Page 1

Instruction manual

Port A Scrub with Power Pack

Page 2

Introduction

Preface

Introduction

Dear customer, It is our desire that the

good characteristics of the Port A Scrub

should justify the confidence you demonstrated by making this purchase.

Prior to the first use, read the chapter

"Safety Information” carefully as this will

ensure safe operation of the machine.

Your own safety, as well as the safety of

others, depends to a great extent on

how the machine is moved and operated. Before using the equipment for the

first time, read this original manual thoroughly, act according to the information

contained and keep it in a safe place for

future reference or subsequent owners.

The manual provides valuable information about operation, service and maintenance. The warning symbols as used

in this manual identifies items relevant

to safety. Please observe the safety

provisions (see chapter "Safety Information”). Your authorized Minuteman

dealer will be pleased to answer further

questions regarding the machine or the

operation and maintenance manual.

Please be advised explicitly that we

cannot accept any legal issues out of

the contents of this manual.

If repair work has to be performed make

sure that only genuine spare parts are

used; only genuine spare parts may

guarantee a dependable machine.

We reserve the right for technical improvement.

Valid as of: April 2009

Minuteman International Inc.

14N845 U.S. Route 20

Pingree Grove, II. 60140

U.S.A.

Proper use

The machine is a vacuum scrubbing

machine for wet cleaning of hard-surfaced floors. Using the machine beyond

this scope of application will be deemed

improper use; The manufacturer cannot

be held liable for consequential damages; the user alone bears the risk.

The term of proper use also includes

operation, maintenance and repair work

to be performed in compliance with the

manufacturer's specifications.

The Port A Scrub may only be used by

persons that are familiar with the machine and aware of possible hazards

involved.

If modifications to the machine are

made in absence of the manufacturer's

prior consent, the latter cannot be held

liable for damage resulting from such

unauthorized modification.

2

Page 3

Introduction

Notes on warranty

The terms of the sales contract apply.

Damages are not subject to warranty if

they are due to non-compliance with the

maintenance and service provisions.

The maintenance work has to be performed by an authorized Minuteman

service center and confirmed in the

"Maintenance certificate" which is the

warranty document.

The following is excluded from warranty: fuses, natural wear, damages

caused by overload, inexpert handling

and unauthorized modification of the

Power Pack. Moreover, any claim for

warranty cannot be accepted if damages of the Power Pack are caused by fitting parts or accessories without

Minuteman's prior and explicit consent

or by non-compliance with the maintenance instructions.

Acceptance of the machine

Upon arrival, check machine for possible damages in transit. Follow unpacking

instructions on shipping pallet. Each

unit has been tested and throughly inspected before shipment. Any damage

is the responsibility of the delivery carrier who should be notified immediately.

Minuteman International Inc.

14N845 U.S. Route 20

Pingree Grove, II. 60140

U.S.A.

3

Page 4

Table of contents

Introduction . . . . . . . . . . . . . 2

Preface. . . . . . . . . . . . . . . . . . 2

Proper use . . . . . . . . . . . . . . . 2

Notes on warranty . . . . . . . . . 3

Acceptance of the machine . . 3

1 Safety information . . . . . . . . 5

1.1 Safety and Warning Symbols. 5

1.2 General Provisions. . . . . . . . . 6

1.3 Operating information. . . . . . . 6

1.4 Maintenance information . . . . 7

1.5 Specific Hazards . . . . . . . . . . 8

1.6 Information for Protection of

Environment. . . . . . . . . . . . . . 8

1.7 Labels on the machine. . . . . . 9

2 Starting Up . . . . . . . . . . . . . 11

2.1 Prior to starting up for the first

time . . . . . . . . . . . . . . . . . . . 11

2.2 Before starting up daily . . . . 14

3 Operation . . . . . . . . . . . . . . 15

3.1 Method of operation . . . . . . . 15

3.1.1 Brush head. . . . . . . . . . . . . . 15

3.1.2 Squeegee. . . . . . . . . . . . . . . 15

3.1.3 Solution tank . . . . . . . . . . . . 16

3.1.4 Recovery tank . . . . . . . . . . . 16

3.1.5 Power Pack . . . . . . . . . . . . . 16

3.2 Operating and indicator

elements. . . . . . . . . . . . . . . . 17

3.2.1 Operating panel . . . . . . . . . . 17

3.2.2 Operating elements on the ma-

chine. . . . . . . . . . . . . . . . . . . 19

3.3 Cleaning operation. . . . . . . . 21

3.3.1 After completing cleaning. . . 22

3.3.2 Troubleshooting . . . . . . . . . . 23

3.3.3 Transport and loading . . . . . 23

4 Technical Data . . . . . . . . . . 24

5 Maintenance and Care. . . . 26

5.1 Minuteman System Mainte-

nance . . . . . . . . . . . . . . . . . . 26

5.2 Maintenance Document. . . . 27

5.3 Maintenance plan. . . . . . . . . 28

5.4 Battery system . . . . . . . . . . . 31

5.4.1 Charging batteries . . . . . . . . 31

5.4.2 Attaching the Power Pack . . 32

5.4.3 Detaching the Power Pack. . 32

5.4.4 Servicing the driving

batteries . . . . . . . . . . . . . . . . 33

5.4.5 Removing the batteries . . . . 33

5.4.6 Inserting the batteries. . . . . . 33

5.4.7 Disposing of batteries. . . . . . 33

5.5 Solution tank . . . . . . . . . . . . 34

5.5.1 Filling the solution tank. . . . . 35

5.5.2 Cleaning the solution filter . . 35

5.5.3 Check the seal . . . . . . . . . . . 35

5.6 Recovery tank . . . . . . . . . . . 36

5.6.1 Emptying the recovery tank . 37

5.6.2 Checking the seal. . . . . . . . . 37

5.6.3 Cleaning the air intake filter . 37

5.7 Brush head. . . . . . . . . . . . . . 38

5.7.1 Checking the brush head. . . 39

5.8 Squeegee. . . . . . . . . . . . . . . 40

5.8.1 Cleaning the squeegee . . . . 41

5.8.2 Changing the sealing strips . 41

4

Page 5

Safety information

1 Safety information

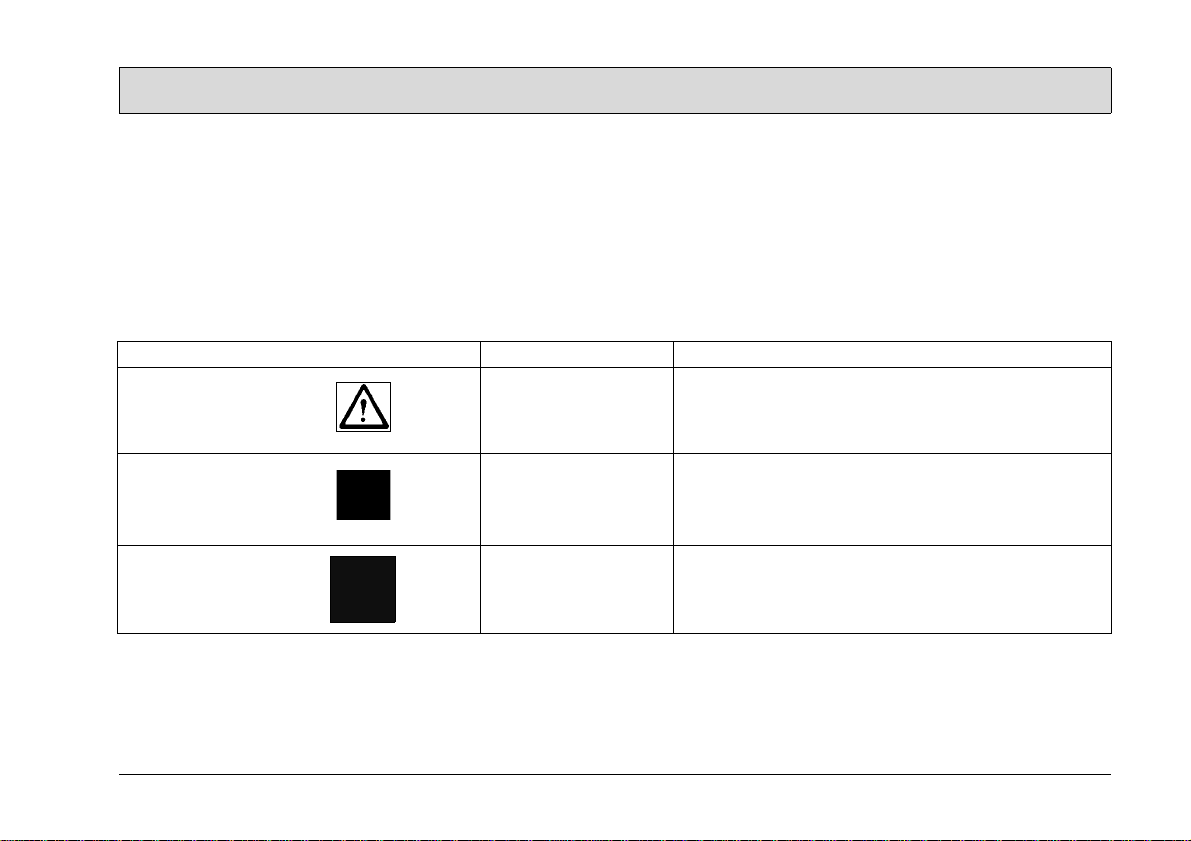

1.1 Safety and Warning Symbols

All paragraphs in this manual referring

to your personal safety, the safety of

your machine and the environment protection are attributed one of the following warning symbols:

Symbol Hazardous for ... Description

Safety Provisions persons and goods Safety Provisions in dangerous situation caused by

misuse inaccurate adherence of instructions or prescribed work routine.

