Page 1

®

Mirage

Propane

Burnisher

Model: M220021H13

OPERATION

SERVICE PARTS

CARE

Page 2

Page 3

TABLE OF CONTENTS

Page

1 Unpacking Instructions, User Tips

2 - 4 General Warning Information

5 - 6 Engine Set-Up

7 Operation

8 - 10 General Maintenance Information

11 - 12 Trouble Shooting

13 - 18 Engine Specifications

19 Warranty Information

Back Cover Warranty

Page 4

UNPACKING INFORMATION

INSPECTION

Carefully unpack and inspect your Burnisher for shipping damage. Each unit is tested and thoroughly inspected before

shipment and any damage is the responsibility of the delivering carrier who should be notified immediately.

ENGINES

Engines are shipped with oil & coolant, if applicable. Refer to engine manual for correct weight and quantity. Briggs Vtwin 16 hp, Briggs 14 hp single cylinder, Kawasaki. Before starting engine check all levels. Do not overfill.

PROPANE TANK

The tank supplied with this equipment is a vertical vapor withdrawal 20 lb. tank. Do not overfill. Fill tank to 80% of rated

capacity. Safety fill, Aluminum unpolished, polished, and steel. All propane tanks are equipped with this special warning

sticker. Please read.

WARNING: Vapor withdrawal tank weight fill only! Failure to weight fill tank will void

warranty and cause damage to propane components! Tare weight is stamped

on the tank.

USER TIPS

• Allow only qualified and trained personnel to operate a

Minuteman Propane Buffer.

• Always maintain your Minuteman Propane Buffer, follow

operating and maintenance instructions.

• Always check oil level before starting.

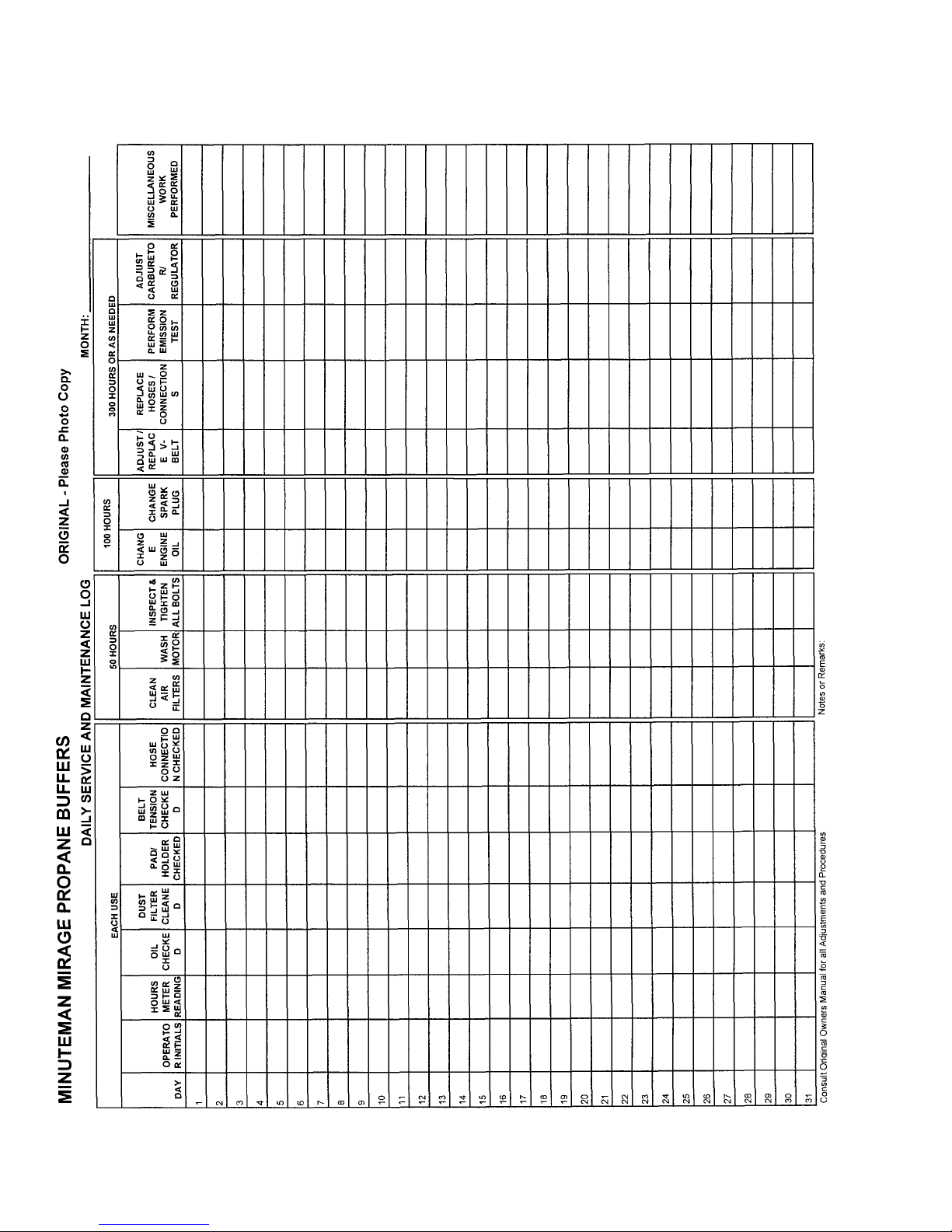

• Always keep accurate records of maintenance and service

in a maintenance log book.

• Never overfill a propane fuel tank. Be sure to follow safety

instructions for venting overfilled tanks in safety section

in this manual.

• Never leave machine unattended with engine running.

• Never change or alter fuel system unless authorized by

Minuteman International Inc. Service Department.

• Always keep nuts and bolts tightened and hose

connection snug.

• Always clean recoil dust filters after 1 hour of use, and

keep propane buffer clean.

• Always store propane tank outside in an approved,

secured, and tamper proof enclosure to provide safety

from vandalism and accidents.

• Never use a non-UL listed fuel tank on your propane buffer.

• Always operate your propane buffer, with exhaust (muffler)

pointed away from merchandise, furniture, etc. Heat from

exhaust may cause damage.

• Never use a spray buff product over top of the engine.

This could cause damage to engine if product got into

cooling system.

• For all engine repairs refer to the engine manual included

with this parts and instruction book.

• Always check fuel system for leaks with soapy water.

(Hoses, regulators, connections)

• Never smoke while operating or working on propane buffer.

• Do not attempt to change a pad while buffer engine is

running.

• Keep hands, feet, hair, clothing, etc. away from buffing

pad, pulleys, and any other moving parts on equipment.

• If you smell gas, do not touch any electric switch,

extinguish any open flame and contact your gas supplier,

and open windows.

• If there is any smell of propane fuel, check immediately

for leaks and shut off tank at valve.

• Do not store any other flammable liquids or vapors in the

vicinity of propane storage area, machine storage area or

any other appliance.

• Do not place flammable objects such as matches, fuel,

etc., close to the engine while it is running.

• Never attempt to repair a propane fuel tank by yourself.

Tanks can only be repaired by a Department of

Transportation authorized facility.

• For repairs or adjustments on your Propane Buffer use

only an authorized Minuteman Service Center.

!

CAUTION

cold (ICE). Degrees (-44) avoid contact.

!

CAUTION

will settle to the lowest possible area and build upwards.

!

CAUTION

area, can cause an explosion if ignited. Operate only in

well-ventilated areas.

