Page 1

747 Wide Area

Model:

Carpet Vacuum

OPERATION

SERVICE PARTS

MC827968 (Canada)

MC827969 115V

MC828237 230V

CARE

Revised 6/02

Page 2

FOR COMMERCIAL USE ONLY

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic precautions should always be followed, including the

following:

READ ALL INSTRUCTIONS BEFORE USING

WARNING - To reduce the risk of fire, electric shock or injury:

• Do not leave appliance plugged in. Unplug from outlet when not in use and before servicing.

WARNING

To avoid electric shock, use indoors only.

• Never allow children or untrained adults to operate this equipment.

• Keep the area of operation clear of all persons, particularly small children, and pets. Keep

bystanders at least 25 feet away from the area of operation.

• Use only as described in this manual. Use only manufacturer’s recommended attachments.

• Do not use with damaged cord or plug. If appliance is not working as it should, been dropped,

damaged, left outdoors, or dropped into water, return it to a service center.

• Do not pull or carry by cord, use cord as a handle, close a door on cord, or pull cord around

sharp edges or corners. Do not run appliance over cord. Keep cord away from heated surfaces.

• Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

• Do not handle plug or appliance with wet hands.

• Do not put any object into openings. Do not use with any opening blocked. Keep free of dust,

lint, hair, and anything that may reduce airflow.

• Keep hair, loose clothing, fingers, and all parts of body away from openings and moving parts.

• Do not pick up anything that is burning or smoking, such as cigarettes, matches, or hot ashes.

• Do not use without dust bag and/or filters in place.

• Turn off all controls before unplugging.

• Use extra care when cleaning on stairs.

• Do not use to pick up flammable or combustible liquids such as gasoline or use in areas where

they may be present.

• Connect to a properly grounded outlet only. See grounding instructions.

SAVE THESE INSTRUCTIONS

1

Page 3

OPERATING INSTRUCTIONS

INSPECTION

Carefully unpack and inspect your machine for shipping damage. Each unit is tested and thoroughly

inspected before shipment, and any damage is the responsibility of the delivering carrier who should

be notified immediately. Read all instructions carefully before operating.

WARNING

To avoid electric shock, use indoors only.

• Electrical motors can cause explosions when operating near explosive materials or vapors.

Do not operate this machine near flammable materials such as solvents, thinners, fuels, grain

dust, etc.

• This machine is designed to operate on a standard 15 amp. 115 volt, 60 hz, AC circuit.

Voltages below 105 volts AC or above 125 volts AC could cause serious damage to the

motor.

ELECTRICAL - 115 Volt

This machine is designed to operate on a standard 15 amp. 115 volt, 60 hz, AC circuit. Voltages

below 105 volts AC or above 125 volts AC could cause serious damage to the motor.

ELECTRICAL - 240 Volt

This machine is designed to operate on a standard 16 amp. type L fused 230 volt, 50 hz, AC circuit.

Voltages below 200 volts AC or above 250 volts AC could cause serious damage to the motor.

I.E.C. Class 1.

