Minuteman MC32036QP, MC32036CE Service Manual

320

Model: MC32036QP

Floor Scrubber

Traction Driven

OPERATION

SERVICE PARTS

MC32036CE

CARE

Revised 8/03

TABLE OF CONTENTS

Page

Safety Instructions 1

Electrical Requirements 2

Control Panel Identification 3

Squeegee Adjustments 4

Operating Instructions 5

Maintenance of Machine 6 & 7

Main Polyethylene Components 8 & 9

Recovery Tank 10

Solution Tank 11

Drive Assemblies 12 &13

Main Frame 14 & 15

Console Assembly 16 & 17

Scrubhead Assembly 18

Squeegee Mechanism Assembly 19

Squeegee Assembly Complete 20

Wiring Diagram Standard Model 21

Wiring Diagram CE Model 22

IMPORTANT SAFETY INSTRUCTIONS

CAUTION

Operators must read and understand this manual before operating or maintaining

this equipment.

• Keep hands and feet clear of moving parts while machine is in operation.

• All switches must be in the “OFF” position when charging batteries.

• Electrical motors and components can cause an explosion when operated near explosive materials

or vapors. Do not operate this machine near flammable materials such as solvents, thinners, fuels,

grain dusts, etc.

• Make sure all switches are turned “OFF” and battery connections are removed before performing

any maintenance procedures.

• Store or park this machine on a level surface only.

• These machines are designed for level floor operation only. DO NOT OPERATE on ramps or

inclines.

• Battery acid can cause burns. When working on or around batteries, wear protective clothing and

safety glasses. Remove metal jewelry. Do not lay tools or metal objects on top of batteries.

• This machine is not suitable for picking up hazardous dust.

• Charging batteries generates explosive gases. DO NOT CHARGE BATTERIES WHEN OPEN

FLAMES OR SPARKS ARE PRESENT. DO NOT SMOKE. Make sure the charger is turned off

before disconnecting it from the batteries. Charge the batteries in a well-ventilated area.

• Maintenance and repairs must be performed by authorized personnel.

SAVE THESE INSTRUCTIONS

1

ELECTRICAL REQUIREMENTS:

This piece of equipment operates on 36 Volt DC.

BATTERY REQUIREMENTS:

6 x 6V 220AH P/N 956720

6 x 6V 275AH P/N 956740

BATTERY SERVICE AND INSTALLATION:

* Warning: Battery acid can cause burns. When working on or around batteries, wear protective

clothing and safety glasses. Remove metal jewelry. Do not lay tools or metal objects on top of batteries.

BATTERY INSTALLATION:

