MN1277 04.2001

NextMove PCI

Installation Manual

MN1277

Issue 2.3

NextMove PCI Installation Manual

ii

MN1277 04.2001

.

Copyright

MN1277 04.2001

iii

Copyright Baldor UK Ltd © 2001. All rights reserved.

This manual is copyrighted and all rights are reserved. This document or attached software may not, in whole or in part, be

copied or reproduced in any form without the prior written consent of Baldor UK.

Baldor Optimised Control makes no representations or warranties with respect to the contents hereof and specifically

disclaims any implied warranties of fitness for any particular purpose. The information in this document is subject to change

without notice. Baldor UK assumes no responsibility for any errors that may appear in this document.

MINT

™

is a registered trademark of Baldor UK Ltd.

Windows 95, Windows 98 and Windows NT are registered trademarks of the Microsoft Corporation.

Limited Warranty

For a period of two (2) years from the date of original purchase, BALDOR will repair or replace without charge controls and

accessories which our examination proves to be defective in material or workmanship. This warranty is valid if the unit has

not been tampered with by unauthorized persons, misused, abused, or improperly installed and has been used in accordance

with the instructions and/or ratings supplied. This warranty is in lieu of any other warranty or guarantee expressed or

implied. BALDOR shall not be held responsible for any expense (including installation and removal), inconvenience, or

consequential damage, including injury to any person or property caused by items of our manufacture or sale. (Some

countries and U.S. states do not allow exclusion or limitation of incidental or consequential damages, so the above exclusion

may not apply.) In any event, BALDOR’s total liability, under all circumstances, shall not exceed the full purchase price of

the control. Claims for purchase price refunds, repairs, or replacements must be referred to BALDOR with all pertinent data

as to the defect, the date purchased, the task performed by the control, and the problem encountered. No liability is assumed

for expendable items such as fuses.

Goods may be returned only with written notification including a BALDOR Return Authorization Number and any return

shipments must be prepaid.

Baldor UK Ltd

Mint Motion Centre

6 Bristol Distribution Park

Hawkley Drive

Bristol

BS32 0BF

U.K.

Telephone: +44 (0) 1454 850 000

Fax: +44 (0) 1454 859 001

Web site: www.baldor.co.uk

Sales email: sales@baldor.co.uk

Support email: technical.support@baldor.co.uk

Baldor Electric Company

Telephone: +1 501 646 4711

Fax: +1 501 648 5792

email: sales@baldor.com

web site: www.baldor.com

Baldor ASR GmbH

Telephone: +49 (0) 89 90508-0

Fax: +49 (0) 89 90508-492

Baldor ASR AG

Telephone: +41 (0) 52 647 4700

Fax: +41 (0) 52 659 2394

Australian Baldor Pty Ltd

Telephone: +61 2 9674 5455

Fax: +61 2 9674 2495

Baldor Electric (F.E.) Pte Ltd

Telephone: +65 744 2572

Fax:+65 747 1708

NextMove PCI Installation Manual

iv

MN1277 04.2001

Safety Information

MN1277 04.2001

v

Safety Notice

:

Only qualified personnel should attempt the start-up procedure

or troubleshoot this equipment.

This equipment may be connected to other machines that have rotating parts or parts that are

controlled by this equipment. Improper use can cause serious or fatal injury. Only qualified

personnel should attempt to start-up, program or troubleshoot this equipment.

Precautions:

WARNING: Do not touch any circuit board, power device

or electrical connection before you first

ensure that no high voltage present at this

equipment or other equipment to which it is

connected. Electrical shock can cause

serious or fatal injury. Only qualified

personnel should attempt to start-up,

program or troubleshoot this equipment.

WARNING: Be sure that you are completely familiar with

the safe operation of this equipment. This

equipment may be connected to other

machines that have rotating parts or parts

that are controlled by this equipment.

Improper use can cause serious or fatal

injury. Only qualified personnel should

attempt to program, start-up or troubleshoot

this equipment.

WARNING: Be sure that you are completely familiar with

the safe programming of this equipment.

This equipment may be connected to other

machines that have rotating parts or parts

that are controlled by this equipment.

Improper programming of this equipment can

cause serious or fatal injury. Only qualified

personnel should attempt to program, startup or troubleshoot this equipment.

WARNING: Be sure all wiring complies with the National

Electrical Code and all regional and local

codes. Improper wiring may result in unsafe

conditions.

NextMove PCI Installation Manual

vi

MN1277 04.2001

WARNING: The stop input to this equipment should not

be used as the single means of achieving a

safety critical stop. Drive disable, motor

disconnect, motor brake and other means

should be used as appropriate. Only qualified

personnel should attempt to program, startup or troubleshoot this equipment.

WARNING: Improper operation or programming of the

control may cause violent motion of the

motor shaft and driven equipment. Be certain

that unexpected motor shaft movement will

not cause injury to personnel or damage to

equipment. Peak torque of several times the

rated motor torque can occur during control

failure.

WARNING: The motor shaft will rotate during the homing

procedure. Be certain that unexpected motor

shaft movement will not cause injury to

personnel or damage to equipment.

CAUTION: To prevent equipment damage, be certain that

the input power has correctly sized protective

devices installed.

CAUTION: To prevent equipment damage, be certain that

input and output signals are powered and

referenced correctly.

CAUTION: To ensure reliable performance of this

equipment be certain that all signals to/from

the controller are shielded correctly.

CAUTION: Avoid locating this equipment above or

beside heat generating equipment or below

water steam pipes.

CAUTION: Avoid locating this equipment in the vicinity

of corrosive substances or vapors, metal

particles and dust.

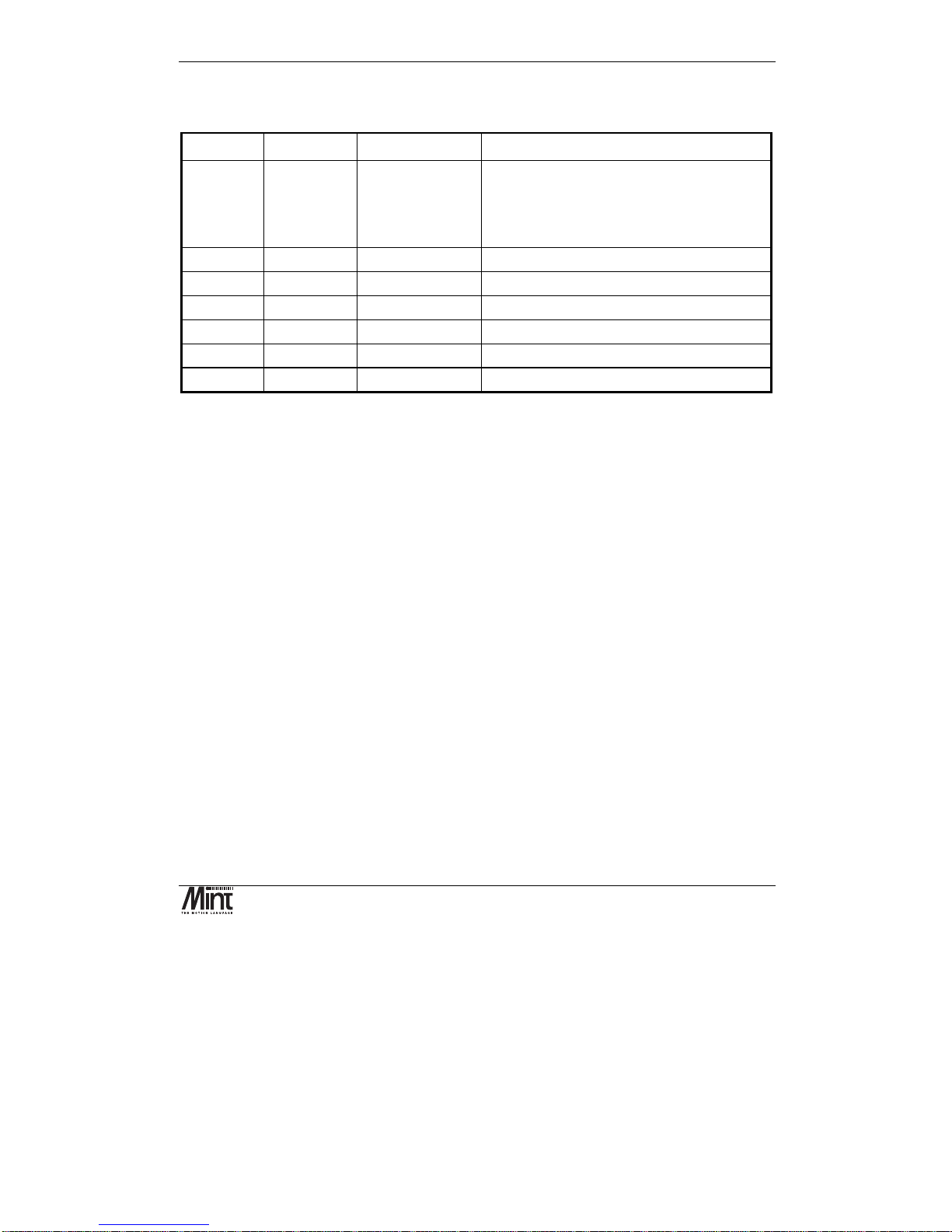

Manual Revision History

MN1277 04.2001

vii

Manual Revision History

Issue Date BOCL Reference Comments

1.0 Nov 1999 UM00506-000 First release of Hardware Guide based on

NextMove PC Manual. Updated sections are:

