Page 1

Parts and Instruction Manual

MRS-6 Maxi-Guard II

Mercury Vacuum

Page 2

This manual is furnished with each new MINUTEMAN MRS-6. This provides the necessary operating

and preventive maintenance instructions. Operators must read and understand this manual before operating or servicing this machine.

This machine was designed to give you excellent performance and efficiency. For best results and

minimal cost, please follow the general guidelines below:

· Operate the machine with reasonable care.

· Follow the manufacturers suggested maintenance instructions as provided in this booklet.

· Use original Minuteman supplied parts.

Model MRS-6

Model No. C86006-11

C86006-12

C86006-13

C86006-14

Page 3

Table of Contents

Inspection............................................................................................................................................ 1

Electrical.............................................................................................................................................. 1

Grounding Instructions...................................................................................................................... 1

Extension Cords ................................................................................................................................. 1

Maintenance and Usage..................................................................................................................... 1

Operating and Filter Care Instructions ............................................................................................. 2

Procedure for Cleaning MRS-6 After Use ......................................................................................... 2

Options ................................................................................................................................................ 2

Changing the Charcoal Filter............................................................................................................. 2

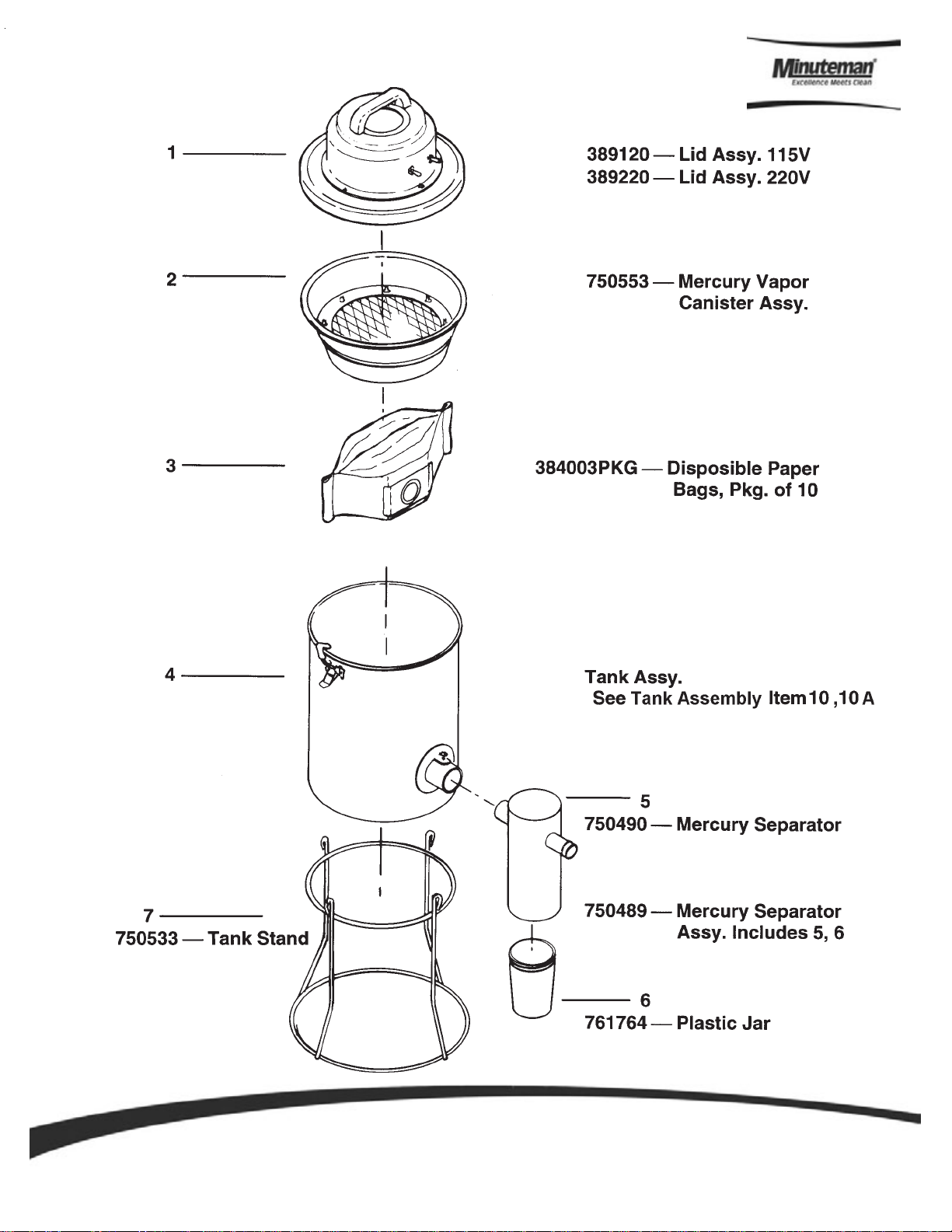

Exploded Views .................................................................................................................................. 3

Main Assembly ................................................................................................................................ 3

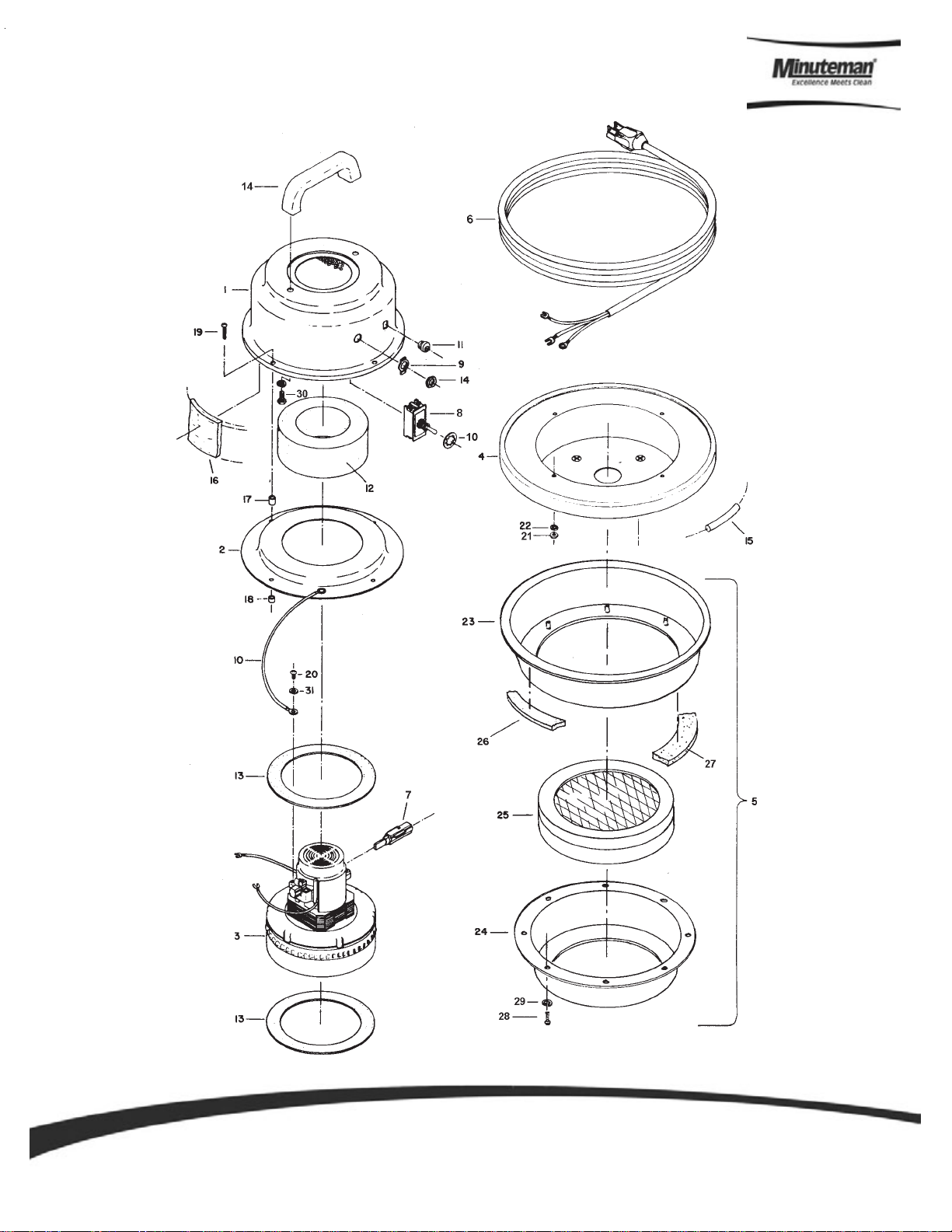

Lid Assembly ................................................................................................................................... 4

