Page 1

Parts and Instruction Manual

MRS Mercury Vacuum

Page 2

This manual is furnished with each new MINUTEMAN MRS Vacuum. This provides the necessary

operating and preventive maintenance instructions. Operators must read and understand this manual

before operating or servicing this machine.

This machine was designed to give you excellent performance and efficiency. For best results and

minimal cost, please follow the general guidelines below:

· Operate the machine with reasonable care.

· Follow the manufacturers suggested maintenance instructions as provided in this booklet.

· Use original Minuteman supplied parts.

Model MRS 1-4

Model No. MRS-1 MRS-2 MRS-3 MRS-4

Stainless Steel C81015-01 C82015-01 C83015-01 C84015-01

Painted C81015-03 C82015-03 C83015-03 C84015-03

Page 3

Table of Contents

EXTENSION CORDS........................................................................................................................... 1

MAINTENANCE AND USAGE............................................................................................................. 1

INSPECTION........................................................................................................................................ 1

WARNING ............................................................................................................................................ 1

SPECIAL WARNING TO PURCHASER .............................................................................................. 1

ELECTRICAL....................................................................................................................................... 1

GROUNDING INSTRUCTIONS ........................................................................................................... 1

OPERA TING AND FILTER CARE INSTRUCTIONS............................................................................ 2

GENERAL INFORMATION .................................................................................................................. 2

Main Assembly MRS 1........................................................................................................................ 4

Assembly Procedure for MRS-2 AND MRS-3 ................................................................................... 5

Procedure for Cleaning MRS-2 AND MRS-3 ..................................................................................... 5

Main Assembly MRS 2 & 3 ................................................................................................................. 6

Assembly Procedure for MRS-4 ........................................................................................................ 7

Procedure for Cleaning MRS-4.......................................................................................................... 7

Main Assembly MRS 4........................................................................................................................ 8

Lid Assembly ...................................................................................................................................... 9

Lid Assembly BOM ........................................................................................................................... 10

Cloth Bag Assembly......................................................................................................................... 11

Adapter Assembly ............................................................................................................................ 12

Tank Assembly.................................................................................................................................. 13

T ank Assembly Bom......................................................................................................................... 14

Minuteman International Made Simple Commercial Limited Warranty........................................ 15

Page 4

INSPECTION

Carefully unpack and inspect your machine for shipping damage. Each unit is tested and thoroughly inspected before shipment, and any damage is

the responsibility of the delivering carrier who should be notified immediately. Read all instructions carefully before operati ng.

WARNING

Models C81015-01, 03; C82015-01, 03; C83015-01, 03 Dry Only

Electrical shock could occur if used on wet surfaces. Do not expose to rain. Store indoors.

WARNING

Models C84015-01, 03, Wet and Dry

To avoid electric shock, do not expose to rain. Store indoors.

Electric motors can cause explosions when operated near explosive materials or vapors. Do not operate this machine near flammable material such

as solvent, thinner, fuels, grain dust, etc.

SPECIAL WARNING TO PURCHASER

Use of replacement filters and/or prefilters not manufactured by Minuteman International Inc. or its designated licensees, will void all warranties

expressed or implied. A potential health hazard exists without exact original equipment replacement.

CAUTION

Hazardous materials must be disposed of properly. Never throw contaminated debris in your usual trash receptacle. Place debris in a plastic bag or

can marked “HAZARDOUS MATERIALS” and take to a hazardous waste handler.

ELECTRICAL

This machine is designed to operate on a standard 15 amp. 115 volt, 60 hz, AC circuit . Voltages below 105 volts AC or above 125 volts AC could

cause serious damage to the motor.

GROUNDING INSTRUCTIONS

To protect the operator from electrical shock, this machine must be grounded while in use. This machine is equipped with an approved threeconductor power cord and grounding type plug to fit the proper grounding type receptacle.

This machine is for use on a nominal 120 volt circuit and has a grounding plug that looks like the plug illustrated in sketch A. Make sure that the

machine is connected to an outlet having the same configuration as the plug. No adapter should be used with this machine.

For equipment rated 150-250 volts: If the machine is provided with an attachment plug as shown in sketch B, it is intended for use on a 240 volt

(nominal) circuit. No adapter is available for this plug

EXTENSION CORDS

If an extension cord is used, the wire size must be at least one size larger than the power cord on the machine and must be limited to 25 feet in length.

Extension cord must be three-wire grounded.

MAINTENANCE AND USAGE

Keep the motor intake cooling air screen clean. If this screen (on top of the motor) becomes clogged, it restricts the flow of cooling air to the motor and

will cause overheating.

No lubrication of the motor is required. Machine is equipped with sealed bearings.