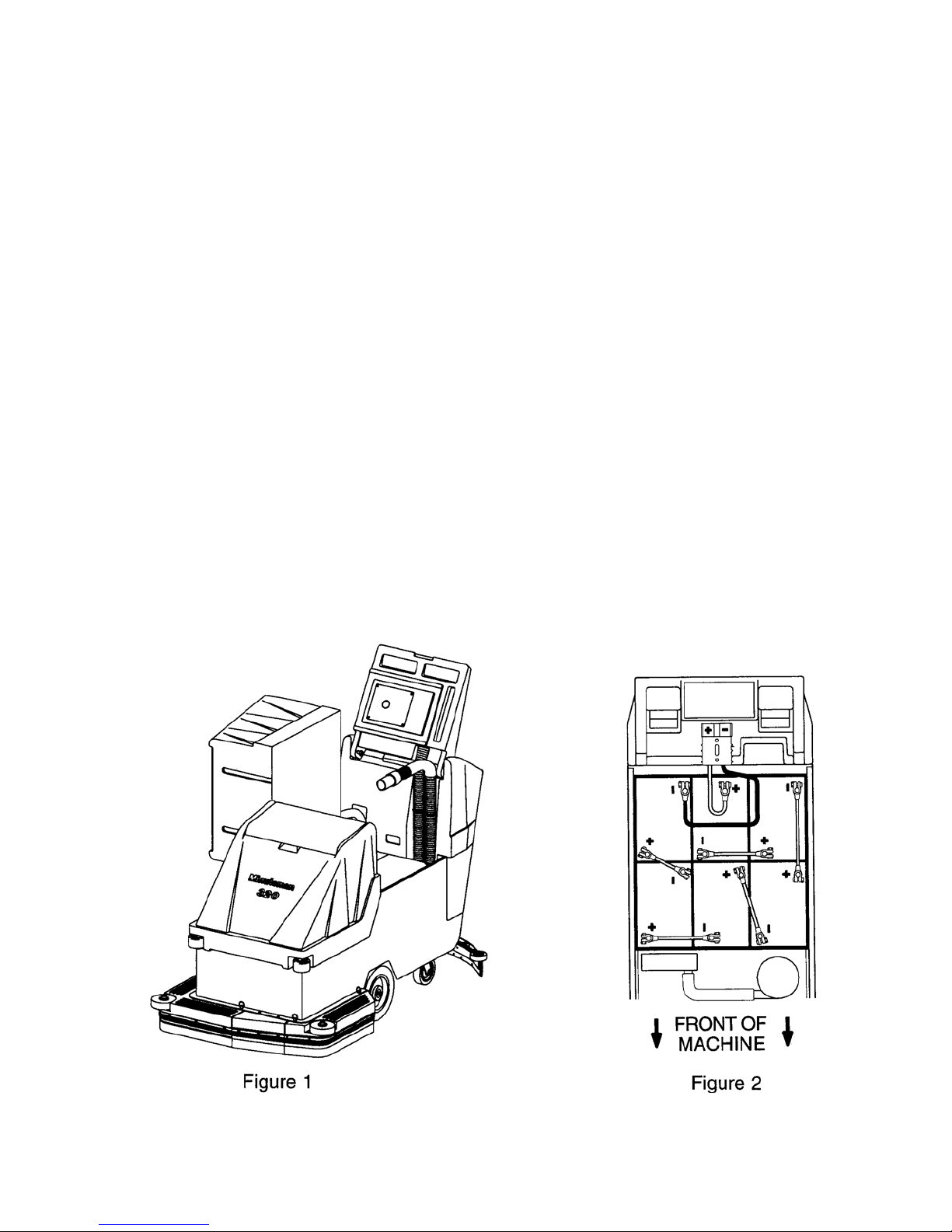

1. Raise tank assembly by raising rear cover and disconnecting vacuum recovery hose, Fig. 1.

2. Tilt recovery tank.

3. Install batteries as shown in figure 2.

CHARGING OF BATTERIES:

Charging of batteries generates explosive gases. DO NOT CHARGE BATTERIES WHEN OPEN

FLAMES OR SPARKS ARE PRESENT. DO NOT SMOKE. Make sure the charger is turned off

before disconnecting it from the batteries. Charge the batteries in a well-ventilated area. Fluid levels

should be checked before and after charging and maintained at the proper levels.

