Page 1

®

BATTERY CHARGER

LOOK FOR THIS SYMBOL TO POINT OUT SAFETY PRECAUTIONS. IT MEANS:

IF YOU DO NOT FOLLOW THESE

PART NO. 957718

PLEASE SAVE THESE IMPORTANT SAFETY AND OPERATING INSTRUCTIONS

For correct operation of the equipment, it is important to read and be familiar

with this entire manual before installing and operating the charger.

DO NOT DISCARD THIS MANUAL AFTER READING.

BECOME ALERT—YOUR SAFETY IS INVOLVED.

SAFETY INSTRUCTIONS, INJURY OR PROPERTY DAMAGE CAN OCCUR.

INTRODUCTION

This battery charger is designed to recharge deepcycle, lead-acid batteries. A ferroresonant

transformer is used to provide a highly reliable, line

compensating unit with a minimum of moving parts,

designed for long, trouble-free service. A patented

electronic timer turns the charger on and off

automatically. This electronic timer determines full

charge of the batteries by measuring the rate at

which the battery voltage increases during charge.

When the voltage stops rising, the battery is fully

charged and the charger turns off.

INITIAL INSTALLATION

The AC line to which the charger is to be connected

must be of the proper voltage as indicated on the

nameplate of the charger and in TABLE 1. The line

must also be capable of supplying 15 amperes to

this charger.

TABLE 1

Part No. Input Voltage

957718 120

CAUTION: TO REDUCE THE RISK OF FIRE

USE THIS CHARGER ONLY ON CIRCUITS

PROVIDED WITH A MAXIMUM OF 20 AMPERE

BRANCH CIRCUIT PROTECTION (CIRCUIT

BREAKER OR FUSE), IN ACCORDANCE WITH

THE NATIONAL ELECTRICAL CODE, ANSI/NFPA

70, AND ALL LOCAL CODES AND ORDINANCES.

The use of an extension cord with the charger

should be avoided.

The use of an improper extension cord could result

in a risk of fire or electric shock. If an extension cord

must be used, use a three-conductor, No. 12 AWG

cord with ground, properly wired, in good electrical

condition and keep it as short as possible. Make

sure that the pins on the plug of the extension cord

are the same number, size, and shape as that of the

plug on the battery charger.

Locate all cords so that they will not be stepped on,

tripped over, or otherwise subject to damage or

stress.

Do not operate this charger with a damaged cord or

plug. Do not operate this charger if it has received a

sharp blow, was dropped or otherwise damaged in

any manner; refer to a qualified service agent.

Provide adequate ventilation for the batteries and

charger. The convection-cooled design requires an

unobstructed flow of cooling air for proper operation.

Keep all charger ventilation openings at least two

inches (2") (5cm) away from walls and other objects.

Do not allow clothing, blankets, or other material to

cover the charger.

WARNING: CHARGERS CAN IGNITE

FLAMMABLE MATERIALS AND VAPORS. DO

NOT USE NEAR FUELS, GRAIN DUST,

SOLVENTS, THINNERS, OR OTHER

FLAMMABLES.

Operating Instructions 1 01370E

Page 2

WARNING: KEEP DRY. DO NOT EXPOSE

CHARGER TO RAIN. FOR STORAGE, KEEP IN A

BUILDING. REPLACE WORN, CUT, OR

DAMAGED POWER CORDS OR WIRES

IMMEDIATELY.

GROUNDING INSTRUCTIONS

This battery charger must be grounded to reduce the

risk of electric shock. This charger is equipped with

an electric cord having an equipment-grounding

conductor and a grounding-type plug. This plug

must be connected to an appropriate receptacle that

is properly installed and grounded in accordance

with the National Electrical Code and all local codes

and ordinances.

DANGER: IMPROPER CONNECTION OF THE

EQUIPMENT-GROUNDING CONDUCTOR CAN

RESULT IN A RISK OF AN ELECTRIC SHOCK.

