Page 1

260

Floor Scrubber

Traction Driven

Brush Driven

Model:Model:

Model:

Model:Model:

MC260024QPBDMC260024QPBD

MC260024QPBD

MC260024QPBDMC260024QPBD

MC260026QPTDMC260026QPTD

MC260026QPTD

MC260026QPTDMC260026QPTD

MC260024CEBDMC260024CEBD

MC260024CEBD

MC260024CEBDMC260024CEBD

MC260026CETDMC260026CETD

MC260026CETD

MC260026CETDMC260026CETD

OPERAOPERA

OPERA

OPERAOPERA

TIONTION

TION

TIONTION

SERVICESERVICE

SERVICE

SERVICESERVICE

PP

P

PP

ARAR

AR

ARAR

TSTS

TS

TSTS

CARECARE

CARE

CARECARE

Revised 9/05

Page 2

TT

ABLE OF CONTENTSABLE OF CONTENTS

T

ABLE OF CONTENTS

TT

ABLE OF CONTENTSABLE OF CONTENTS

Safety Instructions .............................................................. 1

Electrical Requirements .................................................... 2

Control Panel Identification ................................................. 3

Squeegee Adjustments ...................................................... 4

Operating Instructions ........................................................5

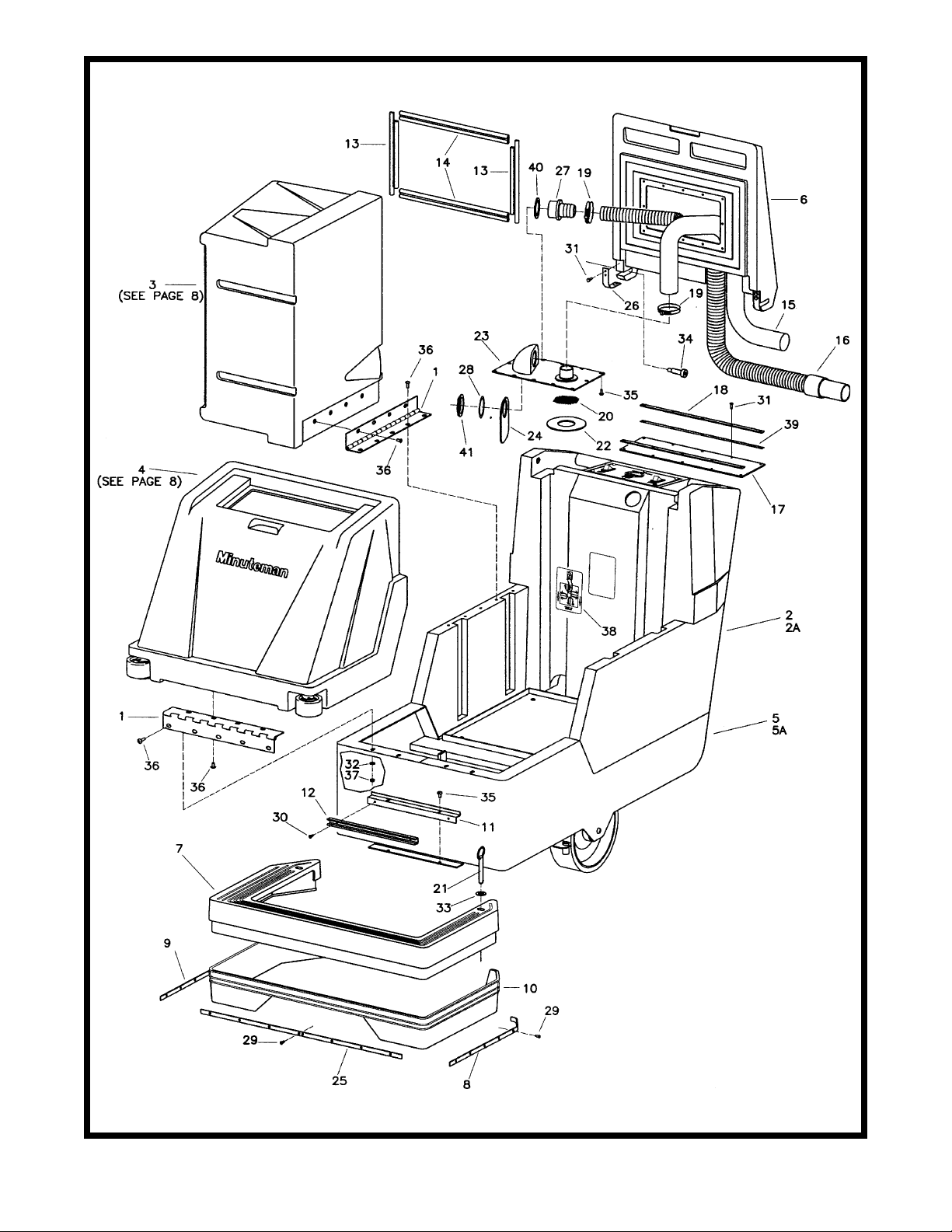

Main Polyethylene Components .................................. 6 & 7

Recovery Tank and Solution Tank................................ 8 & 9

Drive Assemblies (Brush Driven) ............................. 10 & 11

Mainframe (Brush Driven) ....................................... 12 & 13

Console Assembly (Brush Driven) .......................... 14 & 15

Recovery Tank and Solution Tank............................ 16 & 17

Drive Assemblies (Traction Driven) ......................... 18 & 19

Mainframe (Traction Drive) ...................................... 20 & 21

Console Assembly (Traction Driven) ....................... 22 & 23

Squeegee Mechanism Assembly ..................................... 24

Squeegee Assembly Complete ........................................25

Wiring Diagram (Brush Driven) ........................................ 26

Wiring Diagram (Brush Driven, CE Model) ...................... 27

Wiring Diagram (Traction Driven)..................................... 28

Wiring Diagram (Traction Driven, CE Model) ...................29

Page 3

IMPORIMPOR

IMPOR

IMPORIMPOR

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

Operators must read and understand this manual before operating or maintaining

this equipment.

• Keep hands and feet clear of moving parts while machine is in operation.

• All switches must be in the “OFF” position when charging batteries.

• Electrical motors and components can cause an explosion when operated near explosive materials

or vapors. Do not operate this machine near flammable materials such as solvents, thinners, fuels,

grain dusts, etc.

• Make sure all switches are turned “OFF” and battery connections are removed before performing

any maintenance procedures.

• Store or park this machine on a level surface only.

TT

ANTANT

T

ANT

TT

ANTANT

SAFETY SAFETY

SAFETY

SAFETY SAFETY

INSTRUCTIONS INSTRUCTIONS

INSTRUCTIONS

INSTRUCTIONS INSTRUCTIONS

• These machines are designed for level floor operation only. DO NOT OPERATE on ramps or

inclines.

• Battery acid can cause burns. When working on or around batteries, wear protective clothing and

safety glasses. Remove metal jewelry. Do not lay tools or metal objects on top of batteries.

• This machine is not suitable for picking up hazardous dust.

• Charging batteries generates explosive gases. DO NOT CHARGE BATTERIES WHEN OPEN

FLAMES OR SPARKS ARE PRESENT. DO NOT SMOKE. Make sure the charger is turned off

before disconnecting it from the batteries. Charge the batteries in a well-ventilated area.

• Maintenance and repairs must be performed by authorized personnel.

SASA

SA

SASA

VE VE

THESE INSTRUCTIONSTHESE INSTRUCTIONS

VE

THESE INSTRUCTIONS

VE VE

THESE INSTRUCTIONSTHESE INSTRUCTIONS

1

Page 4

ELECTRICAL REQUIREMENTS:ELECTRICAL REQUIREMENTS:

ELECTRICAL REQUIREMENTS:

ELECTRICAL REQUIREMENTS:ELECTRICAL REQUIREMENTS:

This piece of equipment operates on 24 Volt DC.

BABA

BA

BABA

TTERTTER

TTER

TTERTTER

YY

REQUIREMENTS: REQUIREMENTS:

Y

REQUIREMENTS:

YY

REQUIREMENTS: REQUIREMENTS:

4 x 6V 220AH P/N 956720

4 x 6V 275AH P/N 956740

BABA

TTERTTER

BA

TTER

BABA

TTERTTER

**

* Warning: Battery acid can cause burns. When working on or around batteries, wear protective

**

YY

SER SER

Y

SER

YY

SER SER

VICE VICE

VICE

VICE VICE

AND INSTAND INST

AND INST

AND INSTAND INST

ALLAALLA

ALLA

ALLAALLA

TION:TION:

TION:

TION:TION:

clothing and safety glasses. Remove metal jewelry. Do not lay tools or metal objects on top of

batteries.

