Minuteman 260, MC260026CETD, MC260024QPBD, MC260024CEBD, MC260026QPTD Service Manual

260

Floor Scrubber

Traction Driven

Brush Driven

Model:Model:

Model:

Model:Model:

MC260024QPBDMC260024QPBD

MC260024QPBD

MC260024QPBDMC260024QPBD

MC260026QPTDMC260026QPTD

MC260026QPTD

MC260026QPTDMC260026QPTD

MC260024CEBDMC260024CEBD

MC260024CEBD

MC260024CEBDMC260024CEBD

MC260026CETDMC260026CETD

MC260026CETD

MC260026CETDMC260026CETD

OPERAOPERA

OPERA

OPERAOPERA

TIONTION

TION

TIONTION

SERVICESERVICE

SERVICE

SERVICESERVICE

PP

P

PP

ARAR

AR

ARAR

TSTS

TS

TSTS

CARECARE

CARE

CARECARE

Revised 9/05

TT

ABLE OF CONTENTSABLE OF CONTENTS

T

ABLE OF CONTENTS

TT

ABLE OF CONTENTSABLE OF CONTENTS

Safety Instructions .............................................................. 1

Electrical Requirements .................................................... 2

Control Panel Identification ................................................. 3

Squeegee Adjustments ...................................................... 4

Operating Instructions ........................................................5

Main Polyethylene Components .................................. 6 & 7

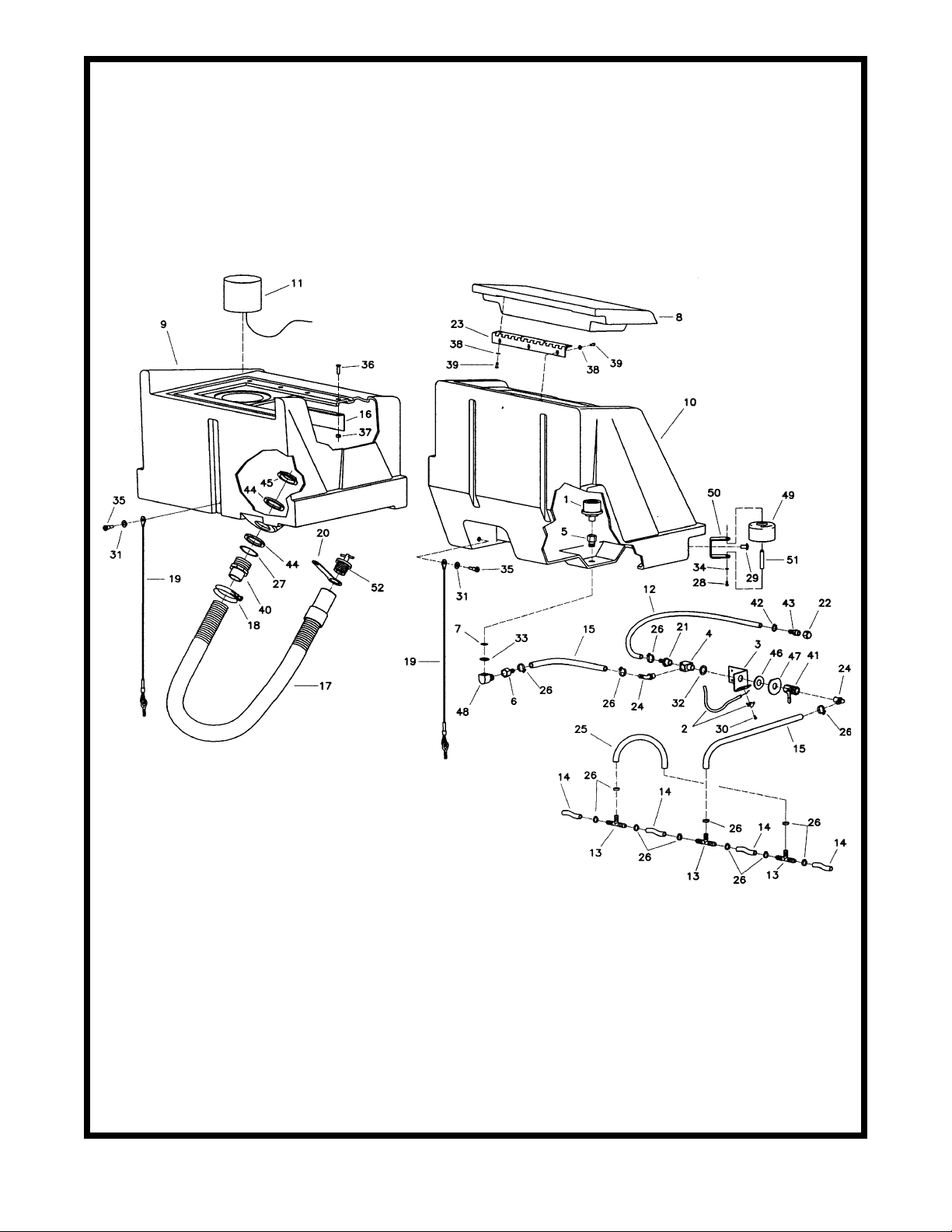

Recovery Tank and Solution Tank................................ 8 & 9

Drive Assemblies (Brush Driven) ............................. 10 & 11

Mainframe (Brush Driven) ....................................... 12 & 13

Console Assembly (Brush Driven) .......................... 14 & 15

Recovery Tank and Solution Tank............................ 16 & 17

Drive Assemblies (Traction Driven) ......................... 18 & 19

Mainframe (Traction Drive) ...................................... 20 & 21

Console Assembly (Traction Driven) ....................... 22 & 23

Squeegee Mechanism Assembly ..................................... 24

Squeegee Assembly Complete ........................................25

Wiring Diagram (Brush Driven) ........................................ 26

Wiring Diagram (Brush Driven, CE Model) ...................... 27

Wiring Diagram (Traction Driven)..................................... 28

Wiring Diagram (Traction Driven, CE Model) ...................29

IMPORIMPOR

IMPOR

IMPORIMPOR

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

