Page 1

170TD

Model: MC17026-00

Automatic

Scrubber

OPERATION

MC17026QP

SERVICE PARTS

CARE

Revised 6/02

Page 2

Page 3

TABLE OF CONTENTS

Page

Safety Instructions 1

Electrical Requirements 2

Control Panel Identification 3

Brush Installation Instructions 4

Operating Instructions/Maintenance 5

Main Polyethelene Components 6 & 7

Solution/Recovery Tank 8 & 9

Vacuum Components 10 & 11

Brush Drive Assemblies 12 &13

Squeegee Assembly 14 & 15

Wiring Diagram 16

Page 4

IMPORTANT SAFETY INSTRUCTIONS

CAUTION: Operators must read and understand this manual before operating or maintaining

this equipment.

• Keep hands and feet clear of moving parts while machine is in operation.

• All switches must be in the “OFF” position when charging batteries.

• Electrical motors and components can cause an explosion when operated near explosive

materials or vapors. Do not operate this machine nearflammable materials such as solvents,

thinners, fuels, grain dusts, etc.

• Make sure all switches are turned “OFF” and battery connections are removed before

performing any maintenance procedures.

• Store or park this machine on a level surface only.

• These machines are designed for level floor operation only. DO NOT OPERATE on ramps or

inclines.

• Battery acid can cause burns. When working on or around batteries, wear protective clothing

and safety glasses. Remove metal jewelry. Do not lay toolsor metal objects on top of

batteries.

• This machine is not suitable for picking up hazardous dusts.

Charging batteries generates explosive gases. DO NOT CHARGE BATTERIES WHEN OPEN

FLAMES OR SPARKS ARE PRESENT. DO NOT SMOKE. Make sure the charger is turned off

before disconnecting it from the batteries. Charge the batteries in a well-ventilated area.

Maintenance and repairs must be performed by authorized personnel.

SAVE THESE INSTRUCTIONS

1

Page 5

ELECTRICAL REQUIREMENTS:

This piece of equipment operates on 24 Volt DC.

BATTERY REQUIREMENTS:

2 x 12V 80 Amp Hour 20 Hour Rate Deepcycle P/N 956721

2 x 12V 105 Amp Hour 20 Hour Rate Deepcycle P/N 956712

BATTERY SERVICE AND INSTALLATION:

*Warning: Battery acid can cause burns. When working on or around batteries, wear protective

clothing and safety glasses. Remove metal jewelry. Do not lay tools or metal objects on top of

batteries.

BATTERY INSTALLATION:

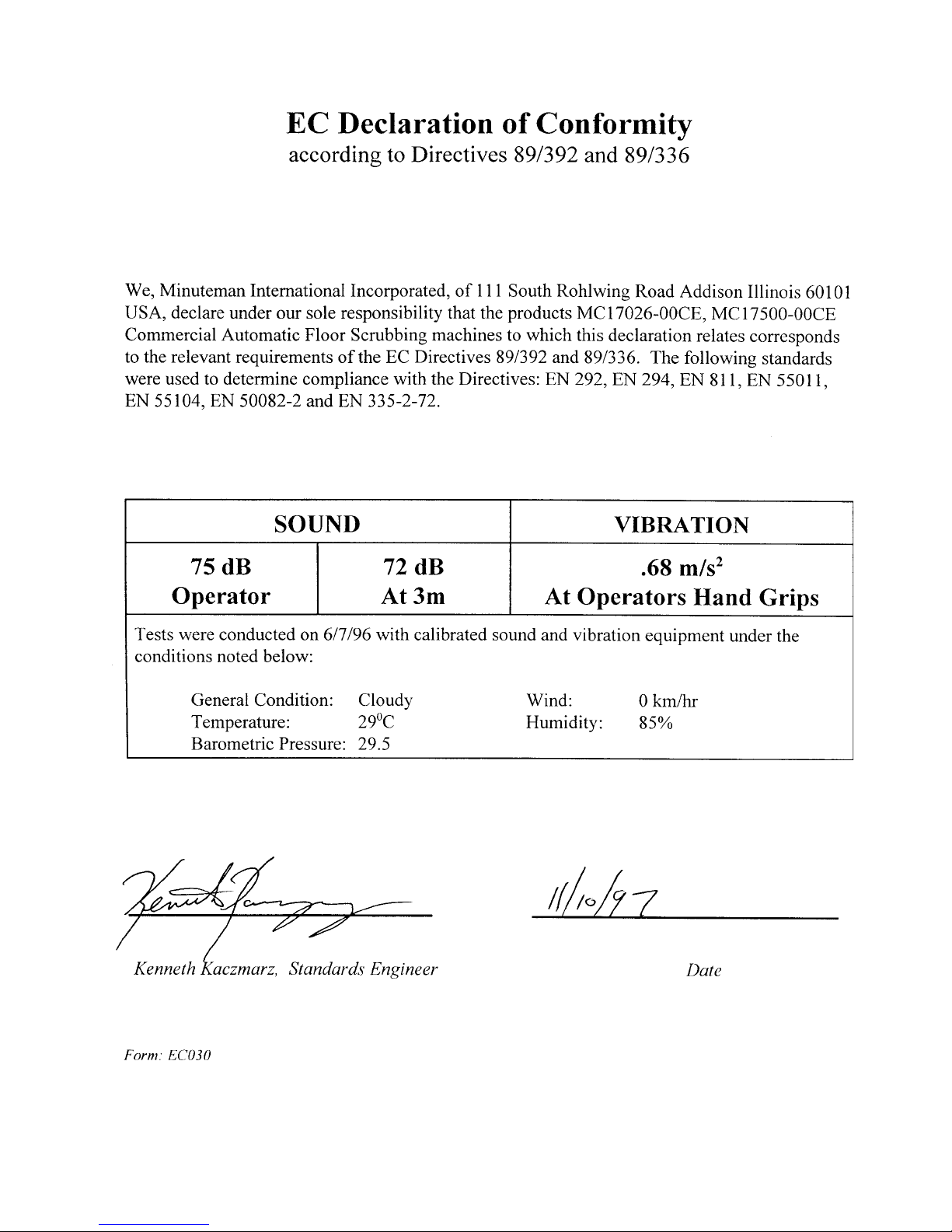

1. Disconnect tank drain hose from rear of machine.

2. Disconnect vacuum recovery hose.

3. Raise tank assembly by gripping side hand holds, and tilting forward.

4. Position tank kickstand as shown below, figure 1, to hold tank in upright position. To lower,

raise tank slightly forward and manually move kickstand to freed position.

5. Install batteries as shown in figure 2.

CHARGING OF BATTERIES:

Charging of batteries generates explosive gases. DO NOT CHARGE BATTERIES WHEN

OPEN FLAMES OR SPARKS ARE PRESENT. DO NOT SMOKE. Make sure the charger is

turned off before disconnecting it from the batteries. Charge the batteries in a well-ventilated

area. Fluid levels should be checked before and after charging and maintained at the proper

levels.

