Page 1

200X

Model: MC20003QP

Brush Drive

Floor Scrubber

Electric

OPERATION

SERVICE PARTS

MC20004CE

CARE

Revised 6/02

Page 2

TABLE OF CONTENTS

Page

Safety Instructions 1

Electrical Requirements 2

Control Panel Identification 3

Operating Instructions 4

Squeegee Adjustments 5

Brush Installation/Removal 6

Base Assembly 7 & 8

Tank Assembly 9 & 10

Upper Assembly 11

Console Assembly 12

Motor Lift Assembly 13

Scrubhead Assembly 14

Back Panel Assembly 15

Squeegee Lift & Mechanism Assembly 16

Squeegee Assembly Complete 17

Wiring Diagram, 115V 18

Wiring Diagram, 230V CE 19

Page 3

Page 4

FOR COMMERCIAL USE ONLY

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic precautions should always be followed, including the

following:

READ ALL INSTRUCTIONS BEFORE USING

WARNING - To reduce the risk of fire, electric shock, or injury:

• Do not leave appliance when plugged in. Unplug from outlet when not

in use and before servicing, cleaning or maintaining.

WARNING

To reduce the risk of electric shock - Do not expose to rain. Store indoors.

• Do not allow to be used as a toy. Close attention is necessary when used

by or near children.

• This machine shall be used only by instructed and authorized persons.

• Use only as described in this manual. Use only manufacturer’s recommended

attachments.

• Inspect cord regularly. Do not use with damaged cord or plug. If appliance

is not working as it should, has been dropped, damaged, left outdoors, or

dropped into water, return it to a service center. Use only cord specified

by manufacturer.

• Do not pull or carry by cord, use cord as a handle, close a door on cord, or

pull cord around sharp edges or corners. Do not run appliance over cord.

Keep cord away from heated surfaces.

• Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

• Do not handle plug or appliance with wet hands.

• Do not put any object into openings. Do not use with any opening blocked;

keep free of dust, lint, hair, and anything that may reduce air flow.

• Keep hair, loose clothing, fingers, and all parts of body away from openings

and moving parts.

• Do not pick up anything that is burning or smoking, such as cigarettes,

matches, or hot ashes.

• Do not use without dustbag and/or filters in place.

• Turn off all controls before unplugging.

• Use extra care when cleaning on stairs.

• Do not use to pick up flammable or combustible liquids such as gasoline or

use in areas where they may be present.

• Connect to a properly grounded outlet only. See grounding instructions.

• This machine is not suitable for picking up hazardous dust.

• Close tank and lid before use.

SAVE THESE INSTRUCTIONS

1

Page 5

INSPECTION

Carefully unpack and inspect your machine for shipping damage. Each unit is tested and

thoroughly inspected before shipment, and any damage is the responsibility of the delivery

carrier who should be notified immediately.

WARNING

• Read Instruction Manual before operating this piece of equipment.

• To reduce the risk of fire use only commercially available floor cleaners and

waxes intended for machine application.

• To reduce the risk of electrical shock, do not expose to rain. Store indoors.

• Do not cross over supply cord, hazard exists when rotating brush passes over cord.

• Electrical motors and components can cause an explosion when operated near volatile

materials and vapors. Do not use this machine near flammable materials such as

solvents, thinners, fuels, grain dust, etc.

ELECTRICAL

(Model MC20003QP) This floor machine is designed to operate on a standard 15 amp.

120 volt, 60 hz, AC circuit. Voltages below 105 volt AC or above 125 volts AC could cause

serious damage to the motor.

(Model MC20004CE) This machine is designed to operate on a standard 16 amp. type L

fused 230 volt, 50 hz, AC circuit. Voltages below 200 volt AC or above 250 volts AC could

cause serious damage to the motor I.E. C. Class 1.