Operators must read and understand this manual before operating or maintaining

this equipment.

• Keep hands and feet clear of moving parts while machine is in operation.

• All switches must be in the “OFF” position when charging batteries.

• Electrical motors and components can cause an explosion when operated near explosive materials

or vapors. Do not operate this machine near flammable materials such as solvents, thinners, fuels,

grain dusts, etc.

• Make sure all switches are turned “OFF” and battery connections are removed before performing

any maintenance procedures.

• Store or park this machine on a level surface only.

TT

ANTANT

T

ANT

TT

ANTANT

SAFETY SAFETY

SAFETY

SAFETY SAFETY

INSTRUCTIONS INSTRUCTIONS

INSTRUCTIONS

INSTRUCTIONS INSTRUCTIONS

• These machines are designed for level floor operation only. DO NOT OPERATE on ramps or

inclines.

• Battery acid can cause burns. When working on or around batteries, wear protective clothing and

safety glasses. Remove metal jewelry. Do not lay tools or metal objects on top of batteries.

• This machine is not suitable for picking up hazardous dust.

• Charging batteries generates explosive gases. DO NOT CHARGE BATTERIES WHEN OPEN

FLAMES OR SPARKS ARE PRESENT. DO NOT SMOKE. Make sure the charger is turned off

before disconnecting it from the batteries. Charge the batteries in a well-ventilated area.

• Maintenance and repairs must be performed by authorized personnel.

SASA

SA

SASA

VE VE

THESE INSTRUCTIONSTHESE INSTRUCTIONS

VE

THESE INSTRUCTIONS

VE VE

THESE INSTRUCTIONSTHESE INSTRUCTIONS

1

ELECTRICAL REQUIREMENTS:ELECTRICAL REQUIREMENTS:

ELECTRICAL REQUIREMENTS:

ELECTRICAL REQUIREMENTS:ELECTRICAL REQUIREMENTS:

This piece of equipment operates on 24 Volt DC.

BABA

BA

BABA

TTERTTER

TTER

TTERTTER

YY

REQUIREMENTS: REQUIREMENTS:

Y

REQUIREMENTS:

YY

REQUIREMENTS: REQUIREMENTS:

4 x 6V 220AH P/N 956720

4 x 6V 275AH P/N 956740

BABA

TTERTTER

BA

TTER

BABA

TTERTTER

**

* Warning: Battery acid can cause burns. When working on or around batteries, wear protective

**

YY

SER SER

Y

SER

YY

SER SER

VICE VICE

VICE

VICE VICE

AND INSTAND INST

AND INST

AND INSTAND INST

ALLAALLA

ALLA

ALLAALLA

TION:TION:

TION:

TION:TION:

clothing and safety glasses. Remove metal jewelry. Do not lay tools or metal objects on top of

batteries.