Fig.1 Fig.2

2

Page 6

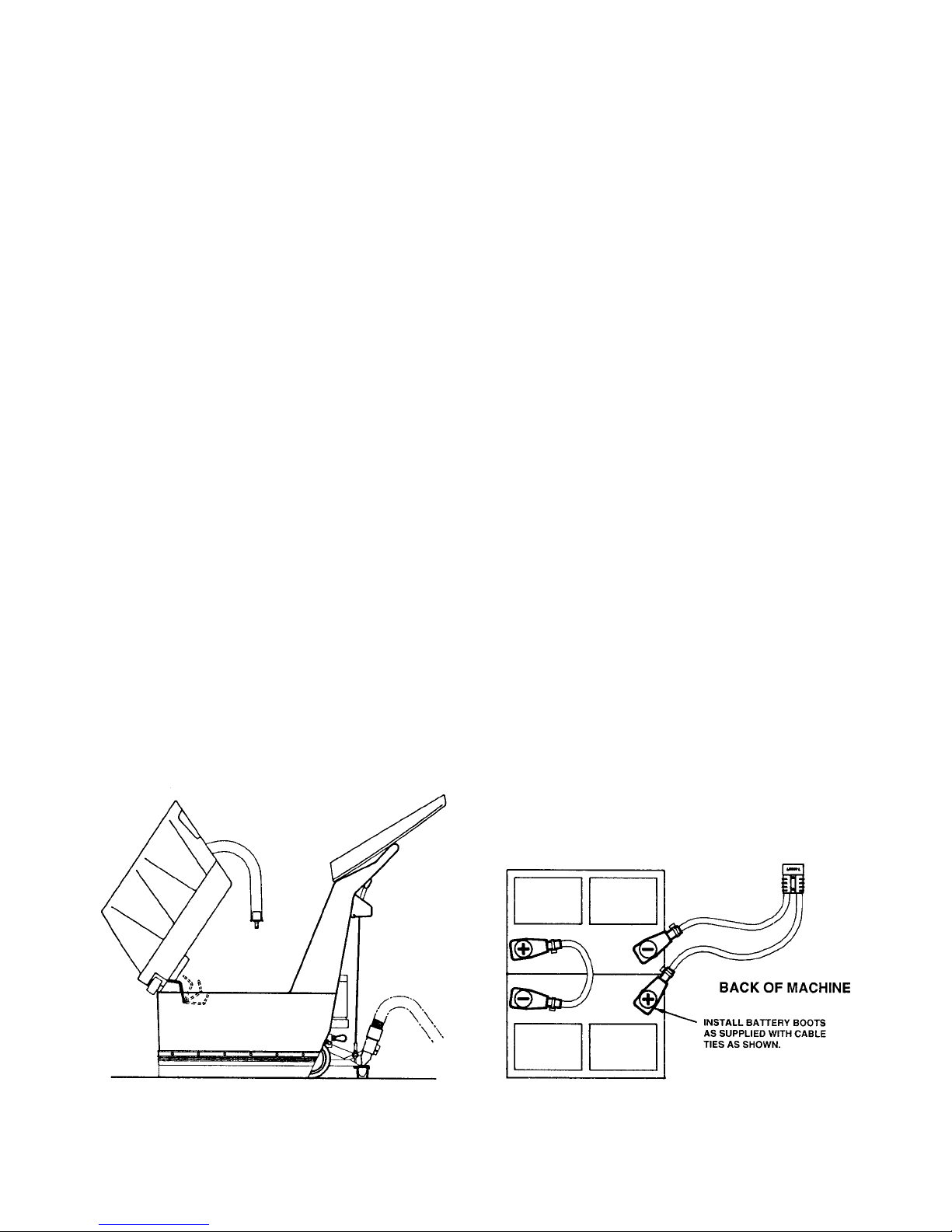

1. Direction switch 7. Main power switch

2. Vacuum switch 8. Speed control knob

3. Squeegee lift lever 9. Drain hose for clean solution tank

4. Battery condition meter 10. Drain hose for recovery tank

5. Solution control lever 11. Vacuum recovery hose

6. Main power indicator 12. Foot pedal for raising/lowering brush

3

Page 7

BRUSH REMOVAL

Empty solution and recovery tanks.

Disconnect batteries.

Remove squeegee assembly.

Lower brush.

Tilt machine as shown (figure 3) until machine rests on foot pedal.

Brush has a snap-on push off clutch plate. Pushing brush away from the machine from the

side, will release brush assembly.

To install: Hold brush in the center and snap on to drive hub.

Fig.3

4

Page 8

OPERATING INSTRUCTIONS

1. Filling: Fill the solution tank with the desired amount of water and add liquid cleaning solution

to the proper dilution ratio. DO NOT USE powdered cleaning chemicals. Powders are unlikely

to dissolve thoroughly, resulting in clogging the in-line solution filter. This can reduce or stop

water flow to the brush.

2. Close lid.

3. Lower brush assembly.

- To lower the brush, first push the pedal slightly towards the center of the

machine (unlock it), then release it slowly.

