Page 1

Parts and Instruction Manual

Lead Vacuum

Dry Only

Page 2

This manual is furnished with each new MINUTEMAN Lead Vacuum. This provides the necessary

operating and preventive maintenance instructions. Operators must read and understand this manual

before operating or servicing this machine.

This machine was designed to give you excellent performance and efficiency. For best results and

minimal cost, please follow the general guidelines below:

· Operate the machine with reasonable care.

· Follow the manufacturers suggested maintenance instructions as provided in this booklet.

· Use original Minuteman supplied parts.

Model Lead Vacuum

Model No.

Voltage

Tank Size

Power

Air Flow

Water Lift

Dry Capacity

Cord

Casters

Weight

TECHNICAL SPECIFICATIONS

C82985-06

115V

6 gal (22 ltr)

1.25 HP

95 CFM

85” (2159 mm)

.46 cu. ft (.013 m³)

16-3, 50’ (15 m)

1-5/8” (1.13 cm)

17 lbs (8 kg)

C82986-06

240V

6 gal (22 ltr)

1.25 HP

95 CFM

85” (2159 mm)

.46 cu. ft (.013 m³)

16-3, 50’ (15 m)

1-5/8” (1.13 cm)

17 lbs (8 kg)

Page 3

Table of Contents

IMPORTANT SAFETY INSTRUCTIONS.............................................................................................. 1

INSPECTION........................................................................................................................................ 2

ELECTRICAL....................................................................................................................................... 2

115 Volt ........................................................................................................................................... 2

240 Volt ........................................................................................................................................... 2

GROUNDING INSTRUCTIONS ........................................................................................................... 2

USER MAINTENANCE INSTRUCTIONS ............................................................................................ 3

CLOTH BAG & HOSE ASSEMBLY ..................................................................................................... 3

CORD STORAGE ................................................................................................................................ 3

Operation and Filter Care Instructions ............................................................................................. 4

Tank/Filter Set-Up Procedure.......................................................................................................... 4

Procedures In Removing Contaminated Filters and Cleaning of Contaminated Tank ..................... 4

Changing The Black Foam Prefilter ................................................................................................ 5

Filter Assembly ................................................................................................................ ................... 6

Changing Of Prefilters ....................................................................................................................... 6

Tools and Accessories....................................................................................................................... 7

Exploded Views .................................................................................................................................. 8

Lid Assembly ................................................................................................................................... 8

Lid Assembly BOM.......................................................................................................................... 9

Tank Assembly .............................................................................................................................. 10

Bag Assembly ............................................................................................................................... 11

Minuteman International Made Simple Commercial Limited Warranty........................................ 12

Page 4

FOR COMMERCIAL USE ONLY

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic precautions should always be followed, including the

following:

READ ALL INSTRUCTIONS BEFORE USING

WARNING

• Do not leave appliance when plugged in. Unplug from outlet when not in use and

before servicing.

• To avoid electrical shock, do not expose to rain, store indoors.

- To reduce the risk of fire, electric shock, or injury:

WARNING:

To reduce the risk of electrical shock - Do not use on wet surfaces. Do not expose to

rain. Store indoors.

• Do not allow to be used as a toy. Close attection is necessary when used by or near

children.

• Use only as described in this manual. Use only manufacturer’s recommended

attachments.

• Do not use with damaged cord or plug. If appliance is not working as it should, has

been dropped, damaged, left outdoors, or dropped into water, return it to a service

center.

• Do not pull or carry by cord, use cord as a handle, close a door on cord, or pull cord

around sharp edges or corners. Do not run appliance over cord. Keep cord away

from heated surfaces.

• Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

• Do not handle plug or appliance with wet hands.

• Do not put any object into openings. Do not use with any opening blocked; keep

free of dust, lint, hair, and anything that may reduce air flow.

• Keep hair, loose clothing, fingers, and all parts of body away from openings and

moving parts.

• Do not pick up anything that is burning or smoking, such as cigarettes, matches,

or hot ashes.

• Do not use without dustbag and/or filters in place.

• Turn off all controls before unplugging.

• Use extra care when cleaning on stairs.

• Do not use to pick up flammable or combustible liquids such as gasoline or use in

areas where they may be present.

• Connect to a properly grounded outlet only. See grounding instructions.