The conductor with insulation having an outer

surface that is green, with or without yellow stripe(s),

is the equipment-grounding conductor. If repair or

replacement of the electric cord or plug is necessary,

do not connect the equipment-grounding connector

to live terminal.

NORMAL OPERATION

REFER TO, READ, and FOLLOW ALL the

instructions and safety precautions printed on the

charger before every use!

WARNING: DO NOT MAKE ANY

CONNECTIONS UNTIL YOU READ THE

CHARGER NAMEPLATE AND VERIFY THAT THE

CHARGER IS FOR USE ON THE INTENDED

INPUT POWER (BOTH VOLTAGE AND

FREQUENCY), BATTERY SYSTEM VOLTAGE,

BATTERY TYPE, AND BATTERY AMP-HOUR

CAPACITY SIZE!

1. With the charger DC output cord disconnected

from the batteries, connect the power supply

cord to the needed AC voltage and frequency as

specified on the charger nameplate.

WARNING: TO REDUCE THE RISK OF AN

ELECTRIC SHOCK, CONNECT THE AC POWER

SUPPLY PLUG ONLY TO A PROPERLY

GROUNDED, SINGLE PHASE (3-WIRE) OUTLET.

REFER TO GROUNDING INSTRUCTIONS.

CAUTION: MAKE SURE THE BATTERY

PACK IS THE CORRECT NUMBER OF SERIES

CONNECTED LEAD-ACID CELLS, SYSTEM

VOLTAGE, AND AMP-HOUR CAPACITY AS

SPECIFIED ON THE CHARGER. USE

OTHERWISE MAY DAMAGE THE CHARGER

AND/OR BATTERIES.

DANGER: TO PREVENT ELECTRIC SHOCK,

DO NOT TOUCH UNINSULATED PARTS OF THE

CHARGER OUTPUT CONNECTOR, BATTERY

CONNECTOR, OR BATTERY TERMINALS. MAKE

SURE THAT BOTH THE CHARGER AND

BATTERY CONNECTORS ARE IN GOOD

WORKING CONDITION.

DANGER: DO NOT USE THE CHARGER IF

EITHER THE CHARGER OR BATTERY

CONNECTORS ARE CORRODED, CRACKED,

SHOW ANY SIGNS OF MELTING, ARE

DAMAGED IN ANY WAY OR DO NOT MAKE A

TIGHT CLEAN ELECTRICAL CONTACT. USING

ANY CHARGER WITH ANY OF THE ABOVE

SYMPTOMS COULD RESULT IN A FIRE,

PROPERTY DAMAGE, OR PERSONAL INJURY.

REPLACE DEFECTIVE, CRACKED OR

DAMAGED CORDS OR WIRES IMMEDIATELY.

DO NOT DISASSEMBLE CHARGER; TAKE IT TO

A QUALIFIED SERVICE AGENT WHEN SERVICE

OR REPAIR IS REQUIRED. INCORRECT

REASSEMBLY MAY RESULT IN A RISK OF

ELECTRIC SHOCK OR FIRE.

2. Connect the charger to a battery system of the

voltage, type, and amp-hour capacity as

specified on the charger. Connect DC output

connector to the battery connector by grasping

the plug body or handle and firmly pushing the

plug straight into the receptacle until the

connectors are fully engaged.

WARNING: DO NOT DISCONNECT THE DC

OUTPUT CONNECTOR FROM THE BATTERY

RECEPTACLE WHEN THE CHARGER IS

OPERATING. THE RESULTING ARCING AND

BURNING OF THE PLUG AND RECEPTACLE

COULD CAUSE THE BATTERIES TO EXPLODE

AND WILL DAMAGE THE CONNECTORS. IF THE

CHARGER MUST BE STOPPED, DEPRESS THE

STOP BUTTON UNTIL THE AMMETER

DECREASES TO ZERO OR DISCONNECT THE

AC PLUG FROM ITS RECEPTACLE. ONLY

AFTER THE AMMETER HAS DROPPED TO

ZERO, THEN DISCONNECT THE CHARGER DC

OUTPUT PLUG FROM THE BATTERY

RECEPTACLE.