BABA

BA

BABA

TTERTTER

TTER

TTERTTER

YY

INST INST

Y

INST

YY

INST INST

ALLAALLA

ALLA

ALLAALLA

TION:TION:

TION:

TION:TION:

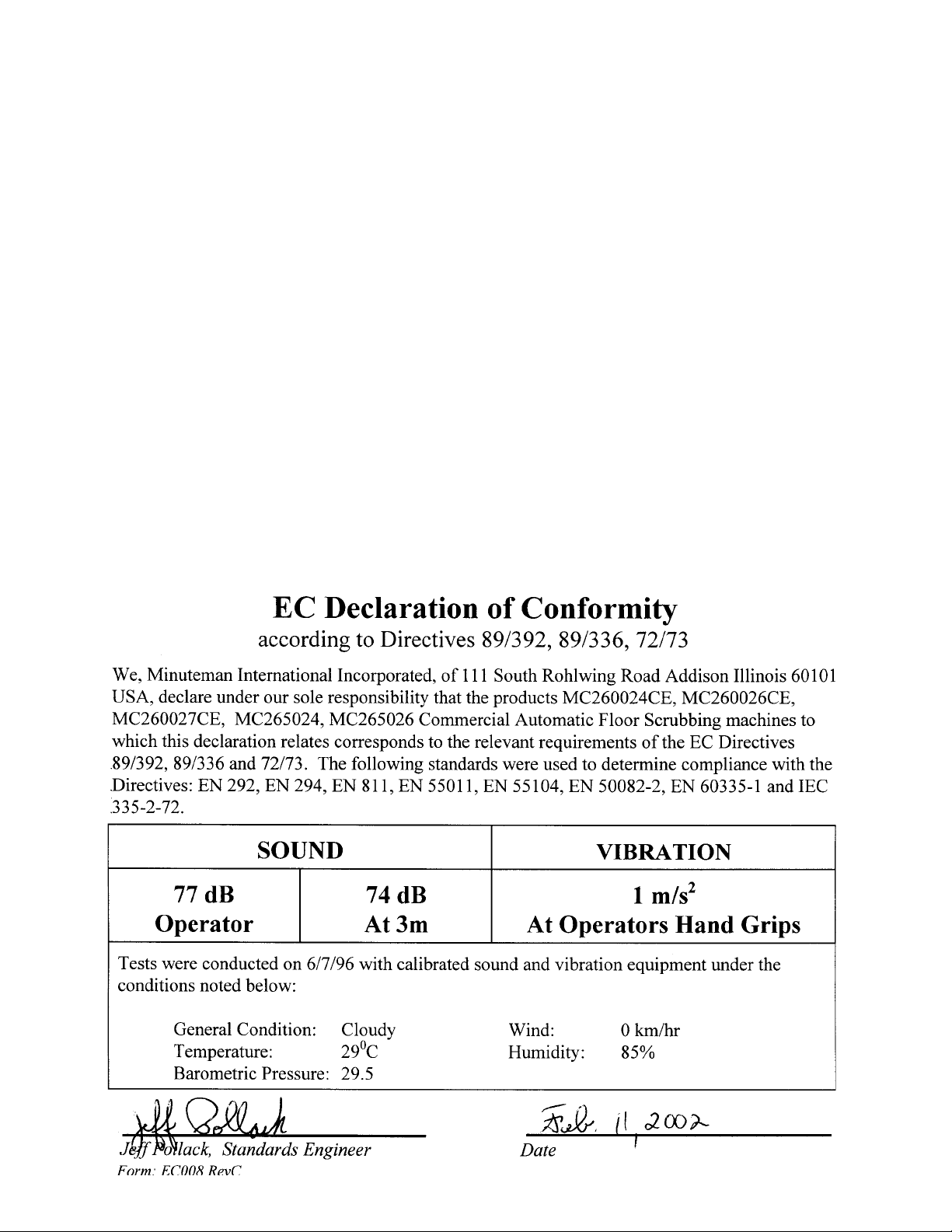

1. Disconnect tank drain hose from rear of machine (6).

2. Raise tank assembly by raising rear cover and tilting tank, Figure 1.

3. Install batteries as shown in Figure 2.

CHARGING OF BACHARGING OF BA

CHARGING OF BA

CHARGING OF BACHARGING OF BA

TTERIES:TTERIES:

TTERIES:

TTERIES:TTERIES:

Charging of batteries generates explosive gases. DO NOT CHARGE BATTERIES WHEN OPEN

FLAMES OR SPARKS ARE PRESENT. DO NOT SMOKE. Make sure the charger is turned off

before disconnecting it from the batteries. Charge the batteries in a well-ventilated area. Fluid levels

should be checked before and after charging and maintained at the proper levels.

2

Page 5

CONTROLCONTROL

CONTROL

CONTROLCONTROL

P P

ANELANEL

P

ANEL

P P

ANELANEL

IDENTIFICA IDENTIFICA

IDENTIFICA

IDENTIFICA IDENTIFICA

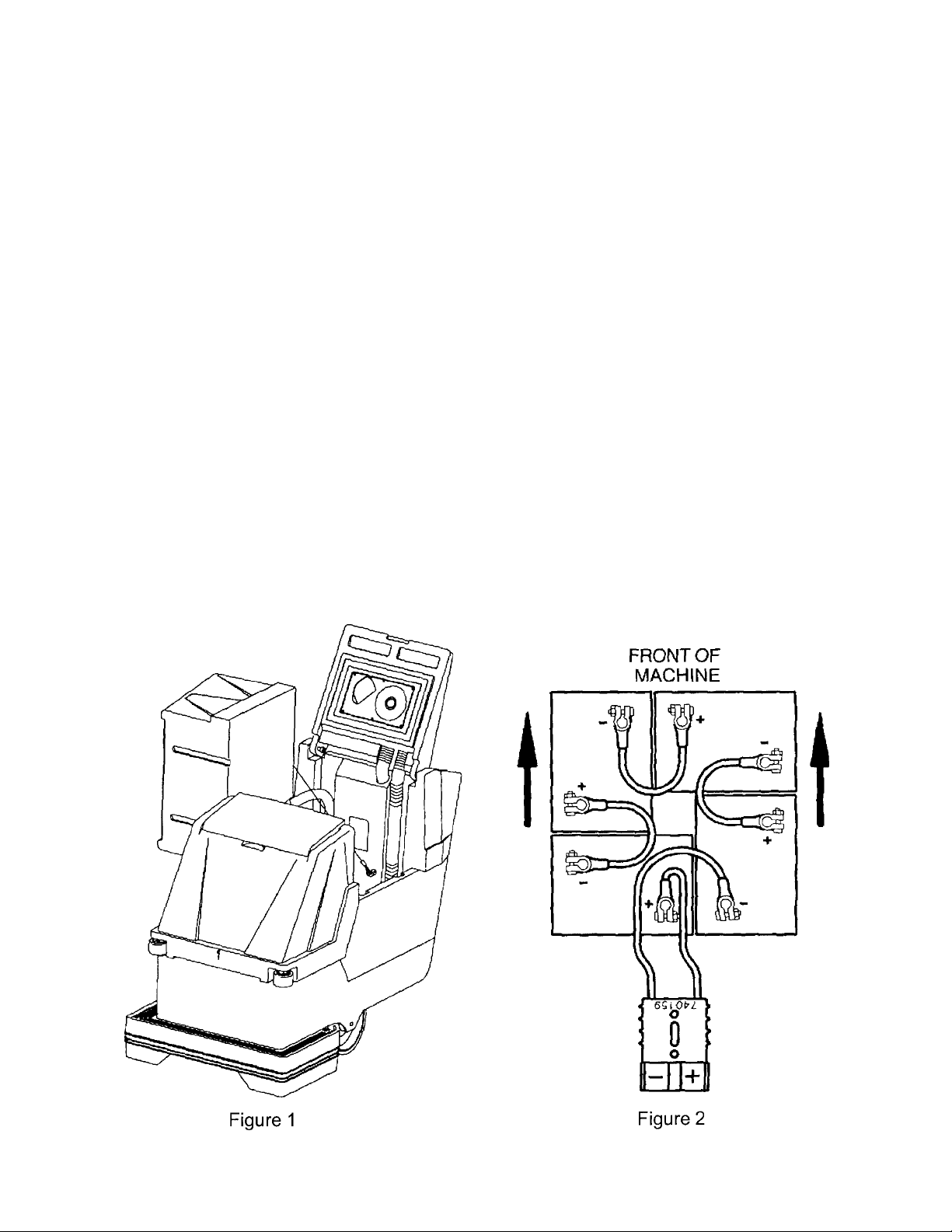

1. Vacuum recovery hose

2. Squeegee lift lever

3. Solution control lever

4. Brush pressure handle

5. Drain hose for recovery tank

6. Foot pedal for lower/raising brush

7. Drain hose for battery tray

8. Reverse control lever

9. Hour meter (optional)

10. Circuit breaker for vacuum motor

11. Circuit breaker for brush motor

12. Brush switch

13. Battery condition gauge

14. Vacuum switch

15. Speed control knob

16. Main power switch

17. Key switch (optional)

18. Forward control lever

19. Pump switch (optional)

20. Quick disconnect aux. out (optional)

21. Dump hose for solution tank

TIONTION

TION

TIONTION

AUTO SCRUBBER BRUSH DESCRIPTIONAUTO SCRUBBER BRUSH DESCRIPTION

AUTO SCRUBBER BRUSH DESCRIPTION

AUTO SCRUBBER BRUSH DESCRIPTIONAUTO SCRUBBER BRUSH DESCRIPTION

TYPE TYPE

TYPE

TYPE TYPE

Bassine Natural Fiber Short Dark Red Light duty

Nylon Nylon Medium Black Tan/Red General cleaning

Dyna-Scrub Nylon impregnated Long Light Red General scrubbing,

Power-Scrub Nylon impregnated Long Rust Red/Blue Moderate aggressive

Poly-Grit Nylon impregnated Long Green Brown/Black Aggressive stripping

Strata-Grit Nylon impregnated Long Dark Black Heavy duty

DESCRIPTION DESCRIPTION

DESCRIPTION

DESCRIPTION DESCRIPTION

with 500 Grit Blue vinyl tile, ceramic

Silicone Carbide tile, epoxy floors,

Fine Bristle, urethane finish,

Dense Fill uneven concrete floors

with 120 Grit Silicon scrubbing, tile floors

Carbide Fine Bristle, concrete floors

Dense Fill

with 80 Grit and scrubbing, tile

Silicon Carbide floors, unfinished

Coarse Bristle concrete floors

with 46 Grit Blue stripping/scrubbing

Silicon Carbide unfinshed

Coarse Bristle concrete

**

Durability is dependent on floor surface, chemicals used and proper care. Durability is dependent on floor surface, chemicals used and proper care.

