Page 1

SERVICE MANUAL

For E Series Scrubbers

Models: E24, E26, E28,

E30, E33, E33XL

,

E30ECO, E2830, E3030,

For:

Training

E3330 and H26

Troubleshooting

Adjustments

Rev 07/07/2014

Page 2

Contents

1 Warnings Page 6

2 General Information Page 7

3 Maintenance Intervals Page 8

3.1 Minuteman System Maintenance K (Customer) Page 9

3.2 Minuteman System Maintenance I (125 hours

of o

p

eration) Page 10

p)

g

3.3 Minuteman System Maintenance II (250 hours

of operation) Page 11

3.4 Minuteman System Maintenance S (500 hrs of

operation, at least yearly)

Page 12

4 Squeegee Cable and Recovery Tank Gasket Page 13

4.1 Squeegee Adjustment (First Version) Page 14

4.2 Squeegee Adjustment (new Style) Page 15

4.3 Squeegee Lift Cable, Micro Switch, Vacuum Motor

Page 16

4.4 Squeegee Wheel Adjustment Page 17

5 Brush Head (Disk Brushes) Connections Page 18

5.1 Brush Motor Information Page 19

2

Page 3

Contents

6 Brush Head Transport Position Page 21

6.1 Brush Switch Page 22

6.2 B

rush Pressure

Adj

ustment on the Disk Models

P

age

23

6.3 Brush Pressure (Disk Decks) Page 24

6.4 Cylindrical Brush Head Electrical Connections Page 25

6.5 Cylindrical Brush Head Adjustment Page 26

7 Drive and Wheels - General Data Page 27

7.1 Electric Brake Page 27

7.2 Transaxle Motor Page 28

7.3 Carbon Brushes

Page 29

7.4 Drive Potentiometer Page 30

8 Water Supply Page 31

8.1 Solenoid Page 31

8.2 Solution Filter

Page 31

8.3 Solution Tank Cleanout Page 32

8.4 Solution Flow Rates Page 33

8.5 Water Pump Page 34

9 The Last E

rror

P

age

35

10 Table of Error Codes and Information Page 36

3

Page 4

Contents

11 Battery Charger Page 38

11.1 Operating Instructions Page 40

11.2 Charger Error Codes Page 40

11.3 Charger Trouble Shooting

Page 44

11.4 Charger Maintenance Points Page 45

11.5 Programming The Charger Page 46

11.6 Replacing The Charger Harness Page 49

12 Batteri

es

P

age

50

12.1 Maintaining Wet Lead Acid Batteries Page 50

12.2 Load Testing Batteries Page 52

12.3 Hydrometer Testing Page 53

13 Fuse Locations Version 2 Page 56

13.1 Controller Version 3 Page 57

4

Page 5

Contents

14 Controller Connections Page 58

15 Trouble Shooting Controller Page 59

16 Contactor Harness Page 60

g

17 Contactor Wiring Page 61

18

Testing the Main Power Relay Page 63

19 Wiring Diagram Models with 19 Gallon Tanks Page 68

20 Wiring Diagram Models with 24 Gallon Tanks Page

7220 Wiring Diagram Models with 24 Gallon Tanks Page 73

20 Wiring Diagram Models with 30 Gallon Tanks Page 7

8

21 Notes Page 83

5

Page 6

1. Warnings

• Disconnect the A.C. Cord from the outlet and and D.C. Cord from the battery

pack before servicing the machine

.

Except for making voltage and current

measurements.

• Before replacing the main fuses, only loosen the nuts. Do not remove them

completely. Failure to do so could cause a short circuit.

• Place the new stripe fuse fully and evenly under the nuts and washers and

make sure not to twist the end tabs, they can easily be torn.

• After an

y

repair work is done, test the machine for proper operation.

yp , pp p

• When servicing the machine always observe the general safety and accident

prevention guidlines.

6

Page 7

2. General Information

•The display offers a service indication. Upon turning on the key switch, a four digit

number describing the software version (e.g. 1.0.0.2) appears for about 3 seconds,

foll

owed by another 4-digit code indicating the last error recorded, then followed by

the hour meter.

•If a failure occurs, the code appears in the control panel and an acoustic signal

sounds. The current error code appears as 4

-

digit alpha

-

numerical code with

flashing dots in the service display. Only if these criteria are met, the error is a

current one!

The error codes are listed in a tables in chapter 10.

•When raising the machine with a car

g

jack use the area of the frame in front of

the caster wheels on the left or the right.

7

Page 8

3. Maintenance Intervals

In a modular structure, the Minuteman System Maintenance determines the specific

technical proceedures to be preformed and sets the time interval between the two

maintenance cycles.

For each of the maintenance cycle, the replaceable parts are determined as well.

Further details described in the specific chapters.

•Minuteman System Maintenance K:

To b

e performed by the customer (in daily or weekly intervals) according to the maintenance

and care instructions as specified in the operating instructions.

The operator must be professionally instructed after delivery of the machine by selling

dealer .

•Minuteman System Maintenance I: (after every

125 h

ours of operation

)

To be preformed by an authorized Minuteman Service Center in accordance with the

machine-specific system maintenance.

•Minuteman System Maintenance II: (after every 250 hours of operation)

To b

e preformed by an authorized Minuteman Service Center in accordance w

ith th

e

machine-specific system maintenance.

•Minuteman System Maintenance S: (after every 500 hours of operation, safety check) To

be performed by an authorized Minuteman Service Center in accordance with the machinespec

ifi

c system maintenance.

8

Page 9

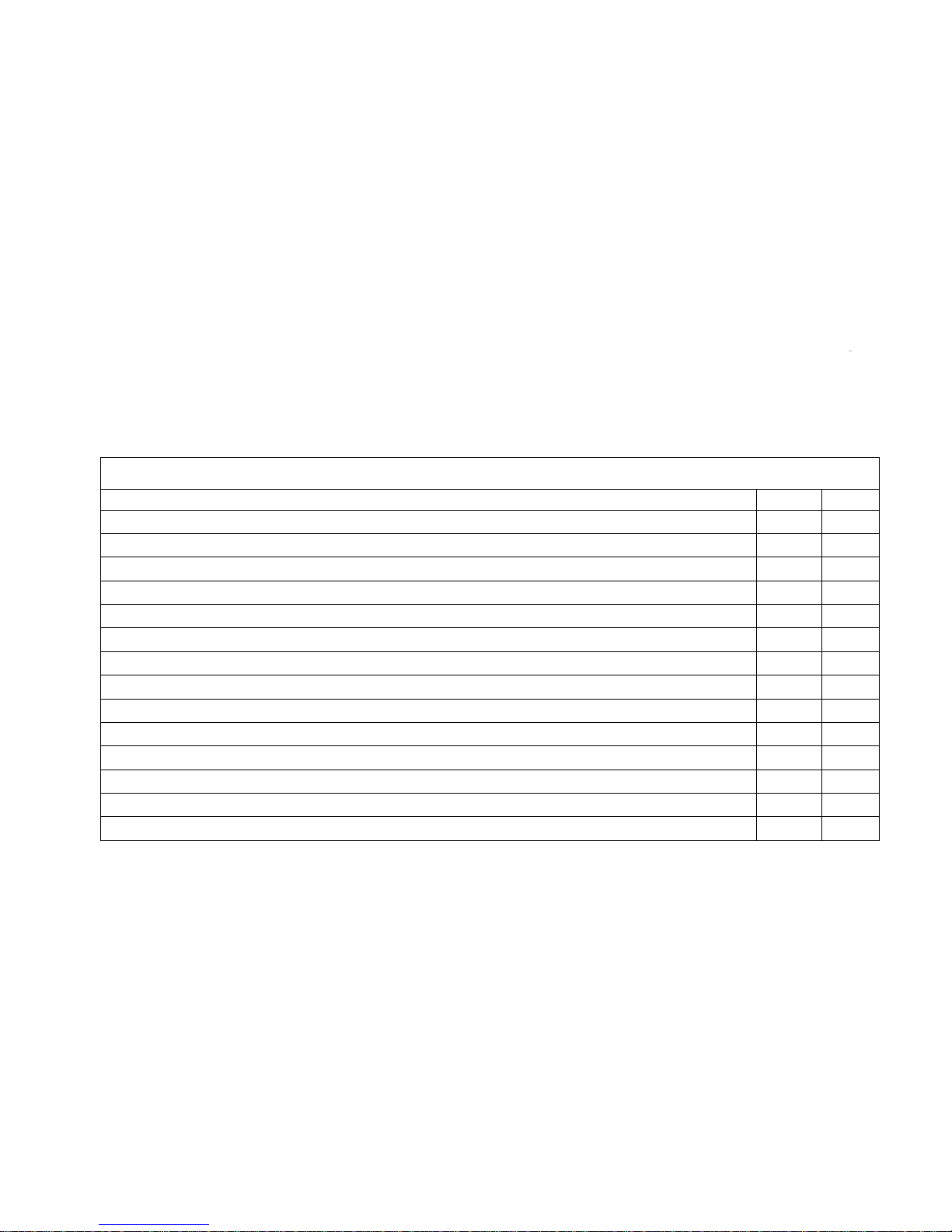

3.1 Minuteman System Maintenance K

Tobeperformedbythe

customer/user

Interval

Daily Weekly

Fillthecleanwatertankandmixtheproperamountandtypeofcleaningsolution. O

Chargethebatteries. O

Check

thebrushhead,Cleanifneededwithadampcloth.Donotgetwaterinsidethemotor

.

O

Checkthesqueegee,cleanifneeded O

Checkthelidgasketontherecoverytank. O

Emptyandflushtherecoverytankwithcleanwater. O

Cl

eanthe

filter/floatinsideth

erecoverytank.

O

Checkthewaterlevelsofallthebatteries.Adddistilledwater,ifneeded.Donotoverfill. O

Checkthepadsandbrushesforwear.Replaceifneeded. O

Checkthesqueegeehoseforclogs,damageandwear.Replaceifneeded O

Check

thesqueegeerubbersforcutsandwear.Fliptheblade(s)overorreplace.