GROUNDING INSTRUCTIONS

• This floor finishing machine should be grounded while in use to protect the operator from

electric shock. The machine is equipped with a three-prong grounding type attachment

plug to fit the proper grounding type receptacle. The green (or green and yellow)

conductor in the cord is the grounding wire. Never connect this wire to other than the

grounding blade.

• If the machine is provided with an attachment plug as shown in Sketch A it is intended

for use on a 120-volt (nominal) circuit. If a properly grounded receptacle as shown in

Sketch A it is intended for use on a 120-volt (nominal) circuit. If a properly grounded

receptacle as shown in Sketch A is not available, an adapter as shown inSketch C is

available and should be installed as shown in Sketch B if the outlet box that houses the

receptacle is grounded. Be sure to fasten the grounding tab with the faceplate screw.

ADAPTER (Not applicable in Canada)

METAL SCREW

COVER OF GROUNDED MEANS

OUTLET BOX

GROUNDING PIN (C)

(A) (B)

2

GROUNDING

Page 6

1. Squeegee lift lever

2. Recovery dump hose

3. Dashboard control panel

4. Solution control lever

5. Solution dump hose

6. Quick disconnect

Aux. out (optional)

7. Food pedal

8. Receptacle

9. Circuit breaker

10. Main power

11. Brush switch

12. Vacuum switch

13. Pump switch (optional)

AUTO SCRUBBER BRUSH DESCRIPTION

TYPE DESCRIPTION DURABILITY* COLOR TO PADS USE

Bassine Natural Fiber Short Dark Brown Red Light duty

Nylon Nylon Medium Black Tan/Red General cleaning

Dyna-Scrub Nylon impregnated Long Light Blue Red General scrubbing,

with 500 Grit vinyl tile, ceramic

Silicon Carbide tile, epoxy floors,

Fine Bristle, urethane finish,

Power-Scrub Nylon impregnated Long Rust Red/Blue Moderate aggressive

Poly-Grit Nylon impregnated Long Green Brown/Black Aggressive stripping

Strata-Grit Nylon impregnated Long Dark Blue Black Heavy duty

Dense Fill

with 120 Grit Silicon scrubbing, tile floors,

Carbide Fine Bristle, concrete floors

Dense Fill

with 80 Grit and scrubbing, tile

Silicon Carbide floors, unfinished

Coarse Bristle concrete floors

with 46 Grit stripping/scrubbing

Silicon Carbide

Coarse Bristle

••

•

Durability is dependent on floor surface, chemicals used and proper care.

••

COMPARISON RECOMMENDED

general cleaning,

acid etching

& scrubbing vinyl

floors, ceramic tile

& concrete floors

uneven concrete floors

unfinished concrete

3

Page 7

OPERATING INSTRUCTIONS

BEFORE STATING, FAMILIARIZE YOURSELF WITHTHE MACHINE AND ITS CONTROLS

(SEE “MACHINE OVERVIEW” & CONTROL PANEL DIAGRAMS)

1. Filling: Fill the solution tank with the desired amount of water and add liquid

cleaning solution to the proper dilution ratio. DO NOT USE powdered cleaning

chemicals. Powders are unlikely to dissolve thoroughly, resulting in clogging the

in-line solution filter. This can reduce or stop water flow to the brush.

2. Close lid.

3. Turn on machine by pressing the main power switch (10).

4. Lower brush assembly.

- To lower the brush, first push the pedal (7) slightly outward on the machine (unlock it),

and then release it slowly.

- To lift the brush, press the pedal (7) down until lift mechanism engages.

5. Turn on brush (11).

6. Adjust solution control feed lever (4).

7. Turn on vacuum switch (12).

8. Lower squeegee assembly by lowering handle (1).

After Use:

1. Turn off solution feed (4).

2. Switch off brush (11) and raise (7).

3. Raise squeegee assembly (1).

4. Turn off vacuum motor (12).

Solution and recovery tanks should be emptied after every use.

MAINTENANCE:

Daily 1. Clean float assembly & squeegee blades. Vac filter.

