Page 1

MCP-E Series

User's Manual

Page 2

1

© Copyright Para Systems, Inc., 2001

MCP-E Series

User's Manual

1. Introduction 2

2. Controls and Indicators 4

3. Installation 6

4. Operation 13

5. Troubleshooting 17

6. Replacing the Battery 20

7. Obtaining Service 24

8. Specifications 25

9. Configurable Parameters & Settings 26

10. Limited Product Warranty 28

1 1. Declaration of Conformity 29

English

TABLE OF CONTENTS

Page 3

2

Thank you for purchasing a MINUTEMAN™ power protection product. It has been

designed and manufactured to provide many years of trouble free service.

Please read the manual before installing your UPS. It provides the information that should

be followed during installation and maintenance of the UPS and the batteries allowing you

to correctly set up your system for the maximum safety and performance. Included is

information on customer support and factory service if it is required. If you experience a

problem with the UPS please refer to the Troubleshooting guide in this manual to correct

the problem or collect enough information so that the MINUTEMAN Technical Support

Department can rapidly assist you.

This symbolt

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS !

NOTICE: This equipment has been tested and found to comply with the limits

for a Class A computing device in accordance with the specifications in Subpart J

of Part 15 of FCC Rules and the Class B limits for radio noise emissions from digital

apparatus set out in the Radio Interference of the Canadian Department of

Communications. These limits are designed to provide reasonable protection against such

interference in a residential installation. This equipment generates and uses radio frequency

and if not installed and used properly, that is, in strict accordance with the manufacturer's

instructions, this equipment may cause interference to radio and television reception. If this

equipment does cause interference to radio or television reception, which can be determined

by turning the equipment off and on, the user is encouraged to try to correct the interference

by one or more of the following measures:

n Re-orient the receiving antenna

n Relocate the computer with respect to the receiver

n Move the computer away from the receiver

n Plug the computer into a different outlet so that the computer and receiver are on

different branch circuits.

n Shielded communications interface cables must be used with this product

After removing your MINUTEMAN UPS from it's carton, it should be inspected for damage

that may have occurred in shipping. Immediately notify the carrier and place of purchase if

any damage is found. Warranty claims for damage caused by the carrier will not be

honored.

Receiving Inspection

WARNING: Changes or modifications to this unit not expressly approved by the

party responsible for compliance could void the user's authority to operate the

equipment.

English

INTRODUCTION

This symbol indicates "A TTENTION"

This symbol indicates "Risk of Electrical Shock"

Page 4

3

WARNING: Risk of electrical shock. Hazardous live parts inside

this power supply are energized from the battery even when the AC

input power is disconnected.

To de-energize the outputs of the UPS:

1. If the UPS is on press the on/off button for 1 second

2. Disconnect the UPS from the AC power outlet

3. To deenergize the UPS completely, disconnect the battery.

This uninterruptible power source contains potentially hazardous voltages. DO

NOT attempt to disassemble the unit. This UPS contains no user serviceable

parts. Repairs and battery replacement must be performed by AUTHORIZED

SERVICE PERSONNEL ONL Y .

CAUTION! To reduce the risk of electrical shock in conditions where load

equipment grounding cannot be verified, disconnect the UPS from the AC power

outlet before installing a computer interface cable. Reconnect the power cord

only after all signaling connections are made.

CAUTION! Connect the UPS to a two pole, three wire grounding AC

power outlet. The receptacle must be connected to appropriate branch protection

(circuit breaker or fuse). Connection to any other type of receptacle may result in

a shock hazard and violate local electrical codes

Para Systems Life Support Policy

As a general policy, Para Systems Inc. (Para Systems) does not recommend the use of any

of its products in life support applications where failure or malfunction of the Para Systems

product can be reasonably expected to cause failure of the life support device or to

significantly affect its safety or effectiveness. Para Systems does not recommend the use

of any of its products in direct patient care. Para Systems will not knowingly sell its

products for use in such applications unless it receives in writing assurances satisfactory

to Para Systems that (a) the risks of injury or damage have been minimized, (b) the

customer assumes all such risks, and (c) the liability of Para Systems Inc. is adequately

protected under the circumstances.

Examples of devices considered to be life support devices are neonatal oxygen analyzers,

nerve stimulators (whether used for anesthesia, pain relief, or other purposes), auto

transfusion devices, blood pumps, defibrillators, arrhythmia detectors and alarms, pacemakers, hemodialysis systems, peritoneal dialysis systems, neonatal ventilator incubators,

ventilators for both adults and infants, anesthesia ventilators, and infusion pumps as well as

any other devices designated as “critical” by the United States FDA.

Hospital grade wiring devices and leakage current may be ordered as options on many

P ARA SYSTEMS UPS systems. PARA SYSTEMS does not claim that units with this

modification are certified or listed as Hospital Grade by PARA SYSTEMS or any other

organization. Therefore, these units do not meet the requirements for use in direct patient

care.

The packing materials that your UPS was shipped in, are carefully designed to minimize any

shipping damage. In the unlikely case that the UPS needs to be returned to MINUTEMAN,

please use the original packing material. Since MINUTEMAN is not responsible for shipping

damage incurred when the system is returned, the original packing material is inexpensive

insurance. PLEASE SA VE THE PACKING MA TERIALS!

English

CAUTION! "High Leakage Current". The UPSs must be connected to the

appropiate building ground.

Page 5

4

Primary Power Switch: Press and release the

ON/OFF button to turn the unit ON or OFF.

Normal Mode Icon: This icon will illuminate

when the utility power is within safe operating

range.

Battery Mode Icon: This icon will illuminate

when the Utility power is outside safe operating

range and the unit is operating in the battery

mode.

Bypass Mode Icon: This icon will illuminate

when the unit is in bypass mode and you do not

have battery backup protection.

Unit Fault Icon: The Fault icon illuminates when

the UPS has detected an internal fault. (see

section 5)

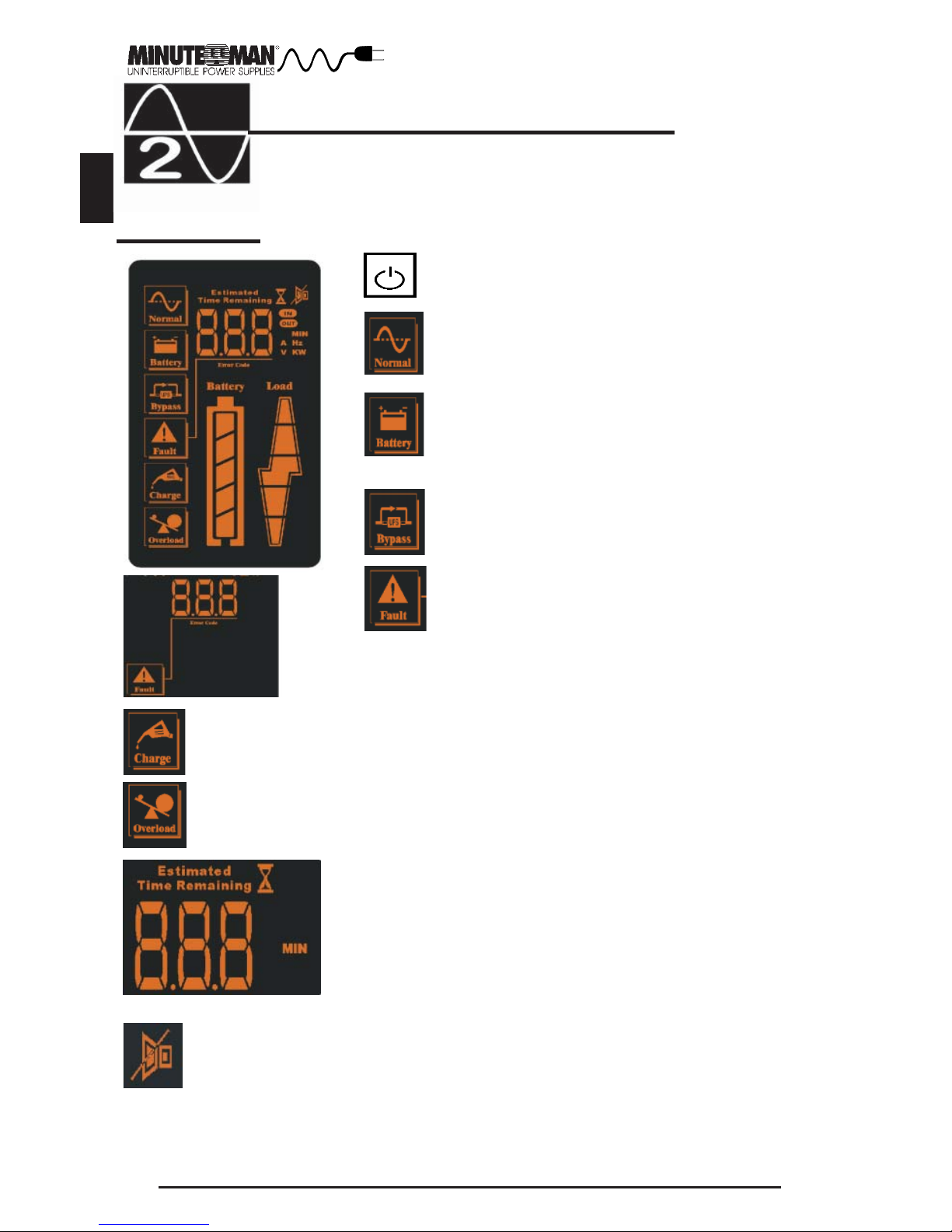

FRONT PANEL (LCD Units)

English

CONTROLS AND INDICATORS

Unit Fault Icon: This icon and error code will illuminate when

the self diagnostics are able to determine the problem.

