Page 1

User Manual

E26ECO/H26ECO Walk-Behind Scrubber

Traction Drive Disc Deck

Page 2

This manual is furnished with each new MINUTEMAN E26ECO/H26ECO. This provides the necessary operating and preventive

maintenance instructions. Operators must read and understand this manual before operating or servicing this machine.

This machine was designed to give you excellent performance and efficiency . For best results and minimal cost, please follow

the general guidelines below:

· Operate the machine with reasonable care.

· Follow the manufacturer’s suggested maintenance instructions as provided in this booklet.

· Use original Minuteman supplied parts.

2

Page 3

Model E26ECO/H26ECO

Model No. E26ECOQP, E26ECOQPG, H26ECOQP, H2ECOQPG

Technical Specifications

Current (Max)

Battery Capacity (Lead Acid)

Battery Capacity (Gel)

Sound Level

Cleaning path width

Squeegee width

Productivity

Working Speed

Transport Speed

Rated voltage

Vacuum flow

Vacuum waterlift

Vacuum power

Brush type

Brush motor(s) power

Number of brushes

Brush RPM

Solution capacity

Recovery capacity

Working Grade

Weight with batteries

Weight without batteries

Dimensions (LxWxH)

Drive Motor Power

40 amps

140Ah @ 20 hr

95Ah @ 20 hr

E26ECO 69 dBA / H26ECO 65.5 dBA

26 in (65 cm)

38 in (95 cm)

30,500 ft2 /hr (2830 m2/hr)

2.7 mph (4.3 km per hr)

2.7 mph (4.3 km per hr)

24 volts

65 cfm (110 m3/hr)

45 inches (112mbar)

.60 HP (450 W)

Disc

3/4 HP (550W)

2

180 RPM

12 Gal (45 liters)

13 Gal (49 liters)

2%

370lbs (168 kg)

235 lbs (107 kg)

48 x 26.0 x 38.0 (112.8 x 47.8 x 107.4 cm)

1/5 HP (150W)

3

Page 4

4

Page 5

Table Of Contents

Safety Instructions ...................................................................................... 6

Unpacking Instructions .............................................................................. 7

Inspection ...................................................................................................... 7

Electrical ........................................................................................................ 7

Batteries ........................................................................................................ 7

Operator Responsibility ................................................................................. 7

Machine Overview ....................................................................................... 8

Controls ....................................................................................................... 10

Bail Handle.......................................................................................... 11

Handle Adjustment Knobs................................................................... 11

Key Switch .......................................................................................... 11

Direction Switch .................................................................................. 11

Squeegee Lift Lever ............................................................................ 11

Battery / Fault Gauge .......................................................................... 11

Speed Control ..................................................................................... 11

Charge Status Indicator ...................................................................... 11

Optional Hour Meter .................................................................................... 12

Vacuum Hose Routing................................................................................. 13

Circuit Breakers........................................................................................... 13

Battery Compartment .................................................................................. 14

Diagnostic Code Guide ............................................................................... 15

Machine Overview....................................................................................... 15

Handle Adjustment ...................................................................................... 16

Angle Adjustment ................................................................................ 16

Horizontal Adjustment ......................................................................... 17

Solution T ank Drain Hose............................................................................ 18

Solution Level Indicator ............................................................................... 18

Solution Fill Filter......................................................................................... 19

Recovery Tank Drain Hose .......................................................................... 19

Screened Float ............................................................................................ 20

Screened Float Removal .................................................................... 21

In-Line Solution Filter Assembly.................................................................. 22

Rear Squeegee ........................................................................................... 23

Cleaning the Squeegee............................................................................... 23

Changing the Squeegee Blades ................................................................. 23

Squeegee Blades ................................................................................ 24

Angle Adjustment ................................................................................ 24

Squeegee Blades ................................................................................ 25

Height Adjustment ............................................................................... 25

Brush Deck .................................................................................................. 26

Brush Loading / Unloading .......................................................................... 26

Aquastop Solution Control .......................................................................... 27

The E26ECO/H26ECO ............................................................................... 28

Machine Operation .................................................................................... 30

To Turn ON Machine: .................................................................................. 30

To Turn ON Vacuum: ................................................................................... 30

To Turn ON Brush Motor: ............................................................................ 30

To Turn on Cleaning Solution:..................................................................... 30

Direction Switch:.......................................................................................... 30

Speed control: ............................................................................................. 30

Driving: ........................................................................................................ 30

To Charge Batteries:.................................................................................... 31

Hour Meter (Optional): ................................................................................ 31

After Use..................................................................................................... 32

Maintenance............................................................................................... 33

Troubleshooting........................................................................................... 36

Warranty ..................................................................................................... 38

5

Page 6

Safety Instructions

IMPORTANT SAFETY INSTRUCTIONS

Operators must read and understand this manual before operating or maintaining this machine.

