Page 1

Service Manual

For the

SCV2832E, SCV2426,

SCV280000 & ES2832

Automatic Scrubbers

For:

o

Training

Troubleshooting

Adjustments

Page 2

Contents

1 Cautions ----------------------------------------------------------------------

Page 4

2 Maintenance Intervals ----------------------------------------------------

2.1 Customer Maintenance ----------------------------------------------

2.2 Maintenance I after every 125 hours of operation--------------

Page 5

Page 6

Page 7

2.3 Maintenance II after every 250 hours of operation

-------------

2.4 Maintenance S after every 500 hours of operation,

minimum once per year-------------------------------------------

3 Service Mode ----------------------------------------------------------------

Page 8

Page 9

Page 10

3.1 Service Mode SC280000 --------------------------------------------

4 Brush Pressure Settings---------------------------------------------------

4.1 ES2832 and CP2832 -------------------------------------------------

Page 11

Page 13

Page 14

5

Error Codes

------------------------------------------------------------------

6 5.1 Table of Error Codes (LCD)------------------------------------------

Page 16

Page 17

Page 2

Page 3

Contents

5.4 Error Codes (LED) --------------------------------------------------------------

6 Side Squeegee Adjustment (cylindrical) -----------------------------------------

6.1 Side Squeegee Adjustment (disk)--------------------------------------------

-------------------------------------------------------

Page 21

Page 25

Page 26

7

Rear

Squeegee

Adjustment

8 Replacing the Brush Actuator On SC2832 Models--------------------------9 Trouble Shooting the Code 8 Error ----------------------------------------------10 Testing the Throttle Potentiometer-----------------------------------------------

Page 27

Page 30

Page 33

Page 36

11 Identifing the Cause of Trio Controllers ---------------------------------------12 Notes------------------------------------------------------------------------------------

Page 38

Page 39

Page 3

Page 4

1. Cautions

• Always disconnect the A.C. Cord from the outlet and and D.C. Cord

from the battery pack before servicing the machine. Except for making

voltage and current measurements.

• Before replacing or disconnecting any electrical componets, disconnect

the battery pack from the machine first. Failure to do so could cause a

short circuit

.

• After any repair work test the machine for proper operation.

• When servicin

g

the machine always observe the general safety and

gygy

accident prevention guidlines.

• Do not attempt to power up the controllers with battery chargers.

Permanent damage will occur to the controller.

36 volt chargers usually have an output in excess of 48 volts.

• Use only Minuteman approved battery chargers.

Page 4

•

Do not apply power directly to the motors without first disconnecting

them from the controller circuit.