Unit Charger Icon: This icon will illuminate when the unit is charging the batteries.

Unit Overload Icon: This icon will illuminate when the unit load has exceed the

rating of the UPS. The UPS will transfer to bypass mode if the overload is not

removed.

Estimated Time Remaining icons: These combination of LCD

icons will illuminate when selected and the UPS is operating

in the battery mode. The first time icon will appear as ">" if

the estimated time remaining is greater than ten (10) minutes.

This symbol will turn off when the estimated time remaining is

less than 10 minutes and the remaining time will appear in the

display.

Unit Audible Alarm Icon: This alarm will illuminate when audible alarm is

silenced.

Page 6

5

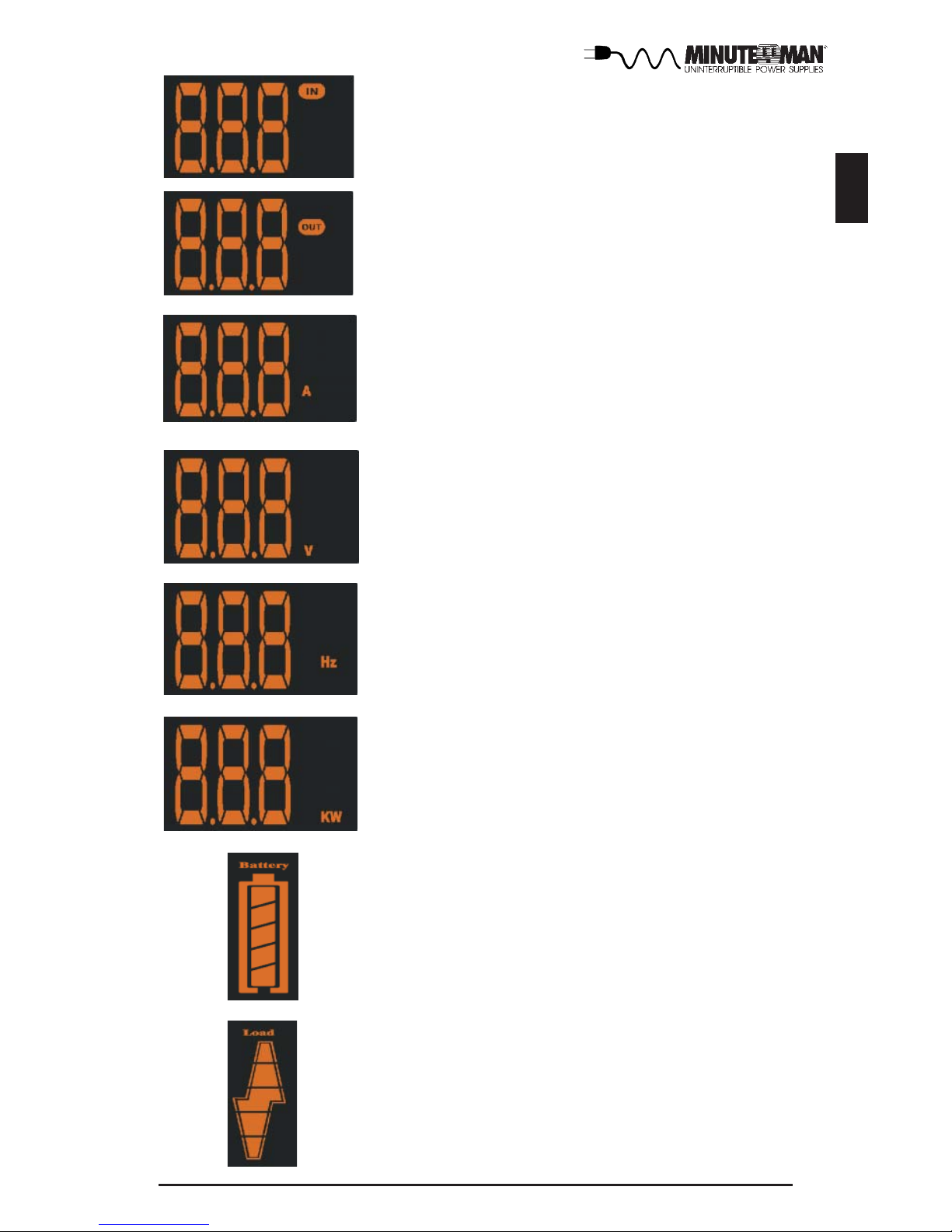

English

!

Unit Input Icon: When selected, this will display the selected

item for the input from utility.

Unit Output Icon: When selected, this will display the selected

item for the output from unit.

Unit Amperage Icon: When selected, this will display the amps

from either the input or output based on selection of input or

output as described previously.

Unit Voltage Icon: When selected, this will display the voltage

from either the input or output based on selection of input or

output as described previously.

Unit Frequency Icon: When selected, this will display the

frequency from either the input or output based on selection of

input or output as described previously.

Unit Load in Watts Icon: When selected, this will display the

load from either the input or output based on selection of input

or output as described previously.

Unit Battery Percentage Status Icon: When selected, this will

display the percentage of battery capability remaining.

Unit Load Percentage Status Icon: When selected, this will

display the percentage of load on the unit.

