Page 1

Parts and Instruction Manual

M2400 Electric Burnisher

W/ Dust Control Option

Page 2

This manual is furnished with each new MINUTEMAN M2400. This provides the necessary operating

and preventive maintenance instructions. Operators must read and understand this manual before operating or servicing this machine.

This machine was designed to give you excellent performance and efficiency. For best results and

minimal cost, please follow the general guidelines below:

· Operate the machine with reasonable care.

· Follow the manufacturers suggested maintenance instructions as provided in this booklet.

· Use original Minuteman supplied parts.

TECHNICAL SPECIFICATIONS

Model M2400

Model No.

M17150-00, 01, 04, 05

M24000-00, 02, 04, 06

M24000-01, 03, 05, 07

M20150-01, 02, 03, 04

M17150-01CE, 05CE

M20150-02CE, 04CE

M24000-01CE, 03CE, 05CE, 07CE

Brush Speed

Brush Diameter

Horse Power

Voltage

Cable Length

PAMS Dust

Control

Wheels

Weight

Pad Housing

Handle

Circuit Breaker

Carbon Brush Light

Pad Pressure

15000 rpm

17” (43cm) or 20” (51cm)

1½ hp

115V or 240V

50’ (15m) 14-3

®

Option

6” (15cm)

84 lbs (38 kg)

Cast Aluminum

Dual switch w/ indicator

light

15 amp

Yes

Adjustable

Dual switch w/ indicator

2400 rpm

20” (51cm)

1½ hp

115V or 240V

50’ (15m) 14-3

Option

6” (15cm)

84 lbs (38 kg)

Cast Aluminum

light

15amp

Yes

Adjustable

1500-2400 rpm

20” (51cm)

1½ hp

115V or 240V

50’ (15m) 14-3

Option

6” (15cm)

84 lbs (38 kg)

Cast Aluminum

Dual switch w/ indicator

light

15amp

Yes

Adjustable

Page 3

Page 4

Table of Contents

IMPORTANT SAFETY INSTRUCTIONS.............................................................................................. 1

INSPECTION........................................................................................................................................ 2

GROUNDING INSTRUCTIONS ........................................................................................................... 2

ELECTRICAL....................................................................................................................................... 2

115 Volt - M24000-00, 02, 04, 06; M17150-00, 04; M20150-01, 03 ................................................ 2

240 Volt - M24000-01, 03, 05, 07; M17150-01, 05; M20150-02, 04;............................................... 2

................M24000-01CE, 03CE, 05CE, 07CE; M17150-01CE, 05CE; M20150-02CE, 04CE ........ 2

Model 2400 Burnisher Operating Instructions................................................................................. 5

Preventive Maintenance..................................................................................................................... 7

Trouble Shooting................................................................................................................................ 7

Exploded Views .................................................................................................................................. 8

Base Assembly................................................................................................................................ 8

Base Assembly BOM ...................................................................................................................... 9

Handle Assembly .......................................................................................................................... 10

Handle Assembly BOM ................................................................................................................. 11

Dust Control Option....................................................................................................................... 12

Dust Control Option BOM ............................................................................................................. 13

Wiring Diagrams ............................................................................................................................... 14

Minuteman International Made Simple Commercial Limited Warranty........................................ 16

Page 5

FOR COMMERCIAL USE ONLY

When using an electrical appliance, basic precautions should always be followed, including the

following:

IMPORTANT SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USING

WARNING - To reduce the risk of fire, electric shock, or injury:

• Do not leave appliance when plugged in. Unplug from outlet when not in use and before

servicing.

WARNING

To reduce the risk of electric shock - Do not expose to rain. Store indoors.

• Never allow children or untrained adults to operate this equipment.

• Keep the area of operation clear of all persons, particularly small children, and pets. Keep

bystanders at least 25 feet away from the area of operation.

• Use only as described in this manual. Use only manufacturer’s recommended attachments.

• Do not use with damaged cord or plug. If appliance is not working as it should, has been

dropped, damaged, left outdoors, or dropped into water, return it to a service center.

• Do not pull or carry by cord, use cord as a handle, close a door on cord, or pull cord around

sharp edges or corners. Do not run appliance over cord. Keep cord away from heated surfaces.

• Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

• Do not handle plug or appliance with wet hands.

• Do not put any object into openings. Do not use with any opening blocked; keep free of dust,

lint, hair, and anything that may reduce air flow.

• Keep hair, loose clothing, fingers, and all parts of body away from openings and moving parts.

• Do not pick up anything that is burning or smoking, such as cigarettes, matches, or hot ashes.

• Do not use without dustbag and/or filters in place.

• Turn off all controls before unplugging.

• Use extra care when cleaning on stairs.

