Page 1

SCV 28/32 RIDER SCRUBBER

OPERATION

■ SERVICE ■ PARTS ■ CARE

Page 2

(

)

This manual is furnished with each new MINUTEMAN SCVTM 28/32. This provides the necessary operating

and preventive maintenance instructions. Operators must read and understand this manual before operating

or servicing this machine.

This machine was designed to give you excellent performance and efficiency. For best results and minimal

cost, please follow the general guidelines below:

• Operate the machine with reasonable care.

• Follow the manufacturers suggested maintenance instructions as provided in this booklet.

• Use original Minuteman supplied parts.

TECHNICAL SPECIFICATIONS

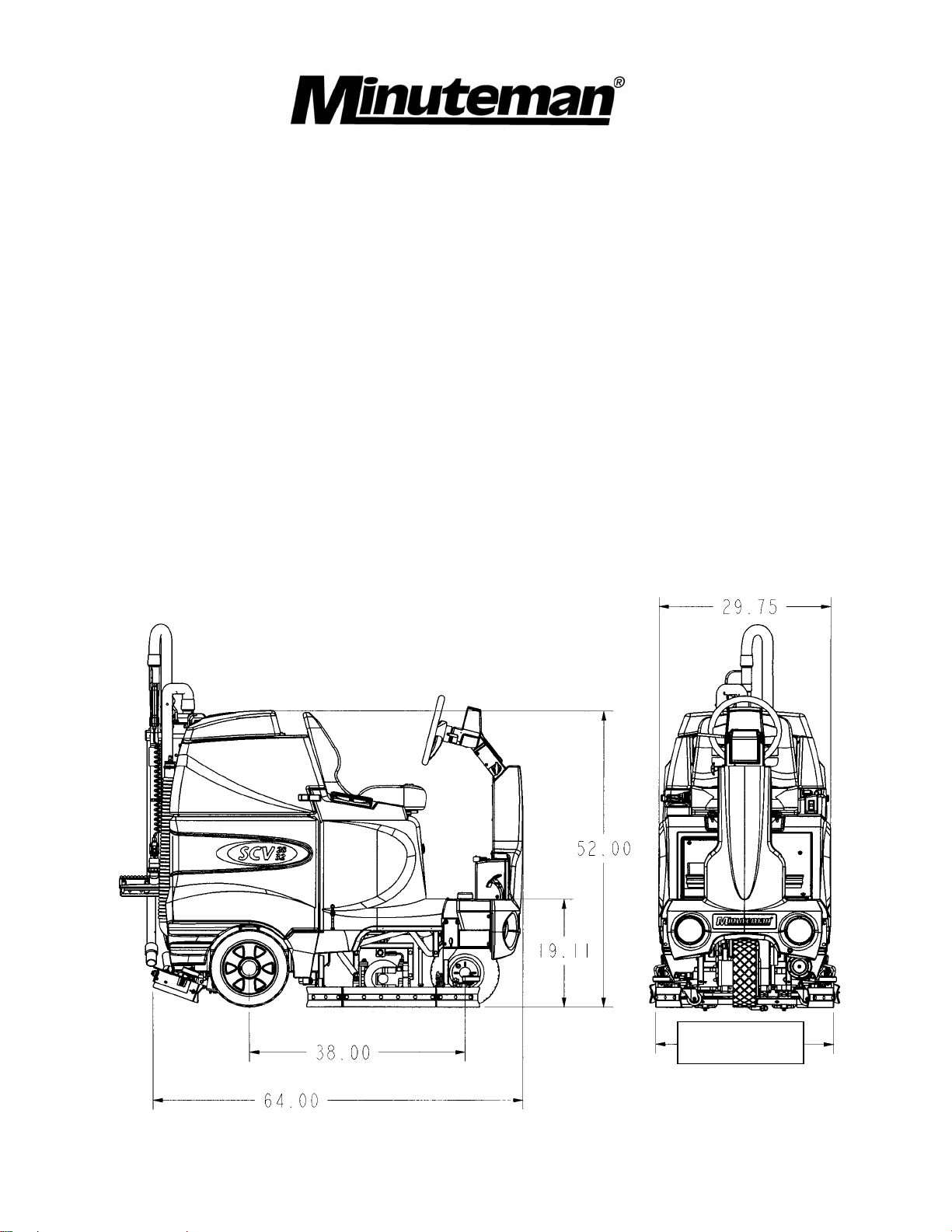

Model SCVTM28/32

Model No. SC280000QP / SC280001QP / SC32000QP / SC320001QP

SC280000CE / SC280001CE / SC320000CE / SC320001CE

Current 65 Amps

Voltage, Batteries 36 volts, 6-6volt

Battery Capacity 370 AH

Sound Level 72 dB

Dimensions (LxWxH) 64” x 31” x 54” (160cm x 78.74cm x 137cm)

Gross Weight 1,495 lbs (678 kg) with batteries

793 lbs (360 kg) without batteries

Working Grade Transport 16% (10°)

Working Grade Cleaning 10% (7°)

Wheel to Floor Pressure 64 PSI Front, 69 PSI Rear

31.00 (SCV 28)

SCV 32

35.00

2

Page 3

3

Page 4

TABLE OF CONTENTS

Operation, Illustration, Spare Parts, and Maintenance

IMPORTANT SAFETY INSTRUCTIONS.........1

FOR SAFETY DURING OPERATION: ........1

FOR SAFETY WHEN SERVICING

MAINTAINING MACHINE: ...........................1

INSPECTION....................................................1

ELECTRICAL ...................................................1

BATTERIES .....................................................1

OPERATOR RESPONSIBILITY ......................1

MACHINE COMPONENTS ..............................1

FRONT .............................................................1

MACHINE COMPONENTS ..............................2

REAR................................................................2

MACHINE COMPONENTS ..............................2

DRIVER’S COMPARTMENT ...........................2

CONTROL CONSOLE .................................3

Key switch................................................3

Off-aisle wand switch ...............................3

Headlight switch.......................................3

Main Keyboard.........................................3

Horn button ..............................................3

Directional switch .....................................3

MAIN KEYBOARD .......................................4

FULL FUNCTION MODE.........................4

DOUBLE SCRUB MODE.........................4

VACUUM ONLY MODE...........................4

TRANSPORT MODE ...............................4

INFORMATION BUTTON ........................4

WATER FLOW ADJUSTMENT ...............5

BRUSH PRESSURE ADJUSTMENT ......5

EMPTY SOLUTION TANK INDICATOR..5

RECOVERY TANK FULL INDICATOR ...5

LCD DISPLAYS............................................5

INFORMATION BUTTON ........................5

DIRECTIONAL SWITCH FORWARD......5

DIRECTIONAL SWITCH REVERSE .......5

FULL FUNCTION MODE.........................6

DOUBLE SCRUB MODE.........................6

VACUUM ONLY MODE...........................6

TRANSPORT MODE ...............................6

BRUSH PRESSURE ADJUSTMENT ......6

WATER FLOW ADJUSTMENT ...............6

OR

EMPTY SOLUTION TANK INDICATOR. 6

RECOVERY TANK FULL INDICATOR... 6

LOW BATTERY INDICATOR.................. 7

DIAGNOSTIC CODE............................... 7

FAULT / DIAGNOSTIC CODE ................ 7

OPERATION OF CONTROLS .................... 8

POWER SAVE MODE................................. 8

ACCELERATOR PEDAL ........................ 8

SEAT ....................................................... 8

STEERING WHEEL ................................ 8

MECHANICAL & PARKING BRAKE....... 9

EMERGENCY DISCONNECT BUTTON 9

CIRCUIT BREAKERS ................................. 9

BATTERY COMPARTMENT..................... 10

SCRUB DECK ........................................... 11

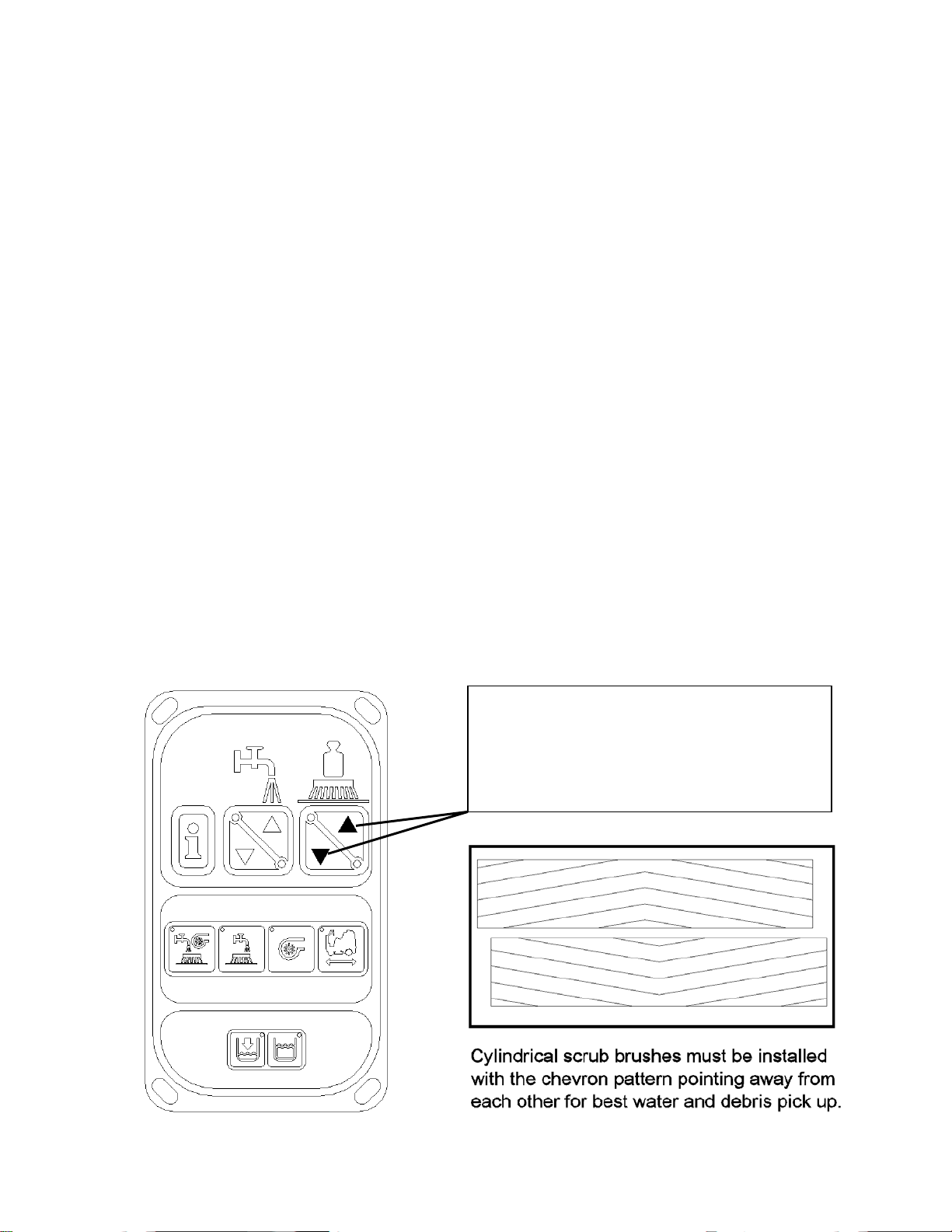

CYLINDRICAL....................................... 11

SCRUB DECK....................................... 11

DISC SCRUB DECK ............................. 11

SCRUB DECK INSTALLATION ................ 12

REAR SQUEEGEE ................................... 14

REAR SQUEEGEE COMPONENTS .... 14

REAR SQUEEGEE ADJUSTMENT...... 15

OFF-AISLE WAND................................ 15

OFF-AISLE WAND TOOL..................... 16

THE SCV RIDER ........................................... 17

MACHINE OPERATION............................ 17

AFTER USE: ......................................... 19

MAINTENANCE SCHEDULE.................... 20

LUBRICATING THE MACHINE ............ 20

GENERAL MACHINE

TROUBLESHOOTING

.............................. 21

SCV 28/32 FAULT / DIAGNOSTIC CODES . 23

EXPLODED VIEWS....................................... 25

MAIN ASSEMBLY I ................................... 25

MAIN ASSEMBLY II .................................. 27

MAINFRAME ASSEMBLY I....................... 29

MAINFRAME ASSEMBLY II...................... 30

FRONT DRIVE ASSEMBLY...................... 32

STEERING ASSEMBLY............................ 34

LCD HOUSING ASSEMBLY ..................... 36

SOLUTION TANK ASSEMBLY ................. 37

ELECTRICAL PANEL ASSEMBLY ........... 39

CONSOLE ASSEMBLY............................. 40

RECOVERY TANK ASSEMBLY I ............. 41

RECOVERY TANK II................................. 43

DIVERTER ASSEMBLY ............................ 44

BATTERY BOX ASSEMBLY ..................... 45

PUMP ASSEMBLY.................................... 46

REAR AXLE ASSEMBLY .......................... 48

SQUEEGEE MECHANISM ASSEMBLY... 49

Page 5

REAR SQUEEGEE ASSEMBLY 28” .........50

REAR SQUEEGEE ASSEMBLY 32” .........52

28” CYLINDRICAL SCRUB DECK

ASSEMBLY ................................................54

28” DISC SCRUB DECK ASSEMBLY .......56

32” CYLINDRICAL SCRUB DECK

ASSEMBLY ................................................58

32” DISC SCRUB DECK ASSEMBLY .......60

CYLINDRICAL DECK AND SIDE

SQUEEGEE MOUNTING ..........................62

DISC SCRUBDECK AND SIDE SQUEEGEE

MOUNTING................................................64

28” SIDE SQUEEGEE (RIGHT SIDE) .......66

28” SIDE SQUEEGEE (LEFT SIDE)..........67

32” SIDE SQUEEGEE (RIGHT SIDE) .......68

32” SIDE SQUEEGEE (LEFT SIDE)..........69

OFF AISLE WAND ASSEMBLY ................70

PLUMBING DIAGRAM ..................................72

WIRING DIAGRAMS......................................73

INPUTS TO CONTROLLER ......................74

OUTPUTS FROM CONTROLLER.............75

KEYBOARD WIRING.................................76

MACHINE SCHEMATIC.............................77

2

Page 6

IMPORTANT SAFETY INSTRUCTIONS

Operators must read and understand this manual before operating or maintaining this machine.