Do not operate this machine in flammable or explosive areas.

This machine is designed solely for scrubbing dirt and dust in an indoor environment. Minuteman does not recommend using this machine

in any other capacity.

The following information below may cause a potential hazard to the operator and equipment. Read this manual carefully and be aware

when these conditions can exist. Take necessary steps to locate all safety devices on the machine and train the personnel operating the

machine. Report any machine damage or faulty operation immediately. Do not use machine if it is not in proper operating condition.

FOR SAFETY DURING OPERA TION

Keep hands and feet clear of moving parts while machine is in operation.

Make sure all safety devices are in place and operate properly. All covers, doors and latches must be closed and fastened before use.

During operation, attention should be paid to other persons in the work area and especially if small children are present.

Electric motors and components can cause an explosion when operated near explosive materials or vapor. Do not operate this machine

near flammable materials such as solvents, thinners, fuels, grain dust, etc.

Store or park this machine on a level surface only. To prevent unauthorized use, machine should be stored or p arked with the key removed.

This machine is designed for level operation only. Do not operate on ramps or inclines greater than 2%.

This machine is not suitable for picking up hazardous dusts.

Use caution when moving this machine into areas that are below freezing temperatures. Any water in the tanks or hoses can cause damage

to the machine.

FOR SAFETY WHEN SERVICING or MAINTAINING MACHINE

Stop on level surface.

Disconnect the power to the machine by unplugging the red Battery connector located under the recovery tank near the batteries.

Avoid moving parts. Do not wear loose jackets, shirts, or sleeves when working on machine.

Avoid contact with battery acid. Battery acid can cause burns. When working on or around batteries, wear protective clothing and safety

glasses. Remove metal jewelry. Do not lay tools or metal objects on top of batteries.

Charging batteries generates explosive gasses.

Do not charge batteries when open flames or sparks are present. Do not smoke.

Make sure the charger is turned off before disconnecting it from the machine.

Charge the batteries in a well-ventilated area with the battery cover removed completely.

Do not clean machine with a pressure washer.

Authorized personnel must perform repairs and maintenance. Use Minuteman supplied replacement parts.

6

SAVE THESE INSTRUCTIONS

Page 7

Unpacking Instructions

Inspection

Carefully unpack and inspect your E26ECO/H26ECO Walk-Behind Scrubber for shipping damage. Follow unpacking

instructions on shipping pallet. Each unit has been tested and thoroughly inspected before shipment.

responsibility of the delivery carrier who should be notified immediately.

Electrical

This machine is battery operated and designed to operate on 24 volts DC (2) 12-volt batteries.

Batteries

The recommended batteries are rated 140Ah WET (Minuteman P/N 956140) or 95Ah Maintenance Free GEL

(Minuteman P/N 956100). W

equal physical size and capacity. If alternate battery sets are used please contact Minuteman for on board charger

settings.

Operator Responsibility

Read this manual carefully before operating this machine.

e do not recommend mixing AMP hour cap

acities. Alternate battery sets can be used if they

Any damage is the

The operator is responsible for t

working condition. The operator must inform the service mechanic or supervisor when the scheduled maintenance intervals

are required as st

Before starting familiarize yourself with the machine and its controls (see “Machine Overview, Front”, “Machine Overview,

Rear”, “Control Console” diagrams).

ated in the MAINTENANCE section of this manual.

aking care of the daily maintenance and check ups of the machine to keep it in good

7

Page 8

Machine Overview

B

A

C

D

E

H

F

G

Machine Overview

- Front

A CUP HOLDER

B SOLUTION FILL PORT

C RECOVERY TANK LID

D RECOVERY T ANK

E BRUSH DECK

F FRONT WHEEL (see note)

G REAR CASTER

H SOLUTION TANK

* NOTE - Front tires are foam filled to be maintenance-free. No air can be added.

8

Page 9

Machine Overview

D

Machine Overview - Rear

A BAIL HANDLE

B SQUEEGEE LIFT LEVER

C RECOVERY TANK DRAIN HOSE

D ONBOARD CHARGER CORD

E CIRCUIT BREAKERS

C

A

G

M

B

F

L

E

K

F RECOVERY HOSE

G CONTROL PANEL

H SOLUTION TANK DRAIN HOSE / LEVEL INDICATOR

J BRUSH DECK LIFT PEDAL

J

N

H

K REAR SQUEEGEE

L DIAGNOSTIC CODE GUIDE

M SOLUTION CONTROL LEVER

N DECK TILT HANDLE

9

Page 10

Machine Overview

A

B

C

D

E

F

G

K

J

H

Controls

A BAIL HANDLE

B HANDLE ADJUSTMENT KNOB

C KEY SWITCH

D DIRECTION SWITCH

E SQUEEGEE LIFT LEVER

F BATTER Y / FAULT GAUGE

G SPEED CONTROL

H CHARGE STATUS INDICAT OR

J SOLUTION CONTROL LEVER

K AQUASTOP SOLUTION SETTING

10

Page 11

Machine Overview

Bail Handle

(A) When the scrub deck is lowered to the floor, the bail handle enables the brush motor and moves the machine forward once depressed.