Page 7

6

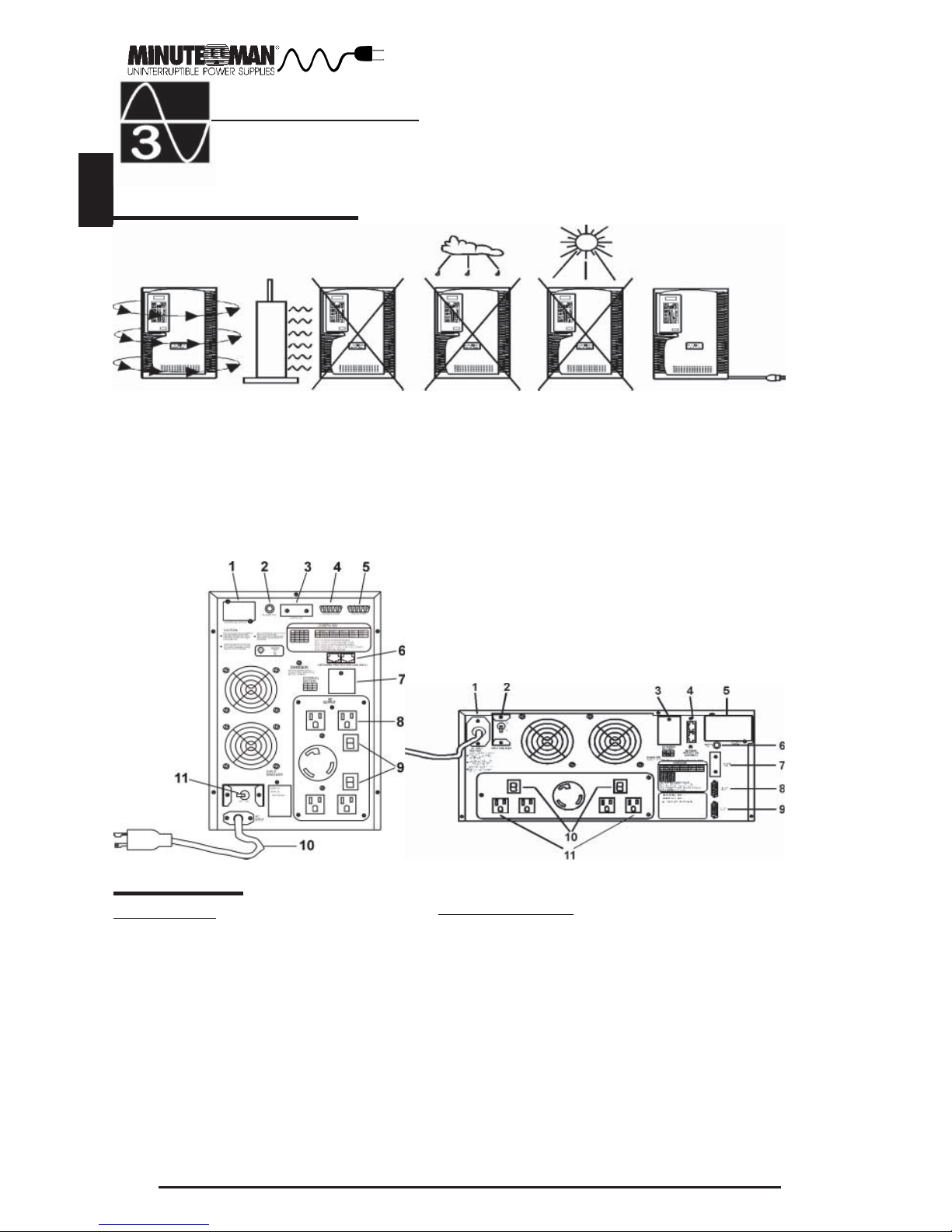

REAR PANEL (120V ac models shown)

INSTALLA TION PLACEMENT

Install the UPS in a temperature controlled environment that is free of conductive contaminants. Select a location which will provide good air circulation for the UPS at all times.

Avoid locations near heating devices, water or excessive humidity, or where the UPS is

exposed to direct sunlight. Route power cords so they cannot be walked on or damaged.

Operating Temperature: 700VA-5000VA: 0 to 40°C, 7000VA: 0 to 32°C

Storage Temperature: -15 to +45°C Operating Elevation: 0 to 3,000 Meters

Storage Elevation: 0 to 15,000 Meters Operating and Storage Relative Humdity: 95%,

non-condensing

Tower Models

1. Smart slot for optional cards

2. Switch, momentary switch used to

change displays or silence alarm

3. Dip switches used to configure unit

parameters

4. Simple Communications port (AS400)

5. RS232 intelligent communications port

6. Network protection (lan only)

7. External battery connection point

8. Output load receptacles

9. Output load circuit breakers

10. Incoming utility power cord

11. Incoming utility circuit breaker

Rackmount Models

1. Incoming utility power cord

2. Incoming utility circuit breaker

3. External battery connection point

4. Network protection (lan only)

5. Smart slot for optional cards

6. Switch, momentary switch used to change

displays or silence alarm

7. Dip switches used to configure unit

parameters

8. Simple Communications port (AS400)

9. RS232 intelligent communications port

10. Output load circuit breakers

11. Output load receptacles

English

INSTALLATION

Page 8

7

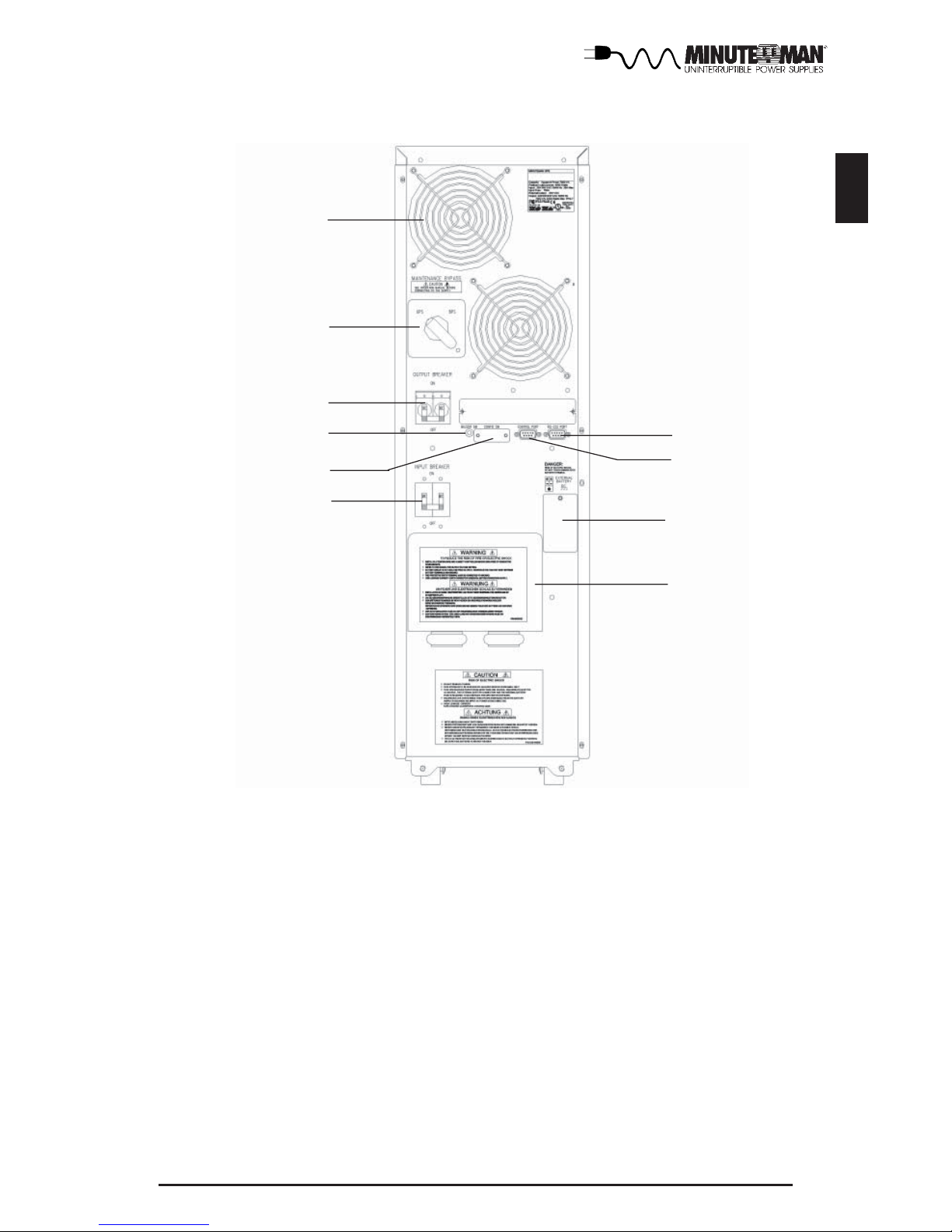

English

MCP 5000iE and MCP 7000iE

1. Fans: Internal Cooling Fans.

2. Maintenance Bypass Switch: In normal operation the switch must be in the UPS position.

When doing routine maintenance the switch must be in the BPS position.

3. Output Circuit Breakers: Turn OFF/ON the output of the UPS.

4. Alarm Silencer: Silences the Alarm in the Battery Mode.

5. Configuration Switches: Must be set before turning the UPS ON (see page 8).

6. Input Circuit Breakers: Turn OFF/ON the input of the UPS.

7. RS232 Port: Intelligent Communications Port.

8. Contact Closure Port: Simple Communications Port (AS400).

9. External Battery Pack Connector: Remove the panel for external Battery Pack Connection.

10. Access Panel for Input/Output Terminals: Remove the panel for Input/Ouptut Connections.

1

2

3

4

5

7

8

9

6

10

Page 9

8

MCP 5000iE and MCP 7000iE Input/Output/Battery Pack Connections

(Must be performed by Authorized Service Personnel ONLY)

Installation instructions for hardwiring the Input/Output Connections:

1. Crimp M6 ring terminals (part number R14-6 or equivalent) to the appropriate size input

and output cables (see page 9) using the appropiate Crimp tool (part number Crimpers RYO14 or equivalent).

Ring T erminal:

Size: M6 (or equivalent)

Part Number: R14-6 (or equivalent)

Manufacturer: Kai Suh Suh Enterprise Company., LTD (or equivalent)

Crimp tool:

Part number: Crimpers RYO-14 (or equivalent)

Manufacturer: Kai Suh Suh Enterprise Company., LTD (or equivalent)

2. Remove the access panel on the rear panel of the UPS.

3. Install the appropriate size strain relief into the input and output access holes.

4. Push the input cable through the strain relief nearest the input terminal block.

5. Connect L1 to the AC Input's "L" terminal, connect L2 to theAC Input's "N" terminal,

connect AC ground to the AC Input's ground terminal. Be sure that all the connections and

the strain relief are tightly secured.