Visible escaping gas vapor is extremely

Propane gas is heavier than air. The gas

Build-up of propane vapor in any enclosed

1

Page 5

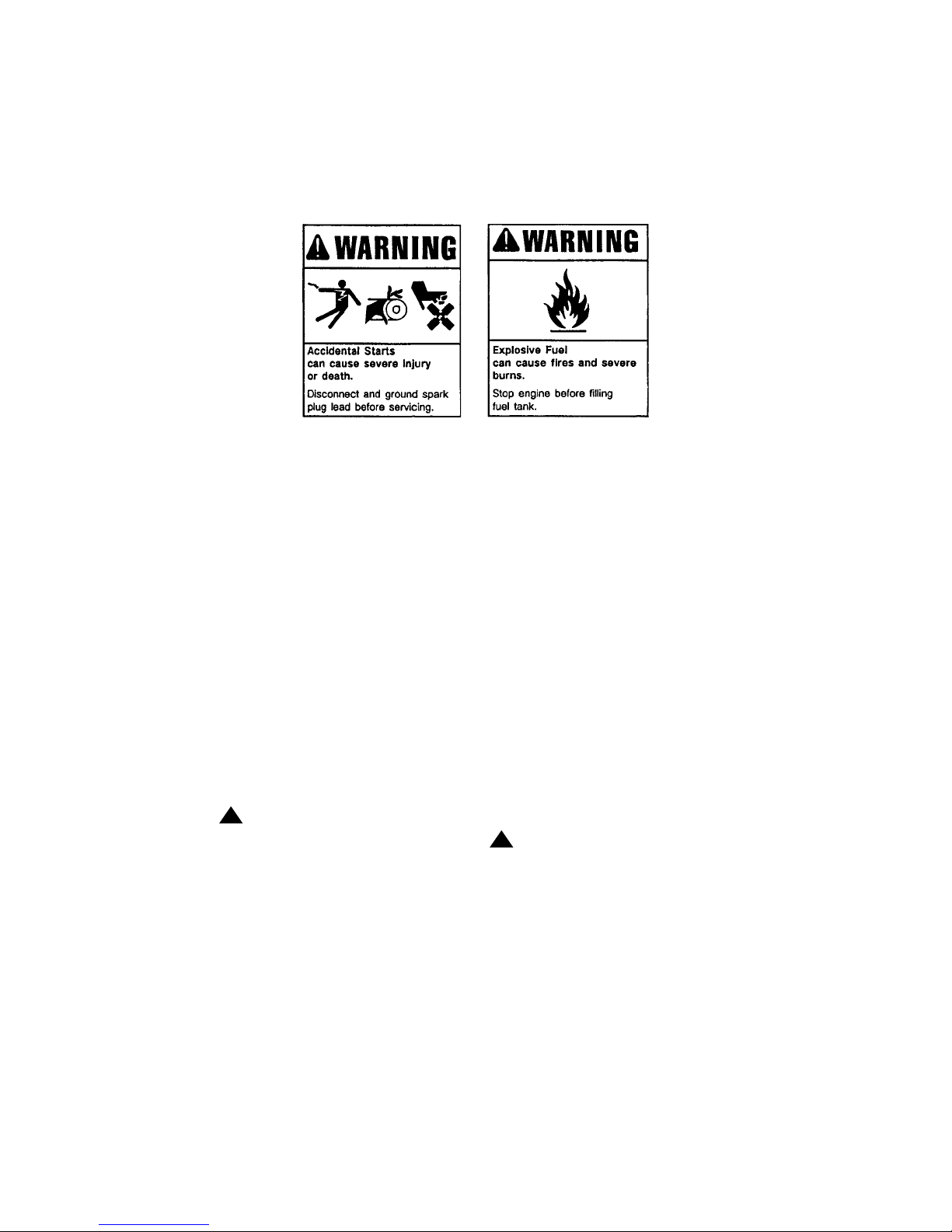

SAFETY PRECAUTIONS

Before operating the engine, read the Operator’s Manual

and become familiar with it and the equipment. Safe and

efficient operation can be achieved only if the equipment is

properly operated and maintained.

The following symbols, found throughout this manual, alert

you to potentially dangerous conditions to the operator,

service personnel, or the equipment.

DANGER

!

hazards that will result in severe personal injury or

death.

WARNING

!

practice that can result in severe personal injury or

death.

!

CAUTION

practice that can result in personal injury or product or

property damage.

Fuels, electrical equipment, batteries, exhaust gases and

moving parts present potential hazards that can result in

severe personal injury. Take care in following these

recommended procedures. All local, state and federal codes

should be consulted and complied with.

This symbol warns of immediate

This symbol refers to a hazard or unsafe

This symbol refers to a hazard or unsafe

FUEL SYSTEM

• DO NOT fill fuel tanks while engine is running.

• DO NOT smoke or use an open flame in the vicinity of

the engine or fuel tank. Internal combustion engine fuels

are highly flammable.

• Fuel line must be LP approved, adequately secured, and

free from leaks. Piping at the engine should be approved

flexible line. Do not use copper piping for flexible lines as

copper will harden and become brittle enough to break.

• Be sure all fuel supplies have a positive shut-off valve.

PROTECT AGAINST MOVING PARTS

• Do not wear loose clothing in the vicinity of moving parts,

such as PTO shafts, flywheels, blowers, couplings, fans

belts, etc.

• Keep your hands away from moving parts.

EXHAUST SYSTEM

• Exhaust products of any internal combustion engine are

toxic and can cause injury, or death if inhaled. When

operating the engine in a confined area, make sure the

ventilation system is operating properly.

• DO NOT use exhaust gases to heat a compartment.

• Make sure that your exhaust system is free of leaks.

Make sure that exhaust manifolds are secure and are

not warped by bolts unevenly torqued.

GENERAL

• Provide appropriate fire extinguishers and install in

convenient locations. Use an extinguisher rated ABC by

NFPA.

• Make sure that all fasteners on the engine are secure

and accurately torqued. Keep guards in position over fans,

driving belts, etc.

• If it is necessary to make adjustments while the engine

is running, use extreme caution when close to hot

exhausts, moving parts, etc.

• Used engine oils have been identified by some state or

federal agencies as causing cancer or reproductive

toxicity. When checking or changing engine oil, take care

not to ingest, breathe the fumes, or contact used oil.

• Do not work on this equipment when mentally or

physically fatigued, or after consuming any alcohol or

drug that makes the operation of equipment unsafe.

EXHAUST GAS IS DEADLY!

Exhaust gases contain carbon monoxide, a poisonous gas

that can cause unconsciousness and death. It is an

odorless and colorless gas formed during combustion of

hydrocarbon fuels. Symptoms of carbon monoxide

poisoning are:

• Dizziness

• Headache

• Weakness and Sleepiness

• Throbbing in Temples

If you experience any of these symptoms, get out into fresh

air immediately, shut down the unit and do not use it until it

has been inspected.

The best protection against carbon monoxide inhalation is

proper installation and regular, frequent inspections of the

complete exhaust system. If you notice a change in the

sound or appearance of exhaust system, shut the unit down

immediately and have it inspected and repaired at once by

a competent mechanic.

KEEP THE UNIT AND SURROUNDING AREA CLEAN

• Make sure that oily rags are not left on or near the engine.

• Remove all unnecessary grease and oil from the unit.

Accumulated grease and oil can cause overheating and

subsequent engine damage and present a potential fire

hazard.

• Vomiting

• Muscular Twitching

2

Page 6

SAFETY INFORMATION

For Your Safety!

These safety precautions should be followed at all times. Failure to follow

these safety precautions could result in injury to yourself and others.

Accidental Starts!

Before servicing the engine or

equipment, always disconnect

the spark plug lead to prevent

the engine from starting accidently.

Ground the lead to prevent sparks that

could cause fires.

On engines equipped with a 12-volt

battery and/or electric start, disconnect

the battery cables from the battery.

Always disconnect the negative (-) cable

first.

Before disconnecting the negative (-)

ground cable, make sure all switches

are OFF. If ON, a spark will occur at the

ground cable terminal which could

cause an explosion if hydrogen gas or

fuel vapors are present.