Lid Assembly BOM .......................................................................................................................... 5

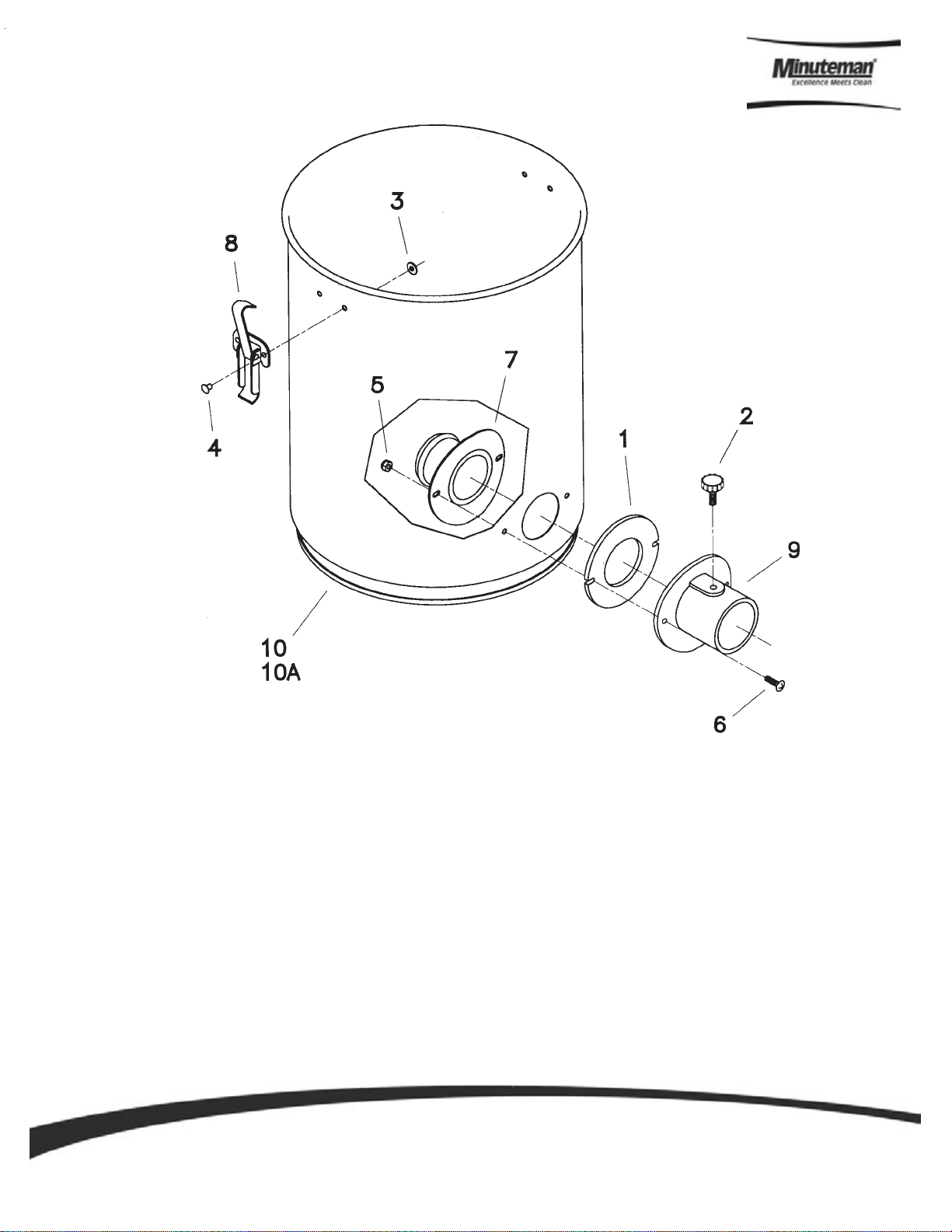

Tank Assembly ................................................................................................................................ 6

Minuteman International Made Simple Commercial Limited Warranty.......................................... 7

Page 4

Inspection

Carefully unpack and inspect your machine for shipping damage. Each unit is tested and thoroughly inspected before

shipment and any damage is the responsibility of the delivering carrier who should be notified immediately. Read all

instructions carefully before operating.