Monthly 1. Check wear on squeegee blades.

2. Grease front wheels.

3. Grease pivot points on brush motor assembly.

Every 500 hours check condition of carbon brushes on vacuum motor and brush drive motor.

4

Page 8

SQUEEGEE ADJUSTMENTS

Squeegee Adjustment

The squeegee set-up is pre-adjusted

at the factory. Adjustments may be required

to get optimum performance for different

floors and conditions.

Pitch Control Adjustment

1. Ensure that the scrubber is on

a relatively flat surface. Pull the

red emergency button away from

the dashboard to activate power.

Turn on the main power switch

and turn the key switch. Raise

the scrubhead off the floor.

Turn the vacuum switch.

2. Lower the squeegee (item 1)

to the floor and move the

machine one or two feet

forward to check the rear

squeegee blade for uniform

deflection to the floor.

3. If uneven deflection or lay is evident, minor adjustments may be necessary to avoid

streaking and uneven wear on the blade.

4. To correct this, pitch adjustment is necessary. Loosen the pivot screw (item 2) and the pitch

screw (item 3). Move the machine forward and allow the squeegee to level itself or adjust

the angular position accordingly to achieve a uniform blade deflection. Re-tighten screws.

5. In certain applications where a different blade set-up is required, the reinforcement blade

(item 4) may be turned upside down. The notch, which is normally on the bottom will now

be located on the topside. This allows the rear squeegee blade a larger deflection than

normal.

5

Page 9

BRUSH INSTALLATION - REMOVAL

INSTALLATION

1. Raise the scrubhead to the “UP” position by depressing the pedal (A) downward as

shown on Fig. 1.

2. Center brush (D) under the scrubhead shroud while lining up the center

hex drive hub and pressing the brush up until the brush engages on the drive hub.

REMOVAL

1. Raise the scrubhead to the “UP” position by depressing the pedal (A) downward as

shown on Fig. 1.

2. Remove the brush (D) by stepping on the “BRUSH RELEASE PIN”

on the top of the scrubhead shroud as shown on Fig. 1 below.

