Minuteman PORT A User Manual

PORT A SCRUB 14

Floor Scrubber Drier

Contents

Instruction Manual

Preface...............................................................................................................

Introduction

Proper Use..........................................................................................................

Notes on Warranty...............................................................................................

Acceptance of the Machine.................................................................................

General Safety Provisions

Operation............................................................................................................

Transport.............................................................................................................

Park Position.......................................................................................................

Handling Mains Cable.........................................................................................

Operation

Machine...........................................................................................................

Useful Advice for Optimum Cleaning..................................................................

Working Principle................................................................................................

First Operation

2

4

5

5

5

6

6

6

7

7

7

Assembly............................................................................................................

Before Operation................................................................................................

Description

Controls..............................................................................................................

Control Panel......................................................................................................

Detergent Infeed................................................................................................

Squeegee Governor............................................................................................

Mount / Dismount Brushes..................................................................................

Squeegee............................................................................................................

Squeegee (Initial Fitting)......................................................................................

Change Sealing Strips.........................................................................................

Clean Nozzle.......................................................................................................

Fill Water..............................................................................................................

Operation

Operation.............................................................................................................

Soiled and Fresh Water Tanks.............................................................................

Electric System....................................................................................................

Technical Data.....................................................................................................

Maintenance

7

7

8

9

9

10

11

12

12

12

12

13

13

14

15

15

Maintenance works.............................................................................................

17

2

Contents

Spare Parts Manual

Chassis Group.....................................................................................................

Handle Group......................................................................................................

Brush Drive Group...............................................................................................

Brush Head Group...............................................................................................

Vacuum Motor Assembly.............................................................. .......................

Vacuum Motor Group.......................................................................... ................

Squeegee Group......................................................... ........................................

Squeegee Lifting System......................................................................................

Water Feed System.............................................................................................

Tank Group..........................................................................................................

Drive Group.........................................................................................................

Electrical Group...................................................................................................

Port A Scrub 14 Assy..........................................................................................

21

23

25

27

29

31

33

35

37

39

41

43

47

3

Instruction Manual

Preface

Dear customer,

It is our desire that the excellent properties of the Port Ascrub 14 should justify the confidence you demonstrated by

making this purchase. Before first operation of your read these instructions carefully. They will

inform you in detail about operation of the item and contains valuable information on operation, service and

maintenance.

Port A scrub 14 machine is an ideal machine to clean floors in small and medium areas like Offices, Hospital,

Restaurant, Shopping complexes and many commercial applications.

hasbeen used in thismanualat several placesandidentifiesparticularareas that areofessencefor your safety. Please

passallsafetyinstructionsontootherpersonsoperatingthismachine.”

The symbol,

hasbeen used in this manualatseveralplacesandidentifiesparticularareas that the operatorshouldbecautious.

Thesymbol,

Port A scrub 14

hasbeen used inthis manualatseveral places andidentifiesparticular areas thatthe operatorshouldnote at thetime of

operation

Priorto first operation, read themanualcarefullyandstrictlycomplywiththeinstructions contained.

Pleasebe advised explicitly that wecannotacceptanylegalclaimsoutofthe contents ofthismanual.

If repair work has to be performed, make sure that only genuine spare parts are used since genuine spare parts

only may guarantee continuous and dependable operation of your machine.

Valid as for JULY 2007

Minuteman International, Inc

111 South Rowling Road,

Addison, IL 60101-4244, USA.

Introduction

Proper Use

The vacuumscrubbing machine hasbeenexclusivelydesigned forfloor cleaning, such as wetscrubbing

PortAscrub14

and vacuuming .Whatever sort of use beyond the specified range will be deemed improper use: the manufacturer can

notbe held liable forconsequentialdamages.

The term of proper use also includes compliance with the manufacturer’s instructions about operation, maintenance

and repair.

The Port A scrub 14 may be used , serviced and repaired by persons only that are familiar with the machine and are

aware of possible hazards involved. The appropriateAccident Prevention Regulations as well as applicable general

regulations about safety and health at work will have to be complied with.

Modifications made to the Port A scrub 14 in absence of the manufacturer’s consent will relieve the manufacturer

from a possible liability for consequential damage.

Thismachine is not suitableforevacuationofdusts, whichareexplosiveordangeroustohealth.

4

Notes on Warranty

The terms of the sales contract apply. Damages are not subject to warranty if they are due to non-compliance with the

maintenanceand service provisions.

Any maintenance work has to be performed by an authorized Minuteman service workshop and confirmed in the

“Maintenancecertificate “which is the warrantydocument.

Thefollowing is excluded from warranty:

Natural wear and tear after overload, blown fuses and damages caused by inexpert handling and unauthorized

modificationof the machine.

Moreover,any claimfor warrantyexpires if damages at themachine are caused by fittingof parts oraccessories without

Minuteman’sprior andexplicitconsentorbynon-compliancewiththemaintenance instructions.

Acceptance of the machine

Upon arrival, check your consignment for possible transit damage. Please have the railway authorities or the freight

forwarderconfirm such damage and mailyourdamagereportandwaybillto:

Ours Address :

MinutemanInternational, Inc

111 South Rowling Road,

Addison, IL 60101-4244, USA.

General Safety Instructions

General Safety Instructions

Apartfrom theinformation contained in thismanual, the generallyapplicable legal provisionsfor safety andprevention of

accidentsmustbe adhered to. Donot putthis manualaside withouthaving readit, evenif youdid alreadyoperate similar

groundcleaningequipmentbefore.Allowyourselfthetimetodosoinordertosafetimeatalatermoment.The operator is

responsiblefor all persons intheworking area. Childrenhave tokeep clearofthe inoperation. Nobody is

allowedto stayinthezoneofdanger.

The warning and instruction plates attachedto the give important advice about safe operation .Replace

lost or illegible stickers. Before starting to work, the operator has to check that the and its working

implementsare inproperandsafeoperatingcondition.

Machines with known defects must not beused. It will be of essence to makeyourself familiar with all accessories and

controls,aswellas theirfunctions, before you start working.Avoidthe mess of having to readthisbookwhile trying to run

themachine.

Operation

Ground cleaning machines may be run by qualified personnel only; such personal will have to have evidenced their

qualification for running the machine to the owner or his authorized representative; operators explicitly will have to be

instructedby the owner or hisauthorizedrepresentativetousethemachine.

Themachine may be used forcleaningsuchsurfacesapprovedbytheownerorthis authorized representative.

PortAscrub 14

PortAscrub14

Port A scrub 14

To prevent damages at the brushes as well as at the floor, do not let the Machine run dry. The machine has been

exclusivelydesigned for wet scrubbing andvacuuming.