Do not operate this machine in flammable or explosive areas.

This machine is designed solely for scrubbing dirt and dust in an indoor environment. Minuteman does not

recommend using this machine in any other capacity.

The following information below may cause a potential hazard to the operator and equipment. Read this

manual carefully and be aware when these conditions can exist. Take necessary steps to locate all safety

devices on the machine and train the personnel operating the machine. Report any machine damage or

faulty operation immediately. Do not use machine if it is not in proper operating condition.

FOR SAFETY DURING OPERATION:

Keep hands and feet clear of moving parts while machine is in operation.

Make sure all safety devices are in place and operate properly. All covers, doors and latches must be

closed and fastened before use.

During operation, attention should be paid to other persons in the work area and especially if small children

are present.

Electric motors and components can cause an explosion when operated near explosive materials or vapor.

Do not operate this machine near flammable materials such as solvents, thinners, fuels, grain dust, etc.

Store or park this machine on a level surface only, with parking brake engaged. To prevent unauthorized

use, machine should be stored or parked with the key removed.

This machine is designed for level operation only. Do not operate on ramps or inclines.

This machine is not suitable for picking up hazardous dusts.

Use caution when moving this machine into areas that are below freezing temperatures. Any water in the

tanks or hoses can cause damage to the machine.

FOR SAFETY WHEN SERVICING or MAINTAINING MACHINE:

Stop on level surface and set parking brakes.

Disconnect the power to the machine by pressing the Red Emergency Disconnect Button when charging

batteries or during installation or removal of brushes.

Avoid moving parts. Do not wear loose jackets, shirts, or sleeves when working on machine.

Avoid contact with battery acid. Battery acid can cause burns. When working on or around batteries, wear

protective clothing and safety glasses. Remove metal jewelry. Do not lay tools or metal objects on top of

batteries.

Charging batteries generates explosive gasses. Do not charge batteries when open flames or sparks

are present. Do not smoke. Make sure the charger is turned off before disconnecting it from the machine.

Charge the batteries in a well-ventilated area with the battery cover removed completely.

Do not clean machine with a pressure washer.

Authorized personnel must perform repairs and maintenance. Use Minuteman supplied replacement parts.

SAVE THESE INSTRUCTIONS

1

Page 7

INSPECTION

Carefully unpack and inspect your SCV Rider Scrubber for shipping damage. Follow unpacking

instructions on shipping pallet. Each unit has been tested and thoroughly inspected before shipment. Any

damage is the responsibility of the delivery carrier who should be notified immediately.

ELECTRICAL

This machine is battery operated and designed to operate on 36 volts DC (6) 6-volt batteries.

BATTERIES

The recommended batteries are rated 370Ah (Minuteman P/N 956715).

We do not recommend mixing AMP hour capacities. Any alternate battery sets can be used if they equal

physical size and capacity. See page 13 for service and installation.

OPERATOR RESPONSIBILITY

Read this manual carefully before operating this machine.

The operator is responsible in taking care of the daily maintenance and check ups of the machine to keep

it in good working condition. The operator must inform the service mechanic or supervisor when the

scheduled maintenance intervals are required as stated in the MAINTENANCE section of this manual.

Before starting familiarize yourself with the machine and its controls (see “Machine Overview, Front”,

“Machine Overview, Rear”, “Operator Compartment”, “Control Console” diagrams).

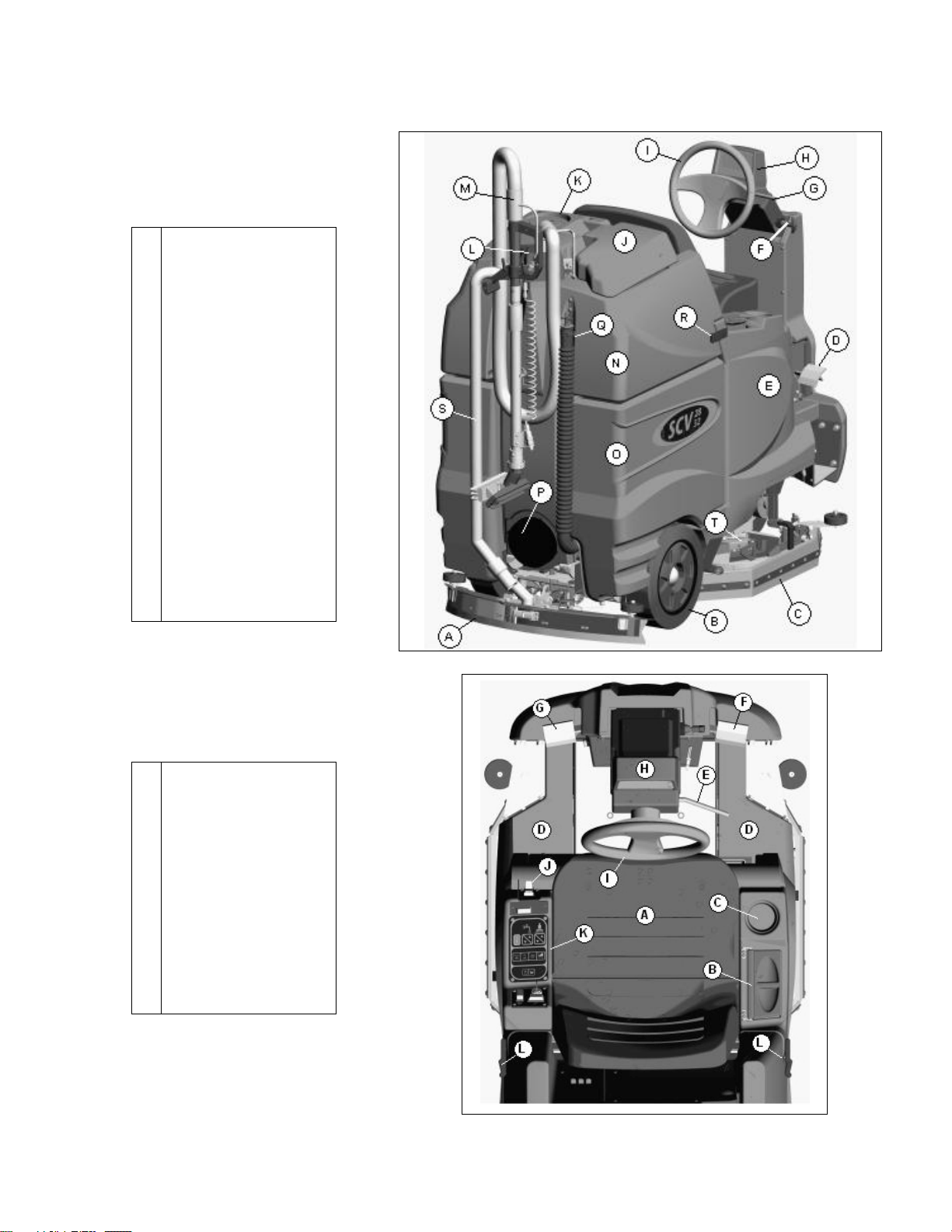

MACHINE COMPONENTS

FRONT

Front drive wheel

A

Side squeegee

B

Headlights

C

Accelerator pedal

D

Tilt-wheel lever

E

Steering wheel

F

Operator’s seat

G

Recovery tank lid

H

Recovery tank

I

Control console

J

Directional switch

K

Safety latch

L

Battery compartment

M

Solution tank

N

Electrical panel

O

Parking brake

P

Rear Squeegee

Q

Rear wheel

R

Scrub deck

S

1

Page 8

MACHINE COMPONENTS

REAR

Rear squeegee

A

Rear wheel

B

Side squeegee

C

Accelerator pedal

D

Solution tank

E

Steering column pivot

F

Tilt-wheel lever

G

LCD display panel

H

Steering wheel

I

Recovery tank lid

J

Vacuum filter access

K

Vacuum diverter

L

Off-aisle wand

M

Recovery tank

N

Battery compartment

O

Clean-out cap

P

Recovery dump hose

Q

Safety latch

R

Recovery hose

S

Scrub deck

T

MACHINE COMPONENTS

DRIVER’S COMPARTMENT

Operator’s seat

A

Solution tank lid

B

Cup holder

C

Solution tank

D

Tilt-wheel lever

E

Accelerator pedal

F

Parking brake

G

LCD display panel

H

Steering wheel

I

Directional switch

J

Control console

K

Safety latch

L

2

Page 9

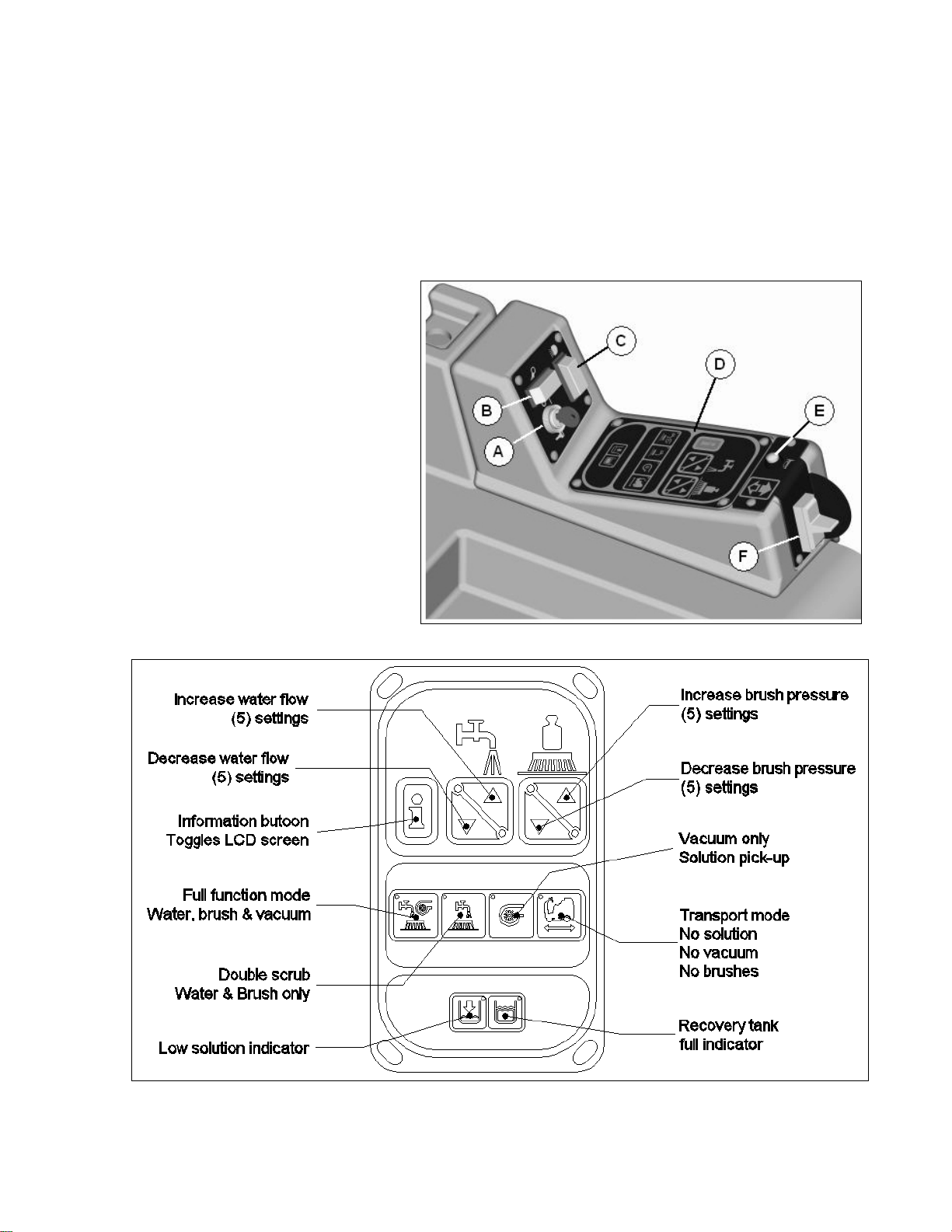

CONTROL CONSOLE

For operator ergonomics, the control console houses all the primary function buttons are grouped in a

central area. The key switch, headlight switch, and off-aisle wand switch are clustered in the back area.

The directional switch (forward and reverse) is located in front of the console for easy fingertip operation.

The horn button, function buttons, and indicators are located in the main central part of the console.

Key switch

(A) Controls the machine’s power (On/Off) with a key for safety. All operational settings are retained even

when the power is turned off and on. This also serves as a reset switch when error or fault codes appear

on the LCD screen.

Off-aisle wand switch

(B) On/Off control for the water supply to

the wand and vacuum motor.

Headlight switch

(C) On/Off control for the headlights.

Main Keyboard

(D) The main keyboard is divided into

three sections: Machine settings,

Machine modes, and tank fluid level

status. See detail descriptions of each

button on the section.

Horn button

(E) Depressing the button will activate the

horn.

Directional switch

(F) When you flip the switch down, the

machine moves forward or flip the switch

upward, the machine will go into reverse

and activate the back-up alarm.

3

Page 10

MAIN KEYBOARD

FULL FUNCTION MODE

When this mode is chosen, a green indicator light will illuminate within the full function icon. When the

machine is running in this mode, all machine functions will be on. When the operator sets the directional

switch to the forward position and steps the accelerator pedal, the solution pump will turn on, the brushes

will turn on and be lowered to the floor, and the rear and side squeegees will be lowered to the floor as the

vacuum motor turns on. While operating in this mode the solution will be dispersed into the brushes, which

will scrub the floor allowing the chemical in the solution to break down the dirt on the floor. As the machine

continues to move forward, the vacuum motor will pull the dirty solution water from the rear squeegee into

the recovery tank. If the operator stops moving forward and switches the directional switch into reverse,

the rear squeegee will rise up (protecting it from damage) and the vacuum motor will turn off after a few

seconds. If the operator stops moving in either direction, the machine will automatically raise and turn off

the brushes, shut-off the water and raise the rear and side squeegees. Some of the functions will take a

little while longer to turn off than others. See the LCD display section in this book to see the image on the

screen looks like when this button is selected.