BABA

BA

BABA

TTERTTER

TTER

TTERTTER

YY

INST INST

Y

INST

YY

INST INST

ALLAALLA

ALLA

ALLAALLA

TION:TION:

TION:

TION:TION:

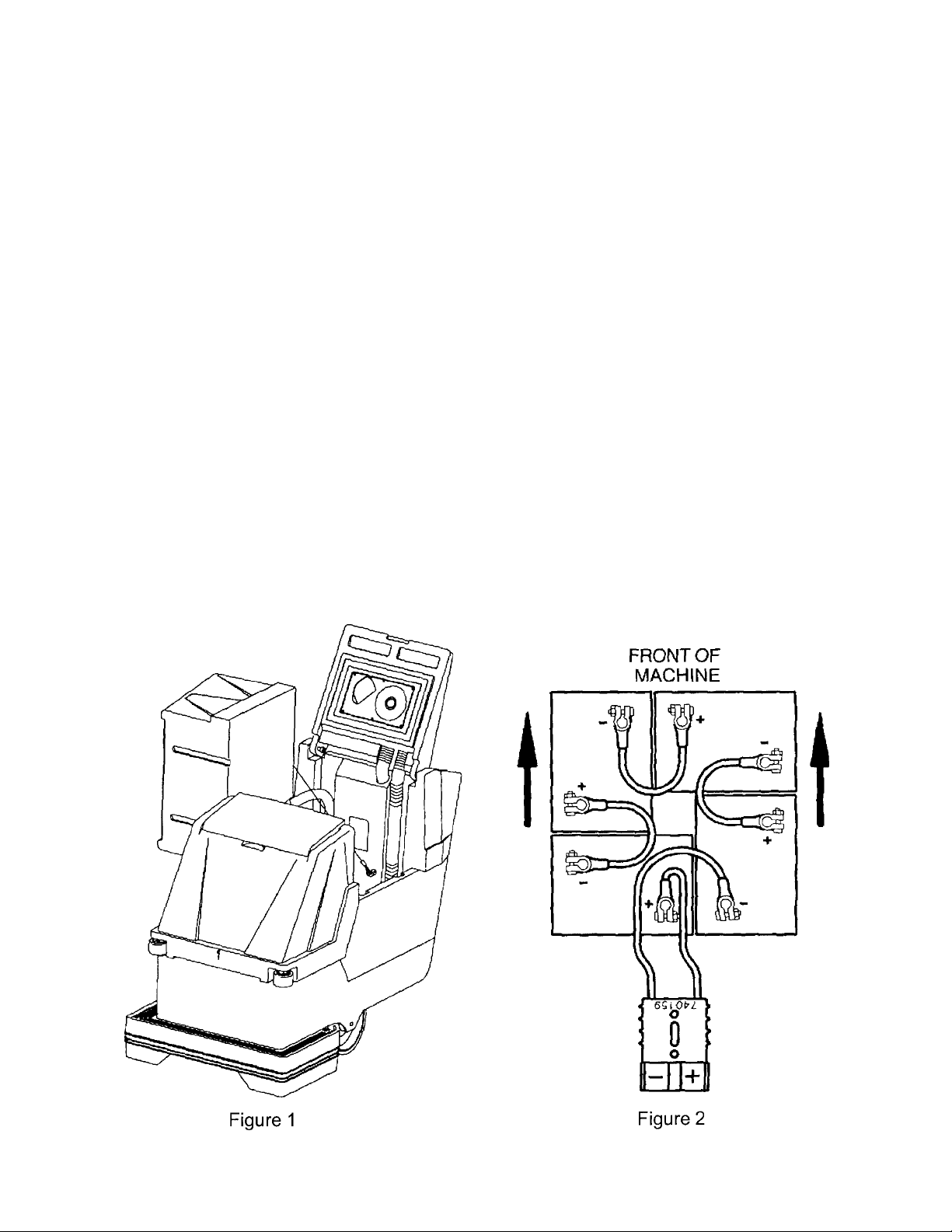

1. Disconnect tank drain hose from rear of machine (6).

2. Raise tank assembly by raising rear cover and tilting tank, Figure 1.

3. Install batteries as shown in Figure 2.

CHARGING OF BACHARGING OF BA

CHARGING OF BA

CHARGING OF BACHARGING OF BA

TTERIES:TTERIES:

TTERIES:

TTERIES:TTERIES:

Charging of batteries generates explosive gases. DO NOT CHARGE BATTERIES WHEN OPEN

FLAMES OR SPARKS ARE PRESENT. DO NOT SMOKE. Make sure the charger is turned off

before disconnecting it from the batteries. Charge the batteries in a well-ventilated area. Fluid levels

should be checked before and after charging and maintained at the proper levels.