NextMove PCI Overview

NextMove PCI Hardware Guide

1.1 July 1999 UM00506-001 Changes for i2 Breakout Unit

1.2 Sept 1999 UM00506-002 Substantial textual amendments

2.0 Nov 1999 UM00506-003 Added detail on using the controller

2.1 March 2000 UM00506-004 Updated for NextMove PCI issue 4

2.2 August 2000 UM00506-005 Updated for Mint v4.2 release

2.3 April 2001 UM00506-006 Updates from 04.2001 errata

NextMove PCI Installation Manual

viii

MN1277 04.2001

Contents

MN1277 04.2001

ix

Read Me First ............................................................................. 1

1.1 Key to Symbols Used in this Manual.........................................................2

Product Overview ...................................................................... 3

Hardware Guide ......................................................................... 7

3.1 Operating Environment.............................................................................8

3.2 Connection to the PCB .............................................................................9

3.3 Digital I/O..................................................................................................9

3.4 Analog I/O ..............................................................................................15

3.5 Encoder Interface ...................................................................................18

3.6 Relay ......................................................................................................19

3.7 Stepper Drive Outputs ............................................................................21

3.8 CAN Bus.................................................................................................22

3.9 Reset State.............................................................................................24

3.10 LEDs.......................................................................................................25

3.11 NextMove PCI Expansion Card ..............................................................26

3.12 Miscellaneous.........................................................................................28

3.13 NextMove PCI Breakout Unit ..................................................................28

Operation and Setup................................................................ 37

4.1 Installing NextMove PCI..........................................................................38

4.2 Baldor Motion Toolkit CD........................................................................40

4.3 Configuring your System ........................................................................42

4.4 Servo Setup............................................................................................46

4.5 Stepper Setup.........................................................................................59

4.6 Methods of Programming .......................................................................61

4.7 Documentation ....................................................................................... 61

4.8 Mint.........................................................................................................62

NextMove PCI Installation Manual

x

MN1277 04.2001

4.9 Motion.....................................................................................................70

Options and Accessories ........................................................ 71

5.1 NextMove PCI.........................................................................................72

5.2 NextMove PCI Expansion Card ..............................................................72

5.3 Digital Output Modules ...........................................................................73

5.4 Breakout Unit..........................................................................................74

5.5 NextMove PC System Adapter ...............................................................75

5.6 Spares ....................................................................................................75

5.7 CAN Nodes.............................................................................................76

5.8 NextMove PCI CAN Bracket Board.........................................................77

5.9 Encoder Splitter/Buffer Board .................................................................79

Specifications and Product Data ............................................ 81

6.1 Machine Control I/O................................................................................82

6.2 Miscellaneous and Mechanical Specification ..........................................83

6.3 100-Pin Connector..................................................................................84

6.4 EMC & CE Marking..................................................................................86

Trouble Shooting Guide .......................................................... 89

Bibliography............................................................................. 93

Read Me First

MN1277 04.2001

1

1. Read Me First

1

Details of the symbols used throughout this document.

NextMove PCI Installation Manual

2

MN1277 04.2001

This manual contains information for installing and commissioning the NextMove PCI intelligent

motion controller.

1.1 Key to Symbols Used in this Manual

Throughout this section various icons and conventions are used to indicate specific functions:

The screwdriver icon indicates that it is necessary to make a physical connection to

NextMove PCI by way of screw terminations.

The disk icon together with filename is used to indicate that a Mint program ( the motion

control language used to program NextMove PCI ) should be downloaded to the controller.

The prompt icon indicates that the following commands should be typed in directly to the

terminal at the Mint P> or C> prompt.

[Ctrl]+[E]

Type

Ctrl

and E at the same time.

Product Overview

MN1277 04.2001

3

2. Product Overview

2

A brief overview of NextMove PCI and the software tools available on the

Baldor Motion Toolkit.

NextMove PCI Installation Manual

4

MN1277 04.2001

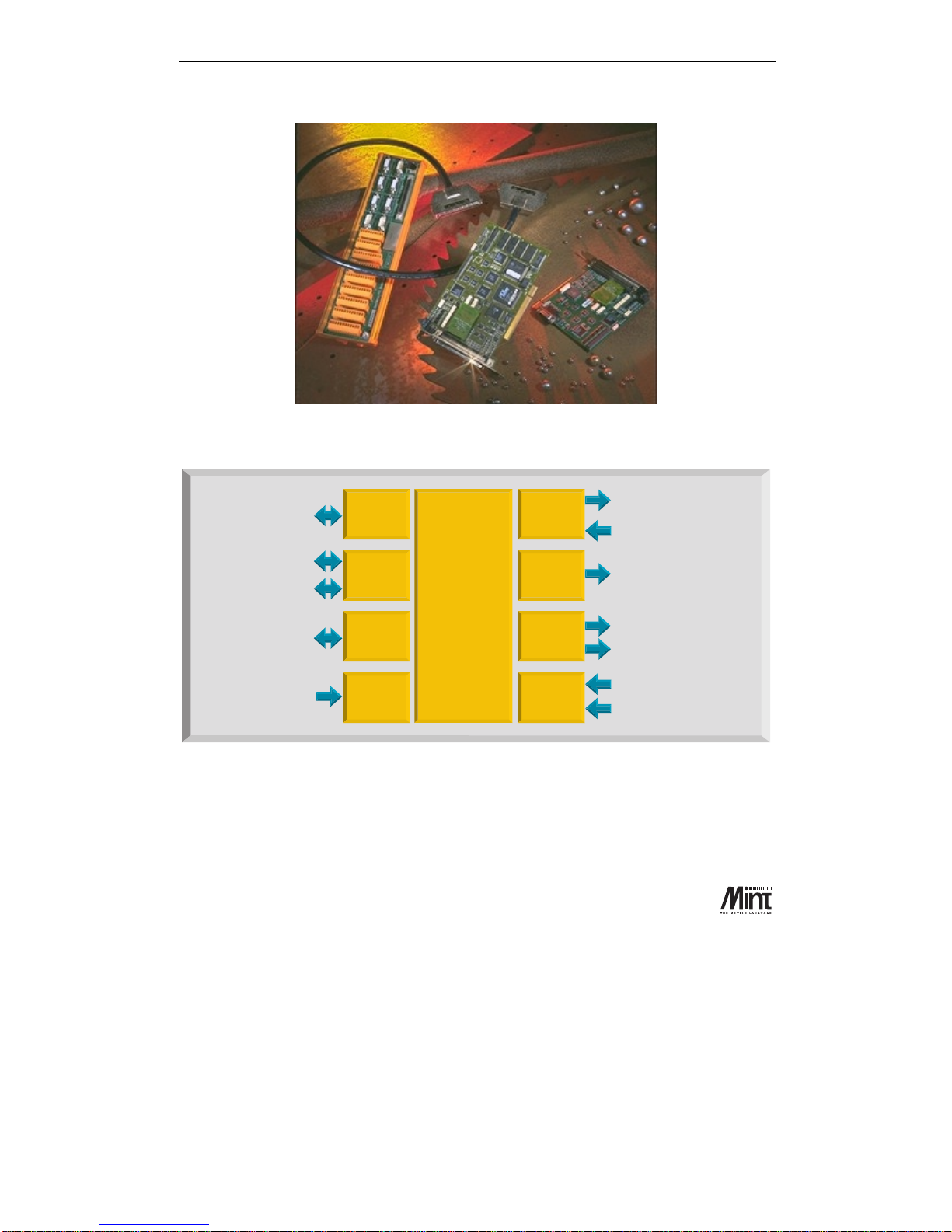

NextMove PCI is a high speed multi-axis intelligent motion controller for use in PCI bus based PC

systems.

Figure 2-1: NextMove PCI, Expansion Card and Breakout Unit

1MBaud serial comms for

high speed card to card

data transfer

High speed

serial

commun-

ications

Analog inputs4x12bit

differential 0-5V, 0-10V

+/-5V or +/-10V

Drive enable / general purpose relay

4 x Servo-amplifier demands

+/-10V, 14 bit

5 x Incremental Encoders,

3 channel, 7.5x10 edges/s max.

6

4Axesof

closed loop

Servo control

12

NextMove

Motion Controller

8

Inputs 0-4 second function

Hardware position latch &

fast interrupt input

32

2 CAN bus 1MBaud Industrial

Local Area Networks for

smart digital drives and I/O

PCI Bus

Interface

4k by 32 bit Dual Ported

RAM for high speed

communications with

PCI bus

4

4

4

5

4 Axes of

stepper

motors

4 x Step and direction signals

to control stepper drives 3MHz

maximum differential.

Digital

Outputs

12 x Digital outputs, opto-isolated

PNP or NPN, 12-24V, 350mA max

20

Digital

Inputs

20 x Digital inputs, opto-isolated

PNP or NPN, 12-24V. User

configurable as uncommitted

inputs, limit inputs, stop input.

Expansion

card

connector

16 bit expansion bus for

'next slot' expansion cards

Analog

Inputs

32 bit Digital Signal

Processor system.

Up to 8 axes of motion

control-4high

performance

closed loop servo,

4 stepper.

expandable to 12

servo or 12 stepper.

MINT or C

programming

language.

2Mb RAM.

Figure 2-2: Technical Overview

Product Overview

MN1277 04.2001

5

NextMove PCI features the MintTM motion control language. Mint is a structured form of Basic,

custom designed for motion control applications, either stepper or servo. It allows users to quickly

get up and running with simple motion control programs. In addition, Mint includes a wide range of

powerful commands for complex applications.

Included with NextMove PCI is the Baldor Motion Toolkit CD. This contains a number of utilities

and useful resources to get the most from you Mint controller. These include:

Mint Configuration Tool

is a rapid getting started and configuration utility designed for use with a

number of Mint v4 controllers. See the ‘Mint Configuration Tool Users Guide’ for details.