O

Checkthesolutionfilter.Cleanifneeded. O

Flushthecleanwatersolutiontankwithwarmwater. O

Testallthefunctionsofthemachine. O

9

Page 10

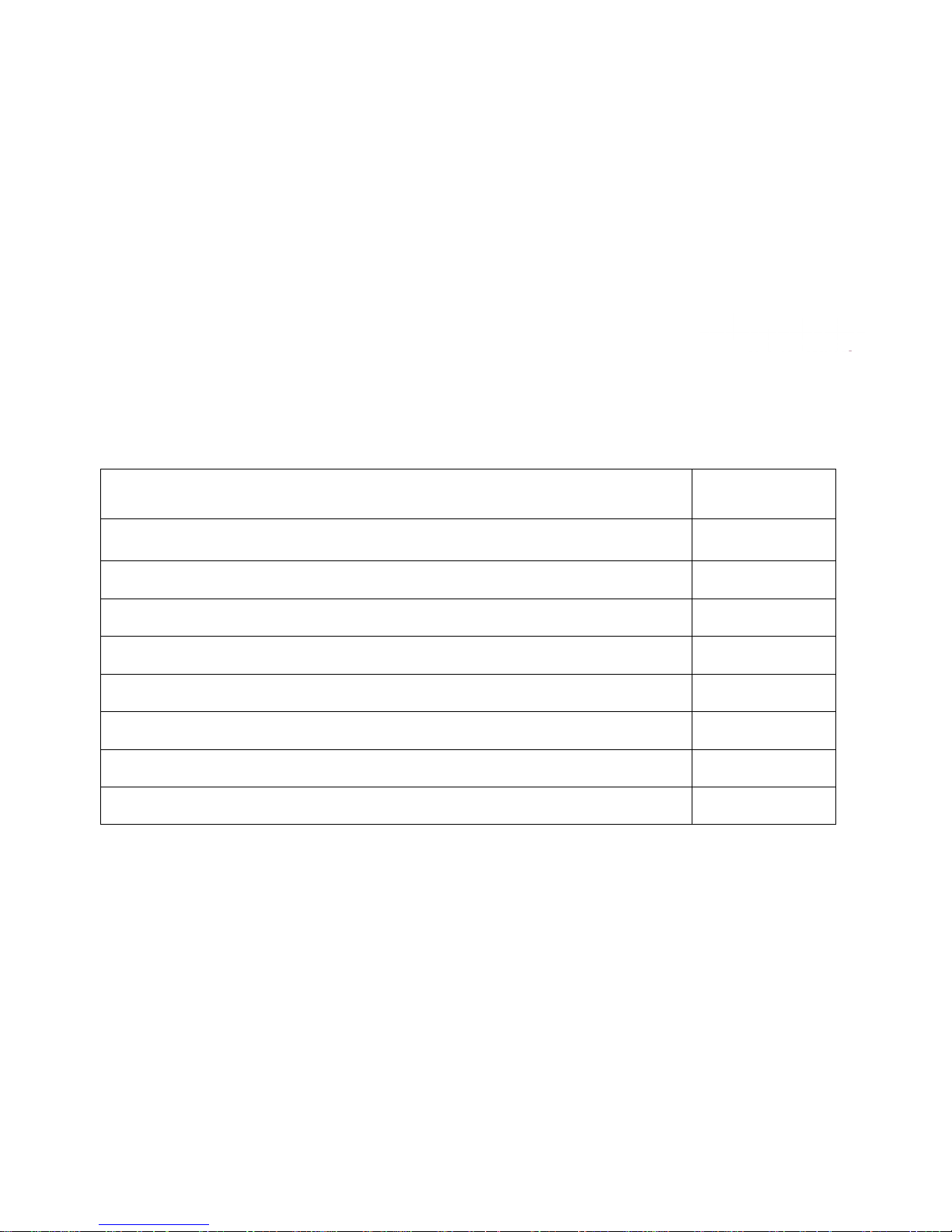

3.2 Minuteman System Maintenance I

Tobeperformedbytheauthorizedservicecenter

Interval

Every125hoursof

operation

Checkthebatterycharger.Makesureitisfunctioningproperly

O

Checktherecoverylidgasket.Replaceifneeded

O

Lubricate

thebrushliftlinkageswithgrease

.

Useasmallbrush

.

O

Checkforloosehardware,tightenifneeded.

O

Checkthetirepressureonpneumaticwheelsat65PSI,ifequipped.

O

Lubricatethesqueegeelinkageswithgrease.Useasmallbrush.

O

Inspecttheentiremachinefordamage,wearandproperoperation.

O

10

Page 11

3.3 Minuteman System Maintenance II

Tobeperformedbytheauthorizedservicecenter

Interval

Every250

hoursof

operation

Inspect

thecasterwheelsforwearanddamage

.

Repair,ifneeded

.

O

Inspectthecarbonbrushesforwearinthetransaxle.Replace,ifneeded. O

Inspecttherecoverydrainhoseforwearordamage.Replace,ifneeded. O

Inspect

thebrushbumperrollersforwearordamage

.

Replace,ifneeded

.

O

Inspectthecarbonbrushesforwearinthebrushmotorsforwear.

Blowoutwithcompressedair. O

Inspecttherecoveryhosefordamageorwear.Replace,ifneeded. O

Inspectthesqueegeeassemblyforproperadjustment.Repair,ifneeded. O

Testthemachineforproperoperation. O

11

Page 12

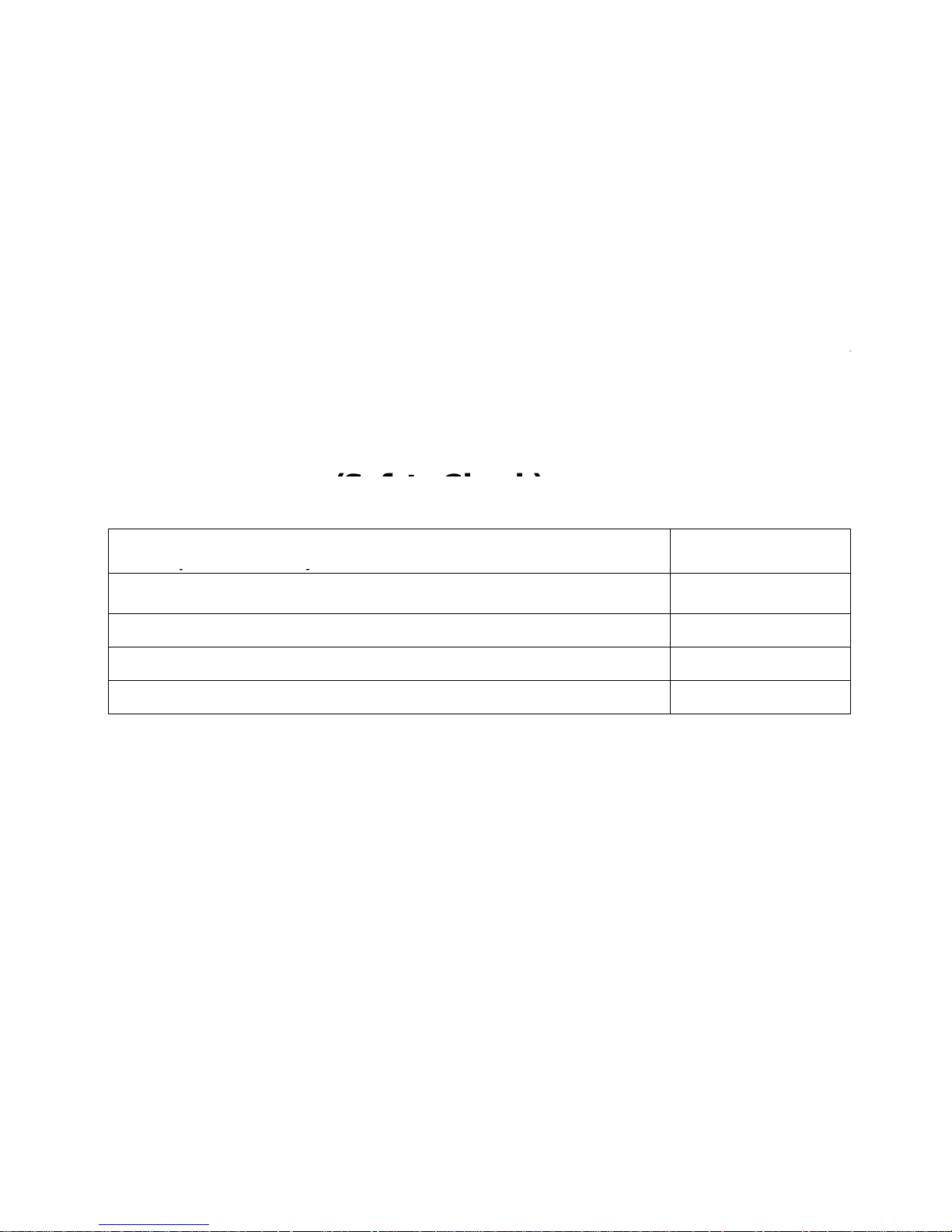

3.4 Minuteman System Maintenance S

Tobeperformedbytheauthorizedservicecenter Interval

(Safety Ch

ec

k)

p y

Every500hoursof

operation

Replacethecarbonbrushesinthetransaxle. O

Replacethecarbonbrushesinthebrushmotors. O

Testthemachineforproperoperation. O

12

Page 13

4. Squeegee Cable And Gasket

4. The squeegee cable is attached to the lift lever (top) via a spring (Fig. 5/5). The bottom is

attached to the eyebolt at the squeegee mechanism (Fig. 5/6). The squeegee lift cable can be

accessed after opening the electronic module cover at the rear of the machine.

The vacuum motor is connected to the A1 at A1.X34:5+6 on the controller. Current

consumption of the vacuum motor amounts to approx. 25A max.

The vacuum water lift in the closed tank is at least 65 inches (150mbar).

Recovery Lid Gasket

Insert the recovery tank cover gasket (Fig. 5/7) so that the seam is positioned at the front center

with a gap of approx. 1mm. The dirty drip water on the top sealing surface will be drawn into the

recovery water tank.

Fig. 5/5

Fig. 5/6

Fig. 5/7

13

Page 14

4.1 Squeegee Adjustment

V

ersion one

4.1 Squeegee Adjustment

Correct squeegee adjustment is prerequisite for optimal suction results.

Before ad

j

ustment first check the pitch of the squeegee and re-adjust if required.

jpqg

jq

1. Place machine on level ground.

2. Loosen nut of the adjustment screw (pos. 3, Fig. 5/1) and adjust sealing strips in

parallel to the floor. Turn adjustment screw clockwise: clearance between squeegee

blade and floor broadens in the center. Turn ad

j

ustment screw counter-clockwise:

j

clearance between squeegee blade and floor narrows in the center.

3. Turn machine on, lower squeegee and check drying pattern.

1 Squeegee

2 Star-shaped knob

3 Adjustment screw

4 Suction hose

5 Toggle-type fastener

Fig. 5/1

14

Page 15

4.2 Squeegee Adjustment

V

ersion Two

4.2 Squeegee Adjustment

Correct squeegee adjustment is prerequisite for optimal suction results.

Before ad

j

ustment first check the pitch of the squeegee and re-adjust if required.

jpqg

jq

1. Place machine on level ground.

2. Loosen the two bolts, located on each side (Fig 5/2A) with the squeegee attached

while holding another wrench on the location shown on Fig 5/2B. Adjust squeegee

rubbers so that the

y

are parallel to the floor, by turning the long adjustment shaft on the

yp ,y g gj

right side with an open end or adjustable wrench (Fig 5/2B). Adjust until the rear

squeegee blade folds equally accross the entire length, while moving the machine

slightly forward.

3. Ti

g

hten the two bolts on the ends while holding the center shaft with the wrench.

gg

4. Turn machine on, lower squeegee and check drying pattern.

Fig 5/2BFig 5/2A

15

Page 16

4.3 Squeegee Wheel Adjustment

4.3 The clearance between the support roller and floor with squeegee unfolded

(Factory setting) is: 0.1181099 Inches

±

0.01968498 inches (3 mm

±

0.5)

.

Note: Some floor surfaces may require adjusting the caster washers for optimum performance.

See following page.

