Page 1

705 Series

Model:Model:

Model:

Model:Model:

Industrial Air

Operated Vacuum

OPERAOPERA

OPERA

OPERAOPERA

TIONTION

TION

TIONTION

SERVICESERVICE

SERVICE

SERVICESERVICE

PP

P

PP

ARAR

AR

ARAR

C70555-55C70555-55

C70555-55

C70555-55C70555-55

C70555-56C70555-56

C70555-56

C70555-56C70555-56

TSTS

TS

TSTS

CARECARE

CARE

CARECARE

Revised 4/05

Page 2

MODEL 705 SINGLE VENTURIMODEL 705 SINGLE VENTURI

MODEL 705 SINGLE VENTURI

MODEL 705 SINGLE VENTURIMODEL 705 SINGLE VENTURI

AIR OPERAAIR OPERA

AIR OPERA

AIR OPERAAIR OPERA

TED WET/DRTED WET/DR

TED WET/DR

TED WET/DRTED WET/DR

YY

Y

YY

V V

V

V V

ACUUMACUUM

ACUUM

ACUUMACUUM

OPERAOPERA

OPERA

OPERAOPERA

INSPECTIONINSPECTION

INSPECTION

INSPECTIONINSPECTION

Carefully unpack and inspect your machine for shipping damage. Each unit is tested and thoroughly

inspected before shipment, therefore, any damage is the responsibility of the delivering carrier who

should be notified. Read all instructions carefully before operating.

SPECIALSPECIAL

SPECIAL

SPECIALSPECIAL

Air operated equipment can generate static electricity during use. S tatic dissipating arcing can be

generated and occur if equipment and accessories are not grounded. Risk of explosion is possible

if operated near explosive materials or vapors. Do not operate this equipment near flammable

materials such as solvents, thinners, fuels, grain dust, etc.

AIR PRESSURE AIR PRESSURE

AIR PRESSURE

AIR PRESSURE AIR PRESSURE

For maximum performance, operate with requirements listed below:

705 Single Venturi 1/2" 100 46

W W

ARNINGARNING

W

ARNING

W W

ARNINGARNING

AND C.FAND C.F

AND C.F

AND C.FAND C.F

Model Air Supply Line Maximum Pressure C.F.M.

.M. VOLUME REQUIRED.M. VOLUME REQUIRED

.M. VOLUME REQUIRED

.M. VOLUME REQUIRED.M. VOLUME REQUIRED

TING INSTRUCTIONSTING INSTRUCTIONS

TING INSTRUCTIONS

TING INSTRUCTIONSTING INSTRUCTIONS

Air pressure control valve can be regulated to operate with lower pressure and C.F .M. when maximum

is not required. OPTIONAL: Air pressure regulator can be attached at air valve for positive air pressure

and C.F .M. control.

ASSEMBLASSEMBL

ASSEMBL

ASSEMBLASSEMBL

1. For wet recovery , attach float assembly #515003, page 4, to underside of vacuum lid with #710359

screw and washer #71 1543 provided.

2. For dry recovery , att ach filter bag assembly #805047, page 5, to underside of vacuum lid. Float

assembly already attached does not have to be removed. To attach filter, refer to page 8 for

assembly .

Always remove the filter bag assembly when vacuum is used for wet recovery .

