Page 1

Parts & Instruction Manual

28” Mirage Propane Burnisher - 17 HP Kawasaki

M220028K17A

Page 2

Table of Contents

Safety Instructions ............................................................................................................................. 2

Transport & Preparation..................................................................................................................... 2

Preparation.......................................................................................................................................... 3

Starting the Engine............................................................................................................................. 3

Operation............................................................................................................................................. 4

Stopping the Engine........................................................................................................................... 4

Procedures.......................................................................................................................................... 4

Maintenance........................................................................................................................................ 4

Machine & Engine Maintenance........................................................................................................... 4

Engine Maintenance Meter................................................................................................................... 4

Troubleshooting the electrical system................................................................................................... 4

Kawasaki Engines .............................................................................................................................. 5

Engine Specifications ........................................................................................................................... 5

Belt Inspection & Replacement............................................................................................................. 5

Adjusting Pad Pressure ........................................................................................................................ 5

Oil Change............................................................................................................................................ 6

Engine Maintenance Schedule............................................................................................................. 7

Engine Troubleshooting........................................................................................................................ 7

Replacement Parts ............................................................................................................................. 8

BODY ASSEMBL Y................................................................................................................................ 8

BODY ASSEMBL Y BOM ...................................................................................................................... 9

HANDLE ASSEMBL Y ......................................................................................................................... 10

HANDLE ASSEMBL Y BOM ................................................................................................................ 11

FUEL SYSTEM ASSEMBLY............................................................................................................... 12

KAWASAKI 603cc ENGINE ASSEMBLY............................................................................................ 13

ENGINE BATTERY START WIRING DIAGRAM ................................................................................ 14

Warranty ............................................................................................................................................ 15

Parts And Instruction Manual

28” Mirage Propane Burnisher

Page 3

Parts And Instruction Manual

28” Mirage Propane Burnisher

Page 1

Page 4

IMPORTANT SAFETY INSTRUCTIONS

READ and UNDERSTAND all instructions and

warnings before operating this machine!

!

WARNING

Do not store or use gasoline or other

flammable vapors and liquids in the vicinity

of this machine. Always store equipment

away from heater rooms, boilers, gas-fired

water heaters or any other source of open

flame. Propane is highly flammable.

Always store LPG tanks (full or empty)

outside in a secure, well ventilated area.

NO SMOKING, NO SPARKS, NO FLAMES

NEAR UNIT OR LPG TANK.

Operate only in well ventilated areas. Buildings

must be provided with:

A. A continuous mechanical ventilation that

removes the products of combustion to the

outdoors of not less than 300 CFM for each

10,000 BTUH or fraction thereof; or

B. Natural ventilation of not less than 300 CFM for

each 10,000 BTUH input or fraction thereof,

based on a maximum of one-quarter air

exchange per hour for the net building volume.

If you smell LPG gas, stop the unit and check

for leaks. Also open windows, don’t touch

electrical switches, extinguish any open flames.

Call your gas supplier if no leaks are found.

Do not adjust the fuel system without the proper

analysis equipment.

!

WARNING

Never tilt the equipment on its side for pad, belt

or brush replacement. It is designed to tilt back

on its rear wheel and handle for maintenance

and repair. A second person should aid in

lifting and securing equipment for repair.

Never tilt & transport while engine is running.

Keep hands and feet clear of all moving parts.

Never try to replace parts or repair equipment

with machine running.

T urn the gas off at the tank to kill the engine.

Remove the LPG tank and store it in an

approved area when not in use. A “NO

SMOKING” sign should be permanently

displayed at the storage area.

Always vent an over-full bottle using the tank’s

bleed valve, out of doors away from all closed

places and away from any fire or flame

producing device. Vent until the white vapor

turns clear.

Keep all objects clear of the exhaust system

during and after operation.

Do not leave this machine unattended while

the engine is running.