Page 5

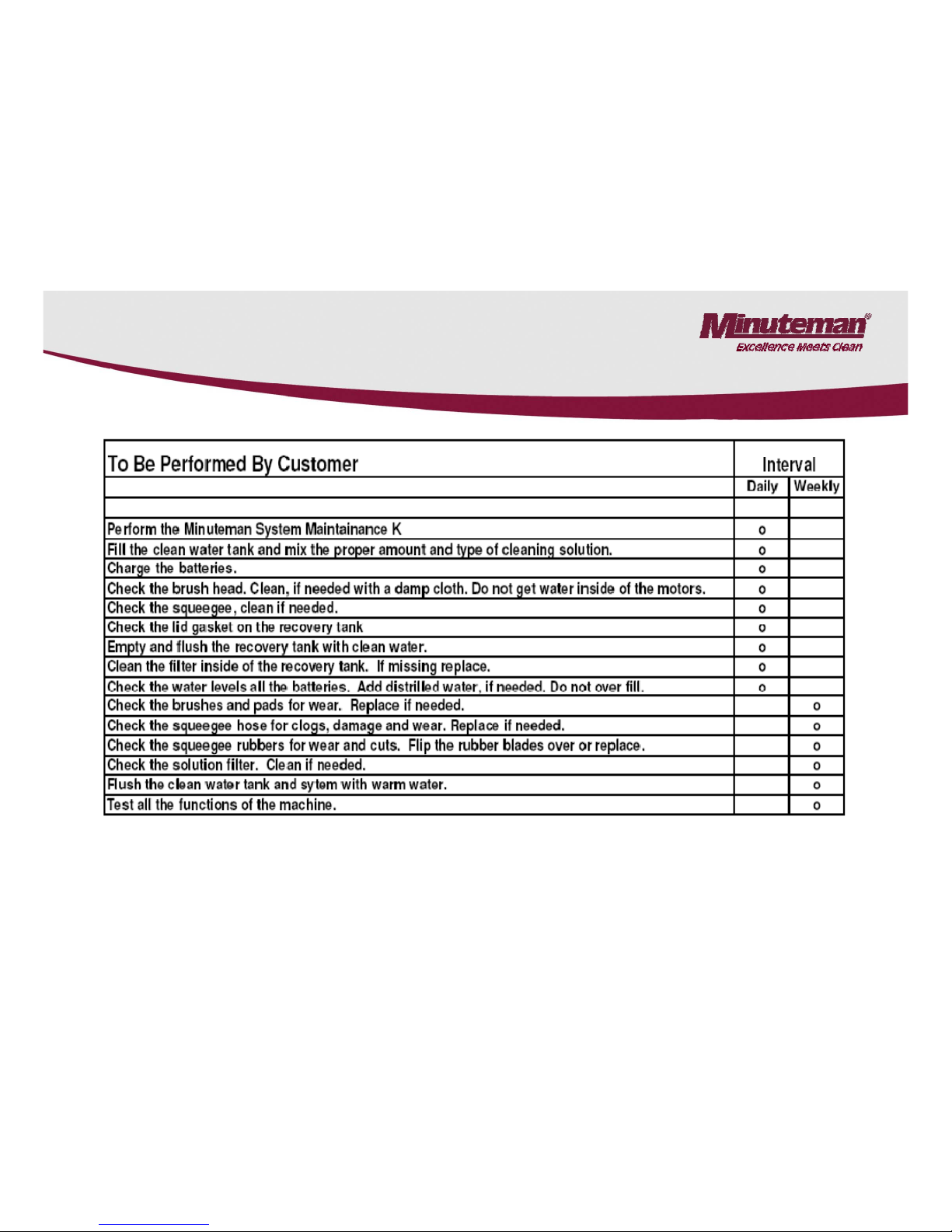

2. Maintenance Intervals

•Maintenance Intervals:

In a modular structure, the Minuteman System Maintenance determines the specific

technical proceedures to be preformed and sets the time interval between the two

maintenance cycles.

For each of the maintenance cycle, the replaceable parts are determined as well.

Further details described in the specific chapters.

•Minuteman System Maintenance K:

To be performed by the customer (in daily or weekly intervals) according to the maintenance

and care instructions as specified in the operating instructions.

The operator must be professionally instructed after delivery of the machine by selling

dealer .

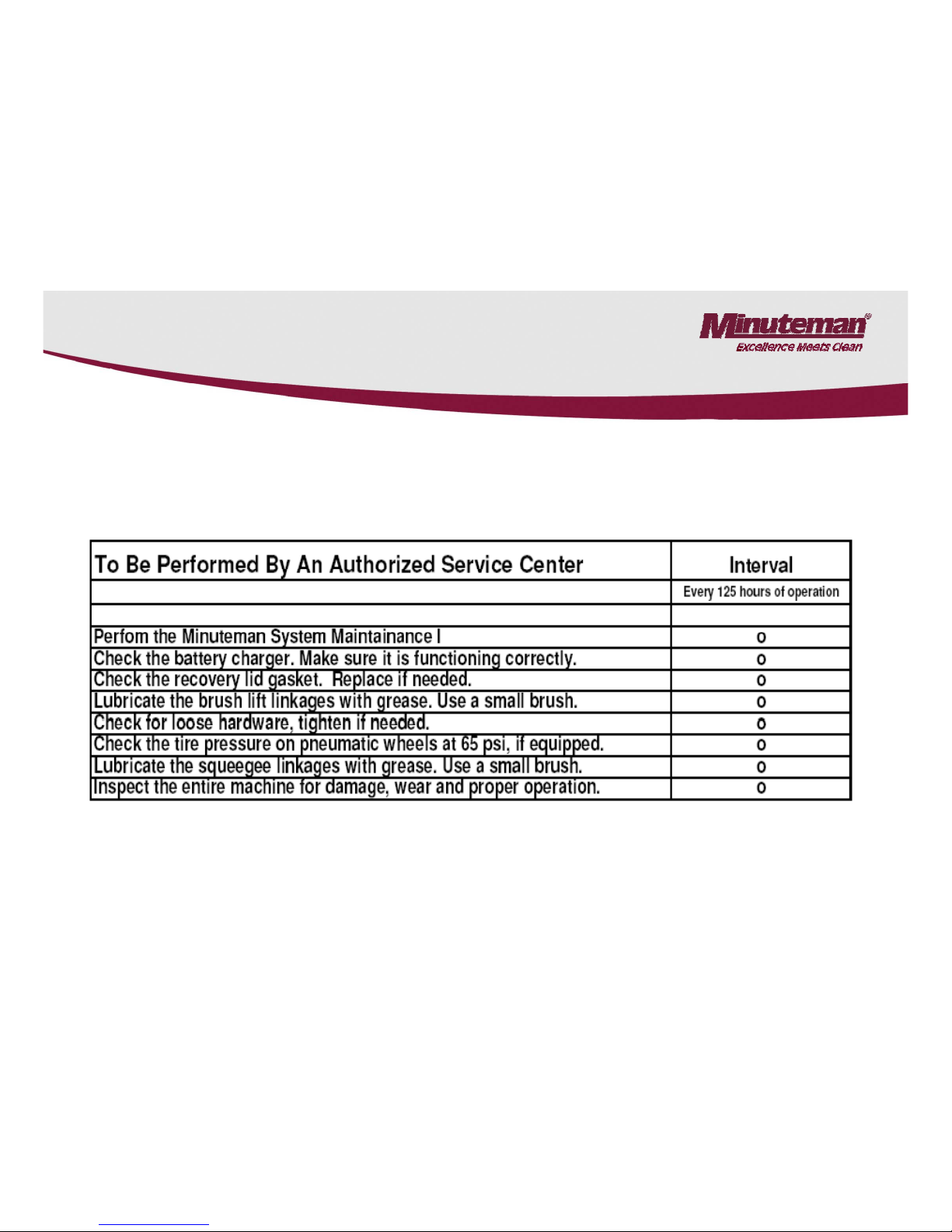

•Minuteman System Maintenance I: (after every 125 hours of operation)

To be preformed an authorized Minuteman Service Center in accordance with the machinespecific system maintenance.