16

Page 17

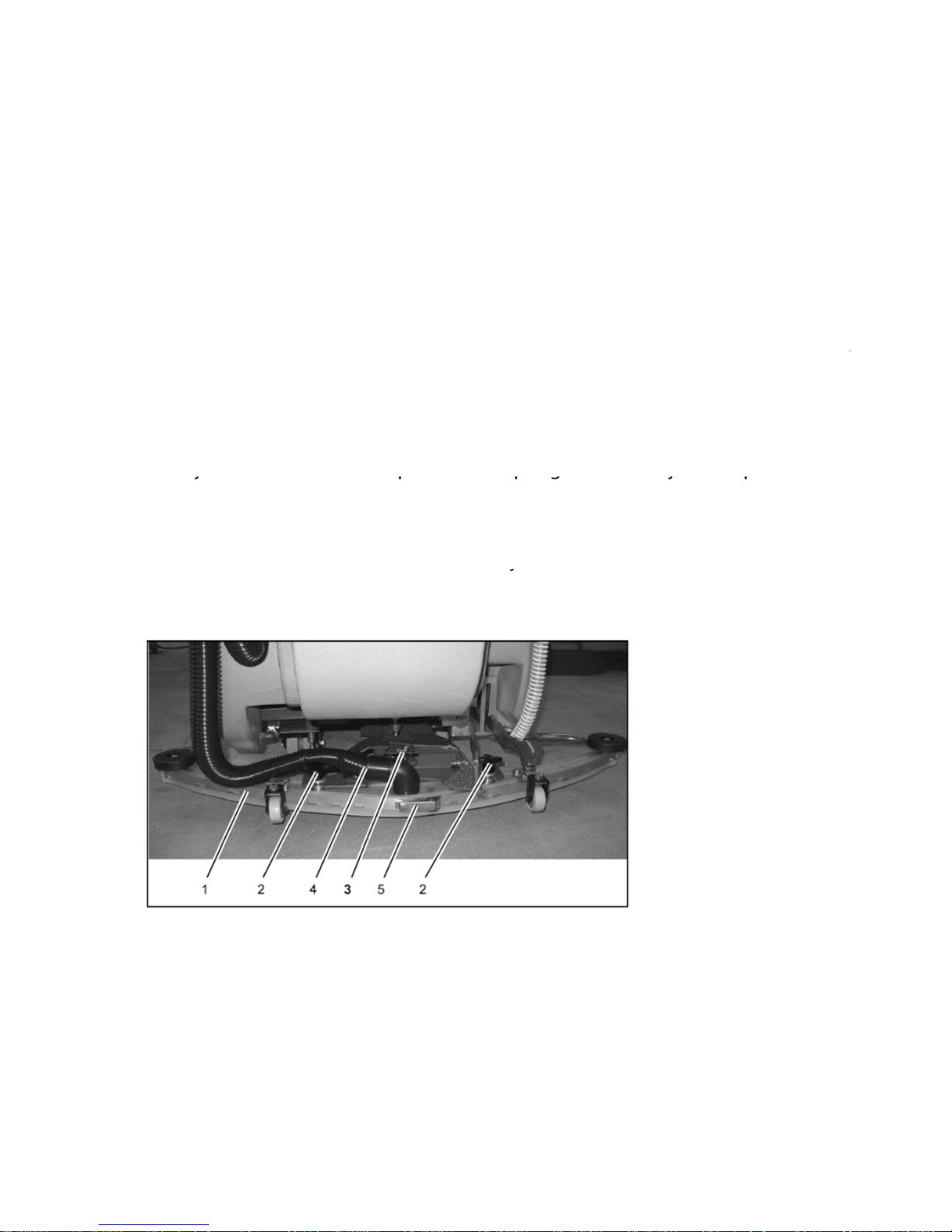

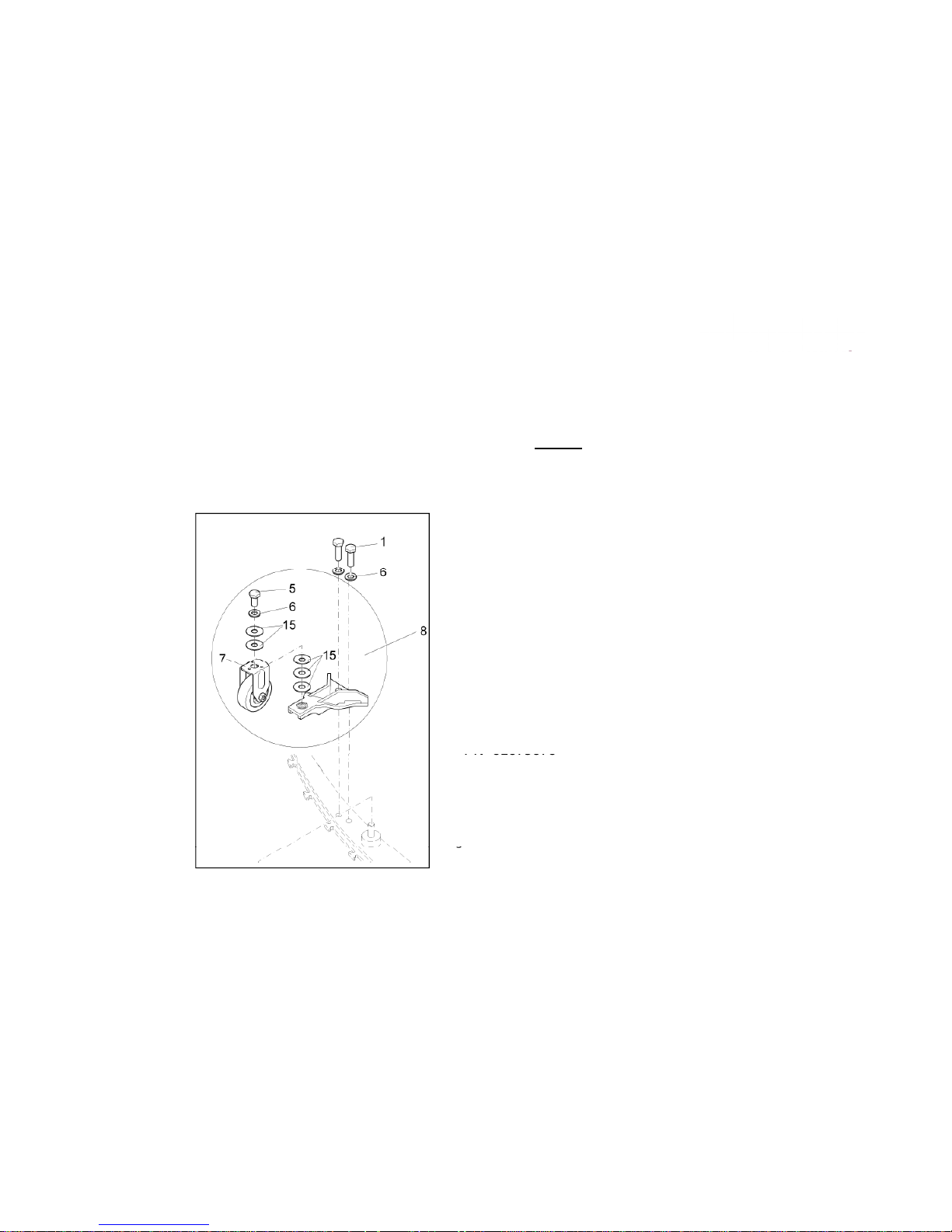

4.4 Squeegee Wheel Adjustment

4.4 Note: When adjusting the wheel height, there should always be 5 washers on each wheel

assembly position # 15 in order fully tighten bolts. Move washers from the top to the bottom of

Pos 1 – Hexagon screw M8x25 A2

PN 01059530

the bracket or visa versa when making adjustments

.

The caster controls the pressure on the

squeegee blade.

Pos 5 – Hexagon screw M8x16 A2

PN 01071740

Pos 6 – Washer B8,4

PN 00101550

Pos 7 – fixed Roller

PN 01077810

Pos 8 – Angle with fixed roller, complet

Fig. 5/3

PN 01079070

Pos 15 – Distance Washer

PN 01079080

g

17

Page 18

4.5 Squeegee Lift Cable, Switch & Motor

4.5 Squeegee Lift Cable, Lever, Micro Switch

and Vacuum Motor

•The vacuum motor micro switch is mounted

behind the squeegee lift lever (Fig. 5/4). Adjust the

micro switch so that the vacuum motor can be

turned off by lifting the squeegee by the lever.

Loosen the screws on the switch to adjust.

•Vacuum motor is switched on upon lowering of the

squeegee.

•The micro switch is a normally open switch which

is terminated to input A1.X9:3+9 on the controller.

When the squeegee is lowered, there should be

continuaty between both contacts (with the plug

A1.X9 being disconnected).

Fig. 5/4

NOTE: The squeegee lift cable spring will need to disconnected from the silver

18

lever before the squeegee lift lever plate can be removed from the machine.

Access can be made from the controller/charger area in the rear of the machine.

See Chapter 4.

Page 19

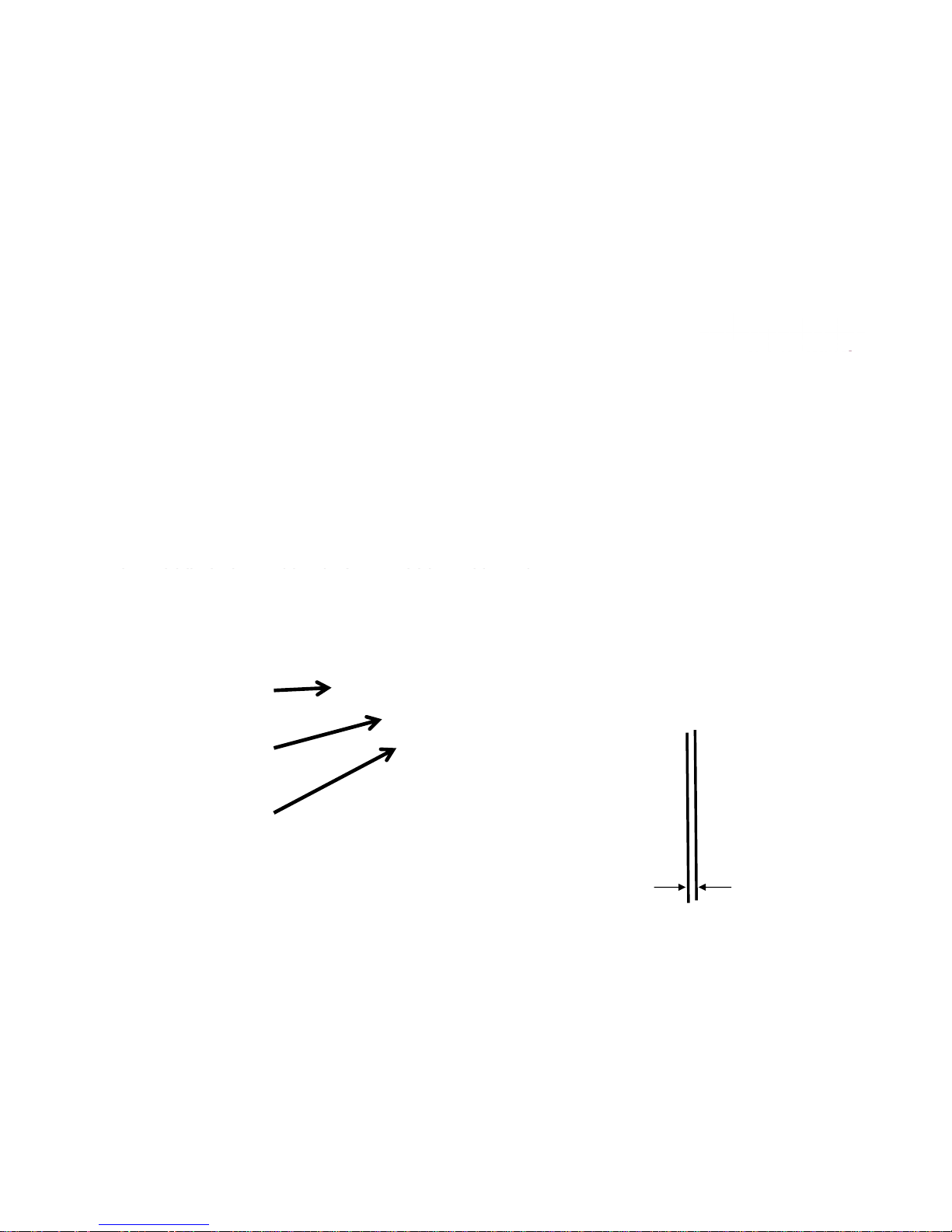

5. Brush Head (Disk) Connections

5. C

onnection of Brush Motors to Disk Brush Hea

d

Connect the brush motors of the disk brush head in accordance with the electric diagrams. Find the

assignment of connecting stud of the motors listed in the below table. Then check the correct

direction of brush motor rotation.