For optimum performance, empty and clean filter bag regularly. A clogged and dirty bag restricts the flow of air and results in reduced vacuum.

Check carbon brush periodically. Replace when worn down to approximately 1/2" in length.

Always unplug the machine when removing the motor head off the tank. This will prevent the accidental starting of the motor and the possibility of fingers

or objects getting into the unprotected impeller intake.

CAUTION

The MRS-1, 2, 3, and 4 Mercury Recovery Vacuums have been designed for the recovery of liquid mercury or mercury oxides as a result of spills. They

should not be used as conventional vacuums for every day cleaning unless it applies to the recovery of mercury contaminated debris.

When not in use the machine and all its components should be stored in a cool, dry and well ventilated room. If possible, the room should be vented to

outside air. Storing area should not have air return vent leading to air circulating central system.

Always wear the required and proper face mask, gloves and protective clothing when cleaning up a mercury spill. Check with your Health/Safety

Department or your work supervisor if you are not familiar with the use and procedure for operating a Mercury Recovery Vacuum.

Parts an d Instruction Manual

Page 1

Page 5

OPERATING AND FIL TER CARE INSTRUCTIONS

The Minuteman Mercury Recovery Vacuums, MRS-1, 2, 3 and 4, have been designed to clean up liquid mercury and mercury

oxide spills. An activated charcoal canister filter is provided to absorb and contain the gas vapor given of f by the liquid mercury.

In some applications where the liquid mercury is in the presence of another dry toxic dust material, a U.L.P.A. (Ultra Low

Penetration Air) filter is also used.

Do not at any time attempt to bypass, remove, substitute, or by any other means change the filters recommended for use with

this vacuum. Use only approved Minuteman filters and filter bags.

Do not at any time, or in any way , attempt to clean or remove dust p articles that may collect or accumulate on the surface of t he

U.L..P.A. filter media.

Do not reverse or attempt to clean “prefilters” which have accumulated dust for the purpose of reusing them.

Since liquid mercury gives off a gas vapor, you are required to remove all traces of it within the vacuum tank assembly and the

mercury separator after each use and prior to storing the vacuum. Any mercury residue left in the vacuum will continue to give

off vapor which will be absorbed by the charcoal filter, thereby reducing the life of the charcoal filter.

Remove disposable collector bag and prefilters at the end of each cleanup period.

The efficiency of your vacuum will be determined by the amount and the density of the material you are vacuuming. All vacuums

will lose efficiency as they become filled. The operator must, therefore, be the one to determine the frequency for emptying and

changing filters based on the efficiency and performance of the vacuum during the cleaning process.

GENERAL INFORMATION

The charcoal filter supplied with your Mercury Recovery V acuum is a specially activated, impregnated carbon design to increase

the absorbent capacity for mercury vapor gases. The life of the charcoal canister is determined by the volume of mercury vapor

it is exposed to. To maximize the life of the charcoal filter, always store them in an air tight bag when not in use.

The vacuum lid assembly is equipped with a timer which will record actual running time of the unit. The timer is not resetable,

therefore, you are required to keep a permanent log book to indicate each replacement of the charcoal filter.

The log will give the vacuum operator a record of the life span of each filter and approximate time for changes.

Monitoring the exhaust air with vacuum running is the only accurate way to determine the continued efficiency of the

charcoal filter.

When not in use, your Mercury Recovery Vacuum and all its components should be stored in a cool, dry and well ventilated

room. If possible, the room should be vented to outside air. S toring area should not have air return vent leading to air circulating

central system.

Parts an d Instruction Manual

Page 2

Page 6

ASSEMBLY PROCEDURE FOR MRS-1

See Main Assembly MRS 1

1. Tank assembly is equipped with intake down tube for attaching disposable collector bag.

2. Carefully open the folds of disposable collector bag No. 8 and insert into tank.

3. Place the cardboard collar onto the intake tube and carefully pull the collar over the tube until the rubber gasket is past

the ring on the end of the tube.

4. Take the paper filter protector No. 7 and insert it into the tank. Snap the elastic band around the rim of the tank. allow

two inches to overlap the tank rim.

5. Place the white Dacron filter into the tank. Snap the elastic band around the rim of the tank in the same manner as the

filter protector.

6. Place bag frame No. 5 down into the Dacron filter.

7. Install adapter assembly No. 4 on top of tank as shown.

8. Assemble charcoal filter module:

a. Place holder assembly No. 2 with rim gasket down, clamps up, on table.

b. Remove any plastic wrapping from charcoal canister No. 3.

c. Place canister into holder with cover toward the seating gasket.

d. Position latches over the rim of the canister and snap down one at a time.