Mint WorkBench

is the IDE and user interface for communicating with a Mint controller.

Installing the Mint WorkBench will also install firmware (NMPCI.OUT) for NextMove PCI. See

the ‘Mint WorkBench Users Guide’ for details.

PC Developer Libraries

allow PC applications to be written that communicate with Mint

controllers. This includes C++ source and ActiveX interface. See the ‘Mint v4 PC Programming

Guide’ for details.

Embedded Developer Libraries

allow embedded C31 applications to be developed using the Texas

Instruments TMS320C3x compiler. See the ‘Mint v4 Embedded Programming Guide’ for details.

Mint Code Analyzer Tool

is a utility designed to help in the process of upgrading to Mint v4. The

utility will scan existing Mint and C application files and highlight the keywords and functions that

have been changed from older firmware versions. See the ‘Mint v4 Code Analyzer Tool’ manual for

details.

NextMove PCI Installation Manual

6

MN1277 04.2001

Hardware Guide

MN1277 04.2001

7

3. Hardware Guide

3

This chapter describes in detail the hardware interface to NextMove PCI.

NextMove PCI Installation Manual

8

MN1277 04.2001

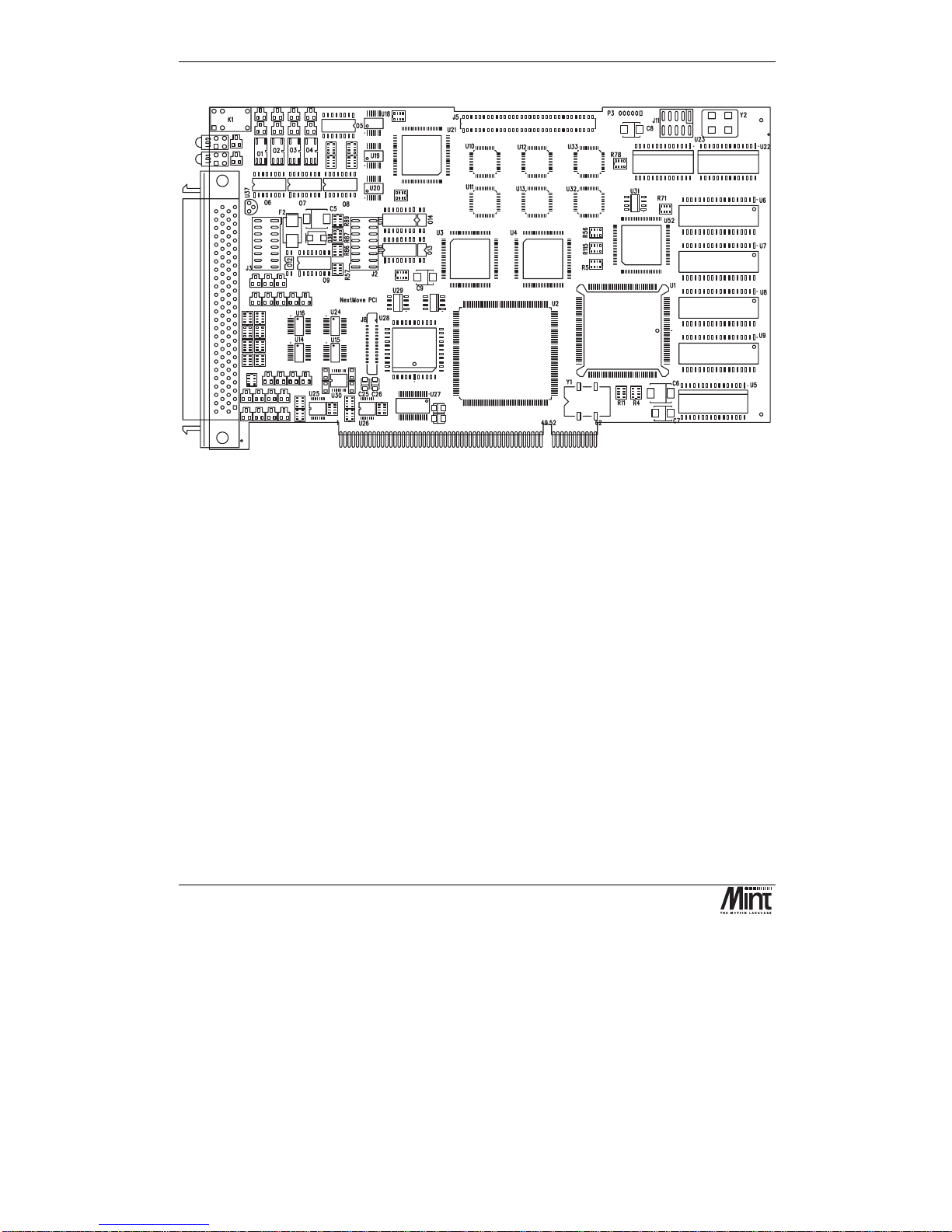

Figure 3-1: NextMove PCI Assembly

3.1 Operating Environment

The safe operation of this equipment depends upon its use in the appropriate environment:

•

At an altitude of

≤

2000m (6560ft) above sea level

•

In an ambient temperature of 0

°

C to 40°C (32°F to 104°F)

•

In relative humidity levels of 80% for temperatures up to 31

°

C (87°F) decreasingly linearly

to 50% relative humidity at 40

°

C (104°F), non-condensing

•

The pollution degree according to IEC664 shall not exceed 2

•

Power is supplied to the board via the PC power supply bus

•

The atmosphere shall not contain flammable gases or vapors

•

There shall not be abnormal levels of nuclear radiation or X-rays

Hardware Guide

MN1277 04.2001

9

3.2 Connection to the PCB

All of the standard interfaces are brought out on the 100 pin D-type connector mounted on the metal

bracket. The PCB connector is an AMP787082-9. For the convenience of the user a kit consisting of

a cable assembly and a DIN rail mounting Breakout Unit is available. There are currently two types

of Breakout Unit available. The standard type uses single part connectors (Baldor part no. PCI003-

501). A unit with two part connectors (Baldor part no. PCI003-502) is also available. These are

described in Section 5.4.

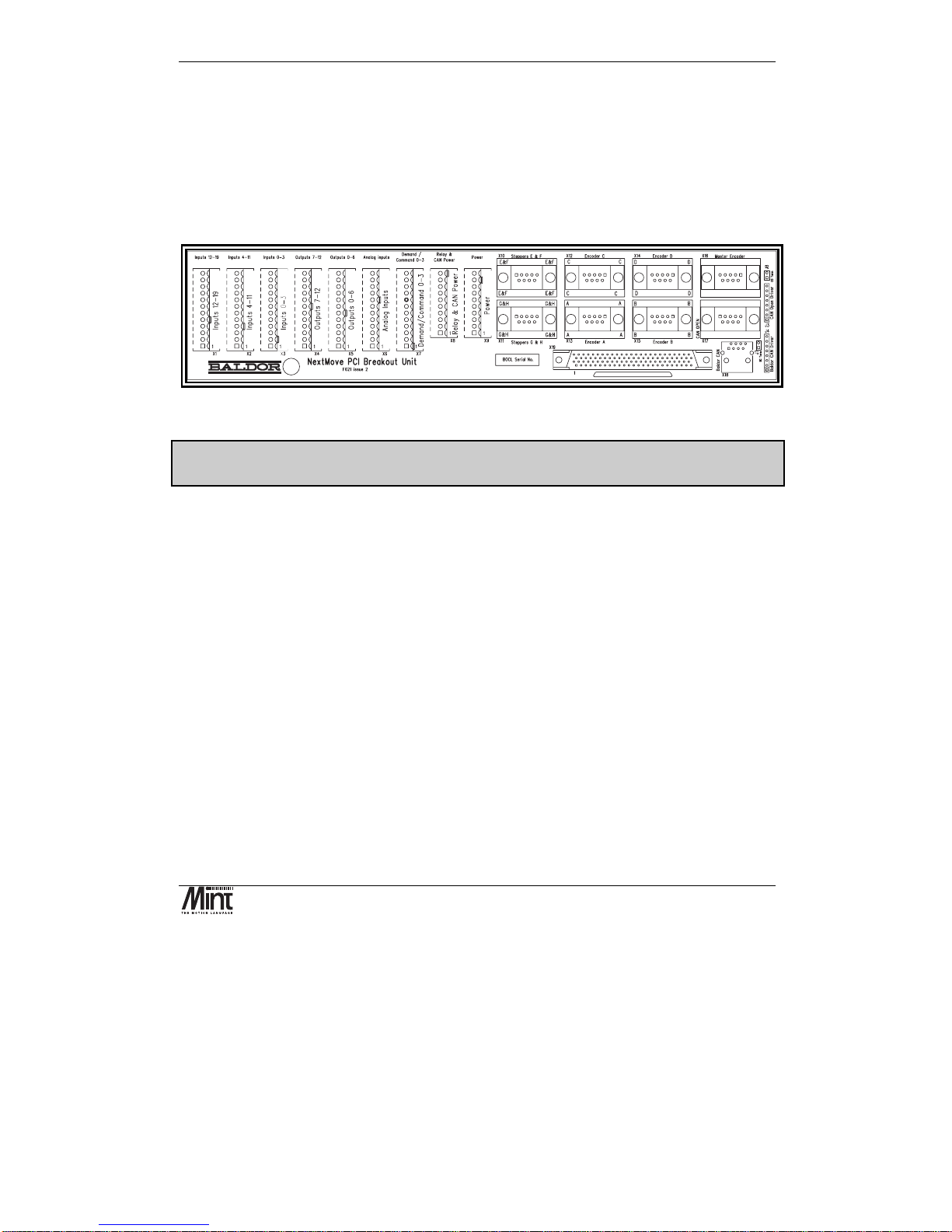

Figure 3-2: NextMove PCI Breakout Unit

For ease of transition from NextMove PC to NextMove PCI, a converter is available to allow

NextMove PC Breakout Unit to be used (contact factory).

