Page 1

Electronic Service

Manuals

This electronic document is provided as a service to our customers.

We do not create the contents of the information contained in this document. Should you have detailed questions pertaining to the information

contained in this document, you may contact Michco, or the manufacturer which provided the original information in this electronic deliverable. Michco’s only part in this electronic deliverable was the electronic

assembly process. By providing this manual on line we are not guaranteeing parts availability.

You may contact Michco through the following methods:

Phone (517) 484-9312 or (800) 331-3339

2011 N. High St. -- Lansing, Michigan -- 48906

Fax: (517) 484-9836

Email: CustServe@Michco.com

Web site: www.Michco.Com

Parts Web site: www.FloorMachineParts.Com

Order Parts on Line at:

www.FloorMachineParts.Com

Directly to Parts & Service:

By Email: Shop@Michco.com

By Fax: (517) 702-2041

By Voice: Use numbers above.

Serving the Cleaning Industry Since 1922

Notice: All copyrighted material remains property of original owners, all trademarks are property of respective owners.

Manuals are subject to Manufacturer’s reproduction limitations. Originals or reproductions were provided by manufacturers

through a request. We make no warranty as to the correctness of information provided in this document and you assume

all risk. By placing these manuals on line we are not declaring our corporation to be an manufacturer authorized dealer or

provider, please check our web site for authorized manufacturers we represent.

Page 2

200X

Model: MC20001QP, CE

Traction Drive

Deluxe

Floor Scrubber

Battery

OPERATION

SERVICE PARTS

MC20002QP, CE

CARE

Page 3

Page 4

TABLE OF CONTENTS

Page

Safety Instructions 1

Electrical Requirements 2

Control Panel Identification 3

Operating Instructions 4

Squeegee Adjustments 5

Brush Installation/Removal 6

Base Assembly - Traction Drive 7, 8

Base Assembly - Deluxe 9, 10

T ank Assembly 11, 12

Upper Assembly 13

Console Assembly 14

Motor Lift Assembly - Deluxe 15, 16

Motor Lift Assembly - T raction Drive 17

Scrubhead Assembly 18

Dashboard & Back Panel Assembly 19

Squeegee Lift & Mechanism Assembly 20

Squeegee Assembly Complete 21

Wiring Diagram 22, 23

Wiring Diagram - CE 24, 25

Page 5

IMPORT ANT SAFETY INSTRUCTIONS

CAUTION

Operators must read and understand this manual before operating or maintaining this equipment.

• Keep hands and feet clear of moving parts while machine is in operation.

• All switches must be in the “OFF” position when charging batteries.

• Electrical motors and components can cause an explosion when operated near explosive materials

or vapors. Do not operate this machine near flammable materials such as solvents, thinners, fuels,

grain dusts, etc.

• Make sure all switches are turned “OFF” and battery connections are removed before performing

any maintenance procedures.

• S tore or park this machine on a level surface only .

• These machines are designed for level floor operation only. DO NOT OPERATE on ramps or

inclines.

• Battery acid can cause burns. When working on or around batteries, wear protective clothing and

safety glasses. Remove metal jewelry . Do not lay tools or met al objects on top of batteries.

• This machine is not suitable for picking up hazardous dust.

Charging batteries generates explosive gases. DO NOT CHARGE BATTERIES WHEN OPEN

FLAMES OR SPARKS ARE PRESENT. DO NOT SMOKE. Make sure the charger is turned off

before disconnecting it from the batteries. Charge the batteries in a well-ventilated area.

Maintenance and repairs must be performed by authorized personnel.

SA VE THESE INSTRUCTIONS

1

Page 6

ELECTRICAL REQUIREMENTS:

This piece of equipment operates on 24 V olt DC.

BATTERY REQUIREMENTS:

2 x 12V 185 Amp Hour 20 Hour Rate Deepcycle P/N 956709

2 x 12V 210 Amp Hour 20 Hour Rate Deepcycle P/N 956210

BATTERY SERVICE AND INSTALLATION:

Warning: Battery acid can cause burns. When working on or around batteries, wear protective clothing

and safety glasses. Remove metal jewelry . Do not lay tools or metal objects on top of batteries.