9. Place charcoal module assembly into the tank with gasket seating around adapter rim.

10. Place the vacuum motor lid assembly No. 1 onto the tank making sure it seats all the way around and engage

lid latches.

11. Screw collector jar No. 11 onto separator No. 10.

12. Insert separator onto tank intake.

13. Press the hose end without cuff onto the intake of the separator.

14. Assemble the wands and curved ends with floor tool on one end and hose adapter on other end. Attach this wand

assembly to end of vacuum hose.

15. Plug in electric cord and turn vacuum on. Spray aerosol anti-static spray in through floor tool for 2 to 3 seconds. Antistatic spray will coat the inside of the wand assembly hose and separator, reducing static electricity during liquid

mercury pickup.

PROCEDURE FOR CLEANING MRS-1

1. Remove wand assembly or other pickup tools from hose; disassemble and place in plastic bag.

2. Remove hose from separator, insert plugs provided at each end, and place in plastic bag with tools.

3. Remove jar from separator, then cap jar and store in safe place.

4. If separator is left on vacuum, plug all openings with caps provided.

5. Unplug electric cord from electric service and remove vacuum lid assembly.

6. Before removing charcoal filter module, take the elastic band of the Dacron filter bag and snap it over the rim gasket

of the module.

7. T o remove filter bag protector, reach down to the bottom of the filter, pull up on the center of the bag so you are turning

it inside out. Pull up as far as possible and carefully remove the elastic band around the rim of the tank without allowing

it to snap off. Crumple the filter bag into a tight ball and place it in a disposable plastic liner bag.

8. Reach into the tank and gently push the collar of the filter bag down and off the intake tube. Place one of the “mercury

caution decals” over the bag opening and carefully remove the disposable filter bag from the tank. Place in plastic liner

bag with other contaminated debris.

9. Using damp disposable paper towels or rags, wipe down the inside of tank assembly . Place wipers in plastic liner bags.

10. All traces of mercury residue must be removed prior to storing Mercury Recovery Vacuum. Inside of tank should be

checked with a “snifter” or comparable air measuring device to determine if all traces of mercury have been removed.

11. Re-assemble vacuum following procedure above on Page 3. Using a “snifter” or other air measuring device, plug in

electric cord and turn on vacuum. Monitor the exhaust air coming through the vacuum with all filters in place. The

highest safe exposure concentration level is 0.05 mg/M3. Any reading above this level coming through the exhaust

would indicate that the charcoal filter requires changing.

12. When charcoal filter is replaced, dispose of canister in same plastic bag with other contaminated debris. (DO

NOT STORE NEAR HEAT OR BURN ANY MERCURY CONT AMINATED ITEMS.)