Do not operate equipment in one location for

more than a few seconds. Damage to floor

surface can occur.

Always store equipment away from possible

damage by falling objects in warehouse-type

areas. Always store LPG tanks outside in a

secure, well-ventilated area.

When the LPG tank is attached to the machine

and not running, the operator should not

leave the machine unattended except for

short periods of time such as rest stops,

washroom or meal stops.

The operator must completely understand all

instructions, warnings and operating

procedures before using this machine.

This machine must be maintained in

accordance with this manual’ s recommended

maintenance instructions and the engine

manufacturer’s recommended maintenance

procedures. Failure to do so may cause

damage to the machine, equipment,

furniture, buildings or personal injury!

A maintenance record should be kept

indicating date of service, hours on engine,

and work done.

TRANSPORT & PREPARATION

!

WARNING

Follow the instructions given in this booklet,

the Engine’s Owners Manual and the

training given by your supervisor for the safe

operation of this machine. Failure to do so

can result in personal injury and/or damage

to the machine or property.

DO NOT OPERATE THIS MACHINE IN AN

EXPLOSIVE ENVIRONMENT!

THIS PROPANE MACHINE IS INTENDED

FOR COMMERCIAL USE.

Parts And Instruction Manual

28” Mirage Propane Burnisher

Page 2

Page 5

Parts And Instruction Manual

28” Mirage Propane Burnisher

Page 3

Page 6

• Propane tanks should be removed &

stored in a protected off site area.

cleaning the unit, check for possible loose nuts

and bolts.

III. OPERATION

Provide and use ear protection during

operation.

Never let an untrained person operate or

perform repairs on the machine. They may hurt

themselves, damage the floor or the

equipment.

Engine speed not to exceed 3400 RPM.

This machine is not suitable for picking up

hazardous dust.

Do not use on surfaces with a gradient

exceeding 2%.

IV. STOPPING THE ENGINE

T urnthe propane tank valve clockwise to a closed

position and turn the key OFF.

NOTE: The exhaust system will be very hot and

takes several minutes to cool, so keep yourself

and all materials clear .

V. PROCEDURES

Follow machine (straight ahead) at moderate

walking speed. Keep moving.

• Do not operate the machine in one location

for more than a few seconds — it will

damage — “burn” the finish.

• When operation is completed remove tank

and store in a secure, protected off site

(preferably outdoor) location.

• Do not use for scrubbing operations.

• Never tilt back machine to maintenance

position while engine is running.

• Never reach under protective shroud when

engine is running.

VI. MAINTENANCE

A. Machine & engine maintenance

1. Refer to engine manufacturer’s owners

manual and comply completely with the

instructions. Change the oil and filter

according to the Engine Owners Manual.

2. Keep a good service log on each machine

with the date, hour meter reading, type(s) of

service performed and the name of the person

who performed them.

3. Clean the entire unit after each use. When

B. Engine maintenance meter

This multi-function meter acts as a preventive

maintenance tool, which benefits you with

increased fuel economy, less down-time and

longer engine life.

The meter’s displays are:

Hour Meter: Displays total run hours when

machine is off.

T achometer: Indicates engine RPM during

operation.

Service Alert: The display flashes to alert you to

lube and change the oil at 25 hour intervals. The

service alert only flashes during operation and it

warns you to change the oil for only two hours.

After the two hours is reached, the alert will

automatically reset to the next 25 hour interval.

Therefore, it is recommended that a separate

maintenance log be kept to track oil changes.

Remember that being safe is a full-time, every

day job. Follow all information posted on the

machine and the LPG tank.

Never allow anyone to operate this machine

who has not read or cannot understand the

given instructions.

C. Troubleshooting the electrical system

1. Check all wire connections for obvious

problems. Remove LPG tank, then remove

battery box cover. Check all connections

visibly and physically. If any “loose”, damaged

or unconnected wires are noticed, replace or

repair as needed.