Figure 1

6

Page 10

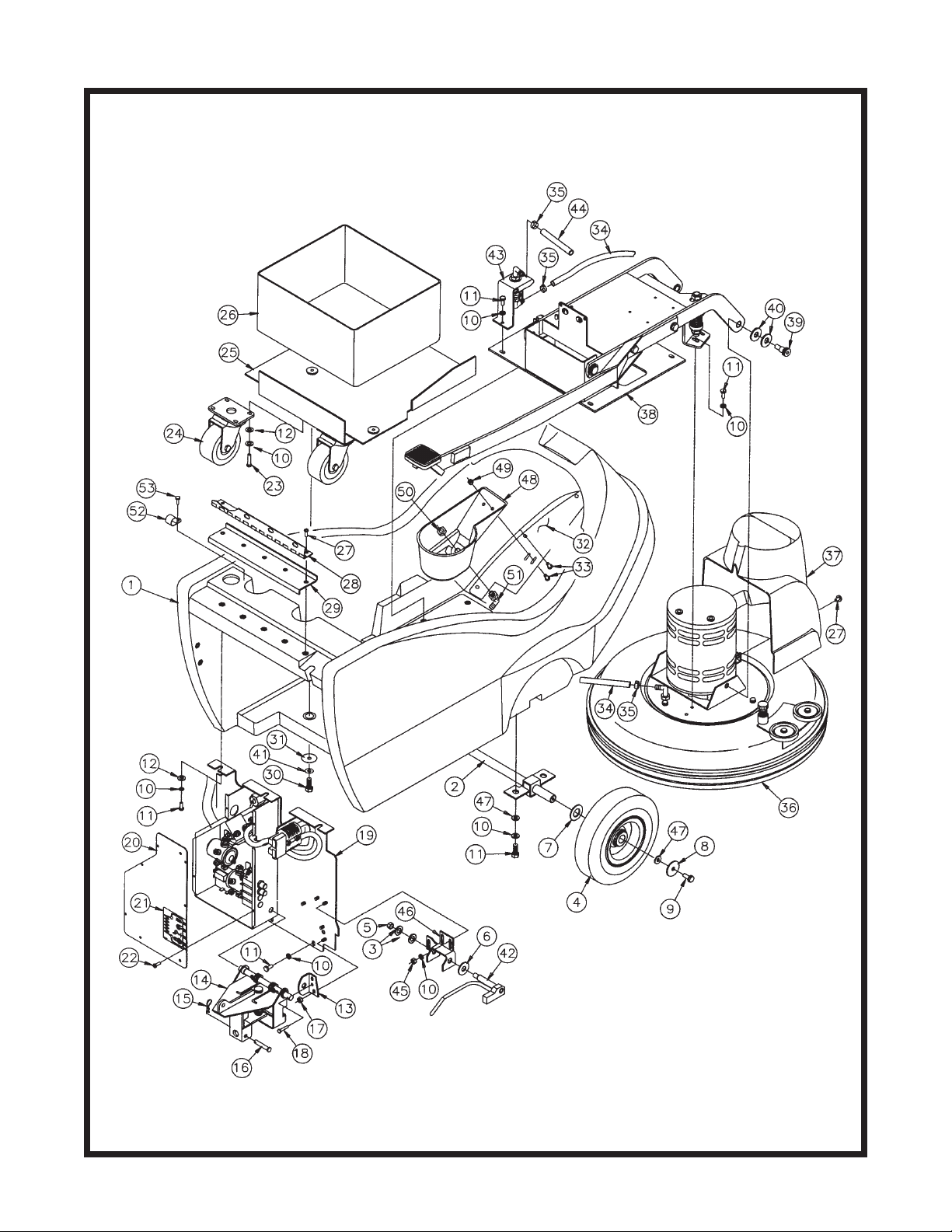

BASE ASSEMBLY

7

Page 11

BASE ASSEMBLY

Parts List

Item Part No. Qty. Description

1 200102 1 Base

2 200250 1 Axle Weldment

3 712301 2 WSR-Flat .38 x .88 x .06

4 762332 2 Wheel, 8 x 2 w/Bearing

5 711375 1 Nut-Nyloc 3/8-16

6 711578 2 WSR-Flat ½ Brass

7 712318 2 WSR-Flat ¾ x 1.12 x .12

8 712759 2 WSR-Flat 5/16 x 1.37 x .06 SS

9 712042 2 Bolt-WSR HH 5/16-18 x .62

10 711544 22 WSR-Helical ¼

11 711203 19 BLT-HH ¼-20 x .62

12 711505 15 WSR-Flat ¼

13 200158 1 Pin Bracket

14 200153 1 Squeegee Mechanism Assy.

15 711808 1 Cotter Pin

16 210415 1 Clevis Pin 5/16

17 260183 3 Nut ¼ NPT Nyloc

18 712564 1 Bolt-HH ¼-20 x 1 SS

19 200265 1 Back Panel Assy., BD

20 200314 1 Electrical Box Cover

21 711125 4 SCR-ST-B #10 x ½

22 710180 10 SCR-MC ¼-20 x ¾

23 200345 2 Caster, 3 ½”

24 200125 1 Battery Tray Weldment

25 210048 1 Battery Liner

26 712565 5 SCR-MC ¼-20 x .62 SS

27 200145 1 Hinge

28 200146 1 Hinge Plate

29 711228 4 Bolt-HH 5/16-18 x ¾

30 711507 4 WSR-Flat .37 x 1.12 x .06

31 200233 1 Bottom Cover

32 712822 3 SCR-THMS 10-24 x ½

33 200235 1 Hose Nylobraid 17.50

34 450076 2 Crimp Clamp 185R SS

35 200315 1 Scrubhead Assy. 115V

36 200328 1 Scrubhead Assy. 240V

36A 200186 1 Motor Cover

37 200280 1 Motor Lift Assy.