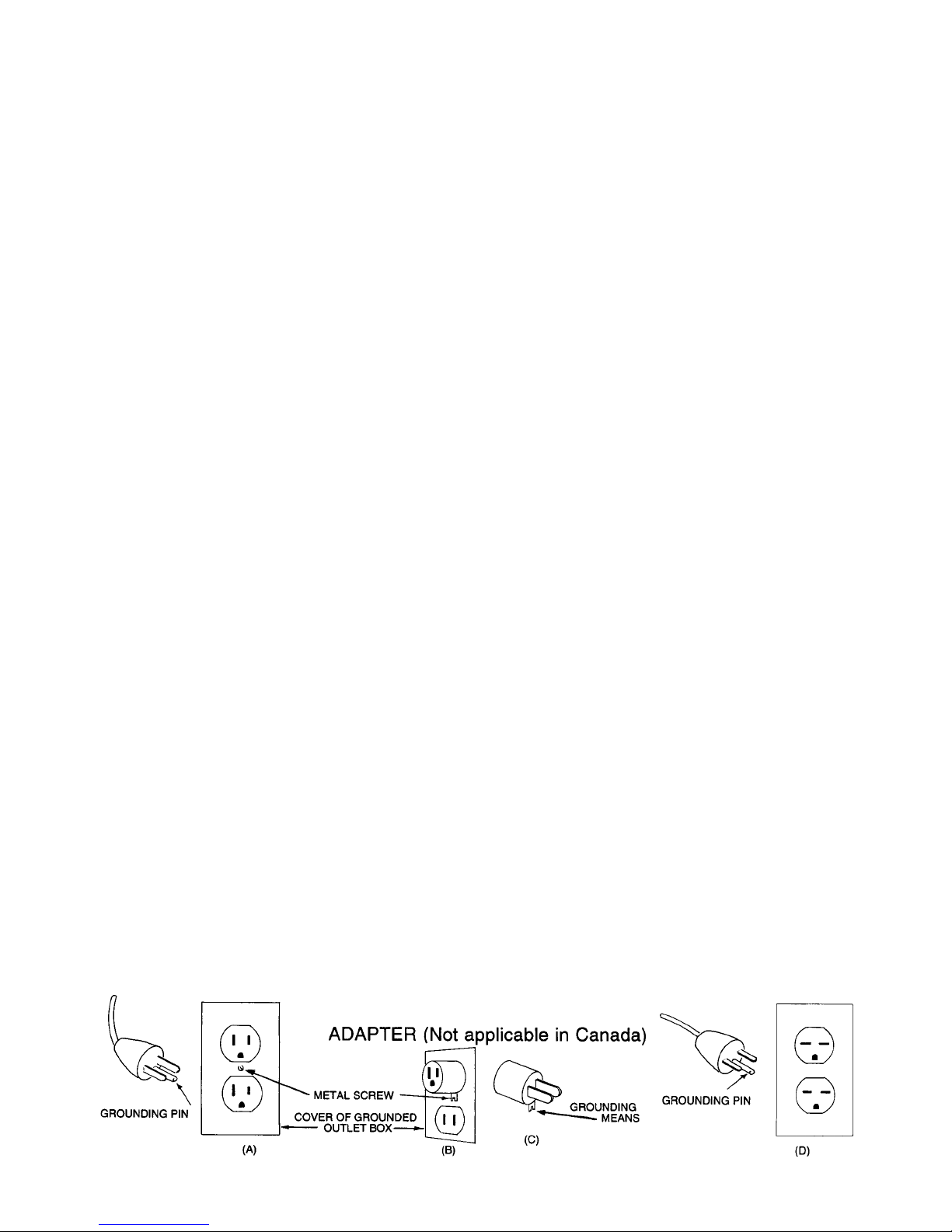

GROUNDING INSTRUCTIONS

To protect the operator from electrical shock, this machine must be grounded while in use. This

machine is equipped with an approved three-conductor power cord and grounding type plug to fit

the proper grounding type receptacle.

This machine is for use on a nominal 120-volt circuit and has a grounding plug that looks like the plug

illustrated in sketch A. Make sure that the machine is connected to an outlet having the same

configuration as the plug. No adapter should be used with this machine.

For equipment rated 150-250 volts: If the machine is provided with an attachment plug as shown in

sketch below, it is intended for use on a 240 volt (nominal circuit.) No adapter is available for this

plug.