Handle Adjustment Knobs

(B) Allows the handle position to be raised or lowered.

Key Switch

(C) Controls the machine’s power (Off/On) with a key for safety. When it is turned to the on position, the machine will operate (after 5 second diagnostic

check, see battery gauge).

Direction Switch

(D) This 3 position switch sets the direction the machine will move when the bail handle is pulled. The middle position is neutral - brushes & vacuum will

operate but machine will not move.

Squeegee Lift Lever

(E) When moved to the top position, the squeegee is lowered and the vacuum motor is turned on. When locked in the bottom position, the squeegee is

raised and the vacuum motor shuts off (after a 10 second delay).

Battery / Fault Gauge

(F) This gauge displays the remaining battery charge. This gauge also displays any fault codes that might occur with the Drive Motor Controller (see

Diagnostic Codes). Gauge will blink for 5 seconds when key is first turned on, to run diagnostic check before machine can be used.

Speed Control

(G) This control sets the speed at which the machine will move.

Charge Status Indicator

(H) This gauge displays the status of the batteries during charging. The gauge has a readout of 3 LEDs. 1 Green, 1 Yellow, 1 Red. Green indicating a full

charge, Yellow indicating 80% charged, Red indicating the batteries are charging.

Solution Control Lever

(J) This lever controls the rate at which solution is dispensed. Moving the lever up will increase the amount of solution. Moving the lever down will decrease

the amount. Moving the lever all the way down shuts off solution flow.

Aquastop Solution Setting

(K) This bracket is a guide to limit the amount of solution dispensed for consistent performance.

11

Page 12

Machine Overview

Optional Hour Meter

Minuteman offers an optional hour meter for the

E26ECO/H26ECO. The optional kit replaces the

power cord mounting bracket at the rear of the

machine with one that contains an hour meter,

which records the brush motor operating time.