YY

PROCEDURE FOR MODEL PROCEDURE FOR MODEL

Y

PROCEDURE FOR MODEL

YY

PROCEDURE FOR MODEL PROCEDURE FOR MODEL

705 WET/DR 705 WET/DR

705 WET/DR

705 WET/DR 705 WET/DR

YY

Y

YY

V V

V

V V

ACUUMACUUM

ACUUM

ACUUMACUUM

1

Page 3

2

Page 4

DescriptionDescription

DescriptionDescription

Description

QtyQty

QtyQty

Qty

Part NoPart No

Part NoPart No

Part No

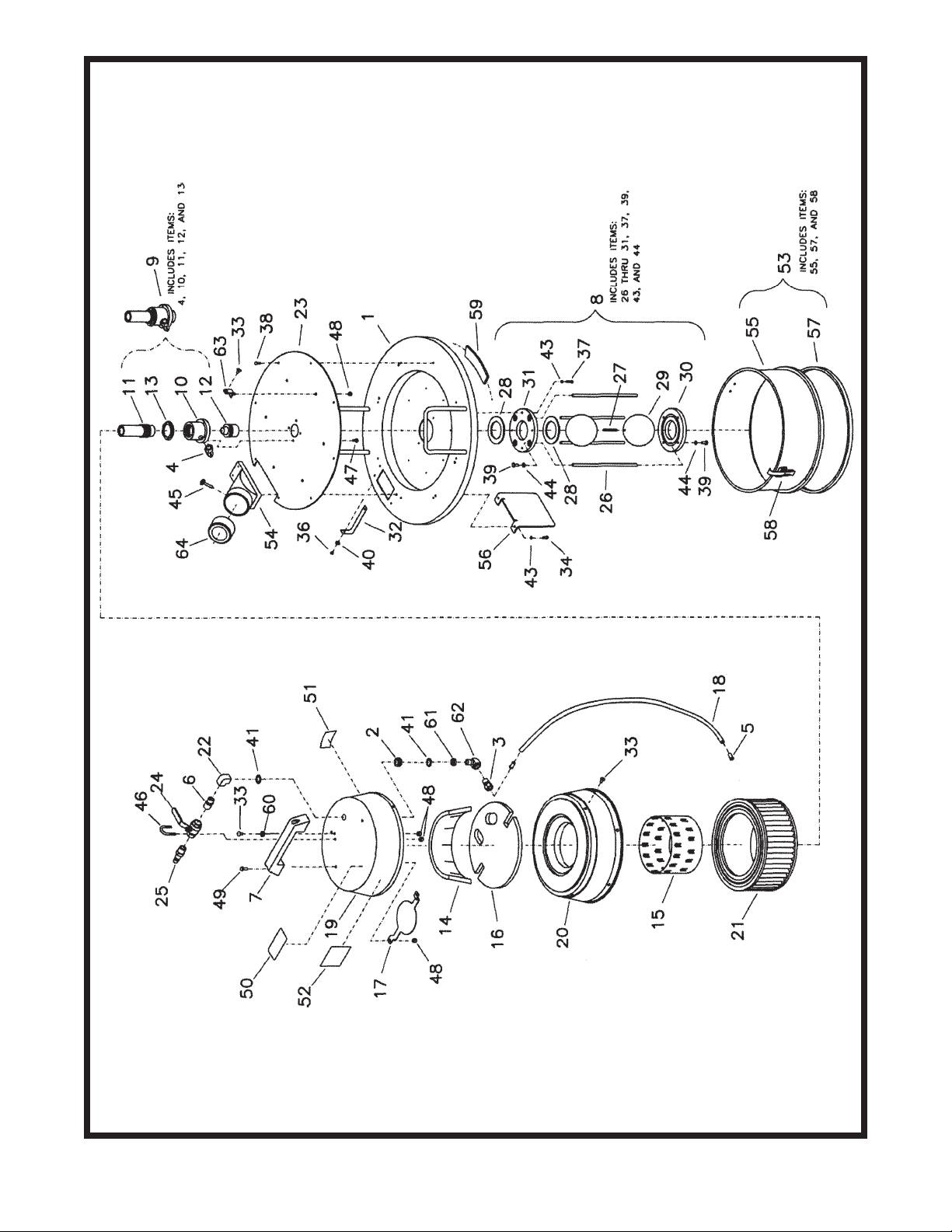

33 710178 10 SCR-MC TR HD 1/4-20 x .50 Zinc

ItemItem

ItemItem

Item

TS LISTTS LIST

TS LISTTS LIST

TS LIST

ARAR

ARAR

AR

PP

PP

P

34 710255 4 SCR-MC 10-32 x .62 Zinc

35 710331 8 SCR-MC 8-32 x .75 Zinc

36 710352 1 SCR-MC 10-32 x .25 Zinc

37 710360 2 SCR-MC 10-32 x 1 Zinc

38 711109 8 SCR-ST-B 12 x .50 Zinc

39 711203 8 BLT-HH 1/4-20 x .62

40 711503 2 WSR-Flat #10

41 711513 2 WSR-Flat .689 x 1.06 x .029 SS

42 711542 8 WSR-Helical #8

43 711543 5 WSR-Helical #10

44 711544 8 WSR-Helical 1/4

45 712016 1 SCR-Thumb 1/4-20 x 1.25 Nickel

46 712105 1 Bolt-U 1/4-20

47 712536 4 SCR-MC 10-24 x .62 SS

48 712667 15 Nut-Hex Nyloc 1/4-20 SS

49 713002 2 BLT HH 1/4-20 x .75 #5

50 715003 1 Decal, Air Pressure 2.00 x 4.00

51 715029 1 Decal, Serial Nameplate

52 715388 1 Decal - QAV

53 750326 1 Splash Shield 55G

54 760008PTD 1 Intake Painted

55 760033 1 Adapter Ring Manometer

56 760159 1 Splash Guard

57 760165 1 Edging 50 3/4” Long

58 761054 2 Latch

59 806006MCH 1 Lid Gasket, Sealing

60 81-120-A 1 Spacer .316x.626x.210

61 829285PL T 1 Spacer-.25x.875x.687 Plate

62 830062 1 Fitting-90 3/8MPT 3/8FPT Brass

63 832106 6 Bracket Mounting T ab