2

Page 4

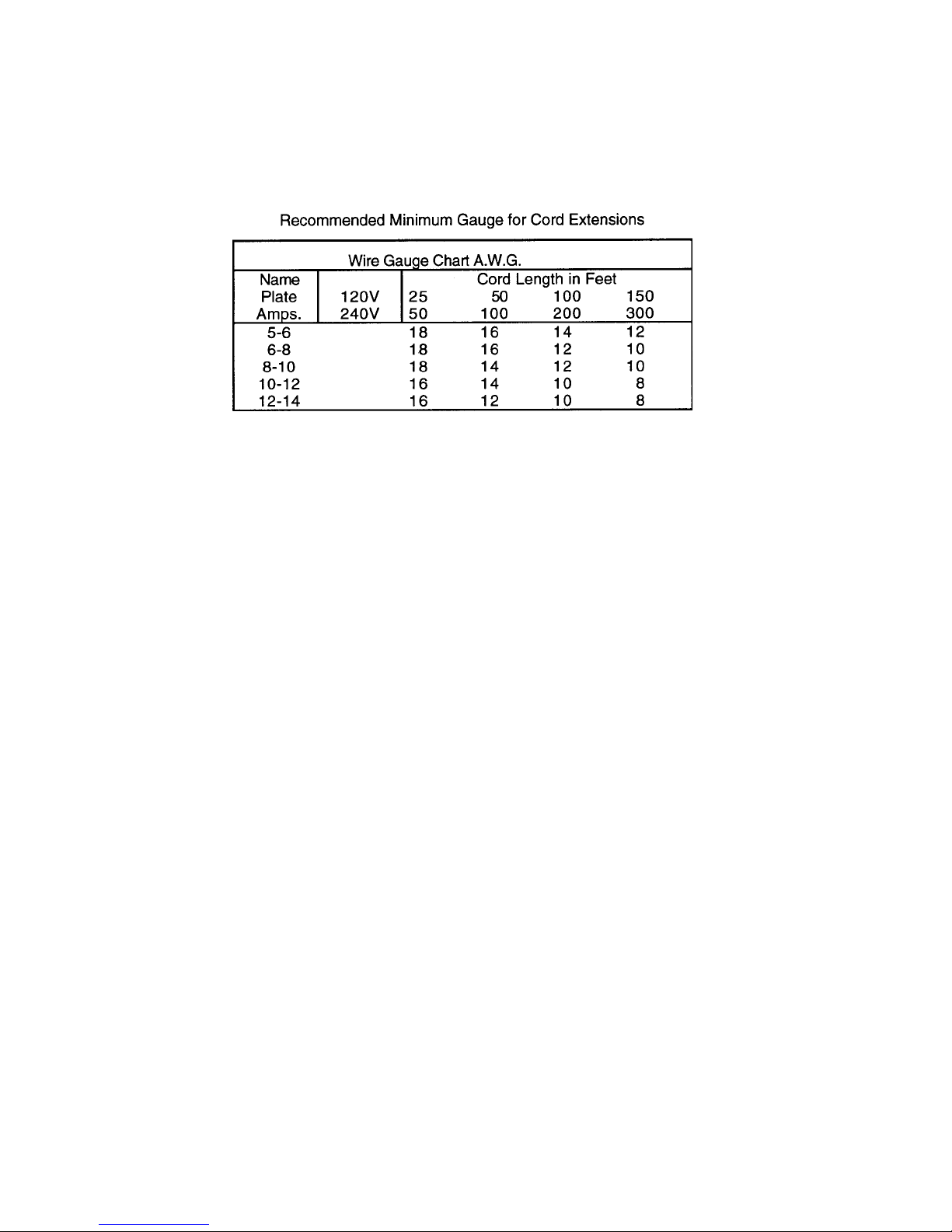

EXTENSION CORDS

Replace damaged or worn cords immediately. The table shows the correct size to use, depending

on cord length and nameplate amperage rating of machine. If in doubt, use the next heavier gauge.

An undersized cord will cause a drop in line voltage, resulting in loss of power and over-heating.

NOTE: the smaller the gauge number, the heavier the cord.

MAINTENANCE AND OPERATION INSTRUCTIONS

FOR AV-747-A VACUUM CLEANER

Though the AV-747-A is designed primarily for use on carpet, it performs very well on hard surface

floors. Sand, dust, paper, and so forth are readily vacuumed from these floors. However, it is not

recommended that this machine be used to vacuum metal slugs, metal shavings or similar type

debris from floors, either carpeted or otherwise.

Inspect the AV-747-A carton for shipping damage when received. Report any damage to delivering

freight carrier immediately.