6. Push the output cable through the strain relief nearest the output terminal block.

7. Connect L1 to the AC Output's "L" terminal, connect L2 to the AC Output's "N" terminal,

connect AC ground to the AC Output's ground terminal. Be sure that all the connections and

the strain relief are tightly secured.

8. Reinstall the access panel on the rear panel of the UPS.

9. Now the UPS is ready for the normal start-up procedure.

INST ALLATION

(Must be performed by Authorized Service Personnel ONLY)

Be sure to read the installation placement and all the cautions before installing the UPS. The

MCP-E series UPS has external Battery Pack capability, please observe the following

warning when connecting the Battery Pack(s). WARNING! DO NOT PLUG THE BATTER Y

P ACK'S CONNECTOR INTO THE UPS's BA TTERY CONNECTOR WHILE THE UPS IS TURNED

ON. NOTE: The red connectors/wires are the battery positive(+) and the black connectors/

wires are the battery negative(-) on all MINUTEMAN configurations.

English

Page 10

9

NOTE: The MCP 5000iE and 7000iE's AC input must be connected to an AC circut breaker

which will provide for an emergency power off. (Must be performed by Authorized

Service Personnel ONLY)

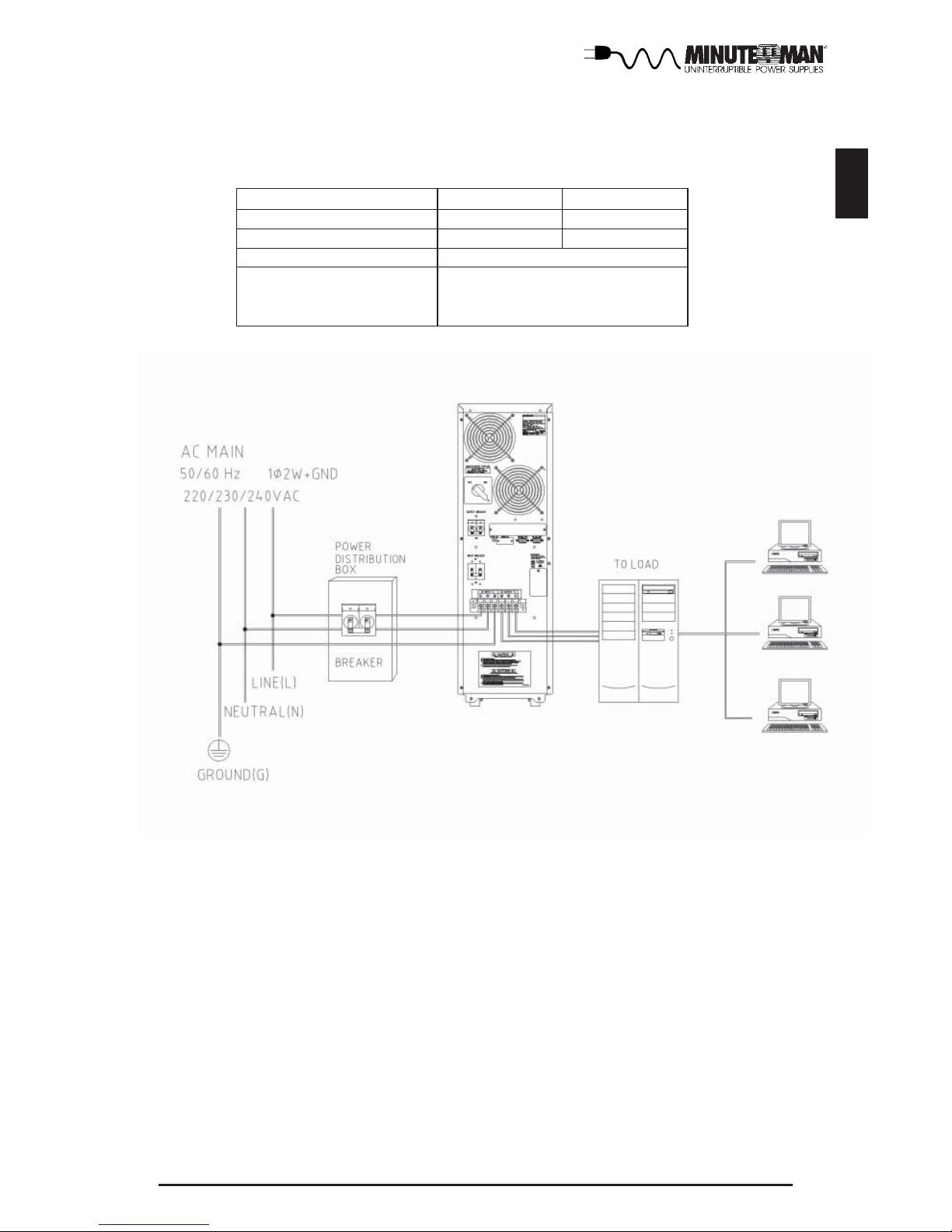

Model MCP 5000iE MCP7000iE

Input Circuit Breaker 40 Amp 50 Amp

Input Wire Size/Temp 8 AWG/min75°C 6 A WG/min75 °C

Wire Conductor Three conductor, copper wire only

Tightening torque for

pressure wire connectors

having screws

Block diagram of the MCP 5000iE and MCP 7000iE input and output wiring.

English

Torque 17.6Lbs (8kg)

Page 11

10

English

Installation of the mounting tray and the stablizing feet.

(Must be performed by Authorized Service Personnel ONL Y)

The MCP 5000iE and the MCP 7000iE must be installed into a stationary position due to the

hardwiring of the input and the output.

1. Move the UPS into the desired location.

2. Lay the mounting tray on the floor next to the UPS as shown below.

3. Roll the UPS onto the mounting tray .

4. Align the four screw holes on the mounting tray with the four screw holes on the bracket

at the front and rear of the UPS.

5. Install the four mounting tray retaining screws.

6. Install the four stablizing feet as shown below, two at the front and two at the rear.

7. Install the eight stablizing feet retaining screws as shown below.

8. The UPS is now ready for hardwiring the input and the output (See page 8).

Page 12

11

English

The Tower Model allows the user to install the UPS next to the tower computer. Use

CAUTION, the UPS is extremely heavy. Place the UPS in the final desired location and

complete the rest of the installation procedure. Now the UPS is ready for the normal start-up

procedure.

The Rackmount Configuration comes with mounting brackets for the standard 19"

(46.5cm) rack. The mounting brackets to fit a 23" (59.2cm) standard rack are also

available. The screws for mounting the UPS to the rack are not included (screw size

varies with rack size). The kit includes, two mounting brackets and four retaining screws.

Locate the mounting bracket screw holes on the side panels of the UPS, at the front of the

UPS. Align the mounting bracket with the mounting bracket screw holes. Attach the

mounting bracket with the retaining screws. WARNING: Use two or more people when

installing the UPS into the rack. Use caution, the UPS is extremely heavy. Do not move the

rack after the units have been installed. The rack may be unstable due to the weight

distribution. Now the UPS is ready for the normal start-up procedure.

The MCP-E Series UPS can be installed in two different configurations.

Page 13

12

CONNECTING TO AN AC SOURCE

Plug the UPS into a two pole, three wire, grounded receptacle only. Do not use extension

cords, adapter plugs, power strips or surge strips. The MCP 5000iE and MCP 7000iE must

be hardwired (see page 8).

COMPUTER INTERFACE CONNECTION (OPTIONAL)

MINUTEMAN Power Management software and interface cables kits can be used with the

MCP-E units. Use only MINUTEMAN or MINUTEMAN approved interface cables with these

UPS’s. Connect the interface cable to the 9 pin computer interface port on the rear of the

UPS. Secure the connector to the UPS via the screws on the connector housing. Connect

the other end of the cable to the device that will be monitoring/controlling the UPS.

NOTE: Connecting to the computer interface port is optional. The UPS works

properly without this connection.

Plug the equipment into the output receptacles on the back panel of the unit. Do not use

extension cords, adapter plugs, power strips or surge strips. The MCP 5000iE and the MCP

7000iE are hardwire output connections only, be sure the output breaker is in the ON

position. Insure that you do not exceed the maximum output rating of the UPS (refer to the

UPS's back panel or the Electrical Specifications in this manual).

CAUTION!