• Do not use to pick up flammable or combustible liquids such as gasoline or use in areas they

may be present.

• Connect to a properly grounded outlet only. See grounding instructions.

Parts an d Instruction Manual

SAVE THESE INSTRUCTIONS

Page 1

Page 6

INSPECTION

Carefully unpack and inspect your machine for shipping damage. Each unit is tested and thoroughly

inspected before shipment, and any damage is the responsibility of the delivery carrier who should

be notified immediately.

WARNING

• Read Instruction Manual before operating this piece of equipment.

• To reduce the risk of fire use only commercially available floor cleaners and waxes intended for

machine application.

• To reduce the risk of electrical shock, do not expose to rain. Store indoors.

• Electrical motors and components can cause an explosion when operated near volatile materials

and vapors. Do not use this machine near flammable materials such a solvents, thinners, fuels,

grain dust, etc.

• Risk of explosion. Floor sanding can result in an explosive mixture of fine dust and air.

Use floor-sanding machine only in a well-ventilated area free from flame or match.

ELECTRICAL

This floor machine is designed to operate on a standard 15 amp. 120 volt, 60 hz, AC circuit.

Voltages below 105 volt AC or above 125 volts AC could cause serious damage to the motor.

ELECTRICAL -

This machine is designed to operate on a standard 10 amp. 230 volt, 50 hz, AC circuit.