BATTERY INSTALLATION:

1. Raise tank assembly by gripping the front of the tank and lift the tank backward as shown in Fig. 1.

2. Install batteries as shown in Figure 2.

CHARGING OF BATTERIES:

Charging of batteries generates explosive gases. DO NOT CHARGE BA TTERIES WHEN OPEN

FLAMES OR SPARKS ARE PRESENT. DO NOT SMOKE. Make sure the charger is turned off

before disconnecting it from the batteries. Charge the batteries in a well-ventilated area. Fluid levels

should be checked before and after charging and maintained at the proper levels.

2

Page 7

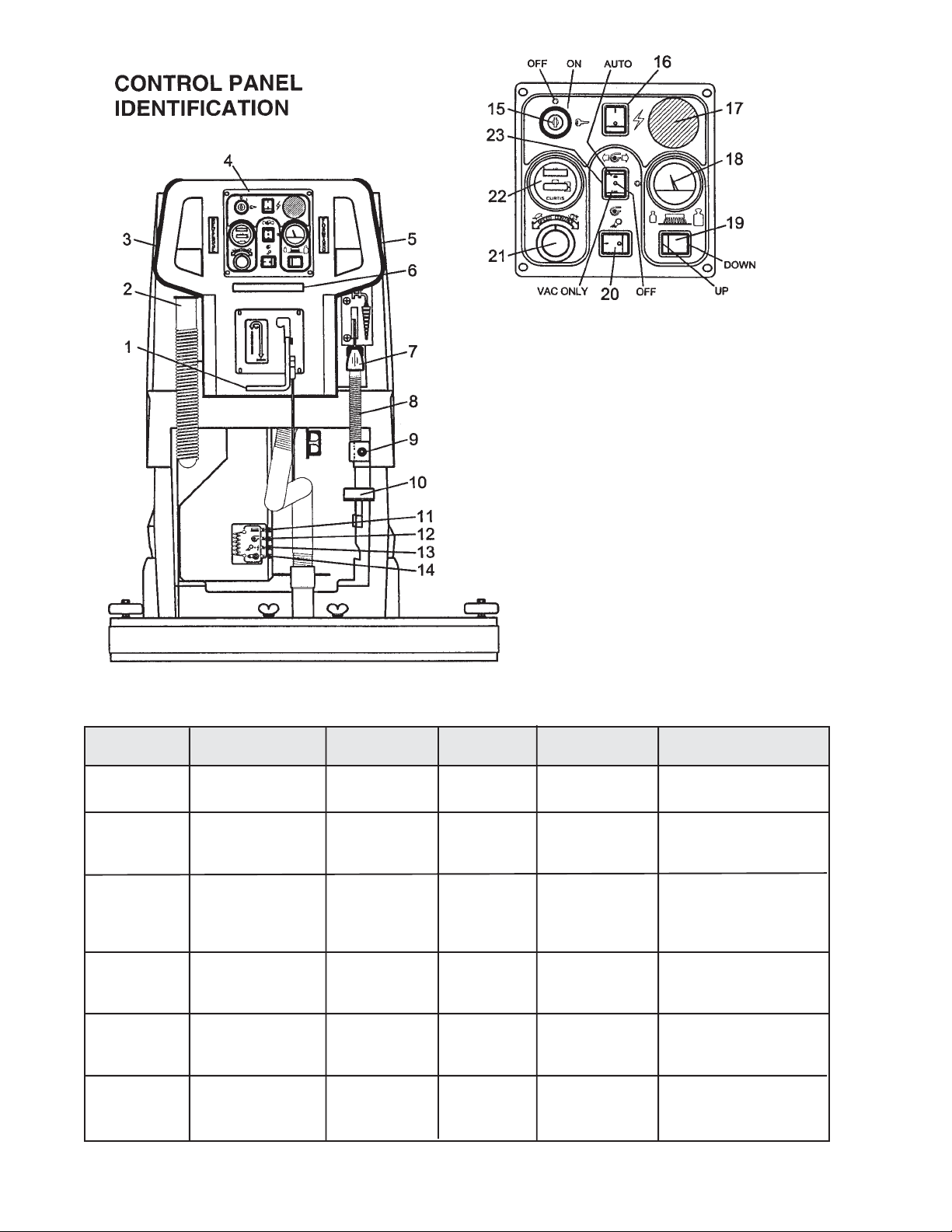

1. Squeegee lift lever

2. Recovery dump hose

3. Reverse handle

4. Dashboard control panel

5. Forward handle

6. Safety bar switch

7. Solution control lever

8. Solution dump hose

9. Quick disconnect - Aux. out (Deluxe only)

10. Foot pedal (TD only)

11. Circuit breaker - Brush

12. Circuit breaker - Vac

13. Circuit breaker - System

14. Circuit breaker - Transaxle

15. Keyswitch

16. Main power

17. Emergency button

18. Brush pressure gauge

19. Brush control

20. Pump switch

21. Speed control

22. Battery condition meter

AUTO SCRUBBER BRUSH DESCRIPTION

TYPE DESCRIPTION DURABILITY* COLOR TO PADS U SE

Bassine Natural Fiber Short Dark Brown Red Light duty

Nylon Nylon Medium Black Tan/Red General cleaning

Dyna-Scrub Nylon impregnated Long Light Red General scrubbing,

with 500 Grit vinyl tile, ceramic

Silicon Carbide tile, epoxy floors,

Fine Bristle, urethane finish,

Power-Scrub Nylon impregnated Long Rust Red/Blue Moderate aggressive

Poly-Grit Nylon impregnated Long Green Brown/Black Aggressive stripping

Strata-Grit Nylon impregnated Long Dark Blue Black Heavy duty

Dense Fill

with 120 Grit Silicon scrubbing, tile floors,

Carbide Fine Bristle, concrete floors

Dense Fill

with 80 Grit and scrubbing, tile

Silicon Carbide floors, unfinished

Coarse Bristle concrete floors