Kit# K-E1720HM

12

Page 13

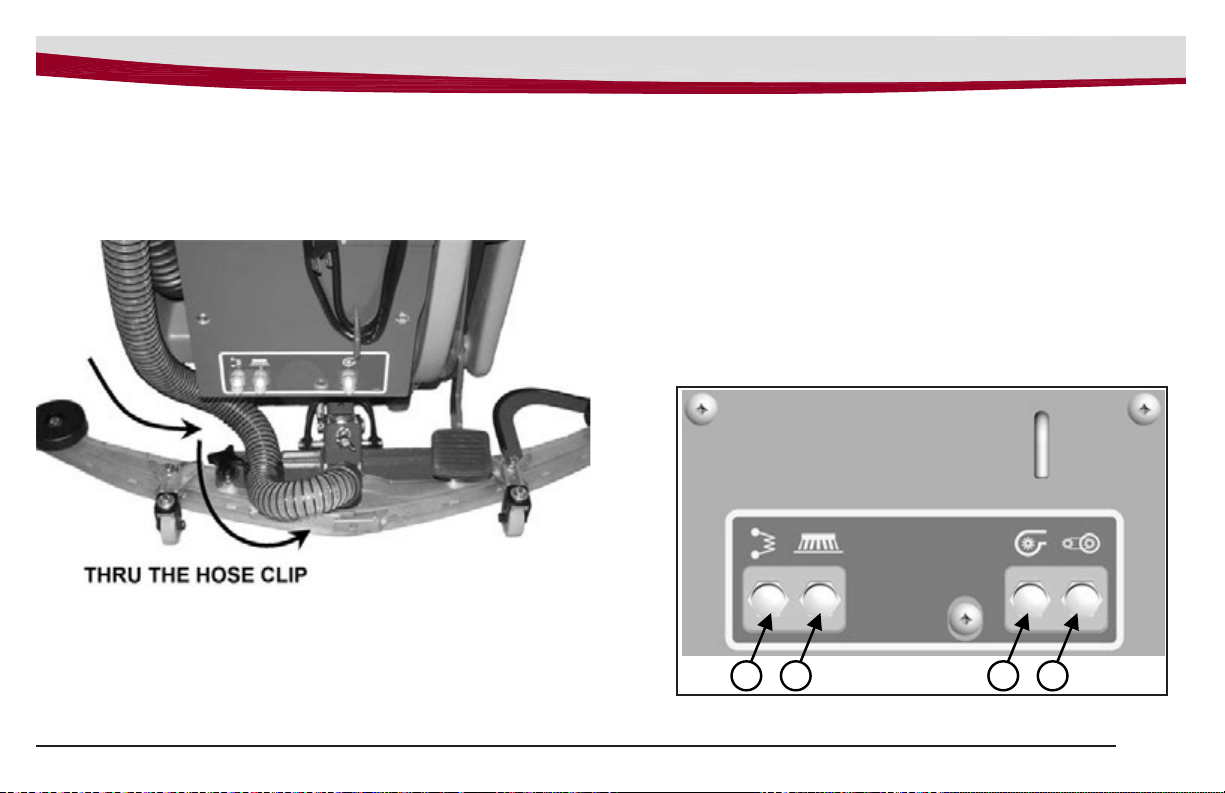

Machine Overview

Vacuum Hose Routing

For best results, route the vacuum hose as shown below:

Circuit Breakers

The circuit breakers are located at the bottom of the back

panel of the machine.

A Main Control Circuit Breaker - 4A

B Brush Motor Circuit Breaker - 30A

C Vacuum Motor Circuit Breaker - 20A

D Drive Motor Circuit Breaker - 20A

If any of the functions above are not operating, check if the

circuit breaker buttons have tripped. Press to reset.

B

A

C

D

13

Page 14

Machine Overview

Battery Compartment

The battery compartment is located under the recovery tank. The

Battery compartment can be accessed for servicing and maintenance by tilting the recovery tank (make sure recovery tank has

been drained before tilting). The battery compartment contains

two 12-volt batteries connected in series. Connect the batteries

according to the battery connection diagram (see diagram). The

recommended batteries are 140Ah (Minuteman P/N 956140) or

95Ah (minuteman P/N 956100) Gel. The battery tray may be

drained if necessary using the orange drain hose located above

the rear caster on the right side of the machine.

14

Page 15

Diagnostic Code Guide

When an error or fault occurs within the machine, a fault

code will appear on the battery gauge represented by a

specified number of flashing LEDs. (See “Troubleshooting”

for further information)

Machine Overview

15

Page 16

Machine Overview

Handle Adjustment

The E26ECO/H26ECO handle was designed with operator comfort

in mind. The angle and horizontal position of the handle can be

adjusted to suit the needs of the operator.

Angle Adjustment

The handle angle can be adjusted without tools by loosening the

Angle Adjustment Knob (A) on each side and rot ating the handle

to the desired position. There are 5 angular positions 1 1.25° apart

for a total of 45° between the minimum and maximum position.

A

16

Page 17

Horizontal Adjustment

Machine Overview

The horizontal position can be adjusted by removing the 4 Mounting

Bolts (B) (2 each side) with a 9/16” socket and sliding the Mounting

Plate (P) to one of the 3 available positions. The machine is shipped

from the factory in position 1.

Plate Position 3

Plate Position 2

(Fully Extended)

3

PB

Plate Position 1

(Shipping Position)

12

17

Page 18

Machine Overview

Solution Tank Drain Hose

The solution tank may be drained by removing the Solution Tank Drain

Hose (A) from the Hose Barb (B) and routing the hose to a floor drain.

18

A

B

Solution Level Indicator

The Solution Tank Drain Hose also serves as a water level indicator for

the solution tank. The amount of water remaining in the solution tank

can be seen through the clear drain hose. Level markers molded into

the solution tank are positioned at 1/4, 1/2, 3/4, and full levels.

Page 19

Machine Overview

Solution Fill Filter

The Solution Fill Filter (B) should be cleaned regularly.

To remove, simply open the Solution Tank Lid (A) and

pull the filter out.

Recovery Tank Drain Hose

Twist Cap to Open and Drain Twist & Lift cap to clean out debris

Note: Debris left on the o-ring will cause a vacuum leak.

A

B

19

Page 20

Machine Overview

Screened Float

20

If the recovery tank (C) is overfilled or a large amount of foaming is

present, the screened float (B) blocks the vacuum intake inside the

tank protecting the vacuum motor and internal electronics from water

damage. It is essential to keep the float in working order through

regular maintenance.

The float should be cleaned daily by thoroughly rinsing with a hose.

Removal of the screened float is not necessary for daily maintenance.

At least once a month the screened float should be completely

removed, cleaned, and checked for any damage to the seal or metal

screen.

WARNING: Damage to the machine may occur if operated

without the screened float properly in place.