DOUBLE SCRUB MODE

When this mode is chosen, a green indicator light will illuminate within the double scrub icon. When the

machine is running in this mode, the machine will perform all operations except dirty solution recovery.

This mode can be used if the floor is heavily soiled and the chemical will need additional time to emulsify

grease and oils that are on the floor. When the operator sets the directional switch to either the forward or

reverse position and steps the accelerator pedal, the solution pump will turn on, the brushes will turn on

and be lowered to the floor. While operating in this mode, the solution will be dispersed into the brushes,

which will scrub the floor allowing the chemical in the solution to break down the dirt on the floor. As the

machine continues to move forward or back, the rear squeegee and vacuum system are not on, which

allows the solution to stay on the floor emulsifying the grease and oil. If the operator stops moving in either

direction, the machine will automatically raise and turn off the brushes. After double scrubbing, the

operator should use the vacuum only mode to recover the dirty solution water from the floor. See the LCD

display section in this book to see the image on the screen looks like when this button is selected.

VACUUM ONLY MODE

When this mode is chosen, a green indicator light will illuminate within the vacuum only icon. When the

machine is running in this mode, the machine will only lower the rear squeegee and turn on the vacuum

system to recover the dirty solution from the floor. This mode is usually chosen after double scrubbing to

recover the dirty solution but it can also be used to pick up spills. When the operator sets the directional

switch to forward, the rear squeegee will be lowered to the floor as the vacuum turns on, pulling the dirty

solution water from the rear squeegee into the recovery tank. If the operator stops moving forward and

sets the directional switch to reverse, the rear squeegee will retract (protecting it from damage) and the

vacuum motor will turn off after a few seconds. If the operator quits moving in either direction, the machine

will automatically raise the squeegee and turn off the vacuum motor after a few seconds. See the LCD

display section in this book to see the image on the screen looks like when this button is selected.

TRANSPORT MODE

When this mode is chosen, a green indicator light will illuminate within the transport icon. When the

machine is set in this mode, none of the cleaning functions of the machine will operate. This mode is only

used to transport the machine from one location to another at a faster rate of speed. See the LCD display

section in this book to see the image on the screen looks like when this button is selected.

INFORMATION BUTTON

Depressing the “

hours, and traction motor hours on the LCD display for a few seconds. Keeping this button depressed will

display these items of information for an indefinite amount of time until you release the button. This button

toggles the information on the screen being displayed from machine settings and hour meter information.

See the LCD display section in this book to see the image on the screen looks like when this button is

selected.

i” button will generate specific information such as the machine hour meter, brush motor

4

Page 11

WATER FLOW ADJUSTMENT

These buttons are used to adjust the flow of solution to the brushes. The buttons can be used to select no

flow or one of five solution flow rates where: 1 bar = .25 gpm, 2 bars = .44 gpm, 3 bars = .63 gpm, 4 bars

= .82 gpm, and 5 bars = 1 gpm. Either pressing the increase or decrease flow rate buttons adjusts the

volume of solution flow to the brushes and is displayed on the LCD screen and represents the flow rate

setting selected. The flow adjustments can be made in either the Full function or Double scrub mode. See

the LCD display section in this book to see the image on the screen looks like when this button is selected.

BRUSH PRESSURE ADJUSTMENT

These buttons adjust the brush pressure. The buttons can be used to select one of five brush pressure

settings: 1 bar = lightest, 2 bars = light, 3 bars = medium, 4 bars = heavy, and 5 bars = heaviest. The

pressure is adjusted either by pressing the increase or decrease brush pressure buttons. The number of

bars displayed on the LCD screen represents the brush pressure setting selected. The brush pressure

adjustments can be made in either the Full function or Double scrub mode. See the LCD display section in

this book to see the image on the screen looks like when this button is selected.

EMPTY SOLUTION TANK INDICATOR

The light inside this icon will be illuminated when the solution tank is empty. At the same instant, the LCD

display will have a flashing bar on the solution flow icon signaling the operator of the solution tank status

and the solution pump shuts off. See the LCD display section in this book to see the image on the screen

looks like when this button is selected.

RECOVERY TANK FULL INDICATOR

The light inside this icon will be illuminated when the recovery tank is full. At the same instant, the LCD

display will have a flashing bar on the vacuum system icon signaling the operator of the recovery tank

status. After this warning, the rear squeegee will automatically raise and the vacuum motor will shut off

automatically after a few seconds. See the LCD display section in this book to see the image on the screen

looks like when this button is selected.

LCD DISPLAYS

The following images below are displayed when selecting the controls or buttons discussed above. The

battery gauge bar will always be displayed whenever the machine is turned on.

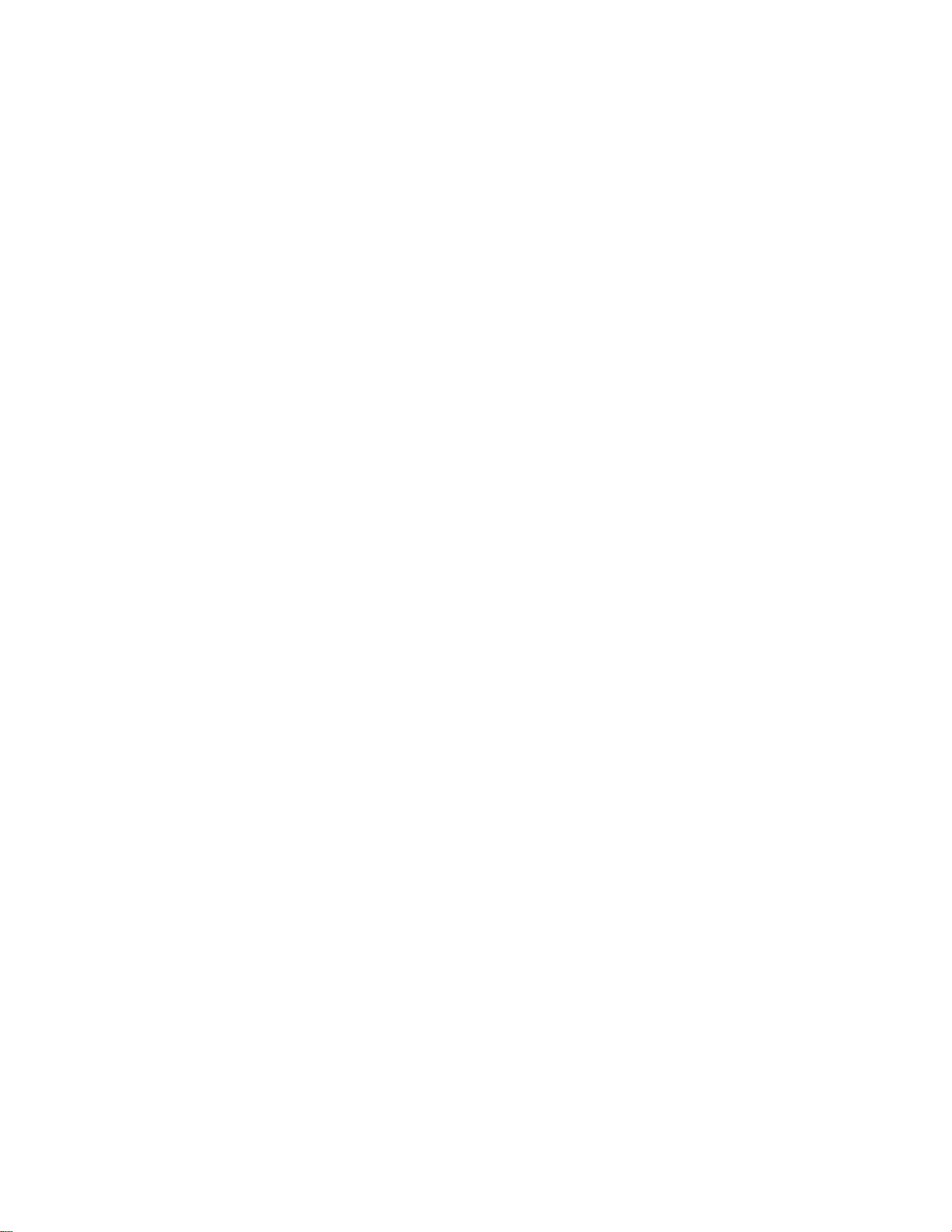

KEY SWITCH

When switch is turned on, the Minuteman logo

will appear in the middle of the screen.

INFORMATION BUTTON

Pressing the “i” button will display hours logged on

specific components

Total Hours

Brush Hours

Traction Hours

DIRECTIONAL SWITCH FORWARD

Silhouette of the machine with arrow pointing

forward.

DIRECTIONAL SWITCH REVERSE

Silhouette of the machine with arrow pointing

backward

5

Page 12

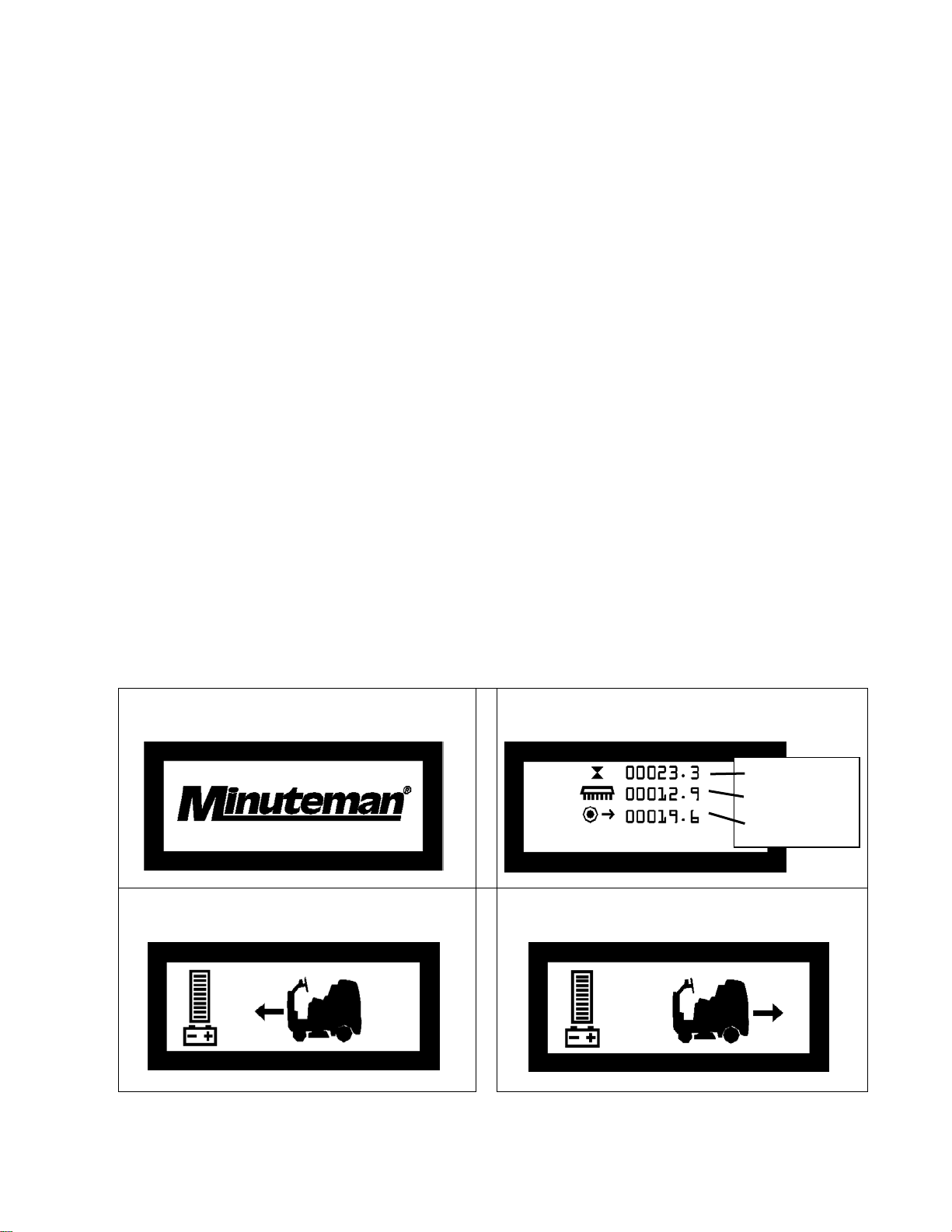

FULL FUNCTION MODE

The vacuum icon with moving arrows, the brush

pressure bars and water flow bars will be

displayed.

DOUBLE SCRUB MODE

The brush pressure bars and water flow bars will

be displayed.

VACUUM ONLY MODE

The vacuum symbol will be displayed and no

bars displayed for brush and flow icons.

BRUSH PRESSURE ADJUSTMENT

Increasing pressure adds more bars to the scale;

decreasing pressure removes bars from the

scale.

TRANSPORT MODE

Silhouette of the machine will be displayed and

arrow pointing to a direction as selected on the

directional switch.

WATER FLOW ADJUSTMENT

Increasing flow adds more bars to scale;

decreasing flow removes bars from scale.

EMPTY SOLUTION TANK INDICATOR

A flashing bar across the water flow icon will be

displayed.

RECOVERY TANK FULL INDICATOR

A flashing bar across the vacuum icon will be

displayed.