2. Check the battery posts and wires. Always

wear a face shield, safety glasses and

protective clothing when working around a

battery! The gases can be explosive and the

acid is highly corrosive to metals, cloth and

ALL HUMAN TISSUE (skin, eyes, etc.) If the

battery post(s) are corroded, remove the wires

and clean posts and wires. Applying some axle

grease on the posts of the battery after they are

cleaned will slow down the battery corrosion

process.

If nothing obvious is noted, a more detailed

investigation is warranted. Before any such

troubleshooting begins, the following things

should be done:

a. Replace propane LPG tank with one from

a machine that runs.

Parts And Instruction Manual

28” Mirage Propane Burnisher

Page 4

Page 7

b. Charge the battery or provide an absolute

source of 12 volt DC power capable of 50

amperes total output. (A pair of good

jumper cables from your car or truck

battery will suffice.) Equip yourself with an

inexpensive 12 volt test light.

c. If the trouble seems to be in the electrical

control equipment, you may wish to

disconnect the starter from the system so

as to check the system without spinning

the engine.

d. Battery rundown. A common problem

is letting the battery run down. What

usually happens is that it takes the crew a

few jobs to get used to the whole system,

so the machine is stopped and started

quite often. Key left in on position, when

engine is turned off, will result in battery

running down – dying.

D. Belt Inspection & Replacement

Inspection

• Fold T -Handle to forward position

• Tilt machine back on rear of body & handle

• If belt is worn, cracked or shredding, belt

needs to be replaced.

Replacement

• Place 3/4" wrench on end of the shaft on the

top of the buffer body.

• Turn pad driver counter-clockwise to

remove.

• Take belt off by turning 3/4" wrench on shaft

and removing belt from pad driver pulley

and engine crank pulley.

• Check pad driver pulley & engine crank

pulley for correct alignment.

• Install new belt on engine crank pulley &

pad driver pulley, using 3/4" wrench.

• Install belt on tension pulley

• Install pad drive onto shaft, and return

buffer to operating position.

E. Adjusting Pad Pressure

The pad pressure may be adjusted by moving

the wheels:

• Forward to reduce weight on the buffer pad

or

• Backward to increase the weight

This adjustment may be required to adjust to

different floor finishes or to the weight variance

of aluminum or steel propane tanks.

KAW ASAKI ENGINES

T une-up Specifications

ITEM SPECIFICATIONS

Ignition Timing Unadjustable

Spark Plugs: Champion – RCJ8Y

Gap 0.75 mm (0.30 in)

Low Idle Speed 1500 RPM

High Idle Speed 3400 RPM

Valve Clearance IN: 0.10-0.15 mm

(0.004-0.006 in)

EX: 0.10-0.15 mm

(0.004-0.006 in)

Other No other adjustment

Specifications needed

NOTE: High and low idle speeds may vary

depending on the equipment on which the engine

is used. Refer to the equipment specifications.

Engine Oil

Check the engine oil daily before starting the

engine otherwise shortage of the engine oil may

cause serious damage to the engine such as

seizure.

• Place the engine on a level surface. Clean the

area around the oil gauge before removing it.

• Remove the oil gauge and wipe it with a

clean cloth.

• Pour the oil slowly to “FULL” mark on the oil

gauge.

• Insert the oil gauge into the tube WITHOUT

SCREWING IT IN.

• Remove the oil gauge to check the oil level.

The oil level should be between “ADD” and

“FULL” marks. Do not overfill.

• Install and tighten the oil gauge.

The following engine oils are recommended:

API Service Classification: SF, SG, SH, or SJ.

Oil Viscosity

Choose the viscosity according to the

temperature as follows:

-20˚C -10˚C 0˚C 10˚C 20˚C 30˚C 40˚C

SAE40

SAE30

SAE10W-30/SAE10W-40

SAE5W-20

-4˚F 14˚F 32˚F 50˚F 68˚F 88˚F 104˚F

NOTE: Using multi grade oils (5W-20, 10W-30, and 10W-40)

will increase oil consumption. Check oil level more frequently.