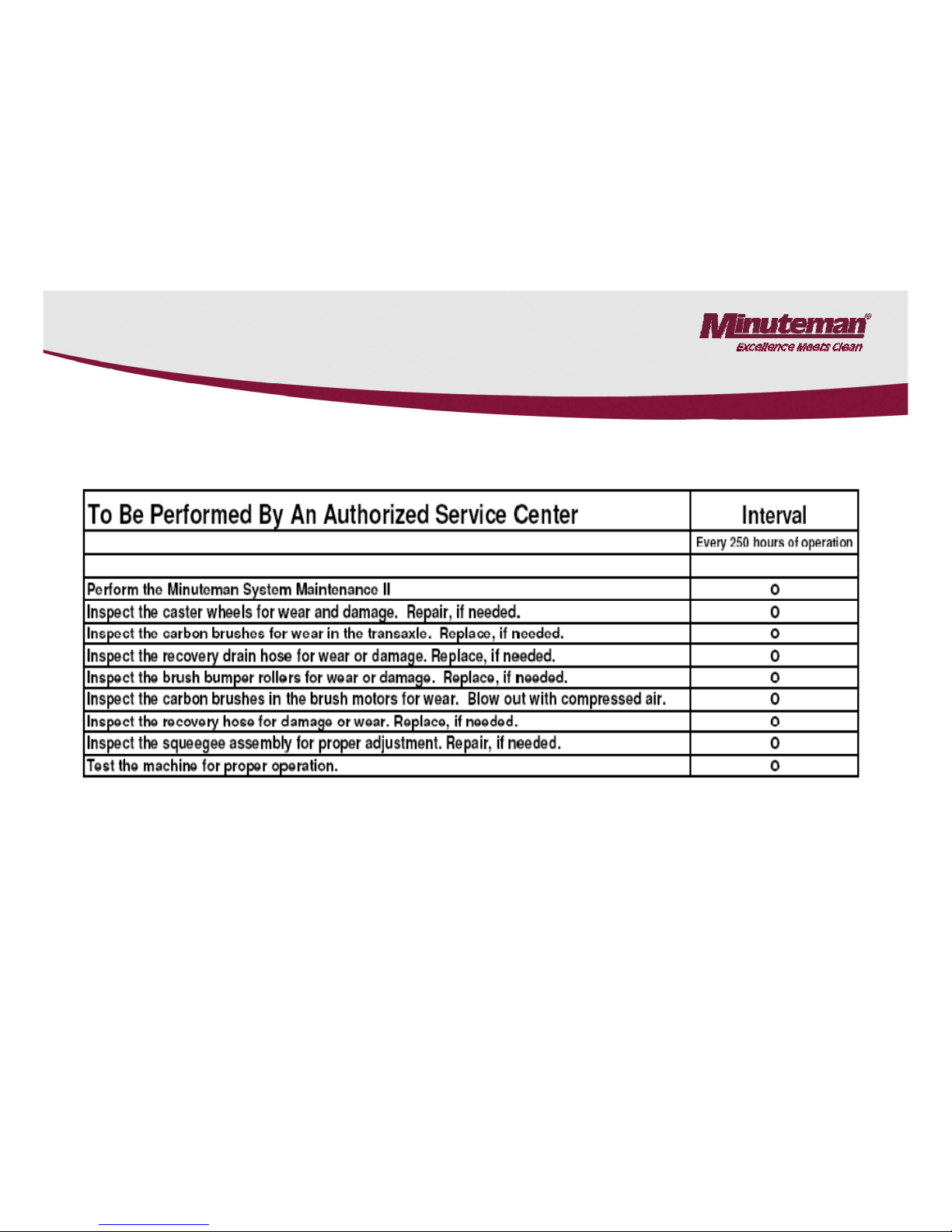

•Minuteman System Maintenance II: (after every 250 hours of operation)

To be preformed an authorized Minuteman Service Center in accordance with the machinespecific system maintenance.