DO NOT CONNECT A LASER PRINTER TO THE BA TTERY BACKUP

RECEPT ACLES ON THE UPS UNLESS THE UPS IS RA TED 2000V A OR

GREA TER. A LASER PRINTER DRAWS SIGNIFICANTLY MORE POWER

WHEN PRINTING THAN A T IDLE, AND MA Y OVERLOAD THE UPS.

NETWORK SURGE PROTECTION CONNECTION (OPTIONAL)

Connect a 10 Base-T network line to the protection sockets on the rear of the UPS (not

available on all models). This connection will require another length of network cable. The

cable coming from the networked system is connected to the port marked “IN”. The “OUT

port is connected to the equipment to be protected.

NOTE: Connecting to the Network Surge Protection connection is optional. The

UPS works properly without this connection.

CONNECTING YOUR EQUIPMENT

English

MAINTENANCE BYP ASS SWITCH

(Must be performed by Authorized Service Personnel ONL Y)

The 5000/7000VA units have a Maintenance Bypass Switch on the rear panel. The

maintenance bypass switch is used to tranfer the utility AC power to the output load without

interrupting the protected equipment, so that general maintenance can be performed. Follow

the steps below to transfer the UPS to the Maintenance Bypass Mode:

1. Turn the Maintenance Bypass Switch to "BPS".

2. Push the ON/OFF button on the front panel.

3. Wait for approximately five minutes before performing any maintenance.

4. The UPS is now ready for general maintenance.

Follow the steps below to switch the UPS back to the Normal On-Line Mode:

1. Push the ON/OFF button on the front panel.

2. Wait for approximately one minute for the inverter to start.

3. Turn the Maintenance Bypass Switch to "UPS".

4. The UPS is now operating in the Normal On-Line Mode.

Page 14

13

TURNING THE UNIT ON/OFF

The UPS is shipped with the unit disabled. Turn dip switch #1 to the ON position before

attempting to turn on the unit. This will enable the unit. Set all of the dipswitches per the

desired setting for your environment prior to turning on the unit.

Turning ON/OFF the 700/1000VA

To turn ON the 700/1000VA. Plug the input power cord into the AC wall outlet. Push and

hold the ON/OFF button (on the front panel) for one beep, then release the button.

To turn OFF the 700/1000VA. Push and hold the ON/OFF button (on the front panel) for one

beep, then release the button. Unplug the input power cord from the AC wall outlet.

Turning ON/OFF the 2000/3000VA

To turn ON the 2000/3000VA. Plug the input power cord into the AC wall outlet. Put the

input circuit breaker (on the rear panel) in the ON position. Push the ON/OFF button on the

front panel.

To turn OFF the 2000/3000VA. Push the ON/OFF button on the front panel. Put the input

circuit breaker (on the rear panel) in the OFF position. Unplug the input power cord from the

AC wall outlet.

Turning ON/OFF the 5000/7000VA

To turn ON the 5000/7000VA. Hardwire the input and the output (see page 8). Put the

circuit breaker at the wall breaker panel to the ON position. Put the input circuit breaker (on

the rear panel) in the ON position. Push the ON/OFF button on the front panel. Put the output

circuit breaker (on the rear panel) in the ON position.

To turn OFF the 5000/7000VA. Put the output circuit breaker (on the rear panel) in the OFF

position. Push the ON/OFF button on the front panel. Put the input circuit breaker (on the

rear panel) in the OFF position. Put the circuit breaker at the wall breaker panel to the OFF

position.

NOTE: Do not turn the UPS OFF and then ON again very rapidly. Once the UPS has been

turned OFF, wait for approximately two minutes before turning the UPS ON again.

Configuration Switches for the MCP 700/1000. The "System Enable" switch must be

enabled for the UPS to operate.

English

OPERATION

Page 15

14

EnglishEnglish

Configuration Switches for the MCP 2000/3000/5000/7000. The "System Enable" switch

must be enabled for the UPS to operate.

MCP 2000 and MCP 3000. RS232 Port, Control Port pinouts and Confirguation Switches.

Page 16

15

English

English

Press and release the main power switch on the front of the unit to turn

on the unit. Press and release again to turn off the unit. Some models

have a circuit breaker on the rear panel that must be turned ON first and

then press the front panel switch to turn the unit ON.

The unit will turn on, perform a self diagnostic test, switch to bypass

mode and then turn on to full inverter mode automatically.

Place your unit in the desired location for use. Connect all equipment power cords to the

receptacles on the rear of the UPS. Please insure you confirm total power requirements

and do not overload the units.

ALARMS

ON BATTERY

When the UPS is operating in the battery mode, the Battery Mode Icon will illuminate and the

audible alarm will sound every 10 seconds. The alarm will stop and the Battery Mode Icon

will extinquish once the UPS returns to AC normal operation.

UPS FAULT

When the UPS detects a fault, the Unit Fault Icon will illuminate and the UPS will emit a

sustained tone. The unit will also display a failure code if available. (see section 5 Troubleshooting for failure code definition)

OVERLOAD

When the amount of load attached to the UPS exceeds its power rating, the Unit Overload

Icon will illuminate and the UPS will emit a sustained tone. This alarm will remain on until the

excess load is removed or the UPS’s self protection circuit takes control. If the unit self

protection circuit takes control, the unit will switch to bypass mode until the overload is

removed. If the load is excessive, the input circuit breaker will open and the unit will shut

down.

REPLACE BATTERY

The UPS automatically tests the battery’s condition and will illuminate the Unit Battery Icon

and emit a short beep. This tone will be repeated every hour until the batteries passes a

self test. It is recommended that the UPS be allowed to charge overnight before performing

a battery test to confirm a Weak/Bad Battery condition.

LOW BATTERY WARNING

The UPS will emit two consecutive beeps every five seconds when the battery reserve

runs low. This continues until AC returns or the UPS shuts down from battery exhaustion.

COMMUNICATIONS PORT

Communications port information for 700VA and 1000VA units only:

The communications port is a standard DB9 female with both RS232 and relay contact

closure capability. The units will poll the port and activate the port for RS232 or contact

closure in accordance with the type of cable it finds connected to the port. To change the

port configuration requires the unit be turned off and restarted with the desired cable

connected. The pinout for the port is depicted per the chart below.

Pin 1: Instant off ( pull and hold this pin low to turn off output receptacles)

Pin 2: /TXD

Pin 3: /RXD and receive ups shutdown command

Pin 4: AC fail, NO closes on event

Pin 5 : Ground

Pin 6: Low battery warning, NO closes on event

Pin 7: Common return for all relays

Pin 8: Summary alarm, NO closes on AC fail, low battery warning, overload, UPS failure

or unit on bypass

Pin 9: Not Used

Page 17

16

Communications port information for 2KVA, 3KVA, 5KVA and 7KVA units only:

These units contain two independent communications ports. Port one is for standard RS232

communications and labeled RS-232 Port. The second port is relay contact closure

configured for standard AS 400 ports. This port is labeled Control Port.

The pinout for the RS-232 port is depicted per the chart below. Note: when using the SNMP

option card, this port will be disconnected. Both the slot and the port may not be used at the

same time.

Communication settings: When using the RS232 port, the following settings should be used.

Baud Rate: 2400

Data Bits: 8

Stop Bits: None

Parity: 1

Pin 1: Not Used

Pin 2: /TXD Transmit Data

Pin 3: /RXD Receive Data and Commands

Pin 4: Not Used

Pin 5 : Ground

Pin 6: Not Used

Pin 7: Not Used

Pin 8: Not Used

Pin 9: Not Used

The pinout for the Control port is depicted per the chart below.

Pin 1: UPS failure (fault)

Pin 2: Summary alarm (normally open, closes on event)

Pin 3: Common for pin 4

Pin 4: EPO or shutdown

Pin 5: Common ground for all relays.

Pin 6: Bypass active=make/ ups on=open

Pin 7: Battery low (normally open, closes on event)

Pin 8: UPS on=make/ bypass active=open

Pin 9: AC fail (normally open, closes on event)

Your UPS unit is shipped standard with SentryII monitoring software. This software may be

used for monitoring the UPS and power when loaded into your computer and connected via

the supplied software communication cable. This software is a detailed tool to help you

manage your power needs.

This software will also support a simpler style of controlled shutdown for the consumer that

is not interested in detail, but is still interested in a controlled unattended shutdown. The

simple software function requires the purchase and installation of a separate cable that is

not provided with the unit. Please contact your local vendor or Minuteman Technical support

department at 800-238-7272 or 972-446-7363 should you need to purchase this software

cable.