2

CONTROLCONTROL

CONTROL

CONTROLCONTROL

P P

ANELANEL

P

ANEL

P P

ANELANEL

IDENTIFICA IDENTIFICA

IDENTIFICA

IDENTIFICA IDENTIFICA

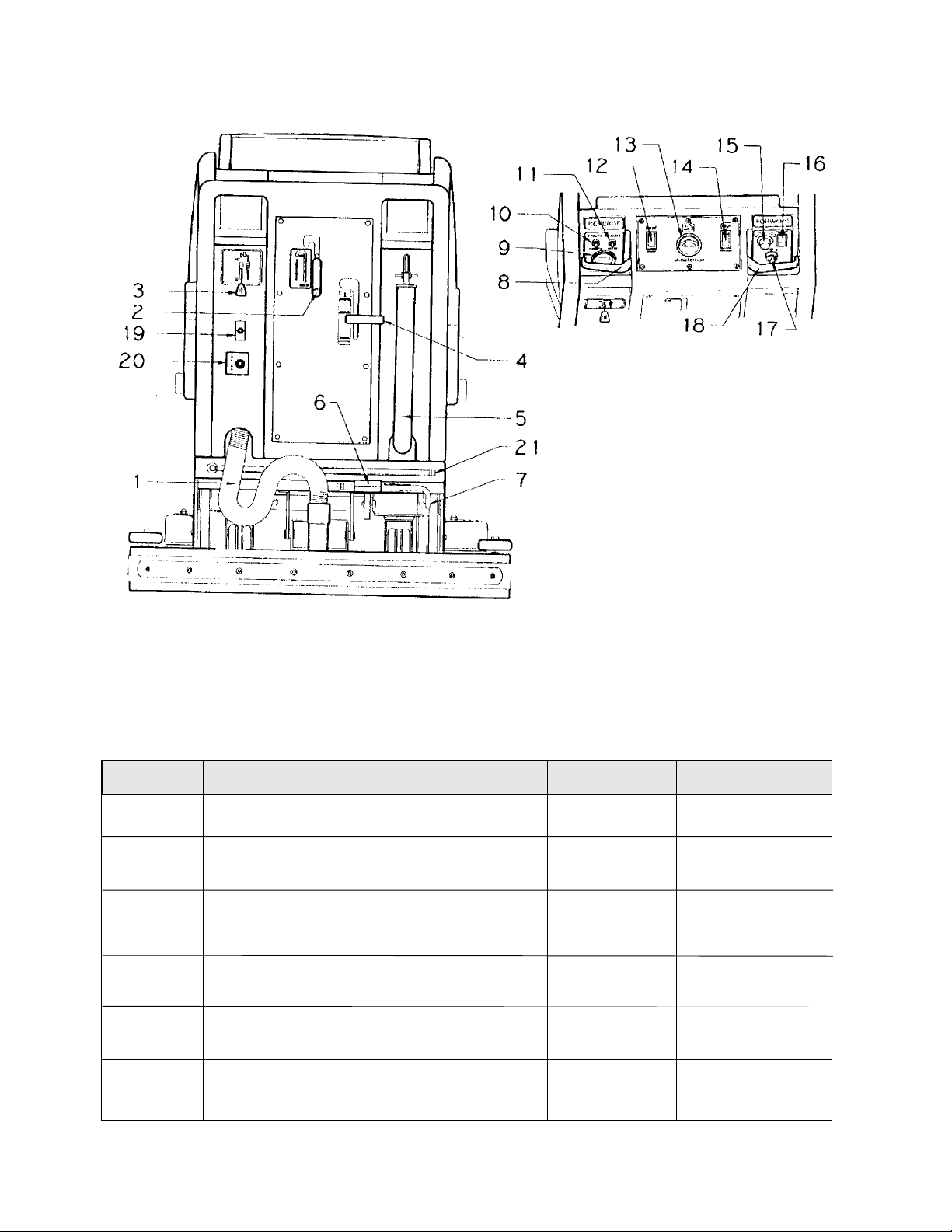

1. Vacuum recovery hose

2. Squeegee lift lever

3. Solution control lever

4. Brush pressure handle

5. Drain hose for recovery tank

6. Foot pedal for lower/raising brush

7. Drain hose for battery tray

8. Reverse control lever

9. Hour meter (optional)

10. Circuit breaker for vacuum motor

11. Circuit breaker for brush motor

12. Brush switch

13. Battery condition gauge

14. Vacuum switch

15. Speed control knob

16. Main power switch

17. Key switch (optional)

18. Forward control lever

19. Pump switch (optional)

20. Quick disconnect aux. out (optional)

21. Dump hose for solution tank

TIONTION

TION

TIONTION

AUTO SCRUBBER BRUSH DESCRIPTIONAUTO SCRUBBER BRUSH DESCRIPTION

AUTO SCRUBBER BRUSH DESCRIPTION

AUTO SCRUBBER BRUSH DESCRIPTIONAUTO SCRUBBER BRUSH DESCRIPTION

TYPE TYPE

TYPE

TYPE TYPE

Bassine Natural Fiber Short Dark Red Light duty

Nylon Nylon Medium Black Tan/Red General cleaning

Dyna-Scrub Nylon impregnated Long Light Red General scrubbing,

Power-Scrub Nylon impregnated Long Rust Red/Blue Moderate aggressive

Poly-Grit Nylon impregnated Long Green Brown/Black Aggressive stripping

Strata-Grit Nylon impregnated Long Dark Black Heavy duty

DESCRIPTION DESCRIPTION

DESCRIPTION

DESCRIPTION DESCRIPTION

with 500 Grit Blue vinyl tile, ceramic

Silicone Carbide tile, epoxy floors,

Fine Bristle, urethane finish,

Dense Fill uneven concrete floors

with 120 Grit Silicon scrubbing, tile floors

Carbide Fine Bristle, concrete floors

Dense Fill

with 80 Grit and scrubbing, tile

Silicon Carbide floors, unfinished

Coarse Bristle concrete floors

with 46 Grit Blue stripping/scrubbing

Silicon Carbide unfinshed

Coarse Bristle concrete

**

Durability is dependent on floor surface, chemicals used and proper care. Durability is dependent on floor surface, chemicals used and proper care.

*

Durability is dependent on floor surface, chemicals used and proper care.

Durability is dependent on floor surface, chemicals used and proper care. Durability is dependent on floor surface, chemicals used and proper care.