WARNING

Electrical shock could occur if used on wet surfaces. Do not expose to rain. Store indoors.

Electrical motors can cause explosions when operated near explosive materials or vapors. Do not operate this machine

near flammable materials such as solvents, thinners, fuels, grain dust, etc.

CAUTION

Hazardous materials must be disposed of properly. Never throw cont aminated debris in your usual trash receptacle. Place

debris in a plastic bag or can marked “HAZARDOUS MATERIALS” and take to a hazardous waste handler.

Electrical - 115 Volt

This machine is designed to operate on a standard 15 amp. 115 volt, 60 hz, AC circuit. Voltages below 105 AC or above

125 volts AC could cause serious damage to the motor.

Electrical - 240 Volt

This machine is designed to operate on a standard 10 amp. 230 volt, 50 hz, AC circuit.

Grounding Instructions

To protect the operator from electrical shock, this machine must be grounded while in use. This machine is equipped with

an approved three-conductor cord and grounding type plug to fit the proper grounding type receptacle. This machine is for

use on a nominal 120 volt circuit and has a grounding plug that looks like the plug illustrated in sketch A. Make sure that the

machine is connected to an outlet having the same configuration as the plug. No adapter should be used with this machine.

For equipment rated 150-250 volts: If the machine is provided with an attachment plug as shown in sketch B, it is intended

for use on a 240 volt (nominal) circuit. No adapter is available for this plug.

Extension Cords

If an extension cord is used, the wire size must be at least one size larger than the power cord on the machine and must be

limited to 25 feet in length. Extension cord must be three-wire grounded.

Maintenance and Usage

Keep the motor intake cooling air screen clean. If this screen (on top of the motor) becomes clogged, it restricts the flow of

cooling air to the motor and will cause overheating. No lubrication of the motor is required. Machine is equipped with sealed

bearings. For optimum performance, empty and clean filter bag regularly. A clogged and dirty bag restricts the flow of air

and results in reduced vacuum. Check carbon brush periodically . Replace when worn down to approximately 1/2" in length.

Always unplug the machine when removing the motor head off the tank. This will prevent the accidental st arting of the motor

and the possibility of fingers or objects getting into the unprotected impeller intake.

CAUTION

The MRS-6 Mercury Recovery V acuum has been designed for the recovery of liquid mercury or mercury oxides as a result

of spills in small quantities. It should not be used as a conventional vacuum for every day cleaning unless it applies to the

recovery of mercury contaminated debris. When not in use, the machine and all of its components should be stored in a

cool, dry and well ventilated room. If possible the room should be vented to outside air. Storing area should not have air

return vent leading to air circulating central system. Always wear the required and proper face mask, gloves and protective

clothing when cleaning up a mercury spill. Check with your Safety Department or your work supervisor if you are not

familiar with the use and procedure for operating a mercury recovery vacuum.

Parts an d Instructio n Manu al

Page 1

Page 5

Operating and Filter Care Instructions

(Refer to “Main Assembly”)

1. Tank assembly is equipped with low intake on outside and 2" tube inside.

2. Carefully open the folds of the disposable collector bag No. 3 and insert into tank.

3. Place the cardboard collar onto the intake tube and carefully pull the collar over the tube until the rubber gasket

4. Place the charcoal filter holder assembly No. 2 onto the rim of the tank making sure that the gasket seats fully

5. Place the motor lid assembly No. 1 onto tank, making sure it is seated.

6. Snap on lid latches from tank to vacuum lid.

7. Install hose assembly onto tank intake.

8. Attach vacuum tools to be used.

9. Plug electric cord into wall receptacle and turn on vacuum.

10. With vacuum on, spray anti-static spray (PN 920372) into end of pickup tool. This will coat the tool and hose to

11. Your MRS-6 is now ready for use.

is past the ring on the end of the tube.

around the tank.

reduce static electricity.