1 15 Volt - M24000-00, 02, 04, 06; M17150-00, 04; M20150-01, -03

-

240 Volt - M24000-01, 03, 05, 07; M17150-01, 05; M20150-02, 04;

M24000-01CE, 03CE, 05CE, 07CE; M17150-01CE, 05CE; M20150-02CE, -04CE

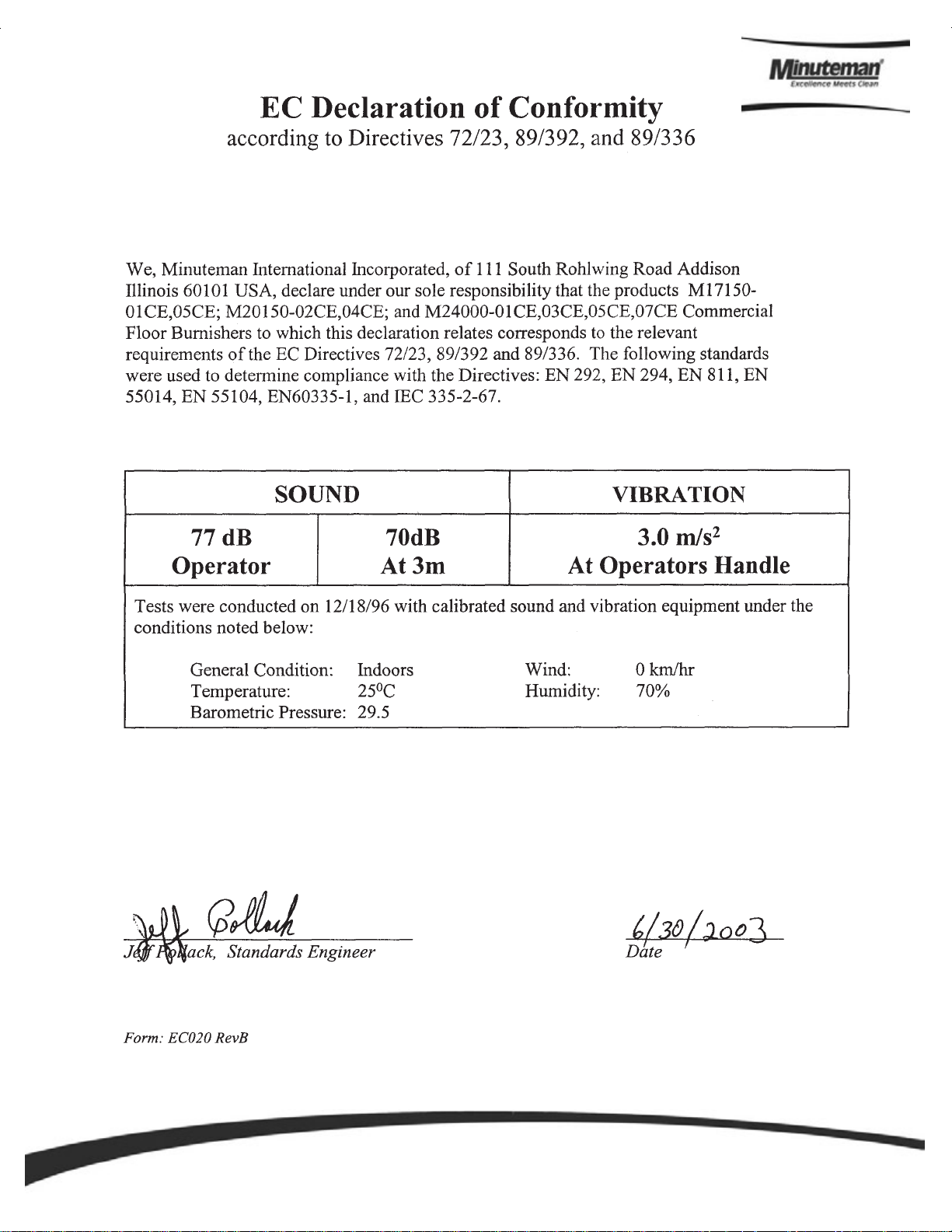

GROUNDING INSTRUCTIONS

• This floor finishing machine should be grounded while in use to protect the operator from electric

shock. The machine is equipped with a three-conductor cord and a three-prong grounding type

attachment plug to fit the proper grounding type receptacle. The green (or green and yellow)

conductor in the cord is the grounding wire. Never connect this wire to other than the grounding

blade.

• Floor Finishing Machines Rated Less Than 150 Volts - If the machine is provided with an

attachment plug as shown in Sketch A it is intended for use on a 120-volt (nominal) circuit. If a

properly grounded receptacle as shown in Sketch A is not available, an adapter as shown in

Sketch C is available and should be installed as shown in Sketch B if the outlet box that houses

the receptacle is grounded. Be sure to fasten the grounding tab with the faceplate screw.

Parts an d Instruction Manual

Page 2

Page 7

POUR USAGE COMMERCIAL SEULEMENT

MODE D’EMPLOI SECURITAIRE

Lorsque l’on utilise un appareil électrique, des précautions de base doivent toujours être suivies

telles que:

BIEN LIRE LE MODES D’EMPLOI AVANT USAGE

AVERTISSEMENT

• Ne pas quitter l’appareil lorsque la prise de courant est branchée. Débrancher de la sortie

électrique lorsque la machine n’est pas en usage ou pour en faire le service.

- Pour réduire les risques de feu, choc électrique ou blessure:

AVERTISSEMENT

Pour réduire le risque de choc électrique - Ne pas exposer à la pluie - Entreposer à l’intérieur.

• Ne jamais laisser des enfants ou des adultes inexpérimentés faire fonctionner cet appareil.

• Garder la zone de fonctionnement libre de toute personne, particulièrement les petits enfants

et les animaux. Garder les spectateurs à une distance d’au moins 7,6 mètres (25 pieds) de la

zone de fonctionnement.

• Utiliser tel que prescrit dans le livre d’opération et seulement avec les attachements recommendés

par le manufacturier.

• Ne pas s’en servir avec corde ou prise de courant endommangée. Si l’appareil ne fonctionne

pas ou a été échappé, endommagé, entreposé à l’extérieur ou déposé dans l’eau, l’appareil

devrait être envoyé à un département de service pour inspection.

• Ne pas tirer ou porter par le câble ou se servir du câble comme poignée. Ne pas fermer de

portes sur le câble ou tirer le câble près d’objets pointus. Ne pas conduire l’appareil écrasant le

câble et soyez certain de protéger le câble entre toutes surfaces de chauffage.

• Ne pas débrancher en se servant du câble. Pour débrancher tirer sur la prise et non sur le

câble.

• Ne pas manipuler la prise ou l’appareil avec les mains mouillées.

• Ne placer aucun objet dans la sortie et ne pas s’en servir si la sortie est obstruée. Eliminer toute

poussière, maillon, cheveux ou quoique ce soit qui pourrait réduire le mouvement d’air.

• N’exposer aucun cheveux, vêtement, doigts ou autres aux ouvertures de l’appareil.

• Ne rien ramasser de ce qui brûle ou de fumée tels que cigarettes, allumettes ou cendres en feu.

• Ne pas employer sans filtre de poussière ou autre en position.

• Fermer tous les contrôles après utilisation.

• Soyez très prudent lors du nettoyage d’escaliers.

• Ne pas ramasser de liquide inflammable ou combustible tel que gazoline et ne pas utiliser dans

les endroits ou ces derniers pourraient être présent.

• Brancher dans une prise avec une prise de terre seulement. Voir références pour prise de terre.

CONSERVEZ CES RECOMMANDATIONS

Parts an d Instruction Manual

DE MODE D’EMPLOI

Page 3

Page 8

INSPECTION

Déballer soigneusement en constatant s’il y, a lieu tout dommage apparent. Chacune des pièces

d’équipement est entièrement inspectée à l’usine et tout dommage de transit est la responsabilité de la

compagnie de transport qui devrait être prévenue immediatement.