CAUTION the machine important information on handling the machine in

order to maintain operability.

Ecological hazard the environment due to use of substances representing an inherent

danger to health of environment

5

Page 6

Safety information

1.2 General Provisions

• The machine fulfills all the applicable

safety and health requirements stipulated in the EU directives with regard to its planning, constructional

design and final construction as introduced by us onto the market. In

the case of modifications to the machine not approved by us, the EC

Declaration of Conformity enclosed

in this operating manual loses its validity.

• Apart from the provisions contained

in this instruction manual, the general safety provisions and the accident

prevention regulations as impose d

by law have to be complied with.

• Before taking your machine into operation, carefully read the instruction

manual as well as other separate instructions for accessories or attached implements and comply with

all points mentioned there during

work.

• Persons being trained by qualified

Minuteman technicians only are authorised to operate, service and repair the machine.

• You are advised to thoroughly study

the safety instructions since precise

knowledge only helps avoiding errors during operation of the machine

and thus guarantee faultless usage

of the machine.

• The operating instructions have to

be at hand at the place of use of the

machine, and therefore have to be

kept readily available at the machine.

• When selling or letting the machine

for rent, hand out these documents

to the new owner/operator and have

the transfer certified!

• The warning and instruction plates

attached to the machine contain

valuable advice about safe operation. Immediately replace incomplete

or illegible labels.

• As far as safety standards are concerned, spare have to equal genuine

spare parts!

1.3 Operating information

• Before starting the machine up for

the first time, the battery to be used

must be fully charged, properly, by

implementing the initial battery

charge routine. Please pay attention

to the operating manual provided

with the charging unit as well as the

manual from the battery manufacturer. Minuteman assumes no liability

for damage to the battery caused by

a fault when the battery is charged

for the first time.

• Check the operational safety of the

machine each time before starting it

up! Clear any faults immediately! In

the case of function faults in respect

of the charger and damage to the

power cable or battery leads, the

Power Pack must not be put into operation. Please contact your nearest

authorized Minuteman service center.

• Before starting work, the operator

must be fully familiar with all adjustment, operating and control elements as well as their respective

function! It is too late to do this when

the machine is actually in operation!

• Always wear heavy duty, non-slip

footwear when working with the machine.

• The machine may only be driven on

and the equipment used on those

surfaces which have been approved

by the contractor or person appointed by him.

• When using the machine, it is essen-

6

Page 7

Safety information

tial to pay attention to third parties,

especially children.

• Start driving immediately after

switching on the brush drive otherwise imprints of the brush could be

produced on the floor.

• Only use cleaning agents suitable for

the vendor (non-foaming) and observe all the use, disposal and warning information provided by the

cleaning agent manufacturer.

• The machine is not suitable for clearing up hazardous, inflammable or

explosive fluids, dust or substances.

• It is forbidden to use the machine in

potentially explosive atmospheres.

• Directly after beginning a cleaning

operation, check that the waste water is cleared up properly. If a floor

remains wet, it represents an increased risk of slipping!

• To prevent unauthorized use of the

machine, switch off the main switch

and disconnect the battery plug.

• When transporting the machine, tip

the brush head up from the floor with

the shaft.

• The machine has been conceived for

use on level surfaces with a maximum gradient of 2%.

1.4 Maintenance information

• Operating personnel must complete

the necessary daily and weekly

maintenance work. All other maintenance work must be completed at

your nearest Minuteman service

center.

• The maintenance work and maintenance intervals prescribed in the operating manual must be adhered to.

• Suitable tools must be used for

cleaning and maintenance work.

• The machine must be inspected by a

recognized technical expert in respect of operational safety, within

the terms of the applicable accident

prevention laws, at reasonable intervals (we recommend at least once a

year) and following modification or

repairs .

• For reasons of safety, always use

original spare parts.

• When carrying out cleaning and

maintenance work or work on the

electrical installation, always switch

the machine off at the main switch

and disconnect the battery plug and

power plug.

• It is not permitted to clean the machine with a pressure washer or

steam blaster.

• It is not permitted to use aggressive

and corrosive cleaning agents.

• Allow the machine to dry after being

cleaned, e.g. over the weekend.

• Only start the machine up when all

the safety equipment has been installed and brought to its protecting

position.

1.5 Specific Hazards

Electric system

• Only use genuine fuses with the

specified ratings.

• In case of malfunction of the electric

system, immediately shutdown machine and remedy.

• Only qualified personnel are authorized to work on the electrical installations and only according to electrotechnical rules.

• Inspect/check the electrical equipment of the machine at regular intervalls. Clear up any defects

immediately, such as loose connections or damaged cables.

Power Pack

• Observe the information in the operating manual provided by the battery

manufacturer.

7

Page 8

Safety information

• Batteries may only be handled and

changed by properly skilled maintenance personnel.

• The machine has been set up for operation using maintenance-free batteries. It is not permitted to use other

battery types.

• Never lay any metallic objects or

tools on batteries - risk of short circuit!

• Ensure sufficient ventilation in the

charging area when charging the

batteries. – Risk of explosion!

• Ensure that the power cable of the

Power Pack cannot be damaged by

being run over, crushed, tugged etc.

• A charger is installed in the Power

Pack and can be used for operation

via the mains power.

• The Power Pack must be protected

from liquids and damp. It is not permitted to clean the machine with a

pressure washer or steam blaster.

Risk of electric shock!

• There is a risk of tipping when attaching and detaching the Power

Pack. Risk of foot injuries!

• Ensure that the power cable of the

Power Pack cannot be damaged by

being run over, crushed, tugged etc.

The power cable must be checked at

regular intervals for signs of damage

and aging.

1.6 Information for Protection of

Environment

• For safe use of substances inheriting

a danger to health and environment

specific knowledge is required.

• Observe the legal directives and lo-

cal regulations for disposal of detergents, see Water Management Act.

• Used batteries labelled as recyclable

contain reusable economic goods.

According to the crossed dustbin label these batteries must not be added to the normal waste. Provide for

agreement with the Minuteman contract dealer on return and disposal.