*

Durability is dependent on floor surface, chemicals used and proper care.

Durability is dependent on floor surface, chemicals used and proper care. Durability is dependent on floor surface, chemicals used and proper care.

**

DURABILITY* DURABILITY*

DURABILITY*

DURABILITY* DURABILITY*

COLOR COLOR

COLOR

COLOR COLOR

Brown general cleaning,

COMP COMP

COMP

COMP COMP

TT

T

TT

ARISONARISON

ARISON

ARISONARISON

O PO P

ADSADS

O P

ADS

O PO P

ADSADS

RECOMMENDED RECOMMENDED

RECOMMENDED

RECOMMENDED RECOMMENDED

USE USE

USE

USE USE

acid etching

& scrubbing vinyl

floors, ceramic tile

& concrete floors

3

Page 6

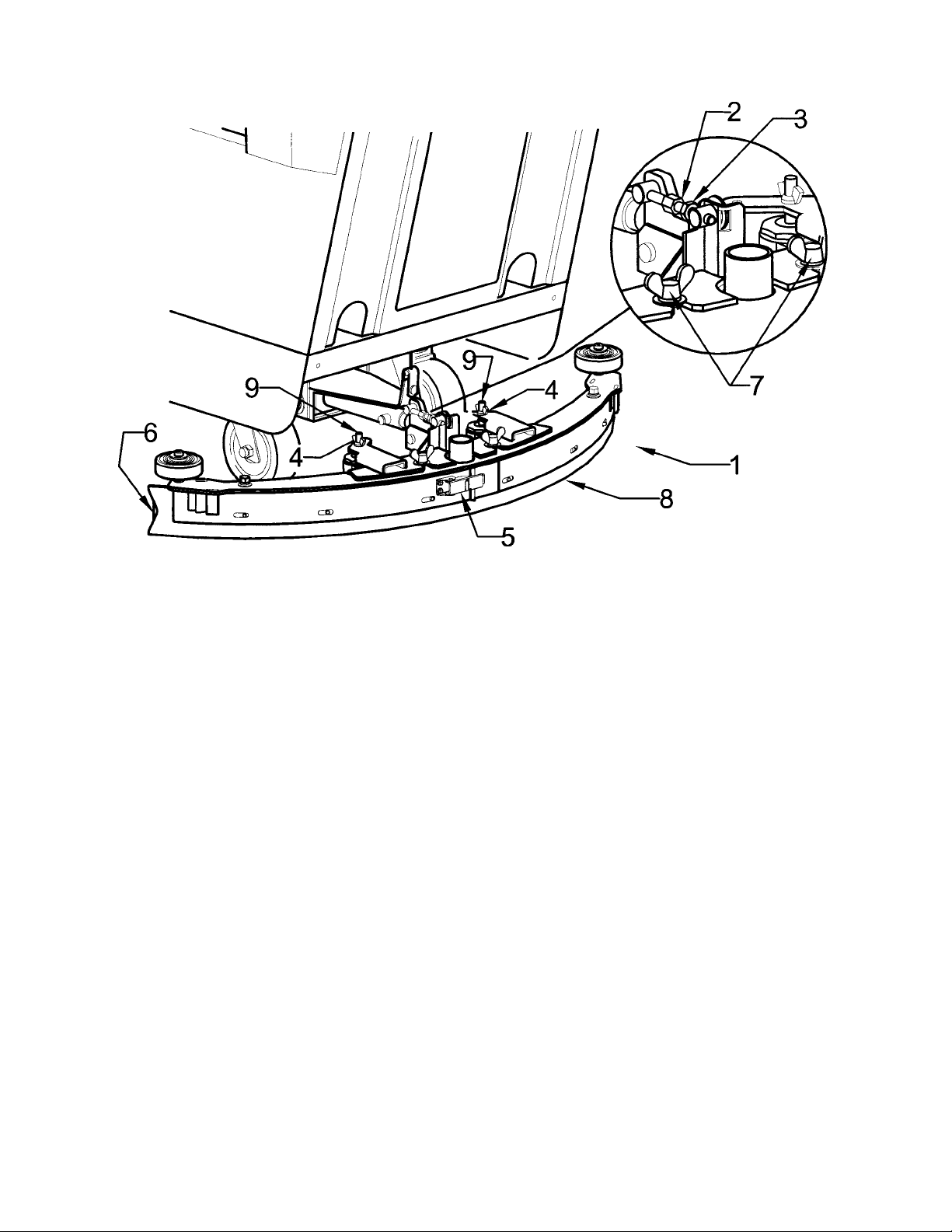

SQUEEGEE SQUEEGEE

SQUEEGEE

SQUEEGEE SQUEEGEE

ADJUSTMENTSADJUSTMENTS

ADJUSTMENTS

ADJUSTMENTSADJUSTMENTS

The squeegee set-up is pre-adjusted at the factory. Adjustments may be required to get optimum performance for

different floors and conditions.

Ensure that the scrubber is on a relatively flat surface. Ensure that the scrubber is on a relatively flat surface.

1.

Ensure that the scrubber is on a relatively flat surface.

Ensure that the scrubber is on a relatively flat surface. Ensure that the scrubber is on a relatively flat surface.

head assembly ofhead assembly of

head assembly of

head assembly ofhead assembly of

2. Turn the speed control knob counter-clockwise to the low speed position. Squeeze the forward control lever to lower

the squeegee (item 1) to the floor. Move the machine one or two feet forward to check the rear squeegee blade (item

8) for uniform deflection to the floor.

3. If uneven deflection or lay is evident, minor adjustments may be necessary to avoid streaking and uneven wear on

the blade.

4. To correct this, loosen the wing jam nut (item 4) in order to adjust the caster height. If the squeegee blade is

deflecting too much, the casters need to be lowered to control the down pressure. Lower the caster by turning the

exposed threaded stem (item 9) on the caster clockwise. Make the adjustment a few turns at a time.

5. Repeat step 2.

6. If the blades are not deflecting enough, raise the caster by turning the stem counter-clockwise to adjust the caster

hieght to allow more down pressure on the squeegee. Repeat Step 2.

7. Make sure that there is an even deflection on the entire length of the rear blade. Adjust the castors and retighten the

wing jam nuts to lockthe caster setting in place.

8. Pitch adjustment is necessary if the outer ends on the squeegee blade does not contact the floor and there is too

much deflection in the middle area or if the outer ends are over deflected and there is no contact in the middle.

9. To adjust pitch, lower the squeegee to the floor. Loosen the lock nut (item 3) in the turnbuckle assembly. Turning

the turnbuckle (item 2) clockwise or counterclockwise controls the forward and backward pitch of the squeegee.

Having the rear blades deflected uniformly along its entire length is the desired setup.

10. Repeat Step 2 until the desired setup is achieved.

11. In certain applications where a non-slotted front wiper blade (item 6) is needed, detach the squeegee assembly by

loosening the wing bolts (item7). Unlock the clamp on the front squeegee to release the straps and flip the blade

over to the non-slotted side. Reattach straps and lock the clamp back in place.

12. You can also easily replace the rear blade by unlatching the latch (item 5) and removing the straps by sliding them

off the assembly.

f the floorf the floor

f the floor

f the floorf the floor

. Set the squeegee/ vacuum switch to the automatic mode.. Set the squeegee/ vacuum switch to the automatic mode.

. Set the squeegee/ vacuum switch to the automatic mode.

. Set the squeegee/ vacuum switch to the automatic mode.. Set the squeegee/ vacuum switch to the automatic mode.

TT

urn on the main power switch and raise the scruburn on the main power switch and raise the scrub

T

urn on the main power switch and raise the scrub

TT

urn on the main power switch and raise the scruburn on the main power switch and raise the scrub

4

Page 7

OPERAOPERA

OPERA

OPERAOPERA

1. Filling: Fill the solution tank with the desired amount of water and add liquid cleaning solution to

the proper dilution ratio. DO NOT USE powdered cleaning chemicals. Powders are unlikely to

dissolve thoroughly, resulting in clogging the in-line solution filter. This can reduce or stop water

flow to the brush.

2. Close lid.

3. Turn on main power switch (refer to Page 3, #16). (Traction Drive Only)

4. Adjust main speed control, #15 to full counter-clockwise position. (Traction Drive Only)

5. Lower brush assembly:

• Depress foot pedal (6) slightly and push in on lever (4) to release, to increase brush pressure

pull up and back on lever (4) to lock in position.

• To lift the brush, press the pedal down until lift mechanism engages.

6. Turn on brush switch.

7. Adjust solution control feed lever.

8. Select vacuum operation:

Brush Driven Models – Turn vacuum switch to “On” position Traction Driven Models

a) “Vacuum On” mode – Vacuum will remain on until switched to the “off” position

b) “Vacuum Auto” mode – Vacuum will come on automatically when forward or reverse handles

are squeezed, and remain on approximately 5 seconds after handle release.

TING INSTRUCTIONSTING INSTRUCTIONS

TING INSTRUCTIONS

TING INSTRUCTIONSTING INSTRUCTIONS

9. Lower squeegee assembly.

10. Squeeze forward handle #18 and adjust forward speed. (Traction Drive Only)

After Use:

1. Turn off solution feed.

2. Switch off brush and raise.

3. Raise squeegee assembly.

4. Turn off vacuum motor.

5. Solution and recovery tanks should be emptied after every use.

MAINTENANCE:MAINTENANCE:

MAINTENANCE:

MAINTENANCE:MAINTENANCE:

Daily

1. Clean float assembly & squeegee blades.

2. Recharge batteries (check battery acid levels before and after charging).

Monthly

1. Check wear on squeegee blades.

2. Grease front and rear wheels.

3. Grease pivot points on brush motor assembly.

Every 500 hours check condition of carbon brushes on vacuum motor and brush drive motor.