**

DURABILITY* DURABILITY*

DURABILITY*

DURABILITY* DURABILITY*

COLOR COLOR

COLOR

COLOR COLOR

Brown general cleaning,

COMP COMP

COMP

COMP COMP

TT

T

TT

ARISONARISON

ARISON

ARISONARISON

O PO P

ADSADS

O P

ADS

O PO P

ADSADS

RECOMMENDED RECOMMENDED

RECOMMENDED

RECOMMENDED RECOMMENDED

USE USE

USE

USE USE

acid etching

& scrubbing vinyl

floors, ceramic tile

& concrete floors

3

SQUEEGEE SQUEEGEE

SQUEEGEE

SQUEEGEE SQUEEGEE

ADJUSTMENTSADJUSTMENTS

ADJUSTMENTS

ADJUSTMENTSADJUSTMENTS

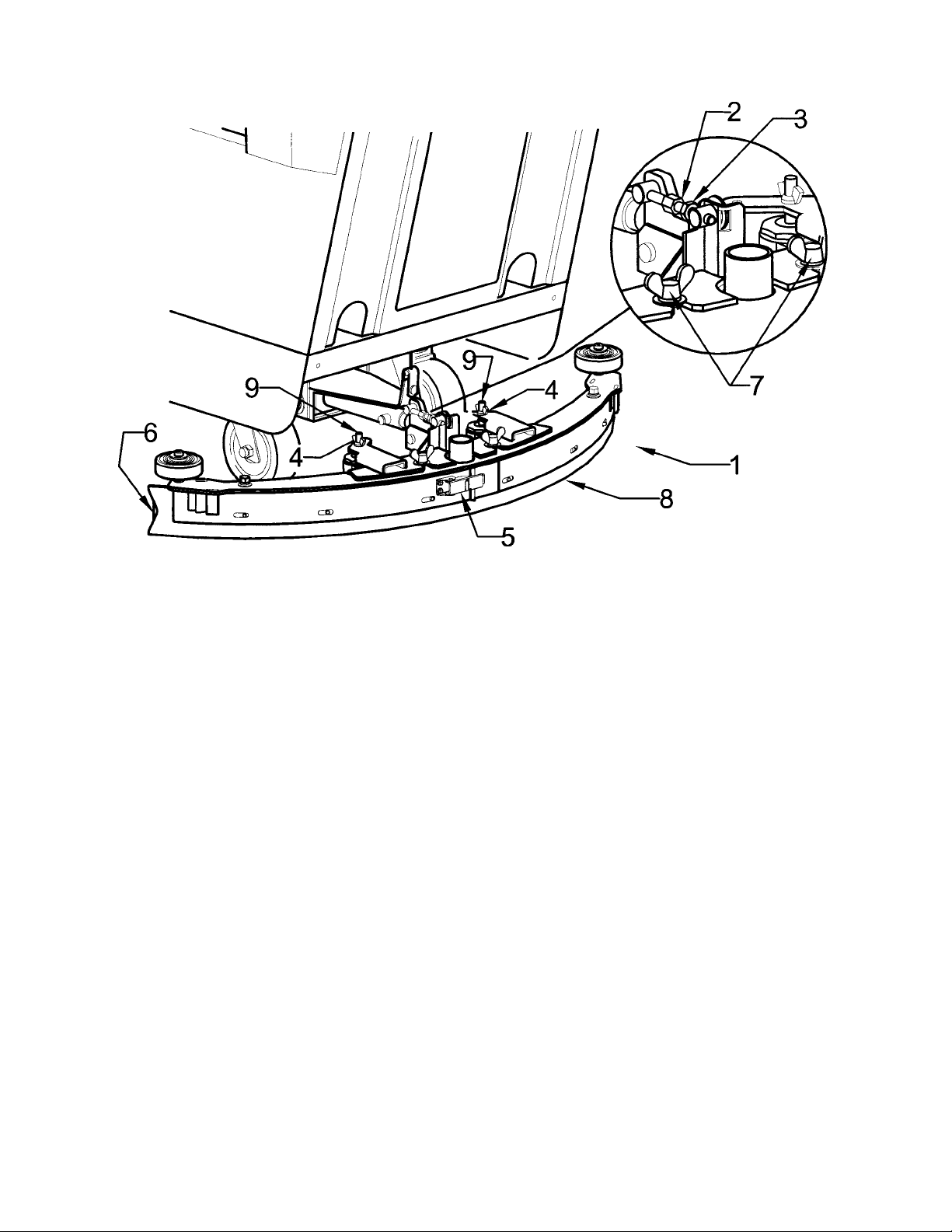

The squeegee set-up is pre-adjusted at the factory. Adjustments may be required to get optimum performance for

different floors and conditions.

Ensure that the scrubber is on a relatively flat surface. Ensure that the scrubber is on a relatively flat surface.

1.

Ensure that the scrubber is on a relatively flat surface.

Ensure that the scrubber is on a relatively flat surface. Ensure that the scrubber is on a relatively flat surface.

head assembly ofhead assembly of

head assembly of

head assembly ofhead assembly of

2. Turn the speed control knob counter-clockwise to the low speed position. Squeeze the forward control lever to lower

the squeegee (item 1) to the floor. Move the machine one or two feet forward to check the rear squeegee blade (item

8) for uniform deflection to the floor.

3. If uneven deflection or lay is evident, minor adjustments may be necessary to avoid streaking and uneven wear on

the blade.

4. To correct this, loosen the wing jam nut (item 4) in order to adjust the caster height. If the squeegee blade is

deflecting too much, the casters need to be lowered to control the down pressure. Lower the caster by turning the