Turn the motors off, fold the support roller and the operating handle down and protect the machine against

unintended movements before leaving it unattended. Use genuine spare brushes as specified by the

manufacturer. Use of other than the indicated brush types may affect safety.

When transporting the , shut down the motors of the working implements. The operator has to use the

machine in accordance to its intended fields of application. During operation, he has to take account of the local

conditions(stairs,obstacles) and of other persons, in particular to children.Turnoffthe machine before any passage over

dormers.

Use cleaning agents only, which are suitable for automatic machines (low foaming), and adhere to the instructions for

use,disposal and to the precautionsspecifiedbythemanufacturerofthecleaningagent.

Port A scrub 14

5

Make sure to connect the to a socket equipped with earthed protective wire and to

Port A scrub 14

mainsof adequatevoltageand frequency

Nevercollect explosive fluids, undiluted acids and solvents!Thisincludese.g.gasoline,paintthinners or fuel oil,

Which-whenpenetrating the air being takeninmayformexplosivevaporsor mixtures; moreover acetone,

Undilutedacids and solventsiftheyshouldbeaggressivetothematerial used for the machinecomponents.

The machine may be used only on indoor hard floorings and for operation on level grounds with a maximum

inclinationof up to 2 %

Using the machine on public roads and places is not admitted. Qualified personnel only are admitted to perform

maintenanceand repairwork.

Turnthe machineoffand disconnect themains plug beforecleaningand maintaining themachine, when replacingparts

orwhen change over to anotherfunction.

Donot clean the machine bymeansofvapourjetorhighpressurecleaning equipment. Do not allow water

penetratethe electrical parts.

Themachine is splash-water proof (IPX3).

Useof the machine in areasendangeredbyexplosionhazardisnotadmitted.