5

Page 8

6

Page 9

PartPart

Part

PartPart

s Lists List

s List

s Lists List

ItemItem

Item

ItemItem

10 260145 1 Splash Skirt

11 260148 1 Solution Dump Bracket 14GA

12 260149 1 U Channel 12”

13 260157 2 Lid Gasket Short 260B

14 260158 2 Lid Gasket 260B

15 260159 1 Hose Vac 1.5 x 78” Wireloc

16 260160 1 Recovery Hose Assy. 260B

17 260169 1 Lid Flap

18 260170 2 Retainer Strip

19 260203 2 Clamp Hose 102120 Murray

20 260212 1 Screen Filter

21 260241 2 Pin Hitch 7/16 x 3

22 260294 1 Gasket 260

23 260299 1 Shut-Off Plate Assy.

24 260301 1 Deflector Flap

25 260336 1 Skirt Retainer - Front

26 260353 2 Lid Pivot Strap

27 450037 1 Adapter MCH

28 450081 1 WSR-1.908 x 2.41 x .03 SS

29 711106 20 SCR-ST-A 10 x .75 PL

30 711124 2 SCR-ST-B 10 x .37 NI

31 711161 10 SCR-Hi/Lo #10 x 3/4 Zinc

32 711505 4 WSR-Flat 1/4

33 711508 2 WSR-Flat .44 x 1.00 x .08

34 712102 2 Bolt - Shoulder 1/2 x 1.5

35 712540 14 SCR-MC 10-24 x .37 SS TH

36 712565 17 SCR-MC 1/4-20 x .62 SS

37 712667 4 Nut-Nyloc 1/4-20 SS

38 715607 1 Decal - Battery Cable Rout

39 760263 2 Foam Tape 1/16 x 1/2

40 828970 1 WSR-Neop 1.87 x 2.4 x .125

41 828971 1 Nut - 1 1/2 Pipe Thread

Part No.Part No.

Part No.

Part No.Part No.

1 260087 2 Hinge 15”

2 260090 1 Rear Base Char Grey

2A 260256 1 Rear Base 260TD Char Grey

3 260091 1 Recovery Tank 260 Light Grey

4 260092 1 Solution Tank 260 Light Grey

5 260093 1 Chassis MMN 260

5A 260360 1 Mainframe MMN 260TD

6 260096B 1 Lid Recovery 260 Burgundy

7 260098 1 Front Skirt 260 Black

8 260142 1 Skirt Retainer L.H.

9 260143 1 Skirt Retainer R.H.

QtyQty

Qty

QtyQty

..

DescriptionDescription

.

Description

..

DescriptionDescription

7

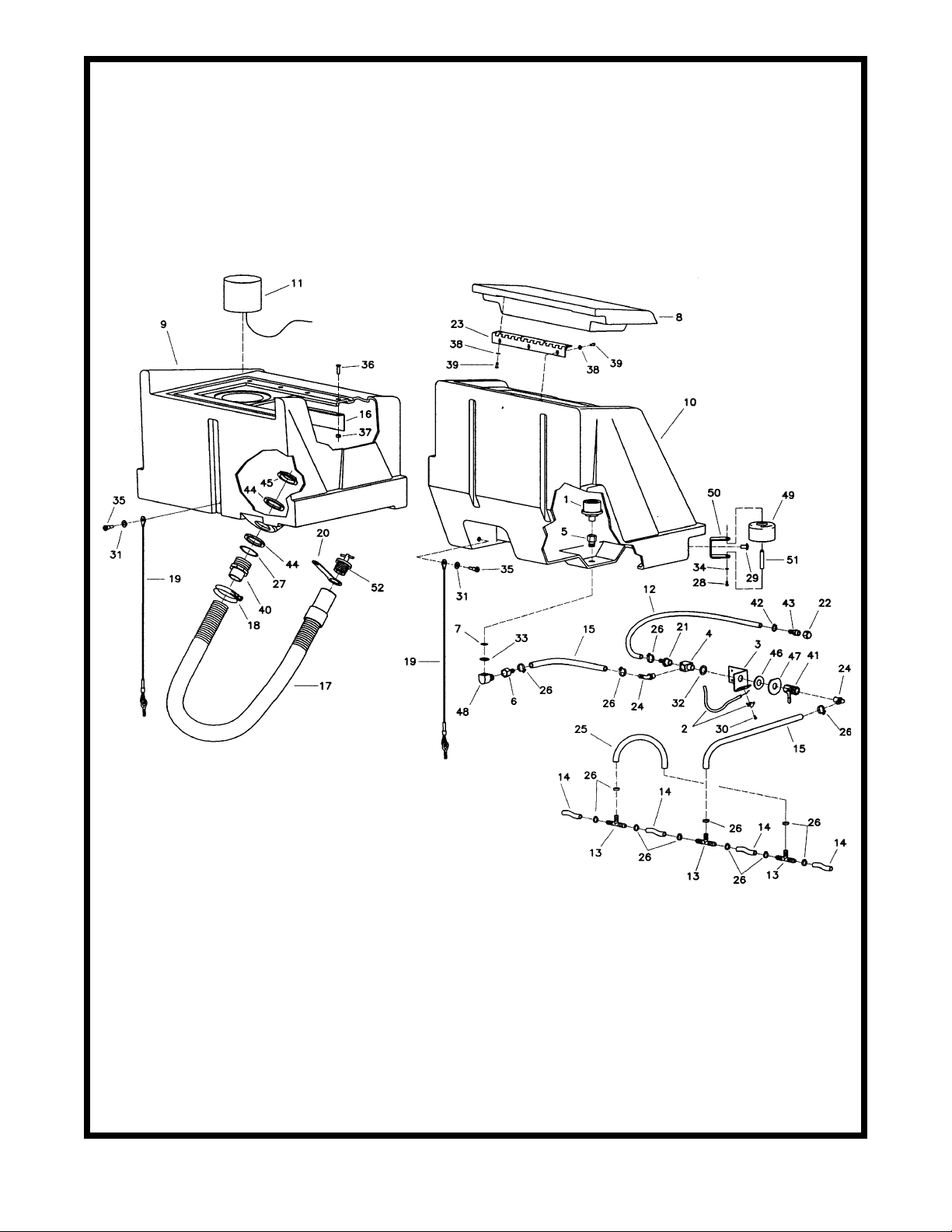

Page 10

Brush DrivenBrush Driven

Brush Driven

Brush DrivenBrush Driven

8

Page 11

PartPart

Part

PartPart

s Lists List

s List

s Lists List

ItemItem

Item

ItemItem

1 130118 1 Strainer Solution M3-40

2 210045 1 Cable Solution Control

3 210370 1 Solution Valve Bracket

4 210408 1 Fitting Brass Tee 3/8MPT x 3/8FPT

5 210409 1 Fitting Brass 3/8MPT x 3/8FPT

6 210410 1 Fitting Brass 3/8FPT x 3/8HOSE

7 210414 1 O-Ring 2-113

8 260029B 1 Solution Lid Burgundy

9 260091 1 Recovery Tank 260 Lt Grey

10 260092 1 Solution Tank 260 Lt Grey

11 260156 1 Float Assembly

12 260162 1 Hose, Solution Dump 38”

12A 260193 1 Solution Hose 3/8 Nylobr

13 260178 3 Fitting Nylon T 3/8 Hose

14 260179 4 Hose Nylobraid 3/8 x 2.38

15 260182 2 Solution Hose C/L 18"

16 260184 1 Support Angle

17 260202 1 Hose Assembly 260B New Style

18 260203 1 Hose Clamp 102120 Murray

19 260214 2 Tank Cable Assy. 260

20 320269 1 Strap, Drain Plug Retaining

21 342430 1 Fitting Brass 3/8MPT x 3/8HOSE

22 430114 1 Fitting Nylon Cap 1/4 FPT

23 450021 1 Hinge

24 450040 2 Elbow PLT 3/8MPT x 3/8BARB

25 450055 1 Hose Nylon 3/8 ID 9"

26 450076 13 Crimp Clamp SS 185R SS

27 450081 1 WSR 1.908 x 2.41 x .03 SS

28 710353 2 SCR-MC 10-32 x .37 Zinc

29 710985 2 SCR-SC 3/8-16 x .62

30 711124 1 SCR-ST-B 10 x .37 NI

31 711506 2 WSR-Flat 5/16 (Narrow) ST PL

32 711512 1 WSR-Flat .75 x 1.37 x .08

33 711513 1 WSR-Flat .689 x 1.06 x .029 SS

34 711553 2 WSR-Internal Lock #10

35 712041 2 Bolt-Shoulder 1/4-20 x .44 x .3

36 712563 4 SCR-MC 1/4-20 x 1.00 SS

37 712667 4 Nut-Hex Nyloc 1/4-20 SS

38 712764 7 WSR #10 SS

39 712822 7 SCR-MC TR HD 10-24 x .50 SS

40 760220MCH 1 1.5 Adapter MCH

41 809413MCH 1 Valve Solution

42 828490 1 Clamp Crimp 140R

43 828952 1 Fitting PP 1/4MPT x 3/8BARB

44 828970 2 WSR-Neop 1.87 x 2.4 x .125

45 828971 1 Nut 1 1/2 Pipe Thread

46 828975 1 WSR-Neop .75 x 1.5 x .09

47 829463 1 SS Washer

48 830062 1 Fitting Brass 90 3/8MPT x 3/8FPT

49 832896 2 Guide Wheel

50 832949 2 Bracket, Bumper

51 833254 2 Bumper Wheel Axle

52 833316 1 Drain Plug

Part No.Part No.