AVERTISSEMENT

• S.V.P. lire le manuel d’instruction avant d’opérer cette pièce d’équipement.

• Pour réduire le risque d’incendie, se servir de ces appareils uniquement pour usage commercial et

avec les produits contruits spécifiquement pour usage avec ces appareils.

• Les moteurs électriques peuvent être la cause d’explosion si ils sont utilisés près de matériaux ou de

vapeurs explosives. Ne pas opérer près de matériaux inflammables tels que solvant, essence,

poussière de grain etc.

ELECTRICITE - 115 Volt Modèles M17120-00, 01, 02 M20120-01, 02, 03

Ces appareils sont congus pour opérer sur un circuit standard de 15 amp, 120 volt, 60 hz, circuit AC.

T out volt age en bas de 105 volt AC ou au-delà de 125 volts AC pourrait occasionner des dommages au

moteur.

ELECTRICITE - 230 Volt Modèles M17240-01, 02, 03 M20240-01, 02, 03

Ces appareils sont congus pour opérer sur un circuit standard AC de 16 amp, fusible type L 230 volt, 50

hz. Tout voltage en bas de 200 volt AC ou au-delà de 250 volts AC pourrait occasionner des dommages

au moteur.

INSTRUCTIONS POUR PRISSE DE TERRE

• Ces appareils doivent posséder une prise de miss à terre pour protéger l’opérateur contre les chocs

électriques. Cet appareil est muni d’une corde électrique à trois fils et d’un receptacle à trois fourchons

et prise de mise à terre pour s’accorder dans un receptacle avec prise de mise à terre réciproque. Le

fil conducteur vert (ou vert et jaune) de la corde électrique est le fil designé comme prise de mise à

terra. Ne jamais relier ce fil à un fil autre que celui de prise de mise à terre.

• Appareils estimés à moins de 150 volts - Si ces appareils offrent une prise de courant tel que dans

le croquis A, ils sont destinés pour utilisation avec un circuit de 120 volt s. Si un receptacle avec prise

de mise à terre n’est pas disponible tel que montré au croquis A, un adapteur tel que vu au croquis C

est disponible et devrait être installé tel que montré au croquis B si la boite électrique est munie d’une

prise de mise à terre. Assurez-vous de bien relier la patte de prise avec la vis.

• Appareils destinés à plus de 150 volts - Si ces appareils offrent une prise de courant tel que demontré

au croquis D, ils doivent être utilisés avec un circuit de 240 volts. Aucun adapteur n’est disponible

pour cette prise.

Parts an d Instruction Manual

Page 4

Page 9

Model 2400 Burnisher Operating Instructions

Install 20 Inch Pad inside pad driver.

Hand Tighten center clip or push straight in.

Hand Tighten or push in. DO NOT FORCE.

1. Install the polishing pad on to the pad driver. Make

sure your installing a true 20” polishing type pad. Then

install the locking centering device cup by lining up

the threads on the pad driver and the cup and push

straight down, or just screw the cup devise onto the

pad driver . Hand tighten the cup to the pad driver . Do

not force the centering cup if cross-threaded. Because

of patented centering cup Just hit the high side of the

cup with the palm of your hand to straighten out the

cross threading problem. T o remove the centering cup

hold onto it with one hand and with the other hand

spin the pad driver in the opposite direction until the

cup is removed.

2. Plug the machine into a standard 1 15-volt grounded

wall outlet. If an extension cord is required, it must

be 3-wire cord. The burnisher is equipped with a 3

wire, 14-gauge cord, 50 feet long. If the extension

cord to be used is more than 25 feet a larger wire

size cord should be used, preferably a 12- gauge

cord no longer than 50 feet long. Failure to use a

lager size cord may result in reduced performance

and motor overheating. After the cord is properly

plugged into the outlet a red light will illuminate on

the rear of the operators handle telling the operator

you now have power to the machine.

3. After the pad is on the machine stand the burnisher up straight on top of the pad so it is flat on the

floor . If you are starting with a new p ad, decrease the pad pressure adjustment centering wheel as far

as it can go. This will raise your pad to the highest position. Next by stepping onto the foot locking

lever, located on the right side of the machine, push downward with your foot to release the handle.

While the handle is lowered down take one of your thumbs and pull either safety interlocking switches,

located at the top of the handle, with you fingers grab the lever switch and pull at the same time.

CAUTION: This machine has a high starting torque. Have both hands on the control handle when

starting to ensure complete control.

Pad Pressure Adjustment Knob. When using new pad, turn

Safety Interlocking switches.