64 900056 1 Adapter Intake

DescriptionDescription

DescriptionDescription

Description

QtyQty

QtyQty

Qty

Part NoPart No

Part NoPart No

Part No

1 252003 1 Lid Weldment w/ Handles

2 260274 1 Grommet

3 420008 1 Male Connector

4 420009 1 Fitting - Elbow Male

5 420011 2 Fitting - Brass Insert

6 420017 1 Fitting - Hex Nipple Reducer

ItemItem

ItemItem

Item

7 460000 1 Handle 460 Lid Black

8 515003 1 50 Gal Water Shut Off

9 700010 1 Single Venturi Assembly

10 700011 1 Venturi Housing

11 700012 1 Venturi Exhaust T ube

12 700013 1 Venturi Int ake

13 700014 1 Venturi Locnut

14 700016 1 Felt Liner

15 700017 1 Perforated Shield

16 700018 1 Dome Felt

17 700019 1 Air Deflector

18 700021 1 Poly Hose 32" Long

3

19 700022PTD 1 Cover 701 PTD

20 700023PTD 1 Outer Housing Painted

21 700026 1 Exhaust Filter

22 700028 1 Fitting-90 3/8FPT x 3/8FPT Brass

23 700051 1 Base Lid Cover 701

24 701009 1 .50 Valve

25 701010 1 .50 Coupler - Male

26 701012 4 Rod, Spacer

27 701013 1 Stud

28 701015 2 Gasket, 2.25 x 3.50 x .12

29 701016 2 Ball, Float 4" Dia

30 701041 1 Plate, End Cap Water Shut

31 701042 1 Plate, End Cap Water Shut

32 701204 1 Wire, Braided Ground Strap

Page 5

Parts ListingParts Listing

Parts Listing

Parts ListingParts Listing

ITEMITEM

ITEM

ITEMITEM

PP

ARAR

TT

NO. NO.

P

AR

T

NO.

PP

ARAR

TT

NO. NO.

QTYQTY

QTY

QTYQTY

DESCRIPTIONDESCRIPTION

DESCRIPTION

DESCRIPTIONDESCRIPTION

1 701012 4 Rod, spacer

2 701013 1 S tud

3 701015 2 Gasket, 2.25 x 3.50 x .12

4 701016 2 Ball, float 4 dia.

