Minuteman C80115-04, C80115-01,C80115-02,C80115-03,C80115-04,C80130-01,C80130-02,C80155-01,C80155-02,C80215-01,C80215-02,C80215-03,C80215-04, C80115-01, C80130-01, C80130-02 Operation Service Parts Care

...Page 1

X-1000 &

Model:

MX-1000

Vacuum

Series

OPERATION

C80115-01,02,03,04

C80130-01,02

C80155-01,02

C80215-01,02,03,04

SERVICE PARTS

CARE

Revised 1/94

Page 2

OPERATING INSTRUCTIONS

INSPECTION

Carefully unpack and inspect your machine for shipping damage. Each unit is tested and thoroughly inspected before

shipment, and any damage is the responsibility of the delivering carrier who should be notified immediately. Read all

instructions carefully before operating.

WARNING

Model (X-1000) Dry Pickup Only, C80115-01, 02, 03, 04, C80130-01, 02, C80155-01, 02

Electrical shock could occur if used on wet surfaces. Do not expose to rain. Store indoors.

Electrical motors can cause explosions when operated near explosive materials or vapors. Do not operate this machine

near flammable materials such as solvents, thinners, fuels, grain dust, etc.

WARNING

Model (MX-1000) Wet & Dry Pickup, C80215-01, 02, 03, 04

To avoid electric shock, do not expose to rain. Store indoors.

CAUTION

Hazardous materials must be disposed of properly. Never throw contaminated debris in your usual trash receptacle.

Place debris in a plastic bag or can marked “ HAZARDOUS MATERIALS” and take to a hazardous waste handler.

ELECTRICAL

This machine is designed to operate on a standard 15 amp. 115 volt, 60 hz, AC circuit. Voltages below 105 volts AC or

above 125 volts AC could cause serious damage to the motor.

GROUNDING INSTRUCTIONS

To protect the operator from electrical shock, this machine must be grounded while in use. This machine is equipped

with an approved three-conductor power cord and grounding type plug to fit the proper grounding type receptacle.