exposed threaded stem (item 9) on the caster clockwise. Make the adjustment a few turns at a time.

5. Repeat step 2.

6. If the blades are not deflecting enough, raise the caster by turning the stem counter-clockwise to adjust the caster

hieght to allow more down pressure on the squeegee. Repeat Step 2.

7. Make sure that there is an even deflection on the entire length of the rear blade. Adjust the castors and retighten the

wing jam nuts to lockthe caster setting in place.

8. Pitch adjustment is necessary if the outer ends on the squeegee blade does not contact the floor and there is too

much deflection in the middle area or if the outer ends are over deflected and there is no contact in the middle.

9. To adjust pitch, lower the squeegee to the floor. Loosen the lock nut (item 3) in the turnbuckle assembly. Turning

the turnbuckle (item 2) clockwise or counterclockwise controls the forward and backward pitch of the squeegee.

Having the rear blades deflected uniformly along its entire length is the desired setup.

10. Repeat Step 2 until the desired setup is achieved.

11. In certain applications where a non-slotted front wiper blade (item 6) is needed, detach the squeegee assembly by

loosening the wing bolts (item7). Unlock the clamp on the front squeegee to release the straps and flip the blade

over to the non-slotted side. Reattach straps and lock the clamp back in place.

12. You can also easily replace the rear blade by unlatching the latch (item 5) and removing the straps by sliding them

off the assembly.

f the floorf the floor

f the floor

f the floorf the floor

. Set the squeegee/ vacuum switch to the automatic mode.. Set the squeegee/ vacuum switch to the automatic mode.