6

Page 13

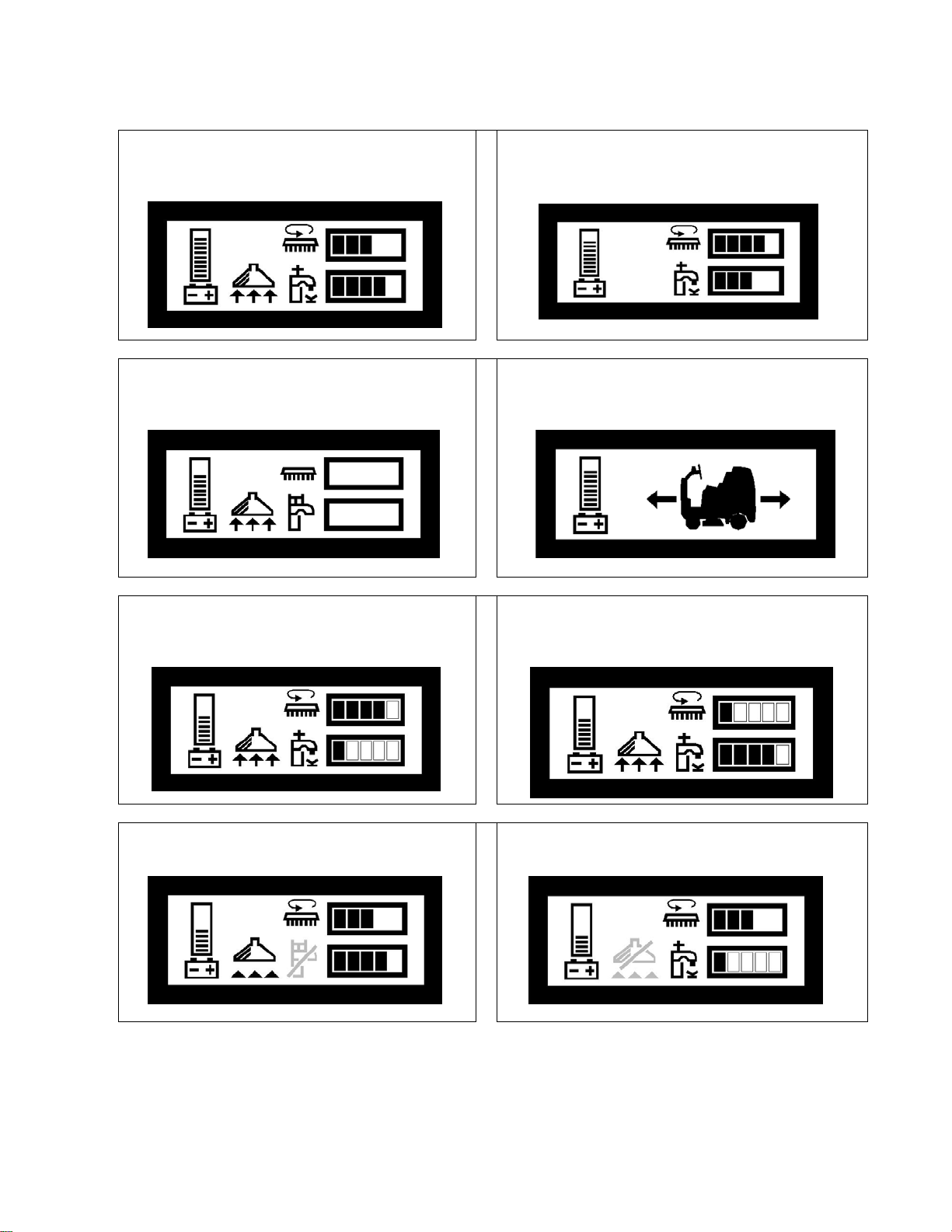

LOW BATTERY INDICATOR

The battery gauge bar icon will be flashing to signal the operator that the machine is almost out of power.

Once this signal is displayed to the operator, all functions will shut off including the transport mode. The

operator has to turn the key switch OFF and then, ON to reset the machine. The machine then will only

have a few minutes left of reserve power for a short Vacuum only mode to pick up remaining solution on

the floor and Transport power.

LOW BATTERY INDICATOR

The battery gauge bar icon will be flashing

indicating that the machine is almost out of

power.

DIAGNOSTIC CODE

At the bottom of the information screen a wrench

symbol with alphanumeric characters will be

displayed when a fault occurs.

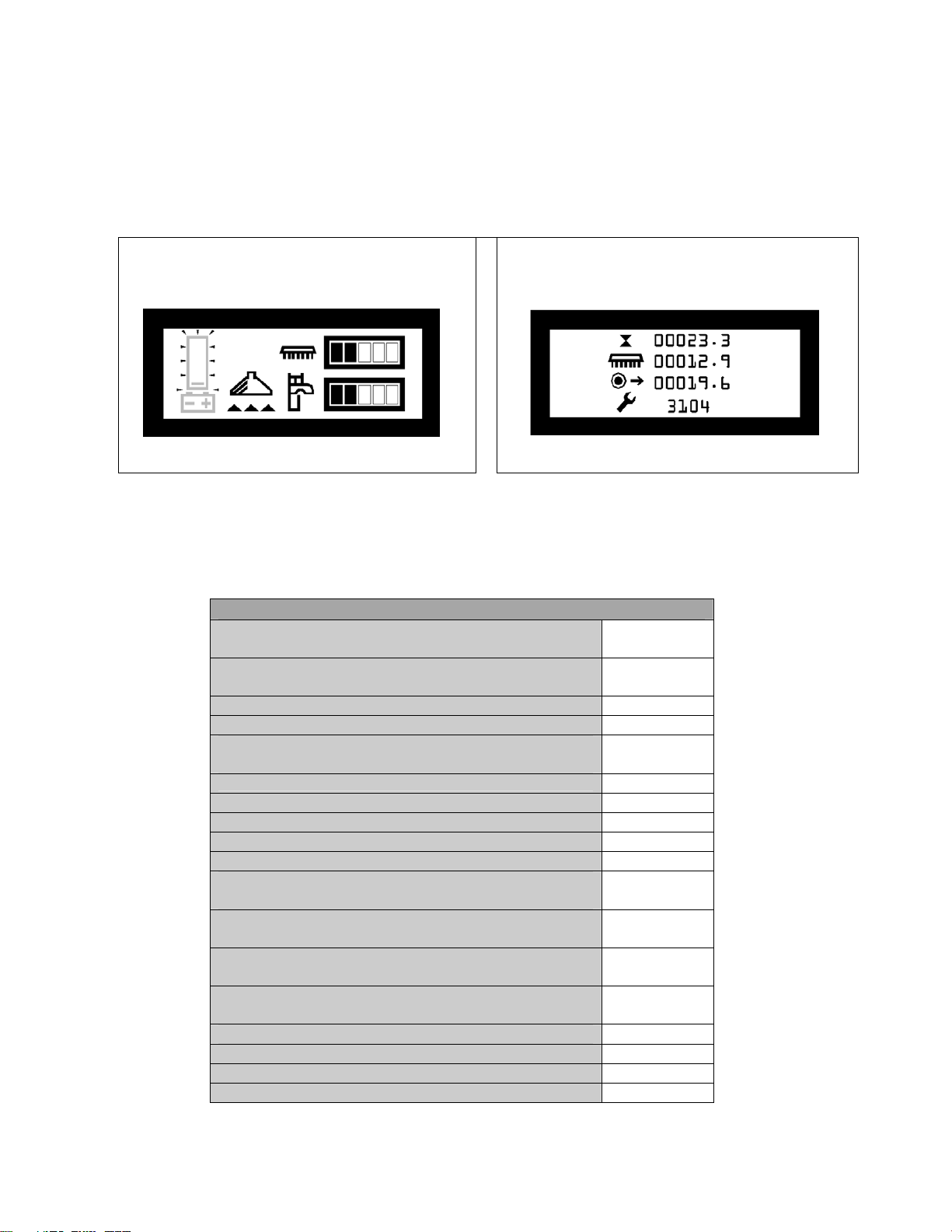

FAULT / DIAGNOSTIC CODE

At the bottom of the information screen a wrench symbol with alphanumeric characters will be displayed

when a fault occurs. In most cases, resetting the machine will correct this condition. The operator has to

turn the key switch OFF and then, ON to reset the machine. If this does not work servicing the machine

may be necessary. Below is a list of fault and diagnostic codes for troubleshooting. See Troubleshooting

tips section for further details.

SCV Fault Codes

Switch Reference Codes

May indicate incorrectly wired input switches

Throttle Codes

May indicate incorrectly wired or faulty potentiometer

Power Down Error 0A01 Supply Over Current 1310 Solenoid Brake Codes

May indicate open or short circuit solenoid brake

High Battery Voltage

Throttle Specification Modified

Inhibit Activated

Low Battery Voltage

Battery Lock Out

Throttle Displaced Code

.

.

.

07xx

081x

150x

1600

1D02

1E03

2C0x

2C02

201

May indicate incorrectly wired or faulty potentiometer.

Bridge Supply Faults

May indicate problem with connection of motors

Freewheel Errors

Check condition of freewheel switch and connections

LCD Module Communications Codes

.

.

310x

700x

750x

Serial connections to LCD Module may be intermittent.

Brush Motor Code 760x Vacuum Motor Code 770x Traction Motor Code 780x Emergency Stop or Belly Button Code 790x

7

Page 14

OPERATION OF CONTROLS

POWER SAVE MODE

The SCV is equipped with a power save feature to conserve battery power. If the key switch power is left

ON and none of the controls are activated for a period of fifteen minutes, the SCV automatically goes into

“power down mode” and turns OFF the power to conserve your batteries in case the operator forgets to

turn the key switch off or leaves the machine unattended.

ACCELERATOR PEDAL

Located on the right side of the operator compartment on the floor is the accelerator pedal. This pedal

controls the propelling speed of the machine. The farther the pedal is pushed down the faster the machine

will travel. As discussed earlier, the directional switch governs the direction of travel the machine will take.

Switching the directional switch with your foot pushed on the pedal will make your machine change

directions (a very slight delay may occur before the direction of travel changes when switching directions

on the fly). The accelerator pedal in interlocked with the seat switch, making machine propulsion not

possible without the operator sitting on the seat.

SEAT

The ergonomically designed seat is located on top of the solution tank. There is a lever under the seat that

allows the operator to adjust the seat forward or backward for operator comfort. There is an interlock

switch located inside the seat. This makes it impossible to engage the traction drive circuitry without the

operator on the seat. If the operator were to fall off the machine, the traction drive circuitry would turn off.

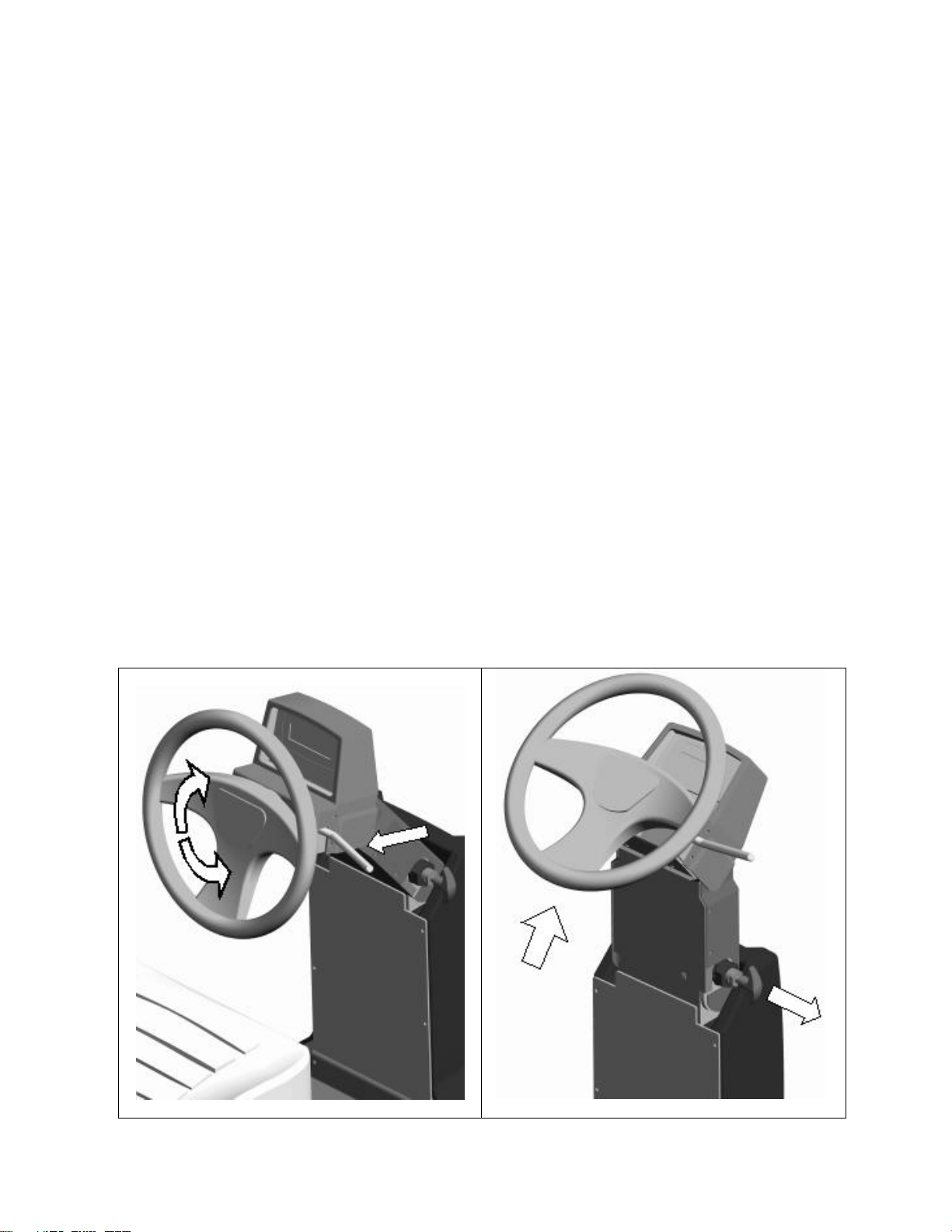

STEERING WHEEL

The steering wheel (FIGURE 1) is adjustable for operator comfort by pulling the tilt-wheel lever back and

positioning the steering wheel up or down (there are four possible positions). Also, a two-position steering

column (FIGURE 2) feature gives the operator easier access to the driver’s compartment when climbing

into and dismounting from the machine. By pulling on the steering column pivot pin and positioning the

steering column in an upright fashion, enables the operator more room when climbing up and down the

machine. The operator can then position the steering column in its normal driving position by returning the

steering column back in its normal position.