Part No.

Part No.Part No.

QtyQty

Qty

QtyQty

..

.

..

DescriptionDescription

Description

DescriptionDescription

9

Page 12

Brush DrivenBrush Driven

Brush Driven

Brush DrivenBrush Driven

10

Page 13

PartPart

Part

PartPart

s Lists List

s List

s Lists List

ItemItem

Item

ItemItem

1 210142 1 Pedal Pad

2 260030 5 Bushing .5015 x .628 x .375 OI

3 260041 2 Bushing-FLG .502 x .750 x .375

4 260043 1 Lift Arm, Left Side

5 260044 1 Lift Arm, Right Side

6 260046 1 Pedal Brace

7 260054 1 Pedal Weldment

8 260055PTD 1 Lift Handle Weldment

9 260075 1 Yoke Weldment

10 260090 1 Rear Base Char Gray

11 260093 1 Chassis MMN 260

12 260125 1 Bushing, Yoke .407 x 1.687 STL

13 260128 1 Spacer-Yoke

14 260130 2 Wheel 10" w/Bushing

15 260136 2 Wheel Axle Bracket Asy

16 260141 1 Spacer - Lift Arm

17 260317 1 Squeegee Mechanical Assy

18 710196 4 SCR-MC 5/16-18 x .62

19 710986 2 SCR BHCS 3/8-16 x 1.00 Zinc

20 710992 1 Shoulder Bolt 1/2 x 1.25 x 3/8

21 711228 8 Bolt HH 5/16-18 x .75 STL Zinc

22 711232 4 Bolt HH 5/16-18 x 1.50

23 711242 8 Bolt HH 3/8-16 x 1.00

24 711250 2 Bolt HH 3/8-16 x 1.25 STL Zinc

25 711374 2 Nut-Nyloc 5/16-18

26 711375 2 Nut-Nyloc 3/8-16 1/2 Nut

27 711380 2 Nut, Nyloc 3/8-16

28 711439 3 Nut Flanged Wizz 3/8-16

29 711507 2 WSR-Flat .37 x 1.12 x .06

30 711512 8 Washer Flat .75 x 1.38 x .08

31 711515 8 WSR-Flat .406 x .812 x .0625

32 711545 16 Washer Helical 5/16

33 711546 12 Washer Helical 3/8

34 711575 22 Washer Flat .31 x .75 x .06 STL

35 711579 2 WSR-Flat .56 x 1.00

36 712081 2 Shoulder Bolt 5/16-18 x .75

37 712099PLT 2 Shoulder Bolt 1/2 x 1/2

38 712310 6 WSR-Flat .52 x .87 x .06 PL

39 712680 4 Nut-Hex 5/16 -18 SS

40 713045 1 Bolt HH 3/8-16 x 1.75 #5

41 713048 1 Bolt HH 3/8-16 x 2.50 #5

42 762107 2 Spacer 1.00 x 1.25 x .25

43 762340 2 Bushing .502 x .625 x .270 STL

44 809247 2 Spacer .442 x .50 x .312

45 827110 2 Caster 5"

46 832829 2 Nut-U Type 5/16-18

Part No.Part No.

Part No.

Part No.Part No.

QtyQty

Qty

QtyQty

..

DescriptionDescription

.

Description

..

DescriptionDescription

11

Page 14

Brush DrivenBrush Driven

Brush DrivenBrush Driven

Brush Driven

12

Page 15

PartPart

Part

PartPart

ItemItem

Item

ItemItem

Part No.Part No.

Part No.

Part No.Part No.

1 210066 2 Drive Hub Retainer Bolt

2A 260002 2 Pad Holder-26B

2B 260003 2 Brush Feed Thru Bassine

2C 260004 2 Brush 26B Nylon

2D 260005 2 Brush Poly-Grit 26B

2E 260006 2 Brush Strata-Grit 26B

3 260009 1 Battery Tray

4 260030 8 Bushing .5015 x .628 x .375 OI

5 260036 12 Pin, Retainer

6 260038PTD 1 Motor Mount Weldment R.H.

7 260039PTD 1 Motor Mount Weldment L.H.

8 260041 13 Bushing-FLG .502 x .750 x .375

9 260042 1 Actuator Bar Weldment

10 260049 4 Linkage Bar

11 260053 2 Cable Push/Pull

12 260066 2 Bushing-FLG .377 x .687 x .406

13 260068 1 Spacer, Spring

14 260076 1 Bracket Anderson Plug

15 260077 1 Motor Frame Weldment

16 260114 2 Linkage Weldment

17 260123 1 Cable Bracket Weldment L.H.

18 260124 1 Cable Bracket Weldment R.H.

19 260137 1 Spring Comp .960 x 2.00 Zinc

20 260150 1 Battery Liner

21 260159 1 Hose Vac 1.5 x 78” Wireloc

22 260175 1 Cable Conduit

23 260183 1 Nut 1/4 NPT NYL

24 260193 1 Solution Hose 3/8 Nylobr

25 260194 1 Pressure Hose 3/8 x 50

26 260203 1 Clamp Hose 102120 Murray

27 260214 2 Tank Cable Assembly 260

28 260224 1 Drain Hose 1/4 x 18 Silicone

29 260315 1 Lift Cable Bracket

30 260377 1 Squeegee Cable

31 290017 1 Molded Vac Motor Gasket

32 320248 2 Clevis, Slotted

33 320271 1 Fitting PP 90 3/8MPT 3/8HOSE

34 320272 2 Nozzle Body Lock Nut

35 320273 1 Hose Shut-Off Clamp

36 364-816 1 Nut-Nyloc 1/2-13 Half

37 380064 1 Foam Ring

38 430035 2 Drive Hub

39 450038-H 2 Z-Bracket 5.7 VDE Zinc

40 450076 4 Crimp Clamp 185R SS

41 710180 2 SCR-MC 1/4-20 x .75 Zinc

42 710823 2 SCR-SC 1/4-20 x .50 Nylon

QtyQty

Qty

QtyQty

..

DescriptionDescription

.

Description

..

DescriptionDescription

s Lists List

s List

s Lists List

ItemItem

Item

ItemItem

Part No.Part No.

Part No.

Part No.Part No.

43 710986 8 SC 3/8-16 x 1.00 Zinc

44 711128 1 SCR-ST-B Hi-Lo 8 x .62 Zinc

45 711160 3 SCR-HI/LO #10 x 5/8 Zinc

46 711161 2 SCR-HI/LO #10 x 3/4 Zinc

47 711203 6 Bolt-HH 1/4-20 x .62

48 711210 2 Bolt-HH 1/4-20 x 1.25 STL Zinc

49 711228 2 Bolt-HH 5/16-18 x .75 STL Zinc

50 711316 2 Nut-Hex 1/4-20 ST PL

51 711334 2 Nut-Hex 1/2-13 ST PL

52 711350 4 Nut-Hex Nyloc 10-32

53 711368 2 Wing Nut Nyloc 1/4-20 PL

54 711375 3 Nut-Nyloc 3/8-16 1/2 Nut

55 711425 9 Nut-Flanged Wizz 1/4-20

56 711505 11 WSR-Flat 1/4

57 711510 1 WSR-Flat .50 x 1.37 x .10

58 711517 2 WSR-Flat .77 x 1.37 x .03

59 711524 2 WSR-Wave .52 x .87 x .01

60 711535 6 WSR-Helical 1/4

61 711545 2 WSR-Helical 5/16

62 711713 14 Ret Ring-E Ext .50

63 711717 2 Ret Ring-E Ext .37

64 712129 2 SCR-TR 1/4-20 x 1.00 HWH

65 712301 2 WSR-Flat .37 x .87 x .06 (Wide)

66 712310 25 WSR-Flat .52 x .87 x .06 PL

67 712545 4 SCR-MC 10-32 x .87 SS

68 712667 1 Nut-Hex Nyloc 1/4-20 SS

69 740132 2 Insulator (Glastic)

70 740159 1 Circuit Brkr-175 Red Housing

71 740209 2 Gearmotor 24V 17B

72 740225 1 Vac Motor 6515 24V

73 762073 1 Bushing .259 x .375 x .265

74 762256PLT 2 Nut Adj LH Zinc PLT

75 809444 1 Clip Cord

76 828264 1 Washer Cup

77 828490 1 Crimp Clamp 140R

78 829067 2 Crimp Clamp 560R

79 832996 1 Terminal Block 2 Pole VDE

80 833191 1 Hose Rubber Flex 2 x 9

81 833265PLT 1 Threaded Spacer PLT Zinc

82 833299 1 Pump 100 PSI 24V DC

83 833325 4 Fitting Nylon 90 1/4MPT 3/8HOSE

84 833638 2 Brass Stud

85 833725 2 Clip-T

86 840011 1 Vac Motor Cover, Top

87 840012 1 Vac Motor Cover, Bottom

QtyQty

Qty

QtyQty

..

DescriptionDescription

.

Description

..

DescriptionDescription

13

Page 16

Brush DrivenBrush Driven

Brush Driven

Brush DrivenBrush Driven

14

Page 17

DescriptionDescription

DescriptionDescription

Description

..

..

.

QtyQty

QtyQty

Qty

Part No.Part No.

Part No.Part No.

Part No.