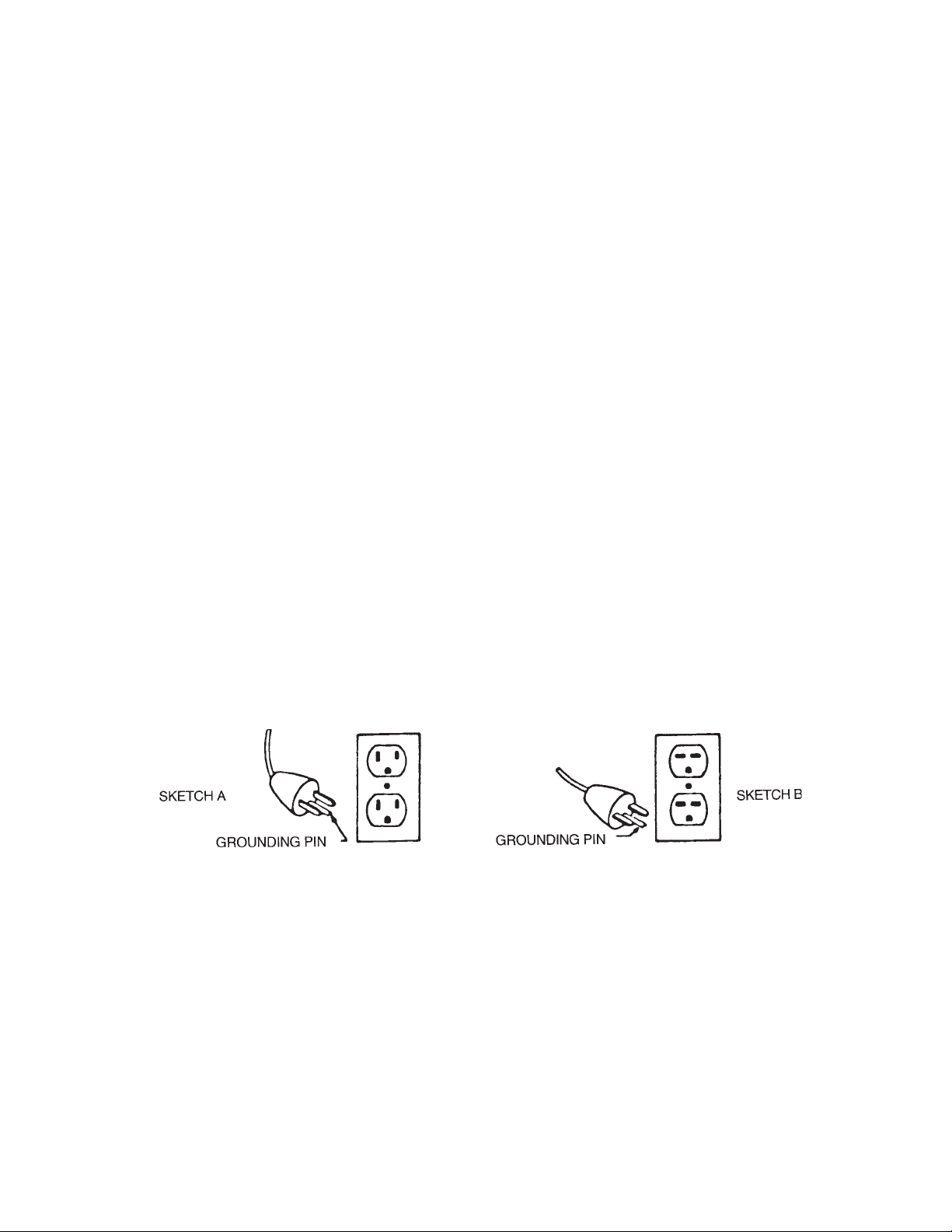

This machine is for use on a nominal 120 volt circuit and has a grounding plug that looks like the plug illustrated in

sketch A. Make sure that the machine is connected to an outlet having the same configuration as the plug. No adapter

should be used with this machine.

For equipment rated 150-250 volts: If the machine is provided with an attachment plug as shown in sketch B, it is

intended for use on a 240 volt (nominal) circuit. No adapter is available for this plug.

EXTENSION CORDS

If an extension cord is used, the wire size must be at least one size larger than the power cord on the machine and must

be limited to 25 feet in length. Extension cord must be three-wire grounded.

MAINTENANCE AND USAGE

Keep the motor intake cooling air screen clean. If this screen (on top of the motor) becomes clogged, it restricts the

flow of cooling air to the motor and will cause overheating.

No lubrication of the motor is required. Machine is equipped with sealed bearings.

For optimum performance, empty and clean filter bag regularly. A clogged and dirty bag restricts the flow of air and

results in reduced vacuum.

Check carbon brush periodically. Replace when worn down to approximately 1/2" in length.

Always unplug the machine when removing the motor head off the tank. This will prevent the accidental starting of the

motor and the possibility of fingers or objects getting into the unprotected impeller intake.

1

Page 3

OPERATING AND FILTER CARE INSTRUCTIONS

The Minuteman Model X-1000 Critical Filter Vacuum has been designed to clean up hazardous and toxic dust of all

types. A special High Efficiency Particulate Air (H.E.P.A.) filter and a series of “prefilters” used with this vacuum reduce

the incidence of airborne dust that would be created by any other method of cleaning.

During the removal of hazardous toxic dust, do not sweep, scoop, shovel, or in any manner handle other than vacuuming.

Do not at any time attempt to bypass, remove, substitute, or by any other means change the filters recommended for

use with this vacuum. Use only approved Minuteman filters and filter bags.

Do not at any time, or in any way, attempt to clean or remove dust particles that may collect or accumulate on the

surface of the H.E.P.A. filter media.

Do not reverse or attempt to clean “prefilters” which have accumulated dust, for the purpose of reusing them.

Since each facility has its own individual and unique cleaning problems, it is suggested that you use the following

guidelines in determining the length of time between filter changes and/or tank emptying:

1. Empty tank after accumulating about 20 pounds of debris.

2. Replace all prefilters each time you empty tank or replace collector bag. In “white room” applications where the

primary objective is to contain non-toxic dust, the “impact” prefilter should be visually checked to determine replacement need. Impact prefilter should be changed when they show dust accumulation.

The efficiency of your vacuum will be determined by the amount and the density of the material you are vacuuming. All

vacuums will lose efficiency as they become filled. The operator must, therefore, be the one to determine the frequency

for emptying and changing filters based on the efficiency and performance of the vacuum during the cleaning process.