Parts an d Instruction Manual

SAVE THESE INSTRUCTIONS

Page 1

Page 5

INSPECTION

Carefully unpack and inspect your machine for shipping damage. Each unit is tested and thoroughly

inspected before shipment, and any damage is the responsibility of the delivery carrier who should

be notified immediately.

ELECTRICAL 115 Volt

This machine is designed to operate on a standard 15 amp. 115 volt, 60 hz, AC circuit. V olt ages

below 105 volts AC or above 125 volts AC could cause serious damage to the motor.

ELECTRICAL -

This machine is designed to operate on a standard 10 amp. 230 volt, 50 hz, AC circuit.

-

240 Volt

WARNING

Electric motors can cause explosions when operated near explosive materials or vapors. Do not

operate this machine near flammable materials such as solvents, thinners, fuels, grain dust, etc.

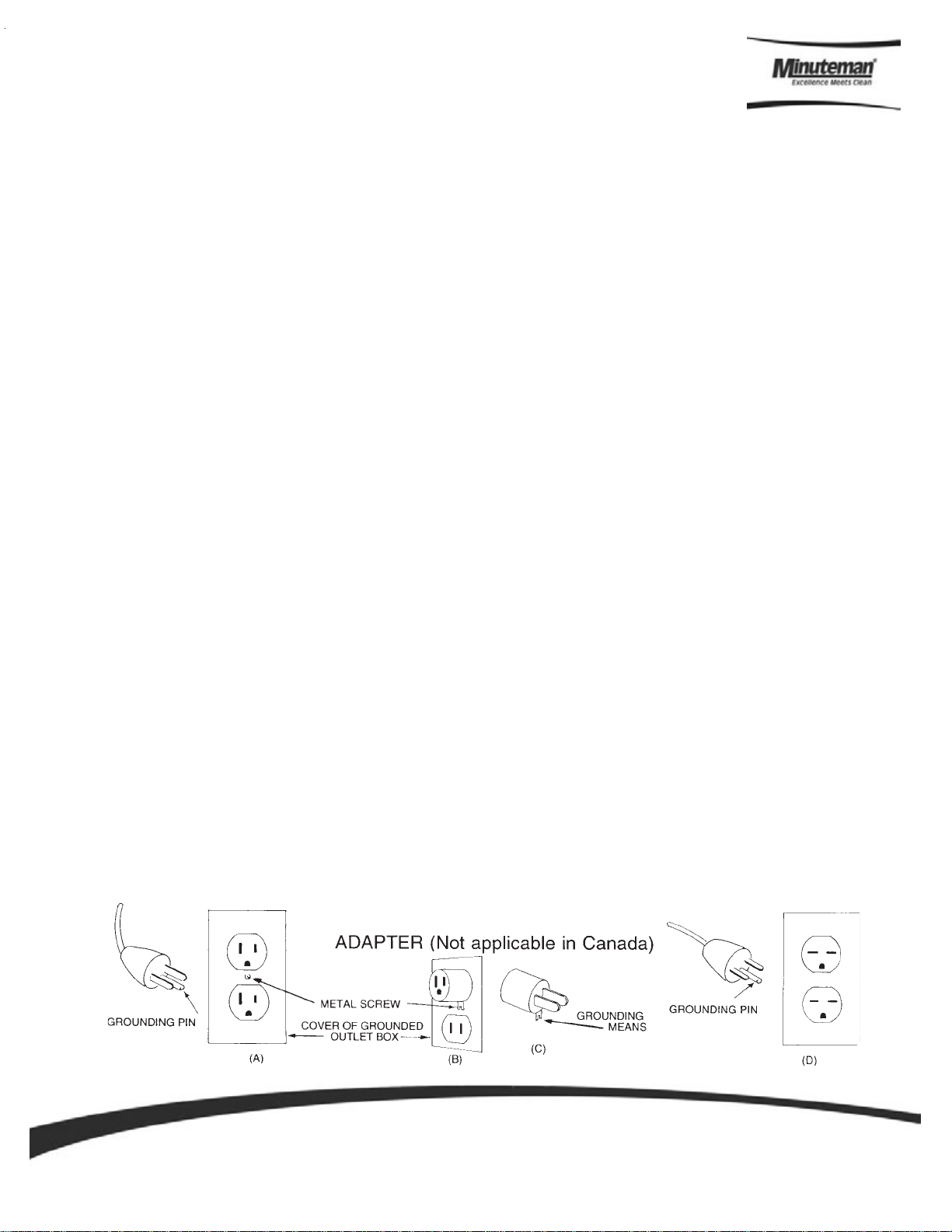

GROUNDING INSTRUCTIONS

This appliance must be grounded. If it should malfunction or breakdown, grounding provides a

path of least resistance for electric current to reduce the risk of electric shock. This appliance is

equipped with a cord having an equipment-grounding conductor and grounding plug. The plug

must be plugged into an appropriate outlet that is properly installed and grounded in accordance

with all local codes and ordinances.