- To lift the brush, press the pedal down until lift mechanism engages.

4. Turn on brush switch.

5. Adjust solution control feed lever.

6. Turn on vacuum switch.

7. Lower squeegee assembly.

After Use:

1. Turn off solution feed.

2. Switch off brush and raise.

3. Raise squeegee assembly.

4. Turn off vacuum motor.

Solution and recovery tanks should be emptied after every use.

MAINTENANCE:

When cleaning, servicing or maintaining the machine the power should be switched off.

Daily 1. Clean float assembly & squeegee blades. Vac filter.

2. Recharge batteries (check battery acid levels before and

after charging).

Monthly 1. Check wear on squeegee blades.

2. Grease rear wheels.

3. Grease pivot points on brush motor assembly.

Every 500 hours check condition of carbon brushes on vacuum motor and brush drive motor.

5

Page 9

6

Page 10

Parts List

Item Part No. Qty. Description

1 430000TD 1 Base 170TD

2 430001MCH 1 170 Sol/Recovery Tank Assy

3 430002 1 Cover Poly 170 Burgundy

4 430044 2 Hinge Lid 17 B/E

5 430046 2 Side Skirt Retainer 17

6 430049 1 Splash Skirt 17 B/E

7 430126 2 Hinge Backing Plate

8 430136 1 Gasket Seal Kit (4)

9 712560 6 SCR-MC ¼-20 x .50 SS

10 712536 6 SCR-MC 10-24 x .62 SS

11 450021 1 Hinge

12 712822 6 SCR-THMS 10-24 x .50 STPL

13 711161 18 SCR-Hi/Lo #10 x ¾ PL

7

Page 11

8

Page 12

Parts List

Item Part No. Qty. Description

1 130118 1 Solution Strainer

2 200173 1 Float Housing

3 210401 2 Solution Hose

4 210409 2 Fitting Brass 3/8MPT 3/8FPT

5 210410 2 Fitting Brass 3/8 FPT 3/8 Barb

6 210414 2 “O” Ring 2-113

7 260203 1 Hose Clamp

8 430001MCH 1 170 Sol/Recovery Tank Assy.

9 430037 2 Bumper Wheel Axle

10 430038 2 U Bracket Wheel Mount

11 430050 1 Filter Screen 4 x 4

12 430089 1 Float 17B

13 430090 1 Float Valve Weldment

14 430098 1 Vac Recover Hose 22 C/L

15 430116 1 Hose 3/8 Nyloc x 34"

16 430121 1 Standpipe Assy. 170/175

17 430199 1 Hose White Wireloc 24”

18 450076 1 Crimp Clamp SS 185R

19 450081 2 WSR SS 1.908 x 2.41 x .03

20 450083 2 Insert Fitting

21 710353 2 SCR-MC 10-32 x .37 STPL

22 710985 2 SCR-SC 3/8 - 16 x .62

23 711504 1 WSR-Flat 1/4 ID SS

24 711513 2 WF .689 x 1.06 x .029 SS

25 712092 1 SCR Nylon 1/4-20 x 2.5

26 712568 1 SCR-MC 1/4 - 20 x 2.25 SS

27 712667 1 Nut-Hex 1/4 - 20 SS Nyloc

28 760343 1 Tube Hose 24/32B

29 762331 2 Wheel, 2.5 D x 1.28 W x .38 ID

30 762384 2 Bushing SS .277 x .375 x .37

31 828970 1 WSR NEOP 1.87 x 2.4 x .125

32 828971 1 Nut 1 1/2 Pipe Thread

33 829559 1 Cable Assy 170/175

34 830062 2 Fitting Brass 90 3/8MPT

35 833316 1 Drain Plug

9

Page 13

10

Page 14

Parts List

Item Part No. Qty. Description

1 250041 1 Seal, Rubber

2 831001 2 Crimp Clamp 44OR

3 290017 1 Molded Vac Mtr Gasket

4 430018 2 Z Bracket

5 430029 2 Caster

6 430042 1 Caster Mounting Bracket

7 430138-1 2 Wheel 6”