OPERATING

a) Be sure the unit is used only on the voltage shown on nameplate.

b) When starting the AV-747-A, push down slightly and momentarily on the handle. Doing this

insures quick, easy starts, even when long pile carpets are being vacuumed.

c) In general, carpets with short naps - such as indoor/outdoor carpeting - are best vacuumed

with a setting of low, 2, or 3. Higher pile carpets are best cleaned with settings above 2. To

adjust brush height, disengage the cam lever (on right side) from the machine base and

position it in desired position. This handle is made to lock loosely in the positioning holes in

the base.

d) The rate at which an operator pushes the machine depends on the debris load, carpet nap

length, and type of debris. In areas where large amounts of “tracked in” sand are present,

carpets should be vacuumed with a double pass - that is a forward and backward pass made

without turning the machine around at the end of one pass. A slow, moderate walk pace by an

operator, normally suffices to give good cleaning results.

e) The filter bag should be kept clean. When it contains 15-20 pounds of normal debris, it is

ready for cleaning. To clean, release bag clamp and remove from machine and empty.

f) When storing, the handle may be folded over the cover. Two screws with wing nuts need to be

removed from the handle assembly when it is put in this folded position.

3

Page 5

MAINTENANCE

a) Keep filter bag clean.

b) A drop of number 30 oil should be applied to the caster bearings and main wheel axles, two or so

times a year.

c) To replace brush, remove brush drive belt from motor pulley by rotating motor shaft by hand and

pulling outwardly on belt. Then, tip machine over on its top or side (hold motor mount assembly in

position when tipping or turning over); remove the sheet metal guard covering the brush pulley.

Use two small wrenches to simultaneously remove brush axle screws on each side of frame, and

slip brush out of brush cavity. Remove screws, axle, pulley and bearing end caps from brush.

NOTE: Inspect and replace the brush bearing, if necessary, at the time of reassembly. When remounting end caps be sure to press them squarely into the machined brush ends. Note: Be sure to

line up holes in caps and brush before pushing caps all the way into the brush core. After caps are

lined up and pressed in squarely, tighten cap screws securely. All parts can now be reassembled.

Turn both axle screws in brush axle at the same time for ease of installation. Also, be sure brush belt

is on brush before putting brush in brush cavity. After brush axle screws are securely tightened, line

up belt on brush pulley and then work the other end of the belt for tightness - it should be snugly tight,

not taught. Adjust tightness, when necessary, by adjusting screw heights on front of motor mount

platform. Check for tightness on fan belt also. If this belt is too loose, move motor toward front of

machine by loosening motor mount screws and sliding motor on forward. Be sure motor is at right

angles (square) with belts, then tighten mount screws. Recheck tightness of brush belt - adjust

again, if necessary. Reassemble other parts and unit is ready for use.

d) When the filter bag is removed for cleaning (or replacement) be sure unit is disconnected from

power source. It is good policy to inspect the fan to see if it has become fouled with debris such

as string, wire and so forth.

e) Periodically inspect the brush to determine whether it has become fouled with string, wire or

similar debris.