Parts an d Instruction Manual

Page 3

Page 7

Main Assembly MRS 1

Parts an d Instruction Manual

Page 4

Page 8

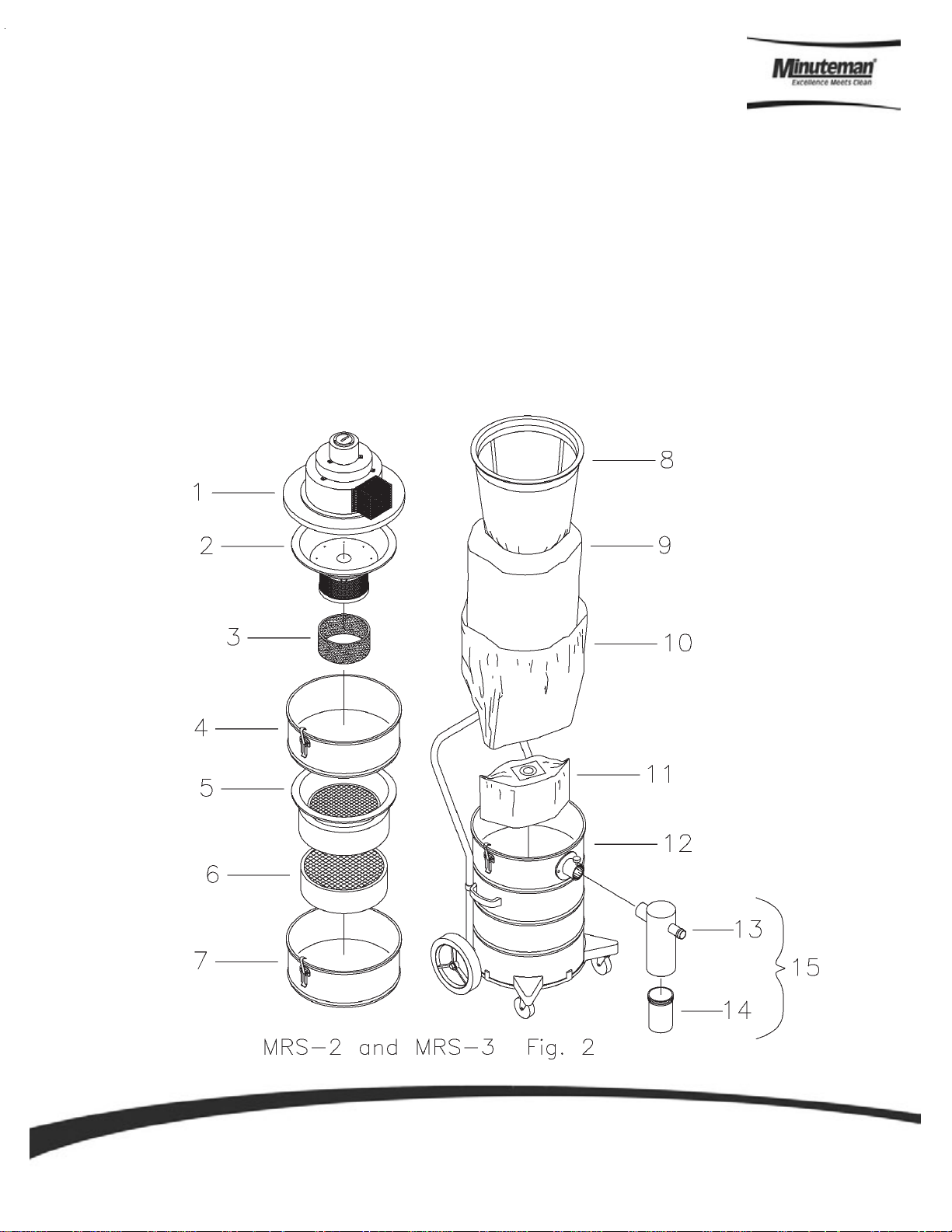

ASSEMBLY PROCEDURE FOR MRS-2 AND MRS-3

Steps 1 through 9 follow same procedure as outlined for MRS-1 on Page 3.

10. Install adapter ring as shown.

11. Assemble U.L.P.A. filter module:

a. Place U.L.P.A. filter module No. 2 with rim gasket down on table.

b. Place prefilter No. 3 over the U.L.P.A. filter.

12. Set U.L.P.A. filter module into adapter assembly. Center so rim gasket seats evenly around tank.

13. Place the vacuum motor assembly No. 1 onto adapter and secure with lid latches.

* The MRS-2 is used for the recovery of mercury contaminated dirt in dry form. Assemble metal hose swivel connector

on hose and insert into hose intake. All dry debris recovered will go into the disposable filter bag.

* For model MRS-3, assembly is same as above with the addition of the separator No. 16 which is inserted into the tank

hose intake. This unit is used to recover liquid mercury spills in the presence of other toxic dust materials. The MRS-3

offers the capability to recover and separate the mercury from the dry material.

See Main Assembly MRS 2&3

PROCEDURE FOR CLEANING MRS-2 AND MRS-3

1. Remove vacuum hose, tools and attachments and place in plastic liner bag.

2. Unplug electric cord from electric service and remove vacuum lid assembly.

3. Remove U.L.P.A. filter assembly, and visually check the prefilter . If prefilter is discolored and p acked with dust particles,

replace it. Follow procedure No. 11 above.

4. Remove 1 to 1 adapter.

5. Remove charcoal filter assembly.

6. Remove white Dacron filter with bag frame.

Steps 7, 8, 9 and 10 follow same procedure as outlined for MRS-1 on Page 3.

11. On MRS-3 where the separator has been in use:

a. Remove jar from separator and then cap. Store in safe place or dispose in plastic liner bag

with other contaminated debris.

b. Remove separator from vacuum, plug all openings with caps provided. Store in plastic bag liner

with other tools and attachments.

c. Plug hose intake on vacuum tank.