with 46 Grit stripping/scrubbing

Silicon Carbide

Coarse Bristle

••

•

Durability is dependent on floor surface, chemicals used and proper care.

••

COMPARISON RECOMMENDED

general cleaning,

acid etching

& scrubbing vinyl

floors, ceramic tile

& concrete floors

uneven concrete floors

unfinished concrete

3

Page 8

OPERATING INSTRUCTIONS

BEFORE STATING, FAMILIARIZE YOURSELF WITHTHE MACHINE AND ITS CONTROLS

(SEE “MACHINE OVERVIEW” & CONTROL PANEL DIAGRAMS)

1. Filling: Fill the solution tank with the desired amount of water and add liquid cleaning solution to

the proper dilution ratio. DO NOT USE powdered cleaning chemicals. Powders are unlikely to

dissolve thoroughly , resulting in clogging the in-line solution filter. This can reduce or stop water

flow to the brush.

2. Close lid.

3. Turn on machine by lifting the red emergency disconnect button (17) so it is in the up position.

Turn keyswitch (15) clockwise to “on” position and turn on main power switch (16).

4. Adjust main speed control (21) to full counter-clockwise position.

5. Lower brush assembly.

- T o lower the brush, first push the pedal (10) slightly outward on the machine (unlock it), and

then release it slowly or by pressing “brush down” switch (19) on Deluxe models.

- T o lift the brush, press the pedal (10) down until lift mechanism engages or by pressing ”brush

up” switch (19) on Deluxe models.

- Brush will come on automatically when brush in on the floor and “forward” (5) or “reverse” (3)

handles are squeezed and remain on approximately 5 seconds after release.

6. Adjust solution control feed lever.

7. Select vacuum operations:

- “V acuum On” mode (23), V acuum will remain on until switched to the “off” position

- “V acuum Auto” mode (23), V acuum will come on automatically when “forward” or “reverse”

handle is squeezed, and scrubhead is on the floor . The brush and vacuum will remain on

approximately 5 minutes.