See section 6.3 for connector details.

3.3 Digital I/O

There are a total of 20 general purpose digital inputs and 12 general purpose digital outputs. The

digital inputs are software configurable for any one of the following functions:

•

forward limit

(end of travel) input on any axis.

•

reverse limit

(end of travel) input on any axis.

•

home input

on any axis.

•

drive error

input on any axis.

•

stop input

(controlled) on any axis.

The inputs can be programmed such that any of the axes can share the same input if necessary.

The inputs are also programmable in software for edge triggered (positive and negative) and their

active level.

The digital outputs can be programmed as a

drive enable

output for any axis or

general error

output

. Again, axes can share the same output. The active level of the output is also software

programmable.

NextMove PCI Installation Manual

10

MN1277 04.2001

As well as the general purpose I/O, NextMove PCI also supports fast position latch inputs (IN0 to

IN3) and optionally, digital outputs for stepper control. The stepper outputs can be programmed in

software as general purpose outputs. The stepper outputs are discussed in section 3.5.

3.3.1 Standard Digital Inputs

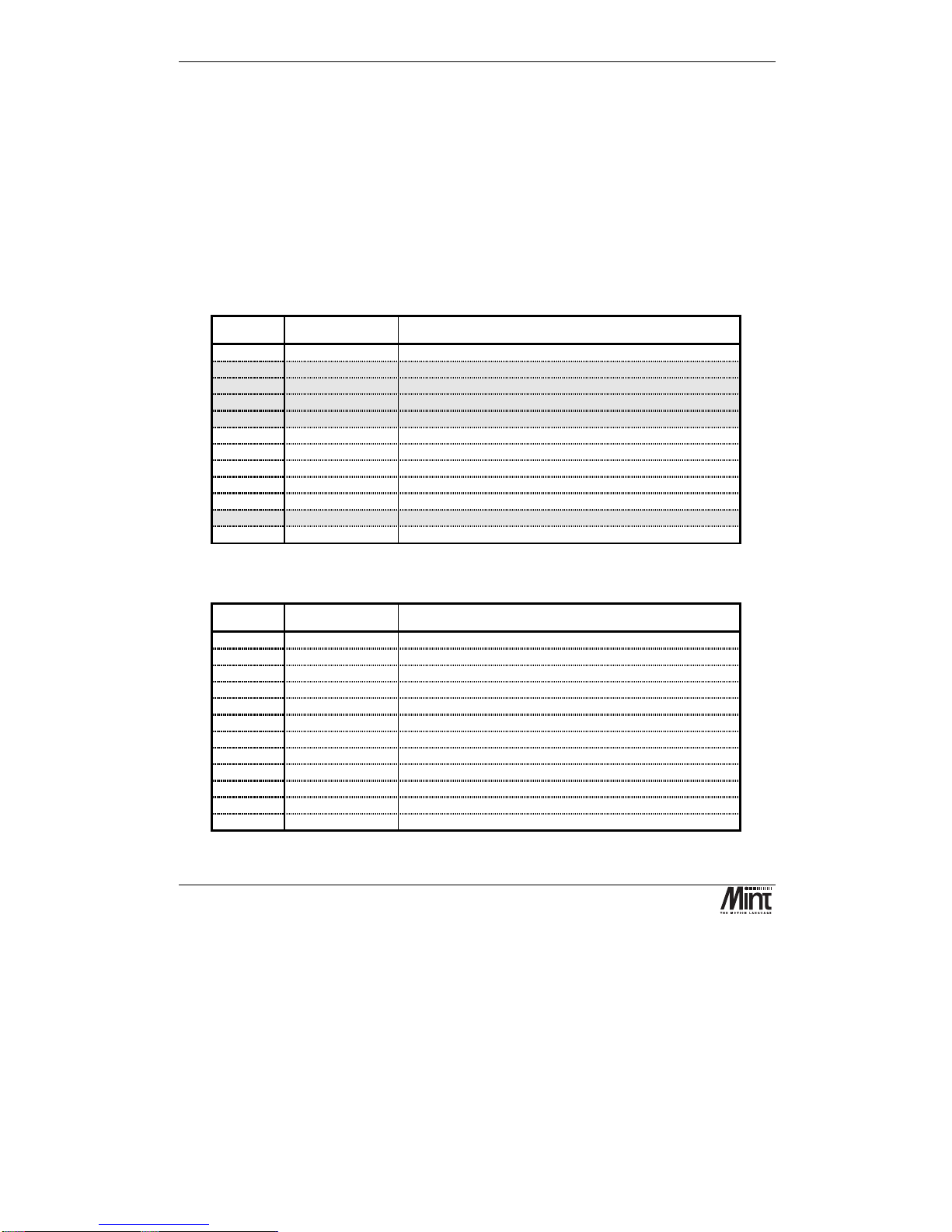

There are sixteen optically isolated standard digital inputs arranged as two banks of 8. Each bank has

its own common rail that must be referred to system ground and cannot be left disconnected. Each

bank can have a separate supply or voltage level.

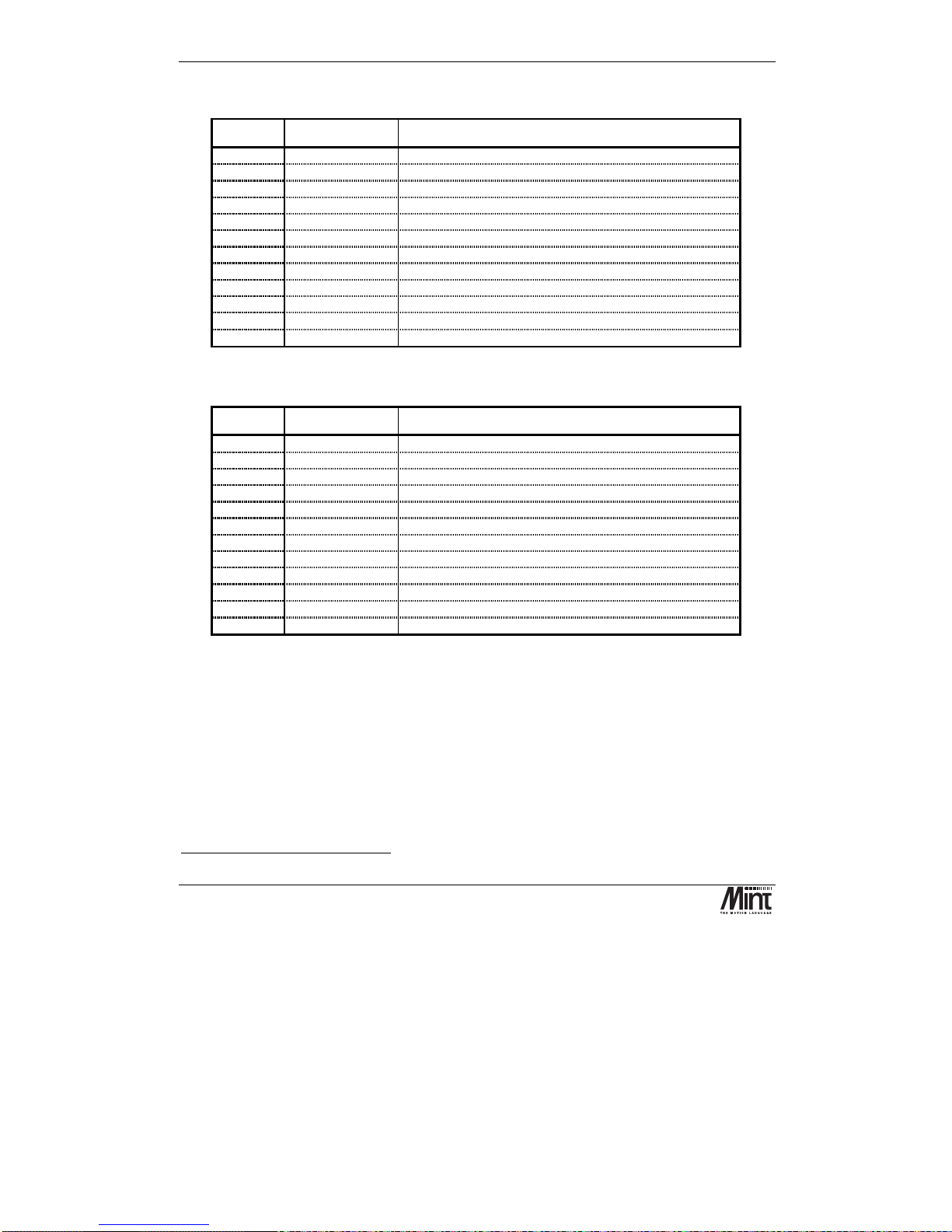

These inputs are available on connectors X1 and X2 on the NextMove PCI Breakout Unit.