WARNING: Over-speed is

!

Hazardous!

Never tamper with the govenor

components or settings to increase the

maximum speed. Severe personal injury

and damage to the engine or equipment

can result if operated at speed above

maximum ratings.

Explosive Fuel

LPG is extremely flammable and is

heavier than air and tends to settle in

low areas where a spark or flame could

ignite the gas. Do not start or operate

this engine in a poorly ventilated area

where leaking gas could accumulate

and endanger the safety of persons in

the area.

To insure personal safety, installation

and repair of LPG fuel supply systems

must be performed only by qualified LPG

system technicians. Improperly installed

and maintained LPG equipment could

cause fuel supply system or other

components to malfunction, causing gas

leaks.

Observe federal, state and local laws

governing LPG fuel and systems.

CAUTION: High Voltage!

!

Never touch electrical wires or

components while the engine is running.

They can be sources of electrical shock

which could cause severe injury or

burns.

3

Page 7

SAFETY INFORMATION CONTINUED

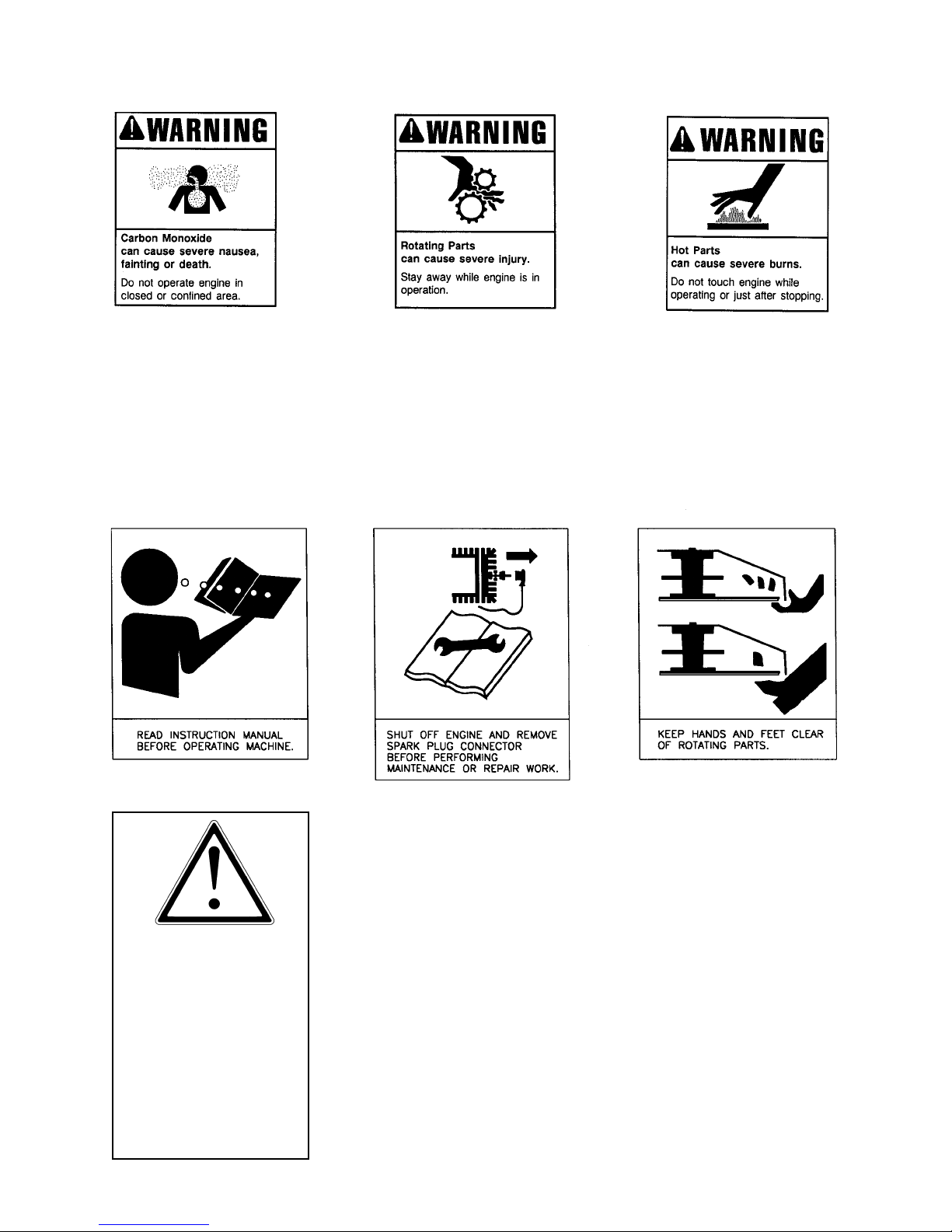

Lethal Exhaust Gases!

Engine exhaust gases contain

poisonous carbon monoxide. Carbon

monoxide is odorless, colorless, and

can cause death if inhaled. Avoid

inhaling exhaust fumes, and never run

the engine in a closed building or

confined area.

Rotating Parts!

Keep hands, feet, hair, and clothing

away from all moving parts to prevent

injury. Never operate the engine with

covers, shrouds, or guards removed.

Hot Parts!

The crankcase, cylinder head, exhaust

system, and other components can

get extremely hot from operation. To

prevent severe burns, do not touch

these areas while the engine is running

- or immediately after it is turned off.

Never operate the engine with heat

shields or guards removed.

WARNING

The 120V A.C. starter is

equipped with a three-wire

power cord and plug, and is

designed to operate on

120V A.C. household current. The starter must be

properly grounded at all

times to avoid the possibility of injury or death from

electrical shock. Always use

a three-wire ground fault interrupted system. 715432

4

Page 8

ENGINE SET-UP

PRE-START CHECKS

Inspect the engine visually. Check for loose or missing parts

and any damage that may have occurred in shipment.

Refer to Engine Owners Manual for the crankcase oil

capacity.

CAUTION

result in severe engine damage. Add oil prior to starting

the engine.

CRANKCASE OIL RECOMMENDATIONS

Use premium quality motor oil with the API (American

Petroleum Institute) designation SG on the container. Figure

1 shows the recommended oil weight for the temperature

range that the engine will be operated in. Make sure the

engine oil weight is correct for the expected temperature

range.

Starting the engine without oil will

!

Single-grade oil is preferable when temperatures are

consistently -over 30°F (0°C). Multigrade oils are best when

wide temperature variations are anticipated.

WARNING

!

oil, that can cause severe personal injury. Do not check

the oil level while the engine is running.

!

CAUTION

consumption, high operating temperatures, and oil

foaming. Do not overfill the crankcase.

Crankcase pressure can blow out hot

Excess oil can cause high oil

TABLE 1 FIGURE 1

5

Page 9

PROPANE BURNISHER SET-UP

CHECK OIL

Refer to engine manual for the type of oil, and instructions for

checking oil. It is important to note engine manufacturers differ

in the way oil is checked. Add oil if needed. Refer to Page 10.

HANDLE ADJUSTMENT

Adjust handle by loosening nuts and bolts on each side of

handle. Push handle handle in or pull out to desired position

and reinstall nuts.

PROPANE TANK INSTALLATION

Buffer is supplied with 20 lb., 5 gallon capacity D.O.T. and U.L.

listed tank. DO NOT OVERFILL. Overfilling will cause regulator

to freeze. This could cause damage to your equipment. Hold

tank in place by clamping the toggle assembly to the tank

band around the tank. Adjustments to the toggle assembly are

made by screwing toggle in or out on the toggle clamp. Connect

fuel hose to the tank valve by turning coupling to the right

(clockwise). Hand tighten only, making sure not to cross thread

the coupling.