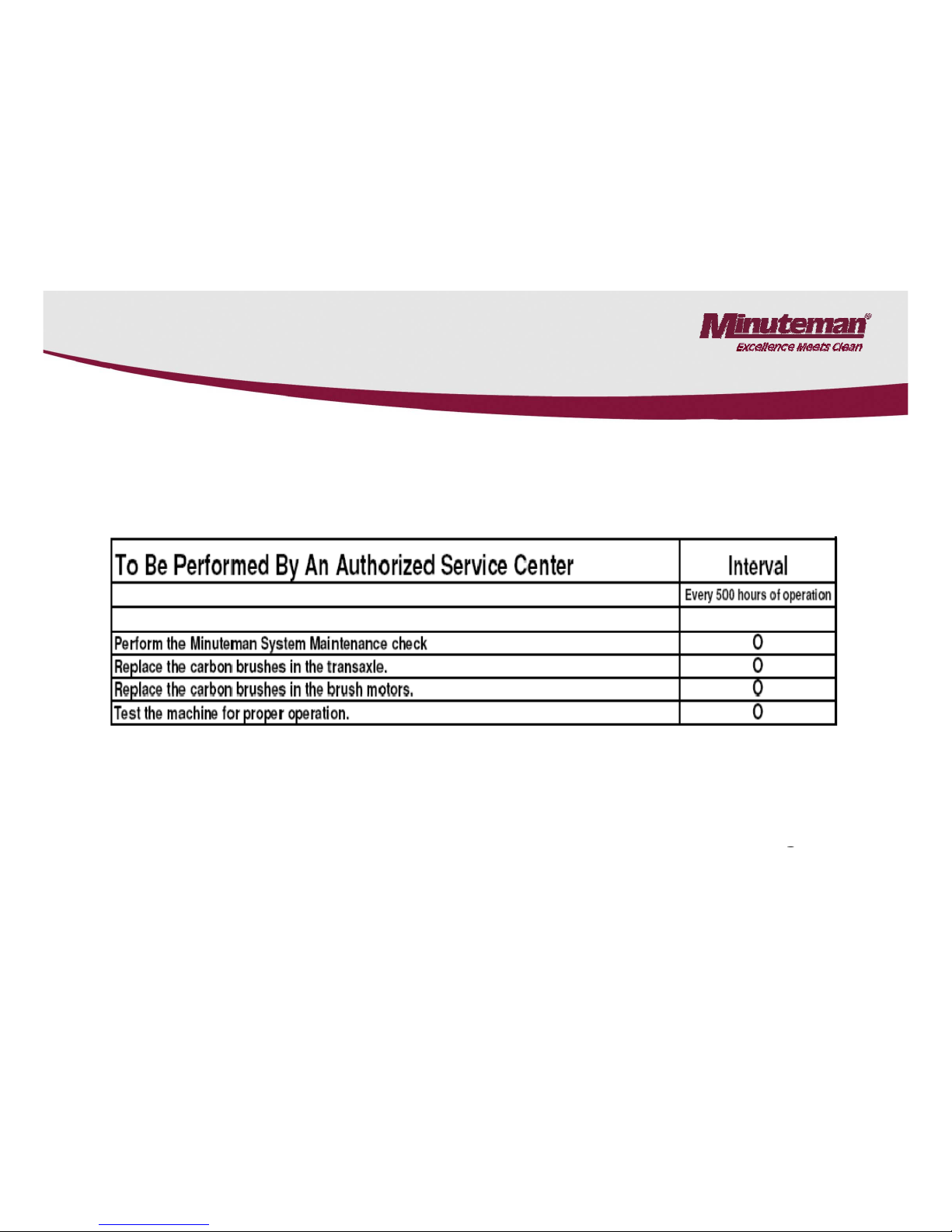

•Minuteman System Maintenance S: (after every 500 hours of operation, safety check) To

be performed by an authorized Minuteman Service Center in accordance with the machinespecific system maintenance.

Page 5

Page 6

2.1 Minuteman System Maintenance K

Page 6

Page 7

2.2 Minuteman System Maintenance I

Page 7

Page 8

2.3 Minuteman System Maintenance II

Page 8

Page 9

2.4 Minuteman System Maintenance S

Page 9

g

Page 10

3. Service Mode

The Service mode switch can be used to lower the brush deck.

Press and hold the switch in the down position and the deck will lower. Once

it is in service mode, the deck can raised and lowered by pressing the top or

lower part of the rocker switch. To return the machine back to normal

operation: Turn the key switch off and back on. The machine will reset.

The switch located below the seat

The switch is located below the recovery

behind the panel on the SCVs. (Not

equipped on the SC280000 models)

tank

on the

ES2832

and

CP2832

models.

Page 10

Page 11

3.1 Service Mode SC280000

Push and hold the brush

pressure down button for

-

15

20 seconds.

Once it is in service mode,

You can raise and lower

the deck b

uy pressing the

brush pressure up and

down arrows.

To return the machine back

to normal operation: T urn

the key switch off and back

Page 11

on. The machine will reset.

Page 12

3.2 Service Mode SCV2426

The Service Mode Switch on

the SCV2426 is located next

to the step on the front of the

’

machine on the operator s

left side.

Once it is in service mode,

the deck can raised and

lowered by pressing the

upper or lower part of the

rocker switch.

To return the machine back to normal operation: Turn the key switch off

and back on. The machine will reset.

Page 12

Page 13

4. Brush Pressure Settings

The brush pressure range can be

changed when changing the type of

deck on the SC2832E, SC2426P,

CP2832 and ES2832 models.

Connect the oran

g

e/violet wire into

g

the terminal block with red/black wire

group for cylindrical decks and

unplug it for the disk decks.

The terminal block is located below

the T rio controller on the SCVs and

below the control panel on the ES

Trio Controller

SCV 2832E Shown

Page 13

Page 14

4.1 ES2832,CP2832, and Phoenix 34

It is now available to change the brush pressure settings in

the field, when changing brush decks on current production

models of the Easy Scrub 28 and 32. No other modifications

will be required.

Changing the brush pressure settings will only be required,

when changing the cylindrical over to the disk deck or disk

over to the cylindrical decks. Changing the size only

(Example: Changing the 28 disk to 32 disk) will not require

changing the settings.