Parts And Instruction Manual

28” Mirage Propane Burnisher

Page 5

Page 8

Parts And Instruction Manual

28” Mirage Propane Burnisher

Page 6

Page 9

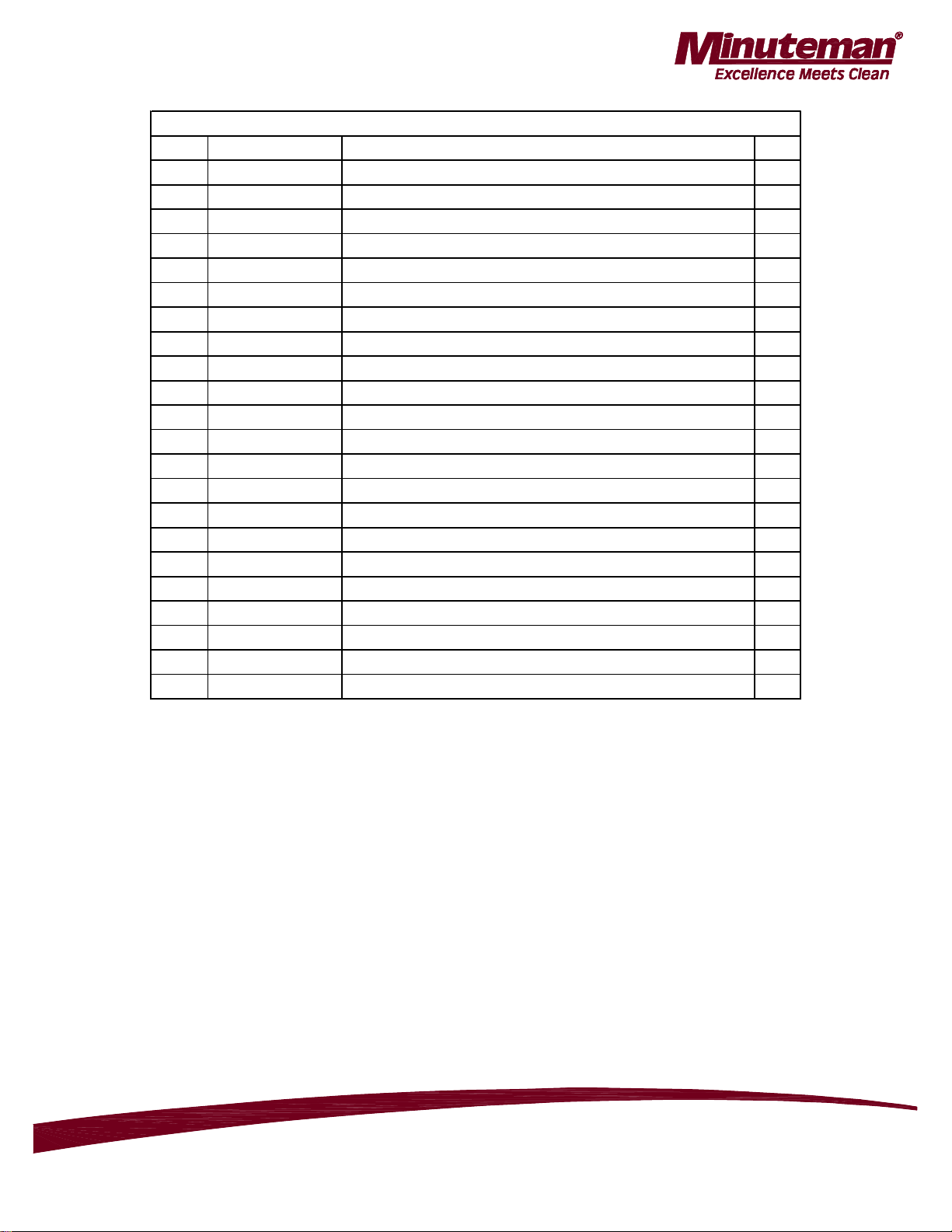

KAWASAKI ENGINE MAINTENANCE SCHEDULE

INTERVAL

MAINTENANCE Daily First 8 hr. Every 25 Hr. Every 50 hr. Every 100 hr. Every 200 hr. Every 300 hr.