The left-hand motor seen in direction of travel is M3, the right-hand one is M4.

Cable

Motor connection

Connectors

M4

M3

Harness

Disk brush

at the motor -M3/4

Stud bolt above

Connection N

Stud bolt below

Connection P

19

Page 20

5.1 Brush Motor Information

5.1 Brush Motors

The brush motors are switched on and off by a micro-switch located at the rear at the brush head

lift-out system. This switch is realised as NO (normally open) switch. To attain safe function of the

brush motors

,

correct adjustment of this switch is required.

,j q

Electric connection of the switch is realised at the central control at A1.X9:4 + 10.

Maximum current consumption of the brush motors (in practical use) must not exceed 30A per

motor on the 26 and 30“ disk brush decks. The maximum amperage for the 33“ disk decks is 40A.

Lower settings are recommended for longer motor life, run time and traction.

When checking the carbon brushes make sure that the scroll spring is pressing the carbon brush

against the commutator, does not contact the guide and that distance to carbon brush guide is

sufficient.

Replace the carbon brushes, if required.

20

Page 21

6. Brush Head

6. Brush Head Transport Position

•The lever provided is for lifting up the brush head. It features 3 positions for adjusting

the lift linkage (Fig. 6/1). The top hole is the transporting and ramp climbing position. In

this position, the lift linkage is to be adjusted so that a 1mm gap appears between the

lever and the screw head at the chassis (Fig. 6/2).

•The m

iddle hol

e pos

iti

on is for scru

bbi

ng w

ith

pads.

•The bottom hole (Fig. 6/1) is the normal scrubing position of the brush head.

Transport Position

Scrubbing position

with pads

Scrubbing position

1 mm

Fig. 6/2

21

with brushes

Fig. 6/1

Page 22

6.1 Brush Switch

6.1 Brush Switch

•The brush motors are switched on and off by a micro-switch located at the rear at the

-

brush head lift

out system Figure 6/3. This switch is a NO (normally open) switch. To

attain safe function of the brush motors, the correct adjustment of this switch is

required.

•Electric connection of the switch is connected to the central control circuit board at

A1.X9:4 + 10 connector

. In

the lifted

-

up position, the switch should open and close

when brush head is lowered.

Fig. 6/3

22

Page 23

6.2 Brush Pressure Adjustment (Disk Models)

Brush Pressure Setting on Disk models.

•

The bolt on the left can be adjusted to increase or

decrease the brush pressure.

•Models with 19 gallon tanks This pressure adjustment

will affect the models in the normal scrubbing mode. (no

extra

p

ressure option

)

Adjustment

Screw

Increase

pressure

pp)

•Models with 30 gallon tanks. This pressure adjustment

will only affect the models in the heavy pressure mode

only (second foot lever activated).

2nd notch

1st notch

•

The indicator on the right should never be set past the

second notch.

•NOTE: When making changes, the current draw should

be less than 30 amps. per motor on the 26 and 30” disk

”

decks under load maximum

. 40

amps max on 33 decks

.

•Lower settings are recommended for longer motor life,

longer run time and traction.

•Verify the current with brushes under load, with a digital

Decrease

pressure

clamp-on meter.

•Only an authorized Minuteman Service Center should

make changes to the brush pressure setting.

23

Note: The factory setting

set at the second notch

Page 24

6.3 Brush Pressure (Disk Models)

Heavy

Brush

Pressure

(2nd Foot

Specific

Surface Pressure

Model

Area Per

Brush

B

rush

Pressure

Pedal

Engaged)

Specific Surface

Pressure

with Heavy Brush

Pressure

E3330

1055 cm²

163.525 inch²

400 N =

90 lb 600 N = 135 lb 0.19 N/cm² = .275 lbs per inch²

0.28 N/cm² = .406 lbs per

inch²

²

=

²=

E3030

761 cm

1 17.955 inch²

320 N

72 lb 600 N = 135 lb 0.21 N/cm² = .35 lbs per inch²

0.39 N/cm

.

565 lbs per

inch²

E2830

280 cm²

43.400 inch²

240 N =

54 lb NA 0.43 N/cm² = .623 lbs per inch² NA

240 cm²

²

260 N =

²

²

E24

37.200

inch

58 lbNA0.54 N/cm = .783 lbs per inch

NA

E26

586.5 cm²

90.908 inch²

350 N =

79 lb NA 0.3 N/cm² = .435 lbs per inch² NA

24

Page 25

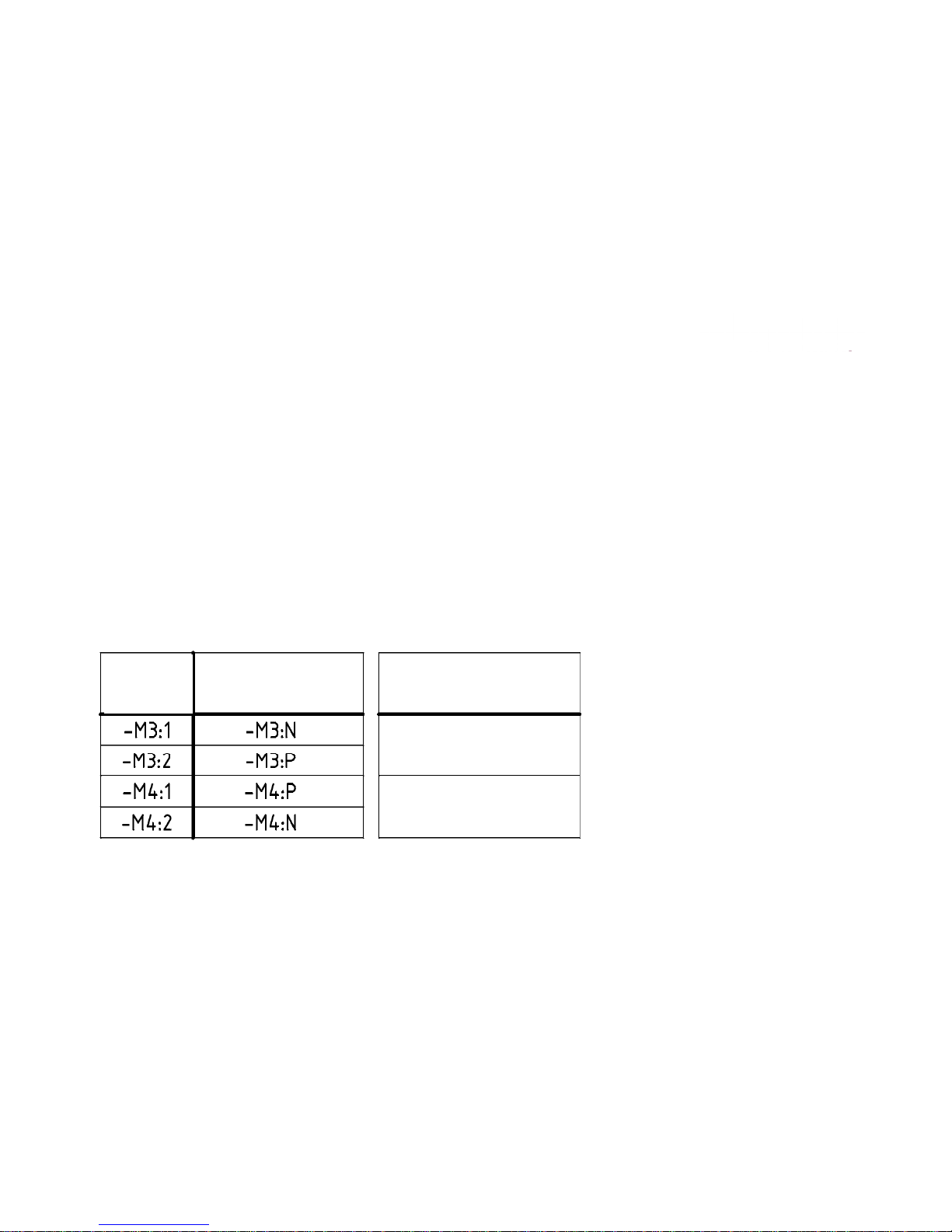

6.4 Brush Head (Cylindrical)

6.4 Electric Connections

• Connect the brush motors of the cylindrical broom head in accordance with

the electric diagrams. Find the assignment of connecting stud of the motors

listed in the below table. Then check the correct direction of brush motor

rotation.

• The left-hand motor seen in direction of travel is M3, the right-hand one is

M4.

M3 M4

Motor connection

Cyl. brush head

Cable

Harness

Connectors

at the motor -M3/4

Stud bolt above

Stud bolt below

Connection P

Connection N

25

Page 26

6.5 Adjusting Cylindrical Deck

Spacer Block on this side also

Spacer Block

26.5 mm high

Part number for the gauges are available by request.

26

Page 27

7. Drive and Wheels

7. General Data

Torque of wheel bolts: 23 foot lbs

Torque of wheel nuts: 18 foot lbs

Wheel speed in max. drive potentiometer position:

Forward: (3.1 mph) 110 min-1 Reverse: (1.55 mph) 55 min-1

Torque of setting for screws on caster mounting: 17 foot lbs

7.1 Electric Brake (E33 and 30 Gallon Tank Models Only)

•The drive motor is equipped with a electric brake on the transaxle. In the display , the

brake is represented by the symbol. The transaxle is locked (lever down) by brake as

pyy ()y

soon as the drive bail handle is in the neutral position.

Release the brake mechanically before pushing the machine. To release, unlock (lever up)

the lever located on the drive motor behind the water filter on the left side of the machine

directly behind the left-hand drive wheel.

y

•If the machine is powered up with the brake in the unlocked position the “flashing H“ will

appear in the hourmeter display. This will prevent the machine from operating for safety

reasons.

• When this occurs the coil volta

g

e will be interupted on the K1 main relay.

gp y

Resistance of the electric brake coil amounts to approx. 37 to 41 Ω.

27

Page 28

7.2 Transaxle Motor

7.2. Transaxle Drive Motor

•Drive motor, axle and differential are a single unit.

•The wheel drive is nearly maintenance-free. Check the

carbon brushes of the drive motor at regular intervals

during maintenance. Carbon brushes are worn if the

scroll spring applying the carbon brushes to the

armature, is approx. 1mm away from the guide. Contact of

the spring and the guide must be avoided since otherwise

the armature can be damaged. Before the check, remove

battery and battery tray from the machine.

•

The thermal switch of the drive motor is integrated in the motor and cannot be

replaced. Such switches are NC (normally closed) switches which interrupt the

circuit, if the motor temperature exceeds the limit. The thermal switch is

connected to the control board at A1.X9:2+8.