English

Page 18

17

Possible Cause

Symptom What To Do

TROUBLESHOOTING

E10 is displayed after

turning on unit

Configuration dip switch is in

the off position

Turn Dip Switch #1 to on position

as defined on page 13

When turned on, the

unit operates in battery

mode only

No AC utility power present

and unit Cold start function is

enabled

Check utility input power and

contact local service company if

required to correct utility problem

The unit switches from

normal to battery mode

frequently

The fluctuation of the input utility

voltage or frequency is beyond

the preset guidelines

Check the input utility condition.

Adjust Sync Range to 3Hz.

Contact loacal service personnel if

utility remains bad

The unit switches to

bypass mode

occasionally and then

switches back

The unit may be overloaded

periodically by a random load

increase

Verify if the load may be affected

by a printer or excessive loading

such as numerous phones etc.

remove excessive load to eliminate

Diagnostic codes for 700VA and 1KVA

The 700VA and 1000VA units use LED displays to notify the User of an error detected by

the internal diagnostics system. The letter "E" is assumed and is not displayed on the LED

graph. The top row of LED's indicate the first number of the "diagnostic error" code. As an

example: if the third LED is illuminated, the first character of the "diagnostic error" code is 3.

The second row of LED's indicates the second number in the diagnostic error code. As an

example: if the second LED is illuminated, the second character of the "diagnostic error"

code is 2. These examples would provide an diagnostic error message of E32 with the "E"

assumed for all error codes. A sample of E32 is shown below for your reference.

LOAD

BATTERY

"EXAMPLE OF DIAGNOSTIC ERROR CODE E32"

English

Page 19

18

Code Definition

E01 System off resulting from Microprocessor checksum error.

E03 Battery voltage is below safe operating range (AC mode).

E04 Battery voltage has exceeded safe operating range (AC mode).

E05 Thermal sensor is dead or unit exceeds safe temperature.

E10 Configuration dip switch is in the off position.

E13 Input/Output voltage difference is out of 6V specification (AC tracking mode).

E22 +DC bus voltage is out of the range of +15% to -10%.

E23 -DC bus voltage is out of the range of +15% to -10%.

E24 Phase unlocks between input and output.

E32 Power is over 100% for 60 seconds.

E32 Power is over 125% for 10 seconds.

E32 Power is over 150%.

E32 Power is over 300%

E32 RMS current is over 100% for 60 seconds.

E32 RMS current is over 125% for 10 seconds.

E32 RMS current is over 150% for 3 seconds

E32 RMS current is over 300%

E32 Power is over 100% or RMS current is over 100% for 5 seconds (DC mode).

E32 Power is over 125% (DC mode).

E40 Temperature is out of range.

E52 Output senses a short circuit.

E53 Battery test error (battery may be bad or needs charge time).

E55 Input voltage is over 150Vrms for 120vac units.

Diagnostic codes not listed are used by Engineering staff for programming purposes.

If your unit should have a problem, please call our Technical Support department to resolve

any issues. Please call, 800-238-7272 or 972-446-7363 and ask for Technical Support.

When you call with a problem, please be prepared to provide the following information to the

technician.

Model number: example: MCP 3000 E

Model Part number: example: 900xxxxx (8-15 characters-always starts with 900)

Model Serial number: example: FC87011200001 (13 characters)

Length in Service: example 25 months

Diagnostic code at time of problem: example: E32

Time of day during failure: example: 4:15 am

Weather conditions during failure: example: clear skies, no power problems.

OurTechnical Support department is open from 8am -5pm Central standard time USA Monday

- Friday. Please feel free to consult our Power Forum on our website for assistance at

www.minutemanups.com

English

Page 20

19

Diagnostic Error Codes for 2KVA, 3KVA, 5KVA, 7KVA units

Error Description

E00 System ROM checksum error.

E01 System RAM data read/write error.

E02 System EEPROM data read/write error.

E0 3 Communication fail between CPU & DSP

E05 Temperature over 100oC.

E07 Battery voltage is over specification (AC mode).

E08 Input voltage fail (Outside of safe operating range & cold start disable).

E10 Configure SW1 is set position “OFF”.

E11 AC Mode input out of range during normal startup.

E12 Battery voltage out of range during cold start.

E14 DC bus voltage out of range during cold start.

E15 Output/input voltage difference out of 3.125% (AC tracking mode).

E16 Output/setting voltage difference out of 3.125% (DC mode).

E17 Input frequency fail (Out of 45 ~ 65 Hz) & cold start disable.

E22 DC bus voltage out of range -85% or +12%

E23 Difference between DC bus is more then 70Vdc.

E25 Input / Output frequency difference out of 1Hz during AC mode normal

E26 Battery voltage low (2K-57V, 3K-76V, 5K-190V, 7K-228V) out of range (DC mode)

E32 RMS current over 100%

E33 Voltage difference more than 10% between setting and output

E40 Temperature over 80oC.

E42 Thermal sensor dead.

E53 Battery test error.(battery may be bad)

E54 Line-Neutral connection error.

E60 Transfer fail during AC Bypass to AC Mode

E63 Transfer fail during Battery Mode to normal AC mode.

E67 DC bypass to Battery mode time out in soft start.

E68 AC bypass to Normal mode time out in soft start.

E69 In/out Sync lasts too long.

E78 DIP Switch setting error(output voltage setting).

E80 DSP initial state data transfer error (clear 0ffh).

E81 No response when send data to DSP.

E82 DSP initial state data transfer error (55,aa,version).

E83 Data lost (every cycle received data less than 20 and more than 60 times).

E84 Input voltage break at bypass mode.

English

Page 21

20

REPLACING THE BA TTER Y

(Must be performed by Authorized Service Personnel ONLY)

The Tower Series UPS has a replacable battery(s), however the unit must be turned off,

disconnected from utility and discharged prior to changing the batteries. The Rack Mount

Series UPS has a hot swappable battery kit. Please read the following warning statements

before attempting to service the battery(s).

NOTE: If there is a power interruption while replacing the hot-swappable batteries, with

the UPS on, the load will not be backed up.

WARNING!

This Uninterruptible Power Source contains potentially hazardous voltages.

Do not attempt to disassemble the unit. This UPS contains no user

serviceable parts. Repairs and Battery replacement must be performed by

Authorized Service Personnel ONLY.

CAUTION:

CAUTION:

Do not dispose of batteries in a fire. The batteries May explode.

The batteries in this UPS are recyclable. Dispose of the batteries properly.

The batteries contain lead and pose a hazard to the environment and

human health if not disposed of properly. Refer to local codes for proper

disposal requirements or return the battery to Minuteman.

MCP-E SERIES

Model #

MCP 700(i) E

MCP 1000(i) E

MCP 2000(i) E

MCP 3000(i) E

MCP 5000i E

MCP 7000i E

Battery

Type

12V7.2AH

12V7.2AH

12V7.2AH

12V7.2AH

12V7.2AH

12V7.2AH

REPLACING THE BATTERY

English

Do not open or multlate batteries. Released electrolyte is harmful to the

skin and eyes and may be toxic.

WARNING!:

Battery

Quantity

3 each

3 each

6 each

8 each

20 each

24 each

Page 22

21

CAUTION:

System voltages range from 24 VDC to 288 VDC. A battery can present a

risk of electrical shock and high short circuit current. The following

precautions should be observed when working on batteries:

1. Remove watches, rings, or other metal objects.

2. Use hand tools with insulated handles.

3. Wear rubber gloves and boots.

4. Do not lay tools or other metal parts on top of batteries.

5. Disconnect charging source prior to connecting or disconnecting battery

terminals.

6. Determine if the battery is inadvertently grounded. If inadvertently

grounded, remove source of the ground. Contact with any part of a

grounded battery can result in electrical shock. The likelihood of such

shock will be reduced if such grounds are removed during installation

and maintenance.

Replace batteries with the same number and type as originally installed in

the UPS. These batteries have pressure operated vents. When replacing

the batteries, replace with the same number:

Manufacturer Model Number

CSB GP/FR 12070 F2

YUSA NP7-12\250

PANASONIC LCR 12V 7.2S1

HIT ACHI HV7-12 F2

These batteries are used in both the UPS and external Battery Packs.

CAUTION:

English

English

Page 23

22

Battery Replacement Procedure for Tower Model

(Must be performed by Authorized Service Personnel ONLY)

PLEASE READ THE CAUTIONS BEFORE A TTEMPTING TO REPLACE THE BA TTERIES

These units are not hot-swappable. Hot-swappable batteries means that the batteries can

be replaced without powering down the whole UPS system.