DANGER

Improper connection of the equipment-grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or service person if you are in doubt as to whether the outlet is

properly grounded. Do not modify the plug provided with the appliance — if it will not fit the outlet,

have a proper outlet installed by a qualified electrician.

This machine is for use on a nominal 120 volt circuit and has a grounding plug that looks like the

plug illustrated in Sketch A. Make sure that the machine is connected to an outlet having the

same configuration as the plug. No adapter should be used with this appliance.

Parts an d Instruction Manual

Page 2

Page 6

WARNING

This vacuum may contain potentially hazardous dust depending on its application. Special handling

of contaminated disposal bags and filters is recommended. Disposal must be in compliance with

local EPA regulations

USER MAINTENANCE INSTRUCTIONS

All service and repair should be performed by qualified vacuum service represent ative or electrician.

No user serviceable components are employed in the electrical vacuum lid head assembly. No

lubrication of the motor is required.

CLOTH BAG & HOSE ASSEMBLY

Cloth bag and hose assembly are user maintenance items and can be replaced when worn out.

For optimum performance, empty and clean filter bag regularly. A clogged and dirty bag restricts

the flow of air and results in reduced vacuum. The hose assembly can be maintained by wiping

off with a dampened cloth of mild liquid soap and water, then allowed to dry.

CORD STORAGE

While not in use storage can be accomplished by winding cord around motor lid assembly. Cord

should be completely unwound from lid assembly during operation.

• Do not use with damaged cord or plug. If appliance is not working as it should, has been

dropped, damaged, left outdoors, or dropped into water, return to service center.

• Do not pull or carry by cord, use cord as handle, close a door on cord, or pull cord around

sharp edges or corners. Do not run appliance over cord. Keep cord away from heated surfaces.

• Do not unplug by pulling cord. To unplug, grasp the plug, not the cord.

• Do not handle plug or appliance with wet hands.

• Always unplug the machine when removing the motor head off the tank. This equipment

should be stored indoors and not exposed to rain.

Always unplug the machine when removing the motor head off the tank. This equipment should

be stored indoors and not exposed to rain.

Parts an d Instruction Manual

Page 3

Page 7

Operation and Filter Care Instructions

The Minuteman Lead Vacuum has been specifically designed to clean up lead dust. Special filters reduce the

incidence of airborne dust that would be created by any other method of cleaning.

• During the removal of hazardous dust, do not sweep, scoop, shovel, or in any manner handle other than by

• Do not at any time attempt to bypass, remove, substitute or by any other means change the filters used in this

• Use only approved Minuteman Lead Vacuum filters and filter bags.

• Before attempting to use and before cleaning, be certain that you fully understand the instructions given

The following instructions include the use of an optional paper filter protector (P.N. 761177PKG).

Tank/Filter Set-Up Procedure (Refer to Filter Assembly)

Each facility has its own individual and unique cleaning problems, it is suggested that you use the following:

1. Take the paper bag that has the cardboard collar attached and open it up by gently pulling the folds apart.

2. You will notice two creases on the top side of the collar; carefully bend the ends down (toward) the bag.

3. Insert this bag into the tank and push it to the bottom.

4. Locate the cardboard collar around the intake tube and gently work it up past the raised ring that runs around

5. Starting at the bottom of the cloth filter, slip the paper filter protector over the entire cloth filter until the elastic

6. Ensure that the inside steel frame that supports the cloth filter is inserted into the t ank with the cut out section

7. Position the lid onto the tank, making sure that the paper filter elastic is inside the cloth filter frame so that the

8. Snap the lid latches into place.

vacuuming.

vacuum.

for the setting up or cleaning/changing of filters of this vacuum.

the tube.

band on the paper filter protector goes around the black plastic frame of the cloth filter.

facing the front of the down tube. Then insert the cloth filter and paper filter protector inside the tank. Be careful

not to rip the paper filter protector when pushing the cloth filter with steel frame into the tank.