Check and add engine oil

Check for loose or lost nuts and screws

Check for fuel and oil leakage

Check battery electrolyte level

Check or clean air intake screen

Clean air cleaner foam element

Clean air cleaner paper element

Clean dust and dirt from cylinder and

cylinder head fins

Tighten nuts and screws

Change engine oil

Clean and gap spark plugs

Change oil filter

Replace air cleaner paper element

Clean combustion chambers

Clean and adjust valve clearance

Clean and lap valve seating surface

•

•

•

•

•

•

•

•

•

••

•

•

•

•

•* •

•

*After the 1st 50 hours

ENGINE TROUBLESHOOTING

COMMON PROBLEMS & PROBABLE CAUSES SOLUTIONS

Engine cranks but will not start

• Fuel cylinder is empty Refill cylinder

• Shutoff valve is closed Open valve

• Clogged, obstructed, kinked or cut fuel or vacuum line Remove obstruction or replace line

• Spark plug lead disconnected Connect lead to spark plug

• Faulty choke or throttle settings Set controls to correct positions

• Faulty ignition coil Replace coil

• Faulty kill switch Replace switch

• Faulty regulator Replace regulator

Engine starts hard

• Faulty choke or throttle settings Set controls to correct position

• Clogged, obstructed, kinked or cut fuel or vacuum line Remove obstruction or replace line

• Faulty regulator Replace regulator

• Low compression Valves need adjustment

Engine will not crank

• Battery is discharged Charge or replace battery

• Loose or faulty connections or wires Tighten, repair or replace wires

• Faulty ignition key switch or starter control switch Repair or replace switch(es)

Engine overheats

• Incorrect fuel settings Have engine serviced

• Air intake filter screen or cooling fins clogged Clean and clear debris or replace filter

• Low oil level Check and add oil

Exhaust emissions or propane odor

• Carburetor or regulator setting incorrect Have engine serviced by a trained technician

• Dirty or clogged air filter Replace air filter

• Choke engaged Adjust to correct settings

• Loose fittings, clamps or hoses cracked, hoses cut or leaking Tighten or seal; check with soap and water solution,