A

B

C

Page 21

Machine Overview

Screened Float Removal

The screened float is positioned between the vacuum manifold (A)

and recovery tank (C). The screened float (B) can be accessed by

removing the 1.5” bolt (D) and two 1.25” bolts (E) that attach the

manifold to the recovery tank using a 7/16” socket.

A Vacuum Manifold

B Screened Float

C Recovery T ank

D 1.5” Bolt

E 1.25” Bolt (2)

F Helical Washer (3)

G Flat Washer (3)

E

B

D

E

F

G

A

21

Page 22

Machine Overview

In-Line Solution Filter Assembly

The solution solenoid, which shuts off solution flow when the bail handle is released, is protected from debris by the in-line filter assembly. The

filter assembly is located at the rear of the machine on the left hand side, just under the solution tank. It is important to check and clean the

screened washer inside the assembly regularly to ensure proper solution flow. To open, unscrew the assembly (Note that the cone of the

washer is facing out toward the rear of the machine). Remove washer and rinse, reinsert and screw assembly together, tightening by hand.

Overtightening with tools may damage the plastic threads.

A Fitting, MGHT

B Screened Washer

C Hose Barb Insert

D Fitting, FGHT

22

A

BDC

Page 23

Machine Overview

Rear Squeegee

A Squeegee

B Star-shaped knob

C Adjusting screw for angle adjustment

D Suction hose

E Blade fastening latch

F Washers for caster height adjustment

G Caster Wheel Axle

Cleaning the Squeegee

Check the squeegee (A) daily and clean as

necessary.

1. Pull off the suction hose (D).

2. loosen the two star-shaped knobs (B).

3. Remove the squeegee (A).

Changing the Squeegee Blades

Check the inner and outer squeegee blades on

the squeegee (A) weekly for signs of wear. The

squeegee blades can be reused by turning them

(can be turned for 4 total uses).

1. Pull off the suction hose (D), loosen the two starshaped knobs (B) and remove the squeegee.

2. Unlock the fastening device (E) and remove the

outer squeegee blade. Turn the squeegee blade

or install a new one, as necessary . Change the

inner squeegee blade in the same way.

23

Page 24

Machine Overview

Squeegee Blades

Angle Adjustment

The angle adjustment is the decisive factor in

ensuring that the squeegee blades on the

squeegee lie evenly on the floor.

1. Park the machine on a level surface and lower

the squeegee.

2. Loosen the lower wing nut (B) on the adjusting screw (C) and adjust the squeegee using

the adjusting screw so that the ends of the

squeegee blades still have contact with the

floor. By turning the adjusting screw (C) counterclockwise, the clearance between squeegee

blade and floor is increased in the center (Fig.

1). When turning the adjusting screw (C) clockwise, the clearance between squeegee blade

and floor is reduced in the center (Fig. 2).

3. Switch the machine on and check the suction

pattern. When the machine is in operation, the

entire surface of the squeegee blades (center

and outer areas) must be applied as evenly as

possible.

4. Tighten the lower wing nut (B) on the adjusting screw (C) against the metal bracket to lock

in the pitch setting.

1

2

B

A

B

A

24

Page 25

Squeegee Blades

Height Adjustment

If streaks are present, despite an optimum

angle adjustment, the clearance between the

caster wheels and floor must be adjusted by

changing the number of washers underneath

the bracket that holds the wheel. The

squeegee height is preset at the factory to

3mm.

In cases of very smooth floors, e.g. finished

floors, PVC, linoleum, etc., see 2mm

illustration for washer configuration.

In cases of very uneven floors, e.g. poorly laid

tiles (water does not run off) ,, configure as

shown in 4mm illustration.

Keep the extra washers by

installing them above the bracket

as shown.

3 mm

2 mm

Machine Overview

4 mm

25

Page 26

Machine Overview

Brush Deck

Brush Loading / Unloading

26

1. Brush Deck may be tilted up for easier

brush installation/removal & to clear

steep ramps. Lift the handle on the

upper lever which connects the brush

deck to the machine, tilt the deck up,

release the handle & the lever will lock

into place. Lift the handle again to move

the deck back to horizontal.

2. Brushes are installed/removed by hand.

Push each brush up onto the hub until

it “clicks”. To remove, pull down on the

edge of each brush.

3. The splash guard may be moved up or

down as the brush/pad wears by loosening the clamp on the back side of the

deck with a flathead screwdriver or 9/

32” (7mm) socket, then slide the splash

guard to the desired height & retighten

the clamp.

Page 27

Aquastop Solution Control

Machine Overview

In order to consistently conserve water when using Aquastop brushes, the guide will stop the solution control lever at a

low rate setting. This setting may be adjusted by loosening the knob, adjusting the lever , and retightening the knob. Slide

the knob all the way forward to dispense maximum solution.