8. Lower squeegee assembly by lowering handle (1).

9. Squeeze “forward” handle (5) and adjust forward speed (21) as desired.

After Use:

1. Turn off solution feed.

2. Raise squeegee assembly .

3. Turn off vacuum motor .

Solution and recovery tanks should be emptied after every use.

MAINTENANCE:

Daily 1. Clean float assembly & squeegee blades. Vac filter

2. Recharge batteries (check battery acid levels before and after charging).

Monthly 1. Check wear on squeegee blades.

2. Grease front wheels.

3. Grease pivot points on brush motor assembly .

Every 500 hours check condition of carbon brushes on vacuum motor and brush drive motor.

4

Page 9

SQUEEGEE ADJUSTMENTS

The squeegee set up is pre adjusted at the factory. Adjustments may be required to get optimum

performance for different floors and conditions.

1 Ensure that the scrubber is on a relatively flat surface. T urn on the main power switch and turn the key

switch clockwise to the on position. Raise the scrubhead off the floor. Turn the vacuum switch to the

“vacuum only” position.

2 Turn the speed control knob counter clockwise to the low speed position. Lower the squeegee (item 1)

to the floorand squeeze the forward control handle, moving the machine one or two feet forward to

check the rear squeegee blade (item 8) for uniform deflection to the floor.

3 If uneven deflection or lay is evident, minor adjustments may be necessary to avoid streaking and

uneven wear on the blade.

4 To correct this, loosen the wing jam nut (item 4) in order to adjust the castor height. If the squeegee

blade is deflecting too much, the castors need to be lowered to control the down pressure. Lower the

castor by turning the exposed threaded stem (item 9) on the castor clockwise. Make the adjustment a

few turns at a time. Repeat Step 2.

5 If the blades are not deflecting enough, raise the castor by turning the stem counter clockwise to adjust

the castor height to allow more down pressure on the squeegee. Repeat Step 2.

6 Make sure that there is an even deflection on the entire length of the rear blade. Adjust the castors and

retighten the wing jam nuts to lock the castor setting in place.

7 Pitch adjustment is necessary if the outer ends on the squeegee blade does not contact the floor and

there is too much deflection in the middle area or if the outer ends are over deflected and there is no

contact in the middle.

8 To adjust the pitch, lower the squeegee to the floor. Loosen the lock nut (item 3) in the turnbuckle

assembly. Turning the turnbuckle (item 2) clockwise or counter clockwise controls the forward and

backward pitch of the squeegee. Having the rear blades deflected uniformly along the entire length is

the desired set up.

9 Repeat Step 2 until the desired set up is achieved.

10 In certain applications where a non-slotted front wiper blade (item 6) is needed, detach the squeegee

assembly by loosening the wing bolts (item 7). Unlock the clamp on the front squeegee to release the

straps and flip the blade over to the non-slotted side. Reattach straps and lock the clamp back in place.

11 You can also easily replace the rear blade by unlatching the latch (item 5) and removing the straps by

sliding them off the assembly.