U.L.P.A. filter will go down inside the cloth filter. Make sure that the motor lid is seated onto the ring of the cloth

filter frame completely around the tank.

For proper cleaning of the tank and removal/changing of the filters, see “Procedures in Removing Contaminated

Filters and Cleaning of Contaminated Tank.”

Procedures In Removing Contaminated Filters and Cleaning of Contaminated Tank

Always wear a facemask and gloves when conducting this procedure.

1. Unplug the machine from the power source.

2. Carefully and slowly unlatch the tank latches and remove the vacuum lid only (be sure when you lift up on the

lid that the cloth filter stays inside the tank.) Set the lid with U.L.P.A. filter assembly aside.

3. Gently remove the cloth and paper filter protector from the t ank. Carefully place the paper and cloth filter into a

plastic bag. With one hand grab the bottom of the paper filter protector through the plastic bag and with the

other hand release the elastic band from around the cloth filter frame. Slide the cloth filter out of the paper bag.

Set the cloth filter and frame aside.

4. Before closing up the plastic bag with the used paper filter inside, check the prefilter attached to the U.L.P.A.

filter for any noticeable dirt. The prefilter should be changed every other time you change the paper filter or if

any dirt particles are noticed during inspection. Then the used prefilter can also be put into the plastic bag

before sealing up for disposal. See “Changing the Black Foam Prefilter”, for more information.

5. Carefully surround the paper debris bag with a plastic bag. Pull the opening of the plastic bag securely around

the down tube with one hand. Make sure the plastic bag completely encapsulates the debris bag. Push downward

on the debris bag on the debris bag’s cardboard collar until it slips off of the downtube.

(Continued on next page)

Parts an d Instruction Manual

Page 4

Page 8

(Cont’d) Procedures In Removing Contaminated Filters and Cleaning of Contaminated Tank

6. Slowly pull the top of the plastic bag upwards. When you have the plastic bag fully extended upwards, slowly

squeeze the plastic bag closed to avoid trapping excess air. Twist the plastic bag until enough plastic can be tied

into a knot.

7. Lift the bag out of the tank and dispose of it properly.

8. Before inserting another paper debris bag, t ake a wet paper towel and wipe out the inside of the tank of any dirt

contaminate. Put this inside the plastic bag along with the used paper filter protector and prefilter. This plastic

bag should also be twisted shut, tied into a knot and disposed of properly.

9. To help prolong the life of the U.L.P.A. filter, a spare cloth filter should be interchanged with the existing cloth

filter. Vacuum out when there is any noticeable dirt or soil. The cloth bag can also be sprayed with a garden

hose from the inside out to remove any soil. Make sure that the cloth filter is completely dry before reinstalling

it into the vacuum.

10. CAUTION: Any hazardous materials must be disposed of properly. Never throw contaminated debris into you

usual trash receptacle. Place debris in a plastic bag or can marked “Hazardous Materials” and take to a

hazardous waste handler.

11. For proper assembly of new filters, see “Tank Filter Set Up Procedures.”

Changing The Black Foam Prefilter

The prefilter should be changed, using all of the precautions previously mentioned.

The prefilter should be changed when any of the following takes place:

1. Anytime there is an indication of a filter tear during normal operation of the unit. This tear could be in any of the

filters used.

a. paper dust containment bag

b. paper bag protector

c. cloth filter bag

These tears would show up during the tank clean-out procedure, or....

2. Every other tank clean-out period. To change the prefilter , do the following before you do Step #3 of the normal

clean-out procedure.

a. Wipe down all of the exposed surfaces on the underside of the removed lid, using the dampened wiping

cloth.

b. Remove the prefilter from the U.L.P.A. filter . Be careful so as not to damage or puncture the U.L.P.A. media

used in the final filter. Do not attempt to clean the prefilter in any way; dispose of by placing it into the tan k

you are now in the process of cleaning. DO NOT USE ANY TOOLS TO REMOVE THE PREFILTER.

d. Before proceeding any further in cleaning the tank, first place a new prefilter (one only) onto the U.L.P.A.

filter.