5 701041 1 Plate, end cap water shut

6 701042 1 Plate, end cap water shut

7 710360 2 SCR-MC 10-32 x 1 Zinc

9 71 1543 2 WSR, Helical #10

8 71 1203 8 BLT , HH 1/4-20 x .62

10 71 1544 8 WSR, Helical 1/4

****

515003 50 gal water shut off

4

Page 6

PP

P

PP

ARAR

TS LISTTS LIST

AR

TS LIST

ARAR

TS LISTTS LIST

ITEMITEM

ITEM

ITEMITEM

PP

ARAR

TT

NO. NO.

P

AR

T

NO.

PP

ARAR

TT

NO. NO.

QTYQTY

QTY

QTYQTY

DESCRIPTIONDESCRIPTION

DESCRIPTION

DESCRIPTIONDESCRIPTION

1 500041PTD 1 Frame Bag Filter PTD

2 805018 1 Gasket, Bag Assy

3 805036 1 Bag Cloth bag only

4 805057 1 Bag assy., complete

5

Page 7

Parts ListingParts Listing

Parts Listing

Parts ListingParts Listing

ITEMITEM

ITEM

ITEMITEM

PP

ARAR

TT

NO. NO.

P

AR

T

NO.

PP

ARAR

TT

NO. NO.

QTYQTY

QTY

QTYQTY

DESCRIPTIONDESCRIPTION

DESCRIPTION

DESCRIPTIONDESCRIPTION

1 900015PTD 1 T ank 55 Gal. PTD No Handles

2 900047 1 Dump V alve 30 & 55 G

*** 805046PKG Drum Liner 55 Gal., Pkg. 12

6

Page 8

Parts ListingParts Listing

Parts Listing

Parts ListingParts Listing

ITEMITEM

ITEM

ITEMITEM

PP

ARAR

TT

NO. NO.

P

AR

T

NO.

PP

ARAR

TT

NO. NO.

QTYQTY

QTY

QTYQTY

DESCRIPTIONDESCRIPTION

DESCRIPTION

DESCRIPTIONDESCRIPTION

1 71 1319 16 Nut-Hex 5/6-18 ST PL

2 71 1545 16 WSR, helical 5/16

3 71 1642 2 Pin-Roll .187 x 1.00

4 750045 1 Weldment dolly 30/55

5 761049 2 Caster , swivel grease seal

6 761050 2 Caster , rigid 5"

7 900051 1 Weldment, handle

8 900052 2 Grip, handle

9 900080 1 Spring, torsion RH Zinc

10 900081 1 Spring, torsion LH Zinc

**** 900048 Dolly cart complete

7

Page 9

8

Page 10

OPTIONALOPTIONAL

OPTIONAL

OPTIONALOPTIONAL

AA

A

AA

INDUSTRIAL INDUSTRIAL

INDUSTRIAL

INDUSTRIAL INDUSTRIAL

TT

OOLS OOLS

T

OOLS

TT

OOLS OOLS

Part No.Part No.

Part No.

Part No.Part No.

800024 3" Rd Dust Brush Complete

800022 5" Rd Dust Brush Complete

800023 Bristle Insert 5"

800175MCH Dust Brush HSG 5"

800176MCH Dust Brush HSG 3"