2

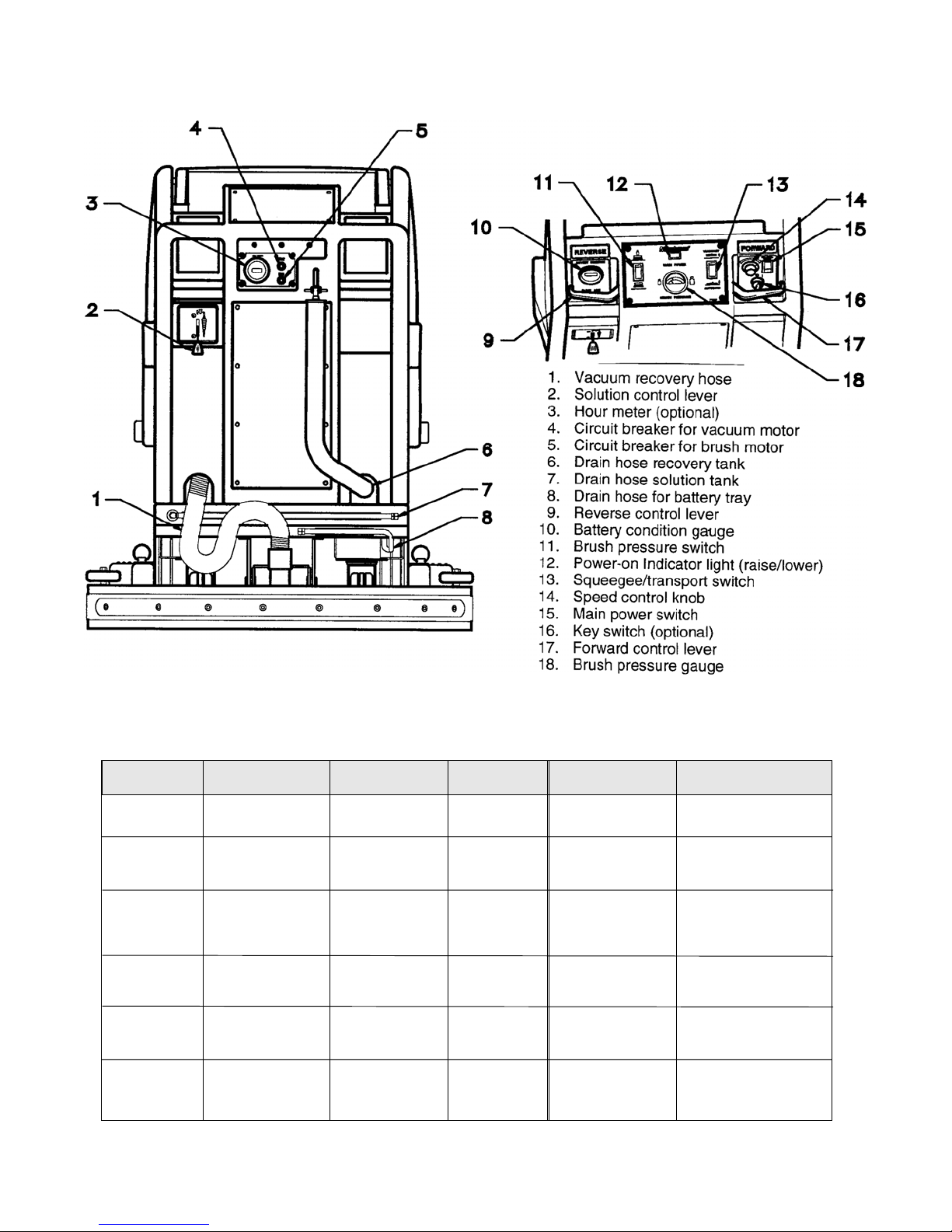

CONTROL PANEL IDENTIFICATION

AUTO SCRUBBER BRUSH DESCRIPTION

TYPE DESCRIPTION DURABILITY* COLOR COMPARISON RECOMMENDED

TO PADS USE

Bassine Natural Fiber Short DarkBrown Red Light duty

Nylon Nylon Medium Black Tan/Red General cleaning

Dyna-Scrub Nylon impregnated Long Light Red General scrubbing,

with 500 Grit Blue vinyl tile, ceramic

Silicone Carbide tile, epoxy floors,

Fine Bristle, urethane finish,

Dense Fill uneven concrete floors

Power-Scrub Nylon impregnated Long Rust Red/Blue Moderate aggressive

with 120 Grit Silicon scrubbing, tile floors

Carbide Fine Bristle, concrete floors

Dense Fill

Poly-Grit Nylon impregnated Long Green Brown/Black Aggressive stripping

with 80 Grit and scrubbing, tile

Silicon Carbide floors, unfinished

Coarse Bristle concrete floors

Strata-Grit Nylon impregnated Long Dark Black Heavy duty

with 46 Grit Blue stripping/scrubbing

Silicon Carbide unfinshed

Coarse Bristle concrete

general cleaning,

acid etching

& scrubbing vinyl

floors, ceramic tile

& concrete floors

* Durability is dependent on floor surface, chemicals used and proper care.

