Minuteman MC380001, MC380003, MC380000QP, MC380002QP, MC380003QP Operation Service Parts Care

...

3800

MC380000 MC380000QP

MC380001 MC380001QP

MC380002 MC380002QP

Rider Scrubber

OPERATION

SERVICE PARTS

MC380003 MC380003QP

CARE

Revised 7/02

PB # 987613

Operation, Maintenance & Troubleshooting

DUMP HOSE:

Under the recovery tank on the left side is the dump hose. This is used for dumping of the

recovery tank. To dump the recovery tank extend the hose from the machine and open the dump

valve. The dump valve is opened by flipping up the tab that is on the end of the valve. The hose

might need to be squeezed in the middle to allow the waste water to flow.

When the recovery tank is empty it is important to replace the valve on the end of the hose.

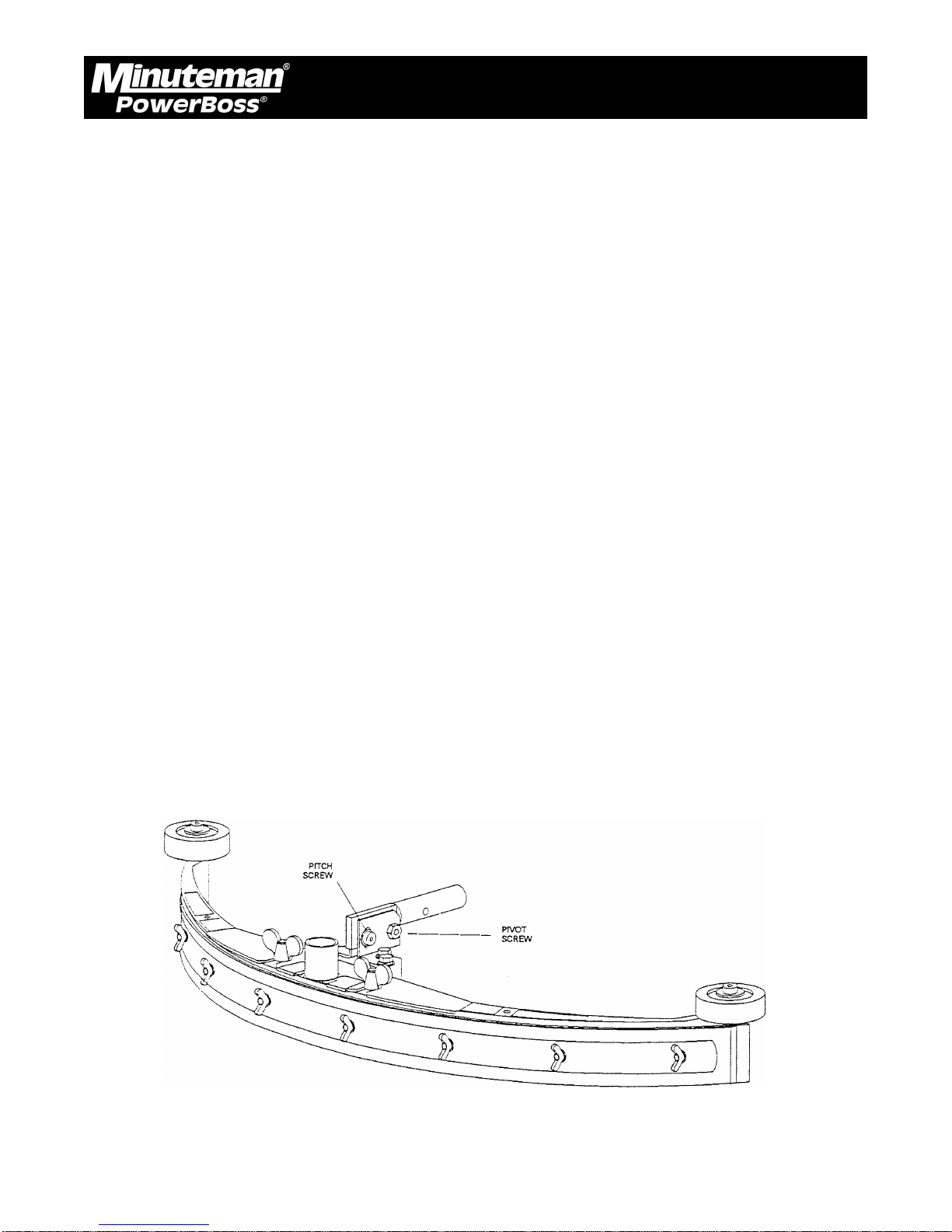

SQUEEGEE ADJUSTMENT:

The squeegee set-up is pre-adjusted at the factory. Adjustments may be required to get optimum

performance for different floors and conditions.