Distinct steps occur in the process of the

charger turning on and charging. Pay attention

to these steps and monitor the initial charge rate

on the ammeter at the instant the charger starts

charging.

Three to five (3-5) seconds after the charger and

battery connectors are engaged, the control

relay inside the charger will pull in with a "click",

Operating Instructions 2 01370E

Page 3

indicating complete electrical circuits between

the electronic timer inside the charger to the

equipment battery pack as well as to live AC

power.

After the control relay pulls in with a click, the

transformer will hum, indicating that the

transformer has been energized by AC power.

After the transformer hums, the ammeter needle

will deflect, indicating initial charge rate.

3. Monitor the ammeter for the initial charge rate.

The correct initial charge rate will vary due to

numerous factors. Refer to the chart to

determine the minimum and maximum initial

charge rate for the specific current rating

charger.

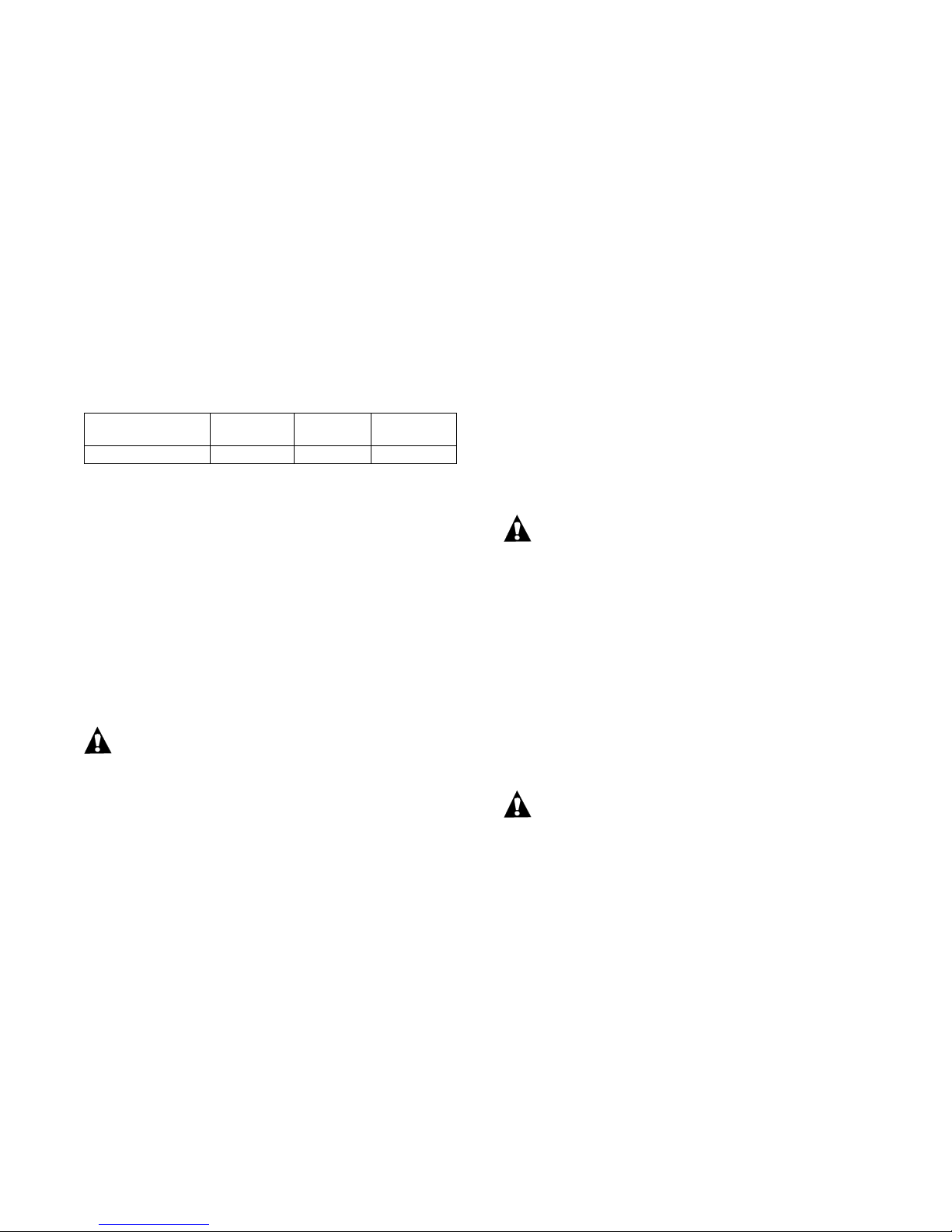

CORRECT INITIAL CHARGE RATE

Charger Current

Rating

40 31 40 48

Minimum Start

Rating

Maximum

If the batteries are heavily discharged and the

AC input line voltage is higher than nominal, the

initial charge rate may exceed the maximum

initial charge rate for the specific current rating

charger. Under normal conditions, the charge

rate will decrease to or less than the specified

maximum charge rate in less than 120 minutes.

If the ammeter still reads in excess of the

specified maximum charge rate after 120

minutes, turn the charger off by depressing the

STOP button until the ammeter decreases to

zero or disconnecting the AC plug from its

receptacle.

CAUTION: TO PREVENT BATTERY

DAMAGE, CHARGER OVERHEATING AND

TRANSFORMER BURN OUT, DO NOT ALLOW

THE CHARGER TO OPERATE FOR MORE THAN

120 MINUTES WITH THE AMMETER READING IN

EXCESS OF THE SPECIFIED MAXIMUM CHARGE

RATE. THIS MISUSE WILL CAUSE OVERHEATING AND TRANSFORMER BURNOUT WILL

RESULT.

This high charge rate is caused if the charger is

connected to a battery pack with a system

voltage lower than, or Amp-Hour capacity

greater than, specified on the charger. If battery