8

Page 9

Safety information

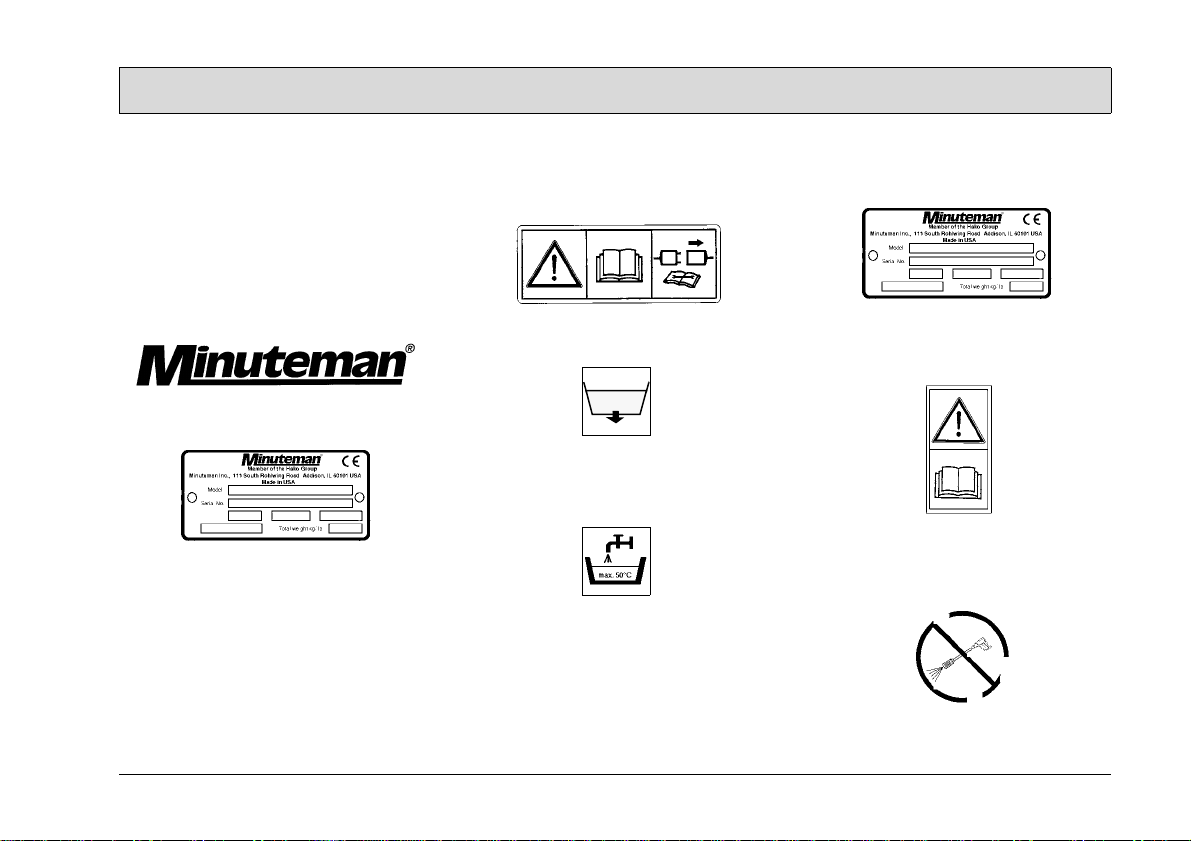

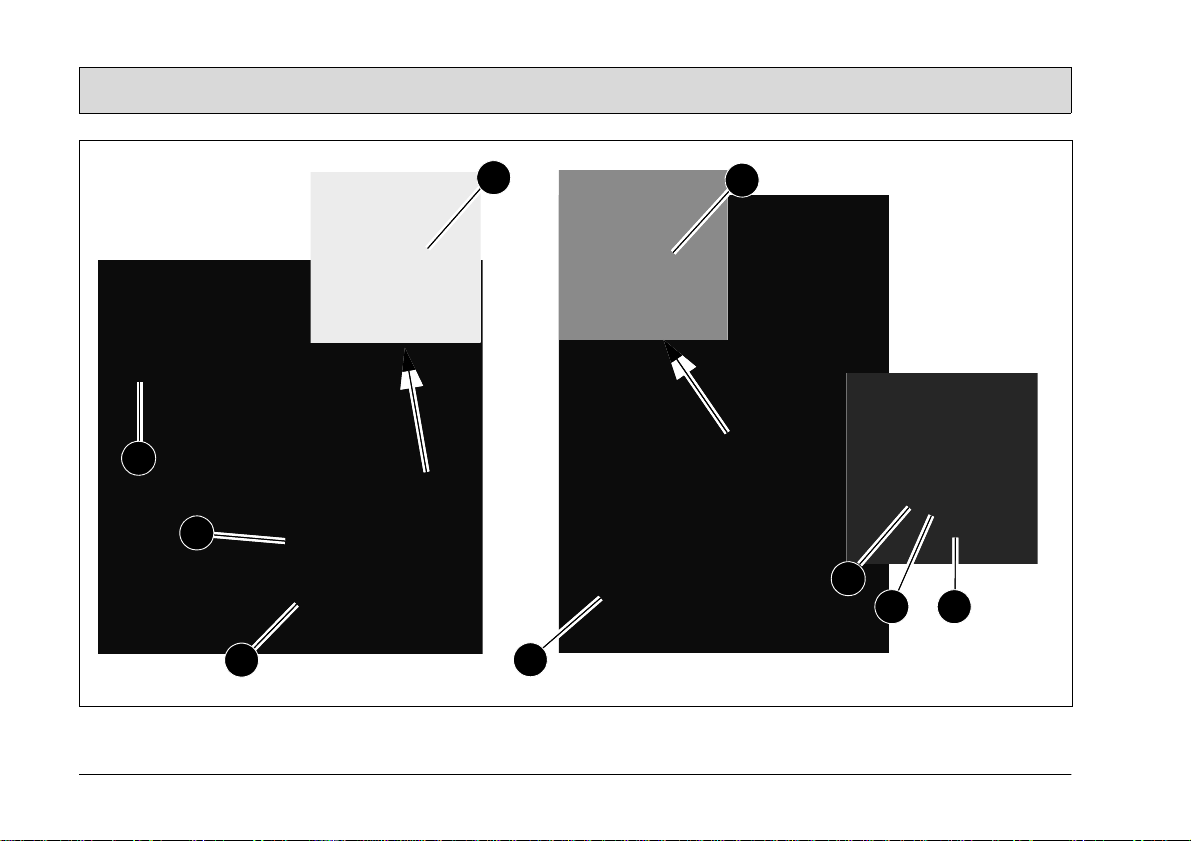

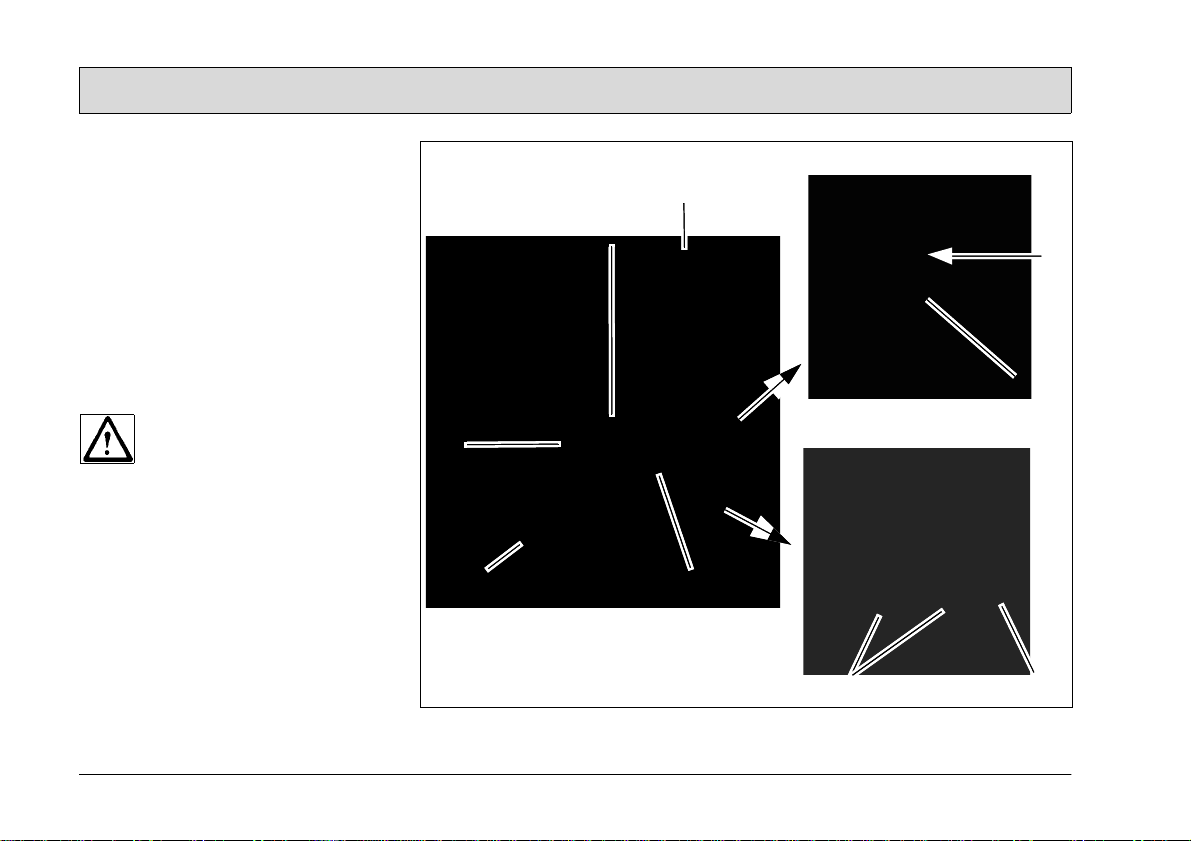

1.7 Labels on the machine

The following safety and warning labels

are attached to the machine where easily legible. Missing or illegible labels

must be replaced immediately.