Procedure for Cleaning MRS-6 After Use

1. Remove hose and insert plugs provided at each end.

2. Place hose and tools used into plastic bag and seal with ties.

3. Unplug electric cord and remove vacuum lid from tank assembly.

4. Remove charcoal filter assembly from tank and store in an air tight bag to maximize filter life.

5. Reach into tank and gently push the collar of the filter bag off the tube, seal bag opening with adhesive backed

“Mercury Caution Decal” provided, and carefully remove collector bag from tank.

6. Place collector bag into plastic bags provided.

7. Use dampened disposable wiper towels or cloth to wipe down inside of tank assembly. Place wipers in plastic

bag for disposal.

8. Inside of tank should be checked with “snifter” or comparable air measuring device to determine if all traces of

mercury have been removed. Any mercury residue left in the tank assembly may result in rapid deterioration of

the charcoal filter.

9. Reassemble vacuum according to the Main Assembly. With vacuum assembled and all filters in place, plug in

electric cord and turn vacuum on. Take a snifter reading of the air exhausted around the motor lid assembly to

determine if charcoal filter requires replacing. The highest safe exposure concentration level is 0.05 mg/M3.

Any reading above this level would require a charcoal filter change.

10. Contaminated charcoal filters must be disposed of in the same manner as the collector bag you removed from

the vacuum. Check with your Health/Safety Department for proper disposal procedures. (DO NOT HEAT OR

BURN ANY MERCURY CONTAMINATED ITEMS.)

Options

1. Mercury separator No. 5 with jar No. 6 can be used with MRS-6 for purpose of collecting and separating

mercury from debris.

2. Tank stand No. 7 is required to elevate vacuum when mercury separator is used.

3. Wheel bracket assembly No. 750003 for mounting MRS-6 vacuum is available for increased portability. Wheel

bracket cannot be used with mercury separator and tank stand.

Changing the Charcoal Filter

1. Place charcoal filter module upside down on table covered with paper.

2. Remove eight retaining screws.

3. Remove holder cover.

4. Remove charcoal filter canister and place in disposable plastic bag.

5. Check sealing gasket, replace if broken.

6. Place new charcoal filter with cover down onto module.

7. Replace cover and screws, fasten screws evenly by using crisscross pattern.

8. Dispose of paper on workbench with charcoal filter canister.

Parts an d Instructio n Manu al

Page 2

Page 6

Exploded Views

Main Assembly

Parts an d Instruction Manual

Page 3

Page 7

Lid Assembly

Parts an d Instruction Manual

Page 4

Page 8

Lid Assembly BOM

Item Part No Qty Description

1 750415 1 Dome

2 750000 1 Assembly Motor Hold Down

3 380001-4 1 Motor, 120V ECM

3A 380054 1 Motor, 220V

4 380063POL 1 Lid Only

5 750553 1 Assy. Filter Module

6 381020 1 Cord Set, 16-3, 50'