12. Re-assemble vacuum following procedure above for MRS-2 and MRS-3, steps 1 through 13.

Parts an d Instruction Manual

Page 5

Page 9

Main Assembly MRS 2 & 3

1 Lid Assy 255115 (115V) 255125 (230V)

2 ULPA Filter Module 750493

3 Prefilter Sleeve 110030PKG (6)

4 Adapter 750080 (PTD) 750081 (SS)

5 Filter Holder 750487

6 Mercury Vapor Cannister 761760

7 Adapter 750080 (PTD) 750081 (SS)

8 Cloth Bag Assy 805062

9 Dacron Filter 805005

10 Filter Protector 805038PKG (10)

11 Disposable Paper Bag 760598PKG (10)

12 Tank 15 Gallon 750612 (PTD) 750610 (SS)

13 Seperator 750490

14 Seperator Jar 761764

15 Seperator Comp 750489

Parts an d Instruction Manual

Page 6

Page 10

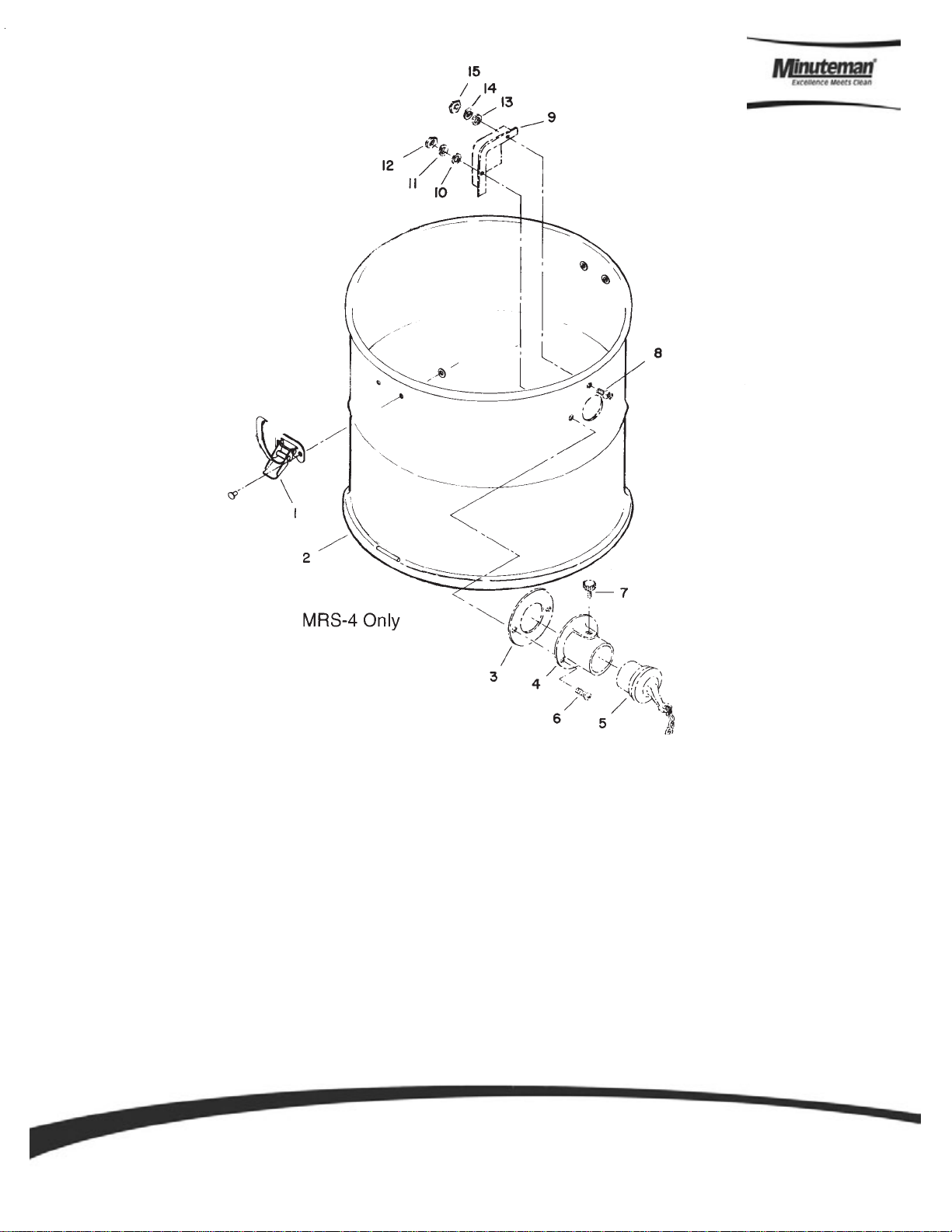

ASSEMBLY PROCEDURE FOR MRS-4

See Main Assembly MRS 4

1. Place water shutoff assembly No. 5 onto tank centering gasket around rim.

2. Place 1 to 1 adapter No. 4 onto tank, center and engage tank lid latches.

3. Install charcoal filter assembly No. 3 into adapter No. 2. Using latches place in assembly No. 4.

4. Place the vacuum motor lid assembly No. 1 onto tank making sure it seats all the way around the adapter rim.

MRS-4 is ready for the recovery of mercury contaminated liquids only.

5. Attach hose assembly and tools required for your job applications.

6. Turn on vacuum and spray anti-static spray into end of tool you are using, proceed with cleanup.

DO NOT USE THIS MACHINE TO PICK UP FLAMMABLE OR EXPLOSIVE LIQUIDS OR OTHER MATERIAL.