FIGURE 1

FIGURE 2

8

Page 15

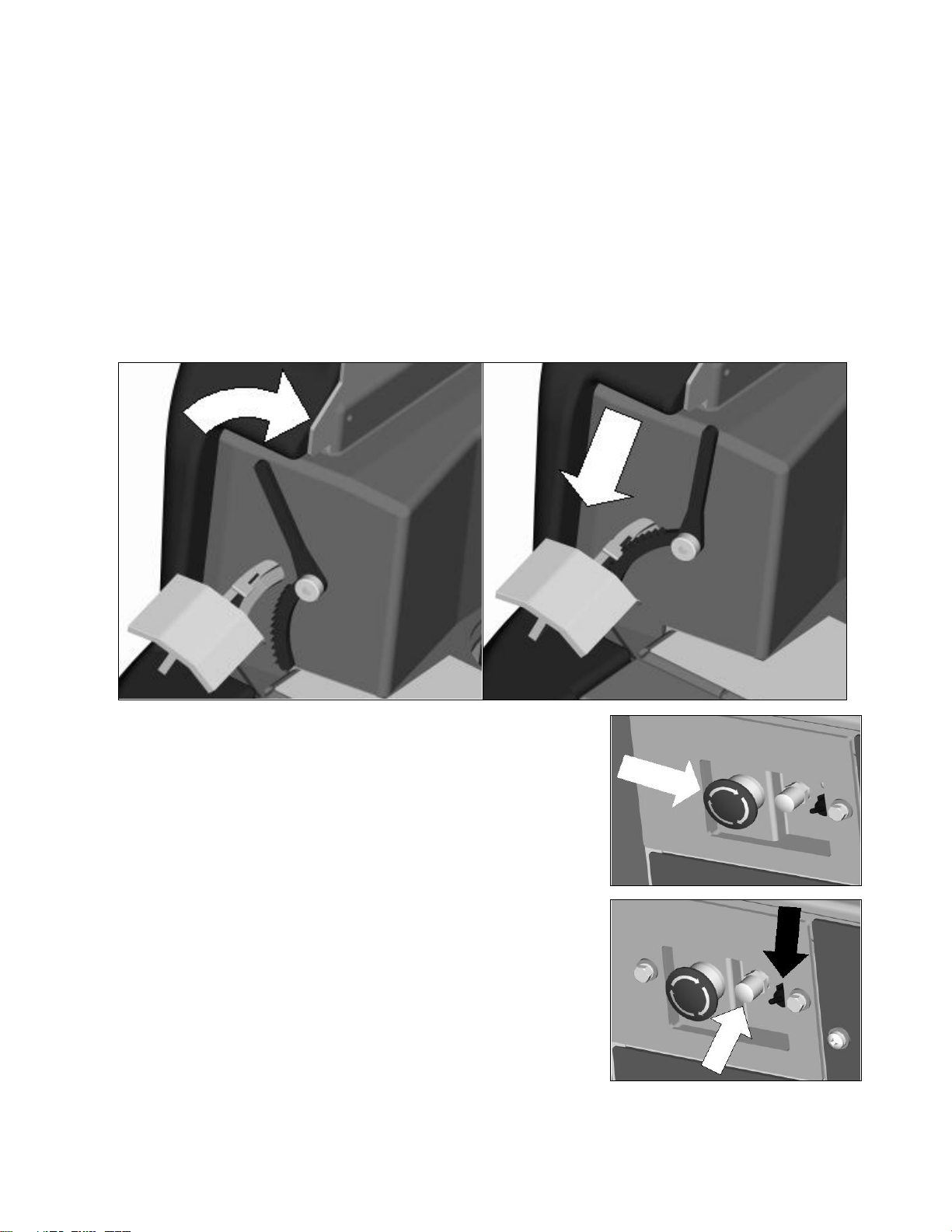

MECHANICAL & PARKING BRAKE

Located on the left side of the operator compartment on the floor is the mechanical brake which doubles as

the parking brake. Even though the machine is equipped with a regenerative braking system, the

mechanical brakes can be activated by pushing down on the pedal and apply brakes on the rear wheels.

The mechanical brake also doubles as a Parking brake. To set the parking brake, press down on the brake

pedal as far down as possible; then, engage the parking brake lever teeth with the brake pedal tab by

rotating the lever clockwise. This will keep the brakes on the rear wheels. To disengage the parking brake,

simply push down on the brake pedal until the parking brake lever disengages itself from the pedal tab.

Another safety feature on the machine is the Electro-magnetic brake built-in on the traction drive motor.

When the machine’s power is turned off (using either the key or the emergency button), the E-mag brake is

activated and the traction motor is prevented from moving.

The mechanical /parking brake system is self-cleaning and periodic use is recommended to avoid

build up of foreign matter that may cause seizing in the mechanism and rust build up.

EMERGENCY DISCONNECT BUTTON

This button is located in the middle of the electrical panel that is

directly underneath the operator’s seat. When the red emergency

button is pressed, power will be turned off. Use this button in case of

a machine emergency. The red knob needs to be raised in order to

run the machine. To reactivate, turn the knob as shown by the arrow

on the switch and the button will pop up. All operational settings are

retained even when the power is turned off and on.

CIRCUIT BREAKERS

The circuit breakers are located next to the emergency disconnect

button. The 6-amp breaker (indicated by white arrow). This breaker

protects all auxiliary circuits on the machine (headlights, horn, and

back-up alarm). The 100-amp breaker (indicated by black arrow)

protects the main system circuit (controller). Each main component is

individually protected with an internal breaker built-in the controller.

(See fault code table) and can be reset by turning the key switch off a

few seconds and then on again.

9

Page 16

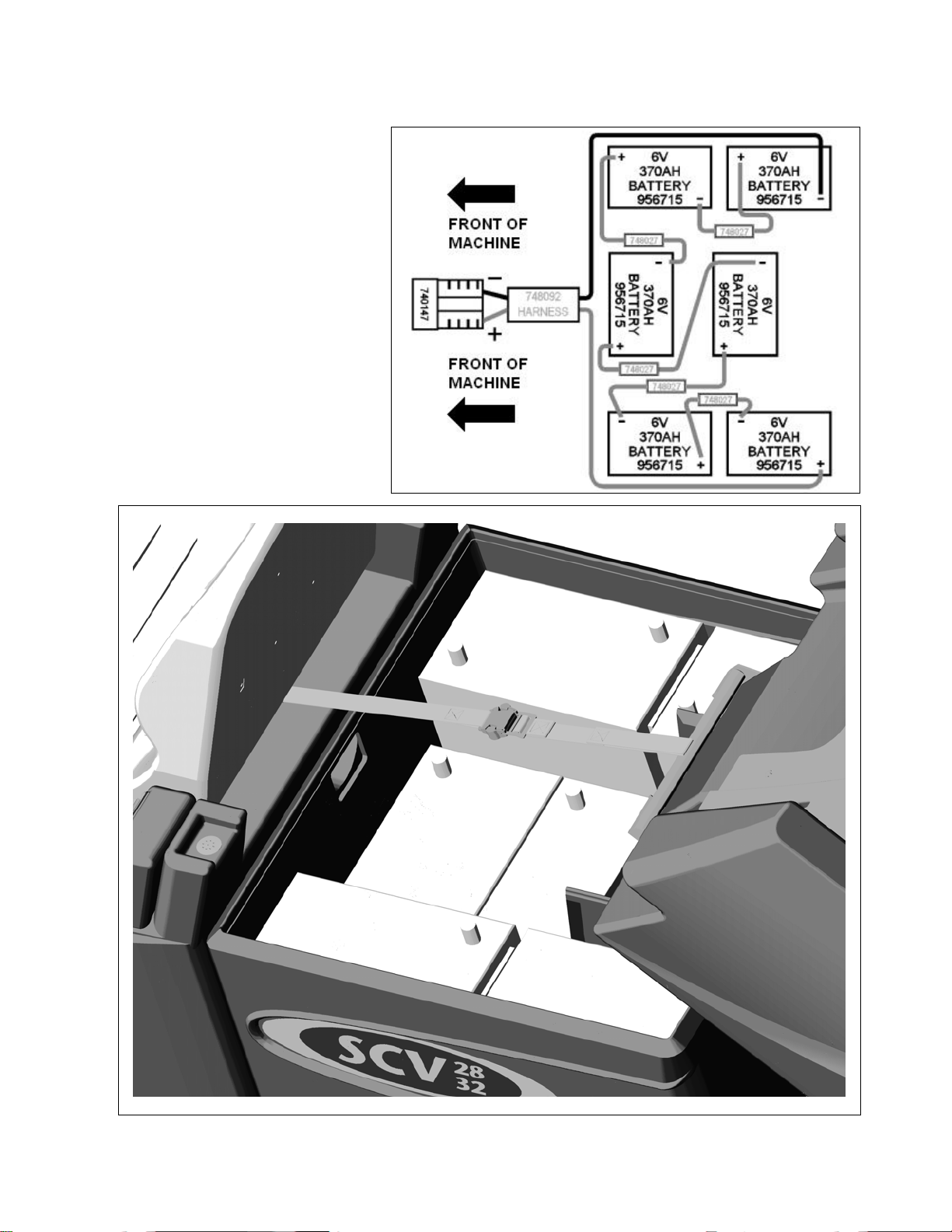

BATTERY COMPARTMENT

The battery compartment is located

on the rear of the machine under the

recovery tank. Unlatching the two

safety latches on the side of the

machine enables the operator to tilt

the recovery tank and access the

batteries for servicing and

maintenance (make sure recovery

tank has been drained before tilting).

The battery compartment contains

six 6-volt batteries connected in

series. Connect the batteries

according to the battery connection

diagram (see diagram). The

recommended batteries are 370Ah

(Minuteman P/N 956715).

10

Page 17

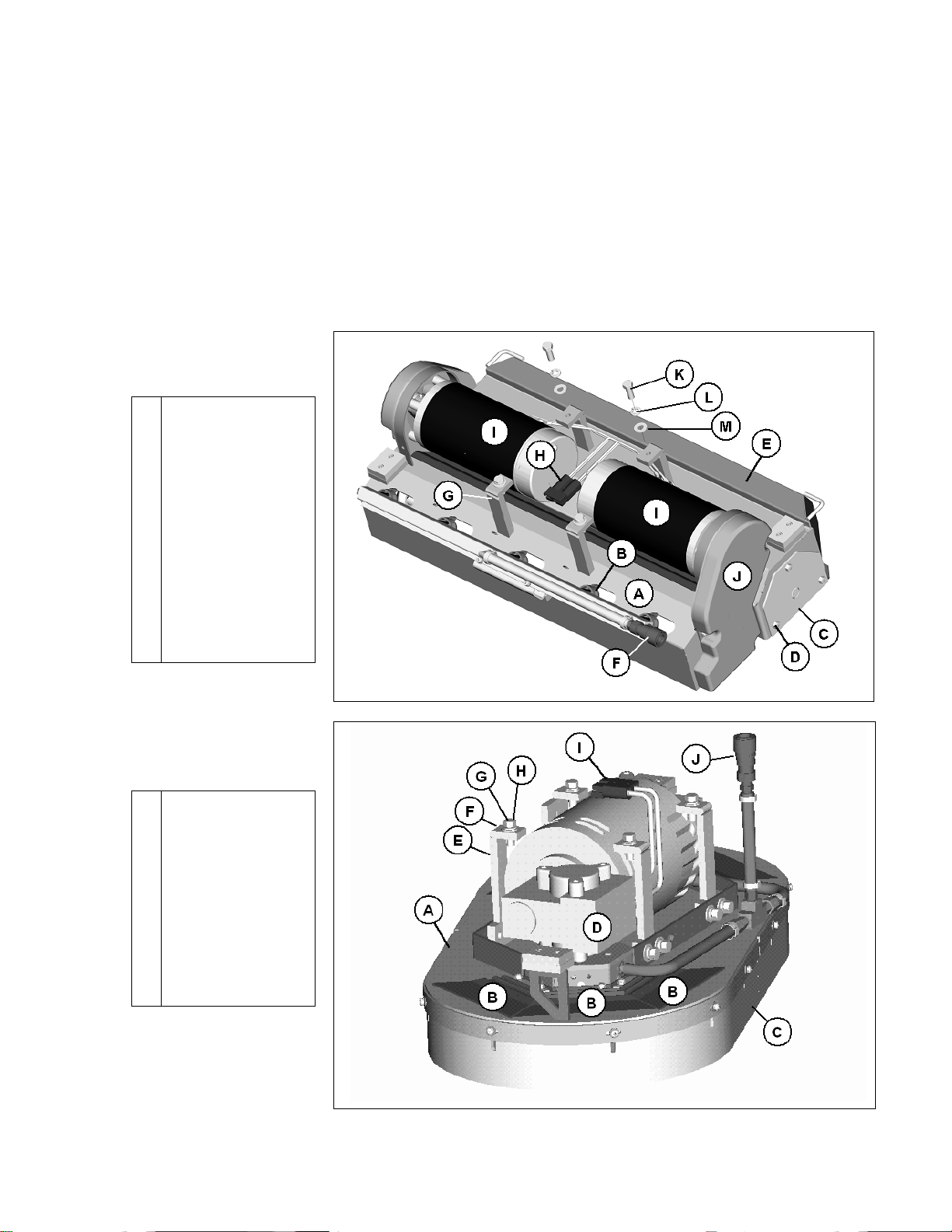

SCRUB DECK

Minuteman offers two deck types (Cylindrical and Disc) to fit your specific needs. The SCV design is very

dynamic wherein the decks are interchangeable in a matter of minutes whenever necessary (removal of

four bolts, and two quick-connects). The cylindrical brush deck has five built-in spray jets to uniformly

dispense cleaning solution on the floor and a wet sweeping debris tray to collect loose objects on the floor.

The disc brush deck dispenses cleaning solution through the center hub and contained within the bristle

area for efficient agitation of cleaning solution to the floor and channeled to the rear of the machine. The

disc brushes are also easily removed and installed with the quick release clamp by using any of the three

access doors. Another nice feature that these scrub decks have is the ability to have uniform brush

pressure applied to the floor at all times. Since the scrub deck brush pressure is computer controlled, it will

automatically adjust and compensate to uneven contours on the floor while maintaining brush pressure.

CYLINDRICAL

SCRUB DECK

Housing

A

Spray jets (5)

B

Access door (2)

C

Nut, Access door

D

Debris box

E

Connector, water

F

Mounting bracket

G

Connector, power

H

Brush motor (2)

I

Pulley cover (2)

J

Bolt (4)

K

Lock washer (4)

L

Flat washer (4)

M

DISC SCRUB DECK

Housing

A

Access door (6)

B

Brush skirt

C

Brush motor

D

Mounting bracket

E

Flat washer (4)

F

Lock washer (4)

G

Bolt (4)

H

Connector, power

I

Connector, water

J

11

Page 18

SCRUB DECK INSTALLATION

When installing a cylindrical deck to a machine:

1. Install brushes after the deck has been mounted to avoid flat spots on the brushes.

2. Use a piece of cardboard underneath the deck to prevent scratches to the painted surface when

sliding the deck under the machine.