28

Page 29

7.3 Transaxle Motor Carbon Brushes

7.3 Carbon Brushes

Close the cover of carbon brushes again as shown in photos 7/2, 7/3

and 7/4. Make sure that the plastic lock is placed in a motor housing

recess for brushes.

29

Page 30

7.4 Drive and Wheels

7.4 Drive Potentiometer Circuit

•Potentiometer Resistance

Value: 5.875 k Ω +- 30%

•Asssignment of connecting plug (A1.X4):

Pin 1: Ground

Pin 2: 24Volts

Pin 3: Digital signal of drive direction 1

Pin 4: Digital signal of drive direction 2

Pin 5: Potentiometer wiper

Pin 6: Potentiometer +

Pin 7: Potentiometer Pin 8: not assigned

Potentiometer

30

Page 31

8. Water Supply

8.1 The solenoid valve releases or stops supply of water flowing to the brushes.

The solenoid valve is located at the front pane of the battery compartment. The

•

solenoid valve is electrically connected to the central controller A1 at

A1.X11:1+2. See Fig. 8/1

•Coil resistance of solenoid: approx. 47 Ω

•Current consumption of solenoid: approx. 0.5 A

•Water amount is regulated by ball valve on all

the 19 gallon and models.

Fig. 8/1

8.2 Solution Filter

The clear water supply line to the

brushes is equipped with a filter

screen. In case of problems with the

supplied water amount, check the

screen and the hoses from clear water

tank and to the brushes

.

See Fig.8/2

Fig. 8/2

31

Page 32

8.3 Water Supply (Solution Tank Clean out)

•The Models E33, E2830, E3030 and E3330 with the 30 tanks will be

equipped with a clean out plug on the solution tank

.

•The plug may be removed to clean out debris that is inside the tank.

32

Page 33

8.4 Solution Flow rates

WaterSetting123456

DiskBrush

30&33"

Gallonspermin

.18 .29 .36 .52 .95 1.45

P

umpVoltage

2.68

3.46

4.61

5.84

9.82

15.43

Cyl.Brush24"

Gallonspermin

.39 .47 .55 .60 .68 .74

PumpVoltage

4.69 5.99 6.85 7.47 8.45 9.24

Cyl.Brush28"

Gallonspermin

.39 .47 .55 .60 .68 .74

PumpVoltage

4.32 5.86 6.77 7.15 8.00 9.86

Note:Values areproportionaltothedrivespeedexceptforposition6

Thisinformationappliestomodelsequippedwithasolutionpumponly.

TheE26ismanuallycontrolledbytheoperator.

33

Page 34

8.5 Water Pump

8.5 Solution Control

• Models equipped with water pump

• The solution flow rate is affected by the speed of the drive

system.

• The controller adjusts the voltage to the pump to regulate water

volume.

• The faster the machine is driven the more water will flow to the

brushes

.

• The controller uses stand still recognition circuitry. The pump

will be shut off, if the water supplied to the pump is to low or

inefficient, when the voltage supplied to the pump is above the 5

,gpppp

volt level. This feature is disabled if voltage is below 5 volts.

34

Page 35

9. The Last Error

9. All Minuteman E24, E26, E2830, E30ECO, E30, E28, E3030, E3330,

E33XL, H26, H30

and 19, 24 and 30 gallon models are equipped w

ith

an

error memory which will indicate the last error that occurred in the

machine. This last error is displayed upon turning on the machine by

key switch. The first numbers that

appea

r will be the software version.

eys tc e st u best atappea bet esot ae eso

The second will be the last error (if one had occured). The third will be

the hour meter .

•If four digit error code is displayed continuously with blinking dots

and the alarm is sounding, the controller has detected a problem in the

system. The machine will be inoperable. See error codes for details.

35

Page 36

10. Table of Error Codes

Error code Error source Remarks

Chec k tem

p

eratur e of br ush motors; check

1.2.5. 2. Thermal swi tch Brush 1/2

p;

current consumption of brush motors; check

wiri ng of thermal switc h (X8 and X9 plugs) of the

brush motors (series connec ti on). Input A1. X9:1

and 7

1.2.6.1.

Blocking protection Brush 1/2 Electroni c

protection of brush motors

Brush motors smooth running? C heck cur rent

consumption? 30A max. per motor

3.1.6.E

.

Fuses of power unit

Group message all fuses on the A1

3.2.1.1. LD S defec ti ve

Is battery voltage identical to voltage at A1:X1

and A1.X2? (i dle r un and under load)

3.4.1. 1. Dri ve rheostat

Chec k dri ve rheostat and wir ing, is dr i ve rheostat

detected at the contr ollers A1X 4 connection?

3.4.1.2.

Off i sle switch on during star t up or Dr ive

Turn off off isle switch and r estar t machine

control defective

If error is permanent, replac e central controller

3.4.5.1. D ri ve motor overheated

Chec k ther mal switch and wiring from dri ve

motor, X10 plug

36

Page 37

10. Table of Error Codes

Error code Error source Remarks

Check connecting cable between central

4.5.2. 5. Co ntrol panel not r ecognized controller and contr ol panel. This error

occurs upon switching on only.

4.5.3. 5. No response control panel (Timeout)

Check connecting cable between central

controller and co ntrol p a nel. This e r ror

occurs upon switching on only.

4.6.1. 2. Int er nal cont r oller err or

If er r or is permanent and even af t er

repeated sw it ching on and off of the

machine, replace central controller

5.1.4. 1. Main contactor does not switch

Does main contactor K1 sw itc h? Check

main contactor wiring. Contacts

If er r or is permanent and even af t er

5.4.6.1.

Error upon system start (signal

states)

repeate

d

switching on and off of the

machine, replace central controller

"H"

"P"

Hand brake unlocked

Hand brake locked

See chapter 7.1

Magnet brake at dr ive motor

37

Page 38

11. 24V - 22A Charger

10.1 Operating Instructions

38

Page 39

11.1 24V - 22A Charger

39

Page 40

11.1 24V - 22A Charger

40

Page 41

11.2 Charger Error Codes

10.2 Note: The following are error indicators that could occur during the battery

charging process. All errors will be in the form of a blinking display picture

of the battery

.

The display indicator figure # 1 will display a blinking doted square, if the

battery malfunctions for the following reasons:

1. The battery has less than 1.25 volts per cell.

2. The battery has less than 15 volts after 30 minutes

3. The batteries are wired incorrectly (reversed polarity).

4. The batteries are missing.

5.Th

e wrong battery type is installed.

6. The selected programming of the charger is incorrect for the

batteries that are installed.

Fig.1

41

Page 42

11.2 Charger Error Codes

The display indicator figure # 2 will blink, when the charger timer times out.

This occurs when the battery voltage on a 24 volt battery pack does not reach

22.8

volts or higher after 30 minutes. The charger w

ill sh

ut off.

Fig. 2

The displ

ay indicator figure # 3 indicates that there is an error in the charger.

1. The charger needs repair or replacing.

Fig. 3

42

Page 43

11.2 Charger Error Codes

The display indicator figure # 4 will blink when the charger is over heating:

1. The coolin

g

air is restricted

g

2. The cooling fan is not working.

3. The cooling hose is not connected or is obstructed.

Fig. 4

Programming button depressed while starting the charging operation.

Fig. 5

43

Page 44

11.3 Trouble Shooting the Charger

•Symptom - charger has no output.

Check for loose or burnt connections on the side of the

charger.

•

Use a test cord by

-

pass the original AC power cord

.

Note: Continuity and voltage tests may not be adequate for

testing the condition of the AC cord.

•Power cords from a desk top computer will make a good test

cord.

44

Page 45

11.4 24V - 14A Charger

•10.4 Charger Maintenance Points

•Check the following, when servicing the machine:

•The charger unit should be secured by rubber strap.

•The wires going to and from the charger should be secured with plastic

gg g p

wire ties. They should be routed so that there are not any kinks, pinched

or crushed wires.

•The charger housing must be insulated from all metallic machine parts.

-

Use a multi

meter to measure the resistance between charger housing and

the frame on the machine. There should not be continuity.

•Repeat the test by checking the resistance between the A.C. Cord ground

pin of the charger and frame of the machine. There should not be

continuity

.

•The ground pin of the A.C. cord must conduct without resistance to the

screws on the charger case.

•The char

g

er ventalation hose must in place and without obstruction.

gp

45

Page 46

11.5 Programming the Charger

10.5 The automatic scrubbers are equipped with the new on board automatic charger.

The charger will be programmed from the factory for the wet lead acid batteries.

Machines that were purchased with gel maintenance free batteries installed at the

factory will be programmed for gel.

1. The charger can be programmed to charge either the gel type battery or wet lead

acid batteries.

2. Follow the instructions below to change the charging mode.

ggg

3. Remove the two Allen head screws on the rear of the machine. Let the

charger/controller-cover drop down. The charger is located on the rear of the

housing.

4. Remove the nut and washer on the backside. Carefully lift the plastic cover off

and set it to the side.

5. Plug the charger’s A.C. power cord into the outlet. The charger will turn on.

6. Locate the small push button switch on the right side of the charger. Located near

the rubber strap.

ProgrammingButton

46

Page 47

11.5 Programming the Charger Cont.

5. Push and hold the button in for 2 to 4 seconds and release. The charger will

turn off.

6. Push and hold the button in again for >10 seconds and release. This puts the

charger into the programming mode. The picture on the machine’s display will

blink rapidly indicating which charging mode has been previously stored in the

7. Push the button for <1 (one) second at a time to select a different charging

mode. The picture will blink slowly, indicating that you’re in the selection mode.

P

ush the switc

h r

epeatedly unt

il the

desired mode is displayed

.

charger

.

us t e s tc epeated y u t t e des ed ode s d sp ayed

8. The charger will show a total of 8 (eight) different charging modes. (See

pictures below for the proper mode). The remaining settings do not have any

additional functions.

47

Page 48

11.5 Programming the Charger Cont.

Mode # 5 is for gel type

batteries using chargers

Mode # 0 is for the

Trojan # 956752

Mode # 1 is for AGM

batteries 956749 (260

prior to charger serial

96117197 7 6992 6

260 Ah batteri

es for the

charger 96137732 only.

Ah) & 956200 (200 Ah)

for the charger

96137732 only.

Mode # 6 is for the wet lead acid

batteries only

. All chargers have

this setting.

Mode # 7 is for gel batteries

only

after charger serial

96117197 7 6992 6 and all

This is the

Default setting

96137732 chargers.

48

Note 1: Settings 2 ,3 and 4 are the same as 5 on the 96137732 charger.

Note 2: Settings 2, 3, 4 and 7 are the same as 5 before serial number 96117197 7 6992 6.

Note 3: Do not use other settings on chargers after serial number 96117197 7 6992 6.

Page 49

11.5 Programming the Charger Cont.

9. To save the desired mode, press and hold the button for more than 5 seconds

and release. The picture on the display will blink rapidly indicating the setting

has been stored.

10. To end the programming mode function, wait about 60 seconds. The charger

will automatically return to its normal operation.

11.Unplug the X31 jumper connector on the main control board harness for the gel

and AGM maintenance free batteries. Connect the X31 plug to the harness for

the lead acid type batteries. Secure the X31 connector with a plastic tie in the

control board area when not in use.

12. Install the plastic cover with the nut and washer.

13. Install the two screws and secure the charger/controller cover to the original

position.

X31 Plu

g

g

49

Page 50

11.6 Replacing the Charger Harness

•When replacing the charger output harness (W8) 97094346 on

19 gallon models or 011722530 on 30 gallon models with the

electric brake.