ItemItem

ItemItem

Item

s Lists List

s Lists List

s List

PartPart

PartPart

Part

36 711595 1 WSR-Flat .59 x 1.18 x .09

37 711668 2 Clevis Pin 3/8 x 1 11-141

38 711671 1 Clevis Pin .31 x 2.13 11-10

39 711808 1 Pin-Hairpin Cotter #13

40 712070 1 Bolt-Shoulder 5/16 x 3/4 x 1/4

41 712100 2 Bolt-Shoulder 3/8 x 2.25

42 712310 1 WSR-Flat .52 x .87 x .06 PL

43 712320 8 WSR-Nylon .22 x .45 x .04 NYL

44 712540 6 SCR-MC 10-24 x .37 SS TH

45 712822 8 SCR-MC TR HD 10-24 x .50 SS

46 715144 1 Decal Aux. Pump (175)

47 715601 1 Decal Forward 260

48 715602 1 Decal Reverse 260

49 715603 1 Decal Squeegee Lift 260

50 715604 1 Decal Solution 260

51 715605 1 Decal Brush Position

52 740131 1 Circuit Breaker 70 amp Push Button

53 740132 2 Insulator (Glastic)

54 740188 1 Switch-20 amp 1.5HP

55 740216 1 Gauge Battery Condition

56 740241 1 Contactor 24V 50 amp

57 740247 1 Circuit Breaker 30 amp Push Button

58 760277 1 Switch Guard

59 760286 1 Wire Formed Hook

60 762400 1 Bushing Heyco 1-5/8 x 2-1/8

61 788147 1 Solenoid 24VDC

62 809311 2 Cotter Pin 7/64 x 1

63 809754 2 Switch Rocker

63CE 740711CE 2 Switch Dreefs w/Splashguard

64 828368 1 BH2-61 Male Coupler

65 831306 1 Fitting Brass 90 1/4MPT 1/4MPT

66 833102 1 Spring Knob .60 x .73 x 1.75 Z

67 833374 2 Pin-Hairpin Cotter 3/8

68 833473 1 Fitting Brass 1/4FPT x 3/8HOSE

69 833638 2 Brass Stud

70 881002 2 Clevis Pin 11-083 Zinc

DescriptionDescription

DescriptionDescription

Description

..

..

.

QtyQty

QtyQty

Qty

Part No.Part No.

Part No.Part No.

Part No.

1 210045 1 Cable Solution Control

2 260053 2 Cable Push/Pull

3 260066 4 Bushing-FLG .377 x .687 x .406

4 260069MCH 1 Left Handle Machined

5 260070MCH 1 Right Handle Machined

ItemItem

ItemItem

Item

6 260081 1 Cable Mount Weldment

7 260084BDSP 1 Dashboard, 260BD Screen Printed

7CE 260084BCEDSP 1 Dashboard, 260BD CE Screen Printed

8 260099 1 Control Lever Mounting Bracket

9 260173 1 Electrical Box MTG

11 260274 2 Grommet Z-421

10 260194 1 Pressure Hose 3/8 x 50”

12 260284 1 Rear Panel Asy 260TD

13 260286 1 Squeegee Handle Weldment

14 260291 1 Handle Grip 260TD

15 260325 1 Handle Bracket

16 260337 1 Squeegee Cable

17 320248 2 Clevis, Slotted

18 320297 1 320 Squeegee Assembly New

15

19 430051 2 Spring-Return .313 x .438 x 2.

20 450059 1 Fitting Brass 1/4MPT 1/4MPT

21 450076 1 Crimp Clamp 185R SS

22 710178 4 SCR-MC TR HD 1/4-20 x .50 Zinc

23 710180 17 SCR-MC 1/4-20 x .75 Zinc

24 711125 2 SCR-ST-B 10 x .50 NI

25 711128 2 SCR- ST-B HI/LO 8 x .62 Zinc

26 711161 2 SCR-HI/LO #10 x 3/4 Zinc

27 711368 2 Wing Nut Nylon 1/4-20 PL

28 711373 1 Nut-Nyloc 1/4-20

29 711420 2 Nut-Hex Jam 5/16-18 STPL

30 711503 2 WSR-Flat #10

31 711505 4 WSR-Flat 1/4

32 711523 4 WSR-WAVE .37 x .68 x .08

33 711544 4 WSR-Helical 1/4

34 711575 1 WSR-Flat .31 x .75 x .06 STL

35 711594 1 WSR-Flat .56 x .88 x .03 Nickel

Page 18

raction Drivenraction Driven

raction Drivenraction Driven

raction Driven

TT

TT

T

16

Page 19

PartPart

Part

PartPart

s Lists List

s List

s Lists List

ItemItem

Item

ItemItem

1 130118 1 Solution Strainer M3-40

2 210045 1 Cable Solution Control

3 210370 1 Solution Valve Bracket

4 210408 1 Fitting Brass Tee 3/8 MPT 3/8 FPT

5 210409 1 Fitting Brass 3/8 MPT 3/8 FPT

6 210410 1 Fitting Brass 3/8 FPT 3/8 Hose

7 210414 1 O-Ring 2-113

8 260029B 1 Solution Lid Burgundy

9 260091 1 Recovery Tank 260 Lt Gray

10 260092 1 Solution Tank 260 Lt Gray

11 260156 1 Float Assembly

12 260162 1 Hose - Solution Dump 38"

13 260178 3 Fitting Nylon T 3/8 Hose

14 260179 4 Hose Nylobraid 3/8 x 2.38"

15 260182 1 Solution Hose C/L 18”

16 260184 1 Support Angle

17 260202 1 Hose Assembly 260B New Style

18 260203 1 Hose Clamp 102120 Murray

19 260214 2 Tank Cable Assembly

20 260215 1 Bracket Water Valve

21 260216 1 Solution Reinforced 3/8 x 14.75

22 320254 1 Solution Reinforced

23 320269 1 Strap, Drain Plug Retaining

24 342430 1 Fitting Brass 3/8 MPT x 3/8 HOSE

25 430114 1 Fitting Nylon Cap 1/4 FPT

26 450021 1 Hinge

27 450040 2 Elbow PLT 3/8 MPT 3/8 Barb

28 450055 1 Hose Nylon 3/8 ID x 9"

29 450076 15 Crimp Clamp 185R SS

30 450081 1 WSR-SS 1.908 x 2.41 x .03 SS

31 710353 2 SCR-MC 10-32 x .37 Zinc

32 710985 2 SC 3/8-16 x .62

33 711124 1 SCR-ST-B 10 x .37 NI

34 711506 2 WSR-Flat 5/16 (Narrow) ST PL

35 711512 1 WSR-Flat .75 x 1.37 x .08

36 711513 1 WSR-Flat .689 x 1.06 x .029 SS

37 711553 2 WSR-Internal Lock 10

38 712041 2 Bolt-Shoulder 1/4-20 x .44 x .3

39 712540 7 SCR-MC 10-24 x .50 SS TH

40 712560 4 SCR-MC 1/4-20 x .50 SS NYL

41 712563 4 SCR-MC 1/4-20 x 1.00 SS

42 712667 4 Nut-Hex Nyloc 1/4-20 SS

43 712764 7 WSR-Flat #10 SS

44 740482 1 Diode Assembly

45 740493 1 Water Valve 24VDC

46 760220MCH 1 1.5 Adapter MCH

47 809413MCH 1 Valve, Solution

48 828490 2 Clamp-Crimp 140R

49 828952 1 Fitting PP 1/4MPT 3/8Barb

50 828970 2 WSR-Neop 1.87 x 2.4 x .125

51 828971 1 Nut 1 1/2 Pipe Thread

52 828975 1 WSR-Neoprene .75 x 1.5 x .09

53 829463 1 SS Washer

54 830062 1 Fitting Brass 90 3/8 MPT 3/8 FPT

55 832896 2 Guide Wheel

56 832949 2 Bracket, Bumper

57 833254 2 Bumper Wheel Axle

58 833316 1 Drain Plug

59 833325 1 Fitting Nylon 90 1/4MPT x 3/8Barb

Part No.Part No.

Part No.

Part No.Part No.

QtyQty

Qty

QtyQty

..

.

..

DescriptionDescription

Description

DescriptionDescription

17

Page 20

TT

raction Drivenraction Driven

T

raction Driven

TT

raction Drivenraction Driven

18

Page 21

PartPart

Part

PartPart

s Lists List

s List

s Lists List

ItemItem

Item

ItemItem

1 210142 1 Pedal Pad

2 260030 5 Bushing-.5015 x .628 x .375 OI

3 260041 2 Bushing-FLG .502 x .750 x .375

4 260043 1 Lift Arm, Left Side

5 260046 1 Pedal Brace

6 260044 1 Lift Arm, Right Side

7 260054 1 Pedal Weldment

8 260055PTD 1 Lift Handle Weldment

9 260075 1 Yoke Weldment

10 260125 1 Bushing, Yoke .407 x 1.687 STL

11 260128 1 Spacer-Yoke

12 260141 1 Spacer-Lift Arm

13 260256 1 Base 260TD Char Grey

14 260317 1 Squeegee Mech. Assy.