X2: Digital Inputs 4 to 11

Pin Signal Function

1

Chassis

Shield connection

2

DIG_IN_4

Digital input 4 (referenced to Common0-7)

3

DIG_IN_5

Digital input 5 (referenced to Common0-7)

4

DIG_IN_6

Digital input 6 (referenced to Common0-7)

5

DIG_IN_7

Digital input 7 (referenced to Common0-7)

6

DIG_IN_8

Digital input 8 (referenced to Common8-19)

7

DIG_IN_9

Digital input 9 (referenced to Common8-19)

8

DIG_IN_10

Digital input 10 (referenced to Common8-19)

9

DIG_IN_11

Digital input 11 (referenced to Common8-19)

10

Chassis

Shield connection

11

Common0-7

Common for inputs 0-7

12

Common8-19

Common for inputs 8-19

X1: Digital Inputs 12 to 19

Pin Signal Function

1

Chassis

Shield connection

2

DIG_IN_12

Digital input 12 (referenced to Common8-19)

3

DIG_IN_13

Digital input 13 (referenced to Common8-19)

4

DIG_IN_14

Digital input 14 (referenced to Common8-19)

5

DIG_IN_15

Digital input 15 (referenced to Common8-19)

6

DIG_IN_16

Digital input 16 (referenced to Common8-19)

7

DIG_IN_17

Digital input 17 (referenced to Common8-19)

8

DIG_IN_18

Digital input 18 (referenced to Common8-19)

9

DIG_IN_19

Digital input 19 (referenced to Common8-19)

10

Chassis

Shield connection

11

n/c

Not connected

12

Common8-19

Common for inputs 8-19

Hardware Guide

MN1277 04.2001

11

The digital inputs use ac opto-isolators. The switching level is 12 to 24V (supplied by the user). If

the driving signal switches high with reference to a low ground, the driving signal ground should be

connected to the input common. If the driving signal switches low with reference to a driving signal

supply rail, the driving supply rail should be connected to the input common.

When using the NextMove PC Breakout Unit and converter board (OPT025-506) the two

banks must use USR-V+ and USR-GND. Jumpers on the converter board select which voltage

is connected to the common rails.

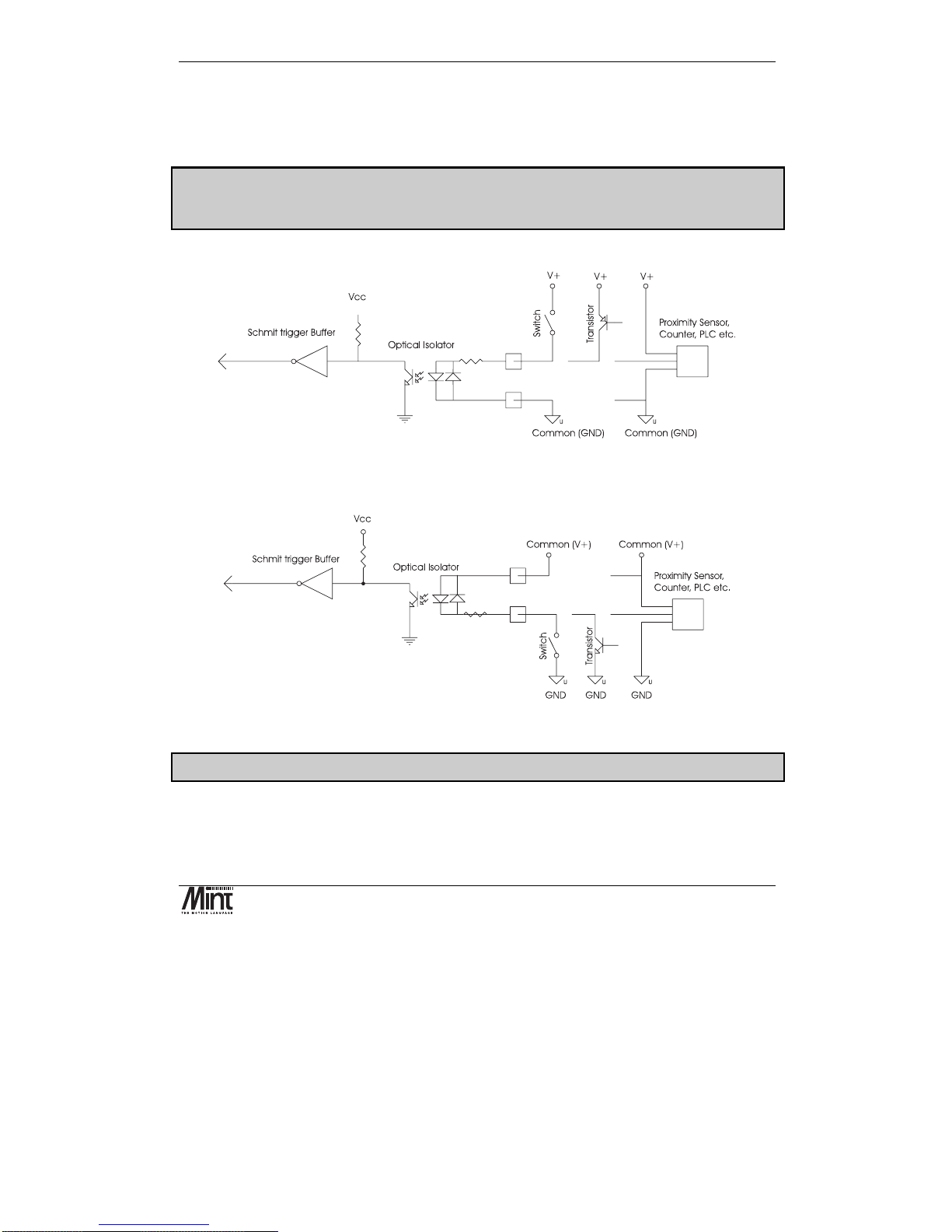

Figure 3-3 shows a digital input connected to high-side (PNP) driving signals.

Figure 3-3:Digital Inputs, PNP configuration

Figure 3-4 shows a digital input connected to low-side (NPN) driving signals.

Figure 3-4: Digital Inputs, NPN Configuration

Note: Sustained voltages above 28V will damage the inputs.

The inputs are conditioned using low pass RC filters and Schmitt trigger buffers. An input pulse

must have a duration of at least 1ms (one software scan) to guarantee acceptance by the application

program when configured as edge triggered.

As with all good wiring practice, the use of screened cable is recommended.

NextMove PCI Installation Manual

12

MN1277 04.2001

Associated Mint keywords are:

#INx, INPUTACTIVELEVEL, IN, INx, INPUTMODE, INPUTNEGTRIGGER,

INPUTPOSTRIGGER, INSTATE

3.3.2 Fast Position Interrupts: Digital Inputs 0 to 3

Digital inputs

DIG_IN_0

to

DIG_IN_3

can be used as high speed position latches.

The inputs are available on connector X3 on the NextMove PCI Breakout Unit.

Pin Signal Function

1

DIG_IN_0

Digital input 0

2

Common0-7

Return for inputs 0-7

3

Chassis

Shield connection

4

DIG_IN_1

Digital input 1

5

Common0-7

Return for inputs 0-7

6

Chassis

Shield connection

7

DIG_IN_2

Digital input 2

8

Common0-7

Return for inputs 0-7

9

Chassis

Shield connection

10

DIG_IN_3

Digital input 3

11

Common0-7

Return for inputs 0-7

12

Chassis

Shield connection

Digital inputs 0 to 3 are sensitive to noise. The use of screened twisted pair cabling is recommended.

The fast position inputs are routed through a programmable cross point switch which allows any

input to cause the position of any combination of axes to be latched within 1µs - a feature essential

in high speed print registration applications. When triggered, the position is captured and a user

interrupt can be triggered to handle this event.

See section ‘Fast Position Latch’ in the ‘Mint v4 Programming Guide’ for more details.