•Use the K-E24261668 Charger Retro fit kit in addition when either the

harness or charger is being replaced.

•Inspect the receptacle on the charger for burnt or damage.

Replace the charger if it is damaged.

•

Use a coating of high temperature dielectric grease

(NYOGEL 760G GREASE) or equivalent, on the pins of the plug

of the harness, before connecting the new harness to the charger.

50

Page 51

12. Batteries

12.1 Maintaining Wet Lead Acid Batteries

1. Always keep the water levels above the plates

2. Fill cells with distilled water only. Tap water can cause an

excessive

build

upofminerals

and

reduce

the

chemical

reaction

of

the batteries. This will shorten the life and performance of the

batteries.

3. Use an appropriate filling device, when filling the batteries. Do not

use a gardenhose.Floodingthebatteries canflus

h

th

eelectrolyte

out of the battery and shorten its life.

4. Fill cells 3/8 to 1/2 of an inch above the separators. Do not fill

above the fill the marker ofthe batteries. Over fillingcan cause the

g

electrolyte to percolate out onto the case while charging.

51

Page 52

12.1 Batteries

5

. Check water level daily.

Fill, if

needed.

6. Keep all the battery cable connections tight.

7. Keep all the battery posts and cables clean. Clean the battery cases

with a mixture of baking soda and water solution or commercial spray

g

py

that neutralizes the acid. Spray the cases with a water displacement

chemical or a silicone. This will help break the flow of current across

the case and reduce the discharge rate .

Note: The electrolyte on the surface of the case can cause:

A. The batteries to discharge faster even while sitting and have a shorter

run time.

B. The battery charger to stay on for extended periods. Thus causing an

over charge condition and shortening the life of the batteries.

C. Never leave batteries in a discharged state for long period of time.

52

Page 53

12.2 Load Testing Batteries

12.2 Load Testi

ng

Load test battery with an automotive type load tester. This test

puts an ampere load on the batteries and measures the voltage

at the same time. If voltage drops too low on the meter this

would indicate that the batteries are weak or discharged. Load

testing can identify dead cells, broken or disconnected plates,

and cells or charge status

.

This is good test however, it can

only detect these types of failures. See Specific Gravity Test for

additional tests.

53

Page 54

12.3 Hydrometer Testing Batteries

12.3 Hydrometer Testing on Lead Acid Wet Batteries

• Hydrometer testing can used to measure the specific gravity of deep cycle

batteries. This allows you to detect weak cells, which are causing loss of

running time. It can only detect these types problems. The hydrometer

should have specific gravity markings such as 1.265, 1.250, 1.225, and so

on.

• Hydrometers with the four balls are not accurate enough for this

test and are not recommended.

• Fully charged batteries should read 1.265 and will decrease as batteries

are discharged until they reach 1.120. This test should be done when

batteries are charged and cooled. Allow one hour or more to cool. It can

also be done after batteries are partially discharged, if they are allowed to

cool. However, you will not be able to detect the full capacity of the

battery.

54

Page 55

12.3 Hydrometer Testing Batteries Cont.

• To do an accurate test,the batterywater level must be high enoughto

,yg

g

extract enough electrolyte to fill hydrometer enough so that the

indicator floats. If the water levels are low, water should be added

prior to charging in order to let the electrolyte to mix.

• The greater the variation between cells readings, the greater the loss

of run time. For example, if the readings are 1.265, 1.265 and 1.225 in

one 6 volt battery

.

The low cell would be considered weak and greatly

reduce the performance of the battery or shorter run time. This

battery would have a point 40 variation. Batteries that have weakened

cells in most cases it can still be used as long they continue provide

adequate run time. A battery with a point 40 variation or more should

be determined defective.

55

Page 56

12.3 Batteries (Wet Lead Acid)

• Minuteman batteries are rated for 500 charge cycles.

gy

Every time the batteries are charged it uses one cycle.

To insure getting the expected life, unnecessary charging should be avoided.

• The specific gravity will reflect the percentage of charge remaining in the

battery.

• 100% charge = 1.265 and above Specific Gravity

•

=

75 % charge

1.225 Specific Gravity

• 50 % charge = 1.190 Specific Gravity

• 25 % charge = 1.120 Specific Gravity

•

N

ote : Gel maintenance free batteries can not be tested with the hydrometer.

Do not attempt to open cell covers or caps. Doing so will destroy the battery.

56

Page 57

13. Fuse Locations (Version 2 Controller)

All the fuses are located on the main

control circuit board.

Part Numbers

00059580 Fuse 125 Amp 80 Volts (Brush & Vac. Motors)

00972420 Fuse 100 Amp. 80 Volts (Brush & Vac. Motors)

00733630 F

use 10 Amp. 32 or 80 Volts (Pump & Water Sol.

)

00902440 Fuse 50 Amp. 80 Volts (Drive)

00972430 Fuse 2 Amp. 32 Volts (Switch)

Note: If the 2 amp fuse blows,

check the main contactor for

bad contacts.

Warning: Do not substitute the value

of the 50, 100 and 125 amp fuses.

They must be correct voltage and

amperage

.

Doing so will produce

system errors. Fuses are used as

shunts in the circuit.

57

Page 58

13.1 Fuse Locations (Version 3 Controller)

10 Amp Fuse

32 or 80 V olts

00733630

125 Amp Fuse

80 Volts

00059580

2 Amp Fuse

32 Volts

00972430

50 Amp Fuse

80 Volts

00902440

5 Amp Fuse

32 Volts

00906120

58

Page 59

14. Controller Connections

59

Page 60

15. Trouble Shooting the Controller

Note: If the 5 amp fuse on the controller blows, It could indicate:

1. A faulty contactor (not closing on the negative side).

2. Poor connection on the battery negative side of the contactor.

3. Poorly crimped terminals on the contactor connections.

-

4.

Incorrect wiring of the contactor. (See chapter 16

17)

• NOTE - Always use a coating of high temperature dielectric

grease (NYOGEL 760G GREASE) or equivalent on the motor

connectors on the bottom of the controller when replacing the

board or motor harnesses.

Caution: Connecting the battery pack polarity

60

incorrectly will permanently damage the controller.

Page 61

16. Contactor Wiring – Harness

61

Page 62

17. Contactor Wiring

Proper wiring of the

contactor is critical

Control Board

To batteries

and charger

62

Page 63

18. Testing the Main Power Relay

B-

Digital Volt M

ete

r

F

rom Batter

y

B+

From Battery

gta ot ete

B-

25 Volts

Controlled

B+

Controlled

Note: Measure the voltage across the

B+ and the B- coil terminals with the

wires attached and the key switch

turned on. It should be about 24 volts.

If

not, poss

ible l

ow battery con

diti

on.

Inspect batteries.

Diode

63

Page 64

18. Testing the Main Power Relay

B

-

From Battery

B+

From Battery

Digital Volt Met

er

25 Volts

+

B

-

Controlled

OR

B

Controlled

Note: Measure the voltage from a battery negative

source to the B+ terminal of the main relay’s coil to

-

+

determined of the B+ is being supplied to the coil. It

should be 24 volts. If not, inspect control board and

key switch circuit

+-

Batteries

64

Page 65

18. Testing the Main Power Relay

Digital Volt M

ete

r

B-

From Battery

B+

From Battery

gta ot ete

B-

25 Volts

+

Controlled

OR

B

Controlled

Note: Measure the voltage from the battery positive

source to the B- terminal of the main relay’s coil to

-

-

+

determined of the B

is being supplied to the coil. It

should be 24 volts. If not, possible blown 5 amp fuse or

relay or key switch circuit problem. Also check

connections on the on-board charger

+-

Batteries

65

Page 66

18. Testing the Main Power Relay

25.5 vol

ts

Note: Measure the

voltage on the

incoming battery side

55 ots

across the B+ & Bterminals when the

machine is powered

up and under load.

B-

From Battery

B+

From Battery

p

B-

B+

Controlled

Controlled

66

Page 67

18. Testing the Incoming Contact Voltage

on the Main Power Relay

22.4

y

Note: The

voltage should

The relay is

defective

-

volts

Volt Meter

b

e exactly the

same as the

Note: The incoming

voltage was 25.5

+

battery side

when the

machine is

volts

under load.

B+

Controlled

B-

Controlled

67

Page 68

Page 69

Page 70

Page 71

Page 72

Page 73

Page 74

Page 75

1174-00

PLOTDATUM : B-Stand : 003 / Ri. / 19.12.07 [004 / kupe / 19.12.07]19.12.2007

-X25

-X1

97098511

-W11

-X26

-G2

-G2.X3:-G2.X2:-G2.X4:

-G2.X1:

-G1

97096986

-W1

-X24

97094346

-W8

-X18

-M7

-K1

-X19

99-7036-50

97094346

-W8

-Y1

-X102

-X101

-S11

97099063

-W9

97094304

-W6

97101547

-W3

-X31

97096721

-W12 (option spray tool)

-A1

-A1.X9:

-A1.X8:

-A1.X21: -A1.X34:

-A1.X20:

-A1.X4:

-A1.X22:

-A1.X1: -A1.X2:

-A1.X11:

connected (state of deliver):

battery type Gis (wet)

disconnected:

battery type GiV (dry)

-S1

-A2

-A2.X1:

-A2.X7:

-A2.X5: -A2.X6:

-S7

97096994

-W2

-S5

-A3

-S6

97099071

-W16

-M3

-M4

-M3.S1

θ

-M4.S1

θ

-X12

-X32

97097786

-W14

-R1

-S4

notice:

-M1

-X8

-M2

-X10

97098503

-W13

-M1.S1

θ

-S3

-X9

97101547

-W3

214

3

Blatt:Blattzahl:Normgepr.

Datum Name

Gezeichnet

Geprüft

NameDatumÄnd.-Nr.Nr.

VES-Nr. :

Ersatz für :

Änd. Nr. :

Benennung

Typ:

Zeichnungs-Nr.

Hako-Werke GmbH

D-23840 Bad Oldesloe

31

Gl.Nr.

1066-00

07.06. kupe19.12.07 Ri.

2007

2 ./.