Port A Scrub

Company logo (Fig. 1/1)

Rating plate (Fig. 1/2)

Machine type (Fig. 1/3)

Port A Scrub

Read and observe the operating manual (Fig. 1/4)

Drain plug for waste water (Fig. 1/5)

Maximum water temperature for the

solution to be filled (Fig. 1/6)

Power Pack

Rating plate (Fig. 1/7)

Read and observe the operating manual (Fig. 1/8)

Do not clean the machine and the Power Pack with a pressure washer (Fig. 1/

9)

9

Page 10

Safety information

2

1

3

4

5

6

9

87

10

Fig.1

Page 11

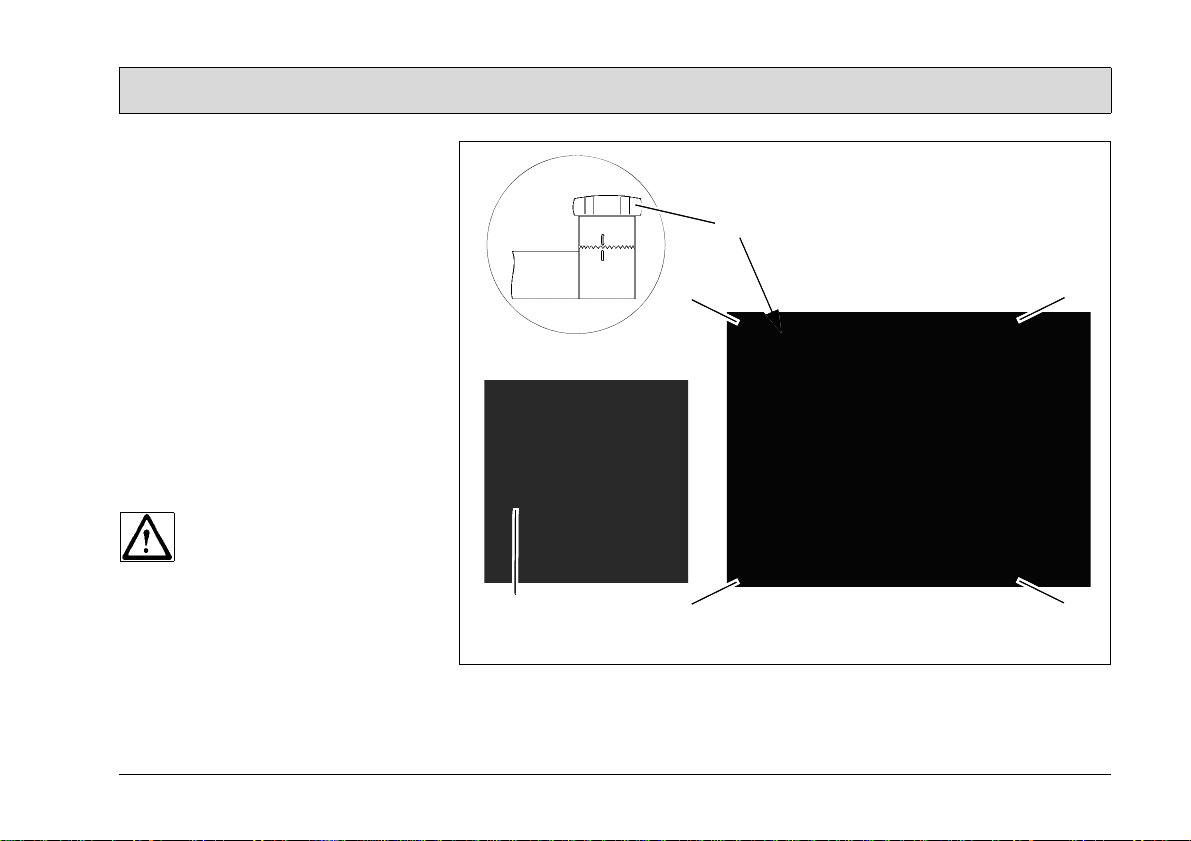

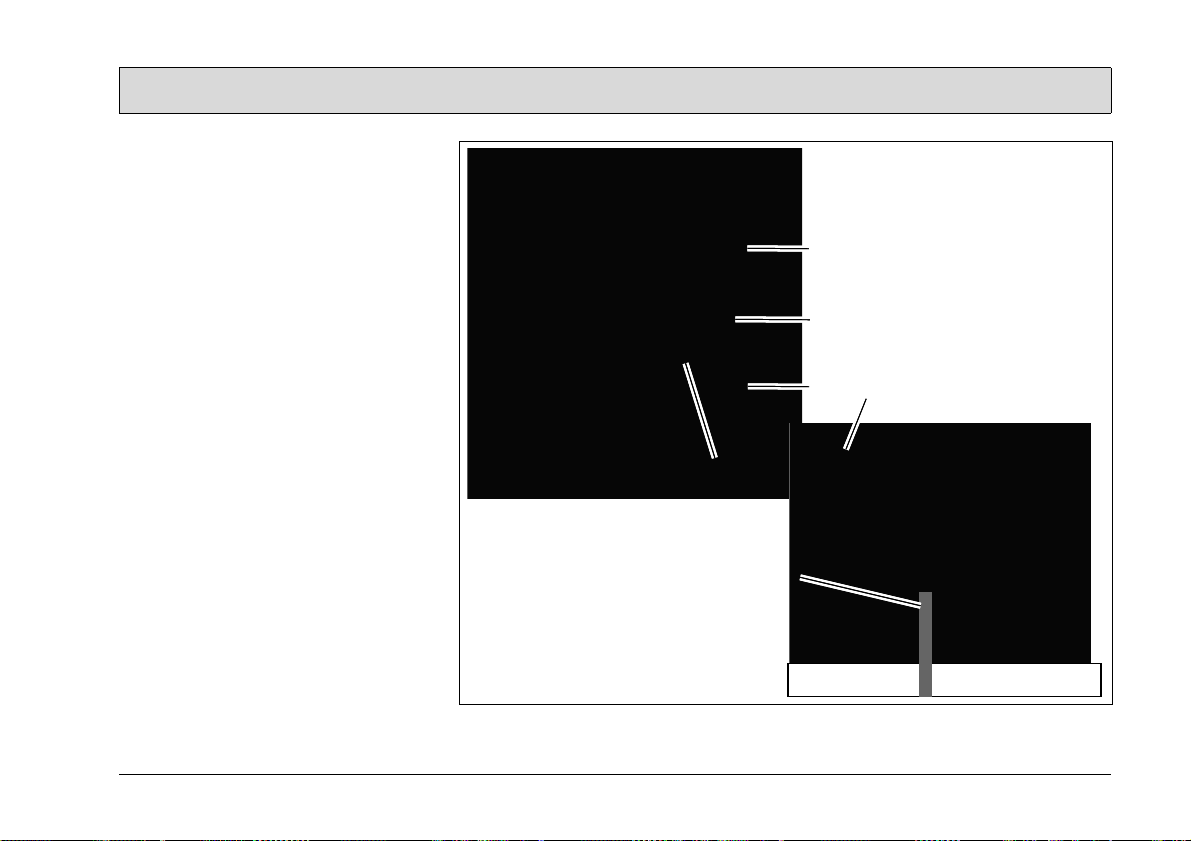

Starting Up

1

1

2

1

1

3

2Starting Up

2.1 Prior to starting up for the

first time

1. Open the box containing the Port A

Scrub at the bottom and pull upwards. Loosen the plastic bands and

remove the machine carefully from

the pallet.

2. Remove the insulation blocks (Fig. 2/

1).

3. Loosen the adjusting knob (Fig. 2/2)

and move the steering shaft to its operating position (guide marks facing

each other). Screw the adjusting

knob tight again.

4. Remove the Power Pack (Fig. 2/3)

from the packaging.

Before starting up the equipment for the first time, you

must fully charge the batteries

to be used by completing the

initial battery charge routine

properly, refer to Section 5.4.1.

Minuteman is not deemed liable for damage to the battery

resulting from failure to complete the initial battery charge

properly.