38 712099PLT 2 Shoulder Bolt ½ x .50

39 711510 4 WSR-Flat .50 x 1.38 x .10

40 711545 4 WSR-Helical 5/16

41 200130 1 Pawl Weldment

42 200260 1 Solution Valve Assy. - BD

43 200234 1 Solution Hose 51.00

44 711316 3 Nut-Hex ¼-20

45 200129 1 Pawl Mounting Bracket

46 711575 2 WSR-Flat .312 x .75 x .06

8

Page 12

TANK ASSEMBLY

9

Page 13

TANK ASSEMBLY

Parts List

Item Part No. Qty. Description

1 200101 1 Solution/Recovery Tank

2 200147 3 Bracket, Vac Motor

3 200173 1 Float, Housing

4 210122 1 Drain Hose Wirelock

5 200232 1 Cable, Tank

6 200251 1 Stand Pipe Assembly

7 200258 1 Muffler Assembly

8 200270 1 Hose, ¾ Solution Drain

9 200023 1 Garden Hose Cap

10 210409 1 Fitting, Brass 3/8 MPT

11 210410 1 Fitting, Brass 3/8 FPT

12 210414 1 “O” Ring 2-113

13 250039 3 Clamp, Plastic 5/16 3305

14 260203 1 Hose Clamp 102120 Murray

15 290017 1 Gasket, Molded, Vac Motor

16 3321335 1 Clamp-Hose 3” NOM

17 383321 1 Elbow ¾ MPT ¾ Barb PP

18 200022 1 ¾” MGHT x Hose Barb

19 829129 2 Clamp, Crimp ¾ Barb

20 430050 1 Filter Screen 4 x 4

21 260155 1 Foam Float

22 430090 1 Float Valve Weldment

23 460019 2 Gasket

24 710207 1 SCR-MC 6-32 x .87 ST PL

25 200234 Ref. Solution Hose

26 130118 1 Solution Strainer

27 712540 3 SCR-MC #10-24 x .375 SS

28 712574 1 CR Bolt SS ¼-20 x 3”