27

Page 28

28

The E26ECO/H26ECO

This machine was designed with total operator comfort and ease of use in mind. All machine components have been designed

as a total system to efficiently clean dirty floors. Please contact your Minuteman representative for specific recommendations

for the correct brush type and chemical applications.

Before using the machine, always perform the following steps to ensure proper machine operation:

• Check under the machine for leaks.

• Check the rear squeegee for wear and damage.

• Check the solution and recovery tank levels.

After using the machine, always perform the following steps:

• Check the battery charge level. Charge batteries if necessary. When charging batteries, extra precaution is required:

- Battery acid can cause burns.

- When working on or around batteries, always wear protective clothing and safety glasses.

- Remove metal jewelry. Do not lay tools or metal objects on top of the batteries.

- Charging batteries generate explosive gasses.

DO NOT CHARGE BA TTERIES WHEN OPEN FLAMES OR SPARKS ARE PRESENT. DO NOT SMOKE.

- Charge the batteries in a well-ventilated area.

- Fluid levels should be checked before and after charging and maintained at the proper levels. If low, add distilled water until

the metal plates are covered.

- If the machine is not used for an extended period of time, batteries should be kept fully charged with a boost charge once a

week.

• Check for wire, string, or twine wrapped around the scrub brushes.

• Check the rear squeegee for wear and damage.

• Check the rear squeegee suction hose for obstructions.

• Drain and rinse the recovery tank.

• Check under the machine for leaks.

• Check the service records to determine maintenance requirements.

Page 29

WARNING!

- Be sure you understand the machine controls and their functions.

- While on ramps or inclines, avoid sudden stops when tanks are filled.

- Avoid abrupt sharp turns. Slow down driving speed when going downhill.

29

Page 30

Machine Operation

To Turn ON Machine:

Turn key to operate position ( I ). W ait for battery gauge to stop flashing, approximately 5 seconds. (If flashing continues, see

troubleshooting guide)

To Turn ON Vacuum:

Lower squeegee into operating position, vacuum motor will turn ON automatically.

To Turn ON Brush Motor:

Lower the scrub deck to the floor by moving the brush lift pedal from the “home” (down) position to the operating position (up).

Depress the operator bail handle. Brush motor will turn ON.

To Turn on Cleaning Solution:

Move solution lever from closed (down) position up to the desired flow position. With the scrub deck on the floor, depress the

bail handle, solution will begin to flow

Note: An electronic solution solenoid valve will stop solution flow whenever the bail handle is released.

Direction Switch:

Select direction of machine by moving the directional rocker switch from the neutral position to the forward or reverse position.

The direction of the machine movement is shown on the operator p

Speed control:

Move the speed dial to the desired position. Turning the dial clockwise increases the speed. T urning the dial counterclockwise

decreases the speed.

.

anel with forward and reverse arrows.

30

Driving:

Depress the operator bail handle, the machine will move in the direction selected.

Page 31

Machine Operation

To Charge Batteries:

When the battery / fault gauge reaches the red zone the batteries need to be recharged. Take the machine to a well ventilated

area, unwind the battery charger power cord from the electrical box cover and plug into an appropriate power source. After

approximately 10 seconds the battery charge status indicator will turn on. Check the battery water levels before each use, refill as

needed with distilled water. Caution: do not overfill. Fill water 1/4 “ - 1/2” above the separators. Failure to maintain the

batteries may result in battery failures.

WARNING: Charging batteries generates explosive gasses. Do not charge batteries when open flames or sparks are

present. Do not smoke. Charge the batteries in a well-ventilated area .

Hour Meter (Optional):

Hour meter will automatically record operating time of the brush motor.

31

Page 32

After Use

After Use

1. When finished scrubbing, lift the scrub deck. Lift the rear squeegee (the vacuum motor will turn off af ter 10 seconds).

Move the machine to a service area for daily maintenance and review items that may need service.

2. Empty the solution tank by disconnecting the solution tank drain hose from the barb fitting and routing hose to a

drain. Rinse the tank with clean water to prevent any buildup of dried chemicals that could clog the plumbing.

3. Empty and clean the recovery tank by flushing with a hose. Be sure to also clean the float shut off screen.

4. Remove the brushes or pad holders and rinse them in warm water and hang to dry.

5. Remove the rear squeegee and recovery hose, rinse with warm water and reinstall after cleaning (see page 13 for

correct hose installation).

6. Check the maintenance schedule in the next section and perform any required maintenance before storing the

machine.

7. Store the machine indoors in a clean dry place. Keep from freezing. Leave solution and recovery tank lids open for

ventilation to prevent odor buildup.