DO NOT USE THIS MACHINE IN AN EXPLOSIVE ATMOSPHERE.

PROCEDURE FOR CLEANING MRS-4

1. Check with your Health/Safety Department for the proper procedure for disposing mercury contaminated liquid which you

have recovered in the MRS-4 vacuum.

2. Unplug electric cord from electric service and remove vacuum lid assembly.

3. Remove charcoal filter assembly.

4. Remove 1 to 1 adapter.

5. Remove water shutoff assembly and wipe down underside of water shutoff. Place wiping material in plastic liner bag

with proper label.

6. Dispose of mercury contaminated liquid in vacuum tank in accordance with procedures set up by your Health/Safety

Department.

7. Wipe down inside of tank assembly, place wiping material in plastic liner bag.

8. Re-assemble MRS-4 following procedure above.

Parts an d Instruction Manual

Page 7

Page 11

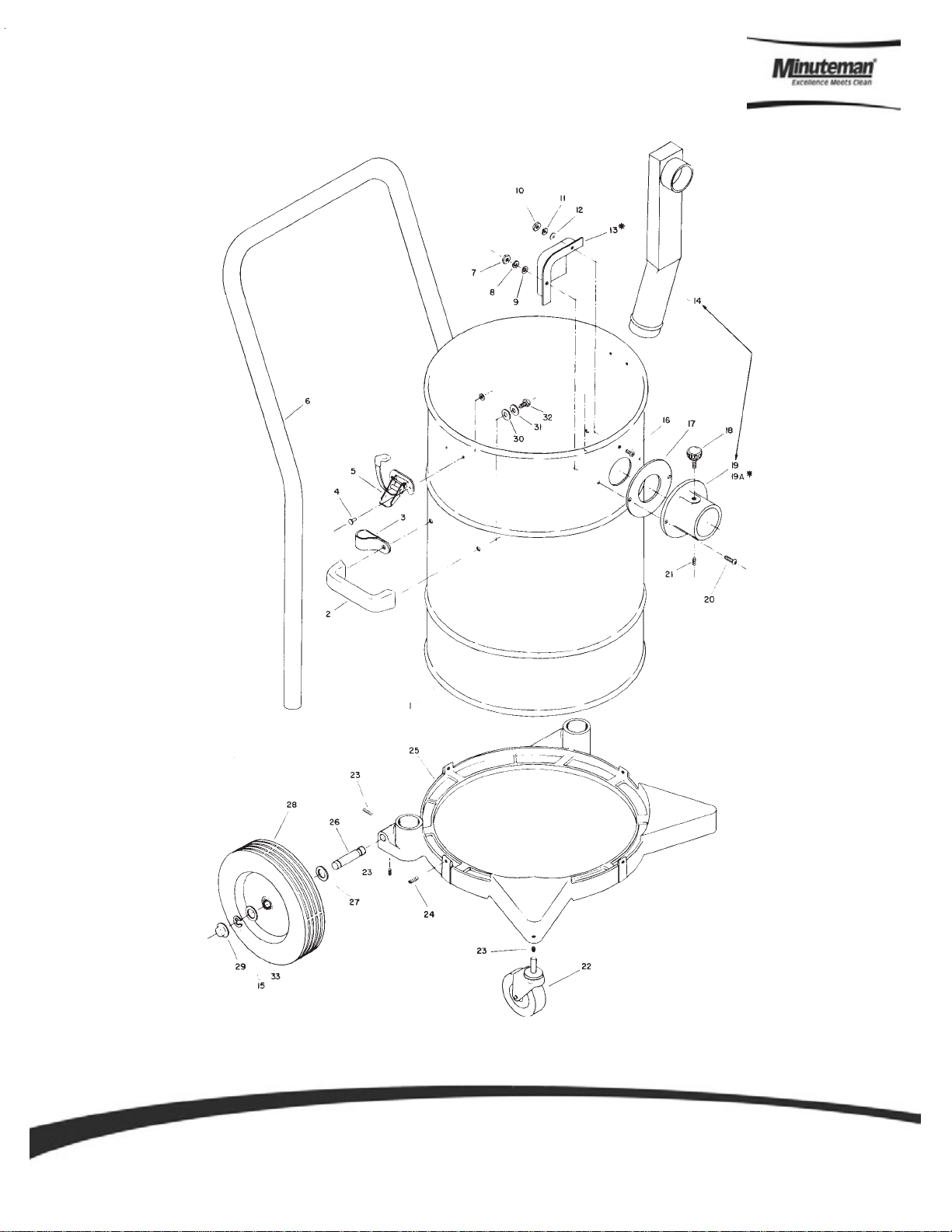

Main Assembly MRS 4

Parts an d Instruction Manual

Page 8

Page 12

Lid Assembly

Parts an d Instruction Manual

Page 9

Page 13

Lid Assembly BOM

ITEM NO. P ART NO. QTY. DESCRIPTION

10 380032 1 Strain Relief

11 381020 1 Cord 16-3 x 50 ft .