5

Page 10

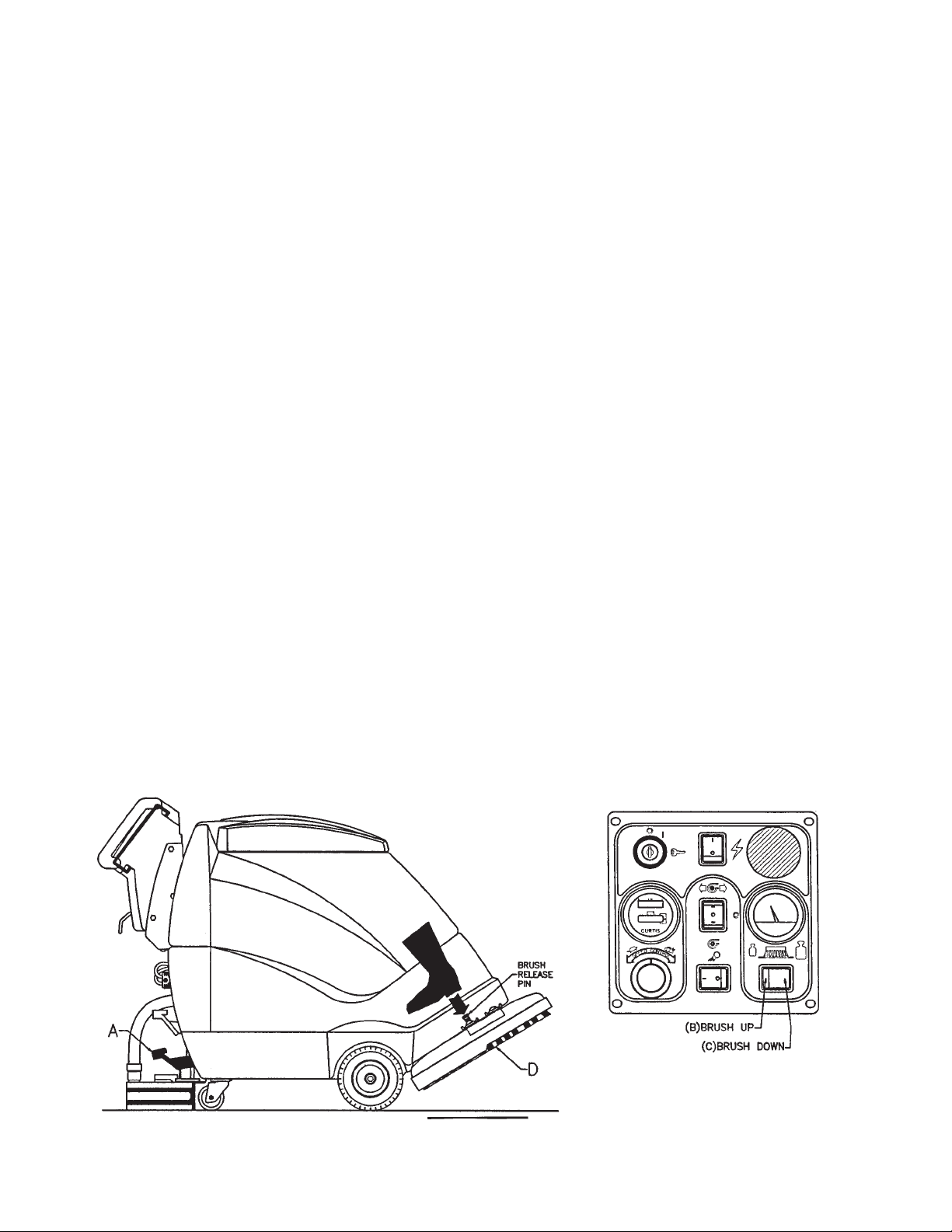

BRUSH INSTALLATION - REMOVAL

INSTALLATION

Traction Drive

1. Raise the scrubhead to the “UP” position by depressing the pedal (A) downward as shown on

Fig. 1.

Deluxe Model

1. Raise the scrubhead to the “UP” position by pressing the switch “BRUSH UP” (B) switch as

shown on Fig. 2 until the scrubhead stops retracting upwards.

2. Center brush (D) under the scrubhead shroud while lining up the center hex drive hub and pressing

the brush up until the brush engages on the drive hub.

REMOVAL

Traction Drive

1. Raise the scrubhead to the “UP” position by depressing the pedal (A) downward as shown on

Fig. 1.

Deluxe Model

1. Raise the scrubhead to the “UP” position by pressing the switch “BRUSH UP” (B) switch as

shown on Fig. 2 until the scrubhead stops retracting upwards.

2. Remove the brush (D) by stepping on the “BRUSH RELEASE PIN” on the top of the scrubhead

shroud as shown on Fig. 1 below .