The Model X-1000-15 vacuum lid assembly is equipped with a motor cooling air recirculating tube to prevent carbon dust

particles, generated within the motor assembly, from being exhausted out of the machine. The recirculating tube directs

the motor cooling air into the vacuum tank and through the prefilter and H.E.P.A. filter before it is exhausted into the

atmosphere. The recirculating tube requires a small amount of vacuum air flow to operate effectively which may result

in a slightly reduced vacuum performance. If you are not operating under “clean room” conditions that would require the

use of this device, you may disconnect it by simply removing the curved tube on the vacuum lid assembly and plugging

the hole/tube in the lid. Do not plug the hole/tube that is in the side of the dome.

TANK/FILTER SET-UP PROCEDURE FOR MODEL X-1000-15

1. Remove vacuum lid assembly from tank.

2. Install impaction prefilter No. 9, Page 5.

3. Place cloth filter bag onto and into tank using formed rubber gasket as a guide and press down firmly onto the tank

rim.

4. Position vacuum lid onto the tank, making sure that gasket of the lid is seated onto the rubber ring of the cloth bag

frame completely around tank.

5. Snap lid latches into place.

OPTION:

A. A disposable “filter bag protector”, No. 5, Page 17, can be used in the tank, installed ahead of the cloth filter bag.

The filter bag protector is inserted into the tank with the elastic band snapped around the rim of the tank. (About 2

inches of the bag should be outside the tank, then proceed with step 3 above.)

B. Intake down tube, see No. 14, Page 9, with disposable collector bag. If your tank assembly has this option, install

disposable bag by locating the cardboard collar around the intake tube and gently work it up past the raised ring

that runs around the tube, then proceed with step 3 above.

2

Page 4

PROCEDURE FOR REMOVING FILTERS AND FOR CLEANING OUT TANK

Model X-1000-15 Dry only when used for white room applications with non-hazardous materials

1. Unplug machine from power source.

2. Remove vacuum lid/motor assembly with H.E.P.A. filter. Inspect impaction prefilter No. 9, Page 5. If impaction filter

shows discoloration due to dust penetration, replace it with clean filter.

3. Remove cloth filter bag assembly No. 6, Page 17. Clean outside surface of filter bag by shaking in waste container

outside of white room. If another vacuum is available, use vacuum to clean bag.

4. If “optional” filter bag protector No. 5, Page 17, has been used, remove from tank and dispose.

5. Dispose of debris in tank assembly.

6. If “optional” tank with “intake down tube” No. 14, Page 9, has been used, remove disposal collector bag at bottom

of tube and dispose.

7. For proper assembly of new filters, see “Tank/Filter Set-up Procedure”, Page 2.

PROCEDURE FOR REMOVING CONTAMINATED FILTER AND

FOR CLEANING OF CONTAMINATED TANK

Model X-1000-15 Dry only when used for recovery of hazardous or toxic materials

For the protection of your health, you should always wear the proper approved or required face mask,

gloves and clothing as specified by your Safety Department for your particular application.

1. Unplug machine from power source.

2. Remove vacuum lid/motor assembly with H.E.P.A. filter.

3. Remove impaction prefilter, No. 9, Page 5, and place in proper hazardous waste disposal container.

4. Gently remove the cloth filter bag assembly; recommended method of cleaning is by vacuuming with another

H.E.P.A. vacuum.

5. Remove filter bag protector and place in hazardous waste disposal container. “Filter bag protector” is optional, No.

5, Page 17, however, it is recommended in all applications where hazardous, toxic materials are being recovered.

6. Dispose of debris in tank assembly.

7. If “optional” tank with “down intake tube”, No. 14, Page 9, has been used, remove disposable collector bag at

bottom of tube and dispose in proper container.

8. For proper assembly of new filters, see “Tank/Filter Set-up Procedure”.

9. CAUTION: Hazardous materials, including disposable filters and prefilters must be disposed of properly.

10. Never throw contaminated debris in your usual trash receptacle. Place debris in proper containers as

recommended by your Safety Department. All vacuum units should be properly tagged or labeled

“HAZARDOUS MATERIAL” and should only be used by authorized, trained personnel.

ASSEMBLY PROCEDURE 1

Model MX-1000-15 Dry only when used for recovery of hazardous or toxic materials

(see Schematic Fig. 1 on Page 17 for assembly)

1. Install No. 3 spacer gasket onto tank using formed rubber gasket as a guide.

2. Install No. 2 heavy-duty 20 gallon plastic bag liner into tank and drape about two inches over rim of spacer gasket.

3. Place No. 4, 1 to 1 adapter with hose intake, onto tank assembly. Center adapter onto spacer gasket and snap lid

latches into place.