1. Turn off the equipment that is plugged into the output receptacles of the UPS.

2. Turn off the UPS using the primary power switch on the front.

3. Turn off the AC circuit breaker on the rear panel of the UPS (if applicable).

4. Unplug the UPS's AC power cord from the AC outlet.

5. Unplug the equipment from the output receptacles of the UPS.

6. Remove the cover of the UPS.

7. Disconnect the battery positive (red) wire and the all of the battery jumper wires.

8. Disconnect the battery negative (black) wire.

9. Remove the top four retaining screws and the top battery retaining bracket.

English

10. Remove the top row of the batteries.

11. Remove the bottom four retaining screws and the bottom battery retaining bracket.

12. Remove the bottom row of the batteries.

13. Install the bottom row of new batteries.

14. Reinstall the bottom battery retaining bracket and the retaining screws.

15. Install the top row of new batteries.

16. Reinstall the top battery retaining bracket and the retaining screws.

17. Reconnect the battery negative (black) wire and the battery jumper wires. Verify proper

polarity, negative (black) wire to the battery negative terminal and the battery jumper wires

are connected properly.

18. Reconnect the battery positive (red) wire to the battery positive terminal. Some

sparking may occur, this is normal.

19. Reinstall the cover on the UPS.

20. Dispose of the batteries properly at an appropriate recycling facility or return them to the

supplier in the packing material for the new batteries. Follow local EPA guidelines when

disposing of batteries. Note: These batteries contain lead and must be disposed of per

environmental guidelines.

21. The UPS is now ready for the normal start-up procedure.

Step 7 Step 9

Step 8

Page 24

23

Battery Replacement Procedure for Rack Mount Models

(Must be performed by Authorized Service Personnel ONLY)

PLEASE READ THE CAUTIONS BEFORE A TTEMPTING TO REPLACE THE BA TTERIES

These units are hot-swappable. Hot-swappable batteries means that the batteries can be

replaced without powering down the whole UPS system. NOTE: If there is a power

interruption while replacing the hot-swappable batteries, with the UPS on, the load will not

be backed up.

1. Utitlize steps 1-5 from page 22 if you do not want to hot-swap. Then proceed.

2. Remove the three retaining screws from front panel of the UPS.

3. Remove the six retaining screws and the battery case retaining bracket.

4. Disconnect the battery wiring harness connector.

5. Remove the battery case.

6. Insert the new battery case.

7.Connect the battery harness connnector.

8. Reinstall the battery case retaining bracket and the retaining screws.

9. Reinstall the front panel and the retaining screws.

10. Dispose of the batteries properly at an appropriate recycling facility or return them to the

supplier in the packing material for the new batteries. Follow local EPA guidelines when

disposing of batteries. Note: These batteries contain lead and must be disposed of per

environmental guidelines.

11. The UPS is now ready for the normal start-up procedure if required.

English

Page 25

24

OBTAINING SERVICE

IF THE UPS REQUIRES SERVICE

1.Use the TROUBLESHOOTING section to eliminate obvious causes.

2.Verify there are no circuit breakers tripped. A tripped circuit breaker is the most common

problem.

3.Call your dealer for assistance. If you cannot reach your dealer, or if they cannot resolve

the problem call or fax MINUTEMAN Technical Support at the following numbers; Voice phone

(972) 446-7363 or 800-238-7272, FAX line (972) 446-9011 or visit our Web site at

www.minutemanups.com the "Discussion Board". Please have the following information

available BEFORE calling the Technical Support Department.

A . Your Name and address.

B. Where and when the unit was purchased.

C. Model number: example: MCP 3000 E

D. Model Part number: example: 900xxxxx (8-15 characters-always starts with 900)

E. Model Serial number: example: FC87011200001 (13 characters)

F. Length in Service: example 25 months

G. Diagnostic code at time of problem: example: E32

H. Time of day during failure: example: 4:15 am

I. Weather conditions during failure: example: clear skies, no power problems.

J. A description of the protected equipment, including model numbers if possible.

K. A technician will ask you for the above information and if possible, help solve your

problem over the phone. In the event that the unit requires factory service, the

technician will issue you a Return Material Authorization Number (RMA #).

L. If the UPS is under warranty, the repairs will be done at no charge. If not, there will be

a charge for repair.

4. Pack the UPS in its original packaging. If the original packaging is no longer available, ask

the Technical Support Technician to send a new set. It is important to properly pack the UPS

to avoid damage in transit. Never use Styrofoam (popcorn) beads for a packing material.

A. Include a letter with your name, address, day time phone number, RMA number, a

copy of your original sales receipt and a brief description of the problem.

5. Mark the RMA # on the outside of all packages. The shipping department cannot accept

any package without the RMA # marked on the outside.

6. Return the UPS by insured, prepaid carrier to:

MINUTEMAN UPS

Para Systems Inc.

1455 LeMay Drive

Carrollton, Tx. 75007

A TTN: Rma # _______

English

Page 26

25

SPECIFICATIONS

NOTE: 230Vac Specs Shown In ( )

500W

700W 2100W

3500W

4900W

36VDC 7.2Ah 288VDC 7.2Ah72VDC 7.2Ah

1400W

96VDC 7.2Ah 240VDC 7.2Ah

100,110,1 15,120 vac (220,230,240 vac)

50 or 60 Hz +/- 1% unless syncronized to line

True Sine Wave

0 ms

Spill proof, maintenance free, sealed lead-acid

10 minutes full load, 28 minutes half load 7-9 full load, 18-25 half load

T opology

Case Type

Agency Approvals

Warranty

Equipment Protection Policy

Input (Non-Battery Operation)

Double Conversion On-Line

T ower and Rack Mount V ersions Available

T ower Version Only

UL, cUL, TUV , CE, EMC, FCC class A

3 year

$40,000 Domestic USA, Canada and Alaska only

Voltage Range

Input Apparent Power Rating

Realized Power Output Limit

Frequency Range

Output (Non-Battery Operation)

Output voltage

Frequency

Surge energy rating (one time, 10/1000 us waveform)

Output (Battery Operation)

Voltage

Voltage Regulation

Frequency

Waveform

Typical Transfer Time

Battery System

Battery Type

Battery system by unit

Typical battery runtimes (internal battery)

700VA 1000VA 2000VA

3000VA 5000VA

7000VA

45 to 65 auto frequency (user defined for start on battery)

100,110,1 15,120 vac (220,230,240 vac)

220,230,240 only

50 / 60 Hz +/-5 Hz.

450Joules

220,230,240

+/- 2% until low battery warning

External Battery Packs available

Y es, available on all models of both T ower and Rack Mount versions

80-138 vac (160-274) 84-138 vac (160-274) 170-274 vac

Typical Full load/Half load Runtimes w/ optional Batteries

T ower unit w/ one external battery

T ower unit w/ two external battery

T ower unit w/ three external battery

T ower unit w/ four external battery

T ower unit w/ five external battery

Rack Mount unit w/ one external battery

Rack Mount unit w/ two external battery

Rack Mount unit w/ three external battery

Rack Mount unit w/ four external battery

Rack Mount unit w/ five external battery

54 / 137

91 / 228

155 / 366

200 / 471

266 / 625

33 / 85

55 / 141

101 / 233

130 / 299

175 / 396

54 / 137

91 / 228

155 / 366

200 / 471

266 / 625

33 / 85

55 / 141

101 / 233

130 / 299

175 / 396

44 / 115

101 / 237

159 / 367

220 / 505

271 / 650

33 / 86

72 / 169

111 / 257

152 / 350

186 / 447

38 / 99

87 / 209

138 / 323

191 / 541

245 / 581

29 / 74

62 / 149

97 / 226

132 / 305

168 / 399

50 / 132

84 / 223

145 / 349

283 / 487

248 / 613

N/A

N/A

N/A

N/A

N/A

41 / 102

85 / 213

120 / 277

168 / 390

206 / 490

N/A

N/A

N/A

N/A

N/A

MCP 700 E MCP 1000 E MCP 2000 E MCP 3000 E MCP 5000 E MCP 7000 E

Mechanical

T ower Model Dimensions net (L x W x H) 405 x 145 x 222mm

T ower Model Dimensions net (L x W x H) 15.9 4 x 5.7 1 x 8. 74i n

448 x 216 x 365mm

17.64 x8.5 x 14.37in

616 x 216 x 678mm

24.25 x 8.5 x 26.69in

T ower Shipping Dimensions (L x W x H)

T ower Shipping Dimensions (L x W x H)