15 260360 1 Mainframe MMN 260TD

16 260366 2 Transaxle Bracket 260TD

17 260370 2 Wheel 10 x 2.75 x .75 BORE

18 260371 2 Key 3/16 x 3/16 x 2.00

19 710196 4 SCR-MC 5/16-18 x .75

20 710986 2 SCR 3/8-16 x 1.00 Zinc

21 710992 1 Shoulder Bolt 1/2 x 1.25 x 3/8

22 711228 8 Bolt-HH 5/16-18 x .75 STL Zinc

23 711232 4 Bolt-HH 5/16-18 x 1.50

24 711250 2 Bolt-HH 3/8-16 x 1.25 STL Zinc

25 711374 2 Nut Nyloc 5/16-18

26 711375 2 Nut-Nyloc 3/8-16 1/2NUT

27 711380 2 Nut, Nyloc 3/8-16

28 711439 3 Nut-Flanged Wizz 3/8-16

29 711507 2 WSR-Flat .37 x 1.12 x .06

30 711512 2 WSR-Flat .75 x 1.37 x .08

31 711545 16 Washer Helical 5/16

32 711546 10 Washer Helical 3/8

33 711575 22 Washer Flat .31 x .75 x .06 STL

34 711579 2 WSR-Flat .56 x 1.00

35 712081 2 Shoulder Bolt 5/16-18 x .75

36 712099PLT 2 Shoulder Bolt 1/2 x 1/2

37 712310 6 WSR-Flat .52 x .87 x .06 PL

38 712680 4 Nut-Hex 5/16-18 SS

39 713042 4 Bolt-HH 3/8-16 x 1.00 #5

40 713045 1 Bolt-HH 3/8-16 x 1.75 #5

41 713048 1 Bolt-HH 3/8-16 x 2.50 #5

42 744160 1 Transaxle 13” 24V

43 762340 2 Bushing .502 x .625 x .270 STL

44 809226 2 WSR-Flat .40 x 1.50 x .12

45 809247 2 Spacer .442 x .50 x .312

46 827110 2 Caster 5”

47 832829 2 Nut-U Type 5/16 x 18

Part No.Part No.

Part No.

Part No.Part No.

QtyQty

Qty

QtyQty

..

.

..

DescriptionDescription

Description

DescriptionDescription

19

Page 22

raction Drivenraction Driven

raction Drivenraction Driven

raction Driven

TT

TT

T

20

Page 23

PartPart

Part

PartPart

s Lists List

s List

s Lists List

ItemItem

Item

ItemItem

Part No.Part No.

Part No.

Part No.Part No.

1 210066 2 Drive Hub Retainer Bolt

2A 260002 2 Pad Driver 26B

2B 260003 2 Brush Feed Thru Bassine

2C 260004 2 Brush 26B Nylon

2D 260005 2 Brush Polygrit 26B

2E 260006 2 Brush Stratagrit 26B

3 260009 1 Battery Tray 14GA

4 260030 8 Bushing .5015 x .628 x .375 OI

5 260036 13 Pin, Retainer

6 260038PTD 1 Motor Mount Weldment R.H.

7 260039PTD 1 Motor Mount Weldment L.H.

8 260041 13 Bushing-FLG .502 x .750 x .375

9 260049 4 Linkage Bar .312 GA

10 260066 2 Bushing-FLG .377 x .687 x .406

11 260068 1 Spacer, Spring

12 260076 1 Bracket Anderson Plug

13 260077 1 Motor Frame Weldment

14 260137 1 Spring Comp .960 x 2.00 Zinc

15 260150 1 Battery Liner

16 260159 1 Vac Hose 1.5 x 78” Wireloc

17 260175 1 Cable Conduit

18 260183 2 Nut 1/4 NPT Nyl

19 260187 1 Retainer Bar Weldment R.H.

20 260193 1 Solution Hose 3/8 Nylobr

21 260194 1 Pressure Hose 3/8 x 50”

22 260203 1 Clamp Hose 102120 Murray

23 260214 2 Tank Cable Assy. 260

24 260224 1 Drain Hose 1/4 x 18” Silicone

25 260250 1 Retainer Bar Weldment L.H.

26 260337 1 Squeegee Cable

27 260315 1 Lift Cable Bracket 3/16 GA

28 290017 1 Molded Vac Motor Gasket

29 320248 2 Pin-Clevis, Slotted

30 320271 1 Fitting PP 90 3/8MPT 3/8HOSE

31 320272 2 Nozzle Body Lock Nut

32 320273 1 Hose Shut-Off Clamp

33 380064 1 Foam Ring

34 430035 2 Drive Hub

35 450038-H 2 Z-Bracket 5.7 VDE Zinc

36 450076 4 Crimp Clamp 185R SS

37 710180 2 SCR-MC 1/4-20 x .75 Zinc

38 710129 2 SCR-MC 8-32 x .50 Zinc

QtyQty

Qty

QtyQty

..

.

..

DescriptionDescription

Description

DescriptionDescription

ItemItem

Item

ItemItem

Part No.Part No.

Part No.

Part No.Part No.

39 710823 2 SC 1/4-20 x .50 Nylon

40 710986 8 SC 3/8-16 x 1.00 Zinc

41 711128 1 SCR-ST-B Hi/Lo 8 x .62 Zinc

42 711160 3 SCR Hi/Lo 10 x 5/8 Zinc

43 711203 2 Bolt-HH 1/4-20 x .62

44 711210 2 Bolt-HH 1/4-20 x 1.25 STL Zinc

45 711228 2 Bolt-HH 5/16-18 x .75 STL Zinc

46 711334 2 Nut-Hex 1/2-13 ST PL

47 711350 4 Nut Nyloc 10-32

48 711368 2 Wing Nut Nyloc 1/4-20 PL

49 364-816 1 Nut-Nyloc 1/2-13 Half

50 711425 10 Nut-Flanged Wizz 1/4-20

51 711505 7 WSR-Flat 1/4

52 711510 2 WSR-Flat .50 x 1.37 x .10

53 711517 2 WSR-Flat .77 x 1.37 x .03

54 711544 2 WSR-Helical 1/4

55 711545 2 WSR-Helical 5/16

56 711713 13 Ret Ring-E Ext .50

57 711808 2 Pin-Hairpin Cotter #13

58 712301 6 WSR-Flat .37 x .87 x .06 (Wide)

59 712310 25 WSR-Flat .52 x .87 x .06 PL

60 712545 4 SCR-MC 10-32 x .87 SS

61 712667 1 Nut-Hex Nyloc 1/4-20 SS

62 740132 2 Insulator (Glastic)

63 740159 1 Circuit Brkr-175 Red Housing O

64 740209 2 Gearmotor 24V 17B

65 740225 1 Vac Motor 6515-13 24V

66 762073 1 Bushing .259 x .375 x .265

67 809444 1 Clip Cord

68 828264 1 Washer Cup

69 828490 1 Clamp-Crimp 140R

70 829067 2 Clamp-Crimp 560R

71 832996 1 Terminal Block 2POLE VDE

72 833191 1 Hose Rubber Flex 2 x 9

73 833265PLT 1 Threaded Spacer PLT Zinc

74 833299 1 Pump 100 PSI 24V DC

75 833325 4 Fitting Nylon 90 1/4MPT 3/8HOS

76 833621 2 Key 1/4 x 1/4 x 1

77 833638 2 Brass Stud

78 840011 1 Vac Motor Cover, Top

79 840012 1 Vac Motor Cover, Bottom

QtyQty

Qty

QtyQty

..

.

..

DescriptionDescription

Description

DescriptionDescription

21

Page 24

TT

raction Drivenraction Driven

T

raction Driven

TT

raction Drivenraction Driven

22

Page 25

45 712070 1 Bolt-Shoulder 5/16 x 3/4 x 1/4

46 712100 2 Bolt-Shoulder 3/8 x 2.25

47 712310 5 WSR-Flat .52 x .87 x .06 PL

48 712320 2 WSR-Nylon .22 x .45 x .04

49 712540 6 SCR-MC 10-24 x .37 SS TH

50 712570 2 SCR-MC 1/4-20 x 1.75 SS

s Lists List

s Lists List

s List

PartPart

PartPart

Part

DescriptionDescription

DescriptionDescription

Description

..

..

.

QtyQty

QtyQty

Qty

52 712822 8 SCR-MC 10-24 x .87 Zinc

51 712814 1 SCR-MC TR HD 10-24 x .50 SS

53 715144 1 Decal Aux. Pump (175)

54 715602 1 Decal Reverse 260

55 715603 1 Decal Squeegee Lift 260

56 715604 1 Decal Solution 260

57 715605 1 Decal Brush Position

58 715608 1 Decal Forward 260TD

59 740131 1 Circuit Breaker 70 amp Push Button

60 740132 2 Insulator (Glastic)

61 740188 1 Switch 20amp 1.5hp

62 740216 1 Gauge Battery Condition

63 740241 2 Contactor 24V 50amp

64 740247 1 Circuit Breaker 30amp Push Button

65 740736 1 Switch - 3 Position

65CE 742102 1 Switch 23670C4D

66 740804 1 Potentiometer Assembly

67 740811 3 Switch Boot CE

68 740944-1 1 SPD Control 24V 1203A225

69 741005 1 Keyswitch On-Off

70 741007 1 Hour Meter 10-80 VDC

71 741037 1 Relay-True Off 24V 5sec

72 760277 1 Switch Guard

73 760286 1 Wire Formed Hook

74 762400 1 Heyco Bushing 1-5/8 x 2-1/8

75 788147 1 Solenoid 24VDC

76 805637 1 SCR Insulator

77 809311 2 Cotter Pin 7/64 x 1

78 809754 2 Switch Rocker

78CE 740711CE 2 Switch Dreefs w/Splashguard

79 809874 1 Knob Speed Control

80 827060 1 Switch-Drive

81 828368 1 BH2-61 Male Coupler

82 828935 2 Spacer

83 831306 1 Fitting Brass 90 1/4MPT 1/4FPT

84 832015 2 Spacer .38 x .5 x .14

85 833102 1 Spring Knob .60 x .73 x 1.75 Z

86 833374 2 Pin Hairpin Cotter 3/8

87 833473 1 Fitting Brass 1/4FPT x 3/8HOSE

88 833638 2 Brass Stud

89 881002 2 Clevis Pin 11-083 Zinc

Part No.Part No.