4. Take the proper filter protector bag No. 5 and insert it into adapter. Then snap the elastic band around the rim of the

adapter. Allow two inches to overlap the adapter rim.

5. Place the cloth filter bag No. 6 onto and into the adapter, using the formed rubber gasket to center it.

6. Position the vacuum lid assembly No. 7 onto the adapter, making sure that the gasket of the lid is seated onto the

rubber ring of the cloth bag frame completely around the tank. Snap lid latches into place.

7. Install the tank plug No. 9 into hose intake on tank. All debris picked up through hose intake on 1 to 1

adapter will be deposited into bag liner No. 2 in tank assembly.

PROCEDURE FOR REMOVING DEBRIS

AND CHANGING FILTERS ON MODEL MX-1000-15 ABOVE

1. Remove the vacuum lid assembly and place on worktable.

2. Carefully remove cloth filter bag without disturbing paper filter protector.

3. Reach into bottom of filter protector; pull protector up while gathering together. Remove elastic band around

adapter rim and insert filter protector into plastic bag liner in lower tank assembly.

3

Page 5

4. Use damp disposable towels and wipe down inside of 1 to 1 adapter. Place wipers into plastic bag liner.

5. Unclamp lid latches and remove 1 to 1 adapter.

6. Unclamp holder on underside of H.E.P.A. filter, remove impaction filter and place in plastic bag liner.

7. Collect plastic bag liner from tank rim and tie closed.

8. Remove spacer gasket.

9. Carefully remove plastic bag liner from tank. Do not lift bag out. Turn tank assembly until it is horizontal with floor.

Slide bag liner out, avoiding intake deflector on inside.

10. Dispose of bag liner with debris in accordance with required procedures.

11. For proper assembly of new filters see “Assembly Procedure I - Model MX-1000-15 Dry only” on Page 17.

ASSEMBLY PROCEDURE II

Model MX-1000-15 wet vacuuming only when for recovery of liquid hazardous materials (see Schematic Fig. 2 on Page

17)

1. Install No. 8 water shut-off assembly into tank assembly, centering rubber gasket around rim of tank.

2. Place No. 10, 1 to 1 adapter onto tank, center, and snap lid latches into place.

3. Take the paper filter protector bag No. 5 and insert it into the adapter, then snap the elastic band around the rim of

the adapter. Allow 2 inches to overlap the adapter rim.

4. Place the cloth filter bag No. 6 onto and into the adapter, using the formed rubber gasket to center it.

5. Position the vacuum lid assembly No. 7 onto the adapter making sure that the gasket of the lid is seated onto the

rubber ring of the cloth bag frame completely around the tank. Snap lid latches into place.

6. Water shut-off will activate at approximately 12 gallon level, choking off vacuum.

OPTIONS: Water dump valve can be installed for emptying tank into floor drain. Must be factory installed.

PROCEDURE FOR EMPTYING TANK

1. Remove the vacuum lid assembly and place on work table.

2. Remove and inspect cloth filter bag for moisture. If bag is wet, allow to dry before reusing or replace with clean, dry

filter bag.

3. Remove and inspect filter bag protector for moisture. If bag is wet, replace with dry filter bag protector.

4. Remove 1 to 1 adapter.

5. Remove water shut-off assembly.

6. Dispose of liquid waste in accordance with required procedures.

7. If tank assembly is elevated above container receiving waste, tilt tank on rear wheels by lowering carriage handle

and dump waste into receiving container.

8. If optional dump valve has been installed, lift handle on valve to allow liquid to run out into receiving waste container

or floor drain.

USE OF 30 GALLON OR 55 GALLON ADAPTER

Conversion Options: Wet/Dry Applications

1. Your Model X-1000-15 vacuum can be converted or adapted to fit a 30 gallon or 55 gallon drum when larger

capacity is required.

2. Model X-1000-30 or X-1000-55 can be supplied as original equipment.

3. If you are converting your present X-1000-15 vacuum to 30 or 55 gallon capacity for dry recovery, you will need:

A. 30 or 55 gallon adapter ring, see Page 11.

B. 30 or 55 gallon drum, see Page 13.

C. Drum dolly, see Page 15.

For wet recovery, in addition to the above, you will need:

A. 1 to 1 adapter, see Page 17, No. 4.

B. Water shut-off, see Page 17, No. 8.

4. For proper assembly of new filters, follow “Tank/Filter Set-Up Procedure” on Page 3, supplementing adapter ring

and drum in place of regular tank assembly.