Fig.2

11

Page 12

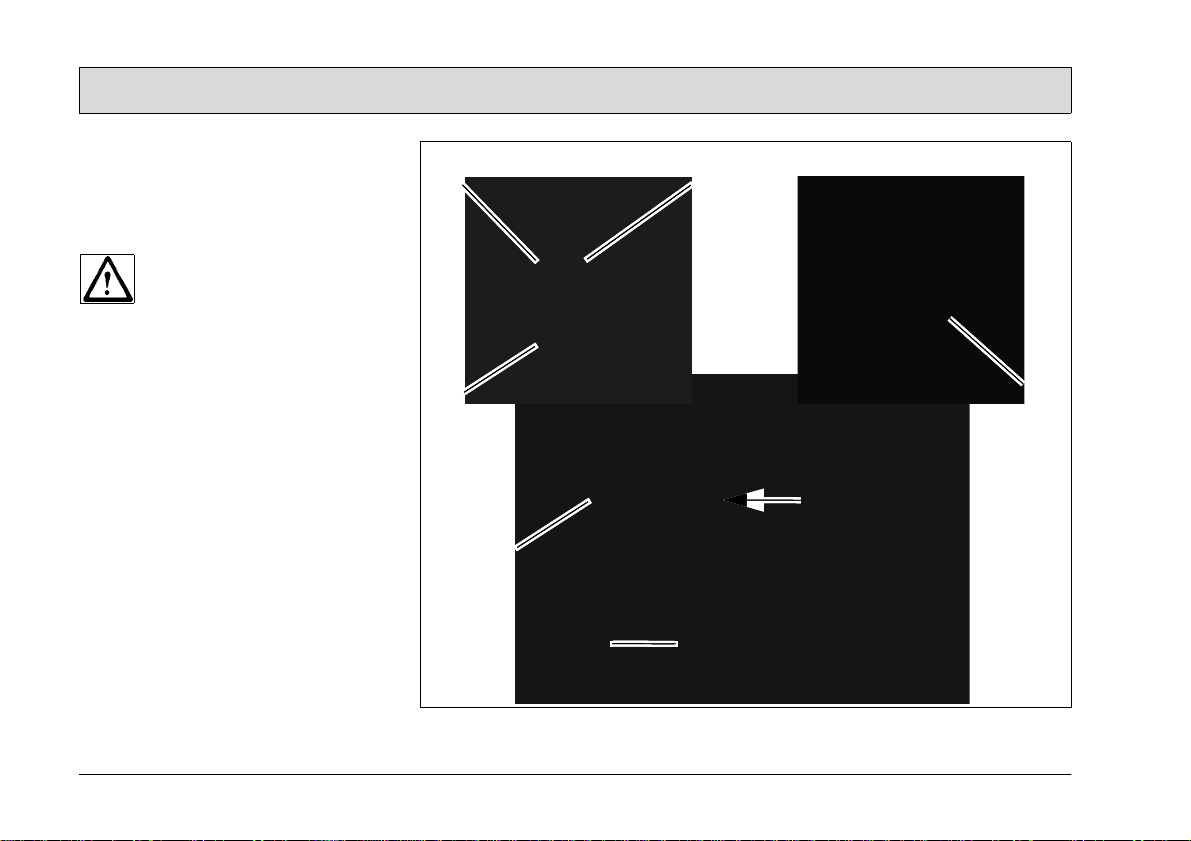

Starting Up

1

2

3

4

5

6

5. Tip the machine back a little using

the shaft (Fig. 3/1) so that it is

against the Power Pack (Fig. 3/2).

6. Slide the bracket (Fig. 3/3) in the

support (Fig. 3/4) of the Power Pack.

Do not hit against the Power

Pack. Risk of tipping!

7. Tip the machine forward again with

the Power Pack attached.

8. Connect the battery plug (Fig. 3/5)

from the Power Pack in the socket

(Fig. 3/6) on the Port A Scrub.

Fig.3

12

Page 13

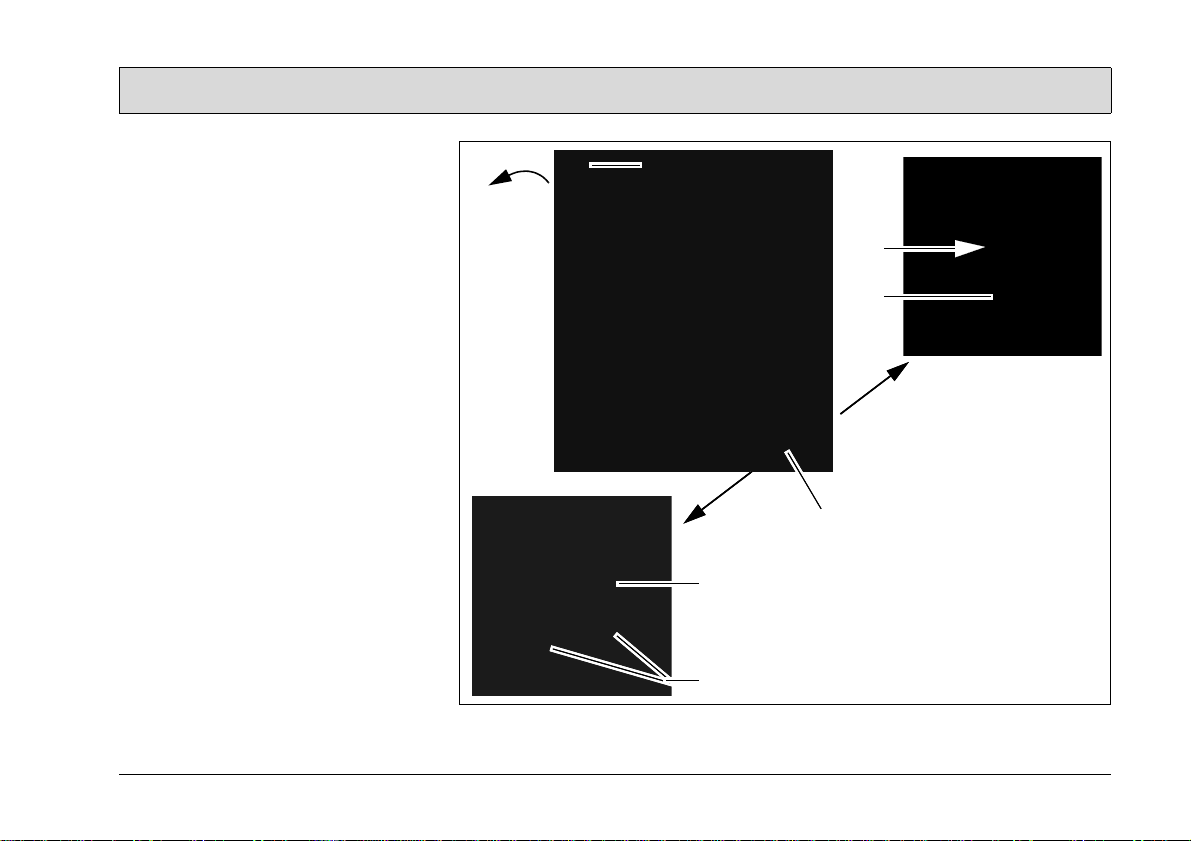

Starting Up

2

3

X

1

4

5

9. Tip the machine a little using the

shaft (Fig. 4/1) until the supporting

rollers (Fig. 4/2) in can be pushed

into parking position (X). Lower the

machine onto the supporting rollers.

10.Loosen the slotted-head screw (Fig.

4/3) with a coin and pivot the cover

(Fig. 4/4) upwards.

11.Insert the brushes (Fig. 4/5) suppli ed

in the brush head, close the cover

and secure it again with the slottedhead screw.

Fig.4

13

Page 14

Starting Up

6

5

7

8

I

X

3

2

4

1

2.2 Before starting up daily

1. Check the following for wear:

- Brushes in the brush head (Fig. 5/

2)

- Sealing strips on the squeegee

(Fig. 5/3)

- Solution filter, air intake filter and

seals in the housing cover (Fig. 5/

4).

2. Check the fill level of the solution

tank (Fig. 5/5), refill as necessary.

Add cleaning agent as necessary,

refer to Section 5.5.1.

3. Check the fill level of the recovery

tank (Fig. 5/6), empty as necessary.

4. Raise the brush head by tipping the

shaft back and slide the supporting

rollers (Fig. 5/8) to the working position (X).

Only use cleaning agents suitable for the vendor (non-foaming) and observe all the use,

disposal and warning information provided by the cleaning

agent manufacturer.

14

Fig.5

Page 15

Operation

1

2

2

3 Operation

3.1 Method of operation

General information

The Port A Scrub is a scrubber drier for

wet cleaning hard floors.

3.1.1 Brush head

The rotating brushes in the brush head

(Fig. 6/1) scrub the dirt free, thoroughly,

with a solution and clean the floor. The

brushes can be disassembled for maintenance purposes.

3.1.2 Squeegee

The moving, suspended squeegee (Fig.

6/2) is adjusted for forward and reverse

operation by means of a hand lever.

The sealing strips on the squeegee

adapt perfectly to the floor. A suction

turbine vacuums up the dirty solution

from the floor.

Fig.6

15

Page 16

Operation

3

1

4

2

3.1.3 Solution tank

The solution tank (Fig. 7/1) for the Port

A Scrub is located under the housing

cover (Fig. 7/2) and has a capacity of

approx. 10 liters. The solution supply is

activated by a button and flows at a rate

of approx. 0.22 liters/min.