12 250026 2 Gasket Motor

13 710356 3 SCR-MC 10-32 x 5/8

14 710330 8 SCR-MC 8/32 x 5/8

15 710356 8 SCR-MC 10/32 x 5/8

16 710365 2 SCR-MC 10/32 x 1 ¾

17 711304 8 Nut-Hex 8/32

18 711552 8 WSR-Lock #8

19 710362 4 SCR-MC 10/32 x

20 750492 1 HSG Weldment

21 750502 1 Lid SS, Incudes Items 33, 34

22 750509 1 Exhaust Air Cover

23 101041PLT 1 Top Dome

24 750508 1 Air Baffle

25 761758 1 Timer

26 101033 2 Insulation

27 101008 2 Grommet

28 480049 2 Gasket

29 711556 1 WSR-Loc ½

30 101009 1 Gasket

31 101007 1 Insulation

32 480049 1 Gasket

33 480052 1 Gasket

34 480053 1 Gasket

35 255008 2 Carbon Brush Replacement

36 101005 1 Rubber Gasket

37 710356 2 SCR-MC 10-32 x 5/8

38 101012 1 Gasket

39 805018 1 Gasket

40 750487 1 Filter Mounting Assy.

41 762184 1 Gasket

42 761760 1 Vapor Canister MRS

43 750494 1 Mercury V apor Assy.

44 762194 1 U.L.P.A. Mounting Plate

45 110039 1 U.L.P.A. Filter

46 110030PKG 1 Impact Filter, pkg. of 6

48 750493 1 U.L.P.A. Filter Assy.

1 101018 1 Cord Assy .

2 101019 1 Switch Box

3 101006PTD 1 Inter Vent Dome

4 101030 3 Bracket

5 255030 1 Gasket

6 255039 1 Motor 115V

7 255049 4 Spacer

8 255046PLT 1 Motor Retainer

9 380002 1 Switch, 1 ½ HP

Parts an d Instruction Manual

Page 10

Page 14

Cloth Bag Assembly

ITEM NO. PART NO. QUANTITY DESCRIPTION

1 750097 1 Bag Frame

2 805054 1 Bag Only

5 750405 1 Assembly-Plate Water Shutoff

6 760231MCH 1 Ring, Bag Retainer

7 380046 1 Ball, Float

8 380045CTD 1 Cage Float Assembly

9 760234 1 Lint Trap Bag

10 760260 1 Spring, Retainer

11 711203 4 BLT, 1/4-20 x .50 HHMS

12 711519 4 WSR, Flat 1/4 ID x 1" OD

13 711373 4 Nut, Nyloc 1/4-20

Parts an d Instruction Manual

Page 11

Page 15

Adapter Assembly

ITEM NO. PART NO. QUANTITY DESCRIPTION

10 711503 2 WSR, Flat #10

11 711543 2 WSR, Lock #10

12 711310 1 Nut-Hex 10/32

13 711502 1 WSR, Flat #8

14 711542 1 WSR, Lock #8

15 711304 1 Nut-Hex 8/32

Parts an d Instruction Manual

1 761054 2 Latch

2 110902 1 Adapter 1:1 PTD Inc. #1

2a 110901 1 Adapter 1:1 SS Inc. #1

3 900036 1 Gasket

4 900112POL 1 Intake

5 750402 1 Plug Assy .

6 710356 2 SCR-MC 10-32 x .62

7 500033 1 Knob

8 710530 1 SCR-MC 8/32 x .50

9 900035 1 Deflector

Page 12

Page 16

T ank Assembly

Parts an d Instruction Manual

Page 13

Page 17

T ank Assembly Bom

ITEM NO. PART NO. QTY. DESCRIPTION

1 900004POL 1 T

1A 900001 1 Tank, PLT 15 Gal.