The orange/violet wire from the controller has been added to

change settings.

Connecting the orange/violet wire to the terminal block puts it

in the low-pressure mode for cylindrical decks.

Disconnecting the orange/violet from the terminal block puts

the brush pressure in the high-pressure mode for disk decks.

pg

p

Instructions:

1. Remove the switch panel, by removing the four screws.

2. Locate the terminal block. See Photograph.

Page 14

Page 15

4.2 ES2832,CP2832, and Phoenix 34

Locate the Red/Black wire group Locate the Orange/Violet wire

Page 15

g

Page 16

5. Error Codes

The model SC280000 Rider scrubber uses a LCD display mounted above the steering wheel which

indicates the error code when they occur . The will be displayed as a four digit code with a picture of

a wrench next it. The to

p

three are the hour meters for Total Time, Brush Motors and Drive Motor .

p,

The SC2832E, SC2426P, ES2862 and CP2832 models uses a 10 light LED display to indicate the

battery condition a error codes. The battery condition will be displayed with 1 to 10 LEDS. 10 LEDs

would be a fully charged battery one LED batteries are discharged.

When a error occurs 1 to 10 LEDS will flash indicating a specific error has occurred. There are two

aspects of the error codes.

A.H

ow many

LEDS

are flashing

B. How many times it is flashing ( referred to as sequence)

Page 16

Page 17

6. Table of Error Codes

Code Information or Fault Description Comments and Corrective Action

0810 TILLER FAULT-1 For all Throttle Potentiometer Circuit Diagnostic Codes:

-

0811

TILLER MAX WIPER DIFFERENCE ERROR

1

Check throttle wiring for shorts or opens

.

Repair or replace as necessary

.

0812 TILLER MAX PULL DOWN DIFFERENCE ERROR 2- If Diagnostic Code is not cleared, then replace throttle.

0813 TILLER MAX PULL SAFE DIFFERENCE ERROR " " " "

0814 TILLER REFERENCE ERROR

Throttle displaced during start up. Check throttle springs (Riders) or drive switches (ES or

CPs)

0815 TILLER LO REFERENCE ERROR 1- Check throttle wiring for shorts or opens. Repair or replace as necessary.

0816 TILLER HI REFERENCE ISO ERROR 2- If Diagnostic Code is not cleared, then replace throttle.

""""

0817

TILLER LO REFERENCE ISO ERROR

0818 TILLER ERROR BOTH HAVE READINGS " " " "

1310 EXCESSIVE CURRENT TRIP Current draw of all output devices connected to TRIO+ exceeded 250 amp maximum limit.

1311 SOFT AUX1 OVERCURRENT OCCURRED

Brush Actuator on Aux-1 exceeded 21 amp max. current limit. Check wiring or replace

device.

1312 SOFT AUX2 OVERCURRENT OCCURRED

Squeegee Actuator on Aux-2 exceeded 21 amp max. current limit. Check wiring or replace

device.

1313 SOFT AUX3 OVERCURRENT OCCURRED Water Pump on Aux-3 exceeded 7 amp max. current limit. Check wiring or replace device.

1314 SOFT AUX4 OVERCURRENT OCCURRED

Water Solenoid on Aux-4 exceeded 7 amp max. current limit. Check wiring or replace

device.

1318 SOLUTION TANK EMPTY Solution Tank Empty signal from float switch

131C SOFT ALARM OVERCURRENT OCCURRED Alarm circuit exceeded 2 amp max. current limit. Check wiring or replace device.

1321 AUX1 OVERCURRENT 2 OCCURRED Device connected to Aux-1 exceeded 12 amps for > .1 sec Check Brush Actuator.

>

1322

AUX2 OVERCURRENT 2 OCCURRED

Device connected to Aux 2 exceeded 12 amps for .1 sec. Check wiring or replace device.

1411 ERROR AUX 1 POSITIVE SHORTED_LOW Check Brush Actuator Motor and wiring. Repair or replace as necessary.

1412 ERROR AUX 1 NEGATIVE SHORTED LOW Check Brush Actuator Motor and wiring. Repair or replace as necessary.

1413 ERROR AUX 2 POSITIVE SHORTED LOW Check Squeegee actuator and wiring. Repair or replace as necessary.

1414 ERROR AUX 2 NEGATIVE SHORTED LOW Check Squeegee actuator and wiring. Repair or replace as necessary.

1500 BRAKE FAULT OPEN CIRCUIT Check Electric Brake circuit for a faulty connection.

1501 BRAKE FAULT 2 Check Electric Brake circuit for a faulty connection.

1507

BRAKE OVER CURRENT ERROR

Check Brake circuit wiring and brake

.

Repair or replace as necessary

.

1600 HIGH BATTERY ERROR Battery is overcharged or damaged. Replace battery.

1D02 FRONT END SPEC CHANGE TRIP Drive parameters have been reprogrammed. Cycle power with key switch.

1E03 INHIBIT ACTIVATED Solution Tank Empty - Check float switch

1E04 INHIBIT ACTIVATED2 Recovery Tank Full - Check float switch

1E06 INHIBIT INPUT OUT OF RANGE Invalid Inhibit signal. Check wiring and device. Repair or replace as necessary.