maintenance has recently been performed, test

to see if an individual battery in the battery pack

has been connected reverse polarity. A

common error is to install one or more of the 6

volt batteries in a battery pack in reverse

polarity. Using a suitable DC voltmeter, test to

be sure all batteries in a battery pack are

correctly installed, and also test by measuring

the battery system voltage at the equipment

battery connector, and compare it to the system

voltage specified in the charger nameplate.

After charging for 120 minutes at this excessive

rate, the measured on-charge voltage should

rise to the voltage specified by the charger

nameplate. Voltage measurements, while

charging, lower than the charger system voltage

indicates an incorrect or failed battery pack that

must be corrected before using the charger.

If the batteries have been recently charged, the

battery is cold (temperature below 65°F), or the

AC input voltage is lower than nominal, the initial

charge rate may only reach the minimum initial

charge rate at turn-on for the specific current

rating charger.

If the initial charge rate is less than half of the

specified minimum initial charge rate at the

moment of turn-on, the charger may be

malfunctioning due to electrical overload

damage. Turn the charger off by depressing the

STOP button until the ammeter decreases to

zero or disconnecting the AC plug from its

receptacle.

CAUTION: DO NOT USE THE CHARGER IF

THE OUTPUT IS LOW. BATTERIES WILL NOT

REACH FULL CHARGE, THEREBY INCREASING

THE POSSIBILITY OF A HARMFUL DEEP

DISCHARGE DURING THEIR NEXT USE.

This too low a charge rate at the instant of turn-

on can be due to a battery pack system voltage

that is higher than specified on the charger, a

charger malfunction resulting from electrical

overload damage, or component failure. Test

for the correct battery pack system voltage with

a suitable voltmeter at the equipment battery

connector and compare with the system voltage

specified on the charger nameplate.

DANGER: TO REDUCE THE RISK OF

ELECTRIC SHOCK, ALWAYS DISCONNECT

BOTH THE POWER SUPPLY CORD AND THE

OUTPUT CORD BEFORE ATTEMPTING ANY

MAINTENANCE OR CLEANING.