29 712667 2 Nut-Hex ¼-20 SS Nyloc

30 200231 1 Gasket, Shutoff

31 712568 1 SCR-MC ¼-20 x 2.25 SS

32 832996 1 Terminal Block 2-Pole VDE

33 833316 1 Drain Plug

34 740232 1 Vac Motor 115V

34A 741030 1 Vac Motor 240V

35 760245 2 Hose Clamp 62P24

36 760343 1 Tube Hose 24/32B

37 762384 2 Bushing .277 x .375 x .37 SS

38 830062 1 Fitting Brass 90 3/8 MPT

39 710180 3 SCR-MC ¼-20 x .75

40 711544 6 Lockwasher - Helical ¼

41 711505 6 Washer ¼

42 715285 1 Decal, 200X

43 200024 1 Black Vinyl Washer

44 712759 4 WSR-Flat .31 x 1.37 x .06 SS

45 310008 1 O-Ring

46 712565 3 SCR-MC 1/4-20 x .625 SS

47 805613 1 Hose Cuff, Grey Vinyl

10

Page 14

UPPER ASSEMBLY

Parts List

Item Part No. Qty. Description

1 200160 1 Tank Assembly

2 200178 2 Gasket, Lid

3 200136 1 Gasket, Solution Lid

4 200103 1 Tank Lid

5 712120 2 Shoulder Bolt ½ x 2

6 710178 6 SCR-MC ¼-20 x ½

7 711503 2 WSR-Flat #10

8 711125 5 SCR-ST-B #10 x ½

9 760286 1 Wire Formed Hook

10 200176 1 Dump Hose Bracket

11 200170 1 Console Assy. - Brush Drive

12 715284 1 Decal, Solution Control

13 383367 1 Spring Clip

14 430053 1 Solution Control Cable

15 711228 6 Bolt-HH 5/16-18 x ¾

16 711545 6 WSR-Helical 5/16

17 711575 6 WSR-Flat 5/16

18 200032 1 Console Back Cover Weldment

19 450054 1 Vacuum Recovery Hose

11

Page 15

CONSOLE ASSEMBLY

Parts List for 200330

Item Part No. Qty. Description

1 200104 1 Console

2 200134 1 Console Bracket Right

3 200135 1 Console Bracket Left

4 200151 1 Hinge Bracket Weldment

5 200322SP 1 Dashboard ASM BD

6 712320 4 WSR-Nylon .22 x .45 x .04

7 712540 8 SCR-MC #10-24 x .37 SS

8 711575 6 WSR-Flat .31 x .75 x.06

9 711545 6 WSR-Helical 5/16

10 711228 6 Bolt-HH 5/16-18 x .75

11 711505 2 WSR-Flat ¼

12 200240 1 Squeegee Lift Assy.

13 711544 6 WSR-Helical ¼

14 711203 6 Bolt-HH ¼-20 x .62

15 740812 3 Switch (optional 4th)

16 740811 3 Switch Boot (optional 4th)