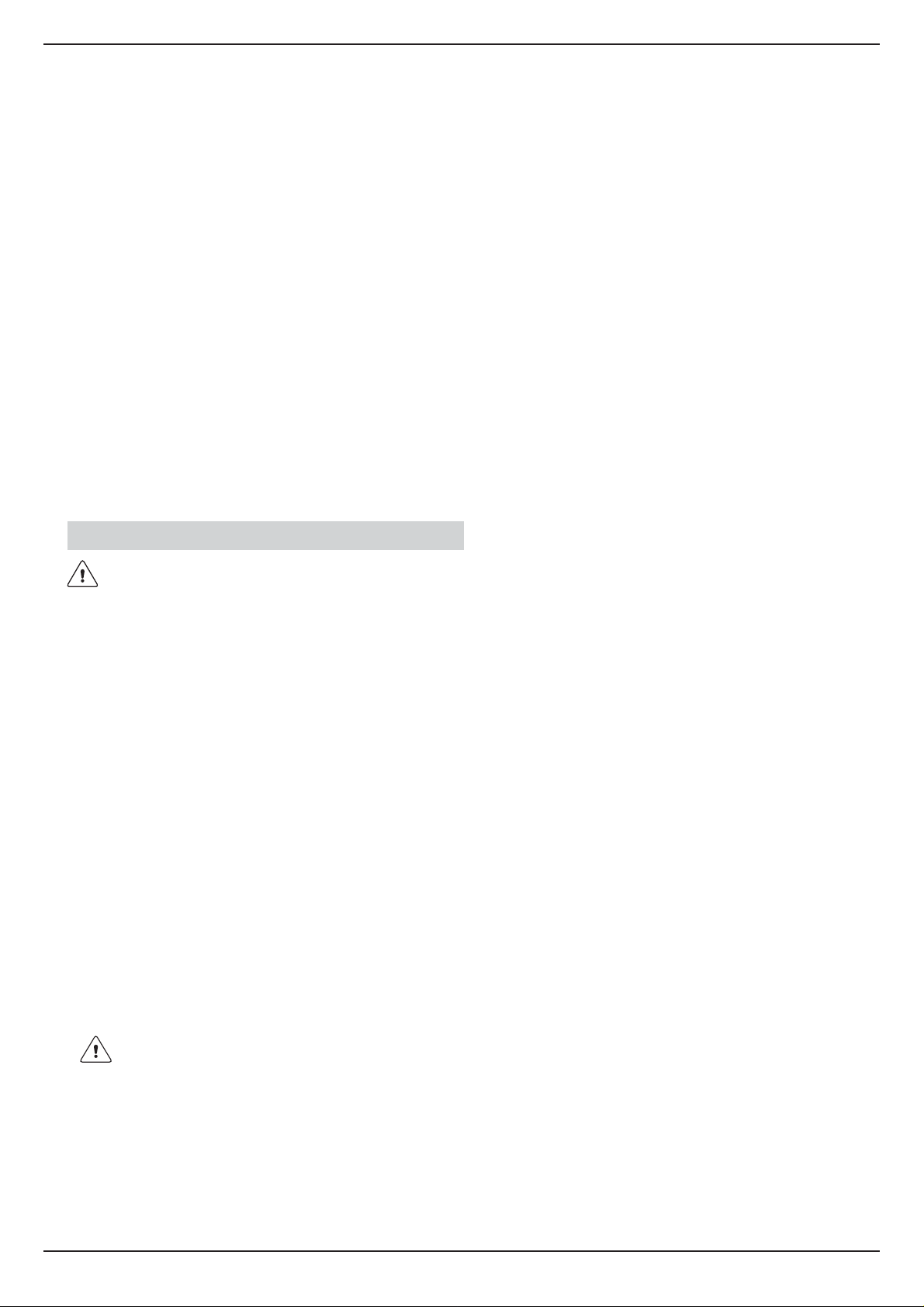

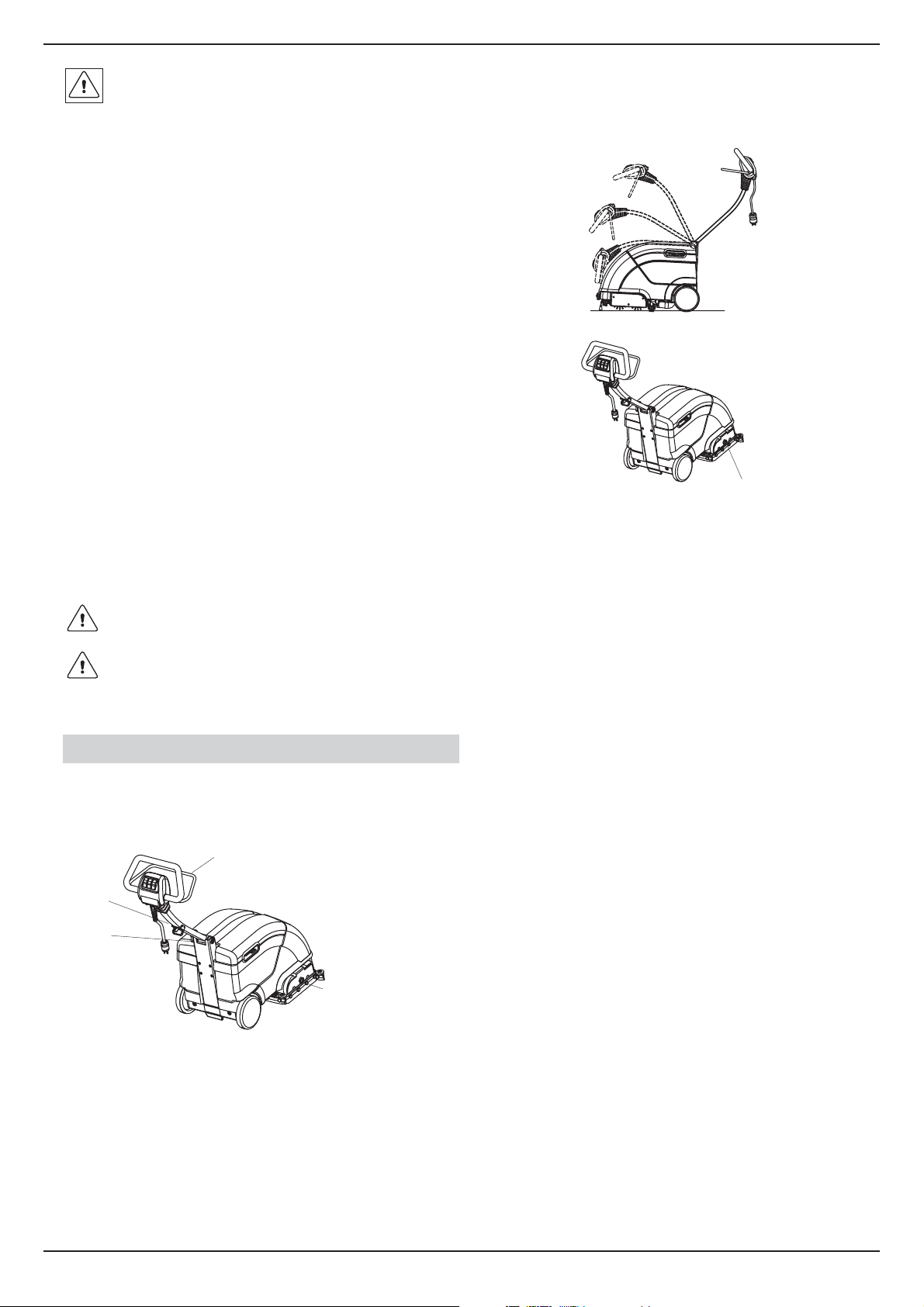

Transport

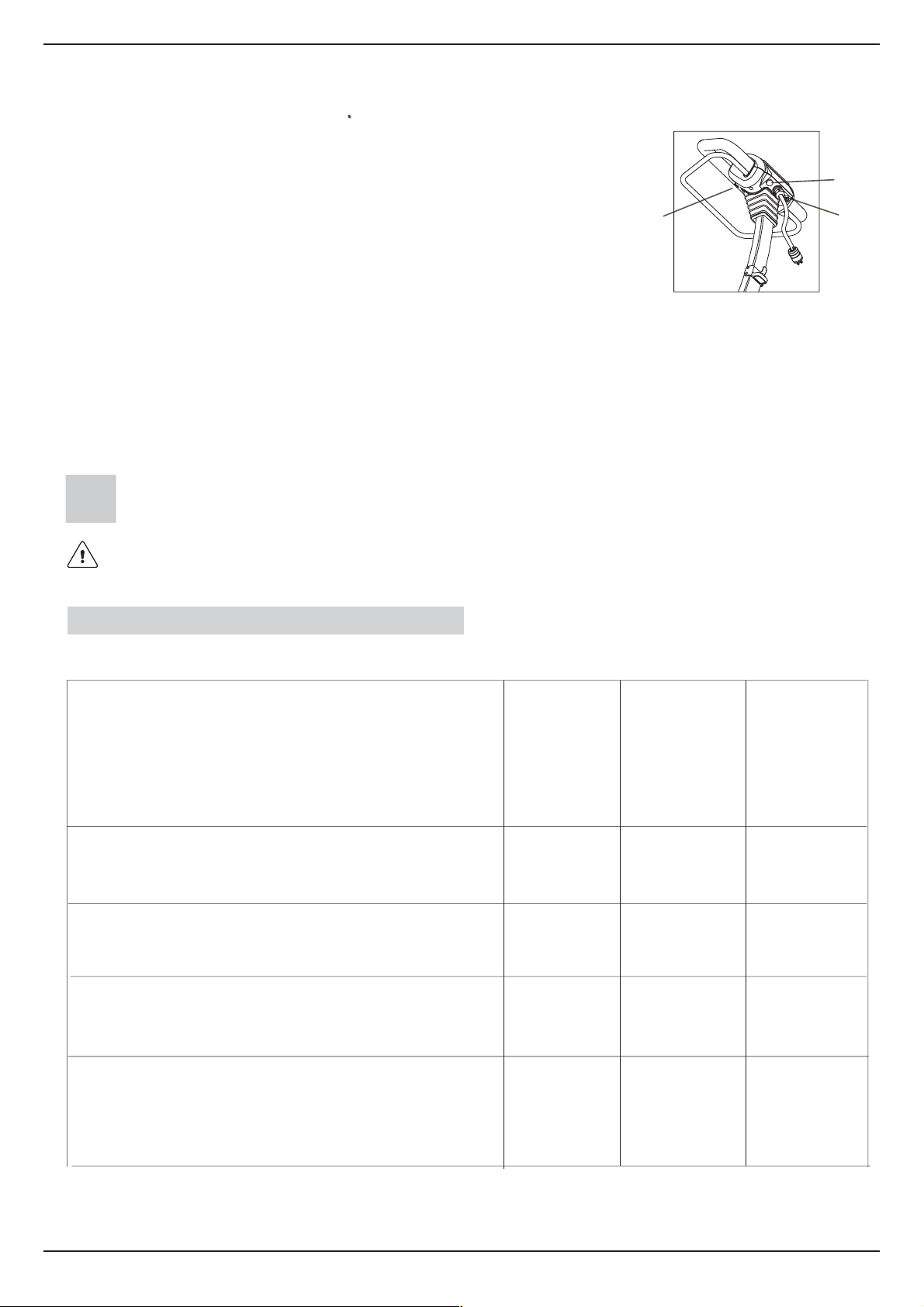

Thefrontrollerof the PortAscrub14hasbeenfittedforparkingthemachineonlyandprecludesdamagestothefloor.Itis

thusrecommended to liftupthebrushheadasrepresentedbeforetransporting the PortAScrub14.