The charger fuses are located behind the front

panel. DO NOT REMOVE THE FRONT PANEL

FOR INSPECTION WITHOUT FIRST DISCON-

NECTING BOTH THE POWER SUPPLY CORD

AND THE OUTPUT CHARGING CORD. RISK

OF ELECTRIC SHOCK.

Visually inspect and electrically test the fuses. A

blown (OPEN) DC fuse indicates an electrical

overload damage caused short circuit failure of a

rectifier diode or reverse polarity connection of

the charger to the batteries. Melted fuses or

fuse links can result from weak fuseholders or

fuseholder connections.

Operating Instructions 3 01370E

Page 4

LOCATE AND CORRECT CAUSE OF

TROUBLE BEFORE REPLACING A BLOWN

FUSE.

DO NOT DISASSEMBLE THE CHARGER.

Take the charger to a qualified service agent to

have the heatsink assembly with diodes and

correct replacement fuse, fuseholder or fuse

assembly installed. Incorrect reassembly may

result in a risk of electric shock or fire.

During the charge, the battery voltage gradually

increases which causes the charge rate to

decrease. Batteries able to deliver their full

rated capacity will still rise to 2.5 volts per cell, or

higher, at 80°F, as they reach maximum charge.

This will allow the charge current to decrease or

taper to the charger's designed finish charge

rate or lower at the end of charge. Refer to

chart.

Charger

Current

Rating

40 Amps 10 Amps 13 Amps or less

Finish Current

@ 2.5 Volts/Cell

@80°°F (27°°C)

Normal Finish

Charge

Current Range

Since each battery cell accepts charge at a

slightly different rate, charging with the ammeter

reading in the normal finish charge range for the

last few hours of charge is important to achieve

equalization of all battery cells every time the

batteries are charged.

As batteries wear out and lose capacity, the end

of charge finish voltage continually decreases.

As the end of charge finish voltage decreases to

less than 2.5 volts per cell, this prevents the

finish charge current from decreasing to the

normal finish charge current range. The

electronic timer still determines when the

batteries have reached their now reduced

maximum charge capacity and will turn the

charger off.

The major factors affecting the required charge

time are charger output current rating, battery

size or capacity in amp-hours, and how heavily

the battery is discharged. A larger, more heavily

discharged battery requires more time to

recharge to maximum charge with the same

current rating charger than a smaller, less

heavily discharged battery.

The electronic timer circuit board contains a

section that stops supplying power to the control

relay if the charger operates continuously for 18

hours and is unable to achieve maximum

charge. The indicator light will blink if maximum

time charge termination occurs. The indicator

light will glow steady for normal charge

termination in 18 hours or less.

If no power outage occurred and the charger

operated continuously longer than 18 hours,

either the control relay is stuck or the electronic

timer circuit board is malfunctioning.

WARNING: DO NOT LEAVE THE CHARGER

DC OUTPUT CONNECTOR CONNECTED TO THE

BATTERY CONNECTOR WHILE UNATTENDED

FOR TWO DAYS OR MORE IN A ROW. SEVERE

OVERCHARGING AND POSSIBLE DAMAGE TO

THE BATTERIES WILL RESULT IF THE

CHARGER SHOULD FALL TO TURN OFF, OR

TURN BACK ON.

APPROXIMATE RECHARGE TIMES

Part

No.

957718 230

Battery Capacity

Ampere Hours

6 Hr. Scale

440

Approximate

Recharge Time

(Hours)

9

18

Newer or colder batteries require greater energy

return, are slower to respond, and consequently

require extended charge time at a low finish

charge current rate to return to maximum

charge. As batteries wear out and lose capacity,

their temperature rise both from use and on

charge becomes significant as an indicator of

the end of life and the battery cannot benefit

from extended charge time. Even though they

are properly charged, older batteries continually

lose capacity, and should be replaced when they

will no longer perform as desired. Very weak

batteries are indicated when the charger turns

off after only 8 hours and the indicator light is

blinking.