Pitch Control Adjustment:

Ensure that the scrubber is on a relatively flat surface. Turn on the main power switch and select

“Vacuum Only” mode.

Move the scrubber forward slowly while someone behind the machine checks the squeegee

blade for uniform deflection.

If uneven deflection or lay is evident, minor adjustments may be necessary to avoid streaking

and uneven wear on the blade.

To correct this, pitch adjustment is necessary. Loosen the pivot screw and the pitch screw. Move

the machine forward and allow the squeegee to level itself or adjust the angular position accordingly

to achieve a uniform blade deflection. Re-tighten the screws.

In certain applications where a different blade setup is required, the reinforcement blade may be

turned upside-down. The notch, which is normally on the bottom, will now be located on the top.

This adjustment allows the rear squeegee blade a larger deflection than normal.

Minuteman PowerBoss Inc. Copyright 2000

9

3800 Rider Scrubber (7/02)

Operation, Maintenance & Troubleshooting

CONTROL SETTINGS ADJUSTMENT AND MAINTENANCE MODE:

The machine settings are easily adjusted with any Windows computer equipped with Hyperterminal.

(Hyperterminal is Windows 95/98 Accessory). The program can be accessed through the “Start”

bar, scroll to “Programs” then scroll to “Accessories”. It is possible that it might be under

“Communication” under “Accessories”. Depending on the specific configuration of the computer,

the “hyperterm” icon might then need to be clicked to run the program.

Once the program is running the “New connection” menu will be open. Type in “3800 Rider” at

the connection name, then hit OK. The “Connect To” menu will then be open. The “Connect

Using” line must be changed to either “Direct to com1”, “Direct to com2”, “Direct to com3” or

“Direct to com4”. Be sure to choose the same com port that your serial input card is plugged into.

Then open the “Configure” menu (It might also be called “Properties” depending on which version

is running). The following are the correct settings.

Bits per second 4800

Data Bits 8

Parity None

Stop Bits 1

Flow Control None

Adjust all of the above to match, then hit “OK”. If the “Configure” window closes it can be opened

by clicking “Properties” under the “File” pull down window. Next, press the “Settings” tab. Under

the “Emulation” line, change it to “VT100”. Then click “OK”. The windows computer is now

configured correctly.

To connect to the 3800 rider, remove the front cover of the computer. This is located on the

steering column. Insert the communication cable (Minuteman P/N 742764) into the 3800 rider’s

computer port that is labeled “laptop”. Insert the other end of the cable into the computer interface

box (Minuteman P/N 742737). Finally, insert the computer interface box into the serial port that

the computer was configured for under “Connect to” above.

In order for the computer to communicate, the 3800 rider must be turned on. Once the machine

is turned on, the setting screen shown should appear on the computer. It is possible that “ControlL” might need to be pressed to reset the screen.

Minuteman PowerBoss Inc. Copyright 2000

10

3800 Rider Scrubber (7/02)

Operation, Maintenance & Troubleshooting

The first screen of the programming menu looks like this:

A BRUSH UP SPEED 40 40

B BRUSH DOWN SPEED 40 40

C BRUSH HYSTERESIS 8 8

D PARTIAL RAISE TIME 5 5

E PUMP START UP TIME 3 3

F (NOT USED)

G SCRUB TO RAISE BRUSH TIME 35 35

H RAISE TO BRUSH OFF TIME 5 5

I VAC TO RAISE SQUEEGEE TIME 70 70

J RAISE TO VAC OFF TIME 120 120

K (NOT USED)

L CLEAN TO FAST TRAVEL TIME 70 70

M CALIB VALUE 30 30

N MEDIUM ADDER 12 12

O HIGH ADDER 25 25

^L REDRAW SCREEN, TAB MORE PARAMS, ^P MAINTENCE

These parameters can be adjusted by pressing the letter next to the parameter that is to adjusted.

The number that is in the left column is the current setting, the number in the right column is the

“factory” setting.

The following is an explanation of the above parameters.

A. Brush up speed An indication of how fast the brush deck will be raised when it

is being adjusted for proper brush pressure. The higher the number the faster the brush deck will

go up, the lower the number, the slower the deck will go up.

B. Brush down speed An indication of how fast the brush deck will be lowered when

it is being adjusted for proper brush pressure. The higher the number, the faster the brush deck

will go down, the lower the number, the slower the deck will go down.

C. Brush hysteresis An indication of how sensitive the controller will be to changing

floor conditions. The higher the number the more sensitive, the lower the number the less sensitive. If the controller is too sensitive, it will constantly be changing the position of the scrub deck

every time that a high or low spot is encountered on the floor.

D. Partial raise time While operating in the full function or double scrub modes, the

brush deck is raised slightly after the machine is no longer moving. The amount of time that the

brush deck is raised is called the partial raise time. The larger the number the higher the scrub

deck will be raised, the lower the number the less it will be raised.