A1

-A1.X9:5

-K1:1 -G1:P(+)

P

35mm²

-K1:3 -G1:N(-)

on-board-charger

supply main

1 2 12 123456

-K1:1

4mm²

N

-A1.X9:12

-X1:PB

P(+)

N(-)

-X1:NB

-K1:3

4mm²

35mm²

1

-A1.X11:12-A1.X11:6

-A1.X21:1

-A1.X21:2

0,75mm²

-A1.X8:2

-A1.X21:5

-X1:PS-A1.X1:

-A1.X21:7

4mm²

-G2.X4:1

-A1.X21:4

-A1.X21:6

0,75mm²

-A1.X8:4-A1.X11:4-M7:RD

water

pump

RD

BK

-A1.X21:8

-X1:NS

4

3A1

A2

1

2

-A1.X2:

-A1.X21:3

4mm²

-G2.X4:2

-A1.X11:9-M7:BK

0,75mm²

-A1.X8:3-A1.X8:1

35mm²

35mm²

0,75mm²

water valve

option

spray tool

-A1.X11:3

1

2

-A1.X11:8

virtual ground

at direction switch

-X101:

1mm²

-X102:

virtual ground

at chassis

-A2.X6:1

spray tool on

-A2.X6:2

0,75mm²

0,5mm²

0,5mm²

0,75mm²

-G2.X3:6

-G2.X3:5

-G2.X3:4

-G2.X3:3

-G2.X3:2

-G2.X3:1

-G2.X2:2

-G2.X2:1

-K1:A1

-K1:A2

-K1:1

-K1:3

-X8:1B

-X9:2B

-X10:1B

-X10:2B

-S3:1

-S3:2

-S4:1

-S4:2

-X25:B

-X26:B

-X31:1B

-X31:2B

-A1.X9:6

-A1.X9:13

1

2

-X31:2S

-X31:1S

35mm²

-Y1:1

-Y1:2

0,5mm²

-K1:2

controller

3

10

4

11

1

8

2

9

5

12

6

13

F1

125A

2

4

3

1

1

2

5

7

4

6

8

3 1

2

3

4

5

6

1

2

1

2

3

4

5

6

7

8

F2

50A

LOGIC

F6

10A

F5

2A

LOGIC

LOGIC

LOGIC

38 49 16510

LOGIC LOGIC

27

7

14

LOGIC

VCC2

F3 5A

-X18:S

-X19:B

35mm²

0,5mm²

-K1:4

-X24:1B

-X24:2B

-M3:1

-M3:2

-M4:1

-M4:2

-X12:1B

-X12:2B

-M1:BK

-M1:RD

-S5:NO

-S6:3

-S6:1

-X32:3B

-S7:C

-X32:2B

6mm²

6mm²

2,5mm²

-A2.X5:1

key

switch

BAT

control

panel

21 12

-X32:1B

dead man

switch right

C

NO NC

-A1X4:6

-A2.X5:2

-S1:

-S1:BAT

-A1.X4:1

dead man

switch left

C

NO NC

-S6:2

key

board

-A1.X4:3

6mm²

6mm²

6mm²

6mm²

-S5:C

2

13

direction

switch

+

-

2,5mm²

-A1.X4:4

brush-

motor

left

brush-

motor

right

0,5mm²

0 1

-A1.X34:1-A1.X34:2-A1.X34:3-A1.X34:4

-S11:

-S11:

-X8:1S-X8:2S-X9:1S-X9:2S

-A1.X34:5

-A1.X34:6

-S7:NO

-A1.X4:5

-A1.X4:7

1

2

1

3

2

-M2:GY

-M2:BK

-R1:

-R1:

-R1

+

-

drive

motor

speed giver

-A1.X9:11

0,75mm²

-A1.X9:4

brush

on

1

24

loom of cables -W13 (97098503) and loom of

cables -W14 (97097786) only for cylindrical

scrub brush. For conical brush connect the wires

of thermal switches direct at -X8 and -X9.

0,75mm²

BK

RD

1

-M3.S1:-A1.X9:1

suction motor

2

-M3.S1:-X9:1B

GY

BK

1

-M1.S1:-A1.X9:2

2

-A1.X9:10

-M1.S1:-A1.X9:9-A1.X9:3

suction

on

1

24

1

-M4.S1:-X8:2B2-M4.S1:-A1.X9:7

0,5mm²

connection conical brush

at motor -M3/4

binder plug topside

connection N

binder plug below

connection P

-M3:1

-M3:2

conical brushmarking

cylindrical

-M3:N

-M3:P

motor connection

cable

-M3:N

-M3:P

-M4:1

-M4:2

-M4:P

-M4:N

-M4:N

-M4:P

scrub brush

91026567

91026567

=

+

wiring diagram E2833

M

-

-

-

-

-

-

-

-

-

connector -X31

M

M

M

M

topview -K1

Für diese Zeichnung behalten wir uns alle Rechte vor.(Gemäß DIN 34) 7062-12/15/18

1 2 3 4 5 6 7 8 91011121314151617181920212223242526272829303132333435 363738 39

Zahl kommt vor

0,1

0

Page 76

1174-00

003 / Ri. / 19.12.07 [ 004 / kupe / 19.12.07 ]date of plot:

-A1 controller /1.2090541483

-A2 control panel /1.2690487216

-A3 key board /1.2990487232

-G1 battery /1.3

-G2 on-board-charger /1.397097679

-K1 main contactor /1.990529942

-M1 drive motor /1.3690526021

-M1.S1 thermal switch drive motor /1.37to -M1

-M2 suction motor /1.3797096200

-M3 conical brush motor left 750 /1.3190507476

or conical brush motor left 850 90507484

or cylindrical brush motor left 700 90417056

-M3.S1 thermal switch brush motor left /1.33to -M3

-M4 conical brush motor right 750 /1.3190507476

or conical brush motor right 850 90507484

or cylindrical brush motor right 700 90417056

-M4.S1 thermal switch brush motor right /1.33to -M4

-M7 water pump /1.897047310

-R1 speed giver /1.3497100416

-S1 key switch /1.2690323437

-S3 suction on /1.3790306002

-S4 brush on /1.3590306002

-S5 dead man switch left /1.2890520446

-S6 direction switch /1.3090516147

-S7 dead man switch right /1.2690520446

-S11 spray tool on (OPTION spray tool) /1.1390224650

19.12.2007

-X1 battery connector 160A /1.2

-X8 connector 2 poles /1.36

-X9 connector 2 poles /1.38

-X10 connector 2 poles /1.37

-X12 connector 2 poles /1.33

-X18 connector 1 poles /1.8

-X19 connector 1 poles /1.9

-X24 connector 3 poles /1.4

-X25 connector 1 poles /1.1

-X26 connector 1 poles /1.3

-X31 connector 2 poles /1.18

-X32 connector 3 poles /1.33

-X101 connection virtual ground at chassis /1.13

-X102 connection virtual ground at direction switch /1.13

-Y1 water valve /1.1290435595

page

pa.

19.12.07 Ri.

Gl.Nr.

1066-00

2007

2

A3

1x

2

circuit diagram

91026567

91026567

E2833

ref. designation pathpart no

ref. designation pathpart no

modified no. date

date

drawn by

checked

name

2

3

07.06.

=

+

D-23840 Bad Oldesloe

no.

name

indemnity for:

modified no.:

kupe

Hako-Werke GmbH

no. available

Page 77

1174-00

PLOTDATUM : B-Stand 003 / Ri. / 19.12.07 004 / kupe / 19.12.0719.12.2007

-X101

-S3

-S5

-A3

-X32

-K1

-S7

-X102

-R1

-S4

driving direction

-A1

-G2

-A3 -A3

-M2

-X12

-M2

-X12

-X1

-X1

-G1

-G1

-X10

-X10

-M1

-M1.S1

-M1

-M1.S1

-M7

-M7

-M3

-M3.S1

-M3

-M3.S1

-M4

-M4.S1

-M4

-M4.S1

-A2

-A2

-A2

Blatt:Blattzahl:Normgepr.

Datum Name

Gezeichnet

Geprüft

NameDatumÄnd.-Nr.Nr.

VES-Nr. :

Ersatz für:

Änd. Nr. :

Benennung

Typ:

Zeichnungs-Nr.

Hako-Werke GmbH

D-23840 Bad Oldesloe

33

Gl.Nr.

1066-00

07.06. kupe19.12.07 Ri.

2007

A2

2

1x

-S6

-X25

-X26

-X24

-X31

-S1 -S11

-S1 -S11 -S1 -S11

-S6

-S6

-S3 -S3

-X18

-X19

-X18

-X19

-Y1

-Y1

91026567

91026567circut diagram

=

+

E2833

2

top view of battery block

-

+

+

-

+

+

Für diese Zeichnung behalten wir uns alle Rechte vor.(Gemäß DIN 34) 7062-12/15/18

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28

Zahl kommt vor

-X8

-X9

-X8

-X9

machine with conical brush

machine with cylindrical brush

Page 78

1177-02

PLOTDATUM : B-Stand : 001 / Ri. / 12.12.07 [002 / kupe / 12.12.07]12.12.2007

-K1

-X1

-G1

24 V

-X1

-K1

-G2

-G2.X3:-G2.X2:-G2.X4:

-G2.X1:

-S3

-S4

-K1

-X25 -X26

-X27

-X31

-Y1

-A1

-A1.X9:

-A1.X8:

-A1.X21: -A1.X34:

-A1.X20:

-A1.X4:

-A1.X22:

-A1.X1: -A1.X2:

-A1.X11:

-X18

-M7

-X19 -X24

-X12

-S7

-M3

-M4

-X32

-M2

-R1

-M3.S1

θ

-M4.S1

θ

-A2

-A2.X1:

-A2.X7:

-A2.X5: -A2.X6:

-X8

-X8

-X9

-X9

-S1

-M1

-M1.S1

θ

-S5

-S6

-A3

99-7036-50

-S11

-M1.Y1

-X17

-M1.S2

-X10

Blatt:Blattzahl:Normgepr.

Datum Name

Gezeichnet

Geprüft

NameDatumÄnd.-Nr.Nr.

VES-Nr. :

Ersatz für :

Änd. Nr. :

Benennung

Typ:

Zeichnungs-Nr.

Hako-Werke GmbH

D-23840 Bad Oldesloe

21

05.11. kupe12.12.07 Ri.

2007

0 Eingeführt lt.

A1

10

2

1

P

P(+)

N(-)

N

10

4

3

on-board-charger

supply main

1 2 12 123456

suction on

1

24

brush on

1

24

A1

A2

11

1

connected (state of deliver):

battery type Gis (wet)

disconnected:

battery type GiV (dry)

battery select

12

water valve

1

2

controller

3

10

4

11

1

8

2

9

5

12

6

13

F1

125A

2

4

3

1

1

2

5

7

4

6

8

3 1

2

3

4

5

6

1

2

1

2

3

4

5

6

7

8

F2

50A

LOGIC

F6

10A

F5

2A

LOGIC

LOGIC

LOGIC

38 49 16510

LOGIC LOGIC

27

7

14

LOGIC

VCC2

F3 5A

1

water

pump

RD

BK

112

1

2

brush

motor

left

brush

motor

right

dead man

switch right

C

NCNO

1

3

2

suction motor

GY

BK

+

-

speed giver

control panel

21 12

drive-

motor

1

2

1

2

key switch

BAT

BK

RD

forward

reverse

dead man

switch left

C

NO NC

2

13

direction switch

key

board

cable

marking

-M3:1

-M3:2

-M4:1

-M4:2

+

-

motor connection

conical brush

-M3:N

-M3:P

-M4:P

-M4:N

0 1

option

spray tool

spay tool on

connection conical brush

at motor -M3/4

binder plug topside

connection N

binder plug below

connection P

213

1

2

4

91026906

91026906

=

+

connec. scheme E 33 / Ph 35

-

-

-

-

-

-

-

-

-

M

M

M

M

M

Für diese Zeichnung behalten wir uns alle Rechte vor.(Gemäß DIN 34) 7311-23/-24

1 2 3 4 5 6 7 8 91011121314151617181920 21222324252627282930313233 3435363738 39

Zahl kommt vor

0,1

0

Page 79

1177-02

B-Stand : 001 / Ri. / 12.12.07 [ 002 / kupe / 12.12.07 ]date of plot:

-A1 controller E24 / E26 /1.18

-A2 control panel /1.28

-A3 key board /1.30

-G1 battery /1.2

-G2 on-board-charger /1.6

-K1 main contactor /1.10

-M1 drive motor /1.29

-M1.S1 thermal switch drive motor /1.30

-M1.S2 brake switch drive motor /1.37

-M1.Y1 brake drive motor /1.35

-M2 suction motor /1.26

-M3 conical brush motor left /1.25

-M3.S1 thermal switch brush motor left /1.27

-M4 conical brush motor right /1.25

-M4.S1 thermal switch brush motor right /1.27

-M7 water pump /1.19

-R1 speed giver /1.26

-S1 key switch /1.29

-S3 suction on /1.7

-S4 brush on /1.9

-S5 dead man switch left /1.30

-S6 direction switch /1.30

-S7 dead man switch right /1.25

-S11 spray tool on (OPTION spray tool) /1.33

-Y1 water valve /1.17

12.12.2007

Blatt

Bl.