Have engine serviced by a trained technician

if bubbles appear, part is still leaking; replace

Parts And Instruction Manual

28” Mirage Propane Burnisher

Page 7

Page 10

Replacement Parts

BODY ASSEMBLY

Parts And Instruction Manual

28” Mirage Propane Burnisher

Page 8

Page 11

BODY ASSEMBL Y BOM

ITEM PART NUMER DESCRIPTION QTY

10 271091 PAD RETAINER (CE NT ER LOK II) 1

11 271094 PAD DRIVE HUB 1

12 271067 WASHER 1

13 271096 PAD DRIVE R 1

14 271095 PAD DRIVE R SUPPORTRI NG 1

15 271007 SPINDLE ASSEMBLY (WITH HUB & BEARINGS) 1

16 271051 BELT 1

17 271097 TENSIONER PULLE Y 1

18 271052 BELT TENSIONER 1

19 271062 HI TCH PIN CLIP 2

20 271060 5" WH EEL 2

21 271061 CLEVIS PIN 2

22 271056 WHEEL BRACKET 2

23 271063 SWIVEL C ASTOR 1

24 271064 NUT 1/ 2-13 X 1 1/2 1

25 271057 BOL T 5/16-18 X 1 1/4 4

26 271054 BOL T 3/8-16 X 2 1

27 271008 BOL T 1/2-13 X 1 4

28 271001 28" ALUMINUM BODY FRAME 1

29 271092 28" MIGHT Y 1

30 271050 SPINDLE PUL LEY (71/2") 1

31 REF ONLY 28" BE IGE PAD 1

PARTS LIST FOR 28" BUFFER BODY ASSEMBLY

Parts And Instruction Manual

28” Mirage Propane Burnisher

Page 9

Page 12

HANDLE ASSEMBLY

Parts And Instruction Manual

28” Mirage Propane Burnisher

Page 10

Page 13

HANDLE ASSEMBLY BOM

ITEM PART NUMBER D ESCRIPTION QTY

1 271033 12V BATTERY 1

2 271029 (+) B ATTERY C A BLE 16.5" 1

3 271032 BATTE RY BOX BOTTOM COV ER 1

4 271099 3/8-16 X 1/2" HEX BOLT 2

5 271026 BATTERY BOX BRACKET 1

6 271038 STARTE R SOL ENOID 1

7 271085 VELCRO TANK STRAP 1

8 271093 TANK STRAP BRACKET LOOP 2

10 271012 1/4-20 X 1 1/2" HEX BOLT 1

11 271011 THROTTLE CABLE 1

12 271076 20LB. LPG CYLINDER 1

13 271101 HANDLE GRIP 2

14 271074 3/8-16 X3" HEX BOLT 1

15 271080 LOCK PIN 1

16 271071 LEFT HANDLE BRACKET 1

17 271070 T-HANDLE 1

18 271072 RIGHT HANDLE BRACKET 1

19 271073 3/8-16 X 1" HEX BOLT 4

20 271002 HANDLE MAINFRAME 1

21 271100 3/8-16 STOVER LOK NUT 7