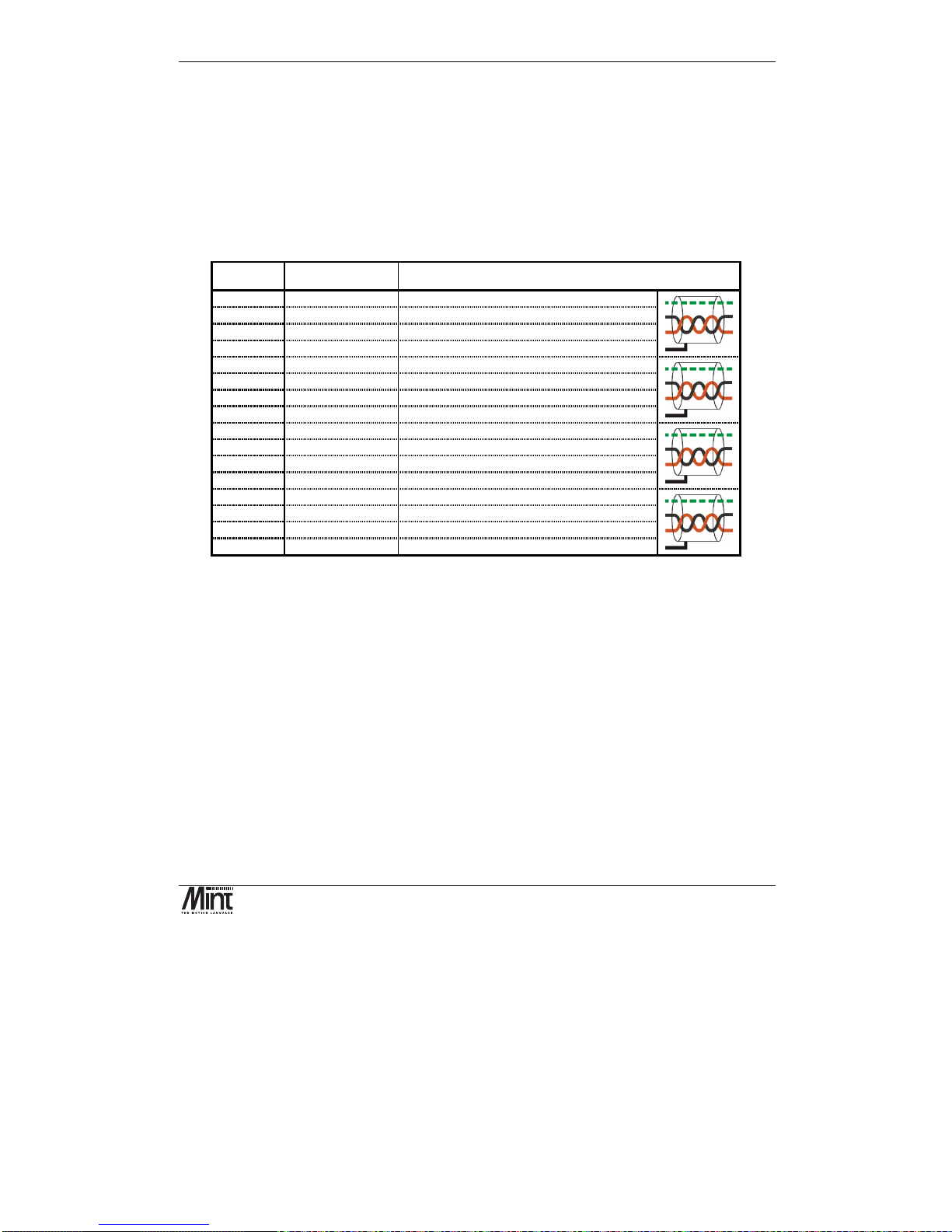

3.3.3 Digital Outputs

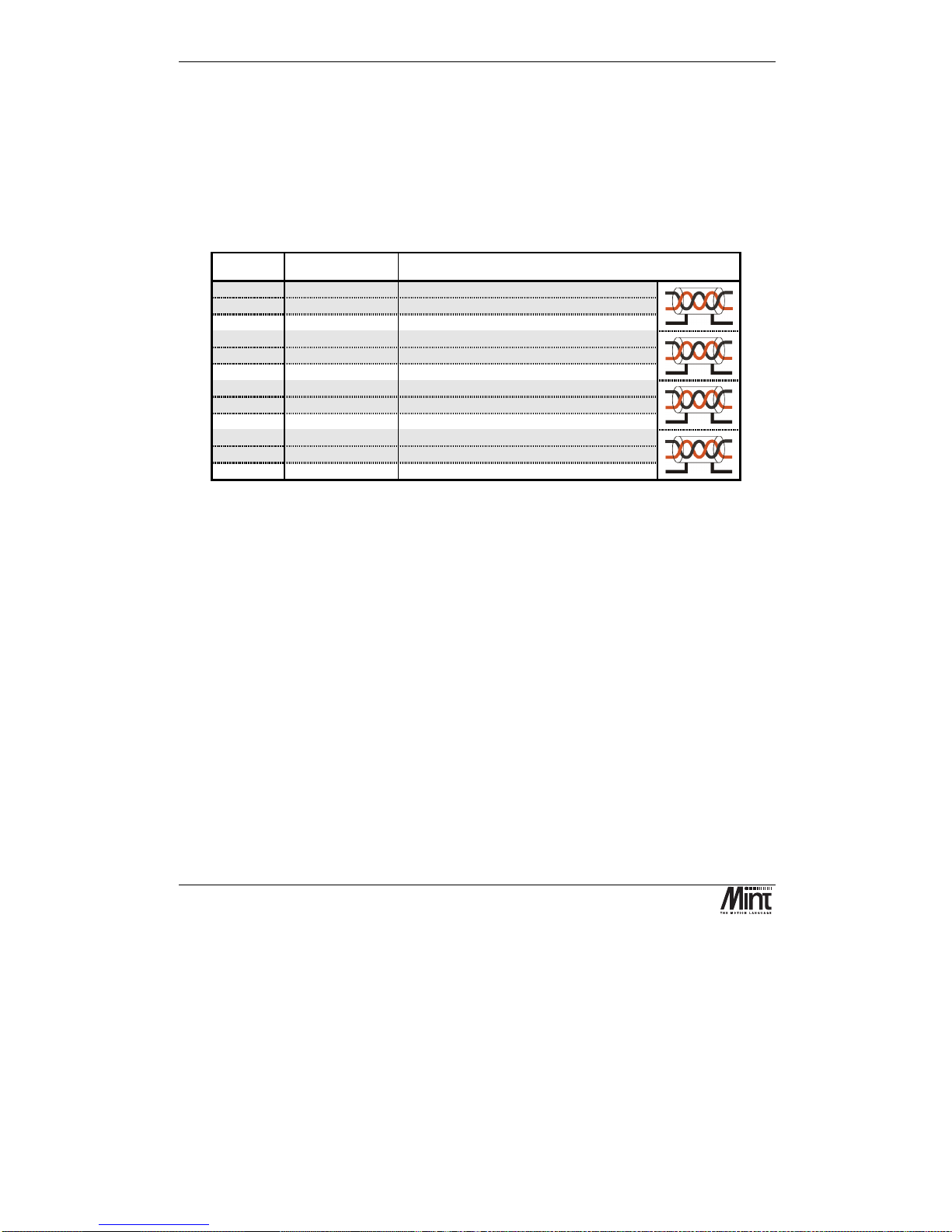

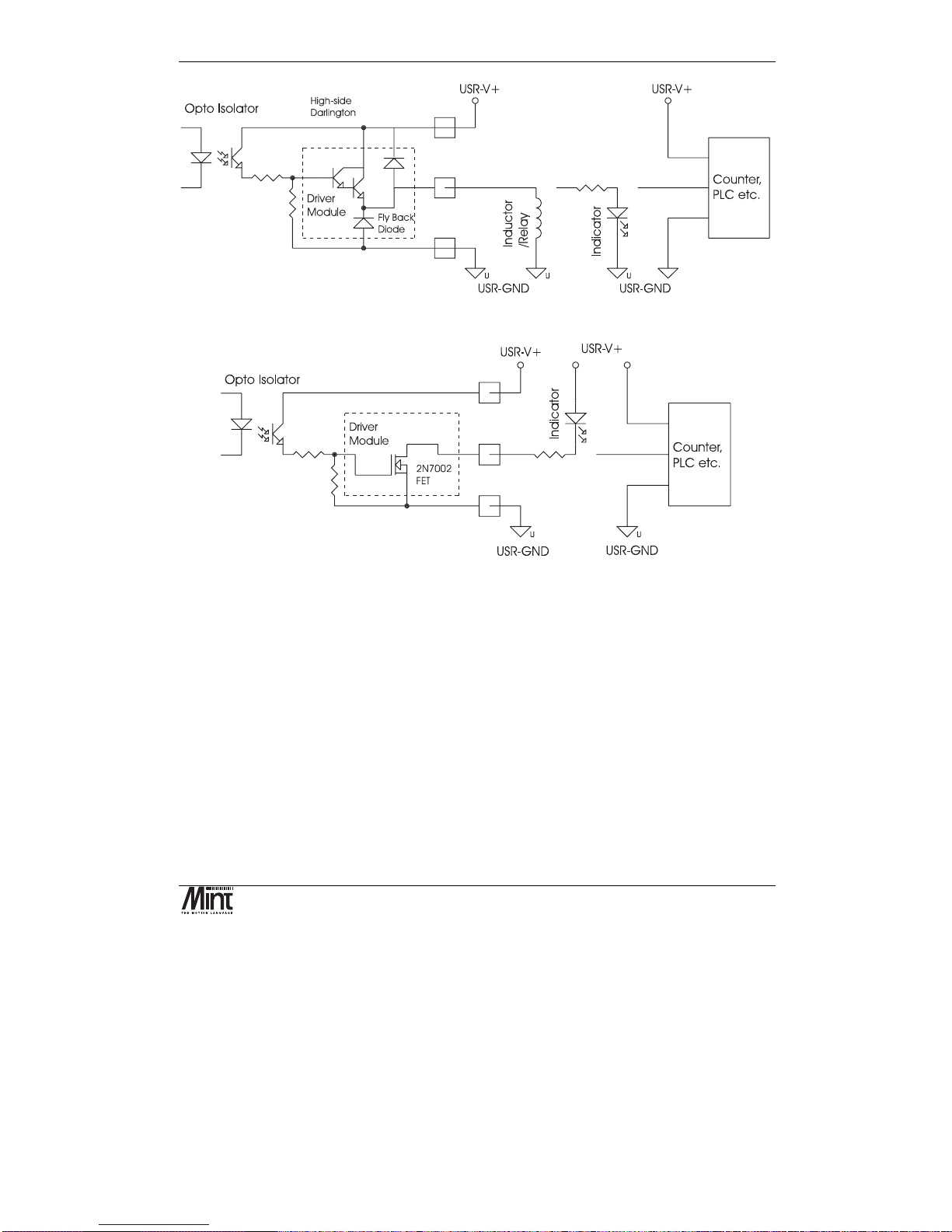

There are twelve opto-isolated digital outputs driven via a module fitted to NextMove PCI. Two

modules types are available:

Current sourcing, ‘PNP’ Darlington with overcurrent and short circuit protection (fitted as standard).

Current sinking, ‘NPN’, open drain N-channel MOSFET.

Hardware Guide

MN1277 04.2001

13

Figure 3-5: Digital Outputs with Current Sourcing Module

Figure 3-6: Digital Outputs with Current Sinking Module

The outputs are available on connectors X4 and X5 on the NextMove PCI Breakout Unit.