Part No.Part No.

Part No.

1 200340 2 Spacer-SCR Board

2 210045 1 Cable Solution Control

3 260066 4 Bushing-FLG .377 x .687 x .406

4 260069MCH 1 Left Handle Machined

5 260070MCH 1 Right Handle Machined

6 260099 1 Control Lever Mounting Bracket

ItemItem

ItemItem

Item

7 260084TDSP 1 Dashboard 260TD Screen Printed

7CE 260084CETDSP 1 Dashboard 260TDCE Screen Printed

8 260194 1 Pressure Hose 3/8 x 50

9 260198 1 Switch Bracket 260TD

11 260253 1 Electrical Panel

10 260210 1 Moisture Guard SCR 260TD

12 260254 1 Switch Actuator 260TD

13 260255 1 Speed Control Bracket 260TD

13CE 260255CE 1 Speed Control Bracket 260TDCE

14 260274 3 Grommet Z-421

15 260284 1 Rear Panel Asy 260TD

16 260286 1 Squeegee Handle Weldment

17 260291 1 Handle Grip 260TD

18 260337 1 Squeegee Cable

23

19 320248 2 Clevis, Slotted

20 320297 1 320 Squeegee Assembly New

21 430051 2 Return Spring .313 x .438 x 2.

22 450059 1 Fitting Brass 1/4MPT 1/4MPT

23 450076 1 Crimp Clamp 185R SS

24 710178 4 SCR-MC TR HD 1/4-20 x .50 Zinc

25 710180 15 SCR-MC 1/4-20 x .75 Zinc

26 711125 2 SCR-ST-B 10 x .50 NI

27 711128 2 SCR-ST-B HI/LO 8 x .62 Zinc

28 711161 6 SCR-HI/LO 10 x 3/4 Zinc

29 711368 2 Wing Nut Nyloc 1/4-20 PL

30 711372 2 Nut-Nyloc 8-32

31 711373 1 Nut-Nyloc 1/4-20

32 711420 2 Nut-Hex Jam 5/16-18 STPL

33 711503 2 WSR-Flat #10

34 711505 4 WSR-Flat 1/4

35 711506 2 WSR-Flat 5/16 (Narrow) STPL

36 711523 4 WSR-WAVE .37 x .68 x .08

37 711544 4 WSR-Helical 1/4

38 711553 1 WSR-Internal Lock #10

39 711575 1 WSR-Flat .31 x .75 x .06 STL

40 711594 1 WSR-Flat .56 x .88 x .03 Nickel

41 711595 1 WSR-Flat .594 x 1.18 x .09

42 711668 2 Clevis Pin 3/8 x 1 11-141

43 711671 1 Clevis Pin .31 x 2.13 11-10

44 711808 1 Pin-Hairpin Cotter #13

Page 26

Squeegee Mechanism Squeegee Mechanism

Squeegee Mechanism

Squeegee Mechanism Squeegee Mechanism

260317260317

260317

260317260317

AssemblyAssembly

Assembly

AssemblyAssembly

PartPart

Part

PartPart

ItemItem

Item

ItemItem

1 210375 1 Swivel Pin

2 210391 2 Torsion Spring .563 x 2.595 SS

3 210400 2 Spacer Tube

4 260041 2 Bushing-FLG .502 x .750 x .375

5 260292 4 Swing Bolt Zinc Plated

6 260312 1 Yoke Weldment 260

7 260314 1 Spring Housing Weldment

8 320008 2 Pivot Bracket Asy

9 430051 2 Return Spring .313 x .438 x 2.0

10 712592 2 SCR-MC TH 1/4-20 x 3.00 SS

11 711425 2 Nut-Flange Wizz 1/4-20

12 711504 1 WSR-Flat 1/4 SS

13 711517 2 WSR-Flat .77 x 1.37 x .03

14 711671 1 Pin Clevis .31 x 2.12 11-10

15 711715 2 Ret Ring-E Ext .75

16 711808 1 Pin-Hairpin Cotter #13

17 712320 2 WSR-Nylon .22 x .45 x .04 NYL

18 712536 2 SCR-MC 10-24 x .62 SS

19 712562 1 Bolt-HH 1/4-20 x .75 SS

20 712665 2 Nut-Hex 1/4-20 SS

21 712758 1 WSR-Helical 1/4 SS

Part No.Part No.

Part No.

Part No.Part No.

s Lists List

s List

s Lists List

QtyQty

..

Qty

.

QtyQty

..

DescriptionDescription

Description

DescriptionDescription

24

Page 27

SQUEEGEE SQUEEGEE

SQUEEGEE

SQUEEGEE SQUEEGEE

320297320297

320297

320297320297

ASSEMBLASSEMBL

ASSEMBL

ASSEMBLASSEMBL

YY

COMPLETE COMPLETE

Y

COMPLETE

YY

COMPLETE COMPLETE

Parts ListParts List

Parts List

Parts ListParts List

25

Page 28

ANDARD MODELANDARD MODEL

ANDARD MODELANDARD MODEL

ANDARD MODEL

WIRING DIAGRAM BRUSH DRIVE STWIRING DIAGRAM BRUSH DRIVE ST

WIRING DIAGRAM BRUSH DRIVE STWIRING DIAGRAM BRUSH DRIVE ST

WIRING DIAGRAM BRUSH DRIVE ST

26

Page 29

WIRING DIAGRAM BRUSH DRIVE CE MODELWIRING DIAGRAM BRUSH DRIVE CE MODEL

WIRING DIAGRAM BRUSH DRIVE CE MODELWIRING DIAGRAM BRUSH DRIVE CE MODEL

WIRING DIAGRAM BRUSH DRIVE CE MODEL

27

Page 30

ANDARD MODELANDARD MODEL

ANDARD MODELANDARD MODEL

ANDARD MODEL

TRACTION DRIVE STTRACTION DRIVE ST

TRACTION DRIVE STTRACTION DRIVE ST

TRACTION DRIVE ST

WIRING DIAGRAM WIRING DIAGRAM

WIRING DIAGRAM WIRING DIAGRAM

WIRING DIAGRAM

28

Page 31

WIRING DIAGRAM TRACTION DRIVE CE MODELWIRING DIAGRAM TRACTION DRIVE CE MODEL

WIRING DIAGRAM TRACTION DRIVE CE MODELWIRING DIAGRAM TRACTION DRIVE CE MODEL

WIRING DIAGRAM TRACTION DRIVE CE MODEL

29

Page 32

LIMITED WLIMITED W

LIMITED W

LIMITED WLIMITED W

Minuteman International, Inc. warrants to the original purchaser/user that this product is free from defects in workmanship and

materials under normal use and service for a period of three years from date of purchase. In addition, Minuteman International,

Inc. will, at its option, honor labor warranty claims for the first 12 months from date of sale, provided such claims are submitted

through and approved by factory authorized repair stations. Minuteman International, Inc. will, at its option, repair or replace

without charge, except for transportation costs, parts that fail under normal use and service when operated and maintained in

accordance with the applicable operation and instruction manuals.

This warranty does not apply to normal wear, or to items whose life is dependent on their use and care, such as belts, cords,

switches, hoses, rubber parts, electrical motor components or adjustments. Parts not manufactured by Minuteman International,

Inc. such as engines, batteries, battery chargers, hydraulic pumps, and tires are covered by and subject to the warranties and/

or guarantees of their manufacturers. Please contact Minuteman International, Inc. for procedures in warranty claims against

these manufacturers.

SS

pecial warning to purchaserpecial warning to purchaser

S

pecial warning to purchaser — Use of replacement filters and/or prefilters not manufactured by Minuteman International, Inc.

SS

pecial warning to purchaserpecial warning to purchaser

or its designated licensees, will void all warranties expressed or implied.

A potential health hazard exists without exact original equipment replacement.

All warranteed items become the sole property of Minuteman International, Inc. or its original manufacturer, whichever the case

may be.

Minuteman International, Inc. disclaims any implied warranty, including the warranty of merchantability and the warranty of

fitness for a particular purpose. Minuteman International, Inc. assumes no responsibility for any special, incidental or consequential

damages.

ARRANTYARRANTY

ARRANTY

ARRANTYARRANTY

This limited warranty is applicable only in the U.S.A. and Canada, and is extended only to the original user/purchaser of this

product. Customers outside the U.S.A. and Canada should contact their local distributor for export warranty policies. Minuteman

International, Inc. is not responsible for costs or repairs performed by persons other than those specifically authorized by Minuteman

International, Inc. This warranty does not apply to damage from transportation, alterations by unauthorized persons, misuse or

abuse of the equipment, use of non-compatible chemicals, or damage to property, or loss of income due to malfunctions of the

product.

If a difficulty develops with this machine, you should contact the dealer from whom it was purchased.

This warranty gives you specific legal rights, and you may have other rights which vary from state to state. Some states do not

allow the exclusion or limitation of special, incidental or consequential damages, or limitations on how long an implied warranty

lasts, so the above exclusions and limitations may not apply to you.

A Minuteman International Company

World HeadquartersWorld Headquarters

World Headquarters Minuteman Canada, Inc.

World HeadquartersWorld Headquarters

Minuteman International, Inc. 2210 Drew Road

111 South Rohlwing Road Mississauga, Ontario

Addison, Illinois 60101 L5S 1B1

(630) 627-6900 (905) 673-3222

FAX (630) 627-1130 FAX (905) 673-5161

988010

Rev. A 9/05

Printed in U.S.A.

Loading...

Loading...