22 271031 BATTERY BOX TOP COVER 1

23 271030 (-) BATTERY CABLE 26" 1

24 271024 KEYSWITCH 1

25 271025 WIRE HARNESS 1

26 271013 1/4-20 FLANGE NUT 1

PARTS LIST FO R BUFFER HANDLE ASSEMBLY

Parts And Instruction Manual

28” Mirage Propane Burnisher

Page 11

Page 14

FUEL SYSTEM ASSEMBLY

ITEM PART NUMBER DESCRIPTION QTY

1 271043 QUICKCOUPLER 1

2 271042 LPG HOSE 14" 1

8 271044 FUEL HOSE FITTING 1

9 271041 FUEL LOK- OUT (12VOLT) 1

10 271040 FUEL REGULATOR( T60-E) 1

Parts And Instruction Manual

28” Mirage Propane Burnisher

PARTS LIST FOR BUFFER FUEL SYSTEM

Page 12

Page 15

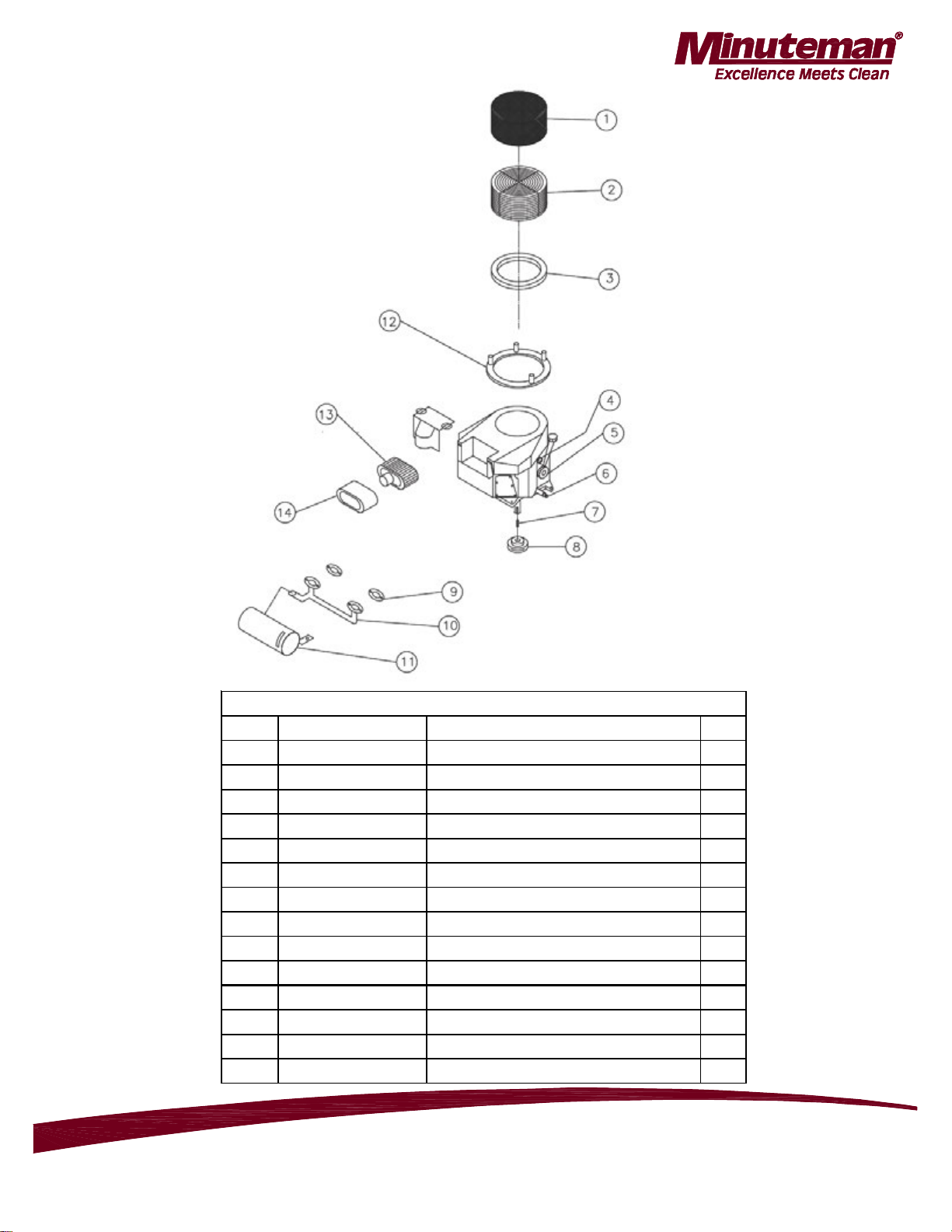

KAWASAKI 603cc ENGINE ASSEMBLY

KAWASAKI 60 3cc ENGINE

ITEM PART NUMBER DESCR IPTIO N QTY

1 271086 FOAM HAT FILTER 1

2 271103 DEBRIS SCREEN 1

3 271104 FOAM HAT SEAL 1

4 271098 OIL PRESSURE SWITCH 1

5 271132 OIL FILT ER 1

6 271088 OIL DRA IN VALV E 1

7 271048 1 / 4 X 1 1 / 4 KEY 1

8 271049 CRANK PULLEY 1

9 271133 EXHAUST MANIFOLD G ASKET 2

10 271134 EX HAUST M ANIFOLD 1

11 271135 CATAL YTIC MUFFLER 1

12 271136 DEBRIS SCREEN ADAPTER 1

13 271137 AIR FILT ER ELE M ENT 1

14 271138 FOAM PRE FILTER 1

Parts And Instruction Manual

28” Mirage Propane Burnisher

Page 13

Page 16

ENGINE BATTERY START WIRING DIAGRAM

Parts And Instruction Manual

28” Mirage Propane Burnisher

Page 14

Page 17

Minuteman International Made Simple Commercial Limited Warranty

r

r

A

r

REVISION E

Minuteman International, Inc. warrants to the original purchaser/user that the product is free from defects in

workmanship and materials under normal use. Minuteman will, at its option, repair or replace without charge, parts

th at fa il un der no rmal use an d servi ce whe n oper ate d and m aintai ned in acco rdanc e with the ap pli cable o perat ion

and instruction manuals. All warranty claims must be submitted through and ap proved by factory aut horized repai

stations.