4. At the finish of charge, monitor the indicator

light, read the ammeter, note the run time, and

listen for transformer hum. Refer to the

following chart.

Operating Instructions 4 01370E

Page 5

Indicator Light Ammeter Drop

Steady Glow Yes 18 Hours or less No MAXIMUM CHARGE ACHIEVED

Flashing Yes 9 Hours No VDC less than 2.25 V/cell in 9 hours

Flashing Yes 18 Hours No

Steady or

Flashing

to Zero

No Yes Malfunction; Relay Stuck or Electronic Timer Failure

Charging Run

Time

Transformer

Hum

WEAK BATTERY SYSTEM

--- OR ---

Too large amp-hour capacity battery system or excessive

discharge

MAXIMUM CHARGE NOT ACHIEVED

TURN OFF CHARGER BY DISCONNECTING CORD

After the charger has turned off, disconnect the

charger DC output connector from the battery

connector by grasping the plug body or handle

and pulling the plug straight out of the

receptacle.

WARNING: TO AVOID DAMAGE TO THE

CHARGER CORD CONNECTOR PLUG, AND

BATTERY CONNECTOR RECEPTACLE, DO NOT

PULL ON THE CHARGER CORD. DO NOT

TWIST, ROCK, OR PULL THE CONNECTOR

PLUG SIDEWAYS.

ON-DEMAND CHARGING

Battery cycle life is directly determined by severity of

use. A battery that has 100% of its available energy

discharged every time it is used will wear out twice

as fast as a battery that has 70% of its available

energy discharged every time it is used. In severe

use situations, some additional battery life can be

realized by instituting short charge periods during

work breaks. This reduces the incidence of full

100% battery depletion before charging.

Follow "Normal Operation" procedures to begin a

short charge period. At the end of any short charge

period where the charger has not turned off, turn the

charger off by depressing the STOP button until the

ammeter decreases to zero or disconnect the AC

plug from its receptacle.

BATTERY STORAGE MAINTENANCE

When the equipment is not in use, charge the

batteries once each week. Remove the DC output

connector at the end of charge.

STORAGE

When the machine is not in use, charge the batteries

once each week.

PROPER CARE OF MOTIVE POWER BATTERIES

Motive power batteries are subjected to severe deep

cycle duty on a daily basis. Although these batteries

are designed to withstand such duty, the following

precautions must be observed to obtain good

performance and maximum cycle life.

CAUTION: ALWAYS WEAR PROTECTIVE

EYE SHIELDS AND CLOTHING WHEN WORKING

WITH BATTERIES. BATTERIES CONTAIN ACIDS

WHICH CAN CAUSE BODILY HARM. DO NOT

PUT WRENCHES OR OTHER METAL OBJECTS

ACROSS THE BATTERY TERMINAL OR

BATTERY TOP. ARCING OR EXPLOSION OF

THE BATTERY CAN RESULT.

1. When installing new batteries, be sure the

polarity of each battery and overall battery pack

is correct. Due to the electrical characteristics

of this charger, it is possible to improperly hook

up the batteries and not blow the fuse when

charging. Battery and/or charger damage can

result.

2. New batteries should be given a full charge

before their first use because it is difficult to

know how long the batteries have been stored.

3. Limit the use of new batteries for the first five

cycles. New batteries are not capable of their

rated output until they have been discharged

and charged a number of times.

4. Do not excessively discharge the batteries.

Excessive discharge can cause polarity

reversal of individual cells resulting in complete

failure shortly thereafter. Limited use of new

batteries will minimize the risk of cell reversals.

5. Maintain the proper electrolyte level by adding

water when necessary. Never allow the

electrolyte level to fall below the top of the

battery plates. Electrolyte levels fall during

discharge and rise during charge. Therefore, to

Operating Instructions 5 01370E

Page 6

prevent the overflow of electrolyte when

charging, it is mandatory that water be added to

cells AFTER they have been fully charged; do

not overfill. Old batteries require more frequent

additions of water than do new batteries.