Minuteman PowerBoss Inc. Copyright 2000

11

3800 Rider Scrubber (7/02)

Operation, Maintenance & Troubleshooting

E. Pump start up time Whenever any of the pumps are turned on to any speed from

being completely off, they are first run at full speed. The length of time that the pumps are run at

full speed is called the pump start up time. The larger the number the longer the pumps will be

run at full speed, the shorter the number the shorter they will be run.

F. Not used

G. Scrub to raise brush time While operating in the full function or double scrub modes the

brush deck is raised slightly after the machine is no longer moving. The amount of time delay

between no longer moving and the brush deck raising is called the scrub to raise brush time. The

larger the number the longer the time delay will be, the smaller the number the shorter the

number will be.

H. Raise to brush off time After the brush deck has been raised there is a delay in turning

off the brushes. This is called the raise to brush off time. The larger the number the longer the

brush motors will stay on after they are raised.

I. Vac to raise squeegee time While operating in the full function or vacuum only modes, the

squeegee is raised after the machine is no longer moving. The amount of time delay between no

longer moving and the squeegee raising is called the vac to raise squeegee time. The larger the

number, the longer the delay will be, the smaller the number, the shorter the delay will be.

J. Raise to vac off time After the squeegee is raised there is a time delay before the

vacuum motors turn off. This amount of time is called the raise to vac off time. The larger the

number the longer the delay will be, the shorter the number, the shorter the delay will be.

K. Not used

L. Clean to fast travel time When going from full function, double scrub, or vacuum only

to transport mode, there is a time delay before the machine will transport at a higher speed. This

amount of time is called the clean to fast travel time. The larger the number the greater the

amount of time before the machine will go into high speed, the smaller the number, the less the

amount of time will be.

M. Calib value The value in amps that the brush motors will draw in the light

brush pressure setting is called the calib value. This value is the total amps that the motors draw.

The higher the value, the greater the scrubbing pressure will be in light brush pressure. THE

VALUE IN SETTING M PLUS SETTING N CANNOT EXCEED 55. THE VALUE IN SETTING M

PLUS THE VALUE IN SETTING O CANNOT EXCEED 55. PERMANENT MOTOR DAMAGE

WILL OCCUR!

Minuteman PowerBoss Inc. Copyright 2000

12

3800 Rider Scrubber (7/02)

Operation, Maintenance & Troubleshooting

N. Medium Adder. The additional amps that the brush motors draw in medium brush pressure is

called the medium adder. This value is added to the calib value in setting M. The higher the

value, the greater the scrubbing pressure will be in medium brush pressure. THE VALUE IN

SETTING M PLUS SETTING N CANNOT EXCEED 55. THE VALUE IN SETTING M PLUS THE

VALUE IN SETTING O CANNONT EXCEED 55. PERMANENT MOTOR DAMAGE WILL OCCUR!

O. High Adder. The additional amps that the brush motors draw in high brush pressure is

called the high adder. This value is added to the calib value in setting M. The higher the value,

the greater the scrubbing pressure will be in high brush pressure. THE VALUE IN SETTING M

PLUS SETTING N CANNOT EXCEED 55. THE VALUE IN SETTING M PLUS THE VALUE IN

SETTING O CANNONT EXCEED 55. PERMANENT MOTOR DAMAGE WILL OCCUR!

To redraw the screen press ^L.

Press TAB to get to the second programming screen. The second screen of the programming

menu looks like this:

PUMP: MIN LOW HIGH MAX

WATER(IF NORM) A 46 46 F 89 89 K 147 147 P 204 204

WATER (RECYCLE) B 33 33 G 54 54 L 83 83 Q 113 113

SOAP (IF LOW) C 13 13 H 28 28 M 46 46 R 64 64

SOAP (IF MED) D 25 25 I 59 59 N 91 91 S 120 120

SOAP (IF HIGH) E 50 50 J 114 114 O 176 176 T 255 255

^L REDRAW SCREEN, TAB MORE PARAMS, ^P MAINTENCE

These parameters can be adjusted by pressing the letter next to the parameter that is to adjusted.

The number that is in the left column is the current setting, the number in the right column is the

“factory” setting.

This table is a table of all of the water flow rates. It is not recommended that adjustments are

made since chemical metering will no longer be calibrated.

The numbers represent a speed value for the pumps: 1 is off and 255 is full speed. The first

column is the pump description, the second column is the pump speed at one light segment on

the main keyboard, the third column is the pump speed at two light segments on the main keyboard,

the fourth column is the pump speed at three light segments on the main keyboard, the fifth

column is the pump speed at four light segments on the main keyboard.