Page 17

Page 18

6. Table of Error Codes

2C00 LOW BATTERY ERROR Battery Charge to low. Recharge battery.

2C01 LOW BATTERY ERROR2 Battery Charge to low. Recharge battery.

2C02 SOFT BATTERY LOCKOUT OCCURRED Batter

y

Charge to low. Recharge battery.

yg g y

2C03 SOFT BATTERY LOCKOUT 2 OCCURRED Battery Charge to low. Recharge battery.

2F01 TILLER DISPLACED ERROR Throttle displaced on Power-up. Release throttle and then re-engage throttle.

3A00 BAD SETTINGS Illegal program parameter settings.

7000 STARTUP WITH PUSH SELECTED Freewheel Input signal detected at startup. Disconnect Freewheel input.

7001 PUSH ACTI VATED IN DRIVE MODE Freewheel Input signal activated while driving. Disconnect Freewheel input.

7500

TILLER COMMS TIMEOUT

Problem with LCD Module or wiring

.

Repair or replace as necessary

.

7600 SOFT BRUSH MOTOR DISCONNECTED ERROR Check Brush Motor wiring and connectors

7601 SOFT BRUSH CURRENT FOLDBACK Too much Brush Pressure/Current. Check for jammed Brushes or Deck or Brush motor short.

7602 SOFT BRUSH CURRENT FOLDBACK2 Too much Brush Pressure/Current. Check for jammed Brushes or Deck or Brush motor short.

7603 SOFT BRUSH CURRENT FOLDBACK3 Too much Brush Pressure/Current. Check for jammed Brushes or Deck or Brush motor short.

7604 SOFT BRUSH INHIBIT Brush Inhibit signal is active.

7605 BRUSH STARTUP OVERCURRENT DETECTION Possible Brush motor problem or shorted brush circuit wiring.

7700 SOFT VACUUM MOTOR DISCONNECTED ERROR Check Vacuum Motor wiring and connectors

7701 SOFT VACUUM CURRENT FOLDBACK Too much Vac motor current. Check for shorted Vac motor or wiring.

7702 SOFT VACUUM CURRENT FOLDBACK2 Too much Vac motor current. Check for shorted Vac motor or wiring.

7703 SOFT VACUUM CURRENT FOLDBACK3 Too much Vac motor current. Check for shorted Vac motor or wiring.

7800 TRACTION MOTOR FAULT-1 Check Traction Motor wiring and connectors

7801 TRACTION MOTOR OVER CURRENT ERROR Too much Traction motor current. Check for shorted Traction motor or wiring.

7802 TRACTION MOTOR IN FOLDBACK STATE Traction Motor was overloaded for too long, Control limiting current to protect motor.

7803 MOTOR LINE VOLTAGES INSTABILITY TIMEOUT Possible Traction Motor or loose wiring problem.

7804 TRACTION MOTOR IN DRIVE BOOST Traction Motor under heavy load or Current Limit / Fold back parameters set too low.

7880

TRACTION SPEED INPUT OUT OF RANGE

Check Throttle

Potentiometer

and wiring

.

7900 EMERGENCY STOP ERROR Emergency Stop function activated.

7901 SOFT BELLY BUTTON ACTIVATED Safety Bar switch is activated. (ES and CP models only)

8000 SERVICE MODE Service Timer limits have been reached.

9000 BRUSHES NOT FITTED Check Brush Deck to make sure Brushes are fitted properly.

Page 18

Page 19

6. Table of Error Codes

0003 For All of these Diagnostic Codes:

-

01001Turn Off

Key switch

and disconnect batteries.

0204 2-Wait 1 minute.

0705 3-Reconnect Batteries and turn on key switch.

0706 4-If Diagnostic Code is not cleared, then replace TRIO+ / TRIO+HD control.

0A01

0B02

IMPORTANT!

0B0B TRIO+ / TRIO+HD can be damaged internally by shorting Batt+ to any of it's Inputs or Outputs.

gyyg ypp

Check Wiring Harness for shorts before installing a replacement Control.

1704 If replacement control fails, then replace Wiring Harness before installing any more Controls.

1705

1706

1800

1802

1B20

1B21

2102

2103

2D01

3100 Shorted Circuit Check For Shorts on the Brush and Drive Motor Circuits. Also Water inside of motors.

3101

3102

3103

3104

3105

3200

3201

3210

3211

Page 19

Page 20

6. Table of Error Codes

3212 For All of these Diagnostic Codes:

3213 1- Turn Off Key switch and disconnect batteries.

3214 2- Wait 1 minute.

3- Reconnect Batteries and turn On Key switch.

-

+

+

36014If Diagnostic Code is not cleared, then replace TRIO / TRIO HD control.

3602

3603

3608

3609 IMPORTANT!

360A TRIO+ / TRIO+HD can be damaged internally by shorting Batt+ to any of it's Inputs or Outputs.

360B Check Wiring Harness for shorts before installing a replacement Control.

360C If replacement control fails, then replace Wiring Harness before installing any more Controls.