Park Position

Working Position

Parking Position

If not operated, the Machine has to be stored in its park position. This position is attained by using the support roller

located at the front of themachine asrepresented.Actuate thesupport bya lever located above the support roller (see

Fig.)Andthebrush head of the machineislightlylifted.This is to precludedeformationofthebrushes.

Handling Mains cable Assembly

Makesure that themains cables arenot damaged bypassingover them bypinching, pulling orother impacts. Check the

mainscablesforageing and damages at regularintervals. Replace themby the type STcable 14AWG/ 3 Core (UL/CSA

approved)with15mlength.Powerplugandconnectorsshallberatedfor125Volts,20Amps (UL/CSAapproved)having

standard NEMA configuration for locking types as specified by the manufacturer.When replacing the coupling plug of

themains cable or when connectinglinesrespectthesplashwaterprotectionandthe tensile strength of thecomponents.

6

Operation

Port A scrub 14

Wet cleaning of hard floorings requires equipment with

squeegee and brushes suitable for the type of floor to be

cleaned.

Therotating brushes and the cleaning lye scrubthedirtandclean

the floor thoroughly while the squeegee collects the lye

immediately. The floor is dry and clean can be stepped on

immediately.

Useful advice for optimum cleaning

Before wet cleaning, sweeping the floor is required. This is not

only to improve the cleaningeffect but to significantly reduce the

wearingof the machine.

In case of heavy soiling or for wax removal (basic cleaning), a

second treatment of the floor may be required. In the first cycle,

the floor is scrubbed with a detergent solution adopted to the

degreeof soiling.

This cleaning agent acts on the floor according to the

specificationsofthemanufacturerfor about 5 to 10 minutes,then

scrubthe floor gain with thesqueegeebeinglowered.

Comply with the instructions for correct dosage of

detergent. Correct dosage will help you save money

And protect the environment.

Working Principle

Occurrence of great quantities of foam will affect functioning of

your machine.

Actually, it indicates excessive dosage or improper suitability of

dosing and degree of soiling. Unused detergent particles in the

soiled water lead to formation of foam. Refer to the detergent

reservoir for information on correct dosage. Take the

manufacturer’s recommendations as a first basis. Test made by

yourself in practice will help you find the ideal type of detergent

andthe perfect dosage applicable toit.

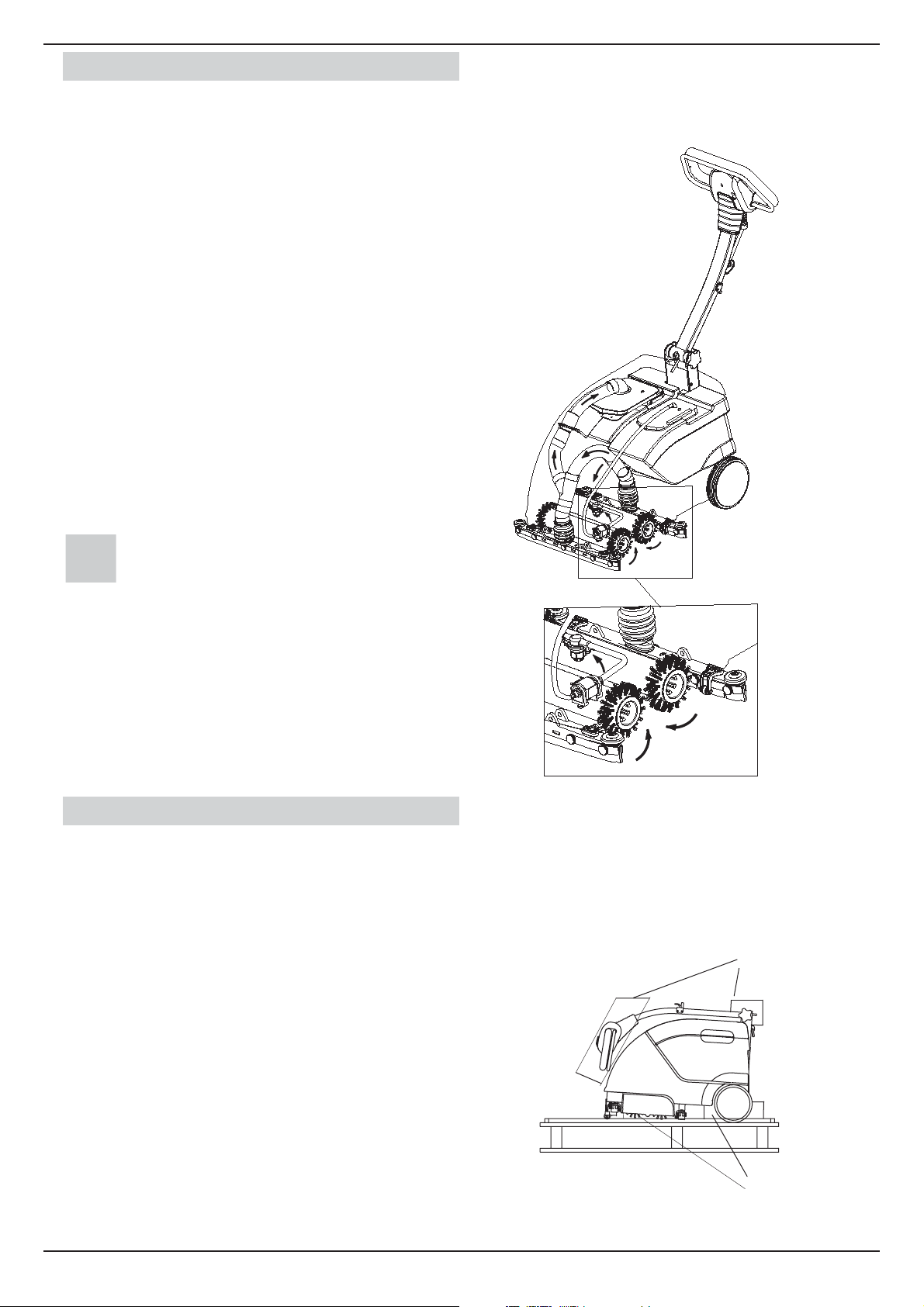

First Operation

Assembly

The isdelivered in acardboard box. The bottomis a woodenpallet towhich themachineis fastened by

PortAscrub14

plastic straps. Open the bottom side of the box and pull it upwards, then loosen the straps and take the machine from

pallet.