Parts an d Instruction Manual

Page 5

Page 9

Filter Assembly

8

7

5

6

1) Intake

2) Disposable Paper Collector Bag, 384003PKG (10/pkg)

3) Disposable Paper Filter Protector, 761177PKG (10/pkg) (Optional)

4) Cloth Filter w/Frame

5) PreFilter

6) U.L.P.A. Filter

7) Safety Interlock

8) Exhaust

3

4

1

2

Changing Of Prefilters

In order to prolong the efficiency and performance of the critical filter it is recommended that each

pre-filter, debris bag and p aper filter protector be changed every time the debris bag is full. Change

the foam prefilter every second time or if a bag breaks or tears. Follow the manual for bag

replacement.

Whenever the vacuum is in operation or being emptied, the operator should be wearing protective

clothing and respirator for protection.

All used pre-filters and debris bags should be handled and disposed of in accordance with federal

E.P.A. regulations.

Parts an d Instruction Manual

Page 6

Page 10

Tools and Accessories

Part No. Description

A

B

C

D

E

829563 Dust Brush Complete

829562 Crevice Tool

1 1/4” (32 mm)

829565MCH Telescoping Wand T ube

829849 Hose Asy 1 1/4” x 8’ (32 mm x 2.4 m)

390013 Hose Cuff

762241 Hose

829566 Curved Hand T ool

829561 Combination Floor Tool

F

G

H

Parts an d Instruction Manual

829564 Upholstery T ool

384003PKG Disposable Paper Replacement

Filter Bags

Package of 10

761 177PKG

Disposable Paper Filter Protector

Package of 10

(Optional)

Page 7

Page 11

Exploded Views

Lid Assembly

Parts an d Instruction Manual

Page 8

Page 12

Lid Assembly BOM

Item Part No. Qty. Description

1 110029 1 Filter-ULP A, X829 Series

2 110030PKG 1 Prefilter Sleeve, 829/839, Pkg of 6

3 290017 2 Molded Vac Mtr Gasket

4 290031 1 Lid Gasket 294/6 Diecut

5 290032 1 Dome Seal 296

6 380001-4 1 Vac Motor 120V (ECM) w/ Wires

6A 380054 1 Vac Motor 240V

7 380005 2 Carbon Brush Replacement (ECM)

7A 380028 2 Carbon Brush Replacement

8 380064 1 Foam Ring

9 381020 1 Cord 16GA-3 50FT Med Grey

9A 740083 1 Cord F2 G1.5 MM 40FT

10 390062 1 O-Ring-Valve Seat Body

11 460001 1 Handle Basic 460 Black

12 460101 1 Motor Cap Black

13 460104MCH 1 Mtr Holdown 829 Series

14 460120 1 Motor Pan Assy 829 Series

15 700287 1 Grommet

16 710307 2 SCR-MC 6/32 x 1 ZINC

17 711124 1 SCR-ST-B 10 x .37 NI

18 711125 3 SCR-ST-B 10 x .5 NI

19 711160 9 SCR Hi/Lo #10 x 5/8 ZINC

20 711161 8 SCR Hi/Lo #10 x 3/4 ZINC

21 711162 2 SCR Hi/Lo #10 x 1 1/2 ZINC

22 711301 2 Nut-HEX 6/32 ST PL

23 711502 2 WSR-Flat #8

24 711551 2 WSR-Internal Lock #6

25 711553 1 WSR-Internal Lock #10

26 715009 1 Decal Warning to Avoid

27 740014 4 Term 14-16G 1/4 Full Ins Female

28 740029 1 Switch Snap SP ST PB NO/NC

29 740938 1 Wire Assy 16G Black 14.00”

30 809754 1 Switch Rocker

31 828893 1 Rivet-BAP KTR64BX

32 831801 1 Receptical

33 831801-1 1 Receptical Clip

34 832201 1 Motor Lid Cover 294 Dry

35 833237 1 Strain Relief w/Nut

*** 829117 1 Lid Assembly Comp Leadvac 115V

*** 829220 1 Lid Assembly Comp 230V

WARNING

This vacuum may contain potentially hazardous dust depending on its appilcation. Special handling of

contaminated disposal bags and filters is recommended. Disposal must be in compliance with local EPA