3.1.4 Recovery tank

The waste water which is vacuumed up

is fed via a suction hose from the

squeegee to the recovery tank (Fig. 7/

3).

3.1.5 Power Pack

The Power Pack (Fig. 7/4) is equipped

with maintenance-free batteries, a fully

automatic battery charger and a total

discharge signal transducer (TSG) to

protect against total discharge. Pay attention to the safety information with regard to this.

For information on driving batteries, refer to Supplementary Sheet 88-10-

2556.

16

Fig.7

Page 17

Operation

31

5

42

3.2 Operating and indicator

elements

3.2.1 Operating panel

1 Battery indicator

2 Button for water pump

3 Button for suction turbine

4 Button for brush drive

5 Main switch

Fig.8

17

Page 18

Operation

Battery indicator (Fig. 8/1)

This control lamp indicates the charge

status of the batteries.

Button for water pump (Fig. 8/2)

When the brush drive is switched on,

this button is used to switch the water

pump on and off. When the water pump

is switched on, the control lamp lights

up.

Button for suction turbine (Fig. 8/3)

This button is used to switch the suction

turbine motor on and off. When the suction turbine motor is switched on, the

control lamp lights up.

Button for brush drive (Fig. 8/4)

This button is used to switch the brush

drive on and off. When the brush drive

is switched on, the control lamp lights

up.

Main switch (Fig. 8/5)

The machine is ready to operate after

switching on the main switch.

18

Page 19

Operation

1

2

4

5

6

3

3.2.2 Operating elements on the

machine

1 Squeegee adjustment lever

2 Adjustable shaft

3 Bracket for Power Pack

4 Battery plugs, Power Pack

5 Power supply line, charger

6 Charge control indicator

Fig.9

19

Page 20

Operation

Squeegee adjustment lever (Fig. 9/1)

The operator can change the squeegee

position according to the direction of

movement.

Draw lever - reverse operation

Release lever - forward operation

Adjustable shaft (Fig. 9/2)

The shaft must be adjusted to the

height of the operator prior to operation.

To adjust the shaft, release the knob.

Bracket for Power Pack (Fig. 9/3)

In order to be able to start a cleaning

operation, the Power Pack must be

hooked into the bracket on the Port A

Scrub.

Battery plug Power Pack (Fig. 9/4)

The Power Pack battery plug is used to

enable power supply to the Port A

Scrub. When in charging mode, the battery plug must be inserted in the socket

on the Power Pack.

Power supply line, charger (Fig. 9/5)

The power supply line supplies power

to the charger during the charging process. After the charging process has

been completed, the cable must be

wound back in the holder.

Charge control indicator (Fig. 9/6)

The charge control lamp indicates the

status of the charger

• LED (A) lights up yellow = <80%

charge

• LED (B) lights up yellow = >80%

charge

• LED (C) lights up green = 100%

charge

Errors are signaled by the red LED (D).

Contact your authorized Minuteman

service center in the event of an error!

20

Page 21

Operation

31 42

5

6

A

B

A

B

3.3 Cleaning operation

Please read the safety information in

Chapter 1 first and complete the working steps described in Section 2.2.

1. Switch the machine on and ready to

operate using the main switch (Fig.

10/5).

2. Check the battery indicator (Fig. 10/

1), recharge the batteries as necessary; refer to Section 5.4.2.

3. Press the button (Fig. 10/3) to switch

on the suction turbine.

4. Press the button (Fig. 10/2) to switch

on the solution supply (with cleaning

agent, if necessary).

5. Press the button (Fig. 10/4) to switch

on the brushes and move the machine.

- Forward operation (A):

Release lever (Fig. 10/6) and push

the machine.

- Reverse operation (B):

Pull lever (Fig. 10/6) and draw the

machine back.

Fig.10

21

Page 22

Operation

8

7

31 42

5

6

9

10

X

11

3.3.1 After completing cleaning

1. Switch the machine off with the main

switch (Fig. 11/5).

2. Check the battery indicator (Fig. 11/

1), recharge the batteries as necessary; refer to Section 5.4.1.

3. Raise the brush head by tipping the

shaft and slide the supporting rollers

(Fig. 11/6) to the parking position

(X).

4. Transport the machine to an appropriate servicing area.

5. Empty and rinse out the solution tank

(Fig. 11/7) and recovery tank (Fig.

11/8).

6. Clean the machine and check the

following for signs of wear:

- Brushes (Fig. 11/9) in the brush

- Sealing strips (Fig. 11/10) on the

- Solution filter, air intake filter and

Observe the applicable laws

and local regulations when disposing of cleaning agents!

head

squeegee

seals in the housing cover (Fig. 11/

11)

22

Fig.11

Page 23

Operation

5

4

3

2

1

6

3.3.2 Troubleshooting

Following poor cleaning results:

• Check the air intake filter (Fig. 12/1)

for blockages.

• Check the sealing (Fig. 12/2) of the

recovery tank.

• Check the suction hose and squeegee in the brush head (Fig. 12/3) for

blockages.

• Empty the recovery tank (Fig. 12/4).

3.3.3 Transport and loading

1. Detach the Power Pack, refer to

Section 5.4.3.

2. Only transport the Power Pack in a

vertical position, protecting it from

tipping and rolling away.

3. Loosen the adjusting knob (Fig. 12/

5) and move the shaft to its transporting position.

4. Remove the brushes and set the

supporting rollers to their working

position. Lash the machine housing

to the transportation device with appropriate load fixation devices (Fig.

12/6).

Fig.12

23

Page 24

Technical Data

4 Technical Data

Machine length

Machine height inch 21.3

Machine width inch 18.5

Working width inch 17.7

Area coverage, theoretic ft²/h 7534.7

Nominal voltage V24

Power consumption, suction turbine W 370

Power consumption, brush motor W 350

No. of brushes Pieces 2

Brush diameter inch 3.9

Solution tank gallon 2.6

Recovery tank gallon 2.9

Dead weight without Power Pack lb 99.2

Dead weight with Power Pack lb 187.4

inch 31.9

24

Page 25

Technical Data

Noise emission value

The sound pressure level (LpA) (at the ear of the operator) measured according

to DIN IEC 60335-2-72 under normal working conditions: dB (A) 65

Measurement inaccuracy (KpA): dB (A) 2

Vibration

The weighted effective value of acceleration, measured in accordance with DIN

EN ISO 5349, to which the upper parts of the body (hand-arm) are exposed under

normal working conditions:

m/s² < 2.5

25

Page 26

Maintenance and Care

5 Maintenance and Care

General

Before proceeding to maintenance and care work you are

advised to read and comply

with the Safety Information

chapter!

Compliance with the recommended

maintenance works will give you the

certitude of always having a reliable

machine at disposition.

Daily or weekly maintenance and repair

works may be executed by the driver/

operator having been trained accordingly. Further Minuteman system maintenance works have to be executed by

qualified personnel only. Please contact

your local Minuteman Service Centre or

Minuteman contract dealer. We cannot

be held liable for damages resulting

from non-compliance with these instructions.

Please indicate the machine's serial

number with any enquiry or spare part

order, see paragraph 1.7 - Nameplate.

26

5.1 Minuteman System Maintenance

The Minuteman System Maintenance:

• guarantees reliable operability of the

Minuteman machines (preventive

maintenance)

• minimizes operating costs, repair

costs and maintenance costs

• ensures long service life and opera-

bility of the machine

The Minuteman System Maintenance is

structured in separate modules and determines specific technical works to be

executed as well as the intervals for

such maintenance works. For any specific maintenance type, the replacement

parts are determined and listed in spare

part kits.

Minuteman System Maintenance

Customer:

To be performed by the customer in accordance to the maintenance and care

instructions contained in the operating

instructions (daily or weekly). The driver/operator will be instructed upon delivery of the machine.

Minuteman-System Maintenance I:

(six monthly)

To be performed by qualified personnel

of authorised Minuteman Service Cen-

tre in accordance with the machinespecific system maintenance including

spare part kit.

Minuteman-System

Maintenance II/S:

(twelve monthly / safety check)

To be performed by qualified personnel

of authorised Minuteman Service Centre in accordance with the machinespecific system maintenance including

spare part kit. Execution of all safetyrelevant inspections according to UVVBGV-TÜV-VDE as prescribed by law.