Minuteman PowerBoss Inc. Copyright 2000

13

3800 Rider Scrubber (7/02)

Operation, Maintenance & Troubleshooting

The first row is the “water (if norm)” row. This is the speed of the solution pump for the various

flow rate settings. The factory settings are .3, .7, 1.1, or 1.5 gal/min.

The second row is the “water (recycle)” row. This is the speed that the solution pump and the

recycle pump will run at if the machine is in recycle mode. The factory settings are .15, .35, .55

or .75 gal/min.

The third row is the “soap (if low)” row. This is the speed that the chemical metering pump will run

at while the machine is running in the low dilution ratio mode. This mode mixes chemical at 1oz/

gal of solution. The factory settings are .3, .7, 1.1 or 1.5 oz/gal.

The fourth row is the “soap (if med)” row. This is the speed that the chemical metering pump will

run at while the machine is running in the medium dilution ratio mode. This mode mixes chemical

at 2 oz/gal of solution. The factory settings are .6, .14, 2.2 or 3.0 oz/gal.

The fifth row is the “soap(if high)” row. This is the speed that the chemical metering pump will run

at while the machine is running in the high dilution ratio. This mode mixes chemical at 4oz/gal of

solution. The factory settings are 1.2, 2.8, 4.4 or 6.0 oz/gal.

To enter into the maintenance mode, press ^P. This mode allows maintenance personnel to

control the outputs of the controller and view the state of the inputs to the controller. The

maintenance screen looks like this:

MAINT MODE V=OVERRRIDE

a b = d e f g h i j k l m n o - - r = 0

I Chms R SolE

H Syst

G Brsh

F VacM O Recy

E Wtrs N TkFl

D Multi M OffA

L Rev

B Sq- K Fwd

A Sq+ J SysR

While in this screen, the state of the output relays are shown (a,b,d,e,f,g,h,i) and the state of the

inputs are shown (j,k,l,m,n,r). The output is “ON” if the letter is capitol and the output is “OFF” is

the letter is lower case. “ON” means that an input as +36V coming in or it means that an output

has +36V coming from it.

Minuteman PowerBoss Inc. Copyright 2000

14

3800 Rider Scrubber (7/02)

Operation, Maintenance & Troubleshooting

The description of the inputs and the outputs are as follows:

Outputs

A Squeegee raise output relay

B Squeegee lower output relay

D Multimode output relay (Connects to speed control board to engage high speed)

E Solution water solenoid output relay

F Vacuum motor output relay

G Brush motor output relay

H System start output relay

I Chemical solenoid output relay

Inputs

J System ready input

K Forward input

L Reverse input

M Off aisle cleaning input

N Recovery tank full input

O Recycle on input

R Solution empty input

The inputs/outputs are self explanatory aside from the system start and system ready. When the

operator presses “1” on the main keyboard the system start output will energize for 1 second.

This will send +36V through the recharge switch and through the keyswitch. If both of these

switches are closed then the main control relay will turn on. When the main control relay turns on

it sends +36V back to the board to the system ready input. If the board does not get +36V to the

system ready input within 1 second then the system start output will deenergize. The only reason

the system ready input would not turn on would be the recharge switch or the keyswitch being

open.

As input changes from 0V to +36V the letter on the first line will change from lower case to a

capitol letter. Conversely, as input changes from +36V to 0V the letter on the first line will change

from a capitol letter to a lower case letter.

Minuteman PowerBoss Inc. Copyright 2000

15

3800 Rider Scrubber (7/02)

Operation, Maintenance & Troubleshooting

When this screen is active the outputs cannot be changed. By pressing “V”, the controller will go

into “Override” mode. The screen will then look like this:

MAINT MODE OVERRRIDE MODE S=SQ UP/DN

a b = d e f g h i j k l m n o - - r = 0

I Chms R SolE

H Syst

G Brsh

F VacM O Recy

E Wtrs N TkFl

D Multi M OffA

L Rev

B Sq- K Fwd

A Sq+ J SysR

When this screen is active, pressing A,B,D,E,F,G,H,I will change the state of the output relays. To

raise/lower the squeegee both the A and B outputs must change. As indicated on the first line,

pressing “S” will raise/lower the squeegee (This actually is changing A and B simultaneously).

Finally, there is a number to the right of the equal sign as shown here:

a b = d e f g h i j k l m n o - - r = 0

This number is the number of amps that the brush motors are actually drawing in real time.

The line below would be 52 amps being drawn by the brush motors.

a b = d e f g h i j k l m n o - - r = 52

Minuteman PowerBoss Inc. Copyright 2000

16

3800 Rider Scrubber (7/02)

Operation, Maintenance & Troubleshooting

AFTER USE:

Turn machine off by pressing the “O” button on the control panel. Machine can be cleaned with

a mild detergent and a damp cloth. Batteries should be charged after each use or when the

battery condition meter shows a low charge. To recharge the batteries, plug the 36V charger into

the recharge port located at the left front side of the machine. The recharge port has an interlock

switch so the machine can not be turned on when the batteries are being recharged. Once the

meter on the battery charger reads 0 amps, the batteries are recharged. This should take

approximately 6-8 hours if the batteries are completely discharged.