516 x 266 x 343mm

20.31 x10.47 x 13.5in

573 x 333 x 510mm

22.6 x 13.1 x 20.1in

830 x 380 x 927mm

32.7 x 15 x 36.5in

T ower Net Weight Kg (lb)

T ower Shipping Weight Kg (lb)

15.3Kg 33.7lb

17.1Kg 38lb

33Kg 72.9lb

35.9Kg 79lb

39.3Kg 86.6lb

42.1Kg 93lb

93Kg 205lb

106Kg 234lb

106Kg 234lb

1 18Kg 261lb

Rack Mount Dimensions net (L x W x H)

Rack Mount Dimensions net (L x W x H)

438 x 425 x 88mm

17.24 x 16.73 x 3.46in

510 x 425 x 177mm

20 x 16.73 x 6.97in

N/A

N/A

Rack Mount Shipping Dims (L x W x H)

Rack Mount Shipping Dims (L x W x H)

Rack Mount Net Weight Kg (lb)

Rack Mount Shipping Weight Kg (lb)

18.93Kg 41.7lb 39Kg 86lb 44.5Kg 98.1lb

N/A

N/A

N/A

N/A

Standard Input Plug Type

Standard Output Receptacle Type (220vac)

5-15P

4-5-15R

(IEC320)

5-20P

4-5-15/20R

(IEC320)

Hardwire Input and Output

Hardwire Input and Output

English

547 x 547 x 225mm

21.5 x 21.5 x 8.9in

21.53Kg 48lb

776 x 596 x 335mm

30.6 x 23.5 x 13.2in

44.4Kg 86lb 50.5Kg 112lb

240Joules

310Joules

L5-30P

4-5-15R&1-

L5-30R (IEC320)

Page 27

26

(These items may require optional software or hardware)

FUNCTION FACTORY DEFAULT DESCRIPTIONUSER CHOICES

EnglishEnglish

CONFIGURABLE PARAMETERS

AND SETTINGS

UPS ID MCP-E SERIES Up to 64 characters to

define the UPS

Use this function to uniquely identify the

UPS in your network configuration

Battery installation date Date of Manufacture Date of Battery Replacement-

day/month/year (xx/xx/xxxx)

Enter the current date when

replacing the batteries

Battery life in days Preset for 1826 days Enter up to 5 characters When replacing the batteries,

calculate the actual number of days in

use after manufacture date and then

enter this expected life for your

environment

Auto Restart:

Enable/Disable

Enabled User may Enable or

Disable Autorestart

When "enabled" , the UPS will

automatically restart and operate in

normal AC mode after a low battery

shutdown and normal AC has returned

Set audible

alarm state

Enabled User may Enable or Disable

until Low Battery Warning

Enabled: The UPS will emit an

audible alarm every 10 seconds

when in the battery mode.

Disabled until Low Battery Warning:

Used when software is controlling the

UPS or to silence the alarm. In

this state, the UPS will not emit

an audible alarm until the unit

reaches low battery warning level.

Enable or Disable all

UPS functions

Disabled User is required to enable prior

to operation. The UPS will not

operate until enabled.

This is a safety feature to prevent

operation while packaged during

shipping.

Set Inverter Output

Voltage

120 vac on 120 volt units.

230 vac on 230 volt units.

120 volt units: 100,110,1 15,120

230 volt units: 220,230,240

Allows the customer to set the voltage

based on the environment in which the

unit will be installed. This voltage is

set via external dip switch. The dip

switch is on the rear panel of the unit.

Page 28

27

Customized Output Receptacle Panels

The MCP-E series UPS has a replacable receptacle panel. The receptacle panel can be

configured with multiple choices of receptacles. This will allow the user to customize the

output receptacles for their specific applications. MINUTEMAN will only use UL or CE

approved receptacles. To customize your MINUTEMAN UPS for your specific application,

contact your local distributor or contact MINUTEMAN at 972-446-7363, 800-238-7272 or

fax 972-446-9011 to find out which opitions are available. Come visit our web site at

www.minutemanups.com to find out about all the Power Protection products available

from MINUTEMAN.

English

The 700VA and 1000VA units may have the following optional panels:

One panel with two (2) duplex receptacles of any size.

One panel with one (1) twistlock receptacle of 20 or 30 amps.

The 2000VA and 3000VA units may have the following option panels:

One panel with one (1) duplex & one (1) twistlock receptacle of any size up to 30 amps.

MINUTEMAN reserves the right to make changes without notice.

Sample of Replacable and Configuarable

panel on 2000VA and 3000VA

Page 29

28

LIMITED PRODUCT WARRANTY

Para Systems Inc. (Para Systems) warrants this equipment, when properly applied

and operated within specified conditions, against faulty materials or workmanship for a

period of three years from the date of purchase. For equipment sites within the United

States and Canada, this warranty covers repair or replacement of defective equipment at

the discretion of Para Systems. Repair will be from the nearest authorized service center.

Replacement parts and warranty labor will be borne by Para Systems. For equipment

located outside of the United States and Canada, Para Systems only covers faulty parts.

Para Systems products repaired or replaced pursuant to this warranty shall be warranted

for the unexpired portion of the warranty applying to the original product. This warranty

applies only to the original purchaser who must have properly registered the product within

10 days of purchase.

The warranty shall be void if (a) the equipment is damaged by the customer, is

improperly used, is subjected to an adverse operating environment, or is operated outside

the limits of its electrical specifications; (b) the equipment is repaired or modified by anyone

other than Para Systems or Para Systems-approved personnel; or (c) has been used in a

manner contrary to the product’s operating manual or other written instructions.

Any technical advice furnished before or after delivery in regard to use or application

of Para Systems’s equipment is furnished without charge and on the basis that it represents

Para Systems’s best judgment under the circumstances, but it is used at the recipient’s sole

risk.

EXCEPT AS PROVIDED HEREIN, PARA SYSTEMS MAKES NO WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING WARRANTIES OF MERCHANT ABILITY AND FITNESS FOR

A P ARTICULAR PURPOSE. Some states do not permit limitation of implied warranties;

therefore, the aforesaid limitation(s) may not apply to the purchaser.

EXCEPT AS PROVIDED ABOVE, IN NO EVENT WILL P ARA SYSTEMS BE LIABLE FOR

DIRECT , INDIRECT , SPECIAL, INCIDENT AL, OR CONSEQUENTIAL DAMAGES ARISING OUT OF

THE USE OF THIS PRODUCT , EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGE.

Specifically, Para Systems is not liable for any costs, such as lost profits or revenue, loss of

equipment, loss of use of equipment, loss of software, loss of data, cost of substitutes,

claims by third parties, or otherwise. The sole and exclusive remedy for breach of any

warranty, expressed or implied, concerning Para Systems’s products and the only obligation

of Para Systems hereunder, shall be the repair or replacement of defective equipment,

components, or parts; or, at Para Systems’s option, refund of the purchase price or

substitution with an equivalent replacement product. This warranty gives you specific legal

rights and you may also have other rights which vary from state to state.

Longer term and F.O.B. job site warranties are available at extra cost. Contact Para

Systems (1-972-446-7363, 800-238-7272 or fax 972-446-7363) for details.

EnglishEnglish

LIMITED PRODUCT WARRANTY

Page 30

29

English

DECLARA TION OF CONFORMITY

Application of Council Directive(s): 89/336/EEC, 7/23/EEC

Standard(s) to which Conformity is declared: EN50091-1, EN50091-2,

EN60555-2, EN61000-3

Manufacturer’s Name: Para Systems, Inc. (MINUTEMAN UPS)

Manufacturer’s Address:1455 LeMay Drive

Carrollton, T exas 75007 USA

T ype of Equipment: Uninterruptible Power Supplies

Model No: MCP 700 E (Y), MCP 1000 E (Y), MCP 2000 E (Y), MCP 3000 E

(Y), MCP 5000 E (Y), MCP 7000 E (Y), MCP 700RM E (Y), MCP 1000RM E

(Y), MCP 2000RM E (Y), MCP3000RM E (Y)

Y ear of Manufacture: Beginning October 15, 2001

I, the undersigned, hereby declare that the equipment specified above

conforms to the above Directive(s).

Date: October 15, 2001

Robert Calhoun

(Signature)

Place: Carrollton, Tx. USA Manager Engineering

(Title)

Page 31

32

Notes:

EnglishEnglish

30

Page 32

Para Systems, Inc.

1455 Lemay Dr .

Carrollton, TX 75007

Phone: 972-446-7363

800-238-7272

Fax: 972-446-9011

Quickfax: 800-263-3933

Internet: minutemanups.com

PN:34000203 Rev 0

Loading...

Loading...