3

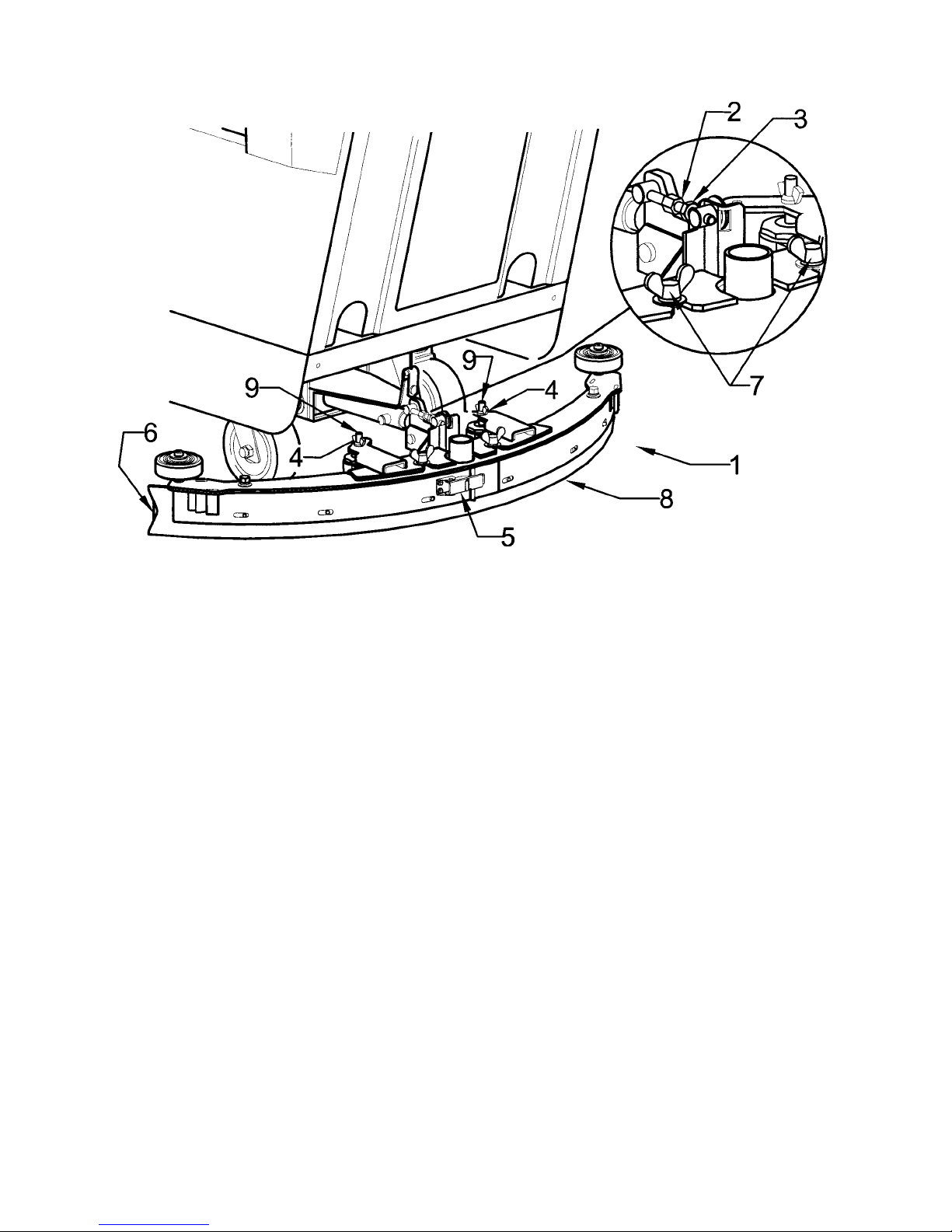

SQUEEGEE ADJUSTMENTS

The squeegee set-up is pre-adjusted at the factory. Adjustments may be required to get optimum performance for

different floors and conditions.

1. Ensure that the scrubber is on a relatively flat surface. Turn on the main power switch and raise the scrub

head assembly off the floor. Set the squeegee/ vacuum switch to the automatic mode.

2. Turn the speed control knob counter-clockwise to the low speed position. Squeeze the forward control lever to lower

the squeegee (item 1) to the floor. Move the machine one or two feet forward to check the rear squeegee blade (item

8) for uniform deflection to the floor.

3. If uneven deflection or lay is evident, minor adjustments may be necessary to avoid streaking and uneven wear on

the blade.

4. To correct this, loosen the wing jam nut (item 4) in order to adjust the caster height. If the squeegee blade is

deflecting too much, the casters need to be lowered to control the down pressure. Lower the caster by turning the

exposed threaded stem (item 9) on the caster clockwise. Make the adjustment a few turns at a time.

5. Repeat step 2.

6. In certain applications where a different blade set-up is required, the reinforcement blade (item 4) may be turned

upside down. The notch, which is normally on the bottom will now be located on the top side. This adjustment

allows the rear squeegee blade a larger deflection than normal.

7. Make sure that there is an even deflection on the entire length of the rear blade. Adjust the castors and retighten the

wing jam nuts to lockthe caster setting in place.

8. Pitch adjustment is necessary if the outer ends on the squeegee blade does not contact the floor and there is too

much deflection in the middle area or if the outer ends are over deflected and there is no contact in the middle.