NextMove PCI Installation Manual

14

MN1277 04.2001

X5: Digital Outputs 0-5

Pin Signal Function

1

Chassis

Shield connection

2

DIG_OUT_0

Digital output 0

3

DIG_OUT_1

Digital output 1

4

DIG_OUT_2

Digital output 2

5

DIG_OUT_3

Digital output 3

6

DIG_OUT_4

Digital output 4

7

DIG_OUT_5

Digital output 5

8

n/c

Not connected

9

n/c

Not connected

10

Chassis

Shield connection

11

USR-V+

∗∗∗∗

Output power supply power

12

USR-GND

Output power supply ground

X4: Digital Outputs 6-11

Pin Signal Function

1

Chassis

Shield connection

2

DIG_OUT_6

Digital output 6

3

DIG_OUT_7

Digital output 7

4

DIG_OUT_8

Digital output 8

5

DIG_OUT_9

Digital output 9

6

DIG_OUT_10

Digital output 10

7

DIG_OUT_11

Digital output 11

8

n/c

Not connected

9

n/c

Not connected

10

Chassis

Shield connection

11

USR-V+

∗∗∗∗

Output power supply power

12

USR-GND

Output power supply ground

Note that USR-GND must be tied to system ground - it must not be left disconnected. When using

current sourcing outputs, the user must supply 12-24V DC between USR-V+ and USR-GND.

The current sink / source capability of the NPN and PNP outputs respectively is 50mA.

As with all good wiring practice, the use of screened cable is recommended.

Associated Mint keywords are:

OUTPUTACTIVELEVEL, OUT, OUTx

∗

This power must be supplied externally

Hardware Guide

MN1277 04.2001

15

3.4 Analog I/O

3.4.1 Analog Inputs

Four 12-bit resolution analog inputs are provided. The inputs are available on connector X6 on the

NextMove PCI Breakout Unit.

X6: Analog Inputs

Pin Signal Function

1

AGND

Analog ground

2

AIN_0+

Analog input 0 positive input

3

AIN_0-

Analog input 0 negative input

6

Chassis

Shield connection

1

AGND

Analog ground

4

AIN_1+

Analog input 1 positive input

5

AIN_1-

Analog input 1 negative input

6

Chassis

Shield connection

7

AGND

Analog ground

8

AIN_2+

Analog input 2 positive input

9

AIN_2-

Analog input 2 negative input

12

Chassis

Shield connection

7

AGND

Analog ground

10

AIN_3+

Analog input 3 positive input

11

AIN_3-

Analog input 3 negative input

12

Chassis

Shield connection

Shielded twisted pairs should be used and connected as shown. The shield connection should be

made at one end only. If the source of the signal is already grounded there is no need to connect

AGND (shown dotted).

The analog inputs pass through a differential buffer and second order Butterworth filter with a 1kHz

cut-off frequency. Both the filtered and unfiltered signals are converted using a multiplexed 12-bit

ADC, which has four software-selectable input voltage ranges: 0-5V, ±5V, 0-10V and ±10V.

The analog inputs are sampled by Mint at a rate of 2.5kHz.

NextMove PCI Installation Manual

16

MN1277 04.2001

Figure 3-7: Analog Buffer and Range Selection

Differential Mode:

The analog inputs are all true differential which means that the signal is measured relative to a

reference rather than the controller ground. The differential mode makes the system more immune to

common mode noise picked up in the cabling.

Figure 3-8: Analog Input, Differential Connection

Associated Mint keywords are:

ADCMODE, ADC

3.4.2 Analog Outputs (Drive Command)

There are four 14bit resolution analog outputs. The outputs are available on connector X7 on the

NextMove PCI Breakout Unit. By default Mint™ and the Mint™ Motion Library use the analog

outputs to control servo drives. Outputs 0 to 3 correspond to axes 0 to 3 respectively.

Hardware Guide

MN1277 04.2001

17

X7: Drive Signals (X7)

Pin Signal Function

1

DEMAND_0

Demand/command signal for axis 0

2

AGND

Analog ground

3

Chassis

Shield connection

4

DEMAND_1

Demand/command signal for axis 1

5

AGND

Analog ground

6

Chassis

Shield connection

7

DEMAND_2

Demand/command signal for axis 2

8

AGND

Analog ground

9

Chassis

Shield connection

10

DEMAND_3

Demand/command signal for axis 3

11

AGND

Analog ground

12

Chassis

Shield connection

Demand signals are outputs to the servo amplifiers. Shielded twisted pairs should be used and

connected as shown. The shield connection should be made at one end only.

The outputs have a range of ±10V (1.22mV per bit).

Outputs 0 to 3 are inverted and buffered by op-amps, and may be used to drive loads of

≥

10kΩ. The

outputs are referenced to PC system ground. DAC channels 4-7 are summed with the first three

outputs with 1/16

th

of the gain i.e. 1/16th of the DAC channel 4 output is added to the DAC channel 0

output, and so on. DAC channels 4 – 7 can therefore be used to trim channels 0 - 3 (trim range

±0.625V).

The analog output buffer circuit is shown below.

Figure 3-9: Analog Output Buffer

Associated Mint keywords are:

DACLIMITMAX, DAC, DACMODE, DACOFFSET

NextMove PCI Installation Manual

18

MN1277 04.2001

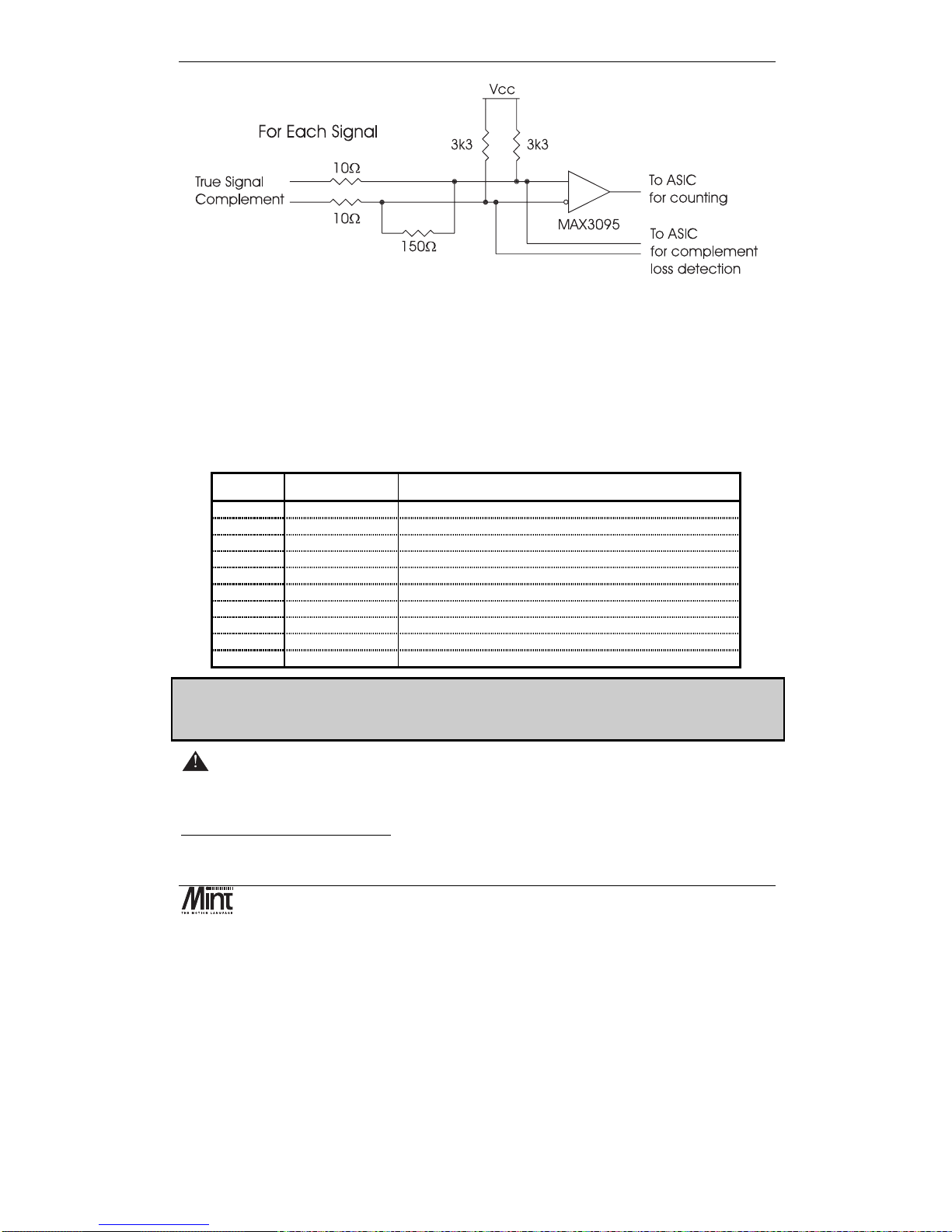

3.5 Encoder Interface

Up to five incremental encoders may be connected to NextMove PCI. The signals are brought out

onto the NextMove PCI Breakout Unit via signals X12, X13, X14, X15 and X16. These are 9-pin

D-type female sockets. The shell of the connector is connected to chassis. When possible, the use of

individually screened twisted pair cable is recommended.

Figure 3-10: Encoder Connector

Pin Signal Function Cabling

1

Encoder V+

1

Power to the encoder

7

gnd

Power and signal ground

5

chA

Channel A true signal

9

!chA

Channel A complement signal

8

chB

Channel B true signal

3

!chB

Channel B complement signal

2

index

Index true signal (channel I or Z or C)

6

!index

Index complement signal (channel I or Z or C)

4

chassis

Chassis connection

Shell

chassis

Screen

The encoders must provide either complementary TTL or differential line drive (RS422/RS485)

signals to operate with NextMove PCI. The input circuit uses MAX3095 differential line receivers

with a pull ups and terminators. Each encoder channel has inputs A, B and Index.