REMOVING TANK

To loosen turn coupling to the left (counter clockwise). Undo

the tank strap, remove tank and store in approved area. Do not

store tank with machine in the janitor’s closet.

INSTALLATION/CHANGING PAD

1. With engine off, turn the machine over on the operator’s

RIGHT side (starter side) for the Briggs & Stratton models.

This can be easily done by pushing down on the right side

of the handle with some force while the machine is tilted

back.

2. Remove the center cup retainer and carefully pull old pad

off the pad driver assembly.

3. Inspect the pad holder for cracks or damage. Replace if

necessary. NOTE: A DAMAGED PAD HOLDER ROTATING

AT HIGH SPEEDS MAY BE AN EXTREME HAZARD IF IT

SHOULD COME APART.

4. Pull center from new pad, enter pad on pad holder and

secure with center cup retainer.

5. Press pad on to the pad driver assembly making sure

pad fits inside the lip of the pad driver assembly, to prevent

pad from elongating, attach center cup retainer.

6. Return machine to the upright position.

TRANSPORTATION

When transporting a propane powered floor machine with the

fuel cylinder attached, the cylinder should be securely fastened

with service valve closed and coupling not attached. The

machine should be secured to the vehicle to avoid movement.

Tanks separate from the machine should be secured to avoid

movement. NEVER STORE MACHINES WITH TANKS IN AN

ENCLOSED VAN OR TRAILER. ALWAYS CHECK TANKS FOR

OVERFILL BEFORE TRANSPORTATION.

STARTING AND OPERATION PROCEDURE

CAUTION: NEVER ALLOW MACHINE TO RUN FOR MORE THAN

10 SECONDS IN ONE SPOT OR DAMAGE WILL OCCUR TO

THE FLOOR!

1. Check oil and fuel levels. Make sure oil and propane tank

is not overfilled.

2. Check and clean recoil dust filter and carburetor filter.

Make sure air filter is free of dust and debris. Never run

buffer for more than 1 hour without cleaning air filter.

Change filters when necessary.

3. Check pad and pad assembly, to make sure pad is

centered and clean, and look for any problems with pad

driver. To do this turn machine over on its right side.

4. Check belt tension, again turn machine over on its right

side and squeeze belt together. Belt should depress

between 1/4 and 1/2 inch. To change see maintenance

instructions. (Page 13)

5. Open propane service valve, turn counter-clockwise to

open.

6. Tilt machine backward with pad off the floor, move bail to

IDLE position. Never start machine with pad on the floor.

7. With 115V starting system, plug in adapter to wall outlet

and the starter box. Turn key to the on position and push

button on start box. If machine fails to start allow

approximately 30 seconds between tries, never engage

starter more than 10 seconds at a time.

a. Never start buffer with pad on the floor, this will

cause the starter to burn out prematurely!

b. Never use starting fluids or any other forms of

flammable substance to assist the engine in

starting!

8. Allow engine to warm up and run at normal operating

speed before engaging pad with floor. Make sure pad is

off the floor before engaging the clutch. Once machine is

at normal operating speed and clutch is engaged, start

walking and slowly lower the machine to the floor and

begin burnishing the floor.

9. Machines with mechanical clutches: NOTE: Never engage

clutch with pad on floor. Once machine has reached

normal operating speed clutch is engaged automatically

at 2400 engine RPM and start burnishing. Start burnishing

when pad has reached top speed.

10. Always burnish on the right hand, so exhaust fumes are

blown to the inside of the aisle. Be careful exhaust fumes

and muffler are extremely hot and will damage

merchandise. NOTE: Do not expose skin to muffler or

manifold - extreme heat, will burn.

11. For normal stops of the machine, turn propane service

valve clockwise, to starve the engine of its fuel. Do not

stop machine by using the bail or ignition key, you can trap

fuel in the lines, which can cause a backfire and cause

damage to the engine. NOTE: In case of emergency

always turn ignition key off. NOTE: Machines without

clutch, the pad starts to rotate immediately when engine

starts. Pad stops rotating when engine is off! No clutch!

6

Page 10

OPERATION INFORMATION

ENGINE BREAK-IN

Engine break-in as a result of proper care during the first

hours of operation of a new or rebuilt engine results in the

ideal fitting of all internal moving metal parts, which is

essential for top engine performance. For controlled engine

break-in.

1. Operate the equipment as it is intended to be operated.

However, for the first 3 hours, if possible, operate the

equipment at about half the available engine power,

occasionally operating at full engine power for brief

periods. Also, if possible, avoid prolonged low-speed,

low-power operation during engine break-in.

2. Proper engine oil is especially critical during break-in

because of the higher engine temperatures that can be

expected. See RECOMMENDED ENGINE OIL.

Change the oil if it is not appropriate for the ambient

temperatures during the break-in periods. See Table 1,

Figure 1 Page 6.

3. Check the oil level twice a day or after every 4 hours of

operation during the first 24 hours of operation.

4. Change the oil and oil filter after the first 5 hours of

operation.

OPERATION IN DUSTY CONDITIONS

1. Keep the engine cooling fins and flywheel air inlet screen

and precleaner (filter) clean.

2. Perform air cleaner maintenance more often than

normal - as required.

3. Change the engine oil more often than normal. See

Table 2, Page 10.

OPERATION IN HOT WEATHER

Pay particular attention to the following items when

operating the engine in temperatures above 100°F (38°C):

1. Keep the engine cooling fins and flywheel air inlet screen

and precleaner (filter) clean: See to it that nothing

obstructs air flow to and from the engine.

2. Check the oil level more frequently.

3. Change the oil more often than normal. See Table 2,

Page 10.

4. Make sure the engine oil viscosity is appropriate for

the ambient temperature and change the oil if

necessary. See Table 1, Figure 1 page 6.

OPERATION IN COLD WEATHER

Pay particular attention to the following items when

operating the engine in temperatures below freezing.

After engine has reached operating temperature while pad

is still off the floor. Before lowering burnishing head, adjust

throttle to operating speed. After slowly lowering machine

to floor, place hands lightly on the handle and allow the

machine to create the floor pressure. Bearing down and

pushing hard will lead to premature belt problems and

operator fatigue. For smoother turns and greater

maneuverability, buff aisles from the right side first.

CAUTION: DO NOT RUN MACHINE FOR MORE THAN 15

SECONDS IN ONE SPOT OR BURNING WILL OCCUR.

IDLING AND STOPPING THE MACHINE

If for any reason the machine needs to be idled for short

periods, simply tilt machine back on its rear caster and

release throttle bail into Idle Position. Machine will now idle

safely. (CAUTION: DO NOT IDLE BUFFER ON REAR

CASTER FOR MORE THAN TWO MINUTES. This will

raise the emissions level.)

To stop machine tilt back on rear caster, turn valve on

propane tank off, and allow fuel in the lines to be used up.

FOR EMERGENCY SHUT OFF ONLY: turn off ignition

switch. Electric start models: use emergency stop switch

on right side of control panel.

STORAGE

Only authorized and properly trained personnel should have

access to propane tanks and machine.

Making sure tank valve is closed, remove tank from buffer.

Local Fire Codes may require storing tank in separate

location. We recommend this, as well as following

Local Fire Codes.

Store machine and tank away from objects that may fall

and damage them.

Never store tank or buffer near open flame or heat producing

devices.

Make sure machine is cleaned properly prior to storage.

To prevent damage pad holder, the pad SHOULD remain on

machine during storage.

EMERGENCY STOP

Turn ignition key to OFF position.

Units with emission control device and clutch. Release bail

on handle to activate kill switch.

Make sure the engine oil viscosity is appropriate for the

ambient temperatures and change the oil if necessary. See

Table 1. If the temperature drops before you have the chance

to change the oil, warm up the engine by moving the

equipment into a heated space before attempting to start

the engine or change oil.