. Set the squeegee/ vacuum switch to the automatic mode.

. Set the squeegee/ vacuum switch to the automatic mode.. Set the squeegee/ vacuum switch to the automatic mode.

TT

urn on the main power switch and raise the scruburn on the main power switch and raise the scrub

T

urn on the main power switch and raise the scrub

TT

urn on the main power switch and raise the scruburn on the main power switch and raise the scrub

4

OPERAOPERA

OPERA

OPERAOPERA

1. Filling: Fill the solution tank with the desired amount of water and add liquid cleaning solution to

the proper dilution ratio. DO NOT USE powdered cleaning chemicals. Powders are unlikely to

dissolve thoroughly, resulting in clogging the in-line solution filter. This can reduce or stop water

flow to the brush.

2. Close lid.

3. Turn on main power switch (refer to Page 3, #16). (Traction Drive Only)

4. Adjust main speed control, #15 to full counter-clockwise position. (Traction Drive Only)

5. Lower brush assembly:

• Depress foot pedal (6) slightly and push in on lever (4) to release, to increase brush pressure

pull up and back on lever (4) to lock in position.

• To lift the brush, press the pedal down until lift mechanism engages.

6. Turn on brush switch.

7. Adjust solution control feed lever.

8. Select vacuum operation:

Brush Driven Models – Turn vacuum switch to “On” position Traction Driven Models

a) “Vacuum On” mode – Vacuum will remain on until switched to the “off” position

b) “Vacuum Auto” mode – Vacuum will come on automatically when forward or reverse handles

are squeezed, and remain on approximately 5 seconds after handle release.

TING INSTRUCTIONSTING INSTRUCTIONS

TING INSTRUCTIONS

TING INSTRUCTIONSTING INSTRUCTIONS

9. Lower squeegee assembly.

10. Squeeze forward handle #18 and adjust forward speed. (Traction Drive Only)

After Use:

1. Turn off solution feed.

2. Switch off brush and raise.

3. Raise squeegee assembly.

4. Turn off vacuum motor.

5. Solution and recovery tanks should be emptied after every use.

MAINTENANCE:MAINTENANCE:

MAINTENANCE:

MAINTENANCE:MAINTENANCE:

Daily

1. Clean float assembly & squeegee blades.

2. Recharge batteries (check battery acid levels before and after charging).

Monthly

1. Check wear on squeegee blades.

2. Grease front and rear wheels.

3. Grease pivot points on brush motor assembly.

Every 500 hours check condition of carbon brushes on vacuum motor and brush drive motor.