Before Operation

Top insulation

1. Upon delivery, the has been secured by

insulation blocks at the bottom and the top to preclude unwanted

movement of the machine. After taking the machine from the

pallet:

Port A scrub 14

block

(I) Open the cardboard box at the top side

(II) Remove the insulation blocks

(III) Take the off the box and avoid any damage

to the machine

(IV)Theoperating handle of the Machineisstillinitstransport

position.

Port A scrub 14

Bottom insulation

block

7

CAUTION: Mains-operated machine! Qualified personnel only is admitted to open the machine; Any work

such as e.g.Maintenance or repairactions atthe electric componentshave to beexecuted withadequate tools

onlyand by qualified personnel only.

2.After taking the to its park position, set the

operating handle into its working position by releasing the

button at the side. After the handle has been set into service

position,engagethebutton again to preclude thehandle from

displacing. After operation, the handle can be folded back

againasdescribed above. In thisfolded positionthe handle is

protected against the damages and requires less storing

space.

3. Open the lateral brush head cover by loosening the screw.

Theninserttheenclosed brushes into thehousing.The

scrub 14

andfastening of the brushes

has been equippedwith screwsto facilitate removal

PortA scrub 14

PortA

Screw

4.Afterfolding of the lid, filling of the fresh water tankispossible.Beforefillingwithfreshwater,takethesupportrollerout

ofits parkingposition.

Makesure that all covers and flapshavebeen fitted before startingoperation

Adamagedmainscablehastobe replaced by specific cable available at themanufactureroran

authorizedservice centre.

Description

Controls

3

1

2

1.Adjustable handle

2.Button for Handle

3.Squeegee Governor (forward, reverse)

4.Screw for brush removal

4

8

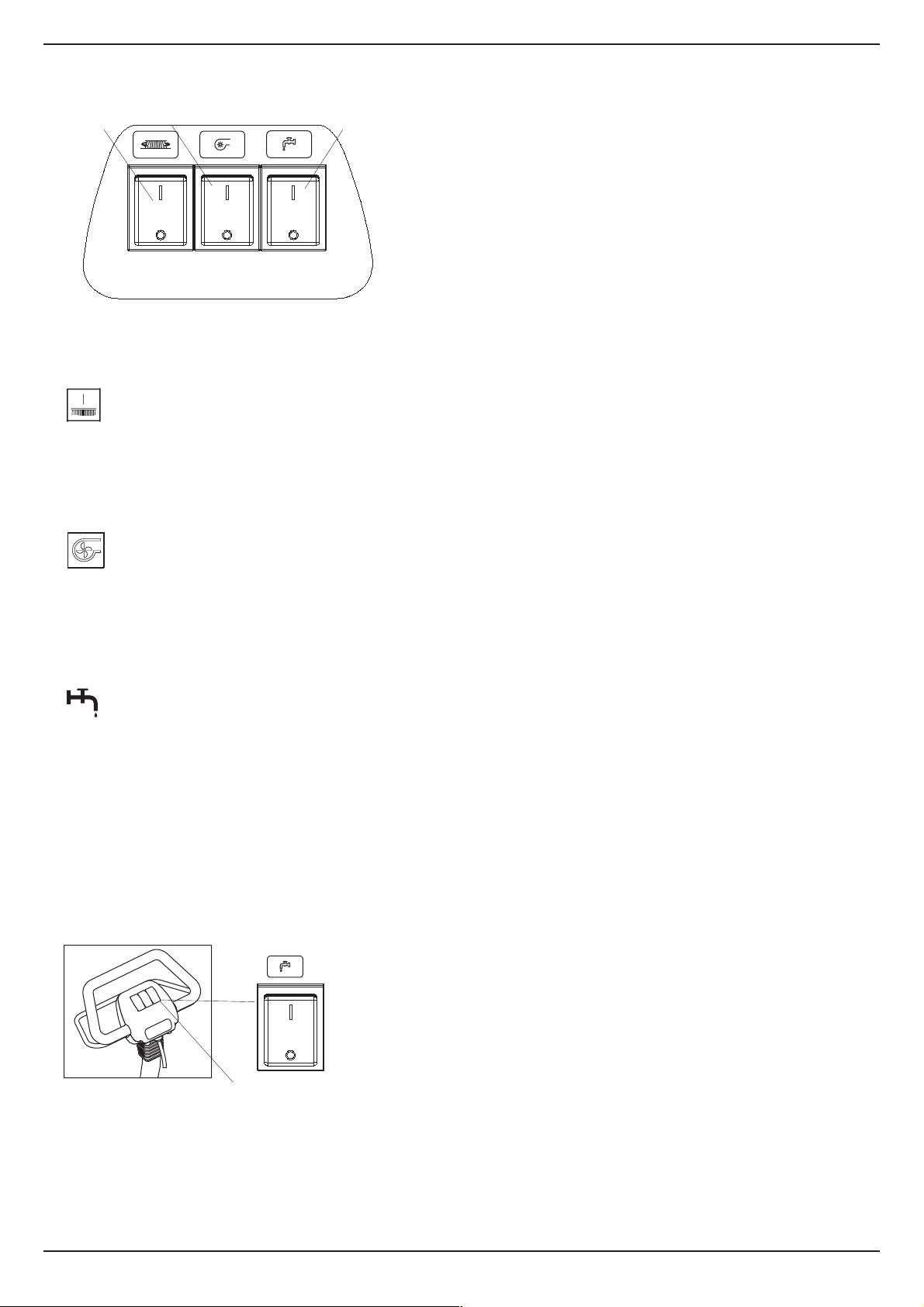

Control panel

A

1. Brush motor, suction motor and water pump switches

A. Brush motor switch ON / OFF

Function in ON if switch “A” is in position “I”

B

C

B. Suction motor switch ON / OFF

Function in ON if switch “B” is in position “I”

C Water pump switch ON / OFF

In “I” position of the switch, water is steadily pumped to the floor.

In “0” position of the switch, no water is pumped.

2.Detergent infeed

Pump Switch

The Port A Scrub 14 allows mixing of cleaning lye and fresh water in the tank. The amount of detergent required for

cleaning can be regulated by the pump switch. If the switch is set to the position “I” the cleaning lye is continuously

supplied.Ifthe solution isrequired byintervals only, press the switchandhold in position “I”.This function helpsto save

detergent.

9

Screw for fitting the Brush

Screw

Disconnect the mainsplug before mountingor dismountingthe brush. Loosenthe screwfor fitting thebrush before use

of themachine and afterwardsfor removal of the brush. Change the brush position after each use in order to preclude

one-sidewearing.