9. To adjust pitch, lower the squeegee to the floor. Loosen the lock nut (item 3) in the turnbuckle assembly. Turning

the turnbuckle (item 2) clockwise or counterclockwise controls the forward and backward pitch of the squeegee.

Having the rear blades deflected uniformly along its entire length is the desired setup.

10. Repeat Step 2 until the desired setup is achieved.

11. In certain applications where a non-slotted front wiper blade (item 6) is needed, detach the squeegee assembly by

loosening the wing bolts (item7). Unlock the clamp on the front squeegee to release the straps and flip the blade

over to the non-slotted side. Reattach straps and lock the clamp back in place.

12. You can also easily replace the rear blade by unlatching the latch (item 5) and removing the straps by sliding them

off the assembly.

4

OPERATING INSTRUCTIONS

1. Filling: Fill the solution tank with the desired amount of water and add liquid cleaning solution to

the proper dilution ratio. DO NOT USE powdered cleaning chemicals. Powders are unlikely to

dissolve thoroughly, resulting in clogging the in-line solution filter. This can reduce or stop water

flow to the brush.

2. Close lid.

3. Turn on main power switch (Refer to Page 3 #16).

4. Adjust main speed control #15 to full counter-clockwise position.

5. Lower brush assembly (ref. page 3 #12) using switch. Brushes will not come on until forward #18

or reverse #10 lever are pulled. Brushes will remain on for 3 to 5 seconds after levers are released.

Adjustments to brush pressure can be made by depressing switch #12 and reading brush pressure

gauge #19.

6. Squeegee Control/Vacuum. Switch #14 has two positions one is for transport/ double scrubbing,

when the switch is in this position the squeegee will raise and the vacuum will turn off. With the

switch in automatic mode the squeegee will automatically lower in forward movement of the

machine and vacuum will turn on. When the machine is reversed the squeegee will automatically

raise and the vacuum motor will turn off.

7. Solution Control #2. The solution lever is a mechanical cable that opens the solution valve. This

lever must be moved to the full on position then decrease to desired flow to operate properly.