5. For dry recovery, use 30 gallon or 55 gallon heavy-duty drum liner draped over rim of drum before putting adapter

on drum. All material recovered will go into bag liner which can then be removed and replaced as required.

6. For wet recovery, 30 or 55 gallon drum can be equipped with dump valve, see No. 2, Page 13.

7. For wet recovery, install water shut-off assembly onto and into adapter ring and follow steps 2, 3, 4, and 5 as

outlined under Assembly Procedure II. Model MX-1000-15 Wet recovery only on Page 4.

4

Page 6

5

Page 7

Parts List

Item Part No. Qty. Description

1 101040PLT 1 Dome Motor

2 101010PTD 1 Cover, Air Exhaust

2a 750005 1 Exhaust Air Cover

3 101006PTD 1 Inter Vent Dome

3a 750007 1 Inter Vent Dome Assy.

4 480042MCH 1 Cast Motor Hold Down MCH

5 831524 1 Motor, 115V

5a 831526 1 Motor, 220V

6 480060 1 Casting, Lid Polished

6a 750640 1 Assy. Lid Cast Sub.

7 110003 1 Filter Mounting Plate

8 110001 1 H.E.P.A.

9 703007PKG 1 Impact Filter, Pkg. of 12

10 760013 1 Retainer Screen

11 750011 1 Filter Retainer Assy. Includes 10

12 381020 1 Cord Set, 16-3 50 Feet

13 101018 1 Assy. Cord M100

14 711515 1 WSR, Orifice

15 101030 3 Bracket

16 380002 1 Switch, Toggle 1.5 HP

17 101019 1 Switch Box

18 101020 1 Plate, Off/On Indicator

19 807297 4 Brush, Carbon

20 101033 1 Insulation, Foam 3 x 15 x 1

22 101007 1 Insulation, Foam Rub. 1 x 2.50 x 23

23 101009 1 Gasket, Rub. .25 x .56 x 28

24 101005 4 Gasket, Rub. .75 x 3.19 x 4.37

25 480049 4 Gasket Motor

26 480052 1 Gasket, .25 x .87 x .50

27 480040 1 Felt, .25 x 3 x 28

28 828995 2 Motor Gasket

29 480044 1 Felt, Perforated Motor

30 101008 2 Grommet, Rubber

31 100028 2 Strain Relief

32 711401 5 Nut-Riv 10-32

33 760006 3 Ring, Clamp On

34 711202 4 Bolt, 1/4-20 x .50 ST PL

35 711544 4 WSR, Helical SPR LOC 1/4

36 711574 4 WSR, Flat 1” OD x .25 ID

37 710355 3 SCR-MC 10-32 x .50 ST PL

38 710331 8 SCR-MC 8-32 x .75 ST PL

39 710329 8 SCR-MC 8-32 x .50 ST PL

40 710365 2 SCR-MC 10-32 x 1.75 ST PL

41 710353 2 SCR-MC 10-32 x .37 ST PL

42 710356 8 MCR-MC 10-32 x .62 ST PL

43 711543 2 WSR, Helical SPR LOC #10

45 740005 3 Cap, Wire 18-14 73B

46 380061 8 Bushing

47 380032 1 Strain Relief, Round

48 761076 1 Hose

49 760877 1 Gasket

53 740043 2 Tube w/Nut

55 711543 3 #10 Lockwasher

56 711304 3 Nut 8/32

**** 110110 Lid Assy. Comp. 115V

**** 110220 Lid Assy. Comp. 220V

6

Page 8

Parts Listing

Item Part No. Qty. Description

1 760131 1 Molded Bag Ring

2 805018 1 Gasket

3 805054 1 Bag Only

4 750097 Cloth Bag Frame

5 750405 1 Assembly - plate water shut-off

6 760231MCH 1 Ring, Bag Retainer

7 380046 1 Ball, Float

8 380045CTD 1 Cage Float Assembly

9 760234 1 Lint Trap Bag

10 760260 1 Spring, Retainer

11 711203 4 BLT, 1/4-20 x .50 HHMS

12 711519 4 WSR, Flat 1/4 ID x 1” OD

13 711373 4 Nut, Nyloc 1/4-20

7

Page 9

Parts Listing

Item Part No. Qty. Description

1 761054 2 Latch

2 110902 1 Adapter 1:1 PTD Inc. #1

2a 110901 1 Adapter 1:1 SS Inc. #1

3 900036 1 Gasket

4 900112POL 1 Intake

5 750402 1 Plug Assembly

6 710356 2 SCR-MC 10-32 x .62

7 500033 1 Knob

8 710530 1 SCR-MC 8-32 x .50

9 900035 1 Deflector

10 711503 2 WSR, Flat #10

11 711543 2 WSR, Lock #10

12 711310 2 Nut-Hex 10/32

13 711502 1 WSR, Flat #8

14 711542 1 WSR, Lock #8

15 711304 1 Nut-Hex 8/32

8

Page 10

9

Page 11

Parts List

15 Gallon Painted/Stainless Tank with Molded Intake

Item Part No. Qty. Description

1 900001 1 Tank, PTD 15 Gallon

1A 900003POL 1 Tank, Polished 15 Gallon SS

2 711352 2 Nut - Acorn 1/4-20 ST

3 900038 2 Clamp, Handle

4 390110 1 Intake Assy., Aluminum

5 761054 2 Latch

6 900037PLT 1 Handle, Plated

7 390016 1 Molded Downtube

8 711915 2 Rivet Tube

9 711503 4 Washer, #10

10 711505 4 Washer, Flat

11 711202 2 BLT-HH 1/4-20 x .50

12 711591 4 WSR-Rubber

13 390087 1 Gasket

14 712537 2 SCR-Truss 10-24 x .75SS

15 760984PTD 1 Bracket, Wheel

16 711005 4 SCR-SK 1/4-20 x .31

17 711006 6 SCR-SK 1/4-20 x .62

18 280016 2 Caster, 3” Swivel

19 900066 2 Axle

20 711524 2 WSR-Wave .52 x .87 x .01

21 900040 2 Wheel, 8.187

22 711594 2 WSR-Flat .88 x .03 NI

23 711713 2 Retaining Ring - E Ext.