3. Make sure the scrub deck is oriented correctly with the spray jets towards the front of the machine.

When installing a disc scrub deck to a machine:

4. Install brushes on the scrub deck; this aids the installer in sliding the deck assembly into position.

5. Make sure the scrub deck is oriented correctly with the solution hose tee fitting towards the front of

the machine.

INSTALLATION INSTRUCTIONS

1. Park the machine on a flat or level surface.

2. Activate the parking brake.

3. Remove the 2 screws that fasten each plastic side covers on the machine.

4. Turn the key switch to the ON position and select the transport mode on keyboard.

5. Slide the scrub deck assembly underneath the machine (follow instructions as described above)

6. Position the scrub deck to align the mounting brackets with the mounting lugs on the lift linkage.

7. Lower the lift linkage to the floor by pressing the increase brush pressure button for ten seconds.

(Pressing the up and down brush pressure button for ten seconds toggles the scrub deck

control into a manual up and down mode for the scrub deck linkage).

8. Lower the lift linkage mounting lugs until they barely touch the scrub deck mounting brackets.

9. Fasten with the four (4) 711242 bolts, 711515 flat washer and 711546 lock washer.

10. For cylindrical scrub deck only:

a. Remove the two access doors (one each end) by removing the (3) nyloc nuts.

b. Install the brushes by sliding through the access opening.

c. Align the notches on the brush with the drive pins on the hub.

d. Push brush all the way until it bottoms out.

e. Insert access door hub to the other end of brush.

f. Reinstall nuts and tighten.

Depressing one of these buttons for ten seconds

will switch you into the manual raise/lower mode.

When you are in this mode, these buttons control

the movement of the lift linkage mechanism. To

get out of this mode, simply reset the machine by

turning the key switch off.

12

Page 19

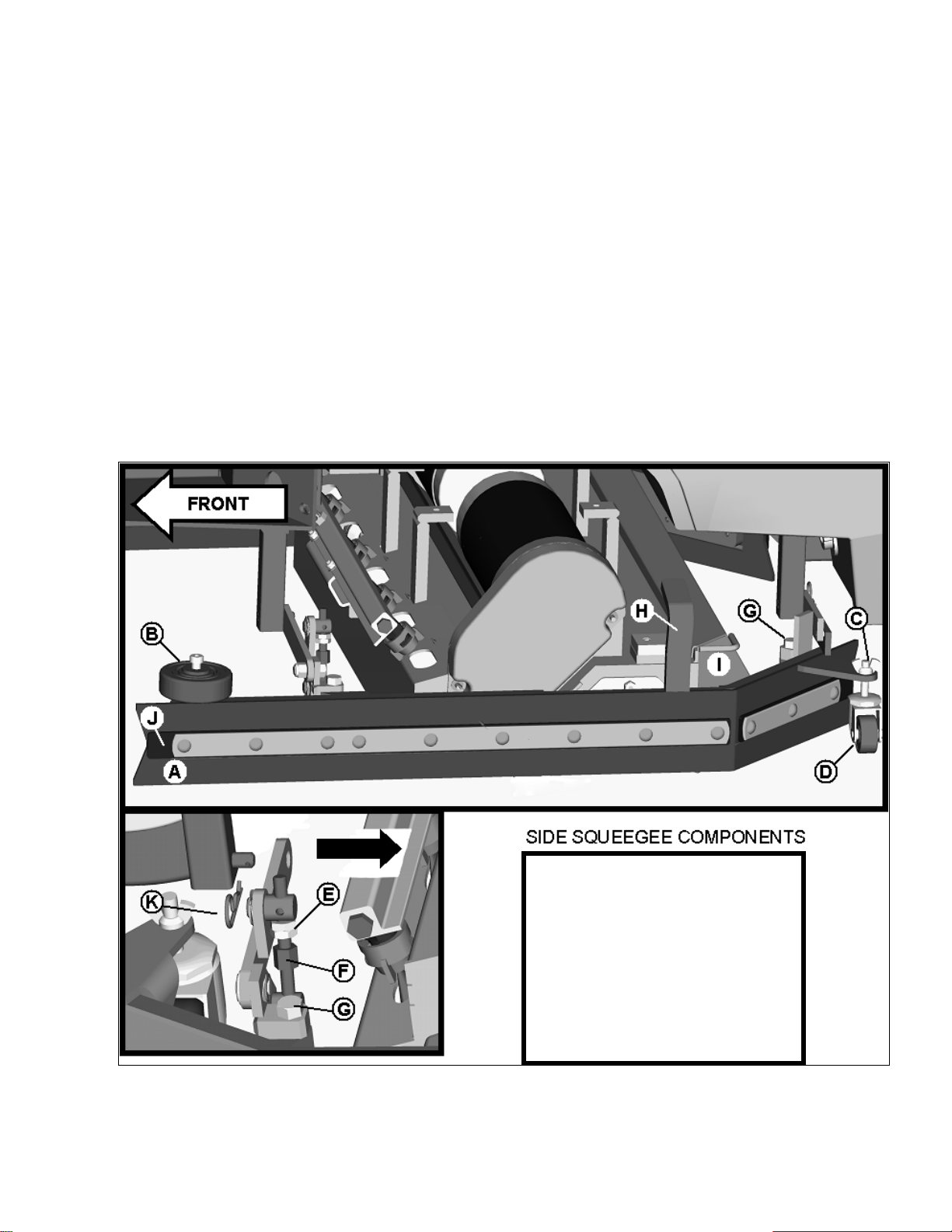

SIDE SQUEEGEE

p

The side squeegees (left and right) are attached to the machine mainframe. These items channel the dirty

solution to the rear squeegee, helping contain the water within the machine’s cleaning path. These

squeegees are raised when the scrub deck is in the raised position. When the scrub deck is deployed, the

side squeegees are also lowered. A lift bracket (item H) raises the side squeegee off the floor when the

machine is in a non-scrubbing mode. The side squeegees are equipped with an adjustable caster (item D)

to control the blade deflection (lowering the caster lessens blade deflection). To adjust the deflection,

loosen the wing jam nut (item C) and turn the caster stem as described below. If the squeegee blade is

deflecting too much, the casters need to be lowered to control the down pressure. Lower the caster by

turning the exposed threaded stem on the caster clockwise. Make the adjustment a few turns at a time. If

the blades are not deflecting enough, raise the caster by turning the stem counter-clockwise to adjust the

caster height to allow more down pressure on the squeegee. A nylon shear bolt (item G) located at the front

and rear of the squeegee prevents undue damage to the assembly in case it hits a solid object. If the side

squeegee is subjected to high impact, the bolt will shear off and prevent severe damage to the assembly. A

turnbuckle adjustment (item F) is provided to adjust the pitch for optimum wiping performance. To adjust,

loosen Lock nut (item E) and turn the turnbuckle to make the necessary adjustments. To clean out the

debris box (item I), set the machine to the double scrub mode and when the scrub deck is lowered to the

floor, turn the key switch off. Slightly lift the debris box up by its handles and slide out towards you.

A. Squeegee blade

B. Roller guide wheel

C. Wing jam nut

D. Swivel caster

E. Lock nut (2)

F. Turnbuckle

G. Shear bolt (2)

H. Lift bracket

I. Debris box

J. Backer strip

K. Cotter

in

13

Page 20

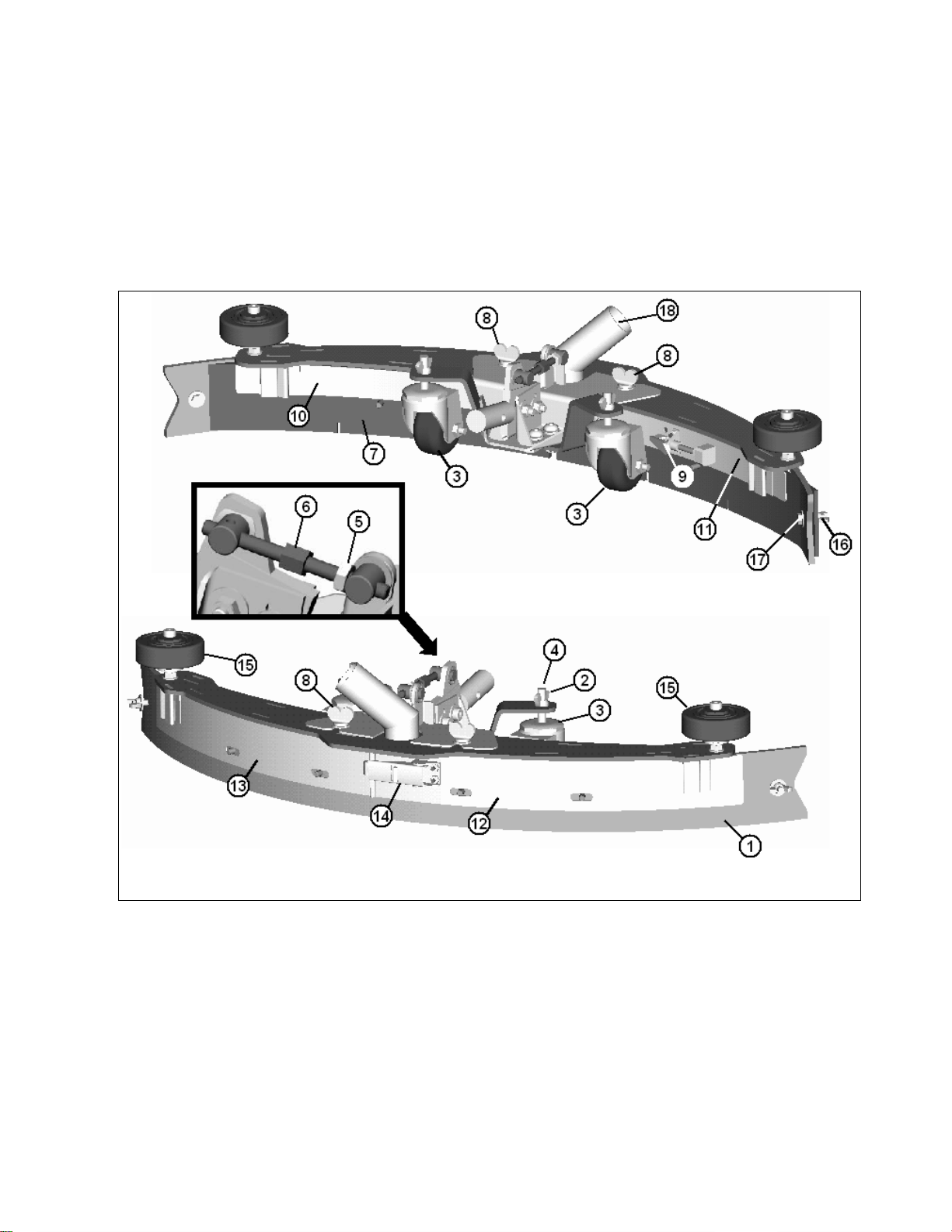

REAR SQUEEGEE

The rear squeegee is the main element that acts as the conduit that transfers the spent solution into the

recovery tank. A daily maintenance check of this component is essential to have optimum machine

performance. The rear squeegee assembly is equipped with a universal front blade that allows the operator

the option to use a slotted and a non-slotted side for specific applications. Each blade configuration has two

usable edges. The rear blade however has four usable edges.

The squeegee is pre-adjusted at the factory. Adjustments may be required to get optimum

performance for different floors and conditions.

REAR SQUEEGEE COMPONENTS

1. Rear squeegee blade

2. Wing jam nut (2)

3. Caster stem

4. Swivel caster (2)

5. Lock nut

6. Turnbuckle

7. Front squeegee blade

8. Wing bolt (2)

9. Toggle clamp

14

10. Front strap (long)

11. Front strap (short)

12. Rear strap (latch side)

13. Rear strap (catch side)

14. Latch

15. Guide wheels (2)

16. Nylon wing bolt (2)

17. Nylon bolt (2)

18. Recovery hose intake

Page 21

REAR SQUEEGEE ADJUSTMENT

1. Ensure that the scrubber is on a relatively flat surface. Turn on the key switch and select the Vacuum

only mode. This lowers the squeegee to the floor and turns the vacuum motor on.

2. Move the scrubber one or two feet forward slowly while someone behind the machine checks the rear

squeegee blade (item 1) for uniform deflection to the floor.

3. If uneven deflection or lay is evident, minor adjustments may be necessary to avoid streaking and

uneven wear on the blade.

4. To correct this, loosen the wing jam nut (item 2) in order to adjust the caster height. If the squeegee

blade is deflecting too much, the casters (item 3) need to be lowered to control the down pressure.

Lower the caster by turning the exposed threaded stem (item 4) on the caster clockwise. Make the

adjustment a few turns at a time. Repeat step 2.

5. If the blades are not deflecting enough, raise the caster by turning the stem counter-clockwise to

adjust the caster height to allow more down pressure on the squeegee. Repeat step 2.

6. Make sure there is even deflection on the entire length of the rear blade. Adjust the casters and

retighten the wing jam nuts to lock the caster setting in place.

7. Pitch adjustment is necessary if the outer ends on the squeegee blade do not contact the floor and

there is too much deflection in the middle area or if the outer ends are over deflected and there is no

contact in the middle.

8. To adjust the pitch, repeat step 2.

9. Loosen the lock nut (item 5) in the turnbuckle assembly. Turning the turnbuckle (item 6) clockwise or

counter-clockwise controls the forward and backward pitch of the squeegee. Having the rear blades

deflected uniformly along its entire length is the desired set-up.

10. Repeat step 2 until desired set-up is achieved.

11. In certain applications where a non-slotted front wiper blade (item 7) is needed, detach the rear

squeegee assembly by loosening the two wing bolts (item 8). Unlock the toggle clamp (item 9) on the

front squeegee to release the front long strap (10) and slide the front short strap (item 11). Flip the

blade over to the non-slotted side. Reattach the straps and lock the clamp back in place.