Parts an d Instruction Manual

Page 5

Page 10

Model 2400 Burnisher Operating Instructions

4. After the machine has started the pad pressure gauge, located at the backside near the rear of the base, should

be reading at the top of the white zone, or telling the operator the pad is off the floor. Now, to increase the pad

pressure keep the burnisher running with one hand and pushing the machine in a back and forth motion. With

the other hand turn the center adjustment knob, in the center of the base, to the increase clockwise position

until the gauge gets to the 15 amp red line. After the meter needle reads between the lower edge of the red

zone, or 15 amps, you have reached the proper polishing pressure. If the burnisher runs over a high spot, the

gauge needle will go into the top of the red zone, but should fall back into the safety-working zone as you go

along. As the pad is being used more pad pressure will be required just by running the machine back and forth

and screwing the adjustment knob to the increase position until the needle reaches 15 amps, or the bottom of

the red safety working zone. If the operator works too long in the red zone the machine will trip the thermo-reset

breaker located at the rear base of the machine. To prevent it from happening again adjust the pad pressure

screw knob counter clockwise to decrease pad pressure.

5. The machine should always be started with the pad

pressure fully decreased when using a new pad, and

then adjusted to the correct pad pressure.

6. Burnish with the machine in a straight line. The pace

of the machine should be determined by the condition

of the floor. Normally the machine can be operated at

a slow to medium walking pace. Overlap with the pad

driver approximately 2” to 3” when making a pass.

For the ease of use, start nearest the wall outlet and

work away from this point. CAUTION: Do not let the

machine sit in one spot for more than 5 to 10 seconds.

Pad Pressure Gauge. Needle will “peg” then drop to its normal

pressure. Adjust pad pressure knob so pad pressure gauge reads

at the 15 amp red line. Be sure to keep unit moving to prevent

damage to the floor.

Due to the high RPM’s of this machine and the heat it

develops, sitting in one spot longer than this may

damage the floor finish and possible the floor itself.

Carbon Brush Wear Indicator Light

Parts an d Instruction Manual

Circuit Breaker

Pad Pressure Gauge

7. The machine employs an adjustable spring loaded

center caster directly in the center of the pad driver.

This caster is preset at the factory to have the machine

operate at 14.0 to 14.5 amps. If the machine circuit

breaker trips, or the wall circuit breaker trips, adjust

the center wheel caster to “decrease” the pad pressure

on the floor. If the machine is not properly burnishing

the floor with full pad contact, adjust the caster to

“increase” the pad pressure on the floor.

8. This machine employs a motor carbon brush wear

indicator light located on the rear base of the machine.

This light will illuminate when the brushes are worn to

the point where there is approximately 250 hours

remaining. The carbon brushes should be replaced

shortly after this light indicates excessive wear.

Page 6

Page 11

Model 2400 Burnisher Operating Instructions

Preventive Maintenance

1. Inspect motor carbon brushes approximately every 250 hours. A set of carbon brushes should

last as long as 2500 hours. Premature wear may indicate other problems with the motor.

These can be inspected by removing the motor cover . Indications for changing carbon brushes

would be if the indicator light comes on or if the carbon brushes are flush with or slightly

recessed in the brass brush holder.

2. Periodically clean the motor by removing the motor cover and blowing it out with compressed

air.

3. Check the drive belt of wear and proper tension. Retention the belt by loosening the four

motor mount screws, then apply force to the motor toward the rear of the machine. Take out

excessive slack. Do not overtighten the belt. This can cause excessive loads to the bearings

and reduce the belt life.

Trouble Shooting

1. Machine will not start.

A. Check to see if the machine circuit breaker is reset.

B. Check to see if there are any disconnected wires at the motor or switches.

C. Check to see if the “on/off” switch and safety switch are activating.

2. Motor will not start, circuit breaker trips.

A. Check rectifiers in the motor for damage.

B. Inspect internal wiring for loose connections or direct shorts.

C. Inspect carbon brushes for excessive wear.

3. Machine runs a short period of time, then the circuit breaker trips.

A. Check motor carbon brushes for wear.

B. Adjust pad pressure to the floor to relieve pad pressure.

C. Extension cord under size, pulling a low voltage.

Parts an d Instruction Manual

Page 7

Page 12

Exploded Views

Base Assembly

Parts an d Instruction Manual

Page 8

Page 13

Base Assembly BOM

Item Part No. Qty. Description

1 130040PTD 1 Handle PTD DK Grey

1A* 130040CTD 1 Handle - Coated

2 150208 1 Motor Bracket 56/56 Frame

3 150209 2 Foam Tape 25 in.