7

Page 11

MAINTENANCE SCHEDULE

PERIODIC MAINTENANCE SCHEDULE

Following the maintenance schedule and using the engine

properly will result in longer engine life, better performance

and safer operation. Perform each maintenance procedure

after the number of operating hours indicated. These service

intervals are recommended for normal operating conditions.

For operation in hot or dusty conditions, service the engine

more frequently. Neglecting routine maintenance can result

in premature engine failure.

TABLE 2. PERIODIC MAINTENANCE SCHEDULE

SERVICE THESE ITEMS 1 8 25 50 100 200

For any abnormalities in operation, unusual noises from

the engine or accessories, loss of power, overheating, etc.,

contact your nearest Engine Service Center.

Refer to the following Maintenance Procedures section for

routine maintenance procedures.

AFTER EACH CYCLE OF INDICATED HOURS

Recoil Dust Filter

Inspect Engine Generally

Check Oil Level

Service Air Cleaner Element and Element Wrapper

Change Crankcase Oil

Replace Oil Filter (Onan, Kawaski Models)

Clean Cooling Fins

Clean Spark Arrester

Check Valve Clearance

Replace Air Cleaner Element

Check or Replace Spark Plug

1 - Check for fuel leaks. With engine running, visually and audibly check exhaust system for leaks.

2 - Perform more often when running under severe operating conditions.

3 - Required for initial break-in only.

4 - Required for initial 100 hours, 200 hour interval thereafter. For detailed maintenance, refer to the Engine Service Manual.

X

X

X

X

X

1

2

X

3

3

X

X

X

2

X

4

X

X

X

X

2

WARNING

!

exhaust elbow, or connecting parts as a supporting step. Damage to these and connecting parts can cause an

exhaust leak.

Breathing exhaust gases can result in severe personal injury or death. Do not use air cleaner,

8

Page 12

MAINTENANCE PROCEDURES

WARNING

!

result in severe personal injury or death. Disconnect

the 110 VAC power cord from the starter switch junction

box or disconnect the negative (-) battery cable on 12

VDC starter models. Also disconnect the spark plug

wire while servicing the engine, controls, or associated

equipment.

HOURLY CHECK

Due to the large amount of dust that can be encountered in

floor care applications, the recoil dust filter should be

checked after each hour of operation. Remove and clean

the filter.

DAILY CHECKS

The operator should make a complete visual and audible

inspection of the engine daily. Check the following before

starting the engine for the first time each day.

1. Check all fuel lines and fitting for possible leakage.

2. Check crankcase oil level with the engine off. If engine

has been run, allow a minimum of 10 minutes for the

oil to drain down before checking. Check oil level with

machine in operating position. Do not operate engine

with the oil level below the ADD mark or above the FULL

mark.

3. Inspect exhaust system for possible leakage and

cracks. Locate leaks in muffler and piping while the

engine is operating. Repair leaks immediately.

4. Inspect air cleaner system for leaks. Make certain all

clamps and fittings are tight and free of potential leaks.

5. Check the engine cooling system to make sure the

cooling fins and ducting area are clean. Remove dust,

dirt or oil from the cooling surfaces.

DAILY (8 HOUR) MAINTENANCE

The operator should check the following before the first

start of the day and after every eight hours of operation:

1. Inspect fuel lines and fittings for leaks. Repair leaks

immediately.

2. Look and listen for exhaust system leaks while the

engine is running. Look for cracks and severe rusting

in the muffler and tailpipe. Have all leaks repaired before

continuing to operate the equipment.

CAUTION

!

burns. Allow the engine time to cool before

servicing the exhaust system.

3. Check the engine for dirt and debris and clean the

flywheel air inlet screen and cylinder cooling fins as

necessary. On floorcare equipment engines, remove

the cooling air precleaner element every 4 to 8 hours of

operation and wash it in warm water and mild detergent.

Rinse it thoroughly and let it dry before reusing it. Do

not oil the element.

CAUTION

!

or screen or dirty cooling fins can cause overheating

and engine damage. Keep the cooling fins and air inlet

screen clean.

Accidental starting of the engine can

Hot exhaust parts can cause severe

A clogged flywheel air inlet precleaner

4. Check the engine oil level. The equipment must be

parked on a level surface and the engine stopped. To

get an accurate reading, wait a minute or so to allow

the oil to settle in the crankcase if the engine has been

running.

ENGINE MAINTENANCE

1. Cooling Fin Maintenance: Remove the blower housing

and other cooling shrouds. Clean the cooling fins as

necessary using compressed air or pressure washer.

Reinstall all housings and shrouds.

2. Head Bolt Maintenance: Refer to Engine Manufacturer’s

Service manual.

BELT MAINTENANCE

NOTE: To inspect the belt it is necessary to turn the machine

over. The machine should be turned to the operator’s right

side for all Briggs & Stratton models. If the belt is badly

cracked or worn, it should be replaced. To check for the

proper tightness, squeeze the belt together. The belt should

depress between 1/4 and 1/2 inch. To change belt follow

these instructions:

• Turn burnisher over on the right side.

• Remove the pad holder by holdng the end of the

shaft on the top of the machine with a 3/4 inch

wrench and turn the pad holder counter-clockwise.

• Using the 3/4 inch wrench to turn the end of the

spindle shaft on the top of the machine while

removing the old belt from the spindle pulley.

• Check engine pulley for correct alignment with the

spindle pulley. Check hardware attaching pulleys

for correct tightness.

• Install the new belt onto the engine pulley.

• Reinstall the new belt onto the spindle pulley using

the 3/4 inch wrench to turn the spindle clockwise.

Make sure the belt is correctly placed on the idler

pulley.

• Check belt for correct operation.

• Check all hardware for correct tightness.

FUEL SYSTEM

The fuel system works from vacuum created by the engine

running. Turning the cylinder service valve on pressurizes

the system for flow to the carburetor once the engine starts

to crank.

1. Engine Dust Filter: FAILURE TO MAINTAIN A CLEAN

ENGINE FILTER MAY CAUSE THE EXHAUST

EMISSIONS TO ELEVATE TO DANGEROUS LEVELS.

ALSO, IT WILL CAUSE THE ENGINE TO OVERHEAT,

AND EVENTUALLY DAMAGE THE ENGINE. The

engine dust filter should be cleaned each hour and

after each use by shaking out the dust and then rinsing

with soapy water. Allow filter to air dry, do not wring

out water, this could damage the filter, (squeeze out).

2. Fuel System Adjustment:The carburetor and regulator

have been pre-set at the factory and do not require any

modification. Only authorized, trained personnel should

work on the fuel system of a propane buffer.

9

Page 13

MAINTENANCE PROCEDURES

NOTE: N.F.P.A. rule 58 8-1.4 states, “In the interest of

safety, each person engaged in installing, repairing,

filling, or otherwise servicing an LP-Gas engine fuel

system shall be properly trained in the necessary

procedures”.

3. Hose and Fuel Connections: Inspection: Check for gas

leaks by using a soapy water solution around all

connections with service valve turned on so the fuel

system is pressurized. Inspect all hoses for abrasions

and other signs of wear. Replace all damaged and worn

hoses. Fixing Leaking Joints: Uncouple bad joint, clean

joint and apply pipe sealing compound (use a Loctite

Pipe Sealant with Teflon or equivalent) to clean joint.

Re-couple the joint, tighten plus 1/2 turn. Recheck for

leaks.

4. Carburetor Air Filter: NOTE: Failure to service and clean

carburetor air cleaner may produce excessive carbon

monoxide emissions.

• Remove cover from the air cleaner.

• Remove foam pre-cleaner and use the same

procedure for cleaning the foam pre-cleaner.

• Rinse in mild detergent and squeeze out excess

water, do not wring out.

• Clean filter seal, making sure no dust is allowed

in the carburetor inlet.

