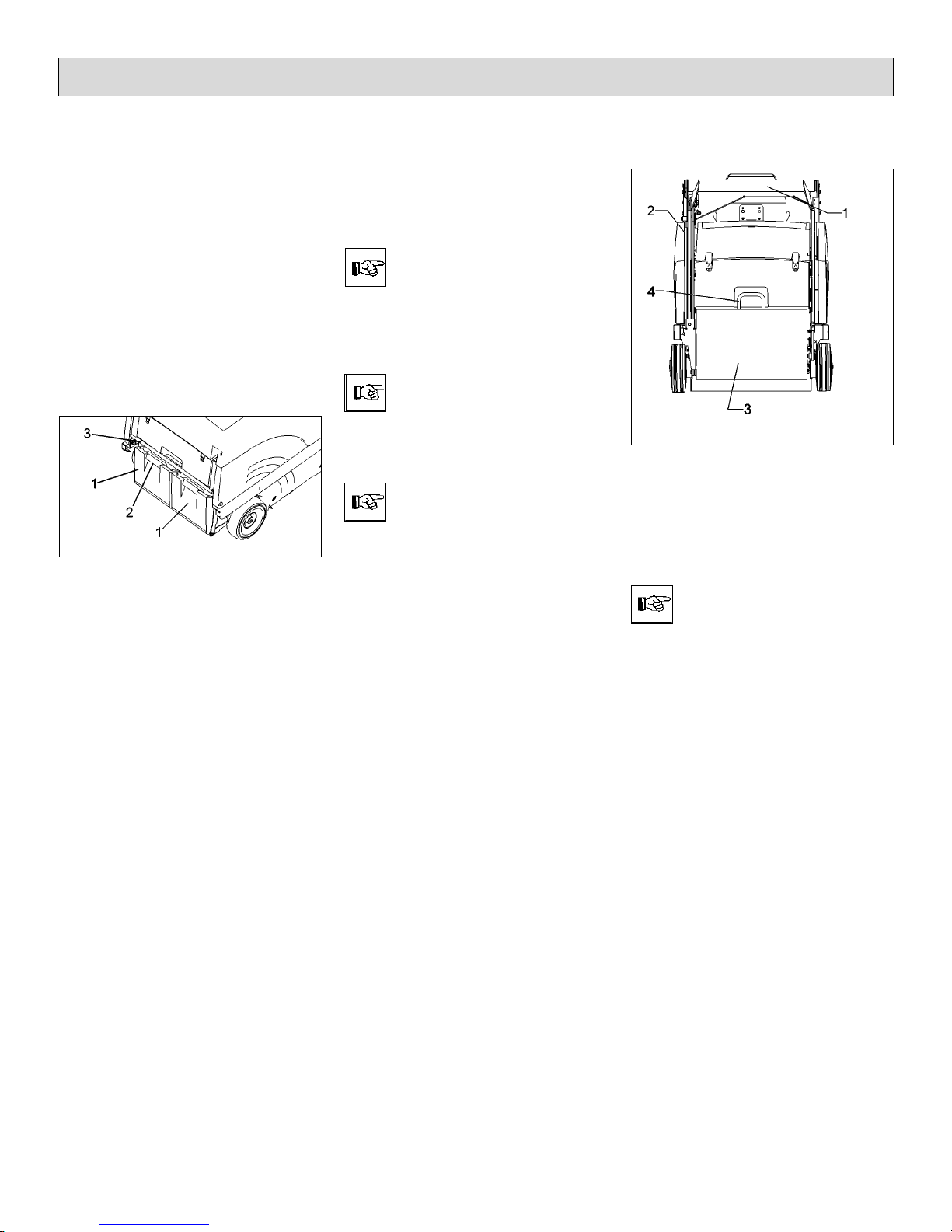

4.3 Empty Dirt Hopper

- Fold bow (Fig. 8/3) up

= the dirt hoppers (Fig. 8/2) are lowe-

red.

- Use the recessed grip (Fig. 8/1) of

one of the hoppers to lift it lightly

and extract it.

- Take the hopper at its bow-type

handle to disposal and empty.

- Empty second dirt hopper as described above.

- Re-insert dirt hopper (Fig. 8/2) and

fold down the bow (Fig. 8/3).

1 Recessed grip in dirt hopper

2 Dirt hopper

3 Bow to lift/lower dirt hoppers

Clean dirt hoppers at

regular intervals.

4.4 Empty Dirt Hopper (Lift-Up

Disposal)

Lift side brush and cylinder

broom before emptying of

the dirt hoppers.

If the hopper is lifted with

the cylinder broom still running, the engine is switched

off.

1 Lift-out arm

2 Lift-out cylinder

3 Dirt hopper

4 Bow-type handle

Clean dirt hopper at regular

intervals.