Loosen the screw before dismounting the brush from the Port A Scrub 14

Dismount the brush from the Port A Scrub 14 after every use. Take the machine into the park position before

Squeegee Governor

1

1.Governing handle

2.Front squeegee

3.Rear squeegee

Reverse

2

3

Forward

·The front or the rear squeegee of the Port A Scrub 14 is lowered and has contact with the floor. The operator may

change squeegee position according to the direction of travel of the machine.

If the port A Scrub 14 is in its working position and pushed forward, the rear

squeegee has contact with the floor while the front squeegee is lifted.

Water

End of operation

Due to the counter-rotation of the brushes, some water remains between the brushes at the end of operation.

Proceed thus as follows at the end of operation

- Take the machine into park position

- Turn suction motor on

- Move the machine a little bit forward

During this movement, the rear squeegee takes in the water.

10

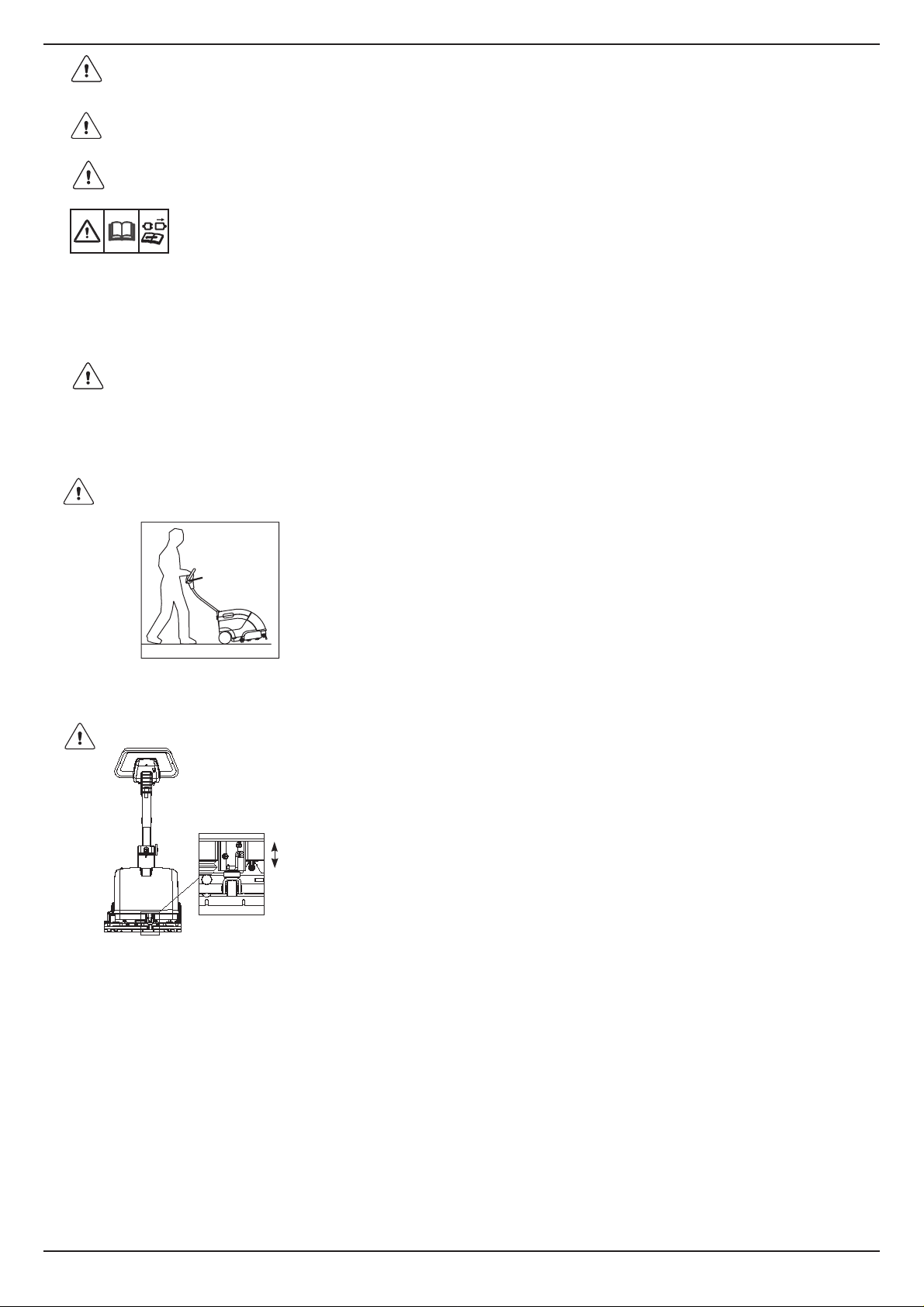

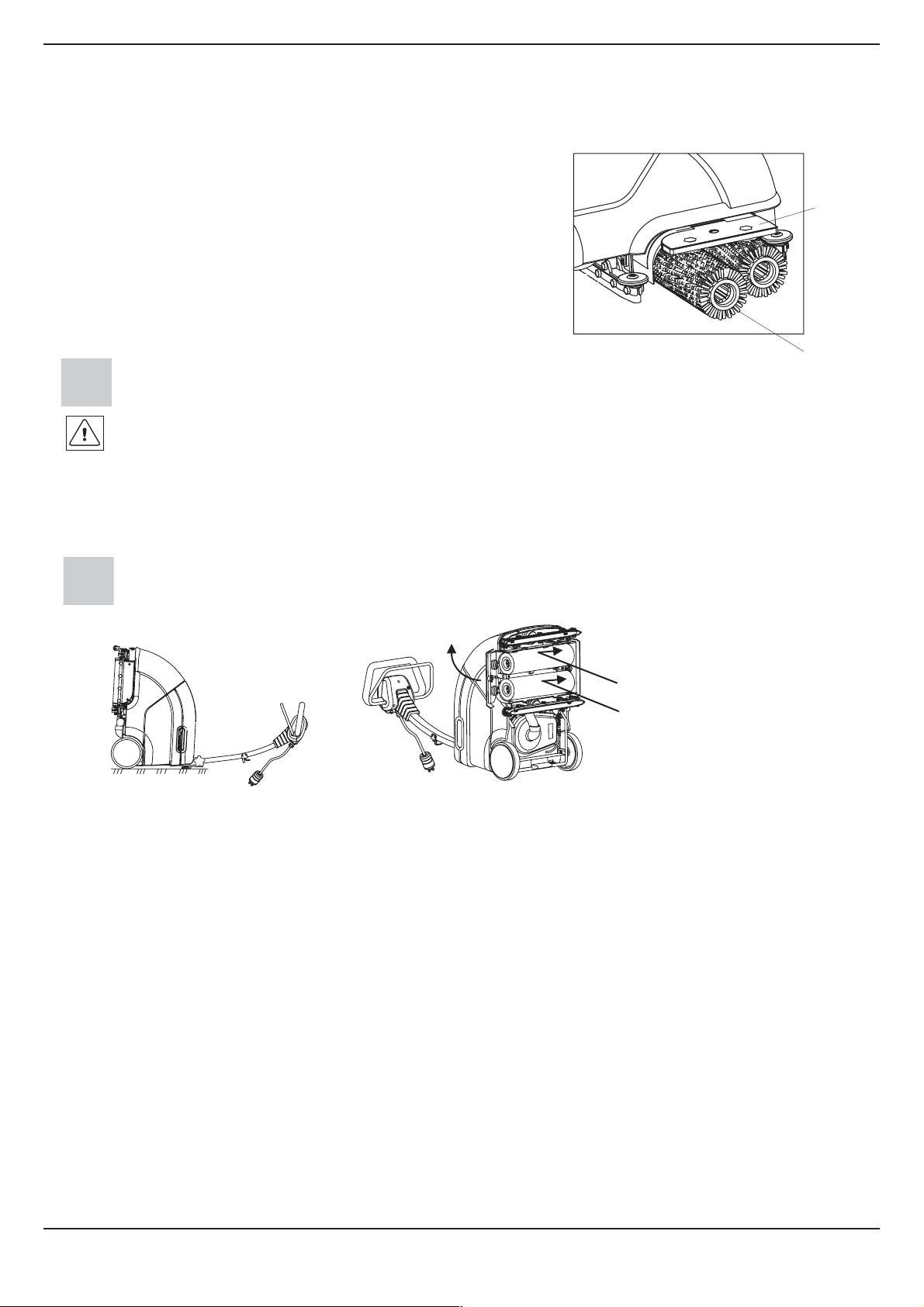

Mount / Dismount brushes

According to the type and degree of soiling, the Port A Scrub14 can be equipped with brushes from the

accessories. Refer to chapter ”Technical Data” on page 17.

Mount Brush

Use the support roller located at the handle side of the Port A Scrub

14 to set the machine into its park position.

Remove screw of the brush cover.

Fasten supplied brushes at the drive rollers at the inside of the

opposite cover.

Close brush cover such that the guiding rollers and the brushes

safely catch.