360D

360E

Page 20

7501

Page 21

5.1 Table Error Codes (LED)

Single flash Low Batteries

-

Charge

the batteries

Single flash Traction drive motor disconnected

Single flash - Brush motor disconnected

Single flash - Brush actuator overload

Two flash – Squeegee actuator overload

Page 21

Page 22

5.1 Table Error Codes (LED)

Single flash

–

Vacuum motor disconnected

Single flash

-

Off Isle Wand Activated

Single flash

-Potentiometer fault

Single flash

-

Control fault check all connections to

controller- see “Trouble Shooting the Code 8 Error”

Page 22

Page 23

5.1 Table Error Codes (LED)

Single Flash- Solution tank empty- Riders onl

y

g

py

y

Two flash

-

Not used

Th

ree flash-Water solenoid fault

Four flash-Water pump fault

Five flash

-

Electric brake circuit fault

-

Check all connection to

the brake.

Page 23

Page 24

5.1 Table Error Codes (LED)

Single flash

-

High battery voltage

-

Check all connections

Ripple-Throttle activated during start up.

Page 24

Page 25

6. Side Squeegee Adjustment

Cylindrical Decks

The side squeegees on the

cylindrical decks can be

SCV2426 & SCV2832E Only

adjusted by loosening the two

black knobs and moving the

squeegee assemble up or

down.

B

The brush assembly may be

accessed by removing the

yellow knob C. The squeegee

E

assembly is hinged at D

.

Remove the three wing nuts

that mount the brush idler

bearing assembly E and

remove the brush roll.

Repeat the process on both

A-Side Squeegee

B-Black Adjustment Knob

-

sides of the machines

C

Yellow Brush Access Knob

D-Side Squeegee Hinge

E-Bush Access Plate

Page 25

Page 26

6.1 Side Squeegee Adjustment

SCV2426 & SCV2832E Only

Disk Decks

The side squeegee

assemblies can be

adjusted by loosening

Wing Nuts

the two wing nuts and

moving the assembly

up or down.

Wing Nuts

Repeat the process on

both sides, if needed.

Squeegee

A

ssembly

Page 26

Page 27

7. Squeegee Adjustment

Later Models Onl

y

y

• The pitch of the squeegee

can be adjusted by turning

Wing Nuts

the knob

. Loosen the wing

nuts before adjusting.

Tighten the wing nuts to

lock into position

.

Adjustment Knob

Page 27

Page 28

7. Rear Squeegee Adjustment

Later Models Only

Page 28

Page 29

7. Rear Squeegee Adjustment

Later Models Onl

y

y

Page 29

Page 30

8. Replacing the Brush Actuator on the SCV 28 or 32

All Versions Of SCV2832E and SC280000

Replacing the Brush Actuator on the SCV 28 or 32

1. Lower the brush deck, so it gently rests on the floor.

2. Remove the side

squeegees

.

2.

Remove the side squeegees.

3. Remove the four bolts that mount the deck to the lift linkage.

4. Unplug the electrical connector and the Quick Connector for the solution from the deck.

5. Slide the deck out from under the machine.

6. Unplug the electrical connector to the actuator motor.

7. Remove the two pins that mount the actuator on each end.

8. Remove the actuator from the machine.

9. Mount the new actuator. Do not connect the electrical connector on the actuator at this point.

10. Connect the battery pack.

11.

Turn the machine on.

12. Put the machine in Service Mode. Hold one of the brush pressure buttons on the touch pad for over 20

seconds and release on the model SC2800000. The SC28/32E’s service mode switch is located in the

controller compartment under the seat, on the operators left side. Push the rocker switch in the down

position for 20 seconds.

13.Connect the actuator electrical connector into the harness

.

14. Use the up and down buttons on the touch pad to adjust the brush linkage height, so that you can slide

the brush deck into position. Do not raise it all the way up, until it is set correctly.

15. Lower the linkage down, using the touch pad or rocker switch, so that it gently rests on the mounting

brackets.

Page 30

Page 31

8. Replacing the Brush Actuator on the SCV 28 or 32

All Versions Of SCV2832E and SC280000

16. Slide the brush deck into position, install the four mounting bolts and tighten. Connect the brush motor

connector and solution quick connector.

17

. Locate the black rubber removable plug on the right side of the actuator and remove.

18. For models with cylindrical decks only. Remove the plastic side deck cover on the operators left side.

This is a gray plastic piece screwed to the side of the solution tank above the deck area.

19. Use the brush pressure up button to raise it up a little at a time. The clearance between the top belt cover

and the under side of the tank should between 1/4 to 3/8 inch, when the deck stops rising up. Do not

allow it to rise any higher or it might over load the actuator. If it continues to rise higher, adjustment w

ill

be required.

20. For Disk machines only, the actuator should be set so that you can slide the brushes under the deck and

not bottom out under the machine.

21. Adjust the actuator adjustment screw to change setting see drawing. Turn the screw no more than 1/8 of a

t

urn at a time. The adjustment screw closest to the shaft controls how high it rises. The screw furthest

from movable controls maximum down pressure. Look at the rubber plug to determine which way to turn

the screw.

22. Lower the brush deck and return it back up for the new settings to change.

23. Adjust the down setting so that the actuator cannot lift the drive motor off the floor. Set it so it only lifts

some pressure off the drive wheel.