Operation

Fig.8

Fig.9

26

Riding with the lifted hopper reduces stability of the

machine significantly. For

this reason, do not lift the

hopper but just before emptying. Before lifting the hopper, the operator has to make sure that no persons or

objects are behind or next

to the machine. Stop the

machine on level ground

before lifting the hopper.

When the hopper is lifted,

the operator has to ride the

machine slowly.

Keep clear of the hazard

zone!

Pinching and shearing hazard. Provide for required

safe distance before lifting

or lowering the dirt hopper.

Control panel (Lift-Up Disposal)

1 Release switch for lifted-up dispo-

sal function

2 Dirt hopper, lift and lower

Proceed to emptying of the dirt

hopper as follows:

- Lift and switch off side brush and

cylinder broom

- Proceed to shaking of the filter

system

- Actuate switch (Fig. 10/1) and hold

(dirt hopper is released)

- Actuate switch (Fig. 10/2) by

pushing = lift dirt hopper

- Dirt hopper (Fig. 9/3) is lifted-out

- Back the SW5X until the dirt hopper is positioned above the container for disposal.

- Pull the safety knob (Fig. 11/1) of

the release lever (Fig. 11/2).

- Release swinging of the dirt hopper by release lever (Fig. 11/2).

- Forward the SW5X after emptying.

Operation

Fig.10

27

- Lower dirt hopper by actuating

switch (Fig. 10/1) and switch (Fig.

10/2); pull lever = lower dirt hopper

Observe the information given in paragraph 4.2/2 on

releasing of lifted-up disposal.

If the hopper is lifted, the

sweeping function is blokked. If the main broom is lo-

wered even if the hopper is

lifted, the combustion engine stops. Starting is then

possible only after sweeping function is turned off

(main broom lever in OFF

position) or the hopper is

lowered. (Under condition

that the driver is seated)

Lifted-up disposal function

is blocked as long as sweeping function is ON.

Release lever, swing dirt hopper

1 Safety knob

2 Release lever, swing dirt hopper

If the cylinder broom is

switched on with the dirt

hopper being lifted, the engine stops.

Should the dirt hopper not

be completely emptied after

swinging, proceed to manual shaking with the handle

(Fig. 9/4).

Clean the dirt hopper in regular intervals.

The dirt hopper is approved

only for a max. filling of 18.5

gal (70 litres) but not more

than a weight of 242.5 lb

(110 kg).

Operation

Fig.11

28

4.5 Working with the machine

The driver is requested to carefully

read this manual. All controls are

marked with easy-to-understand symbols that ease familiarization. First

driving attempts should be limited to

clear areas until you are familiar with

all controls and their functions.

Please comply with the following safety provisions:

When working with the

SW5X all safety measures

generally applicable for

handling vehicles have to

be observed. No passenger

transport is admitted with

the SW5X. Warning and instruction labels attached to

the machine contain important information about safe

operation and guarantee

your personal safety. Before

commencing work, the operator has to make sure that

the machine and its accessories are in proper and safe condition and

comply with the provision

for safety at work. Do not

operate the SW5X without

protective devices.

4.5.1 Before Start of Engine

Open seat hood and check the following:

- Engine oil level

- Visual check of the V-belts

- Fuel filling

- Open fuel cock (is located at a slot

of the air cleaner)

- Close seat hood

4.5.2 Start Engine

For safety reasons, the SW5X is

equipped with a seat contact switch.

Starting the engine is possible only

when the driver is seated.

- Switch all levers and switches to

neutral position. Actuate parking

brake.

- Actuate choke (with cold engine

only)

- Turn ignition key to switch on

ignition

- Continue turning ignition key clok-

kwise to start engine.

If the starting procedure

has to be repeated or if the

engine stops, re-starting is

possible only after ignition

has been turned off. The ignition lock is equipped with

a protection to preclude repeated ignition with the engine running.

Operation

open

closed

29

Interruption of the starting

procedure after 10 seconds

and brief pause between

starting cycles is recommended to save the battery.

- Let the engine run and then slowly

press the choke knob down.

4.5.3 Stop Engine

- Turn ignition key counter-clockwise.

4.5.4 Sweep

- Start engine

- Adjust service speed

In initial position, vacuuming is activated. If the collected dirt is wet, open the

flap.

- Lower cylinder broom and side

brush.

- Release parking brake.

- Slowly depress drive pedal until

desired speed has been attained.

- Regularly actuate shaking device to

clean filter.

- Check filling level of the dirt hopper

and empty if required.

Refer to LPG operating instructions for information

on how to start machine

equipped with liquid propel-

lant gas system.

4.5.5 Stop and Park

- Release drive pedal which returns

automatically into its neutral position and the machine slows down to

standstill.

- Actuate parking brake

- Lift side brush and cylinder broom

- Turn engine off

Slowing down the SW5X is

possible by applying opposite forces with the drive

pedal or by using the service brake.

When leaving the machine

unattended, pull key in order to preclude unauthorized use.

Close the fuel cock in case

of long-term standstill of

the machine.

Operation

30

Loading...

Loading...