Page 27

Maintenance and Care

5.2 Maintenance Document

Handing over

Upgrade

Test drive

Handing over to the customer

carried out on:

System-Maintenance I

six monthly

Workshop stamp

carried out on:

System-Maintenance II

twelve monthly

Workshop stamp

carried out on:

/S

System-Maintenance I

six monthly

Workshop stamp

carried out on:

System-Maintenance II

twelve monthly

Workshop stamp

carried out on:

System-Maintenance II

twelve monthly

Workshop stamp

carried out on:

/S

/S

System-Maintenance I

six monthly

Workshop stamp

carried out on:

System-Maintenance I

six monthly

Workshop stamp

carried out on:

System-Maintenance II

twelve monthly

Workshop stamp

carried out on:

System-Maintenance II

twelve monthly

Workshop stamp

carried out on:

/S

/S

System-Maintenance I

six monthly

Workshop stamp

carried out on:

System-Maintenance I

six monthly

Workshop stamp

carried out on:

27

Page 28

Maintenance and Care

5.3 Maintenance plan

System maintenance, customer

The following maintenance work must

be completed by the customer at the intervals stipulated.

Activity

Check the condition of the power supply line and battery plugs.

Defective cables must be repaired by skilled technicians immediately.

Check the battery charge, recharge as necessary o

Check the filter sieve in the solution tank, clean as necessary o

Empty and clean the recovery tank o

Check the air intake filter in the recovery tank, clean as necessary o

Check the sealing strips on the squeegee, clean or change as necessary o

Check the brushes in the brush head, clean or change as necessary o

Check the seal in the housing cover, clean or change as necessary o

Check the solution feed to the brushes, clean as necessary o

Test drive and function test o

Daily Weekly

o

Interval

28

Page 29

Maintenance and Care

System maintenance I

The following maintenance work must

be completed by an authorized Minuteman service center.

Activity

Interval

Every 6 months

Check the functionality of the operating panel o

Check the seals in the housing cover, change as necessary o

Check the sealing strips on the squeegee, change as necessary o

Check the brushes in the brush head, change as necessary o

Check the solution feed to the brushes, change the nozzles as necessary o

Check the suction hose is fitted properly and for signs of damage, change as

necessary

Check the supporting rollers, change as necessary o

Test drive and function test o

o

29

Page 30

Maintenance and Care

System maintenance II/S (safety

check)

The following maintenance work must

be completed by an authorized Minuteman service center at least once a year.

Activity

All maintenance work in accordance with system maintenance I o

Check the condition of the power supply line and battery plugs, change as

necessary

Check the suction turbine for signs of wear, change as necessary o

Check the water pump in terms of functionality and for signs of wear, change as

necessary

Clean any carbon dust from the suction turbine motor and check the carbon brushes

move easily and for sins of wear, change as necessary

Clean any carbon dust from the brush motor and check the carbon brushes move

easily and for sins of wear, change as necessary

Test drive and function test o

30

Interval

Every 12 months

o

o

o

o

Page 31

Maintenance and Care

1

A

3

2

BCD

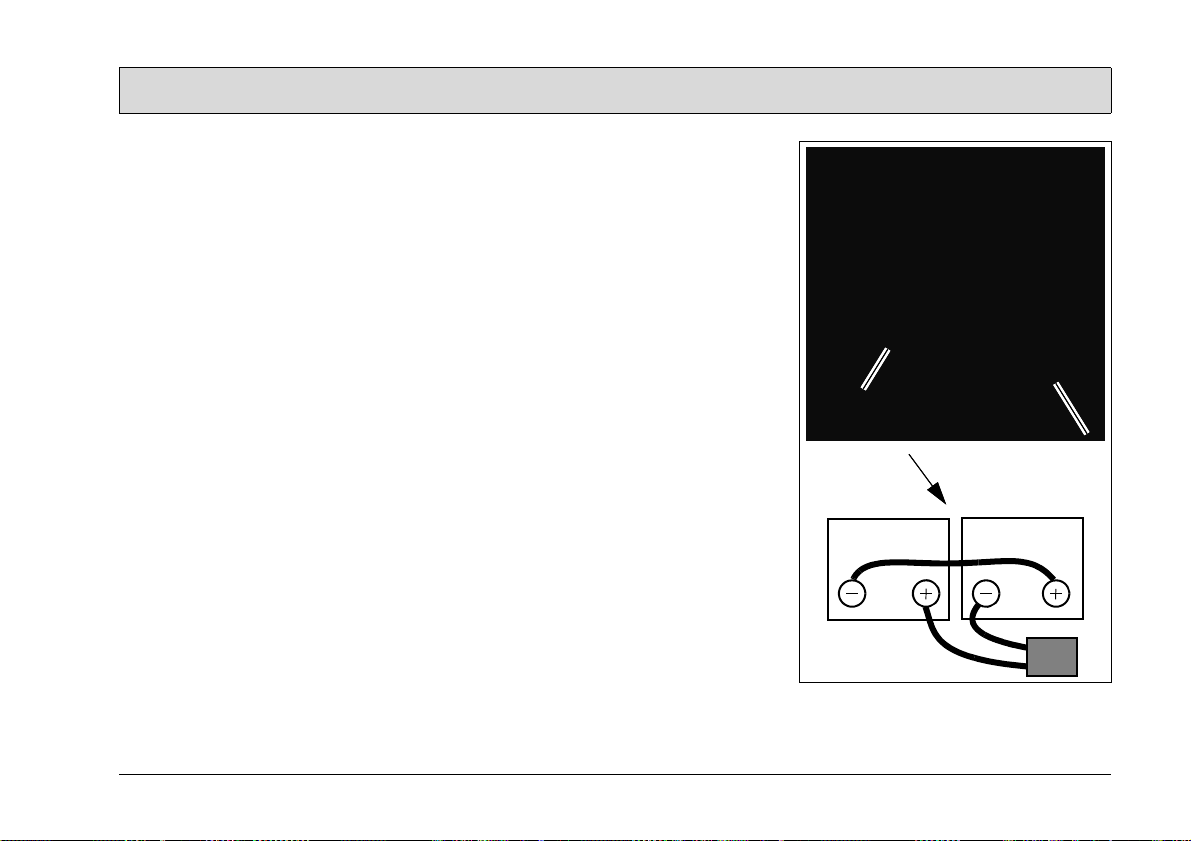

5.4 Battery system

The Power Pack (Fig. 13/1) represents

the power supply for the Port A Scrub.

It is not permitted to clean the

machine with a pressure washer or steam blaster.

Initial battery charge

Before starting the machine up

for the first time, the batteries

to be used must be fully

charged, properly, by implementing the initial battery

charge routine. Minuteman assumes no liability for damage

to the battery caused by a fault

when the battery is charged for

the first time.

5.4.1 Charging batteries

We recommend charging the battery

immediately if the battery indicator (Fig.

14/6) on the Port A Scrub lights up red

during operation. The batteries are

charged using the integrated battery

charger.

1. Connect the battery plug (Fig. 13/3)

to the battery socket on the Power

Pack (as illustrated in the figure).

2. Insert the power plug (Fig. 13/2) in a

mains power socket.

3. The charge status is indicated by

LEDs A to C.

- LED (A) lights up yellow = <80%

charge

- LED (B) lights up yellow = >80%

charge

- LED (C) lights up green = 100%

charge

4. Following the charging process, disconnect the power plug again.

Errors are signaled by the red LED (D).

Contact your authorized Minuteman

service center in the event of an error!

Fig.13

31

Page 32

Maintenance and Care

2

1

3

4

5

5.4.2 Attaching the Power Pack

Please read the safety information in

Chapter 1.

1. Switch off the Port A Scrub using the

main switch (Fig. 14/1).

2. Pull the Port A Scrub against the

Power Pack (Fig. 14/2).

3. Tip the machine to the rear until the

Power Pack can be installed on the

holder (Fig. 14/3).

4. Tip the machine forward again so

that it is horizontal on the floor. The

Power Pack now hangs in the holder.

5. Slide the safety catch (Fig. 14/4) upwards. Plug the battery plug (Fig. 14/

5) in the socket on the Port A Scrub.

5.4.3 Detaching the Power Pack

The Power Pack is detached in the reverse sequence to which it was installed on the Port A Scrub.