17 833827 1 O-Ring 1.25 ID x .187

18 250038 1 Retainer Bag Clip

19 830292 1 Cord Assy. 75 ft. 115V

19A 743287 1 Cord Assy. 25 Meters 240V

20 430103 1 Snap Body

21 760142 1 Clamp Ring

22 450012 1 Strain Relief

23 711161 1 SCR Hi-Lo 10 x .75

12

Page 16

MOTOR LIFT ASSEMBLY

Parts List

Item Part No. Qty. Description

1 200120 1 Base Plate Weldment

2 260036 2 Pin

3 712310 4 WSR-Flat .52 x .88 x .06

4 711527 6 WSR-Flat 5/8 x 1.12 x .12

5 762340 2 Oilite Bushing ½

6 260041 4 Oilite Flanged Bushing ½

7 200115 1 Lift Arm Weldment

8 711713 2 E-Ring ½

9 710207 2 SCR-MC 6-32 x .87

10 740128 1 Microswitch

11 711430 1 Tinnerman Clip

12 833638 2 Brass Stud

13 711368 2 Wing Nut

14 740132 2 Insulator Glastic

15 711546 2 WSR-Helical 3/8

16 711241 2 Bolt-HH 3/8-16 x ¾

17 711376 1 Nut-Nyloc ½-13

18 260137 1 Compression Spring

19 200110 1 Spring Bracket

20 200149 1 Adjustment Rod

21 200116 1 Pedal Arm Weldment

22 762294MCH 1 Pedal

23 711202 2 Bolt-HH ¼-20 x ½

24 711544 2 WSR-Helical ¾

25 450040 2 Elbow 3/8 Barb x 3/8 MPT

26 809413MCH 1 Solution Valve Machined

27 829463 1 WSR-Flat SS

28 828975 1 WSR-Neoprene .75 x 1.5 x .09

29 200259 1 Valve Bracket

13

Page 17

SCRUBHEAD ASSEMBLY

Parts List

Item Part No. Qty. Description

1 200109 1 Motor Platform Weldment - BD

2 200187 1 Brush Shroud Weldment

3 200194 1 Pin, Brush Release

4 200294 2 Shroud Strap

5 210066 1 Retainer Bolt

6 200293 1 Shroud Skirt

7 260183 1 Nut ¼ NPT Nylon

8 320268 1 Key, ¼ x 5/16 x 1.00

9 430035 1 Drive Hub

10 500033 1 Locking Screw

11 710986 4 SCR-SC 3/8-16 x 1.00

12 711202 3 SCR-MC ¼-20 x ½

13 711544 3 WSR-Helical ¼

14 711615 1 Roll Pin 1/8 x ¾

15 712318 1 WSR-Flat ¾

16 740428 1 Gear Motor 115V

16A 740432 1 Gear Motor 240V

17 833102 1 Spring

18 833325 1 Hose Barb 90° Nylon

19 711578 2 WSR-Flat ½ Brass

20 712310 8 WSR-Flat .52 x .87 x .06

21 430085 2 Bumper Wheel

22 712759 2 WSR-Flat .31 x 1.37 x .06 SS

23 710975 2 SCR-SC 5/16-18 x .87

24 712560 8 SCR-MC ¼-20 x .50 Nyloc

25 200029 1 Pitch Adj. Bar Weldment

26 711334 1 Nut-Hex ½-13

27 710754 1 Bolt-HH ½-13 x 2 ¾

28 711505 1 WSR-Flat ¼

29 711373 1 Nut-Nyloc ¼-20

30 743425 1 Ground Wire

14

Page 18

BACK PANEL

Parts List

Item Part No. Qty. Description

1 742307 2 Switch, McGill, VDE

2 200229 1 Bracket, Kill Switch

3 710307 4 SCR-MC 6-32 x 1

4 200326 1 Cover Switch Box

5 711125 10 SCR-ST #10 x .5

6 711316 2 Nut-Hex ¼-20

7 711544 2 WSR-Helical ¼

8 711430 2 Nut-Tinnerman 6-32

9 200332 1 Wire Guard Cover

10 200311 1 Back Panel Weldment

11 742748 1 Boot, Circuit Breaker

12 740220 1 Circuit Breaker, 20A

13 830540 1 Flg. Male Receptacle 115V

13A 832682 1 230V Receptacle

14 200317 1 230V Receptacle Bracket

15 742256 1 RFI Filter 230V Only

16 712818 2 SCR-MC 10-24 x .5

17 741300 1 Terminal Block

18 740202 1 Receptacle Bridge 230 Only

19 712813 5 SCR-MC 10-24 x .75

20 712908 2 Nut-Flange Wizz 10-24

21 712635 2 Nut-Hex 10-24 SS

22 711543 2 WSR-Helical #10

15

Page 19

BACK PANELDASHBOARD

Parts List for 200265

1 200124 1 Backpanel Weldment

2 742749 2 Circuit Breaker Plug

3 711368 2 Wing Nut, ¼-20

Item Part No. Qty. Description

4 740132 2 Insulator (Glastic)