12.12.07 Ri.

Bennenung :

2007

0

A3

Eingeführt lt.

connection scheme

91026906

ref.

designation path ref. designation path

91026906

E 33 / Ph 35

Änd.-Nr. Datum

Datum

Gezeichnet

Geprüft

Normgepr.Name

2

2

05.11.

=

+

D-23840 Bad Oldesloe

Nr.

Name

VES-Nr. :

Ersatz für :

Änd. Nr. :

kupe

Hako-Werke GmbH

Zahl kommt vor

Page 80

1177-02

PLOTDATUM : B-Stand : 001 / Ri. / 12.12.07 [002 / kupe / 12.12.07]12.12.2007

-X25

-X1

97098511

-W11

-X26

-G2

-G2.X3:-G2.X2:-G2.X4:

-G2.X1:

-G1

97096986

-W1

-X24

97094346

-W8

-X18

-M7

-K1

99-7036-50

-X19

97094346

-W8

-Y1

-S11

-X27

-X102

-X101

97101869

-W9

97094304

-W6

97101547

-W3

-X31

97096721

-W12 (option spray tool)

-A1

-A1.X9:

-A1.X8:

-A1.X21: -A1.X34:

-A1.X20:

-A1.X4:

-A1.X22:

-A1.X1: -A1.X2:

-A1.X11:

connected (state of deliver):

battery type Gis (wet)

disconnected:

battery type GiV (dry)

-S1

-A2

-A2.X1:

-A2.X7:

-A2.X5: -A2.X6:

-S7

97096994

-W2

-S5

-A3

-S6

97099071

-W16

-M3

-M4

-M1

-M3.S1

θ

-M4.S1

θ

-X10

-M1.S1

θ

-X32

-X12

-R1

-X17

-S4

-M1.Y1

-X8

-X9

-M1.S2

-M2

-S3

97101547

-W3

97101869

-W9

214

3

Blatt:Blattzahl:Normgepr.

Datum Name

Gezeichnet

Geprüft

NameDatumÄnd.-Nr.Nr.

VES-Nr. :

Ersatz für :

Änd. Nr. :

Benennung

Typ:

Zeichnungs-Nr.

Hako-Werke GmbH

D-23840 Bad Oldesloe

31

09.11. kupe12.12.07 Ri.

2007

0 Eingeführt lt.

A1

-A1.X9:5

-K1:1 -G1:P(+)

P

35mm²

-G1:N(-)-K1:3

on-board-charger

supply main

1 2 12 123456

-K1:1

4mm²

N

-A1.X9:12

-X1:PB

P(+)

N(-)

-X1:NB

-K1:3

4mm²

35mm²

1

-A1.X11:12-A1.X11:6

-A1.X21:1

-A1.X21:2

0,75mm²

-A1.X8:2

-A1.X21:5

-X1:PS-A1.X1:

-A1.X21:7

4mm²

-G2.X4:1

-A1.X21:4

-A1.X21:6

0,75mm²

-A1.X8:4-A1.X11:4-M7:RD

water

pump

RD

BK

-A1.X21:8

-X1:NS

4

3A1

A2

1

2

-A1.X2:

-A1.X21:3

4mm²

-G2.X4:2

option

spray tool

-A1.X11:9-M7:BK

-X17:4B-A1.X8:1

0,75mm²

35mm²

35mm²

water valve

-A1.X11:3

1

2

-A1.X11:8-A2.X6:1

spray tool on

-A2.X6:2

virtual ground

at direction switch

-X101:

1mm²

-X102:

virtual ground

at chassis

0,75mm²

-A1.X8:3-X17:3B

0,75mm²

0,5mm²

0,5mm²

0,75mm²

-G2.X3:6

-G2.X3:5

-G2.X3:4

-G2.X3:3

-G2.X3:2

-G2.X3:1

-G2.X2:2

-G2.X2:1

-X27:B

-K1:A2

-K1:1

-K1:3

-X8:1B

-X9:2B

-X10:1B

-X10:2B

-S3:1

-S3:2

-S4:1

-S4:2

-X25:B

-X26:B

-X31:1B

-X31:2B

-A1.X9:6

-A1.X9:13

1

2

-X31:2S

-X31:1S

35mm²

-Y1:1

-Y1:2

0,5mm²

-K1:2

controller

3

10

4

11

1

8

2

9

5

12

6

13

F1

125A

2

4

3

1

1

2

5

7

4

6

8

3 1

2

3

4

5

6

1

2

1

2

3

4

5

6

7

8

F2

50A

LOGIC

F6

10A

F5

2A

LOGIC

LOGIC

LOGIC

38 49 16510

LOGIC LOGIC

27

7

14

LOGIC

VCC2

F3 5A

-X18:S

-X19:B

35mm²

-X17:1B

-X17:2B

0,5mm²

-K1:4

-X24:1B

-X24:2B

-M3:1

-M3:2

-M4:1

-M4:2

-X12:1B

-X12:2B

-M1:BK

-M1:RD

-S5:NO

-S6:3

-S6:1

-X32:3B

-S7:C

-X32:2B

6mm²

6mm²

2,5mm²

-A2.X5:1

key

switch

BAT

control

panel

21 12

-X32:1B

dead man

switch right

C

NO NC

-A1X4:6

-A2.X5:2

-S1:

-S1:BAT

-A1.X4:1

dead man

switch left

C

NO NC

-S6:2

key

board

-A1.X4:3

-S5:C

2

13

direction

switch

6mm²

6mm²

6mm²

6mm²

-A1.X4:4

+

-

brush-

motor

left

brush-

motor

right

0,5mm²

drive motor

0 1

-A1.X34:1-A1.X34:2-A1.X34:3-A1.X34:4

2,5mm²

BK

RD

-S11:

-S11:

1

-M1.S1:-A1.X9:2

-S7:NO

-A1.X4:5

-A1.X4:7

1

3

2

-R1:

-R1:

-R1

2

-M1.S1:-A1.X9:12

-A1.X34:5

-A1.X34:6

1

2

-M2:GY

-M2:BK

+

-

speed giver

-A1.X9:11

1

cable

marking

-M3:1

-M3:2

-M4:1

-M4:2

-A1.X9:4

brush

on

1

24

-M1.Y1:-A1.X11:5

2

motor connection

conical brush

-M3:N

-M3:P

-M4:P

-M4:N

-M1.Y1:-A1.X11:10

-M3.S1:

-M3.S1:

-M4.S1:

-M4.S1:

1

2

1

2

-A1.X9:1

-X9:1B

-X8:2B

-A1.X9:1

suction motor

3

-M1.S2:-X27:S

GY

BK

-A1.X9:10

-A1.X9:3

suction

on

1

24

4

-M1.S2:-K1:A1

connection conical brush

at motor -M3/4

binder plug topside

connection N

binder plug below

connection P

0,5mm²

0,75mm²

91026898

91026898

=

+

wiring diagram E 33 / Ph 35

M

-

-

-

-

-

-

-

-

-

connector -X31

M

M

M

M

topview -K1

Für diese Zeichnung behalten wir uns alle Rechte vor.(Gemäß DIN 34) 7311-23/-24

1 2 3 4 5 6 7 8 91011121314151617181920 21222324252627282930313233 3435363738 39

Zahl kommt vor

0,1

0

Page 81

1177-02

001 / Ri. / 12.12.07 [ 002 / kupe / 12.12.07 ]date of plot:

-A1 controller E24 / E26 /1.2090541483

-A2 control panel /1.2690487216

-A3 key board /1.2990487232

-G1 battery /1.3

-G2 on-board-charger /1.397097679

-K1 main contactor /1.990529942

-M1 drive motor /1.3290539750

-M1.S1 thermal switch drive motor /1.33to -M1

-M1.S2 brake switch drive motor /1.37to -M1

-M1.Y1 brake drive motor /1.35to -M1

-M2 suction motor /1.3797096200

-M3 conical brush motor left 850 /1.3190507484

-M3.S1 thermal switch brush motor left /1.33to -M3

-M4 conical brush motor right 850 /1.3190507484

-M4.S1 thermal switch brush motor right /1.33to -M4

-M7 water pump /1.897047310

-R1 speed giver /1.3497100416

-S1 key switch /1.2690323437

-S3 suction on /1.3790306002

-S4 brush on /1.3590306002

-S5 dead man switch left /1.2890520446

-S6 direction switch /1.3090516147

-S7 dead man switch right /1.2690520446

-S11 spray tool on (OPTION spray tool) /1.1290224650

-X1 battery connector 160A /1.2

-X8 connector 2 poles /1.37

-X9 connector 2 poles /1.37

-X10 connector 2 poles /1.33

-X12 connector 2 poles /1.34

-X17 connector 4 poles /1.35

-X18 connector 1 poles /1.8

-X19 connector 1 poles /1.9

-X24 connector 3 poles /1.4

-X25 connector 1 poles /1.1

-X26 connector 1 poles /1.3

-X27 connector 1 pole /1.13

-X31 connector 2 poles /1.18

-X32 connector 3 poles /1.33

-X101 connection virtual ground at chassis /1.13

12.12.2007

-X102 connection virtual ground at direction switch /1.13

-Y1 water valve /1.1290435595

page

pa.

12.12.07 Ri.

2007

0

A3

Eingeführt lt.

circuit diagram

91026898

91026898

E 33 / Ph 35

ref. designation pathpart no

ref. designation pathpart no

modified no. date

date

drawn by

checked

name

2

3

09.11.

=

+

D-23840 Bad Oldesloe

no.

name

indemnity for:

modified no.:

kupe

Hako-Werke GmbH

no. available

Page 82

1177-02

PLOTDATUM : B-Stand 001 / Ri. / 12.12.07 002 / kupe / 12.12.0713.12.2007

-X101

-S3

-S5

-A3

-X32

-K1

-S7

-X102

-R1

-S4

driving direction

-A1

-G2

-A3

-M2

-X12

-X1

-G1

-X10 -X17

-M1

-M1.S1

-M1.S2

-M1.Y1

-M7

-M3

-M3.S1

-M4

-M4.S1

-A2

-A2

Blatt:Blattzahl:Normgepr.

Datum Name

Gezeichnet

Geprüft

NameDatumÄnd.-Nr.Nr.

VES-Nr. :

Ersatz für:

Änd. Nr. :

Benennung

Typ:

Zeichnungs-Nr.

Hako-Werke GmbH

D-23840 Bad Oldesloe

33

09.11. kupe12.12.07 Ri.

2007

A2

0

Eingeführt lt.

-S6

-X25

-X26

-X24

-X31

-S1

-X27

-S11

-S1 -S11

-S6

-S3

-X18

-X19

-Y1

91026898

91026898circut diagram

=

+

E 33 / Ph 35

top view of battery block

+

+

-

+

-

+

Für diese Zeichnung behalten wir uns alle Rechte vor.(Gemäß DIN 34) 7311-23/-24

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28

Zahl kommt vor

-X8

-X9

Page 83

21. Notes

83

Loading...

Loading...