regulations

Parts an d Instruction Manual

Page 9

Page 13

T ank Assembly

Parts an d Instruction Manual

Item Part No. Qty. Description

1 390087 1 Gasket Diecut VNN

2 3901 10 1 Intake Assembly Aluminum

3 460109 1 Tank 6 Gal Low Intake

4 460114 2 Latch Poly Tank

5 460115 1 Dolly, Plast Vac Tnk Blk

6 460118 4 Caster

7 711160 4 SCR Hi/Lo #10 x 5/8 Zinc

8 712320 2 WSR .22 x .45 x .048 NYL

9 712638 2 Nut Hex 10-24 SS Nyloc

10 712824 2 SCR-MC 10-24 x .75 TRUSS HD ST

11 750118 1 Intake Assy Tube 4/6 Gal

12 828893 4 Rivet-BAP KTR64BX

*** 290010 1 Tank Asy 6 GIM LI IT

Page 10

Page 14

Bag Assembly

Parts an d Instruction Manual

Item Part No. Qty. Description

1 711909 4 Rivet Pop .19x.44 AL

2 712764 4 Washer #10 SS

3 760244MCH 1 Plastic Bag Frame w/Hole

4 760406PLT 1 Bag Frame 6 gal Plated

5 805040 1 Bag, Cloth Bag Only 6G

*** 800056 1 Bag Asy w/Frame 6gal

Page 11

Page 15

Minuteman International Made Simple Commercial Limited Warranty

Minuteman International, Inc. warrants to the original purchaser/user that the product is free from defects in

workmanship and mat erials under normal use. Minuteman will, at its option, repair or replace without charge, parts

that fail under normal use and service when operated and maintained in accordance with the applicable operation and

instruction manuals. All warranty claims must be submitted through and approved by factory authorized repair

stations.

This warranty does not apply to normal wear, or to items whose life is dependent on their use and care, such as belt s,

cords, switches, hoses, rubber parts, electrical motor components or adjustments. Parts not manufactured by

Minuteman are covered by and subject to the warranties and/or guarantees of their manufacturers. Please cont act

Minuteman for procedures in warranty claims against these manufacturers.

Special warning to purchaser -- Use of replacement filters and/or prefilters not manufactured by Minuteman or its

designated licensees, will void all warranti es expressed or implied. A potential health hazard exits wit hout original

equipment replacem ent .

All warranted items become the sole property of Minuteman or its original manufacturer, whic hever the case may be.

Minuteman disclai ms any implied war ranty, including the warranty of mer chantability and the warranty of fitness for a

particular purpose. Minuteman assumes no res ponsibility for any special, incidental or consequential damages.

This limited warranty is applicable only in the U.S.A. and Canada, and is extended only to the original user/purchaser

of this product . Customers outside t he U.S.A. and Canada should contact their local distributor for export warranty

policies. Minuteman is not responsible for costs or repairs performed by persons other than those specifically

authorized by Minut eman. This war ranty does not apply to damage from transportat ion, alterati ons by unauthorized

persons, misuse or abuse of the equipment, use of non-compatible chemicals, or damage to property, or loss of

income due to malfunct io ns of th e product.

If a difficulty develops with this machine, you should contact the dealer from whom it was purchased.

This warranty gives you specific legal rights, and you may have other rights which vary from state to state. Some

states do not allow the exclusion or limitation of special, incidental or consequential damages, or limitations on how

long an implied warr anty lasts, so the above exclusions and limitat i ons m ay not apply to you.

Cord Electric Group………. Three years parts, two years labor, ninety days travel (Not to exceed tw o hours)

Exceptions………. Port-A-Scrub, one year parts, six months labor

MPV 13, one year parts

MPV 14 and 18, two years parts, one y ear labo r

RapidAir blower, one year parts, one year labor

Explosion-Proof Vacuum, one year parts, one year labor

Pneumatic Vacuums, three years parts, one year labor

Battery Op er ated Group ….. Three years parts, two years labor, ninety days travel

(Not to exceed two hours )

Exceptions……Sweepers, one year parts, one year labor, ninety days travel

(Not to exceed two hours )

Internal Combustion Group….One year parts, one year labor, ninety day travel

(Not to exceed two hours)

Replac ement Parts……………..N i nety days

Batteries………………………….0-3 months replacement, 4-12 mont hs pro-rate

Polypropylene Plastic Tanks…Ten years, no additional labor

Parts an d Instruction Manual

111 South Rohlwing Road · Addison, Illinois 60101 USA

Phone 630- 627-6900 · Fax 630- 627-1130

E-Mail, www.minutemanintl.com

A Member of the Hako Group

987815

Page 12

Rev B 08/07

Loading...

Loading...