8. Turn Key switch OFF (O) and remove key.

32

Page 33

Maintenance

Daily Weekly Monthly Yearly

Charge Batteries

Check/Clean Tanks &

Hoses

Che ck/Clea n/Ro tate

the Brushes

C h eck/C lean the

Squeegee

C h eck/Cl ean Vacuum

Shut-Off Fl oat i n

Recovery Tank

Have a qualified service technician check the vacuum motor carbon motor brushes once a year or after 300 operating hours.

The brush motor and transaxle motor carbon brushes should be checked every 500 hours or once a year.

NOTE: Refer to the Service Manual for more detail on maintenance and service repairs.

Regularly scheduled lubrication of certain machine parts should be performed to insure trouble-free operation of the

machine. Apply a generous amount of grease into the fittings on the machine until grease seeps out around the bearings.

The grease points are listed below:

• Rear caster swivel (2)

Apply lubricant or light machine oil to lubricate the:

• Pivot mounting point of the squeegee lift mechanism to the chassis (1)

• Rear squeegee caster wheel axle (2)

Inspect Brush

De ck S plas h

Guard for Debris

Inspect an d

Clean In-Line

Solution Filter

Rinse off the

under side of

brush deck

Check Each

Battery Cel l (s )

Water Level

Lubr ication –

Grease Fittings

Check Carbon

Brush es

33

Page 34

Troubleshooting

Problem Possible Cause Remedy

Poor wate r pi ck-up

Poor scrubbing performance

Inadequate solution flow or

no solution to the floor

Ma c hin e does not move

Worn or torn squeegee blades Rotat e or replace blades

R ecovery tank full Empt y reco very tank

Recovery tank dr ain hose le ak Secure drai n ho s e cap or replace

R ecov ery tank lid gask et leak Replace ga sk et lid cover pro perly

Debris caught in squeegee Clean squeegee

Recovery hose clogged Remove debr is and flu s h hose

Recovery hose to s queegee or tank

disconnected or da maged

Worn brushes Rotat e or replace brushes

Wrong brush or cleaning ch em ical Cons ult Mi nuteman

Debris caught on scrub brushes Remove deb ris

Moving machine to o fast Use appropriate speed

Lo w battery charge Recharge ba tteries

N ot us i ng enough solution Adjust soluti on flow setting

So l ut ion ta nk em pty Fill soluti on t ank

Solution lines or filter clogged Flush lines and clean solution filter

Brush mot or circuit breaker has tripped Res et ci rcuit breake r

So l ut ion Lever in do wn position Rais e lever up

Squeegee is down and directional

sw it ch is in reverse position

Tractio n drive circuit breaker has tripped Reset ci rcuit breaker

Ba tt er ies lost power Re char ge batter ies

D i r ectional sw itch in neutral posit ion Act i vate FWD or REV p osition

Rec onnect or replace rec ov ery hose

Raise squeegee when in reverse

mode

34

Page 35

Problem Possible Cause Remedy

y

ging

Tri pped Cont rol Power ci r cui t breaker R eset c ir cuit brea ke r

Batteries have low charge Recha rge batteries

Machine does not

operate

Vacuum motor does not

turn on

Batteries do not charge

Battery charger operating Unplug ba ttery charger when charge is complete

Key switch of f Turn key on

Bail handle depressed too quickly after

turning key on

Recover

Excessive foaming in recovery tank.

Squeegee in rai s ed position Lo wer squeegee

Tripped vacuum motor ci rcuit breaker Reset breaker

Broken v acuum l imit swit ch R epl ac e s witch

Carb on Br ushes w or n R eplace carbon brushes

Vacuum switch disconnected Conn ect wiri ng

Cha rger not plugged to w all outlet Plug into wall outlet

Circui t breaker tripped in wall outle t Res et breaker

Battery disconnec te d f rom machin e Connect bat tery to mac hi ne

Cha rger m alfunction C all service

tank full Empty recovery tank

Turn key of f, t urn on, wait until battery gauge lights

up without flashing

Empty recovery tank.

R inse off t he s c reened fl oat in s ide rec overy ta nk .

U se les s or change chemica l.

U se de-foaming agent.

Charger Warning In dicators

LED Status Description

RED LED lamp blink once

Warning

RED LED lamp blink twice

Ou t put open circuit or s hort circuit or re v erse polarity c onnection of charge r to

ba tter y . B at tery volta ge is too high (may be connect ed to wr ong vo ltag e batt ery).

Abnormal cycle (ma y be we ak or ba d ba ttery)

Char

time has safety timed out due to battery prob lem.