800025 Bristle Insert 3”

AND AND

AND

AND AND

ACCESSORIESACCESSORIES

ACCESSORIES

ACCESSORIESACCESSORIES

DescriptionDescription

Description

DescriptionDescription

BB

B

BB

CC

C

CC

DD

D

DD

EE

E

EE

FF

F

FF

GG

G

GG

800034 24" Crev Tool Aluminum, Complete

800015 Wand Assy. 1-1/2, Complete

800017 Set Tube, High-up 10'

800064 5' Tube Lower Section

800019 5' Section Upper

800116 Swivel, Hose End Exp, Complete

800016 Coupling Nylon

800020 Hose Coupling

711916 Rivet

801010 Hose Assy. 1-1/2 x 10'

801014 Cuff

801044 Hose

800032 6" Curved Pipe Tool, Complete

711006 Set Screw

800033 Bristle Insert Curved 6'

800193POL 6" Curved Pipe Tool

HH

H

HH

II

I

II

JJ

J

JJ

KK

K

KK

800070 12" Gulper Tool, Complete

710356 SCR-MC 10-32 x .65

711503 SCR-MC 10-32 x .75

800187PTD Gulper Nozzle

800217 Fibre Shoe Rear

800218 Fibre Shoe Front

800108 14" Fibre Tool Complete

710530 Screw 8/32 x 1/2 Brass

800003MCH Fibre Shod

800178PTD Tool Casting

800038 6" Tool w/Handle Tube, Complete

800029 Bristle Insert Replacement

711005 Set Screw

800059 Bumper

800139 Al. Tube

800177MCH Uphl. Nozzle

800109 14" Squeegee, Complete

710330 SCR-SC 8-32 x .62

800121 14" Retaining Strip

800178PTD Casting, Tool MCH

800239 Blade Sqeegee Wide

800240 Blade Squeegee Narrow

9

Page 11

LIMITED WLIMITED W

LIMITED W

LIMITED WLIMITED W

Minuteman International, Inc. warrants to the original purchaser/user that this product is free from defects in workmanship and

materials under normal use and service for a period of three years from date of purchase. In addition, Minuteman International,

Inc. will, at its option, honor labor warranty claims for the first 12 months from date of sale, provided such claims are submitted

through and approved by factory authorized repair stations. Minuteman International, Inc. will, at its option, repair or replace

without charge, except for transportation costs, parts that fail under normal use and service when operated and maintained in

accordance with the applicable operation and instruction manuals.

This warranty does not apply to normal wear, or to items whose life is dependent on their use and care, such as belts, cords,

switches, hoses, rubber parts, electrical motor components or adjustment s. Parts not manufactured by Minuteman International,

Inc. such as engines, batteries, battery chargers, hydraulic pumps, and tires are covered by and subject to the warranties and/

or guarantees of their manufacturers. Please contact Minuteman International, Inc. for procedures in warranty claims against

these manufacturers.

SS

pecial warning to purchaserpecial warning to purchaser

S

pecial warning to purchaser — Use of replacement filters and/or prefilters not manufactured by Minuteman International, Inc.

SS

pecial warning to purchaserpecial warning to purchaser

or its designated licensees, will void all warranties expressed or implied.

A potential health hazard exists without exact original equipment replacement.

All warranteed items become the sole property of Minuteman International, Inc. or its original manufacturer, whichever the case

may be.

Minuteman International, Inc. disclaims any implied warranty, including the warranty of merchantability and the warranty of

fitness for a particular purpose. Minuteman International, Inc. assumes no responsibility for any special, incidental or consequential

damages.

ARRANTYARRANTY

ARRANTY

ARRANTYARRANTY

This limited warranty is applicable only in the U.S.A. and Canada, and is extended only to the original user/purchaser of this

product. Customers outside the U.S.A. and Canada should contact their local distributor for export warranty policies. Minuteman

International, Inc. is not responsible for costs or repairs performed by persons other than those specifically authorized by Minuteman

International, Inc. This warranty does not apply to damage from transportation, alterations by unauthorized persons, misuse or

abuse of the equipment, use of non-compatible chemicals, or damage to property, or loss of income due to malfunctions of the

product.

If a difficulty develops with this machine, you should contact the dealer from whom it was purchased.

This warranty gives you specific legal rights, and you may have other rights which vary from state to state. Some states do not

allow the exclusion or limitation of special, incidental or consequential damages, or limitations on how long an implied warranty

lasts, so the above exclusions and limitations may not apply to you.

WW

orld Headquartersorld Headquarters

W

orld Headquarters Minuteman Canada, Inc.

WW

orld Headquartersorld Headquarters

Minuteman International, Inc. 2210 Drew Road

1 11 South Rohlwing Road Mississauga, Ontario

Addison, Illinois 60101 L5S 1B1

(630) 627-6900 (905) 673-3222

FAX (630) 627-1130 FAX (905) 673-5161

987707

Printed in U.S.A.

Loading...

Loading...