24 130032 2 Cap, Retainer

25 712638 2 Nut-Hex 10-24 SS Nyloc

26 712764 2 WSR-Flat #10 SS

27 711372 1 Nut-Hex 8-32 Nyloc

28 711502 1 WSR-Flat #8

29 900035 1 Deflector, Intake

30 710530 1 SCR-MC 8-32 x .50

** 390012 Molded Adapter 1 1/4

** 390015 Molded Adapter 1 1/2

** 390020 Molded Adapter 2.00

** 750220 Tank Assembly Complete, 15 Gal. PTD Asbestos

** 750221 Tank Assembly Complete, 15 Gal. SS Asbestos

** 750322 Wheel Bracket Assembly Complete

** 750387 Tank Assembly SS w/Downtube

** 750392 Tank Assembly PTD w/Downtube

** 750382 Tank Assembly SS w/Deflector

** 750381 Tank Assembly PTD w/Deflector

10

Page 12

Parts List

Item Part No. Qty. Description

1 806016PTD 1 55 Gal. Adapter, Painted

1a 806015PTD 1 30 Gal. Adapter, Painted

2 390100 1 Molded Intake

3 900035 1 Deflector, Intake

4 761054 2 Latch

5 390087 1 Gasket Diecut Poron Intake

7 806006 1 Gasket, Raw

8 710530 1 SCR-MC 8-32 x .50 BR

9 712824 2 SCR-THMS 10-24 x .75 STPL

10 711915 4 Rivet-Tube .19 x .28 NIPL

11 711503 6 WSR-Flat #10

12 711543 2 WSR-Helical #10

13 712638 2 Nut, Hex 10/24 SS Nyloc

14 711502 1 WSR-Flat #8

15 711542 1 WSR-Helical #8

16 711304 1 Nut-Hex 8-32 ST PL

*** C80601-70 30 Gal. Adapter Assy.

*** C80601-80 55 Gal. Adapter Assy.

11

Page 13

Parts Listing

Item Part No. Qty. Description

1 900078PTD 1 Tank 55 Gal. PTD Less Handles

1a 900015PTD 1 Tank 55 Gal. PTD No Handles

2 900047 1 Dump Valve

3 900031POL 2 Handle, Tank Polished

4 711203 4 BLT, HH 1/4-20 x .62

5 711591 4 Washer, Rubber

6 711505 4 WSR, Flat 1/4

*** C90007-80 Tank 30 Gal. Complete

*** 805037PKG Drum Liner 30 Gal. Pkg. 12

*** 805046PKG Drum Liner 55 Gal. Pkg. 12

12

Page 14

Parts Listing

Item Part No. Qty. Description

1 750045 1 Weldment Dolly 30/55

2 900051 1 Weldment, Handle

3 900052 2 Grip, Handle

4 900080 1 Spring, Torsion RH

5 900081 1 Spring LH

6 711642 2 Rollpin

7 761050 2 Caster, Rigid 5”

8 761049 2 Caster, Swivel 5”

9 711545 16 WSR, Helical SPR LOC 5/16

10 711319 16 Nut-Hex 5/16-18 ST PL

**** 900048 Dolly Cart Complete

13

Page 15

Parts Listing

1 750381 1 Tank Assy. Painted

Item Part No. Qty. Description

1a 750382 1 Tank Assy. SS

2 762237PKG 1 Plastic Liner, Pkg. of 10

3 110409 1 Gasket Spacer

4 110903 1 Adapter 1:1 w/Intake SS

4a 110904 1 Adapter 1:1 w/Intake Painted

5 805038PKG 1 Disposable Paper Bag, Pkg. of 12

6 805057 1 Cloth Bag Assembly

7 110110 1 Lid Assembly, Complete

8 110408 1 Water Shut-off Assembly

9 750402 1 Plug Assembly

10 110901 1 Adapter 1:1 SS

10a 110902 1 Adapter 1:1 Painted

14

Page 16

LIMITED WARRANTY

Minuteman International, Inc. warrants to the original purchaser/user that this product is free from defects in workmanship and

materials under normal use and service for a period of three years from date of purchase. In addition, Minuteman International,

Inc. will, at its option, honor labor warranty claims for the first 12 months from date of sale, provided such claims are submitted