BATTERY SERVICE AND INSTALLATION:

WARNING

Battery acid can cause burns. When working on or around batteries, wear protective clothing

and safety glasses. Remove metal jewelry. Do not lay tools or metal objects on top of batteries.

CHARGING OF BATTERIES:

Charging batteries generates explosive gasses. DO NOT CHARGE BATTERIES WHEN OPEN

FLAMES OR SPARKS ARE PRESENT. DO NOT SMOKE. Make sure the charger is turned off

before disconnecting it from the batteries. Charge the batteries in a well-ventilated area. Fluid

levels should be checked before and after charging and maintained at the proper levels. If low,

add water until the metal plates are covered. If the machine is not used for extended periods of

time, batteries should be kept fully charged with a boost charge once a week.

CARBON BRUSH REPLACEMENT:

Design life of carbon brushes is between 1800-2000 hours. Replace brushes if worn to 3/8" or

less, broken, or chipped. All carbon brushes should be replaced when motor is serviced.

Minuteman PowerBoss Inc. Copyright 2000

17

3800 Rider Scrubber (7/02)

Operation, Maintenance & Troubleshooting

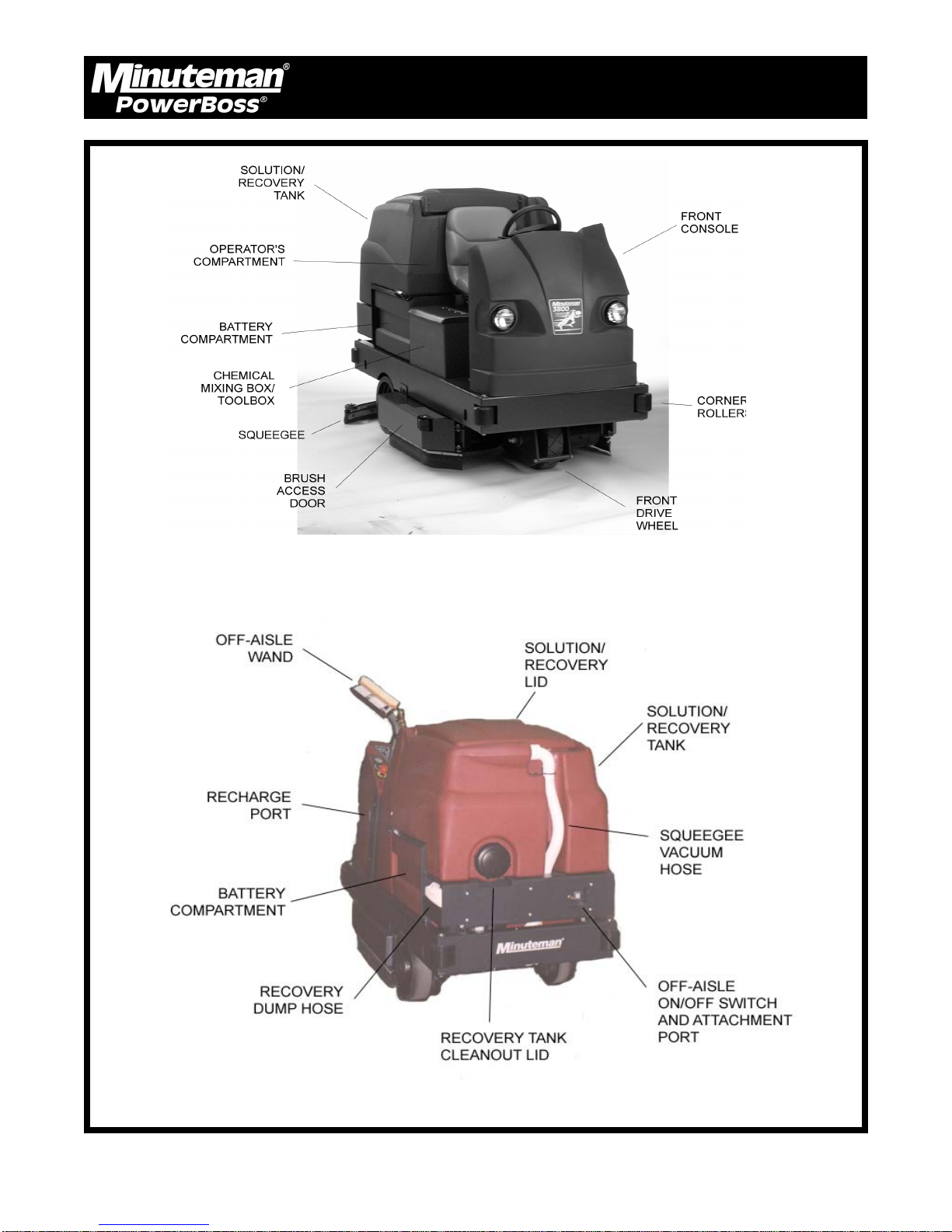

MACHINE OVERVIEW, FRONT

MACHINE OVERVIEW, REAR

Minuteman PowerBoss Inc. Copyright 2000

18

3800 Rider Scrubber (7/02)

Operation, Maintenance & Troubleshooting

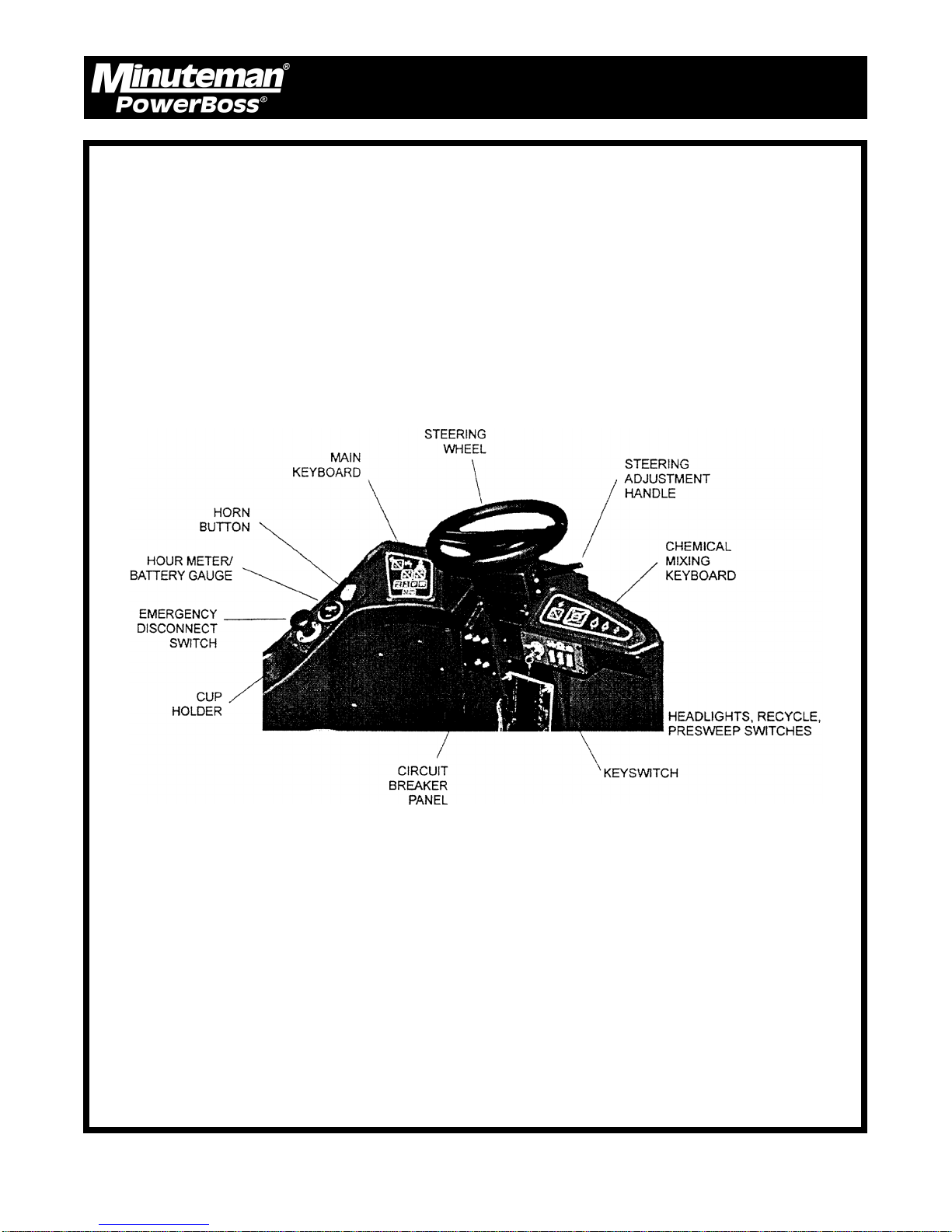

OPERATOR COMPARTMENT

Minuteman PowerBoss Inc. Copyright 2000

19

3800 Rider Scrubber (7/02)

Operation, Maintenance & Troubleshooting