8 430069 1 Vacuum Manifold Assembly

9 828264 1 Spring Washer Cup

10 430099 1 Vacuum Hose

11 450038 2 Z Bracket

12 460019 1 Gasket 3.75x5.75x.75

13 710178 7 SCR-MC ¼-20 x .50 STPL

14 712129 3 SCR-TR ¼-20 x 1.00 HWH

15 711106 4 SCR-ST-A 10 x .75 PL

16 711161 5 SCR-Hi/Lo #10 x ¾ PL

17 711210 3 BLT-HH ¼-20 x 1.25 STPL

18 711243 6 BLT-HH 3/8-16 x 1.5 STPL

19 711380 8 Nut-Nyloc 3/8-16

20 711425 3 Nut-Flanged ¼-20

21 711439 2 Nut-Flanged Wizz 3/8-16

22 711506 3 WSR-Flat 5/16 STPL

23 711509 6 WSR-Flat ½

24 430149 4 Bushing .531 x 1 x .25 SS

25 711515 12 WSR-Flat .406 x .812 x .062

26 712090 2 Shoulder Bolt ½ x 3.5

27 740063 1 Vac Motor 24V

28 740132 1 Insulator, Glastic

29 760859 1 Clamp, Hose

30 762398 1 Hose, Rubber Flex 2 x 13

31 801013 1 Sleeve, Hose

32 832136 1 Nylon Sleeve Sol. Feed

33A 430034 1 Nylon Brush

33B 430108 1 Pad Driver

33C 430111 1 Poly Grit Brush

33D 430132 1 Strato Grit Brush

34 710986 2 SCR-SC 3/8-16 x 1.00

35 364-816 1 Nut-Nyloc ½

36 711510 3 Washer

37 828301 1 Spring

38 711559 1 WSR-Internal Lock 3/4

39 210083 1 Adj. Rod Weldment

40 450040 1 Elbow 3/8 MPT x 3/8 Barb

41 450076 1 Crimp Clamp SS

42 210401 1 Solution Hose 3/8

43 809413MCH 1 Solution Valve

44 829463 1 WSR-Flat 0.75 x 2.00 x .05

45 828975 1 WSR-Neo .75 x 1.50 x .09

46 210370 1 Solution Valve Bracket

47 711106 3 SCR-ST-A 10 x .75 PL

48 711513 1 WSR-Flat .689 x 1.06 x .029

49 342430 1 Hose Barb 3/8 MPT x 3/8 Barb

50 742254 1 Torriod Ferrite

51 840112CTD 1 Vac Cover

52 832996 1 Terminal Block

53 742281 1 Ground Strap

54 380035 1 Foam Ring

11

Page 15

12

Page 16

Parts List

Item Part No. Qty. Description

1 740209 1 Gear Motor 24V

2 210124 1 Bearing Stud

3 361254 1 Bearing

4 430013 1 Stabilizer Bracket

5 740241 2 Contactor 24V 50A

6 711425 8 Nut-Flanged Wizz ¼-20

7 711535 4 WSR-Helical .26 x .50 x .02

8 711202 12 BLT-HH ¼-20 x .50 STPL

9 430106 1 Stabilizer Bar - Lower

10 711380 1 Nut-Nyloc 3/8-16

11 430009MCH 1 Motor Bracket Weldment Machined

12 710986 3 SCR-SC 3/8-16 x 1.00 STPL

13 430035 1 Drive Hub

14 711555 1 WSR-Loc Internal

15 320268 1 Pin

16 210066 1 Drive Hub Retainer

17 450076 2 Crimp Clamp SS

18 833473 1 Hose Barb ¼ FPT x 3/8 Barb

19 100000 1 Mounting Bracket Quick Disc.