12. You can also easily replace the rear blade by unlatching the latch (item 14) and removing the two rear

straps (items 12 & 13) by sliding them off the assembly. You can then flip the blade over in order to

use a new edge for better wiping action.

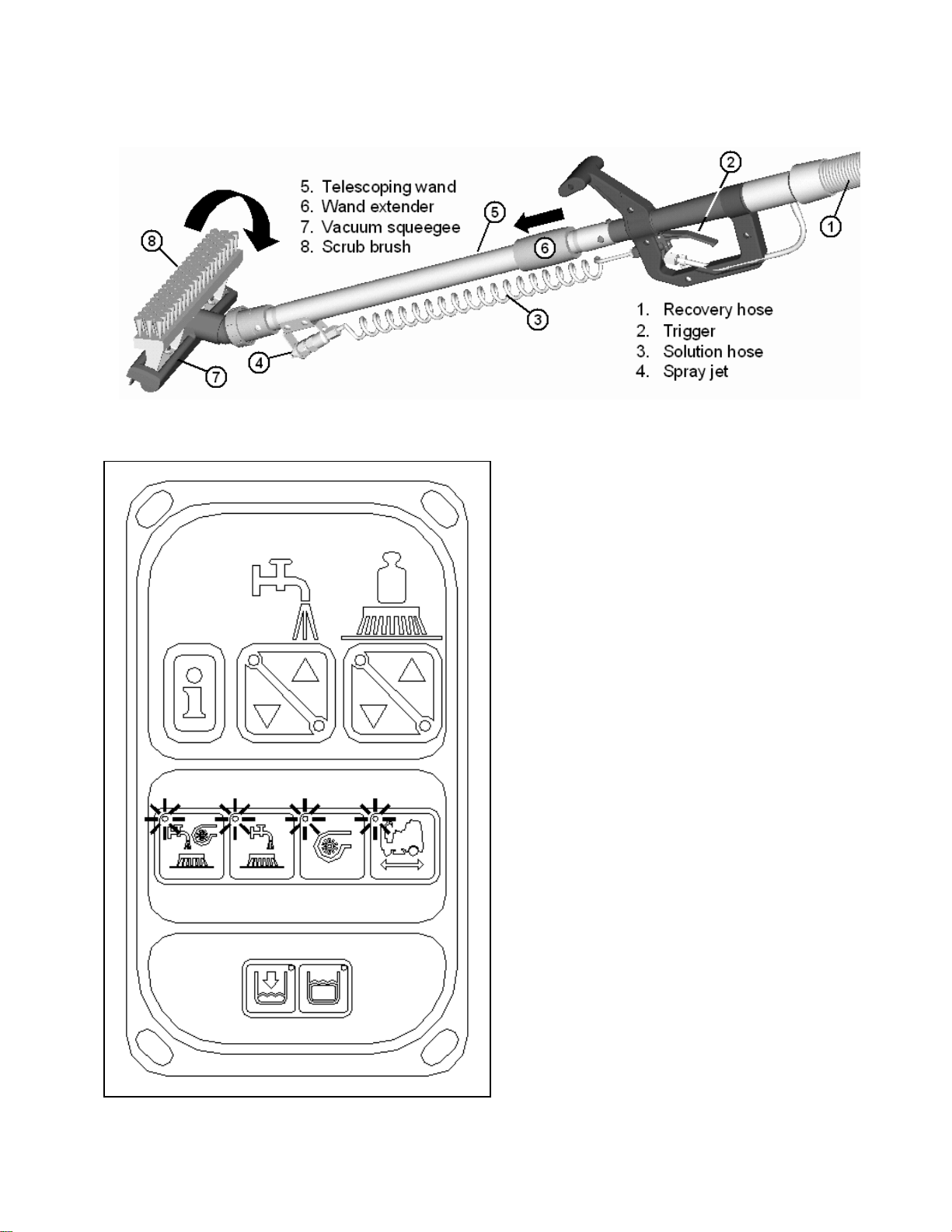

OFF-AISLE WAND

The SCV is equipped with a ready-to-use built-in telescoping off-aisle wand (item A) system for use in hard

to reach areas. This integrated system eliminates attaching hose for use and detaching hoses for storage.

By turning the pump switch ON (located on the control console) and flipping a lever that doubles as the

wand hanger, the off-aisle wand is ready to use in seconds. Flipping the lever up (item D) diverts the

vacuum flow from the main rear squeegee intake (item E) to the off-aisle wand intake (item F). After use,

simply flip the lever back down to its normal position to use as the hand hanger. The wand is also

equipped with the patented flip-flop tool that allows the operator to switch from scrub brush to squeegee

tool by just rotating the tool end.

15

Page 22

OFF-AISLE WAND TOOL

The off-aisle wand tool as described in the previous page is composed of the following items:

1. The recovery hose is connected to the end of

the wand on one end and to the diverter

assembly (item F) on the other end. This hose

has swivel cuffs on both ends that allow the

operator a good range of motion and the

solution hose to be inside the recovery hose.

2. The trigger controls the solution flow to the

spray jet. Squeezing the trigger opens an

internal valve to dispense cleaning solution.

3. The coiled solution hose acts as a conduit

from the trigger to the spray jet, and allows

hose to be extended along with the wand.

4. The spray jet dispenses the cleaning solution

to soak soiled areas that are not accessible to

the main scrub deck.

5. The telescoping wand allows the length to be

adjusted for operator comfort and better

storage when not in use.

6. Sliding the wand extender forward (as shown

above) extends the wand length during use

and retracts the wand by pulling it back for the

storage position.

7. The flip-flop tool gives the operator complete

flexibility when changing from the scrub

brush mode to vacuum squeegee mode by

simply rotating the end.

When the off-aisle wand switch is turned ON, the

four (full function, double scrub, vacuum only and

transport) mode lights in the keyboard will flash to

indicate that you are in the off-aisle tool mode.

This switch turns on the pump to supply solution to

the wand spray jet and the vacuum motor to

recovery the dirty water. When the recovery tank

is full, the vacuum motor and the solution pump

automatically shuts off.

16

Page 23

THE SCV RIDER

This machine was designed with total operator comfort and ease of use in mind. All machine components

have been designed as a total system to efficiently clean dirty floors. The SCV has four available scrub

head types and sizes to fit specific applications. Please contact your Minuteman representative for specific

recommendations for the correct scrub head type, size, and brush type and chemical applications.

Before using the machine, always perform the following steps to ensure proper machine operation.

• Check under the machine for leaks.

• Check the rear and side squeegees for wear and damage.

• Check the steering for proper operation.

• Check the solution and recovery tanks.

After using the machine, always perform the following steps:

• Check the battery charge level. Charge batteries if necessary. When charging batteries, extra

precaution is required:

Battery acid can cause burns. When working on or around batteries, always wear

protective clothing and safety glasses. Remove metal jewelry. Do not lay tools or metal

objects on top of the batteries.

Charging batteries generate explosive gasses. DO NOT CHARGE BATTERIES WHEN

OPEN FLAMES OR SPARKS ARE PRESENT. DO NOT SMOKE. Make sure the charger

is turned off before disconnecting it from the batteries. Charge the batteries in a wellventilated area. Fluid levels should be checked before and after charging and maintained

at the proper levels. If low, add water until the metal plates are covered. If the machine is

not used for an extended period of time, batteries should be kept fully charged with a

boost charge once a week.

• Check for wire, string, or twine wrapped around the scrub brushes.

• Check the squeegees for wear and damage.

• Check the rear squeegee suction hose and off-aisle wand hose for obstructions.

• Empty and clean the debris box (cylindrical systems only).

• Drain and clean the recovery tank.

• Check under the machine for leaks.

• Check the service records to determine maintenance requirements.

WARNING!

• Be sure you understand the machine controls and their functions.

• While on ramps or inclines, avoid sudden stops when tanks are filled.

• Avoid abrupt sharp turns. Slow down driving speed when going downhill.

• Always drive up when cleaning ramps.

MACHINE OPERATION

Follow the instructions in preparing the machine for use as described in this manual.

1. While seated on the machine, adjust the steering wheel to desired position (for comfort and

unobstructed view of the LCD panel) using the tilt wheel lever.

2. Turn the Key switch ON (I). The LCD panel will light up and display the Minuteman logo for a few

seconds and display the Battery Condition icon and the last functional setting when the machine

was turned off.

3. Release the Parking Brake as described in the Mechanical & Parking Brake section of this manual.

4. Select one of the four available Modes on the Control Console for the required task. Refer to the

Main Keyboard section of this manual for a complete description of the functions.

5. Adjust the Solution Flow and or Brush pressure to desired setting.

6. Determine the direction you need to travel by selecting forward or reverse on the Directional

Switch. The LCD screen will display an icon as described LCD Section in this manual. Vary the

pressure exerted on the accelerator pedal to propel the machine at the desired speed. Stepping on

the accelerator pedal activates.

17

Page 24

7. Stepping on the Accelerator Pedal turns on the Transport, Brushes, Water Flow, Vacuum and

lowers the Rear Squeegee accordingly to the Mode selected. If the operator steps on the

accelerator pedal before, or turns the key switch “ON” at the same time, the machine will not move

as a safety precaution. Simply remove your foot off the pedal and step on the pedal again to drive

the machine. Please refer to the Main Keyboard section of this manual for a complete description of

the functions.

8. When Reverse is selected on the Directional Switch, the Back-up Alarm will be activated and the

Rear Squeegee automatically is raised when you step on the accelerator pedal. However, the

Scrub brushes will continue to rotate and solution will continue to flow.

9. Start scrubbing by driving the machine forward in a straight line at 3/4 speed and overlap each path

by 2 to 3 inches. Adjust your speed; brush pressure and solution flow according to the condition of

the floor.

CAUTION!

To avoid any damage to the floor, keep the machine moving when the brushes are turned on.

10. When scrubbing, check behind the machine occasionally to see that all the dirty water is being

picked up. If streaking occurs, your Water Flow setting may be too high, the Recovery Tank may

be full, the Squeegee hose may be clogged, or the Rear Squeegee may require some adjustment.

11. Make the necessary adjustments on the Rear and Side Squeegees if streaking occurs both in

straight paths and in turns. Pleas refer to the Rear Squeegee and Side Squeegee section of this

manual before making any adjustments.

12. In cases where the floors are extremely soiled and dirty, the Double Scrub mode may be needed.

As described in the Main Keyboard section of this manual, this mode allows the operator to be able

to scrub an area without recovering the cleaning solution with the rear squeegee in the raised

position (no vacuum) to allow the cleaning solution a longer time to loosen dirt. A final pass on the

same area is made with the mode switched over to either Full Function or Vacuum Only mode to

recover the dirty water.

13. The recovery tank has two safeguards for overflow protection to guard against water from entering

the vacuum system when the recovery tank is full. When the indicator light is lit up in the Keyboard,

the Vacuum icon in the LCD Screen will be flashing (see the LCD Display section of this manual).

The vacuum will stay ON for 15 seconds and then shut-off automatically. A ball float shut-off system

has also been integrated into the Recovery Tank. When the dirty water reaches a certain level, the

ball gets suctioned into the vacuum manifold and blocks the airflow thus, preventing the machine

from picking up more liquid. When this happens, the operator is then required to stop scrubbing and

empty the recovery tank.

14. To stop scrubbing, select the Transport mode. This will automatically stop the Solution Flow,

raise the Scrub deck, and raise the Rear squeegee (there is a 15 second delay for the vacuum

motor).

15. Drive the SCV to a designated dirty water disposal area and empty the Recovery tank. To empty,

remove the Drain hose from its storage hanger. Unscrew the plug and hold the hose end above

the water level in the tank to avoid sudden, uncontrolled flow of dirty water. With the plug

completely off, carefully direct the water flow to the desired drain. Reinsert the plug and tighten and

return to its storage hanger.

16. The recovery tank should be rinsed out to remove solids in the tank. Open the Cleanout cap to

remove the Stopper plug. Tilt the recovery tank (similar to accessing the batteries) and clean the

sludge that has settled in the sump area by either back flushing or by scraping it out. Be sure to

tightly secure the Stopper plug and cleanout cap before continuing to operate the scrubber.

17. Refill the solution tank and continue scrubbing until the job is done or when the machine runs out of

power.

18. The battery gauge bar icon will flash to signal the operator that the machine is almost out of

power. Once this signal is displayed to the operator, all functions will shut off (brush will turn off and

the scrub deck will raise up, water flow will cease, the rear squeegee will raise up and the vacuum

motor will turn off) including the transport mode. The operator has to turn the key switch OFF and

then, ON to reset the machine. The machine then will only have a few minutes left of reserve

power for a short Vacuum only mode to pick up remaining solution on the floor and Transport power

to drive to the battery recharging station.

18

Page 25

AFTER USE:

1. When finished scrubbing, select the Transport mode, all functions will shut off (brush will turn off

and the scrub deck will raise up, water flow will cease, the rear squeegee will raise up and the

vacuum motor will turn off). Drive the machine to a service area for daily maintenance and review

items that may need service.

2. Empty the solution tank, by directly opening the Garden hose valve underneath the machine into a

drain on the floor or use a garden and attach it to the fitting to remotely drain the solution tank.

Rinse the tank with clean water to prevent any build-up of dried up chemicals that could cause

clogging in the plumbing.

3. Empty the recovery tank as described on line 15 and 16.

4. Remove the brushes or pad holders and rinse them in warm water and hang to dry.

5. Remove the rear squeegee, rinse with warm water and reinstall after cleaning.

6. Remove the side squeegees, rinse with warm water and remove the debris box (cylindrical

system only) and clean thoroughly. The debris box can be removed from either side of the machine

by tilting the box up and away from the housing and then pulling it out. Reinstall the debris box and

side squeegees after cleaning.

7. Check the maintenance schedule on the next page and perform any required maintenance before

storing the machine.

8. Store the machine indoors in a clean dry place. Keep from freezing. Leave solution and recovery

tank lids open for ventilation to prevent odor build-up.