• Inspect paper element. Replace if dirty, bent or

damaged.

• Install the clean paper element, pre-cleaner, and

attached air cleaner cover.

If the oil level is low, add API Class SG or SH oil (also SG/

CD, SG/CE, SH/CD or SH/CE) having an SAE viscosity

grade appropriate for the expected temperatures, as

indicated by Table 1.

DO NOT FILL TO A LEVEL ABOVE THE FULL MARK ON

THE DIPSTICK. Drain the excess oil if too much has been

added.

CAUTION

!

consumption, high operating temperatures and oil

foaming. Too little oil can cause severe engine damage.

Keep the oil level between the Full and Add marks on

the dipstick.

Reinstall the dipstick and cap after checking or adding oil,

turning it clockwise until it is secure.

Too much oil can cause high oil

OIL CHANGE

WARNING

!

contacts the skin. Wear protective clothing and keep

fingers and hands clear when draining oil.

Used oil is harmful to the environment. Pour used oil into a

sealed container and deliver it to the nearest recycling

center or automotive service station.

CHANGING THE OIL

1. Run engine for 5 minutes to warm oil, then stop engine

by closing the service valve on the tank. Turn the key

to the off position.

2. Locate the oil drain located the right side of the engine

at its base. Remove the cap on the oil drain tube by

turning counter clockwise with a wrench.

3. Allow oil to drain completely into the receptacle.

4. Replace the cap by turning clockwise.

5. Remove oil fill cap. Always refer to the Engine Manual

for recommended oil and amount.

6. Check oil level with dip stick in oil fill cap. Add additional

oil if necessary. NOTE: TO CHECK OIL ON THE

BRIGGS & STRATTON MODELS, SCREW THE CAP

IN AND OUT AGAIN. ALWAYS MAKE SURE THE

MACHINE IS SITTING LEVEL WHEN CHECKING OIL.

7. Replace fill cap. Hand tighten only.

Hot crankcase oil can cause burns if it

OIL FILL CAP AND DIPSTICK

10

Page 14

TROUBLESHOOTING

Table 3 provides basic troubleshooting guidance. If you fail to

resolve the problem after taking the corrective actions

suggested, contact the equipment or engine dealer.

WARNING

!

hazards that can result in severe personal injury or death.

Only qualified service personnel with knowledge of fuels,

electricity, and machinery hazards should perform service

procedures. Review Safety Precautions.

Many troubleshooting procedures present

WARNING

!

Always allow the engine time to cool before performing any

maintenance or service.

Hot engine parts can cause severe burns.

TABLE 3. TROUBLESHOOTING

Problem Corrective Action

1. The engine fails to crank a. Not pluged into outlet.

2. The engine cranks slowly. a. Change engine oil having the proper viscosity for ambient temperature.

See table 1.

b. Check oil level for overfilling.

c. Check starter electrical connections.

3. The engine cranks but fails a. Check the fuel tank or LPG container and fill as necessary.

to start. b. Check, and if necessary, reconnect the fuel line to the vapor-withdrawal

fitting on the LPG container.

c. Open any closed fuel shut-off valve (check keg in on position).

d. Check engine oil level and add oil as necessary.

e. Service the air cleaner.

f. Clean the air precleaner (floorcare engines).

g. Replace the spark plugs.

4. The engine runs and a. Check the fuel tank or LPG container and fill as necessary. On cold days

then stops. the LPG container may have to be kept at least half full to provide the rate

of vaporization necessary to keep up with the engine fuel demand.

b. Check, and if necessary, reconnect the fuel line to the vapor-withdrawal

fitting on the LPG container.

c. Check the engine oil level and add oil as necessary. Drain excess oil if the

level is above the dipstick FULL mark.

5. The engine exhausts a. Service the air cleaner.

black smoke.

6. The engine misfires. a. Replace the spark plugs.

11

Page 15

TROUBLE SHOOTING

ENGINE WILL NOT START

CAUSES:

No fuel, blown head gasket, bad ignition coil, dirty air

cleaner, wires broken or disonnected, engine overload,

insufficient vacuum, bag spark plug, fuel system out of

adjustment.

SOLUTION:

Refer to engine manual for servicing and instruction.

HARD TO START

CAUSES:

Kinked fuel line, dirty air filter, bad spark plug, blown head

gasket, low oil, engine overload, carburetor needs

adjustment, regulator needs adjustment, insufficient

vacuum, improper timing, coil or valves need adjusting.

SOLUTION: Refer to engine manual for servicing and

instruction.

ENGINE LACKS POWER

EXCESS VIBRATION

CAUSE:

Engine overload, loose bolts on engine or deck of unit, low

fuel level, dirty air filters, faulty spark plug, pad not centered.

SOLUTION:

Refer to engine manual for servicing and instruction.

MACHINE PULLS TO ONE SIDE

CAUSE:

Bent wheel bracket, wheel is wearing too much on one

side.

SOLUTION:

Check for bent bracket or worn wheel.

MACHINE “BOGS DOWN” WHEN IN USE

CAUSE:

Too much pressure or operator is bearing down too hard.

Dirty air filters.

CAUSES:

Head gasket leaks, governor improperly adjusted, check

air filter, insufficient vacuum, bad spark plug, no

compression worn rings, improper valve clearance, kinked

fuel line, improper oil level.

SOLUTION:

Refer to engine manual for servicing and instruction.

SMELL OF BURNED RUBBER

CAUSE:

Belt out of adjustment.

SOLUTION:

Refer to Maintenance Procedures.

SOLUTION:

Follow proper operating instructions, let machine operate

on its own weight, do not apply upward pressure to handle

of machine.

ENGINE STOPS RUNNING

CAUSE:

Out of fuel, faulty spark plug, low oil, dirty air filters, high

exhaust emissions.

SOLUTIONS:

Refer to engine manual for servicing and instruction.

HIGH FUEL CONSUMPTION

CAUSE:

Dirty air filters, dirty air cleaners.

SOLUTION:

Keep engine and air filters clean.

12

Page 16

ENGINE 13HP HONDA

13

Page 17

PARTS LIST for 13HP HONDA

Item Part No. Qty. Description

1 360108 1 Handle Sleeve

2 712638 2 Nut-Hex 10-24 Nyloc

3 711503 4 WSR-Flat #10

4 515-10-24 2 SCR-RD HD 10-24 x 1 1/2

5 220131 1 Buckle TB2-61

6 715343 1 Decal, Propane Warning

7 220118 1 Propane Tank Steel

8 220393 1 Battery Cover Weldment

9 711505 4 WSR-Flat 1/4

10 220056 2 Felt 2 x 10

11 711373 8 Nut-Nyloc 1/4-20

12 220385 1 Engine 13 HP Prop Honda

13 711515 4 WSR-Flat .406 x .812 x .06

14 711439 4 Nut-Wizz 3/8-16

15 711506 6 WSR-Flat 5/16

16 713031 2 BLT-HH 5/16-18 x 2.00

17 220482 1 Starter Assy, 115V Tecumseh

18 220021PTD 1 Casting

19 711544 4 WSR-Helical 1/4

20 711203 4 BLT-HH 1/4-20 x .62

21 713043 4 BLT-HH 3/8-16 x 1 1/4 #5

22 831306 1 90

23 220221 1 Electric Lockoff Assy

24 350280 1 Hose Barb 1/8 x 1/8 NPT

25 220246 1 Elbow-90 1/8mpt x 1/8fpt

26 220483 1 Regulator Beam T60-E

27 220237 1 Regulator Bracket

28 220245 1 Elbow-45 3/8mpt x 3/8fpt

29 342430 1 Hose Barb

30 450076 2 Crimp Clamp

31 220269 1 Fuel Hose - 3/8 ID x 30”