32

Fig.14

Page 33

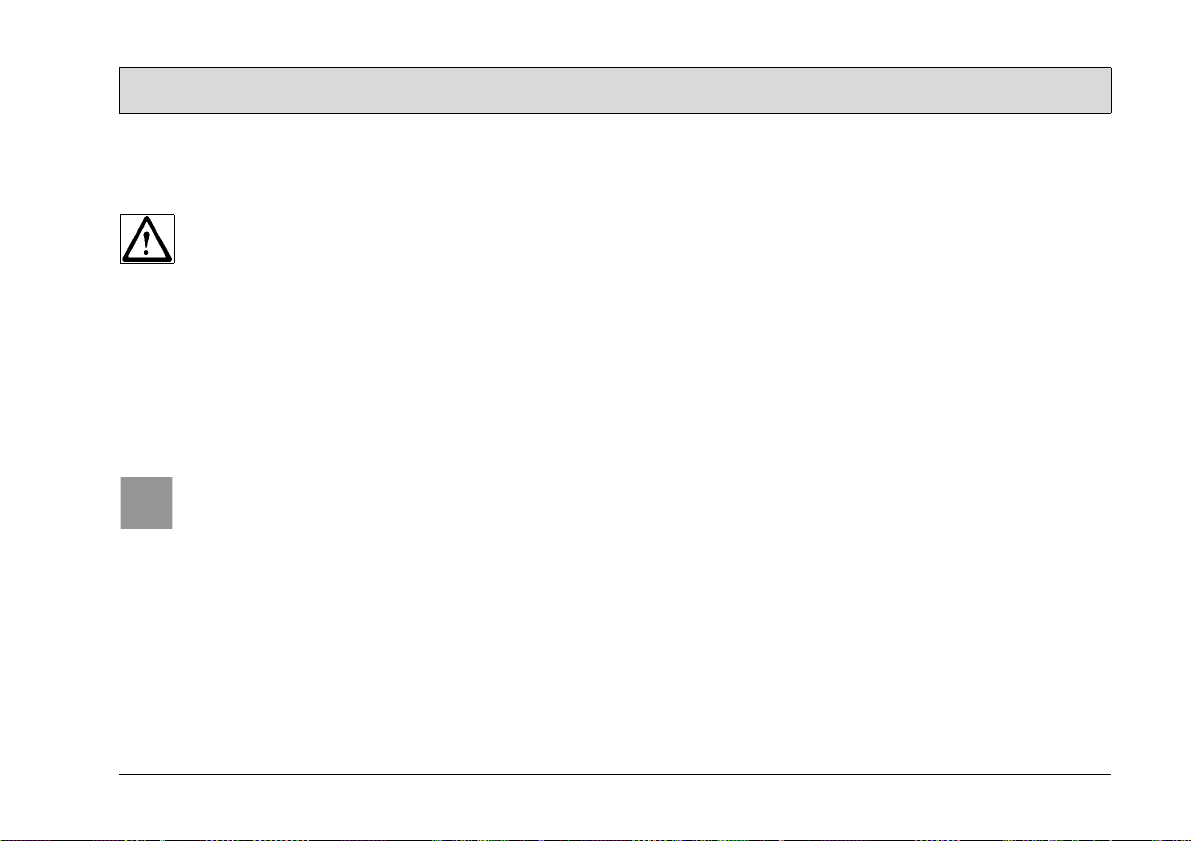

Maintenance and Care

2

5.4.4 Servicing the driving batteries

For information on servicing driving batteries, refer to operating manual 88-60-

2556.

5.4.5 Removing the batteries

1. Park the machine on a level area of

floor.

2. Switch the Port A Scrub off at the

main switch.

3. Disassemble the Power Pack from

the Port A Scrub, refer to Section

2.7.

4. Loosen the four screws (Fig. 15/1)

and lift the cover (Fig. 15/2) off.

5. Remove the battery connection cables.

6. Remove the batteries.

5.4.6 Inserting the batteries

1. Install the batteries in the Power

Pack.

2. Connect the battery poles in accordance with the connection plan (Fig.

15/3) using the connection cables.

Ensure they are connected firmly.

3. Replace the cover (Fig. 15/2) and

secure in place with the screws.

5.4.7 Disposing of batteries

Used batteries with the recycling symbol contain reusable commodities. In

accordance with symbol with the

crossed out bin, these batteries must

not be disposed of in domestic waste.

Return and recycling must be agreed

on with a Minuteman authorized dealer. in

accordance with § 8 BattV (Battery Directive)!

1

3

Fig.15

33

Page 34

Maintenance and Care

1

2

43

5.5 Solution tank

1 Solution tank

2 Solution filter

3Seal

4 Housing cover

34

Fig.16

Page 35

Maintenance and Care

5.5.1 Filling the solution tank

Fill the solution tank (Fig. 16/1) before

starting work or as necessary.

The solution temperature must

not exceed 50 °C!

1. Switch off the machine using the

main switch and disconnect the battery plug.

2. Open the housing cover and remove

the solution tank (Fig. 16/1).

3. Fill fresh water up to the marking, approx. 10 liters (add a cleaning agent

if necessary).

4. Reinstall the solution tank.

Observe the applicable laws

and local regulations when disposing of cleaning agents!

5.5.2 Cleaning the solution filter

Check the solution filter (Fig. 16/2) daily

and clean or change it as necessary.

1. Switch off the machine using the

main switch and disconnect the battery plug.

2. Open the housing cover and disconnect the solution filter (Fig. 16/2)

from the hose.

3. Rinse the solution filter with water or,

if necessary, install a new one.

5.5.3 Check the seal

Check the solution tank seal (Fig. 16/3)

weekly and clean or change as necessary.

1. Switch off the machine using the

main switch and disconnect the battery plug.

2. Open the housing cover and remove

the seal (Fig. 16/3) from the housing

cover.

3. Clean the seal and reinstall it or insert a new one.

35

Page 36

Maintenance and Care

1

2

3

4

5

5.6 Recovery tank

1 Recovery tank

2Drain plug

3Seal

4 Air intake filter

5 Housing cover

36

Fig.17

Page 37

Maintenance and Care

5.6.1 Emptying the recovery tank

Clean the recovery tank (Fig. 17/1) every day or as necessary.

1. Switch off the machine using the

main switch and disconnect the battery plug.

2. Open the housing cover and remove

the recovery tank (Fig. 17/1).

Observe the applicable laws

and local regulations when disposing of cleaning agents!

3. Bring the recovery tank to an applicable disposal point, open the drain

plug (Fig. 17/2) and empty th e recovery tank completely.

4. Flush out the remaining dirt with

fresh water.

5. Replace the drain plug and reinstall

the recovery tank.

5.6.2 Checking the seal

Check the recovery tank seal (Fig. 17/3)

weekly and clean or change as necessary.

1. Switch off the machine using the

main switch and disconnect the battery plug.

2. Open the housing cover and remove

the seal (Fig. 17/3) from the housing

cover.

3. Clean the seal and reinstall it or insert a new one.

5.6.3 Cleaning the air intake filter

Check the function of the air intake filter

(Fig. 17/4) daily and clean it as necessary. The air intake filter can be disassembled by means of a clip

mechanism.

37

Page 38

Maintenance and Care

1

2

3

4

5.7 Brush head

1Brushes

2 Slotted-head screw

3Cover

4 Catches

38

Fig.18

Page 39

Maintenance and Care

5.7.1 Checking the brush head

Check the brush head daily and clean

or change the brushes (Fig. 18/1) as

necessary.

1. Switch off the machine using the

main switch and disconnect the battery plug.

2. Tip the machine a little using the

shaft until the supporting rollers can

be pushed into parking position.

Lower the machine onto the supporting rollers.

3. Loosen the slotted-head screw (Fig.

18/2) with a coin and pivot the cover

(Fig. 18/3) upwards.

4. Remove the brushes (Fig. 18/1) from

the brush head.

5. Install the new brushes and secure

the cover again with the slotted-head

screw.

When installing the brushes,

pay attention that they latch securely and properly in the

catches (Fig. 18/4) provided.

39

Page 40

Maintenance and Care

1

3

4

2

2

3

5

5.8 Squeegee

1 Squeegee

2 Rear sealing strips

3 Front sealing strips

4 Knurled screws

5 Support strip

40

Fig.19

Page 41

Maintenance and Care

5.8.1 Cleaning the squeegee

Check the squeegee (Fig. 18/1) daily

and clean it as necessary .

To clean it, tip the machine to the rear

and lay it carefully on the shaft.

5.8.2 Changing the sealing strips

Check the rear (Fig. 18/2) and front

(Fig. 18/3) sealing strips on the squeegee weekly for signs of wear. The sealing strips can be changed without the

need of tools.

1. Switch off the machine using the

main switch and disconnect the battery plug.

2. Tip the machine to the rear and lay it

carefully on the shaft.

3. Unscrew the knurled screws (Fig.

18/4) and remove the support strips

(Fig. 18/5).

4. Check the rear (Fig. 18/2) and front

(Fig. 18/3) sealing strips, change as

necessary.

The rear sealing strips (Fig. 18/

1) can be turned when worn.

41

Page 42

Excellence Meets Clean

Minuteman International Inc. · 14N845 U.S. Route 20 · Pingree Grove, II. 60140 · U.S.A.

Phone: (630) 627-6900 · Fax (630) 627-1130

988733um REV * 05/09 (Ref.)

Loading...

Loading...