4 230002 1 Housing Plate

5 230003 1 Housing Plate Gasket

6 230004 1 Curved Sealing Plate 17"

6A 230022 1 Curved Sealing Plate 20"

7 230005 1 Rear Closure 17"

7A 230023 1 Rear Closure 20"

8 230006 1 Motor Shroud

9 230010 1 Release Pedal Weldment

10 230013 1 Axle

11 230016 1 Release Weldment

12 230017PTD 1 Base Casting 17" Painted

12A* 230017PTDCE 1 17" Casting CE Painted

12B 230020PTD 1 Base Casting 20" Painted

12C* 230020PTDCE 1 20" Casting CE Painted

13 230019 1 Clamp Band Assy. 17" HS

13A 230030 1 Clamp Band Assy. 20" HS

14 230021 1 Dust Skirt 17" HS

14A 230037 1 Dust Skirt 20" HS

15 230024 1 Spring Bracket

16 230031 1 Non-Skid Strip

17 230036 1 Foam Gasket

18 230038 1 Shielding Bracket

19* 230040 1 Line Filter Bracket

20 230043 2 Wheel, 6” w/Nylon Brushing

21 260581MCH 1 Pad Grabber, Ring Machined

22 430051 1 Spring-Return .313x.438x2.

23 450050 1 Bushing - Heyco .875x.875x1.

24 710196 2 SCR-MC 5/16-18x.62

25* 710360 2 SCR-MC 10-32x1 Zinc

26 710579 2 SCR-MC 1/4-20x.62 Zinc

27 710985 2 SC 3/8-16 x .62

28 710986 4 SC 3/8-16 x 1 Zinc (1500 rpm)

28A 711246 4 BLT-HH 3/8-16 x .87 (2400 rpm & V.S.)

29 710987 2 SC 3/8-16 x 1.50 Zinc

30 711142 11 SCR-ST-F 10-24 x .37 Zinc

31 711243 1 Bolt-HH 3/8-16 x 1.50 STL Zinc

32* 711350 2 Nut-Nyloc 10-32

33 711379 1 Nut-Flanged Wizz 5/16-18

34 711380 2 Nut-Nyloc 3/8-16

35 711387 2 Nut-Nyloc 1/4-20 1/2Nut

36 711400 1 Nut-Pipe Lock 1/2

37 711508 4 WSR-FLT .44 x 1.00 x .08

38 711512 3 WSR-Flat .75 x 1.37 x .08

39 711515 2 WSR-Flat .406 x .812 x .0625

40 711519 2 WSR-Flat .25 x 1.01 x .06

41 711524 4 WSR-WAVE .52 x .87 x .01

42 711544 2 WSR-Helical 1/4

43 711553 3 WSR-Internal Lock #10

44 711555 4 WSR-Internal Lock 3/8 (1500 rpm)

44A 711556 4 WSR-Lock Internal 1/2 (2400 rpm &

V.S.)

45 711592 3 WSR-FLT .50 x .90 x .075 NYL

46 712081 1 BLT-SDR 5/16-18 x .75

47 712822 1 SCR-MC TR HD 10-24 x .50 SS

48 713002 2 BLT-HH 1/4-20 x .75 #5

49 715061 1 Decal, General Warning

50 715067 1 Decal, Brush Wear Indicate

51 710159 1 Decal, 1500

51A 715193 1 Decal, 2400

52 715234 1 Decal-Pad Pressure

Item Part No. Qty. Description

53 740044 1 Cap-Wire 12-18 74B

54 740220 1 Circuit Breaker 20AMP 2-Terminal 115V

54A 740106 1 Circuit Breaker 9AMP Push Button

240V

54B 741400 1 Circuit Brkr 10A Push Btn (Norway)

55 742115 1 Motor 1.5 HP 115V 66 Frame E623

55A 742230 1 Motor 1.5 HP 230V 66 Frame

56* 742254 1 RFI Shield Torroid

57* 742256 1 RFI Filter

58 742260 1 Triac Control Asy. 115V

58A 742261 1 Triac Control Asy. 230V

59 190031 1 Knob

60 230039 1 Heat Sink 2400

61 710377 1 SCR 1/4-20 x .37 Zinc

62 712666 1 Nut-Hex Jam 1/4-28 SS

63 715191 1 Decal - Speed Control

64 760028 1 Pulley MTR 4” ODX .62ID (1500 rpm)

64A 832409 1 Pulley (2400 rpm & V.S.)