9. Turn Key switch OFF (O) and remove key.

19

Page 26

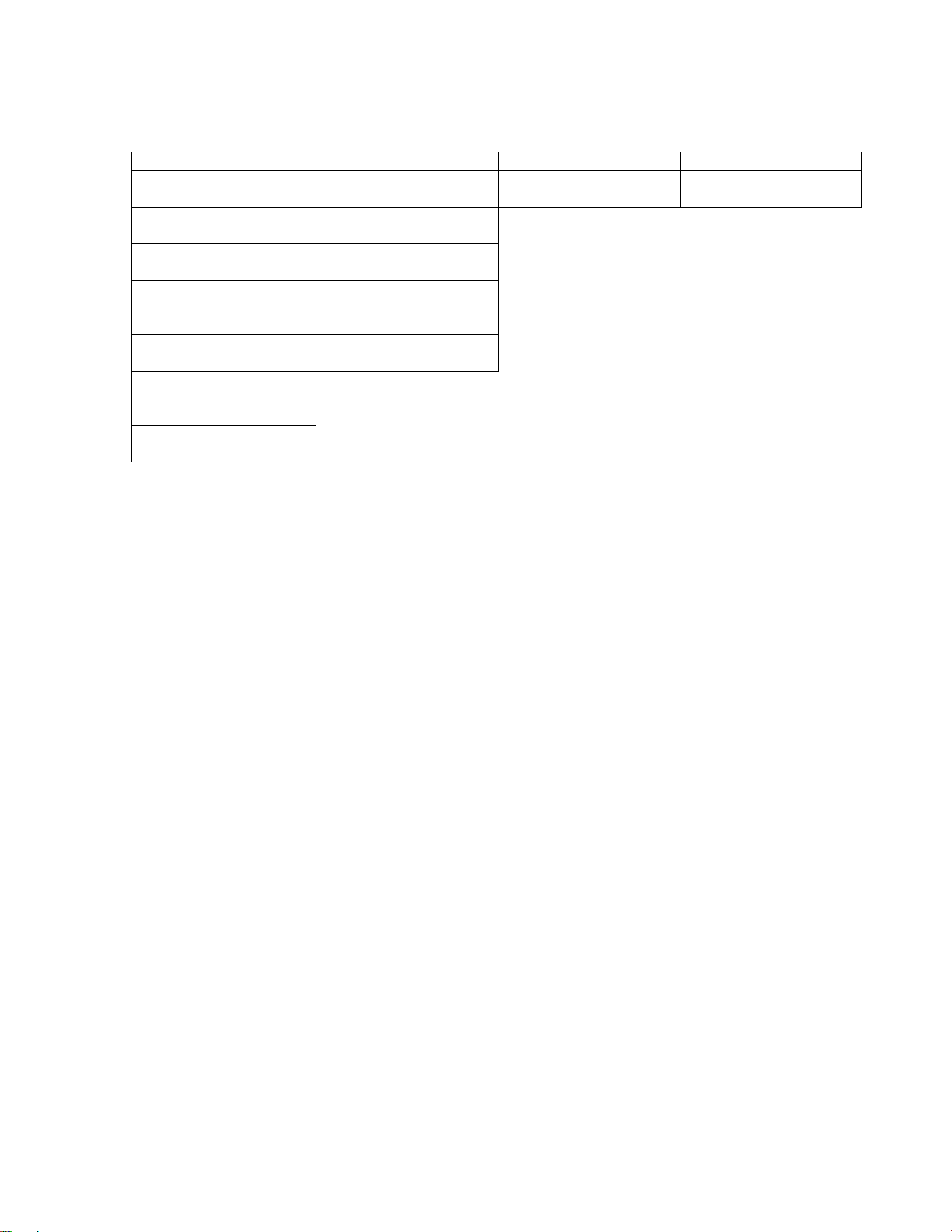

MAINTENANCE SCHEDULE

Daily Weekly Monthly Yearly

Charge Batteries

Check/Clean Tanks &

Hoses

Check/Clean/Rotate the

Brushes/Pads

Check/Clean the

Squeegee

Check/Clean Vacuum

Shut-Off Float

Check/Clean the

Vacuum Motor Foam

Filter

Clean Hopper on

Cylindrical System

• Have Minuteman check the vacuum motor carbon motor brushes once a year or after 300

operating hours. The brush motor carbon brushes should be checked every 500 hours or once

a year.

NOTE: Refer to the Service Manual for more detail on maintenance and service repairs.

LUBRICATING THE MACHINE

Regularly scheduled lubrication of certain machine parts should be performed to insure trouble-free

operation of the machine. Apply a generous amount of grease into the fittings on the machine until grease

seeps out around the bearings.

The grease points are listed below:

Rear squeegee caster wheel axle (2)

Rear squeegee caster wheel stem (2)

Side squeegee caster wheel axle (2)

Side squeegee caster wheel stem (2)

Steering wheel chain sprockets and idlers

Apply lubricant or light machine oil to lubricate the:

Rear squeegee general pivot points

Side squeegee general pivot points

Scrub deck linkages

Drive wheel assembly seals.

Check Each Battery

Cell(s) Water Level

Inspect Scrub Housing

Skirts

Inspect and Clean

Solution Filter

Check Foot/Parking

Brake for Wear &

Adjustment

Clean Spray jets on

Cylindrical System

Lubrication – Grease

Fittings, chains, etc.

Check Carbon Brushes

20

Page 27

GENERAL MACHINE TROUBLESHOOTING

Problem Possible Cause Remedy

Poor water pick-up

Poor scrubbing

performance

Inadequate solution flow

or no solution to the floor

No solution to off-aisle

wand spray jet

Machine does not run

No FWD/REV drive

Worn or torn squeegee blades Rotate or replace blades

Squeegee out of adjustment Adjust so blades touch floor

Recovery tank full Empty recovery tank

Recovery tank drain hose leak Secure drain hose cap or replace

Recovery tank lid gasket leak Replace gasket lid cover properly

Debris caught in squeegee Clean squeegee

Vacuum hose clogged Remove debris and flush hose

Using too much solution Adjust solution control valves

Vacuum hose to squeegee or

recovery tank disconnected to

squeegee or damaged

Worn brushes Rotate or replace brushes

Wrong brush or cleaning chemical Consult Minuteman

Debris caught on scrub brushes Remove debris

Moving machine too fast Slow down

Not using enough solution Adjust solution flow setting

Low battery charge Recharge batteries

Fault code on LCD screen 760x

(Brush motor)

Solution tank empty Fill solution tank

Recovery tank full Empty recovery tank

Solution lines, valves, filter or spray

jets clogged

Solution solenoid valve Clean or replace valve

Recovery tank full Empty recovery tank

Solution tank empty Refill solution tank

Emergency stop switch tripped Activate switch by turning as

Operator seat safety switch Operator has to be seated.

Main system controller Check error fault codes

Tripped 100 amp circuit breaker Check for electrical short circuit

Drive system speed controller.

Fault code on LCD screen 780x

(Traction motor)

Emergency stop switch tripped Activate switch by turning as

evenly across entire width

Reconnect or replace squeegee

hose

Reduce scrub brush pressure.

Broken brush drive belts on

cylindrical system, replace belt(s).

Check power connection.

Reconnect plugs.

Reset machine: Turn key switch

off and restart.

Flush lines, and clean solution

filter and spray jets.

indicated by arrows.

Check for open circuit and replace

(See service manual)

Reset machine: Rest breaker and

turn key switch off and restart.

Check error fault codes

(See service manual)

Reset machine: Turn key switch

off and restart.

indicated by arrows.

21

Page 28

Vacuum motor does not

turn on

Poor sweeping

performance (Cylindrical

System)

Solution tank empty

indicator light on

Recovery tank full

indicator light on

Recovery tank full Empty recovery tank

Excessive foaming in recovery tank. Empty recovery tank.

Use less or change chemical.

Use defoaming agent.

Fault code on LCD screen 7700

(Vacuum motor)

Check for motor overload.

Reset machine: Turn key switch

off and restart.

Debris box full Empty and clean debris box

Brushes worn Replace brushes

Bristles have taken a set Rotate brushes

Solution tank empty Refill solution tank

Faulty float switch Replace float switch

Recovery tank. full Empty recovery tank.

Float switch full of debris Clean float switch.

Faulty float switch Replace float switch

22

Page 29

Code Technical

Description

0705 2.5V reference

error

0706 High switch

reference

error

0810

1500

1600 High battery

7500

7600

7601 Brush current

7700 Vacuum motor

7701 Vacuum current

7800

7801 Traction over

Potentiometer

Fault 1

Brake fault 1

voltage

LCD Module

communications

timeout

Brush motor

disconnected

error

foldback

disconnected

error

foldback

Motor fault 1

current error

SCV 28/32 FAULT / DIAGNOSTIC CODES

Probable Cause

All 070x codes – Wiring short

circuit between potentiometer

Hi and Lo reference.

All 081x codes – Throttle wiring

short or open circuits.

All 150x codes – Check brake and

wiring for open or short circuit.

Voltage exceeds maximum.

Wiring fault on 6-way serial link

between SCV and LCD

Open circuit on brush motors or

brush motor wiring.

Brush current overload (“thermal”

trip).

Open circuit on vacuum motors or

vacuum motor wiring.

Vacuum current overload

(“thermal” trip).

Open circuit on traction motor or

traction motor wiring.

Possible short circuit on traction

motor or wiring.

Check for wiring short circuits on the 20way connector on the SCV, the 16-way

connector on the LCD (if used) and the

wiring to the front panel switches &

controls and those switches & controls

themselves.

Check for wiring short circuits or broken wires

on the 20-way connector on the SCV, the 5

way connector on the LCD (if used) and the

wiring to the front panel speed / throttle

control and the speed / throttle control itself.

Check the traction motor connection on the

SCV and check the wiring from this connector

down to the traction motor and checking

connections all the way. Otherwise possible

fault in electro brake on traction motor or

possible controller fault.

Can be caused by poor or corroded

connections to the batteries or a battery

charger being connected.

Check the wiring and connectors on the 6 way

connections on the SCV and LCD.

Check the brush motor connection on the SCV

and check the wiring from this connector down

to the brush motor and checking connections

all the way. Otherwise possible brush motor

fault.

Incorrect programming, incorrectly specified

brush motor, brush motor developing a fault,

excessive resistance on brushes or brushes

pushing down too hard on floor.

Check the vacuum motor connection on the

SCV and check the wiring from this connector

down to the vacuum motor and checking

connections all the way. Otherwise possible

vacuum motor fault.

Incorrect programming, incorrectly specified

vacuum motor, vacuum motor developing a

fault, debris in vacuum motor or airways

blocked by debris.

Check the traction motor connection on the

SCV and check the wiring from this connector

down to the traction motor and checking

connections all the way. Otherwise possible

traction motor fault.

Check the traction motor connection on the

SCV and check the wiring from this connector

down to the traction motor and checking

connections all the way. Otherwise possible

traction motor fault.

Service Action

23

Page 30

7802 Traction motor

in foldback state

7900

2C00 Low battery

2F01

Emergency stop

error

error

Potentiometer

displace error

Traction motor current has

exceeded current limit for the

foldback time.

E-stop input active or wiring fault.

Low voltage warning. Recharge batteries immediately.

Throttle in drive position during

switch on.

Excessive driving up an incline, or machine

driven up against an obstacle or step.

Check for wiring short circuits on the 20-way

connector on the SCV, the 16-way connector

on the LCD (if used) and the wiring to the

emergency stop switch and the emergency

stop switch itself. Otherwise incorrect

operation of machine.

Incorrect operation of machine. Otherwise

check the mechanical condition of the throttle

mechanism. Otherwise check for wiring short

circuits on the 20-way connector on the SCV,

the 16-way connector on the LCD (if used)

and the wiring to the front panel switches &

controls and those switches & controls

themselves.

24

Page 31

25

MAIN ASSEMBLY I

EXPLODED VIEWS

Page 32

26

Page 33

27

MAIN ASSEMBLY II

Page 34

28

Page 35

MAINFRAME ASSEMBLY I

29

Page 36

30

MAINFRAME ASSEMBLY II

Page 37

31

Page 38

FRONT DRIVE ASSEMBLY

32

Page 39

33

Page 40

STEERING ASSEMBLY

34

Page 41

35

Page 42

LCD HOUSING ASSEMBLY

36

Page 43

SOLUTION TANK ASSEMBLY

37

Page 44

38

Page 45

ELECTRICAL PANEL ASSEMBLY

39

Page 46

CONSOLE ASSEMBLY

40

Page 47

RECOVERY TANK ASSEMBLY I

41

Page 48

42

Page 49

RECOVERY TANK II

43

Page 50

DIVERTER ASSEMBLY

44

Page 51

BATTERY BOX ASSEMBLY

45

Page 52

PUMP ASSEMBLY

46

Page 53

47

Page 54

48

REAR AXLE ASSEMBLY

Page 55

SQUEEGEE MECHANISM ASSEMBLY

49

Page 56

50

REAR SQUEEGEE ASSEMBLY 28”

Page 57

51

Page 58

52

REAR SQUEEGEE ASSEMBLY 32”

Page 59

53

Page 60

54

28” CYLINDRICAL SCRUB DECK ASSEMBLY

Page 61

55

Page 62

28” DISC SCRUB DECK ASSEMBLY

56

Page 63

57

Page 64

58

32” CYLINDRICAL SCRUB DECK ASSEMBLY

Page 65

59

Page 66

60

32” DISC SCRUB DECK ASSEMBLY

Page 67

61

Page 68

CYLINDRICAL DECK AND SIDE SQUEEGEE MOUNTING

62

Page 69

63

Page 70

DISC SCRUBDECK AND SIDE SQUEEGEE MOUNTING

64

Page 71

65

Page 72

28” SIDE SQUEEGEE (RIGHT SIDE)

66

Page 73

28” SIDE SQUEEGEE (LEFT SIDE)

67

Page 74

32” SIDE SQUEEGEE (RIGHT SIDE)

68

Page 75

32” SIDE SQUEEGEE (LEFT SIDE)

69

Page 76

70

OFF AISLE WAND ASSEMBLY

Page 77

71

Page 78

PLUMBING DIAGRAM

72

Page 79

POWER WIRING

WIRING DIAGRAMS

73

Page 80

INPUTS TO CONTROLLER

74

Page 81

OUTPUTS FROM CONTROLLER

75

Page 82

KEYBOARD WIRING

76

Page 83

77

MACHINE SCHEMATIC

Page 84

1/03

78

Loading...

Loading...