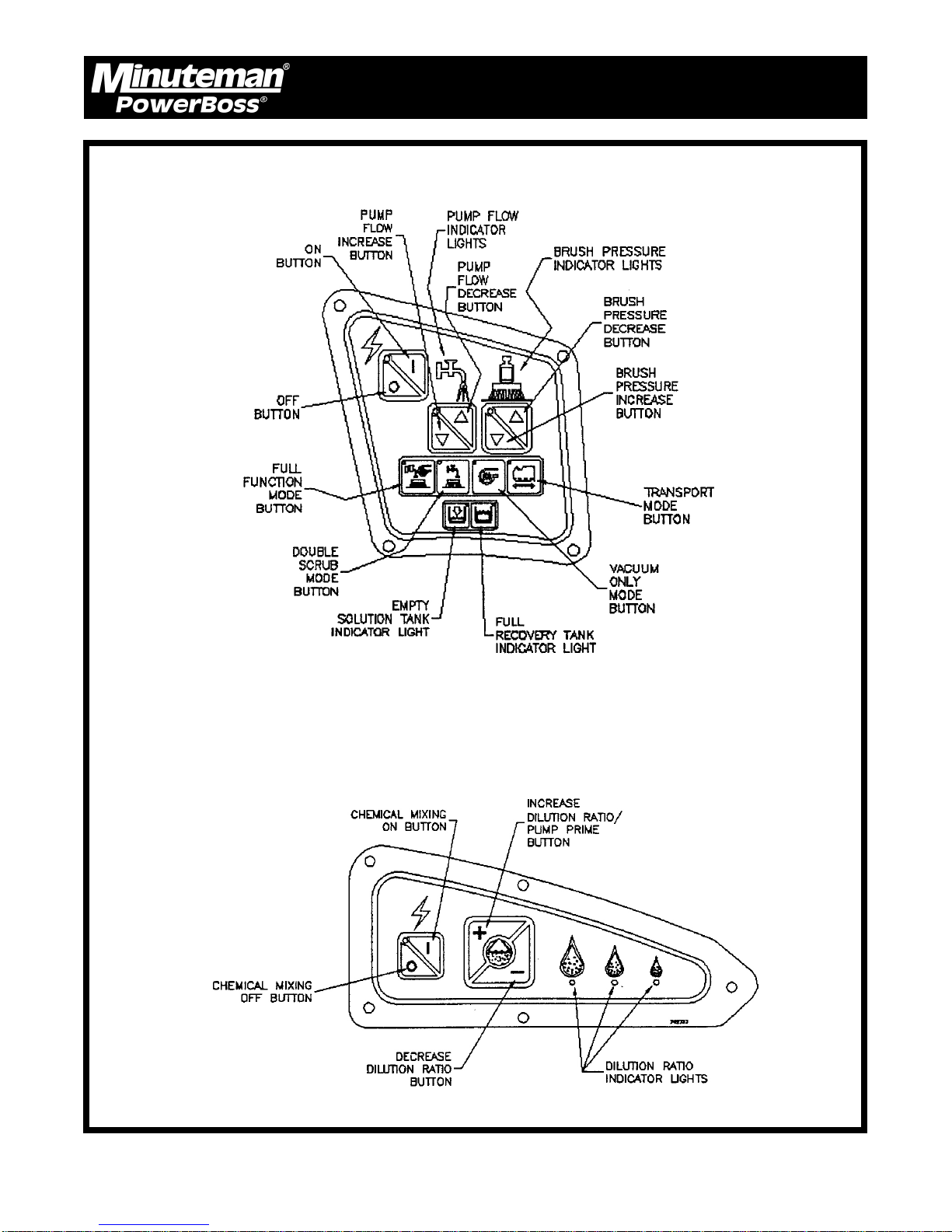

MAIN KEYBOARD

CHEMICAL MIXING KEYBOARD

Minuteman PowerBoss Inc. Copyright 2000

20

3800 Rider Scrubber (7/02)

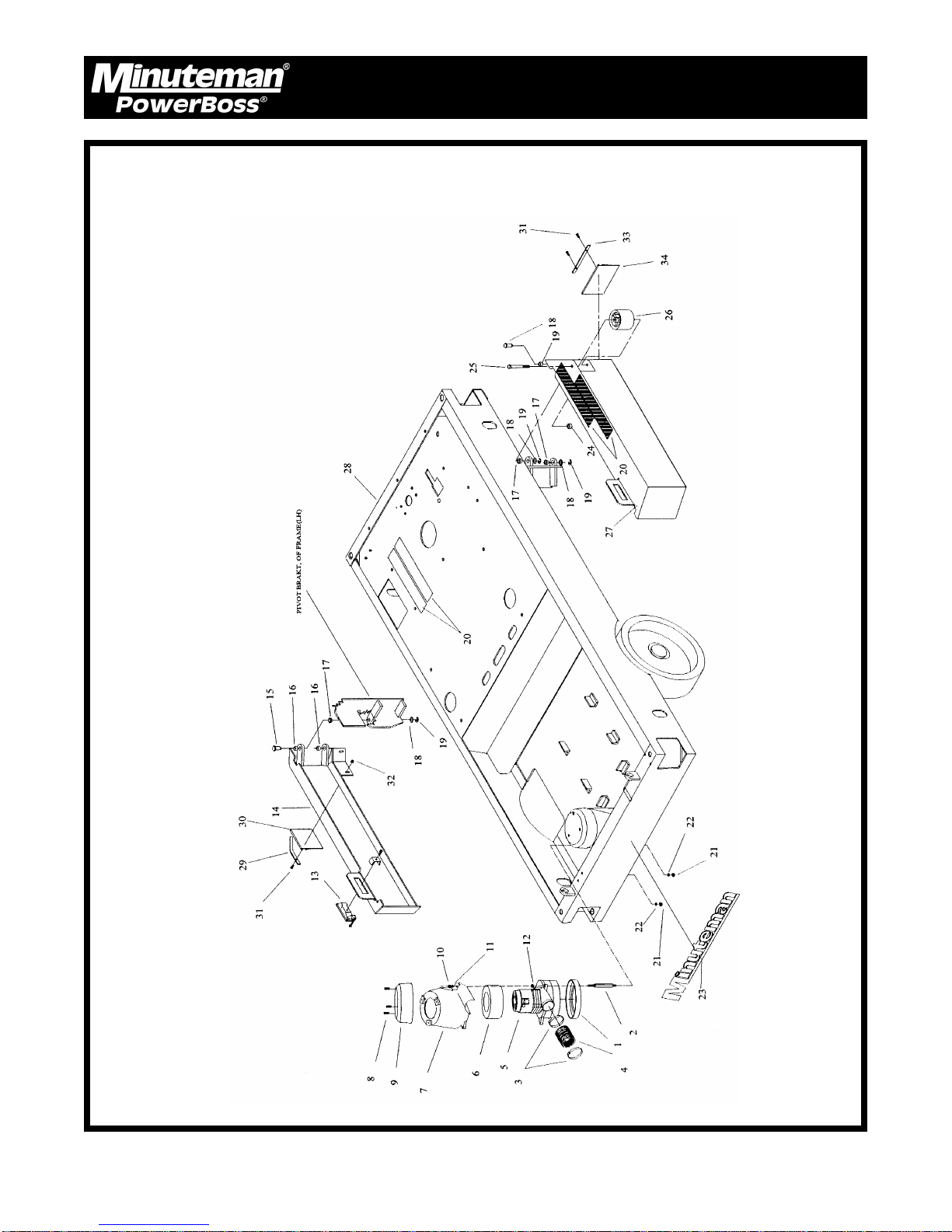

MAIN ASSEMBLY PART I

Parts

Minuteman PowerBoss Inc. Copyright 2000

24

3800 Rider Scrubber (7/02)

Parts List

ITEM PART NO. QTY. DESCRIPTION

1 290017 1 Vac Motor Gasket

2 383143 3 Vac Motor Stand-off

3 829067 2 Hose Clamps

4 383375 1 Short Vac Motor Hose

5 742772 1 Vac Motor Assy.

6 380064 1 Foam Ring

7 840012 1 Vac Motor Cover Bottom

8 711160 3 SCR-Hi/Lo #10 x 5/8

9 840011 1 Vac Motor Cover Top

10 711373 3 Nut-Nyloc 1/4-20

11 711505 3 WSR-Flat 1/4

12 832015 3 Spacer .38 x .50 x .14

13 383256 2 Latch

14 383765 1 Skirt Support Weldment LH

15 260036 4 Pin, Retainer

16 260030 4 Oilite Bushing

17 260041 4 Oilite Flange Bushing

18 711594 4 WSR-Flat .56 x .88 x .03

19 711713 4 Retaining Ring

20 383196 4 Anti-Skid Strips

21 712667 3 Nut-Hex 1/4-20 SS Nyloc

22 711504 3 WSR-Flat 1/4 SS

23 715387 1 Decal, Minuteman

24 711380 1 Nut-Hex 3/8-16 Nyloc

25 711280 1 BLT-HH 3/8-16 x 3.5

26 76-56-A 1 Roller

27 383764 1 Skirt Support Weldment RH

28 383001 1 Mainfame

29 383758 1 Skirt Retainer LH

30 383763 1 Skirt LH

31 712536 4 SCR 10-24 x .62

32 712638 4 Nut Hex 10-24 SS

33 383761 1 Skirt Retainer RH

34 383762 1 Skirt RH

Parts

Items 1-12 are optional.

Minuteman PowerBoss Inc. Copyright 2000

25

3800 Rider Scrubber (7/02)

Loading...

Loading...