5 742748 2 Boot, Circuit Breaker

6 740247 1 Circuit Breaker 30

7 742000 2 Diode Assembly

8 740549 1 Circuit Breaker 50

9 711210 2 SCR-HH ¼-20 x 1 ¼

11 743260 1 Wire Harness, 200X BD

10 740159 1 CB175 Red Housing Only

12 788147 2 Solenoid 24VDC

13 833638 2 Brass Stud

14 711425 6 Whiz-Nut ¼-20

16

Parts List for 200299

1 200179 1 Dashboard Plate

2 715283 1 Decal 200 Dashboard

3 740216 1 Battery Gauge

Item Part No. Qty. Description

4 740711 3 Switch Dreefs

5 742202 1 Disconnect Switch 125A

6 740811 3 Switch Boot

Page 20

Item Part No. Qty. Description

16 260273 1 Front Blade Strap

17 260322 1 Squeegee Blade 260 Quarry

18 320191 1 Squeegee Mounting Bracket

19 711578 2 WSR-Flat ½ Brass

Parts List for 200219

1 711668 2 Clevis Pin 3/8 x 1

2 711507 7 WSR-Flat .37 x 1.12 x .06

3 711808 2 Cotter Pin - Hair #13

Item Part No. Qty. Description

4 210153 2 Roller Wheel

20 260287 2 Wing Bolt ½-13 x 1.00

21 320156 1 Mounting Bracket - Right

22 200169 1 Pitch Control Weldment

23 320157 1 Mounting Bracket - Left

24 712301 1 WSR-Flat .37 x .87 x .07

25 711379 1 Nut- Flanged Wizz 5/16-18

26 711374 1 Nut-Nyloc 5/16-18

27 712562 4 Bolt-HH ¼-20 x .75 SS

5 762281 2 Bushing .37 x .500 x .25

6 200222 1 Squeegee Casting, 200

7 260203 1 Rear Squeegee Blade

8 260264 1 Reinforcement Blade

9 260272 1 Rear Blade Strap

11 712668 8 Wing Nut ¼-20 SS

10 711504 12 WSR-Flat .25 x .56 SS

12 712571 2 Bolt-SS Carr ¼-20 x 1.50

13 712572 2 Bolt-SS Carr ¼-20 x 2.00

28 712758 4 WSR-Helical ¼ SS

29 712081 2 Bolt-Shoulder 3/8 x .75

14 712573 2 Bolt-SS Carr ¼-20 x 2.50

15712574 2Bolt-SS Carr ¼-20 x 3.00

17

Page 21

WIRING DIAGRAM, 115V

18

Page 22

WIRING DIAGRAM, 240V CE

19

Page 23

LIMITED WARRANTY

Minuteman International, Inc. warrants to the original purchaser/user that this product is free from defects in workmanship and

materials under normal use and service for a period of three years from date of purchase. In addition, Minuteman International,

Inc. will, at its option, honor labor warranty claims for the first 12 months from date of sale, provided such claims are submitted

through and approved by factory authorized repair stations. Minuteman International, Inc. will, at its option, repair or replace

without charge, except for transportation costs, parts that fail under normal use and service when operated and maintained in

accordance with the applicable operation and instruction manuals.

This warranty does not apply to normal wear, or to items whose life is dependent on their use and care, such as belts, cords,

switches, hoses, rubber parts, electrical motor components or adjustments. Parts not manufactured by Minuteman International,

Inc. such as engines, batteries, battery chargers, hydraulic pumps, and tires are covered by and subject to the warranties and/

or guarantees of their manufacturers. Please contact Minuteman International, Inc. for procedures in warranty claims against

these manufacturers.

Special warning to purchaser — Use of replacement filters and/or prefilters not manufactured by Minuteman International,

Inc. or its designated licensees, will void all warranties expressed or implied.

A potential health hazard exists without exact original equipment replacement.

All warranteed items become the sole property of Minuteman International, Inc. or its original manufacturer, whichever the case

may be.

Minuteman International, Inc. disclaims any implied warranty, including the warranty of merchantability and the warranty of

fitness for a particular purpose. Minuteman International, Inc. assumes no responsibility for any special, incidental or consequential

damages.

This limited warranty is applicable only in the U.S.A. and Canada, and is extended only to the original user/purchaser of this

product. Customers outside the U.S.A. and Canada should contact their local distributor for export warranty policies. Minuteman

International, Inc. is not responsible for costs or repairs performed by persons other than those specifically authorized by

Minuteman International, Inc. This warranty does not apply to damage from transportation, alterations by unauthorized persons,

misuse or abuse of the equipment, use of non-compatible chemicals, or damage to property, or loss of income due to malfunctions

of the product.

If a difficulty develops with this machine, you should contact the dealer from whom it was purchased.

This warranty gives you specific legal rights, and you may have other rights which vary from state to state. Some states do not

allow the exclusion or limitation of special, incidental or consequential damages, or limitations on how long an implied warranty

lasts, so the above exclusions and limitations may not apply to you.

World Headquarters Minuteman Canada, Inc.

Minuteman International, Inc. 2210 Drew Road

111 South Rohlwing Road Mississauga, Ontario

Addison, Illinois 60101 L5S 1B1

(630) 627-6900 (905) 673-3222 986765

FAX (630) 627-1130 FAX (905) 673-5161 Printed in U.S.A.

Loading...

Loading...