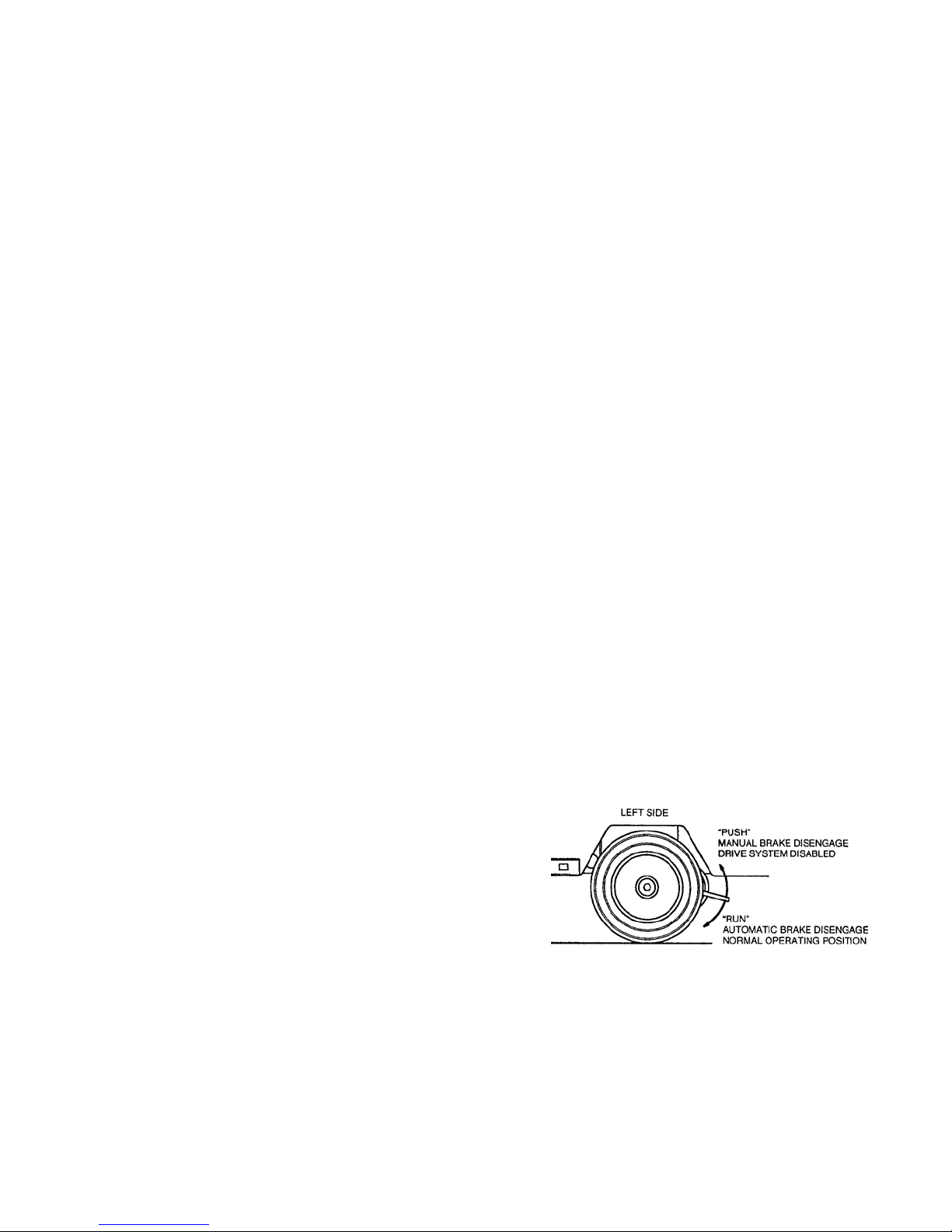

AUTOMATIC PARKING BRAKE OPERATION (CE Only):

Brake lever located behind left wheel.

Run Mode - Normal operation; Brake lever in down position.

• When the power is turned off the brake is automatically engaged.

• When the power is turned on the brake is automatically disengaged and the drive system is enabled.

Push Mode - Machine inoperable; Brake lever in up position.

• Brake is manually disengaged.

• Power is shut off to the drive system.

MAINTENANCE:

Daily

1. Clean float assembly & squeegee blades. Vac filter.

2. Recharge batteries (check battery acid levels before and after charging).

Monthly

1. Check wear on squeegee blades.

2. Grease rear wheels.

3. Grease pivot points on brush motor assembly.

5

MAINTENANCE OF MACHINE

VACUUM MOTOR

Motor brushes can be replaced with Brush Set, Part No. 741008. Brushes should be replaced only

once. More than once brush replacement will cause very high current consumption. This undue current consumption lowers overall machine performance and is not in the best interest of economical

machine use.

CARBON BRUSHES IN DRIVE MOTOR

Inspect these brushes once every 18 months or 720 hours.

The brushes can now be inspected by removing the brush caps near the end of the drive motor.

Examine all four brush lengths; if the back end of a brush is even with the edge of the brush holder or

shorter, the brush must be replaced. Replace with Brush Set, Part No. 744155. When installing new

brushes, also inspect cummutator for pits and/or excessive wear. If it is in poor condition, replace

drive motor with Part No. 744154.

CARBON BRUSHES IN BRUSH DRIVE MOTORS

Inspect these brushes once every six months or 360 hours.

Remove scrub head assembly. Examine brush lengths; if the back end of brush is even with the edge

of the brush holder or shorter, the brush must be replaced. Replace with Part No. 833474. When

installing new brushes, also inspect commutator for pits and/or excessive wear. Replace motor with

Part No. 742714 if commutator is in poor condition.

LUBRICATION

1. Grease casters once every week (two fittings per caster) or 15 hours.

2. Oil all moving parts such as hinges and pressure points once every month or every 60 hours.

SQUEEGEE RUBBERS

When the thick rear squeegee rubber is damaged or worn excessively, it will cause streaking and

poor solution pickup. Extended rubber life and be obtained by reversing it, provided it is not torn or

otherwise damaged. Do not tighten screws so tightly that squeegee rubbers are made to bulge and

show an uneven edge.

TANKS

At the end of a day’s work (or work cycle, both the vacuum and solution tanks should be drained and

flushed with warm water.

Once a week for 15 hours the vacuum tank should be cleaned of settled debris. This can be done by lowering the drain hose and

washing out the debris.

BATTERIES (956720, 956740)

Periodically remove batteries from machine. Clean batteries, battery tray, and battery compartment

with a solution of baking soda and water. Check all battery cables and wiring for signs of damage or

wear. Replace as needed. Check battery fluid level each charge. Check electrolyte with hydrometer

every 15 hours.

6

Loading...

Loading...