4

Page 6

5

Page 7

PARTS LIST

Item No. Part No. Qty. Description

1 1219 1 Clip Axle

2 601056 1 Ring Lock

3 601163 1 Switch Assembly

4 710195 4 SCR-MC 5/16-18 x .50

5 711599 1 Flatwasher

6 710755 2 SCR-MC 1/4-20 x .50

7 710776 1 SCR-MC 5/16-18 x 2.25

8 711016 2 SCR-SK 1/4-20 x .50

9 711114 1 SCR-ST-A 8 x .50

10 711115 1 SCR-ST-A 8 x .62

11 711141 4 SCR-ST-F 10-24 x .50

12 711221 3 BLT-HH 1/4-20 x 2.25

13 711227 2 BLT-HH 5/16-18 x .62

14 711228 10 BLT-HH 5/16-18 x .75

15 711231 4 BLT-HH 5/16-18 x 1.25

16 710776 2 BLT-HH 5/16-18 x 2.50

17 711276 1 BLT-HH 3/8-16 x 1.75

18 711328 2 Nut-Hex 3/8-16

19 711359 2 Nut-Acorn 5/16-18BR

20 711366 2 Nut-Wing 5/16-18

21 711379 15 Nut-Flanged Wizz 5/16-18

22 833929 1 Compression Spring

23 711439 5 Nut-Flanged Wizz 3/8-16

24 711503 2 WSR-Flat #10

25 711506 8 WSR-Flat 5/16 ST PL

26 711516 1 WSR-Flat .31 x 1.25 x .05

27 711535 3 WSR-Helical .26 x .50 x .02

28 711540 10 WSR-Helical .32 x .62 x .03

29 711544 2 WSR-Helical 1/4

30 711575 2 WSR-Flat .31 x .75 x .06

31 712064 4 SCR-Wood FH 9 x 1.50

32 712300 1 WSR-Finish #8

33 712307 17 WSR-Helical .20 x .37

34 712317 2 WSR-Flat .41 x .81 x .06

35 712565 2 SCR-MC 1/4-20 x .62

36 712635 1 Nut-Hex 10-24

37 712667 4 Nut-Hex 1/4-20

38 712810 4 SCR-MC 10-24 x .37

39 712811 13 SCR-MC 10-24 x .62

41 712813 1 SCR-MC 10-24 x .75

42 712822 4 SCR-THMS 10-24 x .50

43 712825 1 BLT-Eye 10-24 x 1.50

44 712904 1 Nut-Acorn 10-24

45 712905 1 Nut-Hex 10-24

46 712908 12 Nut-Flanged Wizz 10-24

47 715005 1 Decal, Minuteman

48 715029 1 Decal, Serial Name Plate

49 740015 3 Term, Ring #10

51 808697 2 Clamp Cord

52 808706 1 Blower Hose

53 752001 1 Brush Plate

54 808720 1 Bumper Clip

*55 830557 2 Doortight (ft.)

56 808737 2 Bumper Clip

57 808744 2 Hose Clamp

58 827871 2 Wheel

Item No. Part No. Qty. Description

59 808756 4 E Ring

60 808758 2 Mount Bracket

61 808760 1 Handle Bracket

62 808766 1 Motor, 115V, 60 hz

62A 832812 1 Motor, 230V, 50 hz

62B 808115 1 Brush Motor, 1 hp Canada)

63 808767 2 Multi V Belt

64 808776 1 Motor Pulley

65 808785 1 Motor Cord

66 827703 1 Key

67 808803 2 Brkt. Hold Down

68 808829 1 Wheel, Truck

69 809443 2 Clip Cord

70 809444 2 Clip Cord

72 827664 1 Latch

73 827665 1 Strike

74 827666 2 Rivet Pop

75 829214 4 Rivet

76 827855 1 Base Weld

77 827873 1 Mount Motor

78 827880 1 Fan Assembly

79 827890 1 Box Switch

80 827892 1 Brush

81 827906 1 Hinge Base

82 827912 1 Baffle

83 927973 1 Cover Base

84 827998 1 Clamp

85 827999 1 Spring

86 828596 2 Grommet

87 828778 1 Label Caution

88 828893 6 Rivet Pop

89 829182 1 Bumper Assembly

90 829184 2 Caster Pivot

91 819186 2 Caster Brkt.

92 829187 1 Shaft

93 829202 2 Axle Rear

94 829205 1 Brkt. Handle

95 829296 3 Roll Pin 1/4 x 7/8

96 829297 4 Roll Pin 1/4 x 1 1/4

97 829299 2 Swivel Caster

98 829310 2 Spring

99 829880 1 Cord 75 ft.

*100 830786 1 Bag, Cloth

101 832206 1 Strain Relief

102 832963 1 Handle

103 833472 1 End Cap

104 833695 1 Cover Plate

105 833928 1 Handle Adj.

106 833926 1 Mount Handle Adj.

107 833699 1 Gasket Handle

108 715506 1 Decal Handle Adj.