7 380005 2 Brush, Carbon Replacement ECM

7A 380028 2 Brush, Carbon Replacement

8 380002 1 Switch, Toggle 1.5 HP

9 101020 1 Plate, Off/On Indicator

10 711556 1 1/2 Lock Washer

11 380004 1 Relief, Strain

12 380064 1 Ring, Foam

13 290017 2 Gasket , Vac Motor

14 130040POL 1 Handle, Polish

15 380044 1 Lid Gasket Only

16 380040 1 Felt, 25 X 2.5 X 25

17 380061 4 Bushing

18 380037 4 Bushing

19 710360 4 SCR-MC 10-32 X 1.00 ST PL

20 710353 1 SCR-MC 10-32 X .37 ST PL

21 711310 4 Nut-Hex 10-32 St Pl

22 711543 5 WSR-Helical SPR Loc #10

23 762037PTD 1 Filter Holder Includes

24 762035PTD 1 Filter Retainer

25 750555 1 Mercury Vapor Canister

26 805042 1 Gasket

27 762141 1 Gasket

28 710357 1 SCR-MC 10-32 X .75

29 711543 1 WSR-Lock #10

30 711202 2

*** 389120 1 Lid Assy. Complete 1 15V

*** 389220 1 Lid Assy. Complete 220V

BLT-HH 1/4-20 X .50 STL ZINC

Parts an d Instruction Manual

Page 5

Page 9

T ank Assembly

Parts an d Instruction Manual

Item Part No Qty Description

1 390087 1 Gasket

2 500033 1 Knob

3 711503 4 Washer - Flat #10

4 711915 4 Rivet .19 X .28 X .37 HD STNI

5 712638 2 Nut-Hex 10-24 SS Nyloc

6 712824 2 SCR-THMS 10-24 X .75 SS

7 750118 1 Intake Tube Assembly

8 761054 2 Latch

9 900039 1 Intake

10 900093 1 Tank, 6 Gal. SS Low Intake

10A 900092 1 Tank, 6 Gal. PTD Low Intake

*** 384003PKG 1 Disposable Paper Bag (10)

*** 762237PKG 1 Plastic Bags (10)

Page 6

Page 10

Minuteman International Made Simple Commercial Limited Warranty

Minuteman International, Inc. warrants to the original purchaser/user that the product is free from defects in

workmanship and materials under normal use. Minuteman will, at its option, repair or replace without charge, parts

that fail under normal use and service when operated and maintained in accordance with the applicable operation and

instruction manuals. All warranty claims must be submitted through and approved by factory authorized repair

stations.

This warranty does not apply to normal wear, or to items whose life is dependent on their use and care, such as belts,

cords, switches, hoses, rubber parts, electrical motor components or adjustments. Parts not manufactured by

Minuteman are covered by and subject to the warranties and/or guarantees of their manufacturers. Please cont act

Minuteman for procedures in warranty claims against these manufacturers.

Special warning to purchaser -- Use of replacement filters and/or prefilters not manufactured by Minuteman or its

designated licensees, will void all warranti es expressed or implied. A potential health hazard exits without original

equipment replacem ent .

All warranted items become the sole property of Minuteman or its original man ufa cturer, whicheve r the case ma y be.

Minuteman disclai ms any implied war ranty, including the warranty of merchantability and the warranty of fitness f or a

particular purpose. Minuteman assumes no responsibilit y fo r a ny specia l, incidental or consequential damages.

This limited warranty is applicable only in the U.S.A. and Canada, and is extended only to the original user/purchaser

of this product . Customers outside the U.S.A. and Canada should cont act t heir local distributor for export warranty

policies. Minuteman is not responsible for costs or repairs performed by persons other than those specifically

authorized by Minuteman. This warranty does not apply to damage from transportation, alt erations by unauthorized

persons, misuse or abuse of the equipment, use of non-compatible chemicals, or damage to property, or loss of

income due to malfunct io ns of th e product.

If a difficulty develops with this machine, you should contact the dealer from whom it was purchased.

This warranty gives you specific legal rights, and you may have other rights which vary from state to state. Some

states do not allow the exclusion or limitation of special, incidental or consequential damages, or limitations on how

long an implied warr anty lasts, so the above exclusions and limitat i ons m ay not apply to you.

Cord Electric Group………. Three years parts, two years labor, ninet y days travel (Not to exceed tw o hours)

Exceptions………. Port-A-Scrub, one year parts, six months labor

MPV 13, one year parts

MPV 14 and 18, two years parts, one y ear labo r

RapidAir blower, one year parts, one year labor

Explosion-Proof Vacuum, one year parts, one year labor

Pneumatic Vacuums, three years parts, one year labor

EX 12 and EX12H, one year parts, one year labor

Battery Op er ated Group ….. Three years parts, two years labor, ninety days travel

(Not to exceed two hours)

Exceptions……Sweepers, one year parts, one year labor, ninety days travel

(Not to exceed two hours )

Internal Combustion Group….One year parts, one year labor, ninety day travel

(Not to exceed two hours)

Replac ement Parts……………..N i nety days

Batteries………………………….0-3 months replac em ent, 4-12 months pro-rate

Polypropylene Plastic Tanks…Ten years, no additional labor

111 South Rohlwin g Ro ad · Addison, Illi nois 60101 USA

Phone 630- 627-6900 · Fax 630- 627-1130

E-Mail, www.minutemanintl.com

A Member of the Hako Gr oup

987844

Rev A 05/07

Loading...

Loading...