20 711579 1 WSR-Flat .56 x 1.00

21 430081 1 Wheel Mount U Strut Left

22 430114 1 Nylon Cap ¼ FPT HC4

23 430118 1 Clear Dump Hose C/L 22”

24 828952 1 3/8 barb x ¼ MPT

25 833325 1 Elbow ¼ MPT x 3/8 Barb

26 742330 1 Transaxle 170TD

27 711505 2 WSR-Flat ¼

28 430313 2 Nut-Nyloc M6

29 430308 1 Wheel

30 430319 1 Motor Mount Weldment

31 711553 4 WSR-Int. Tooth #10

32 711355 4 SCR-MC 10-32 x .500

33 711374 1 Nut-Nyloc 5/16-18

34 430066 2 Squeegee Return Spring Long

35 430067 1 Squeegee Return Spring Short

36 711246 1 BLT-HH 3/8-16 x .87 STPL

37 711227 1 BLT-HH 5/16-18 x .62

38 430030 1 Squeegee Mount Weldment

39 711515 3 WSR-Flat .44 x .87 x .07

40 430306 1 Mounting Plate Weldment

41 712569 2 SCR-MC ¼-20 x 1.50 SS

42 430088 1 L Bracket Motor Lift

43 430113PLT 1 Bushing

44 430014 1 Motor Lift Weldment

45 210142 1 Pedal

46 430064 1 Wheel Mount U Strut Right

47 430051 1 Return Spring

48 711379 1 Nut-Flanged Wizz 5/16-18

49 711212 1 BLT-HH ¼-20 x 1.50

50 361203 1 Rubber Skirt

51 361205 1 Skirt Retainer

52 711106 3 SCR-ST-A 10 x .75

53 430116 1 Hose 3/8 Nylon x 34”