109 833927 1 Adj. Plate

110 808778 1 E-Ring

111 832448 1 Shoulder Screw

112 715504 1 Decal, Disengage

*XX 829277 1 Paper Liner Bag

Diagrams for above part numbers on Pages 5 and 7

* Not Shown

6

Page 8

7

Page 9

Fan Assembly No. 827880

PARTS LIST

Item Part No. Qty. Description

1 827881 1 Housing, Fan (bottom)

2 827883 1 Housing, Fan (top)

3 808724 1 Fan

4 801535 2 Bearing Ball

5 808733 2 Ring, Retaining

6 808734 1 Pulley, Fan

7 829183 1 Shaft, Bearing

8 808821 1 Key

10 829285 1 Spacer

13 710751 7 Screw (1/4 - 20 - 3/4) 811441)

14 711536 8 Lock Washer (1/4 STD) (811889)

15 711015 8 Screw, Set (#10 - 24 x 3/8) (812006)

18 827885 1 Gasket, Housing

8

Page 10

Brush Assembly No. 827892

PARTS LIST

Item Part No.Qty. Description

2 711162 12 Screw (#10 x 1 1/4)

3 711553 12 Washer, Helical .20 x .37

4 712318 2 Flat Washer (1 1/8 OD x 3/4 x 1/8) (812121)

5 827893 1 Nylon Tynex Brush Core

6 827894 2 Cup, Bearing

7 827896 1 Cover, Bearing

8 827897 1 Shaft, Brush

9 827898 1 Pulley, Brush

10 827903 4 Washer, Bellville

11 828145 2 Ring, Retaining

12 828588 2 Bearing

9

Page 11

Optional Accessories

831641 Cloth Bag w/Zipper

829277 Paper Bag Liner

827892 Nylon Tynex Brush Asy

827893 Nylon Tynex Brush Core

830721 Static-Free Brush Assembly

828927 Static-Free Brush Core

10

Page 12

LIMITED WARRANTY

Minuteman International, Inc. warrants to the original purchaser/user that this product is free from defects in workmanship and

materials under normal use and service for a period of three years from date of purchase. In addition, Minuteman International,

Inc. will, at its option, honor labor warranty claims for the first 12 months from date of sale, provided such claims are submitted

through and approved by factory authorized repair stations. Minuteman International, Inc. will, at its option, repair or replace

without charge, except for transportation costs, parts that fail under normal use and service when operated and maintained in

accordance with the applicable operation and instruction manuals.

This warranty does not apply to normal wear, or to items whose life is dependent on their use and care, such as belts, cords,

switches, hoses, rubber parts, electrical motor components or adjustments. Parts not manufactured by Minuteman International,

Inc. such as engines, batteries, battery chargers, hydraulic pumps, and tires are covered by and subject to the warranties and/

or guarantees of their manufacturers. Please contact Minuteman International, Inc. for procedures in warranty claims against

these manufacturers.

Special warning to purchaser — Use of replacement filters and/or prefilters not manufactured by Minuteman International, Inc.

or its designated licensees, will void all warranties expressed or implied.

A potential health hazard exists without exact original equipment replacement.

All warranteed items become the sole property of Minuteman International, Inc. or its original manufacturer, whichever the case

may be.

Minuteman International, Inc. disclaims any implied warranty, including the warranty of merchantability and the warranty of

fitness for a particular purpose. Minuteman International, Inc. assumes no responsibility for any special, incidental or consequential

damages.

This limited warranty is applicable only in the U.S.A. and Canada, and is extended only to the original user/purchaser of this

product. Customers outside the U.S.A. and Canada should contact their local distributor for export warranty policies. Minuteman

International, Inc. is not responsible for costs or repairs performed by persons other than those specifically authorized by Minuteman

International, Inc. This warranty does not apply to damage from transportation, alterations by unauthorized persons, misuse or

abuse of the equipment, use of non-compatible chemicals, or damage to property, or loss of income due to malfunctions of the

product.

If a difficulty develops with this machine, you should contact the dealer from whom it was purchased.

This warranty gives you specific legal rights, and you may have other rights which vary from state to state. Some states do not

allow the exclusion or limitation of special, incidental or consequential damages, or limitations on how long an implied warranty

lasts, so the above exclusions and limitations may not apply to you.

World Headquarters Minuteman Canada, Inc.

Minuteman International, Inc. 2210 Drew Road

111 South Rohlwing Road Mississauga, Ontario

Addison, Illinois 60101 L5S 1B1

(630) 627-6900 (905) 673-3222

FAX (630) 627-1130 FAX (905) 673-5161

987839

Printed in U.S.A.

Loading...

Loading...