Troubleshooting

35

Page 36

Troubleshooting

Fault / Diagnostic Codes

The Battery / Fault gauge will flash when a fault is detected. A decal labeled “Diagnostic Codes” is located below the battery gauge as an abbreviated

and convenient guide to determine the cause of the fault and the remedy (refer to machine or see “Diagnostic Code Guide” section of this manual). The

flashing codes are for the following:

36

The battery needs charging, there is a bad

connection to the battery or dependent on

programming, may indicate that the battery

lockout function is active and the controller is

in a restricted mode of operation. Check the

connections to the battery. If the connections

are good, try charging the battery.

There is a bad connection to the motor. Check

all connections between the motor and the

controller.

The motor has a short circuit to a battery

connection. Contact your service agent.

The battery charge level has fallen below the

Battery Lockout level and the controller is

inhibiting certain machine functions. Charge

the battery.

Page 37

Troubleshooting

Not used.

The controller is being inhibited from driving,

this may be because the battery charger is

connected.

The bail handle was activated prior to turning

the machine on. Make sure that the bail handle

is in the rest position. Restart the key switch.

A controller fault is indicated. Make sure that

all connections are secure.

Not used.

An excessive voltage has been applied to the

controller. This is usually caused by a poor

battery connection. Check the battery

connections.

37

Page 38

Minuteman International Made Simple Commercial Limited Warranty

REVISION F EFFECTIVE 6/1/2009

Minuteman International, Inc. warrants to the original purchaser/user that the product is free from defects in workmanship and materials

under normal use. Minuteman will, at its option, repair or replace without charge, parts that fail under normal use and service when operated

and maintained in accordance with the applicable operation and instruction manuals. All warranty claims must be submitted throu gh and

approved by factory authorized repair stations.

This warranty does not apply to normal wear, or to items whose life is dependent on their use and care, such as belt s, cords, switches, hoses,

rubber parts, electrical motor components or adjustments. Part s manufactured by Minuteman are covered by and subject to the warranties

and/or guarantees of their manufacturers. Please contact Minuteman for procedures in warranty claims against these manufacturers.

Special warning to purchaser — Use of replacement filters and/or prefilters not manufactured by Minuteman or its designated licensees, will

void all warranties expressed or implied. A potential health hazard exists without original equipment replacement.

All warranted items become the sole property of Minuteman or its original manufacturer, whichever the case may be.

Minuteman disclaims any implied warranty, including the warranty of merchantability and the warranty of fitness for a particular purpose.

Minuteman assumes no responsibility for any special, incidental or consequential damages.

This limited warranty is applicable only in the U.S.A. and Canada, and is extended only to the original user/purchaser of this product.

Customers outside the U.S.A. and Canada should contact their local distributor for export warranty policies. Minuteman is not responsible for

costs or repairs performed by persons other than those specifically authorized by Minuteman. This warranty does not apply to damage from

transportation, alterations by unauthorized persons, misuse or abuse of the equipment, use of non-compatible chemicals, or damage to

property, or loss of income due to malfunctions of the product.

If a difficulty develops with this machine, you should contact the dealer from whom it was purchased.

This warranty gives you specific legal rights, and you may have other rights which vary from state to state. Some states do not allow the

exclusion or limitation of special, incidental or consequential damages, or limitations on how long an implied warranty lasts, so the above

exclusions and limitations may not apply to you.

38

Page 39

Cord Electric Group: Three years parts, two years labor, ninety days travel (Not to exceed two hours)

Exceptions……….

Model Parts Labor Poly Travel

Port A Scrub 1 yr 6 months 10 yrs 0

MPV 13 1 yr 0 0 0

MPV 14 & 18 2 yrs 1 yr 0 0

V Series Upright Vacuums 1 yr 1yr 0 0

Rapid Air Blower 1 yr 1 yr 10 yrs 0

Explosion Proof Vacuum 1 yr 1 yr 0 0

X12, X12H & TRS 14 1 yr 1 yr 10 yrs 0

E17 & E20 Electric Scrubbers 1 yr 6 months 10 yrs 0

Pneumatic Vacuums 3 yr 1 yr 0

0

Description Parts Labor Poly Travel

Battery Operated Group 3 yrs 2 yrs 10yrs 90 days

Sweepers 1 yr 1 yr 10yrs 90 days

Internal Combustion Group 1 yr 1 yr 10yrs 90 days

Not to exceed two hours

Exception: PAS 14B 1 yr 1 yr 10 yr 0

Battery Chargers: One year replacement

Replacement Parts: Ninety days

Batteries: 0-3 months replacement, 4-12 months pro-rate

Polyethylene Plastic Tanks: Tanks have 10yr warranty, no additional labor

39

Page 40

Rev B 12/10

988737UM

A Member of the Hako Group

www.minutemanintl.com

Phone 800-323-9420 · Fax 800-422-6933

Minuteman International · 14N845 U.S. Route 20 · Pingree Grove, Illinois 60140 USA

Loading...

Loading...