This warranty does no t apply to normal wear , or t o items whose life is depende nt on their use and care, such as be lts,

cords , sw it c hes, hose s, rub ber part s, electrical motor components or adjustments. Part s manu factured by Minuteman

are cover ed by and su bject to the w ar r anties and/or guarant ees of the ir manuf acturers. Please contact Minut eman fo

pro cedures in warranty claims again st t hese manu fact ur ers.

Spe c ial wa rning to pu rc h a se r -- Use of replacement filters and/or prefilters not manufactured by Min uteman or its

designated licensees, will void all warranties expressed or implie d. A potential health hazard exists w ithout original

equipmen t repla cement.

ll warranted items become the sole property of Minuteman or its original manufacturer, whichever the case may be.

Minuteman disclaims any implied warranty, including the warranty of merchantability and the warranty of fitness for a

par ti cula r purpose . Minuteman assumes no responsi bility for any special, inc idental or consequential dam ages.

Th is limited warr a nt y is ap pl i ca ble on ly in the U. S. A. an d Can a da , an d is ex te nd e d on l y to t he ori gi n al use r /p ur ch as e

of this product. Customers outside the U.S.A. and Canada should contact their local distributor for export warranty

policies. Minuteman is not responsible for cos ts or repairs performed by persons other than those specifi cally

authorized by Minuteman. This warranty does not apply to damage from transportation, alterations by unauthorized

persons, misuse or abuse of the equipment, use of non-compatible chemicals, or damage to property, or loss of

inc ome d ue t o malfu nctio ns of th e product .

If a difficulty de velops with this machi ne, you should co ntact th e dealer from who m it was purchas ed.

This warranty gives you specific legal rights, and you may have other rights which vary from st ate to state. Some

states do not allow the exclusion or limitation of special, incidental or consequential damages, or limitations on how

long an implied war r ant y lasts, so the ab ove exclusions and li mi tations may no t appl y to you.

Cord Electri c Group………. T hree years par ts, two ye ar s labor, nin et y days trave l (Not t o exceed two hours)

Exceptions………. Port-A-Scrub, one year parts, six months labor

X12 and X12H, one year parts, one year labor

TRS 14, one year parts, one year labor

E17/E20 electric scrubbers, one year parts, six months labor

Battery Operated Group….. Three years pa rts, two years labor, ninet y days t r avel

Exceptions……Sweepe r s , o ne yea r parts, one year labor , ni net y days travel

Internal Combustion Group….One year parts, one year labor, ninety day travel

Exceptions………..Mira ge pr opane burnishe r, o ne year p arts, o ne ye a r labor

Battery Chargers

………………. ..One year replacement

Replacement Parts……………..

Batteries………………………….0-3 months replacement, 4-12 months pro-rate

Polypropylene Plastic Tanks…Te n years, no a dditional labo r

14N845 U.S. Route 20 Pingre e grove, I L 60140

EFFECTIV E 1/ 1 /2009

MPV 13, one year parts

V Series Upright Vacuums, One year parts, one year labor

MPV 14 and 18, two year s parts, one y e ar labor

Ra pi dAir bl ow er, one ye ar pa r ts , on e yea r labo r

Explosion-Proof Vacuum, one year parts, one year labor

(Not to exceed two hours)

(Not to exceed two hours)

(Not to exceed two hours)

Ninety days

Phone: 800-237-3192

E-M ail: www. minu temanintl.c om

999378

Rev C 08/11

Loading...

Loading...