When mounting, check the safe catching of rollers and brushes..

Before cleaning or maintaining the machine as well as before replacing parts of it, turn the machine

off and disconnect the plug.

Dismount Brushes

Use the support roller located at the handle side of the Port A Scrub 14 to set the machine into its park position.

Brush

Cover

Brush

Loosen screw.

When inserting the brushes for the next operation, make sure to change position of the brush such

that one- sided brush wearing is precluded.

Brush maintenance

2

1

Remove fresh and soiled water tanks

Use the support roller located at the handle side of the Port A Scrub 14 to set the machine into its park position.

Use the adjustment screw to set the operating handle of the machine into vertical position, and then tilt the

machine down as represented.

Loosen screw and fix the brushes manually as represented in Fig. 2 in direction 1.

Open brush cover in direction 2.

Fig. 1

Fig. 2

Remove brushes

Clean brush compartment

Insert brushes, close brush cover and secure with screw.

Set Port A Scrub 14 in upright position.

Use adjustment screw to set the operating handle into working position

.

Set front support roller into working position.

Re-insert fresh and soiled water tanks.

11

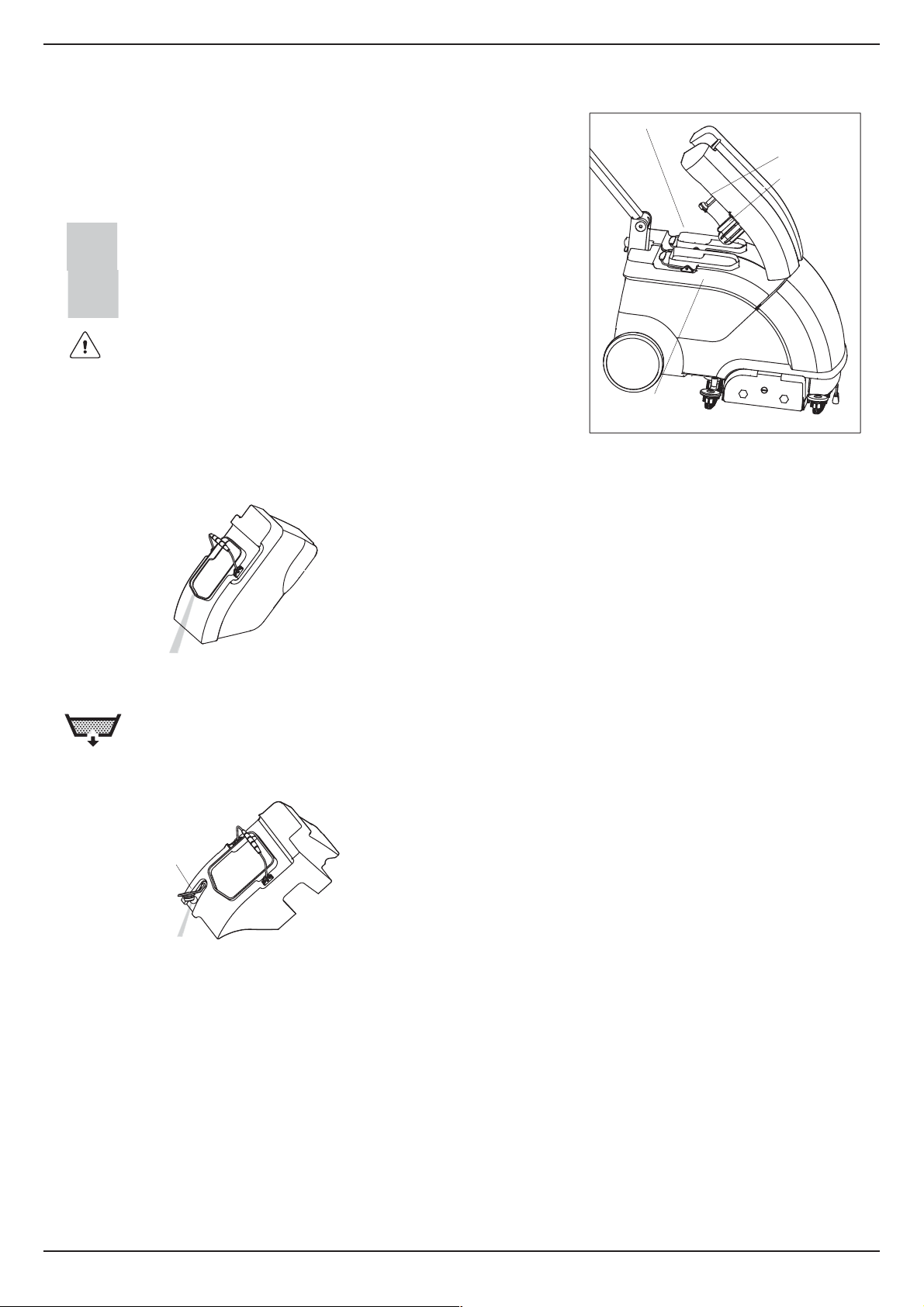

Squeegee

The Port A scrub 14 has been equipped with a squeegee of 450 mm working width. The squeegees can be liftedout alternately

Check the squeegee for collected foreign particles and

Mount Squeegee (Initial Fitting)

Lift squeegee and hold it to the squeegee holders (3).