through and approved by factory authorized repair stations. Minuteman International, Inc. will, at its option, repair or replace

without charge, except for transportation costs, parts that fail under normal use and service when operated and maintained in

accordance with the applicable operation and instruction manuals.

This warranty does not apply to normal wear, or to items whose life is dependent on their use and care, such as belts, cords,

switches, hoses, rubber parts, electrical motor components or adjustments. Parts not manufactured by Minuteman International,

Inc. such as engines, batteries, battery chargers, hydraulic pumps, and tires are covered by and subject to the warranties and/

or guarantees of their manufacturers. Please contact Minuteman International, Inc. for procedures in warranty claims against

these manufacturers.

Special warning to purchaser — Use of replacement filters and/or prefilters not manufactured by Minuteman International, Inc.

or its designated licensees, will void all warranties expressed or implied.

A potential health hazard exists without exact original equipment replacement.

All warranteed items become the sole property of Minuteman International, Inc. or its original manufacturer, whichever the case

may be.

Minuteman International, Inc. disclaims any implied warranty, including the warranty of merchantability and the warranty of

fitness for a particular purpose. Minuteman International, Inc. assumes no responsibility for any special, incidental or consequential

damages.

This limited warranty is applicable only in the U.S.A. and Canada, and is extended only to the original user/purchaser of this

product. Customers outside the U.S.A. and Canada should contact their local distributor for export warranty policies. Minuteman

International, Inc. is not responsible for costs or repairs performed by persons other than those specifically authorized by Minuteman

International, Inc. This warranty does not apply to damage from transportation, alterations by unauthorized persons, misuse or

abuse of the equipment, use of non-compatible chemicals, or damage to property, or loss of income due to malfunctions of the

product.

If a difficulty develops with this machine, you should contact the dealer from whom it was purchased.

This warranty gives you specific legal rights, and you may have other rights which vary from state to state. Some states do not

allow the exclusion or limitation of special, incidental or consequential damages, or limitations on how long an implied warranty

lasts, so the above exclusions and limitations may not apply to you.

World Headquarters Minuteman Canada, Inc.

Minuteman International, Inc. 2210 Drew Road

111 South Rohlwing Road Mississauga, Ontario

Addison, Illinois 60101 L5S 1B1

(630) 627-6900 (905) 673-3222

FAX (630) 627-1130 FAX (905) 673-5161

987804

Printed in U.S.A.

Loading...

Loading...