24. Once the correct setting is made replace the rubber plug into the side of the actuator motor.

25. Replace side plastic cover.

26. Turn the key switch off and back on.

27. Test the machine.

Page 31

Page 32

8.1 Actuator Adjustment

Page 32

Page 33

8.2 Entering Service Mode with a Stuck Actuator

Page 33

Page 34

9. Trouble Shooting the Code 8 Error

ES2832,CP2832,SCV2426andSC2832EModelsOnly)

1.Check for loose or burnt connections on the controller, batteries, cables and

the circuit breaker. Make the sure the circuit breaker is not damaged.

2.Measure the total battery voltage at the batteries and at the battery

yg y

connections on the controller. They should be exactly the same. A 1/10 of a

volt or more difference would indicate a problem in the connections.

3.Check to see, if the operator has recently washed the machine down and got

water inside of the brush motor or in the controller area.

4.On the ES2832 and CP2832 only disconnect the plug on the Service Mode

Switch. This is accessible by tilting the solution tank forward. Power the

machine up with it disconnected

. If

error code is cleared replace the switch

.

5.Check for a disconnected or an open circuit or faulty potentiometer on the

throttle or speed circuit. Controller may not be detecting it in the circuit. Do a

continuit

y

test. See “Testing the potentiometer” section.

ygp

Page 34

Page 35

9. Trouble Shooting the Code 8 Error

6. Disconnect one motor connector from the Trio controller at a time and

disconnect the batteries for 1 minute and restart the machine. If the code

8 disappears and is replaced by a different code, the circuit disconnected

should be considered suspect. For example the brush was disconnected.

The code 8 is replaced by code 3. Code 3 indicates the brush motor is

disconnected

.

Check for a loose or broken connection at the brush deck

.

Check to see if water has gotten inside the brush motor. Check for a

shorted motor.

7. Static electricity. Check both the ground chains; there is one on the brush

deck

and one on the rear of the machine. They should be contacting the

floor. The one on the deck should touch the floor when the deck is down.

They also should have continuity between the end of the chain and the

frame of the machine. R

epa

ir or clean if n

eeded

if n

eeded

.

a e o t e ac e epa o c ea eeded eeded

8. If everything checks OK, replace the Trio Controller.

Note controllers can be damaged by loose connections on inputs and outputs, static

electricity and water on electrical components such as on or in the controller and motors.

Page 35

Page 36

10. Testing the Throttle Potentiometer

1. The throttle potentiometer resistance can be measured with an ohmmeter.

2. Unplu

g

the throttle potentiometer at the connector next to it.

g

3. Analog type meters are recommended for this test.

4. Measure the resistance across the red and white wire on the potentiometer assembly. It should

measure approximately 5K (5 thousand ohms).

5. Measure across the black and white wires on the

p

otentiometer, the resistance should be zero

p

ohms with pedal on the riders in the neutral position or speed knob on the ES2832 and CP2832 in

the full counterclockwise position. When the pedal or knob is moved to the full throttle position, in

should be a smooth resistance change without dropping out. It should measure approximately 5K

(5 thousand ohms) in the full position.

6.M

easuring across the black an

d

th

e red wire the resistance should be approximately 5K (5

thousand), when in the neutral position. When the pedal is at full throttle or the knob is full speed

position, the resistance should drop to zero.

7. If adjustment is needed, loosen the nut and screw on the throttle arm. Adjust the potentiometer

shaft with a flat tip screw driver, until it is set according to the information above (on the riders

only).

Page 36

Potentiometer Assembly

Adjust Here

Page 37

10. Testing the Throttle Potentiometer

8. If they do not find a problem here, have them retest at the connector at the Trio

controller.

9. Reconnect the plug at the throttle potentiometer.

10. Unplug the P3 connector (The large white connector) on the controller under the seat on the riders

and behind the two rear panels on the ES2832s and CP2832s.

11. L

ocate the black/orange and the black/pink wire.

12. Measuring across the black/orange and black/pink wires the resistance should be zero ohms in the

neutral position. It should 5k in the full throttle position.

13. Measure across the black/pink and the black/white wires. The resistance should be 5K (5

thousand) in the neutral position. When the pedal is at full throttle the resistance should drop to

zero.

14. If your reading is different with this test check all the connections between the controller and the

throttle control, including the seat switch.

Note: when moving the throttle to the

full position, the resistance should be smooth, without

dropping out for both tests. If the resistance does not go to 5K during the test, the arm and

the potentiometer may need to be adjusted to achieve it.

Page 37

Page 38

11. Identifying the Cause of Trio Failures

1. Check for loose or burnt connections on the controller, batteries, cables and the circuit breaker.

Make the sure the circuit breaker is not damaged (burnt or cracked).

2. Test the chassis drive motor harness for broken wires (riders only). Disconnect the plug labeled

Traction on the Trio controller. Connect a digital multi-meter to the plug on the two large wires.

Set the meter for Ohms (resistance). The resistance should be .3 to .4 ohms. Turn the steering

wheel in both directions until it stops several times

.

Monitor the meter while turning. The

resistance should not change or vary while turning. Any variation even .1 ohm would be indicate

a broken wire, which could cause spikes and surges, that could damage the Trio controller.

3. Measure the total battery voltage at the batteries and at the battery connections on the controller.

The

y

should be exactly the same. A 1/10 of a volt or more difference would indicate a problem in

yy p

the connections.

Page 38

Page 39

12. Notes

Page 39

Loading...

Loading...