32 220192 1 Tank Frame Weldment

33 220070-1 1 High Pressure Hose

34 220065 1 45° Male Elbow 1/4 x 3/8

35 62-252-A 1 Connector - Female

36 715501 1 Decal - Made in USA

37 715245 1 Decal - Ignition Switch

38 740539 1 Hour Meter

39 715192 1 Decal - Dashboard

40 715242 1 Decal - Propane Warning

41 741056-1 2 Key-Ignition, Replacement

42 741056 1 Keyswitch w/Ground

43 829052 2 Nylon Bushing

44 711721 2 Retaining Ring

45 220112 1 Torsion Spring

46 55-161-A 2 WSR-Special

47 220343 1 Handle

48 711374 2 Nut-Nyloc 5/16

49 220338 1 Handle Bracket LH

50 220339 1 Handle Bracket RH

51 711207 4 BLT-HH 1/4-20 x 1.00

52 713036 2 BLT-HH 5/16-24 x 1.25 BZ

53 711380 4 Nut-Nyloc 3/8-16

54 711213 4 BLT-HH 1/4-20 x 1.62

55 712538 2 SCR-MC 10-24 x 1.75 SS

56 255045 1 Spacer, .19 x .37 x .47

57 220328-1 1 Cable, Lined

58 711301 2 Nut-Hex 6-32

59 711551 2 WSR-Internal LOC #6

60 220270 1 Bail, Throttle LH Cable

61 711225 4 BLT-HH MM6 x 1.0 x 20mm

62 711388 2 Nut-Hex 6mm

63 711504 2 WSR-Flat 1/4 SS

64 713042 4 BLT-HH 3/8-16 x 1.00 #5

65 711439 4 Nut-Flanged Wizz 3/8-16

66 715432 1 Decal, GFCI Warning

o

Elbow Street 1/4-1/4

14

Page 18

ENGINE 13HP HONDA

15

Page 19

PARTS LIST for 13HP HONDA

Item Part No. Qty. Description

1 711545 6 WSR-Helical 5/16

2 711354 1 Nut-Acorn 3/8-16

3 711546 1 WSR-Helical 3/8

4 430029 1 Caster

5 711506 6 WSR-Flat 5/16

6 713165 4 SCR-FH SC 5/16-18 x 1.00

7 220330 2 Wheel Bracket Weldment

8 220049 2 Bushing .381 x .5 x 1.75

9 220340 2 Wheel 6”

10 713049 2 BLT-HH 3/8-16 x 2.75

11 220198 1 Spacer

12 72-179-A 1 Spacer

13 833621 1 Key 1/4 x 1/4 x 1.00

14 220197 1 Pully-4.6 OD

15 82-138-B-3 1 Special Washer

16 350242 1 Belleville Washer 7/16

17 60-716-24 1 BLT-HH 7/16-20 x 1.5

18 712112 1 BLT-HH 1/2-13 x 2.75

19 220040 1 Rotary Tensioner

20 77-81-A 1 Spacer

21 220041 1 Belt Idler w/Bushing

22 364-816 1 Nut-Nyloc 1/2-13

23 220010 1 Belt Tensioner Assy.

24 220097 1 V Belt BX44T (M220021K17,K17C)

25 220019 6 Gimbal Spacer Disc

26 760401 1 Center Cup

27 760402 1 Center Cup Retainer

28 220005 1 Metal Spinning (M220021K17,K17C)

29 220020 12 BLT-Special Elevator

30 220018 1 Gimbal Disc

31 220022 1 Adapter

32 220045 1 Split Tapered Bushing

33 220044 1 Pulley

34 711719 2 Retaining Ring, Ext. 1.00

35 220003 1 Key, Woodruff 5/16 x 1

36 220002 1 Shaft, Pad Driver

37 762093 2 Bearing

38 220023MCH 1 Bearing Housing

39 220016 1 Skirt (M220021K17,K17C)

40 220119 1 Skirt Retainer (M220021K17,K17C)

41 828894 12 Pop Rivet

42 715385 1 Decal - Minuteman

43 220021PTD 1 Casting

44 55-161-A 2 WSR-Special

45 711374 12 Nut-Nyloc 5/16

46 711380 2 Nut-Nyloc 3/8-16

16

Page 20

WIRING DIAGRAM 13HP HONDA

17

Page 21

MODEL 50 DRY-GAS REGULATOR, CROSS SECTION, PARTS LIST

Item Part No. Qty. Description

** 60-RBK Kit, Rebuilding

** 60-RCK Kit, Complete

** 60-RK Kit, Repair

1 P3-13 1 Plug, 1/8” Pipe, Hex 1 1

2 50-1 1 Casting, Reg. Body

3 2G-150 1 Gasket with 60-10A

4 60-10A 1 Diaphragm, Primary 1 1 1

5 60-7 1 Cover, Primary

6 60-8 1 Spring, Primary 1 1

7 60-31 1 Retainer Spring

8 60-32A 1 Cap, Retainer

9 60-4 1 Spring, Primary 1 1

10 60-2B 1 Lever, Primary 1 1 1

11 103205-F 2 Screw, Machine 2 2

12 60-5 1 Bridge Primary

13 60-3 1 Pin, Pivot 1 1

14 103210-FS 10 Screw with Lockwasher10 10 4

15 60-29A 1 Orifice, Primary 1

16 60-15A 1 Diaphragm, Vac Lock 1 1 1

17 60-14 1 Spring, Vac Lock 1 1

18 60-22A 1 Diaphragm, Secondary 1 1 1

19 60-23 1 Cover, Secondary

20 103206-P 4 Screw, Machine 4 4

21 60-16 1 Ring, Vac Lock

22 60-17 1 Spring, Machine 1 1

23 60-18 1 Pin, Pivot 1 1

24 60-19B 1 Lever, Secondary 1 1 1

25 60-28 1 Orifice, Secondary 1

26 400-21 1 Spring, Idle 1 1

27 PS-20A 1 Screw, Idle 1 1

NS 103204-P 2 Screw, Machine 2 2

REGULATOR OPERATION

LP-gas vapor enters at point (A), then passes into primary area

(B) at point (28), where pressure is reduced from up to 250 p.s.i.

at the tank to 4 p.s.i. in area (B). Fuel pressure against diaphragm

(4) overcomes spring (6) and as movement increases, spring (9)

will close lever (10). The primary diaphragm breather (not shown

in drawing), is vented to secondary chamber so that rupture of

this diaphragm would direct fuel into the carburetor.

Fuel now moves through passage (E), past secondary valve (29)

into secondary area (C). As negative pressure (vacuum) is created

at carburetor venturi and is transmitted through dry-gas hose to

chamber (C) atmospheric pressure, exerted through vent hole

(G), forces down secondary diaphragm (18), secondary lever

(24) and spring (22). Fuel will flow in proportion to air velocity

through carburetor venturi, insuring an ideal mixture at all engine

speeds.

Whenever engine is operating, vacuum diaphragm (16) is down

against floor (H) and spring (17) is collapsed. The idle and starting

adjustment is made with tapered screw (27) which regulates the

whisker wire system (not shown), opening up secondary orifice

slightly (but only when vacuum diaphragm is drawn down). Very

little vacuum is needed to start this vacuum diaphragm travel; 0.2”

Mercury to start and 0.5” Mercury for full travel. The instant engine

stops rotating, loss of vacuum in section (D) releases diaphragm

(16), causing bumper (K) to push against secondary lever (24),

overcoming action of whisker wire and insuring 100% lockoff.

This patented Beam design will lock off primary pressures up to

five times in excess of normal, permits starting without priming or

choking.