Figure 1 Figure 2

6

Page 11

BASE ASSEMBLY - TRACTION DRIVE

7

Page 12

TRACTION DRIVE Parts List

8

Page 13

BASE ASSEMBLY - DELUXE

9

Page 14

DELUXE Parts List

10

Page 15

T ANK ASSEMBLY

11

Page 16

T ANK ASSEMBLY Part List

12

Page 17

UPPER ASSEMBLY

Parts List

13

Page 18

CONSOLE ASSEMBL Y

Parts List

14

Page 19

MOTOR LIFT - DELUXE

15

Page 20

Parts List

Item Part No. Qty. Description

1 200249 1 Base Plate Weldment - Deluxe

2 260036 2 Pin

3 712310 4 WSR-Flat .52 x .88 x .06

4 711527 6 WSR-Flat 5/8 x 1.12 x .12

5 762340 2 Oilite Bushing 1/2

6 260041 4 Oilite Flanged Bushing 1/2

7 200242 1 Lift Arm Weldment - Deluxe

8 711713 2 E-Ring 1/2

9 710312 2 SCR-MC 6-32 X 1.75 ZINC

10 740128 2 Microswitch

11 711430 1 Tinnerman Clip

12 833638 2 Brass Stud

13 711368 2 Wing Nut

14 740132 2 Insulator Glastic

15 743032 1 Terminal Block

16 712822 2 SCR-THMS 10-24 x 1/2

17 711807 1 Cotter Hair Pin

18 711672 1 Clevis Pin 1/2

19 711376 1 Nut-Nyloc 1/2-13

20 828264 2 Cup Washer

21 260137 1 Compression Spring

22 200110 1 Spring Bracket

23 711334 1 Nut-Hex 1/2-13

24 200149 1 Adjustment Rod

25 712126 1 Shoulder Bolt 5/16 x 1.75

26 711515 6 WSR-Flat .406 x .81 x .063

27 711373 1 Nut-Nyloc 1/4-20

200290 Motor Lift Assembly

200285 Pump/Actuator Assembly

28 200174 1 Pump Mounting Bracket

29 712638 4 Nut-Nyloc 10-24 SS

30 200248 1 Pivot Tube

31 831965 1 Clevis Pin 3/8 x 1.63

32 711808 1 Cotter Pin

33 743503 1 Actuator

34 833299 1 Pump

35 711505 4 WSR-Flat 1/4

36 712532 4 SCR-MC 10-24 x 1 SS

37 833325 2 Elbow 3/8 Barb x 1/4 NPT

38 450076 2 Crimp Clamp 185R

39 200282 1 Hose Pump Inlet

40 200281 1 Hose Pump Outlet

41 710329 2 SCR-MC 8-32 x .5 C.E. Only

42 742391 1 RFI Filter, Corcom C.E. Only

43 200335 1 RFI Bracket C.E. Only

44 711372 2 Nut-Nyloc 8-32 C.E. Only

200139 Valve Assembly - Deluxe

45 342430 2 Fitting 3/8 Barb x 3/8 MPT

46 743505 1 Water Solenoid 24V

47 829463 1 WSR-Flat SS

48 828975 1 WSR-Neoprene .75 x 1.5 x .09

49 830062 1 3/8 Street 90

50 383332 1 3/8 Closed Nipple

51 809413MCH 1 Solution Valve Machined

52 200259 1 Valve Bracket

53 210408 1 Fitting Brass Tee 3/8 NPT

54 450040 1 Elbow 3/8 Barb x 3/8 MPT

q Brass

16

Page 21

Parts List

MOTOR LIFT TRACTION DRIVE

17

Page 22

SCRUBHEAD ASSEMBL Y

Parts List

18

Page 23

Parts List

ITEM PART NO. REQ’D DESCRIPTION

1 200124 1 BACK PANEL WELDMENT

2 711210 2 BLT-HH 1/4-20 X1.25 STL ZINC

3 711368 2 NUT-WING NYLOC 114-20 PL

4 711425 8 NUT-FLANGEDWIZZI/4-20

5 712320 1 WSR.22X.45X.O4NYL

6 712536 2 SCR-MC 10-24 X .62 SS

7 712823 1 SCR-THUMB 10-24 Xl ZINC

8 740132 2 INSULATOR (GLASTIC)