2 900031POL 2 Handle, Tank Polished

3 900038 2 Clamp, Handle

4 711915 4 Rivet .19 x .28 x .37HD STNI

5 761054 2 Latch

6 900037PLT 1 Handle, Plated Common

7 711310 2 Nut, Hex 10-32 STPL

8 711543 2 WSR, Helical SPR LOC #10

9 711503 6 WSR, Flat #10

10 711304 1 Nut, Hex 8-32

11 711542 1 Washer, LOC #8

12 711502 1 Washer FLT #8

13 900035 1 Deflector

14 750498 1 Down Tube

15 711713 2 Retaining Ring E Type

16 710530 1 SCR-MC 8/32 x .50

17 900036 1 Gasket

18 500033 1 Knob

19 900113POL 1 Intake Polished for Item #14

‘ 19A 900112POL 1 Intake Polished for Item #13

19B 900113PTD 1 Intake Plated MRS only for Item #14 MRS

20 710356 2 SCR-MC 10-32 x .62 STPL

21 711005 1 Screw, Set ¼-20 x .31

22 900033 2 Caster, Swivel

23 711005 4 SCR, Set ¼-20 x .31

24 711006 4 SCR, Set /14-20 x .62

25 760984PTD 1 BKT, Wheel

26 900066 2 Axle

27 711582 2 WSR, Wave

28 900040 2 Wheel

29 130032 2 Cap, Retainer

30 711591 4 Washer, Rubber

31 711505 4 WSR, Flat ¼

32 711203 4 BLT, HH ¼-20 x .62

33 711594 2 Washer, FLT

**** 750322 Wheel Bkt. Assy. Complete

**** 750610 Tank Assy. Comp. SS w/Down Tube

**** 750612 Tank Assy. Comp. Painted w/Down Tube

**** 750616 Tank Assy. Comp. SS w/Deflector

**** 750614 Tank Assy. Comp. PTD w/Deflector

ank, Polished 15 Gal. SS

Parts an d Instruction Manual

Page 14

Page 18

Minuteman International Made Simple Commercial Limited Warranty

Minuteman International, Inc. warrants to the original purchaser/user that the product is free from defects in

workmanship and materials under normal use. Minuteman will, at its option, repair or replace without charge, parts

that fail under normal use and service when operated and maintained in accordance with t he applicable operati on and

instruction manuals. All warranty claims must be submitted through and approved by factory authorized repair

stations.

This warranty does not apply to normal wear, or to items whose life is dependent on their use and care, such as belts,

cords, switches, hoses, rubber parts, electrical motor components or adjustments. Parts not manufactured by

Minuteman are cover ed by and subject to the warranties and/or guarantees of their manufacturers. Please contact

Minuteman for procedures in warranty claims against these manufacturers.

Special warning to purchaser -- Use of replacement filters and/or prefilters not manufactur ed by Minuteman or its

designated licensees, will void all warranties expressed or implied. A potential health hazard exits without original

equipment replacem ent .

All warranted items become the sole property of Minutem an or its original manufactu rer , whichever the case may be.

Minuteman disclaims any implied warranty, including the warranty of merchantability and the warranty of fitness for a

particular purpose. Minuteman assumes no res ponsibility for any special, incidental or consequent ial damages.

This limited warranty is applicable only in the U.S.A. and Canada, and is extended only to the original user/purchaser

of this product. Customers outside the U.S.A. and Canada should contact their local distributor for export warranty

policies. Minuteman is not responsible for costs or repairs performed by persons other than those specifically

authorized by Minut eman. This war ranty does not apply to damage from transportation, alterations by unauthorized

persons, misuse or abuse of the equipment, use of non-compatible chemicals, or damage to property, or loss of

income due to malfunct io ns of th e product.

If a difficulty develops with this machine, you should contact the dealer from whom it was purchased.

This warranty gives you specific legal rights, and you may have other rights which vary from state to state. Some

states do not allow the exclusion or limitation of special, inci dental or consequent ial damages, or limit ations on how

long an implied warr anty lasts, so the above exclusions and limitations may not apply to you.

Cord Electric Group………. Three years parts, two years labor, ninety days travel (Not to exceed two hours)

Exceptions………. Port-A-Scrub, one year parts, six months labor

MPV 13, one year parts

MPV 14 and 18, two years parts, one y ear labo r

RapidAir blower, one year parts, one year labo r

Explosion-Proof Vacuum, one year parts, one year labor

Pneumatic Vacuums, three years parts, one year labor

EX 12 and EX12H, one year parts, one year labor

Battery Op er ated Group ….. Three years parts, two years labor, ninety days travel

(Not to exceed two hours)

Exceptions……Sweepers, one year parts, one year labor, ninety days travel

(Not to exceed two hours )

Internal Combustion Group….One year parts, one year labor, ninety day travel

(Not to exceed two hours)

Replac ement Parts……………..N i nety days

Batteries………………………….0-3 months replac em ent, 4-12 months pro-rate

Polypropylene Plastic Tanks…Ten years, no additional labor

111 South Rohlwin g Ro ad · Addison, Illi nois 60101 USA

Phone 630- 627-6900 · Fax 630- 627-1130

E-Mail, www.minutemanintl.com

A Member of the Hako Group

987842

Rev A 05/07

Loading...

Loading...