65 760401 1 Center Cup New Style

66** 762160 4 Carbon Brush 115V

66A** 740281 4 Motor-Brush Carbon 240V

67 762318PLT 1 Sleeve .375 x .623 x .75

68* 762410 2 Bushing-.20x.312x.265 Alm

69 77-81-A 2 Spacer .53x.75x.25

70 829014 2 Flanged Bushing

71 829194 1 Top Cover w/Screen Print

72 832122 1 Spacer .384x.50x.31

73 832480 1 Caster Asy Complete

74 711319 1 Nut-Hex 5/16-18 ST PL

75 712533 1 SCR-MC 10-24 x 1.25 SS

76 712638 1 Nut-Hex 10-24 SS Nyloc

77 712763 2 Bearing Race Washer SS

78 712764 1 WSR #10 SS

79 762018 1 Caster Center

80 787791 1 Brush Shaft

81 831089 2 Shaft Bushing .375x.56x.75

82 831542 1 Spring .31x.42x1.5

83 832186 1 Thrust Bearing

84 832418 1 Adjustment Knob 5/16x18

85 832448 1 Shoulder Screw

86 832453 1 SCR-ADJ 5/16x18

87 833102 1 Spring-Knob .60x.73x1.75 Z

88 833224 1 Caster Weldment Yoke SS

89 833368 1 Bushing-Cast .203x.4995x.7

90 833507PLT 1 Cap Nut M2300PLT

91 880023 1 Nut-Nyloc 3/4x16

92 832552 1 Meter 115V 25 AMP w/Clip

92A 832819 1 Meter 230V 0-15 AMP

93 832603 1 Decal-CB Reset

94 832619 1 Spring

95 832623 1 Spring Clamp

96 832829 2 Nut-U Type 5/16x18

97 832859-1 1 Indicator Light 115V Asy

97A 742313-1 1 Lamp Assy 230V VDE

98 833073 1 Belt A38 (1500 rpm)

98A 832574 1 Belt V (2400 rpm & v.s.)

99 833199 1 MultiFlex 17" Assy.

99A 833900 1 MultiFlex 20" Assy. New

100 833212 1 Pulley Asy w/Bearings

101 833122 1 Drive Pulley Machined

102 881060 2 Bearing 3/4”

103 881317 2 Ret. Ring

104 833823 1 Dome Plug 2” Black

Parts an d Instruction Manual

Page 9

Page 14

Handle Assembly

Parts an d Instruction Manual

Page 10

Page 15

Handle Assembly BOM

Item Part No. Qty. Description

1 150002 1 Cord-14GA-3 50FT Med Grey

1A 740600 1 Cord-European F3 G1.5MM 50Ft B

2 150003 1 Strain Relief 100x50

2A 150004 1 Strain Relief Heyco 3251

3 170040PLT 1 Cord Hook Plated

4 190006 2 End Cap

5 190008 1 Switch Cap

6 190009B 2 Safety Button Black

7 190010 1 Strain Relief

8 190015 2 Trigger Spring

9 190016 2 Foam Grip 4 1/2 I/L

10 190022 1 Switch Box Front Cover Black

11 190023 1 Switch Box Back Cover Black

12 190024 1 Electrical Box Cover Black

13 190029 2 Bushing .270 x .343 x 1.250

14 190033B 2 Switch Trigger Long Black

15 230025 1 Tube Handle

16 230027 1 Yoke Weld

17 710186 2 SCR-MC TR-HD 1/4-20 x 2 1/4

18 710380 2 SCR-MC 1/4-20 x .75 Zinc

19 711128 4 SCR-ST-B HI/LO 8 x .62 Zinc

20 711160 4 SCR-HI/LO #10 x 5/8 Zinc

21 711162 4 SCR-HI/LO #10 x 1 1/2 Zinc

22 711214 2 Bolt-HH 1/4-20 x 2.00 STL Zinc

23 711316 2 Nut-Hex 1/4-20 ST PL

24 711373 2 Nut-Nyloc 1/4-20

25 711387 2 Nut-Nyloc 1/4-20 1/2Nut

26 711400 1 Nut - Pipe Lock 1/2

27 711504 2 WSR-Flat 1/4 SS

28 711554 4 WSR-INT Lock 1/4

29 711619 2 Roll Pin 1/8 x 1 3/5

30 711620 2 Roll Pin .25 x 1.25

31 715175 1 Decal - MMAN Runner

32 715237 1 Decal - Read Instruction

33 715501 1 Decal - Made in USA

34 715950 1 Label - Patent Numbers

35 740029 2 Switch - Snap SPST PB NO/NC

36 740361 1 Wire Assembly 14G White 6.00"

37 740362 1 Wire Assembly 14G Black 6.00"

38 741129 3 Splice, Crimp, End

39 742259 1 Cable Assy, 2400 Handle

40 742313 1 Lamp-230V VDE

40A 832859 1 Indicator Light (115V)

Parts an d Instruction Manual

Page 11

Page 16

Dust Control Option

Parts an d Instruction Manual

Page 12

Page 17

Dust Control Option BOM

Item Part No. Qty. Description

1 230034 1 Dust Tube

2 230101 1 Hose 2” C/L 14”