5

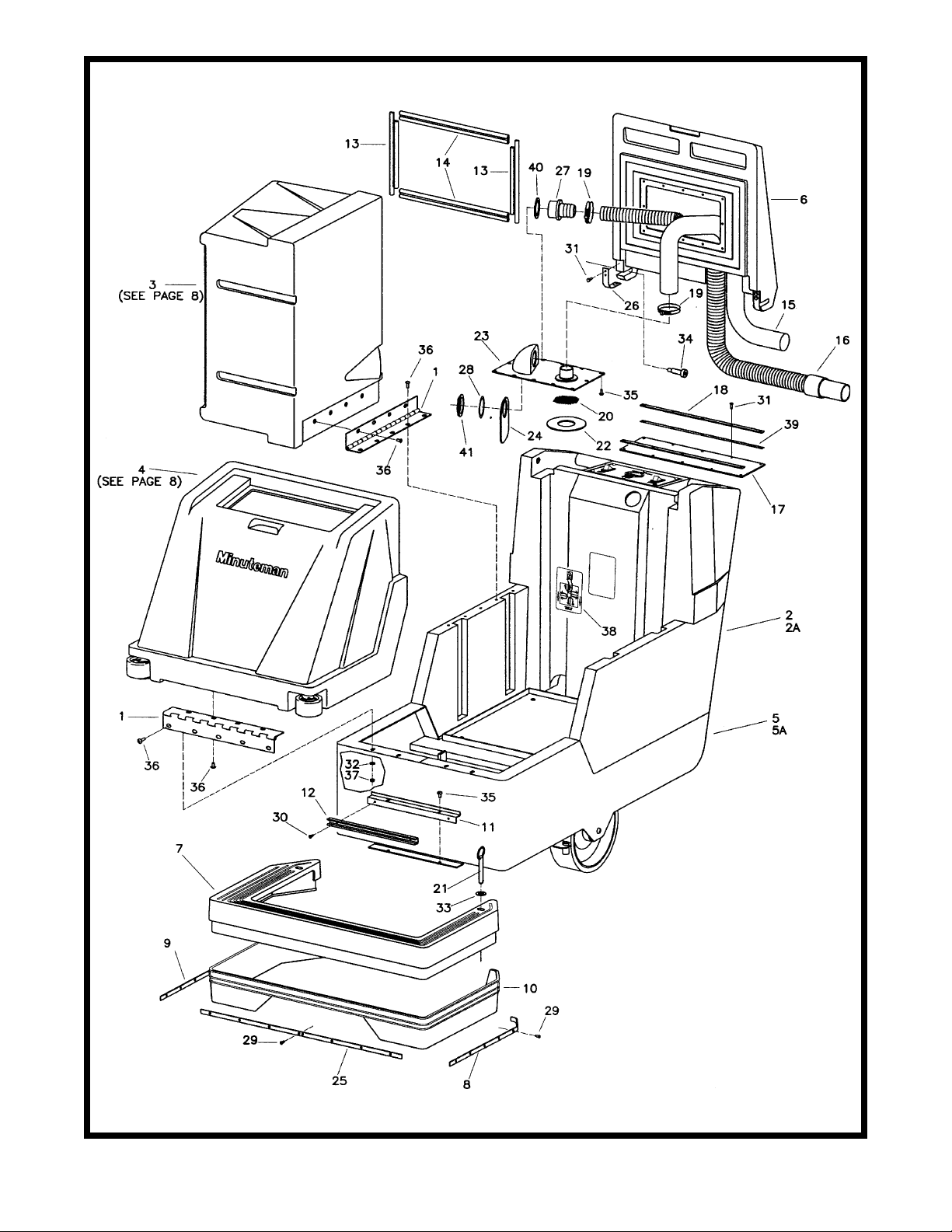

6

PartPart

Part

PartPart

s Lists List

s List

s Lists List

ItemItem

Item

ItemItem

10 260145 1 Splash Skirt

11 260148 1 Solution Dump Bracket 14GA

12 260149 1 U Channel 12”

13 260157 2 Lid Gasket Short 260B

14 260158 2 Lid Gasket 260B

15 260159 1 Hose Vac 1.5 x 78” Wireloc

16 260160 1 Recovery Hose Assy. 260B

17 260169 1 Lid Flap

18 260170 2 Retainer Strip

19 260203 2 Clamp Hose 102120 Murray

20 260212 1 Screen Filter

21 260241 2 Pin Hitch 7/16 x 3

22 260294 1 Gasket 260

23 260299 1 Shut-Off Plate Assy.

24 260301 1 Deflector Flap

25 260336 1 Skirt Retainer - Front

26 260353 2 Lid Pivot Strap

27 450037 1 Adapter MCH

28 450081 1 WSR-1.908 x 2.41 x .03 SS

29 711106 20 SCR-ST-A 10 x .75 PL

30 711124 2 SCR-ST-B 10 x .37 NI

31 711161 10 SCR-Hi/Lo #10 x 3/4 Zinc

32 711505 4 WSR-Flat 1/4

33 711508 2 WSR-Flat .44 x 1.00 x .08

34 712102 2 Bolt - Shoulder 1/2 x 1.5

35 712540 14 SCR-MC 10-24 x .37 SS TH

36 712565 17 SCR-MC 1/4-20 x .62 SS

37 712667 4 Nut-Nyloc 1/4-20 SS

38 715607 1 Decal - Battery Cable Rout

39 760263 2 Foam Tape 1/16 x 1/2

40 828970 1 WSR-Neop 1.87 x 2.4 x .125

41 828971 1 Nut - 1 1/2 Pipe Thread

Part No.Part No.

Part No.

Part No.Part No.

1 260087 2 Hinge 15”

2 260090 1 Rear Base Char Grey

2A 260256 1 Rear Base 260TD Char Grey

3 260091 1 Recovery Tank 260 Light Grey

4 260092 1 Solution Tank 260 Light Grey

5 260093 1 Chassis MMN 260

5A 260360 1 Mainframe MMN 260TD

6 260096B 1 Lid Recovery 260 Burgundy

7 260098 1 Front Skirt 260 Black

8 260142 1 Skirt Retainer L.H.

9 260143 1 Skirt Retainer R.H.

QtyQty

Qty

QtyQty

..

DescriptionDescription

.

Description

..

DescriptionDescription

7

Brush DrivenBrush Driven

Brush Driven

Brush DrivenBrush Driven

8

Loading...

Loading...