54 711517 3 WSR-Flat .77 x 1.37 x .03

55 430003 1 Motor Mount Weldment

56 430009 1 Motor Bracket Weldment

57 833102 3 Compression Spring

58 260041 3 Flange Bushing

59 710992 3 Shoulder Bolt ½ x 1.25

13

Page 17

14

Page 18

Parts List

Item Part No. Qty. Description

1 430301 1 Speed Control Cover

2 711161 14 SCR-Hi/Lo 10 x 5/8

3 430316 1 Edge Seal

4 740944 1 Speed Control Board

5 740368 1 Potentiometer Assembly

6 809874 1 Knob

7 711430 1 Tinnerman Plate

8 210362 1 Switch Bracket

9 833329MCH 1 Micro Switch

10 710307 2 6-32 x 1.00 Screw

11 711002 1 SCR-SK 8-32 x .500

12 430312 1 Cam Assembly

13 829052 2 Nylon Flanged Bushing

14 711721 2 Retaining Ring

15 430313 1 Wire Handle

16 809754 1 Switch, Rocker

17 742102 1 Switch, 2-Position

18 740216 1 Gauge, Battery Condition

19 715752 1 Decal

20 712822 6 SCR-THMS 10-24 x .50 STPL

21 711124 2 SCR-ST-B 10 x .37

22 712320 2 WSR-Nylon .22 x .45 x .04

23 740591 1 Panel Light Assembly

24 740711 1 Switch

25 430053 1 Solution Control Cable

26 430307 1 Dashboard

27 760592 1 Knob, Oval Tapered

28 430060 1 Squeegee Lift Arm Assembly

29 430052 1 Squeegee Lift Cable Assembly

30 711506 2 WSR-Flat 5/16 STPL

31 712041 2 BLT-Shoulder ¼-20 x .44 x .37

32 711523 1 WSR-Wave .37 x .68 x .02

33 829014 1 Flanged Bushing

34 762058 1 Spacer .319 x .375 x .250

35 711301 2 Nut-Hex 6-32

36 711551 2 WSR-Internal Lock #6

37 430087 1 Anderson Plug Bracket

38 740097 1 SB50 Red 111783G2FOR B43

39 710207 2 SCR-MC 6-32 x .87 STPL

40 711161 7 SCR-Hi/Lo #10 x ¾

41 742350 1 Circuit Breaker 6A

42 710180 2 SCR-MC ¼-20 x .75

43 711352 1 Nut-Acorn ¼-20

44 430059 1 Squeegee Lift Bracket Assembly

45 711373 1 Nut-Nyloc ¼-20

46 711505 1 WSR-Flat ¼

47 740131 1 Circuit Breaker, Dive Motor

48 741037 1 5 Sec. Delay Timer

49 711211 1 BLT-HH ¼-20 x 1.37

50 740132 1 Insulator, Glastic

51 710356 2 SCR-MC 10-32 x .62 STPL

52 740241 1 Contactor, 24V 50A

53 710178 1 SCR-MC ¼-20 x .50

54 711425 6 Nut-Flanged Wizz ¼-20

55 711503 4 WSR-Flat #10

56 711350 2 Nut-Nyloc 10-32

57 760286 1 Wire Formed Hook

58 430120 1 U Channel

59 711808 1 Cotter Pin - Hair #13

60 430105 1 Clevis Pin .312 x .175

61 430070 1 Squeegee Mount Assembly

62 430073 1 Gasket, Diecut

63 430074 6 Adjusting Nut

64 430085 2 Squeegee Bumper Wheel

65 430078 1 U Profile

66 11-145 1 Squeegee Blade

67 430076 2 Nylon Squeegee Insert

68 712517 4 SCR-MC 8-32 x 1 SS FH

69 430079 1 Casting, Squeegee Assembly

70 370031 2 Wheel

15

Page 19

WIRING DIAGRAM

16

Page 20

LIMITED WARRANTY

Minuteman International, Inc. warrants to the original purchaser/user that this product is free from defects in workmanship and

materials under normal use and service for a period of three years from date of purchase. In addition, Minuteman International,

Inc. will, at its option, honor labor warranty claims for the first 12 months from date of sale, provided such claims are submitted

through and approved by factory authorized repair stations. Minuteman International, Inc. will, at its option, repair or replace

without charge, except for transportation costs, parts that fail under normal use and service when operated and maintained in

accordance with the applicable operation and instruction manuals.

This warranty does not apply to normal wear, or to items whose life is dependent on their use and care, such as belts, cords,

switches, hoses, rubber parts, electrical motor components or adjustments. Parts not manufactured by Minuteman International,

Inc. such as engines, batteries, battery chargers, hydraulic pumps, and tires are covered by and subject to the warranties and/

or guarantees of their manufacturers. Please contact Minuteman International, Inc. for procedures in warranty claims against

these manufacturers.

Special warning to purchaser — Use of replacement filters and/or prefilters not manufactured by Minuteman International, Inc.

or its designated licensees, will void all warranties expressed or implied.

A potential health hazard exists without exact original equipment replacement.

All warranteed items become the sole property of Minuteman International, Inc. or its original manufacturer, whichever the case

may be.

Minuteman International, Inc. disclaims any implied warranty, including the warranty of merchantability and the warranty of

fitness for a particular purpose. Minuteman International, Inc. assumes no responsibility for any special, incidental or consequential

damages.

This limited warranty is applicable only in the U.S.A. and Canada, and is extended only to the original user/purchaser of this

product. Customers outside the U.S.A. and Canada should contact their local distributor for export warranty policies. Minuteman

International, Inc. is not responsible for costs or repairs performed by persons other than those specifically authorized by Minuteman

International, Inc. This warranty does not apply to damage from transportation, alterations by unauthorized persons, misuse or

abuse of the equipment, use of non-compatible chemicals, or damage to property, or loss of income due to malfunctions of the

product.

If a difficulty develops with this machine, you should contact the dealer from whom it was purchased.

This warranty gives you specific legal rights, and you may have other rights which vary from state to state. Some states do not

allow the exclusion or limitation of special, incidental or consequential damages, or limitations on how long an implied warranty

lasts, so the above exclusions and limitations may not apply to you.

World Headquarters Minuteman Canada, Inc.

Minuteman International, Inc. 2210 Drew Road

111 South Rohlwing Road Mississauga, Ontario

Addison, Illinois 60101 L5S 1B1

(630) 627-6900 (905) 673-3222 983205

FAX (630) 627-1130 FAX (905) 673-5161 Printed in U.S.A.

Loading...

Loading...