3 380035 1 Gasket 4.31 x 5.81 x .19

4 390061 1 O-Ring - Valve Stem

5 710197 2 SCR-SC 5/16-18 x .75

6 710556 2 SCR-MC 10-32 x .75 Zinc

7 711202 1 BLT-HH 1/4-20 x .50 STL Zinc

8 71 1350 2 Nut-Nyloc 10-32

9 711505 1 WSR-Flat 1/4

10 711524 1 WSR-Wave .52 x .87 x .01

11 711594 1 WSR-Flat .56 x .88 x .03 Nickel

12 711903 1 Rivet-Pop .19 x .25 AL

13 715100 1 Decal - Pams Light Grey

14 762131PTD 1 Hose Fitting D/C 2300

15 762132 1 Dust Collection Tray

16 762396B 1 Filter Housing Burgundy

17 762403 1 Filter Pad 9” 5per

18 762404 1 Filter Gasket

19 762409PLT 1 Thrd Pin Retainer Zinc PL

20 462410 1 Bushing .20 x .312 x .265 ALM

21 762411 1 Gasket - Dust Collection

22 762415 1 Filter Housing Cover

23 762416PLT 1 Threaded Spacer Plated

24 805042 3.166 Ft Gasket

25 833214 1 Knob - 3 Sided 1/4 20 Insert

Parts an d Instruction Manual

Page 13

Page 18

Wiring Diagrams

Parts an d Instruction Manual

Page 14

Page 19

Parts an d Instruction Manual

Page 15

Page 20

Minuteman International Made Simple Commercial Limited Warranty

Minuteman International, Inc. warrants to the original purchaser/user that the product is free from defects in

workmanship and mat erials under normal use. Minuteman will, at its option, repair or replace without charge, parts

that fail under normal use and service when operated and maintained in accordance with the applicable operation and

instruction manuals. All warranty claims must be submitted through and approved by factory authorized repair

stations.

This warranty does not apply to normal wear, or to items whose life is dependent on their use and care, such as belt s,

cords, switches, hoses, rubber parts, electrical motor components or adjustments. Parts not manufactured by

Minuteman are covered by and subject to the warranties and/or guarantees of their manufacturers. Please cont act

Minuteman for procedures in warranty claims against these manufacturers.

Special warning to purchaser -- Use of replacement filters and/or prefilters not manufactured by Minuteman or its

designated licensees, will void all warranti es expressed or implied. A potential health hazard exits wit hout original

equipment replacem ent .

All warranted items become the sole property of Minuteman or its original manufacturer, whichever the case may be.

Minuteman disclai ms any implied war ranty, including the warranty of mer chantability and the warranty of fitness for a

particular purpose. Mi nut em an assumes no responsibility for any specia l, incidental or consequent ial damages.

This limited warranty is applicable only in the U.S.A. and Canada, and is extended only to the original user/purchaser

of this product . Customers outside t he U.S.A. and Canada should contact their local distributor for export warranty

policies. Minuteman is not responsible for costs or repairs performed by persons other than those specifically

authorized by Minut eman. This war ranty does not apply to damage from transportat ion, alterati ons by unauthorized

persons, misuse or abuse of the equipment, use of non-compatible chemicals, or damage to property, or loss of

income due to malfunct io ns of th e product.

If a difficulty develops with this machine, you should contact the dealer from whom it was purchased.

This warranty gives you specific legal rights, and you may have other rights which vary from state to state. Some

states do not allow the exclusion or limitation of special, incidental or consequential damages, or limitations on how

long an implied warr anty lasts, so the above exclusions and limitat i ons m ay not appl y to you.

Cord Electric Group………. Th ree years parts, t w o y ears labor, ninety days travel (Not to exceed two hours)

Exceptions……… . Port-A-Scrub, one year parts, six months labor

MPV 13, one year parts

MPV 14 and 18, two years parts, one y ear labo r

RapidAir blower, one year parts, one year labor

Explosion-Proof Vacuum, one year parts, one year labor

Pneumatic Vacuums, three years parts, one year labor

Battery Op er ated Group….. Three years parts, two years labor, ninety days travel

(Not to exceed two hours )

Exceptions……Sweepers, one year parts, one year labor, ninety days travel

(Not to exceed two hours )

Internal Combustion Group….One year parts, one y ear labor, ninety day travel

(Not to exceed two hours)

Replac ement Parts……………..N i nety days

Batteries………………………….0-3 months replacement, 4-12 mont hs pro-rate

Polypropylene Plastic Tanks…Ten years, no additional labor

111 South Rohlwing Road · Addison, Illinois 60101 USA

Phone 630- 627-6900 · Fax 630- 627-1130

E-Mail, www. minutemanintl.com

A Member of the Hako Group

988563

Rev A 02/07

Loading...

Loading...