Order by Part No. NOT by Reference No

18

Page 22

WARRANTY INFORMATION

CARB SMALL ENGINE CERTIFICATION

MANUFACTURER: HONDA

INTERNATIONAL INC

ENGINE FAMILY:

WMNTS.4372K1

XMTRS.2492K3

XMTRS.4942K2

CALIFORNIA EMISSION CONTROL

SYSTEM WARRANTY STATEMENT

The California Air Resources Board and

Minuteman International, Inc. are pleased

to explain the emission control system

warranty on your 1998 and later utility

engine. In California, new utility and lawn

and garden equipment engines must be

designed, built and equipped to meet the

State’s stringent anti-smog standards.

Minuteman International, Inc. must

warrant the emission control system the

your utility equipment engine for the

periods of time listed below provided

there has been no abuse, neglect or

improper maintenance for your utility

equipment engine.

Your emission control system may

include parts such as the carburetor or

fuel injection system, the ignition system

and catalytic converter. Also included may

be hoses, belts, connectors and other

mission-related assemblies.

Where a warrantable condition exists,

Minuteman International, Inc. will repair

your utility equipment engine at no cost

to you including diagnosis, parts and

labor.

MANUFACTURER’S WARRANTY

COVERAGE

The 1998 and later utility and lawn and

garden equipment engines are

warranted for two years. If any emissionrelated part on your engine is defective,

the part will be repaired or replaced by

Minuteman International, Inc.

OWNER’S WARRANTY

RESPONSIBILITIES

As the utility and lawn and garden

equipment, you are responsible

for the performance the required

maintenance listed in your owner’s

manual. Minuteman International, Inc.

recommends that you retain all receipts

covering maintenance on your utility

equipment, but Minuteman International,

Inc. cannot deny warranty solely for

the lack of receipts or for your failure

to ensure the performance of all

scheduled maintenance. As the utility

equipment engine owner you should,

however, be aware that Minuteman

International, Inc. may deny you warranty

coverage if you utility equipment engine

or a part has failed due to abuse,

neglect, improper maintenance or

unapproved modifications.

You are responsible for presenting your

utility equipment to a Minuteman

International, Inc. distribution center as

soon as the problem exists. The warranty

repairs should be completed in a

reasonable amount of time, not to exceed

30 days.

If you have any questions regarding your

warranty rights and responsibilities, you

should contact Minuteman International,

Inc. at 1-800-323-9420. Minuteman

International, Inc. 111 South Rohlwing

Road, Addison, IL 60101.

MANUFACTURER’S EXPLANATION OF

WARRANTY COVERAGE

The engine manufacturer warrants to the

original owner and each subsequent

purchaser that each subsequent

purchaser that each new engine will be

free from manufacturing defects in

materials or workmanship under normal

use during a period of two (2) years from

the date of delivery, provided it is operated

and maintained in accordance with

engine owner manual operating

instructions.

Repair or replacement of any warranted

part will be performed at no cost to the

owner at a warranty station. For the

Minuteman International, Inc. repair

station nearest you call 1-800-323-9420.

CARB SMALL ENGINE CERTIFICATION

MANUFACTURER: HONDA

INTERNATIONAL, INC.

ENGINE FAMILY:

WMNTS.4372K1

XMTRS.2492K3

XMTRS.4942K2

Any warranted part which is not

scheduled for replacement as required

maintenance, or which is scheduled only

for regular inspection to the effect of

“repair or replace as necessary” is

warranted for the warranty period. Any

warranted part which is scheduled for

replacement as required maintenance is

warranted for the period of time up to

the first scheduled replacement point for

that part.

The owner will not be charged for

diagnostic labor which leads to the

determination that a warranted part is

defective; if the diagnostic service is

performed at a warranty station.

Minuteman International, Inc. is liable for

damages to other engine components

caused by failure of a warranted part still

under warranty. Minuteman International,

19

Inc. is not liable for failure of warranted

parts caused by the use of add-on

modified parts.

Warranty service or repairs are available

at all Minuteman International, Inc service

centers that are franchised to service this

engine.

Any Minuteman International, Inc.

approved replacement part may be

used in the performance of warranty

maintenance or repairs on emissionrelated parts and will be provided to the

owner without charge if the part is still

under warranty.

The owner is responsible for the

performance of the required

maintenance, as defined in the

Minuteman International, Inc. owner’s

manual for this engine.

SPECIFIC EMISSION-RELATED

WARRANTED PARTS

Fuel Metering System

Carburetor and internal parts

LPG Regulator

Air Induction System

Air intake manifold

Air filter element

Air filter element-prefilter

Ignition System

Spark plug

Magneto

Catalyst or Thermal Reactor System

Exhaust manifold

Muffler

Miscellaneous items used in above

systems

Fuel line and vacuum hoses, wire

harness, connectors & assemblies

To obtain warranty service, you must take

your equipment together with proof of

original retail purchase date, at your

expense to an authorized engine dealer

If upon a warranty inspection, a defect is

identified, such warranty repairs or

replacement will be made without charge

for parts or labor. All parts replaced under

warranty will be considered as part of the

original product and any warranty on

those parts will expire coincident with the

original product warranty.

Issue Date: 11/11/97

IHNXS.3892U meets US EPA SNRE P#2

2005 and CARB Tier II 2002 SORE

Regulations.

Page 23

LIMITED WARRANTY

Minuteman International, Inc. warrants to the original purchaser/user that this product is free from defects in workmanship and

materials under normal use and service for a period of two years for the engine and three years for machine components from

date of purchase. In addition, Minuteman International, Inc. will, at its option, honor labor warranty claims for the first 12 months

on machine components only from date of sale, provided such claims are submitted through and approved by factory authorized

repair stations. Minuteman International, Inc. will, at its option, repair or replace without charge, except for transportation costs,

parts that fail under normal use and service when operated and maintained in accordance with the applicable operation and

instruction manuals.

This warranty does not apply to normal wear, or to items whose life is dependent on their use and care, such as belts, cords,

switches, hoses, rubber parts, electrical motor components or adjustments. Parts not manufactured by Minuteman International,

Inc. such as engines, batteries, battery chargers, hydraulic pumps, and tires are covered by and subject to the warranties and/

or guarantees of their manufacturers. Please contact Minuteman International, Inc. for procedures in warranty claims against

these manufacturers.

Special warning to purchaser — Use of replacement filters and/or prefilters not manufactured by Minuteman International, Inc.

or its designated licensees, will void all warranties expressed or implied.

A potential health hazard exists without exact original equipment replacement.

All warranteed items become the sole property of Minuteman International, Inc. or its original manufacturer, whichever the case

may be.

Minuteman International, Inc. disclaims any implied warranty, including the warranty of merchantability and the warranty of

fitness for a particular purpose. Minuteman International, Inc. assumes no responsibility for any special, incidental or consequential

damages.

This limited warranty is applicable only in the U.S.A. and Canada, and is extended only to the original user/purchaser of this

product. Customers outside the U.S.A. and Canada should contact their local distributor for export warranty policies. Minuteman

International, Inc. is not responsible for costs or repairs performed by persons other than those specifically authorized by Minuteman

International, Inc. This warranty does not apply to damage from transportation, alterations by unauthorized persons, misuse or

abuse of the equipment, use of non-compatible chemicals, or damage to property, or loss of income due to malfunctions of the

product.

If a difficulty develops with this machine, you should contact the dealer from whom it was purchased.

This warranty gives you specific legal rights, and you may have other rights which vary from state to state. Some states do not

allow the exclusion or limitation of special, incidental or consequential damages, or limitations on how long an implied warranty

lasts, so the above exclusions and limitations may not apply to you.

World Headquarters Minuteman Canada, Inc.

Minuteman International, Inc. 2210 Drew Road

111 South Rohlwing Road Mississauga, Ontario

Addison, Illinois 60101 L5S 1B1

(630) 627-6900 (905) 673-3222

FAX (630) 627-1130 FAX (905) 673-5161

999189

Printed in U.S.A.

Loading...

Loading...