Mount squeegee (1) to the squeegee holder by means of screws (2) as

represented

Check the smooth running of the bottom sleeve at the squeegee

holders for perfect hinging.

Dismount Squeegee

Lift brush head of the PortA Scrub 14 in order to access the squeegee screws.

Remove both screws (2) as represented.

Pull squeegee to the bottom to remove it from the machine.

Change Sealing Strips

No tools are required for dismounting the sealing strips. Proceed as

follows:

Dismount squeegee (refer to paragraph “Dismount squeegee” ).

Unscrew knurled screw (1)

Remove support strip

Proceed to mounting of new sealing strip in reverse order.

3

2

1

1.squeegee

2.squeegee screw

3.squeegee holder

3

2

1

1. Knurled screw

2. Support strip

3. Sealing strip

Tighten the knurled screws (by hand) and from the centre towards the

outsides (slotted sealing strips point to the front, plain ones to the back)

The rear sealing strip can be turned round if worn at the front edge.

Clean nozzle

The nozzle clogs after some hours of operation. It thus

required to clean the nozzle at daily intervals before start of

operation.

Proceed as follows for cleaning the nozzle:

(I) Remove nozzle

Dismount brushes from the Port A Scrub 14 (see

“Dismount/Mount Brushes”).

Lift machine and lay down on its back as represented.

Turn the nozzle to the left

(II) Clean nozzle

·

Clean nozzle by compressed air or water

(III) Mount nozzle

·

After cleaning, insert nozzle by screwing clockwise

.

make sure that the nozzle slot is as the mounting direction of the brushes.

Upright machine

Loosen

Tighten

NOZZLE

Nozzle Slot

12

max.

50°C

Fill water

Fill fresh water and detergent as described below before start of operation.

Open tank lid and fold back

.

Fill fresh water tank with water (50°C max.) And detergent in relation to the dirt encountered and according to the

specifications by the manufacturer.

Filling Amount : 10 litres max.

Use detergents suitable for automatic machines (low foaming) in order to preclude damages at the

suction turbine. We recommend Minuteman detergents for cleaning and care, which are perfectly

adopted to the Port A Scrub 14. These products fulfil the requirements of the DetergentsAct

Operation

Operation

Use the button to take the support into working position.

Turn switch “A” ON to make the brush rotate.

Turn switch “C” ON to open supply of fresh water with or without detergent.

Turn switch “B” ON to start suction turbine running.

Turn all switches OFF after operation and remove the brushes from the Port A Scrub 14. Mount the brushes in inverse

order of dismounting before next operation. This measure extends service life of the brushes.

Start operation of the machine by pushing forward immediately after switching on. This measure

extends Service life of the brush motor. When bushing in reverse direction lift the rear squeegee with

the squeegee governor. Make sure that during the operation of the machine the mains cable always

Turn the brush drive off before passing over dormers of a height of 10mm and more.

Danger when passing over the mains cable with rotating brushes.

Startcleaning in the socket area and clean by stripes. Ifthe surface is not obstructed, start at borders and

forwardcounter-clockwise. Clean the remaining surface by stripesandstartingin the socket area.

Divide partly obstructed surfaces into areas in the reach of the mains cable. Within shortest time, the operator

willknow to avoid unnecessary hindrance causedbythemainscable.

At the end of cleaning:

Turn machine off and set it to its park position

Empty and rinse soiled water tank (see paragraph ”Soiled and Fresh Water Tanks”)

Clean sealing strips of the squeegee

Check the sieve at the inlet opening of the fresh water tank and clean if required in order to maintain suction

performance.

Do not clean the machine by means of a water jet or high-pressure cleaning equipment to avoid

endangering your safety and the operability of the machine.

13

Soiled and fresh water tanks

The PortAScrub 14 is equipped witha soiledand a fresh water tank(lye

tank). The filling amounts to 10 litres. Do not fill beyond the maximum

markand do not exceed awatertemperatureof50°C

Asuctionhosedelivers the soiled water intothesoiledwatertank.

Do not take in larger amounts of secondary water (water

pools)

To avoid settling of residues empty and rinse the soiled

And fresh water tanks after work on principle.

Comply with the legal provisions for disposal of soiled

Water. Check and clean the suction filter in the tank lid for

soiling in regular intervals.

Clean soiled and fresh water tanks

Fresh water tank

Filter

Floater

Soiled water tank

Slowly tilt the tank as represented to drain water before cleaning the tank

Empty Soiled water tank

Cap

Hold the tank as represented

Open the tank and drain water

Close cap

14

Electric System

Theelectricsystem ofthePortAScrub 14 operates at a mainsvoltageof110-120V/

60Hz.

After opening the machine top, the brush motor and the suction turbine are well

accessible.

AT10A fuse (E) protects the suctionturbine and has tobe replaced bythe same type

ifblown (Tstandsforslow-blow).

The suction turbine is low-maintenance type; its carbon brushes only have to be

checkedafter every200hoursofoperation.

G

F

E

Thebrush motoris protected bya cutout (G)which can bemanually reset.Incase of

trippedcut-out, detect the cause andremedybeforere-startingthemachine.

Thepump is protected by aT0.5Afuse(F).Replacebythesame type of fuse.

Reset the cut-out by pushing down the transparent dome of the fuse box. After

tripping,wait for approx. 30 secondsbeforeresetting.

In case of repeated fuse blowing detect the cause. We recommend having all work at the electric

System done by qualified personnel only.

Before starting work at the electric system, disconnect the mains plug. After work at the electric

system is finished, proceed to a safety test

E .Suction motor fuse

F. Pump fuse

G. Brush motor cut-out

Technical Data

Dimensions

Length mm 700

Width mm 470

Height (with closed Handle) mm 540

Working width

Squeegee mm 450

Scrubbing mm 350

Surface performance,

Theoretical m2/h 1400

Driving speed Up to km/h 4

Weights

Deadweight, dry kg 40-43

Total weight, ready to operate, wet kg 50-53

15

Loading...

Loading...