6. When the temperature falls below 65°F, the

batteries should be placed on charge as soon

after use as possible.

7. The tops of the batteries and battery holddowns must be kept clean and dry at all times

to prevent excessive self-discharge and flow of

current between the battery posts and frame.

8. Follow all operating instructions, cautions, and

warnings as specified in this manual and on the

charger case.

Operating Instructions 6 01370E

Page 7

WIRING DIAGRAM

TRANSFORMER

BATTERIES

RELAY

STOP

LED

120 Vac

INPUT

black

tan

1

2

black

black

3

yellow

yellow

brown

brown

orange

orange

green

DIODES

DC FUSE

black

red

blue

1

4

7

9

10

11

12

13

14

15

ELECTRONIC

TIMER

red

+

TO

black

-

AMMETER

AC

FUSE

green

white

L2120S06

REPLACEMENT PARTS LIST

AMMETER FRONT BOTTOM PANEL

TRANSFORMER CASE ASSEMBLY, COMPLETE

TIMER, ELECTRONIC SWITCH, PUSHBUTTON

HEATSINK ASSEMBLY LED HOLDER

RELAY CAPACITOR, 6 MFD, 660 VAC

FUSE, AC COVER

FUSE, DC BACK PANEL

CONTROL CABLE LEFT SIDE PANEL

FUSEHOLDER RIGHT SIDE PANEL

CORDSET, AC INNER MOUNTING PANEL

CORDSET, DC, SB-175 RED PLUG FUSE PANEL

BASE ASSEMBLY FRONT TOP PANEL

4

tan

DIODES

CAPACITOR

Operating Instructions 7 01370E

Page 8

L I M I T E D W A R R A N T Y

Minuteman warrants each new Minuteman Battery Charger for defects in material and workmanship for a period of one

year from the date of original purchase of the complete unit. Repairs can be made at the Minuteman factory. To do so send

the defective unit with transportation charges prepaid to:

Minuteman, Inc.

111 South Rohlwing Road

Addison, Illinois 60101

Attention: Service Department

For repairs made at other than the Minuteman factory, Minuteman will provide only the replacement parts. Defective parts

should be sent with transportation charges prepaid to the Minuteman factory at the previously mentioned address.

If the unit or parts are found in the reasonable judgment of Minuteman to be defective in material or workmanship, repair,

or replacement will be made by Minuteman without charge for parts or labor. Repair or replacement will be at the discretion of

Minuteman, with replacements being made using current models or parts performing the equivalent function. Labor charges

other than those incurred at the Minuteman factory are not covered under this warranty. All expenses associated with

delivering defective items to the Minuteman factory and the expense of returning repaired or replaced items from the

Minuteman factory to the owner will be paid for by the owner. All warranty work accomplished at the Minuteman factory will be

completed within a reasonable time after receipt of defective items.

This warranty does not cover any semiconductor parts, such as diodes, which are vulnerable to electrical overloads

beyond the control of Minuteman.

This warranty does not cover any charger that has been subject to misuse, neglect, negligence, or accident, or operated

in any way contrary to instructions specified on the charger case and in the owner's manual. No claim of breach of warranty

shall be cause for cancellation of the contract of sale of any Minuteman charger. Minuteman assumes no responsibility for

loss of time, inconvenience, or other damage, consequential or otherwise, resulting from a defective charger. All implied

warranties (including merchantability) are limited in duration to the one year warranty period.

Some states do not allow the exclusion or limitation of incidental or consequential damages; or limitations on how long an

implied warranty lasts, so the above limitations may not apply to you. This warranty gives you specific legal rights, and you

may also have other rights which vary from state to state.

Minuteman's obligation under this warranty is strictly and exclusively limited to the repair or replacement of defective

items. Minuteman issues this warranty in good faith and with full confidence in the workmanship and quality of Minuteman

products.

Operating Instructions 8 01370E

Loading...

Loading...