9 740159 1 CIRCUIT BRKR-175 RED HOUSING

10 740238 2 CIRCUIT BRKR-18AMP PUSH BUTTON

11 740247 1 CIRCUIT BRKR-3OAMP PUSH BUTTON

12 740549 1 CIRCUIT BRKR-5OAMP PUSH BUTTON

13 742091 1 TIMER-DELAY ON BREAK 24VDC

14 742000 3 DIODE ASY 24/26/32/38/AC

15 742403 1 SHUNT, CALIBRATED

16 742748 4 CIRCUIT BRKR-BOOT

17 743250 1 ELECTRICAL ASSY 200XD

18 788147 3 SOLENOID-24VDC

19 833638 2 BRASS STUD

DASHBOARD BACK P ANEL

Parts List

19

Page 24

SQUEEGEE LIFT SQUEEGEE MECHANISM

Parts List Parts List

20

Page 25

Parts List

21

Page 26

WIRING DIAGRAMS

22

Page 27

200X TRACTION DRIVE AND DELUXE

23

Page 28

200X TRACTION DRIVE AND DELUXE

24

Page 29

CE 200X TRACTION DRIVE AND DELUXE

25

Page 30

CE 200X TRACTION DRIVE AND DELUXE

26

Page 31

LIMITED WARRANTY

Minuteman International, Inc. warrants to the original purchaser/user that this product is free from defects in workmanship and

materials under normal use and service for a period of three years from date of purchase. In addition, Minuteman International,

Inc. will, at its option, honor labor warranty claims for the first 12 months from date of sale, provided such claims are submitted

through and approved by factory authorized repair stations. Minuteman International, Inc. will, at its option, repair or replace

without charge, except for transportation costs, parts that fail under normal use and service when operated and maintained in

accordance with the applicable operation and instruction manuals.

This warranty does not apply to normal wear, or to items whose life is dependent on their use and care, such as belts, cords,

switches, hoses, rubber parts, electrical motor components or adjustments. Parts not manufactured by Minuteman International,

Inc. such as engines, batteries, battery chargers, hydraulic pumps, and tires are covered by and subject to the warranties and/

or guarantees of their manufacturers. Please contact Minuteman International, Inc. for procedures in warranty claims against

these manufacturers.

Special warning to purchaser — Use of replacement filters and/or prefilters not manufactured by Minuteman International,

Inc. or its designated licensees, will void all warranties expressed or implied.

A potential health hazard exists without exact original equipment replacement.

All warranteed items become the sole property of Minuteman International, Inc. or its original manufacturer, whichever the case

may be.

Minuteman International, Inc. disclaims any implied warranty, including the warranty of merchantability and the warranty of

fitness for a particular purpose. Minuteman International, Inc. assumes no responsibility for any special, incidental or

consequential damages.

This limited warranty is applicable only in the U.S.A. and Canada, and is extended only to the original user/purchaser of this

product. Customers outside the U.S.A. and Canada should contact their local distributor for export warranty policies. Minuteman

International, Inc. is not responsible for costs or repairs performed by persons other than those specifically authorized by

Minuteman International, Inc. This warranty does not apply to damage from transportation, alterations by unauthorized persons,

misuse or abuse of the equipment, use of non-compatible chemicals, or damage to property, or loss of income due to

malfunctions of the product.

If a difficulty develops with this machine, you should contact the dealer from whom it was purchased.

This warranty gives you specific legal rights, and you may have other rights which vary from state to state. Some states do not

allow the exclusion or limitation of special, incidental or consequential damages, or limitations on how long an implied

warranty lasts, so the above exclusions and limitations may not apply to you.

Minuteman International, Inc.

111 South Rohlwing Road

Addison, Illinois 60101

Phone 630-627-6900

Fax 630-627-1 130

www.minutemanintl.com

986764

Rev . A 01/07

Printed in U.S.A.

Loading...

Loading...