1

The encoder power rail on X9 must be connected to VCC or supplied externally

Hardware Guide

MN1277 04.2001

19

Figure 3-11: Encoder Line Receiver Interface

The maximum input frequency of the encoder input is 7.5 million quadrature counts per second, one

count per edge. This equates to a maximum frequency for the A and B signals of 1.87MHz.

Within Mint, ‘complement loss detection’ is highlighted as an ‘encoder transition warning’ within

the AXISWARNING keyword. It must be enabled with the AXISWARNINGDISABLE keyword.

Associated Mint keywords are:

ENCODER, ENCODERSCALE, ENCODERVEL, ENCODERWRAP, POS, SCALE, VEL

X9: Encoder Power

Pin Signal Function

1

Vcc

5V power connection (from the PC)

2

Vcc

5V power connection (from the PC)

3

Encoder V+

1

Power to the encoder connectors (normally +5V)

4

Encoder V+

1

Power to the encoder connectors (normally +5V)

5

GND

Digital ground (from the PC)

6

GND

Digital ground (from the PC)

7

USR-V+

2

Output power supply

8

USR-V+

2

Output power supply

9

USR-GND

Output power supply ground

10

USR-GND

Output power supply ground

Note: The encoder power can be linked to Vcc to supply the encoders with +5V, provided that

the total current consumption of the encoders does not exceed 500mA. For externally powered

encoders, the maximum is 30V provided total current consumption does not exceed 3A.

Warning – Encoder power must be connected before switching on.

If the encoders are not powered then there will be no position feedback which could cause violent

motion of the motor shaft if the system is enabled.

1

Encoder V+ must be connected to VCC or supplied externally

2

USR-V+ must be supplied externally

NextMove PCI Installation Manual

20

MN1277 04.2001

The encoder connectors are powered from pins 3 and 4 of the power connector X9. This voltage is

with respect to digital ground. This connection scheme is to allow correct powering of the encoders

where the required voltage is not 5V and/or the total current exceeds 500mA. For encoders

requiring 5V power at a total current, for all encoders, of 500mA or less, the encoder V+ rail may be

connected to V

CC

by linking pins 2 (VCC) and 3 (Encoder V+) of X9. A link is fitted in this position

at the factory.

Baldor CAN

Note:- Replacing issue 1 units

If replacing issue 1 breakout units, connections to pins 3, 4, 5 and 6 of the issue 1 unit power

connector(J10) must be connected to pins 5 and 6 only of the issue 2 unit power connector (X9).

3.6 Relay

A single pole change-over relay is included on the card to provide a volt-free contact for system

enabling or general use. The relay signals are available on the NextMove PCI Breakout Unit via

connector X8.

X8: Relay and CAN Power

Pin Signal Function

1

CAN-V+ 1

Power input for CAN 1 network (

CAN

open

). (12-24V)

2

CAN-GND 1

Ground for CAN 1 network (

CAN

open

)

3

CAN-V+ 2

Power input for CAN 2 network (Baldor CAN) (12-24V)

4

CAN-GND 2

Ground for CAN 2 network (Baldor CAN)

5

Relay-NC

Normally closed relay connection

6

Relay-NO

Normally open relay connection

7

Relay-COM

Common relay connection

8

USR-V+

2

Output power supply power

9

USR-GND

Output power supply ground

10

Chassis

Shield connection

Only isolated CAN channels require 24V to power to opto-isolation. Non isolated CAN

channels must not be powered.

The relay pins are isolated from any internal circuits on the NextMove PCI.

Hardware Guide

MN1277 04.2001

21

The relay is controlled by a latch, which is cleared during reset of NextMove PCI. Reset occurs on

power-down, watchdog error or under control of the host PC. The relay is energized under software

control. The relay is the default global error output channel.

Due to the track rating on the PCB, the relay is limited to a rating of 150mA at 24V DC. The

relay should be used for voltage free signal switching and should not be used for power.

Associated Mint keywords are:

RELAY, DRIVEENABLEOUTPUT, GLOBALERROROUTPUT

3.7 Stepper Drive Outputs

Eight stepper motor control outputs are available via connectors X10 and X11.

X10/X11: Stepper Drive Outputs

Figure 3-12: Stepper Output Connectors

The stepper drive outputs can operate at up to 3MHz. The signals from the controller are at TTL

levels and is converted to differential drive on a module mounted on the Breakout Unit. The

differential connections are brought out on 9 pin D-type connectors to allow 360° shielding when

using high step rates. Two axes are brought out on to each connector. The outputs can be connected

directly to drives with single ended logic inputs by connecting the compliment of the differential

signal to the drive ground.

Signal Pin Nos. Function Cabling

Step n

1,5 Step signal True

!Step n

6,9 Step signal Complement

Dir n

2,4 Direction signal True

!Dir n

7,8 Direction signal Complement

GND

3 Signal ground

chassis

Shell Screen

NextMove PCI Installation Manual

22

MN1277 04.2001

The outputs may be programmed in software for the following functions:

•

Step and direction for driving stepper motor drives.

•

Digital outputs for general purpose use. See the STEPPERIO keyword for details.

The outputs are all CMOS level signals and are referred to system ground.

3.8 CAN Bus

CAN (Controller Area Network) is a 1Mb/s local area network. Two transceivers for the CAN are

fitted to NextMove PCI. Access to both channels it is made via a 10 pin 2mm pin header

J11

. The

connections are as follows:

Figure 3-13: NextMove PCI CAN Header Location

Pin No. Signal

1 CAN2 RX0 (from IC)

2 to Breakout Unit

3 CAN2 TX0 (from IC)

4 to Breakout Unit

5 CAN1 RX0 (from IC)

6 to Breakout Unit

7 CAN1 TX0 (from IC)

8 to Breakout Unit

9 GND

10 +5V

Hardware Guide

MN1277 04.2001

23

Note: the signals on this connector are referenced to the PC host, there is no isolation. As standard,

jumper links are present linking pin pairs 1 and 2, 3 and 4, 5 and 6, 7 and 8. These jumpers route the

CAN signals to the Breakout Unit.

Pins 9 and 10 should NEVER be connected to together.

Removing the jumpers allows connection to a bulkhead mounted drive circuit and a connector or

connector pair of the required type in the next PCI slot plate. These can be RJ45 for connection to

other Baldor CAN nodes or 9 pin ‘D’ connectors for connection to other networks such as

CAN

open

. A CAN bracket card is available which is suitable if the customer is intending to only

use NextMove PCI as a CAN master, since this no longer requires the Breakout Unit.

CAN connections on the Breakout Unit are one RJ45 connector for CAN2 and a 9 pin D-type for

CAN1; used for connection to

CAN

open

networks. If NextMove PCI is at the end of either network

a termination resistor must be connected by fitting the termination jumper on the Breakout Unit.

A range of CAN based I/O expansion modules is available for NextMove PCI. See section 5.7 for

further details.

A very low error rate of CAN communication can only be achieved with a suitable wiring scheme.

The following points should be observed:

1. CAN must be connected via twisted pair cabling. The connection arrangement is normally

a simple multi-point drop. The CAN cables should have a characteristic impedance of

120Ω and a delay of 5ns/m. Other characteristics depend upon the length of the cabling:

Cable length Max bit rate

Non Isolated

Max bit rate

Isolated

Specific

resistance

Conductor area

0-40m (0-157ft) 1 Mbit/s 500 kbit/s

70m

Ω

0.25-0.34mm

2

40m-300m

(157ft-1180ft)

200 kbit/s 100 kbit/s

<

60m

Ω

0.34-0.60 mm

2

300m-600m

(1180-2362ft)

100 kbit/s 50 kbit/s

<

40m

Ω

0.50-0.60 mm

2

600m-1000m

(2362ft-3937)

50 kbit/s 25 kbit/s

<

26m

Ω

0.75-0.80 mm

2

2. Terminators should be fitted at each end of the network only.

3. To reduce RF emissions, and more importantly to provide immunity to conducted

interference, shielded twisted pair cabling should be used. If two CAN channels are

bundled in a cable then each requires a twisted pair.

4. The 0V rails of all of the nodes on the network must be tied together through the CAN

cabling. This ensures that the CAN signal levels transmitted by a NextMove PCI or CAN

peripheral devices are within the common mode range of the receiver circuitry of other

nodes on the network.

NextMove PCI Installation Manual

24

MN1277 04.2001

CAN cables are available. See the section 5.7 for details on CAN accessories.

On the Breakout Unit, CAN is available on connectors X17 and X18.

Figure 3-14: CAN Connectors

Where an isolated transceiver module is used a supply of 12-24V, 60mA is required between CANV+ and CAN-GND. Non isolated module should not be powered.

Signal Function D-type Pin RJ-45 Pin Cabling

can+

CAN data signal 7 1

can-

CAN data signal 2 2

can V+

Power to the CAN nodes 9 5

gnd

Signal ground 3 4

chassis

Screen pin 1 -

NC No connection 4,5,6,8 3,6,7,8

chassis

Screen Shell Shell

3.9 Reset State

During PC power-up, NextMove PCI is held in reset (a safe non-operational state). It will also go

into reset if the 5V supply drops below approximately 4.75V in order to prevent any uncontrolled

operation of any of the integrated circuits during power down.

When NextMove PCI is in reset for any reason, most of the controlled interfaces fall into known

states as detailed in the following sections.

It is also possible for NextMove PCI to be in a state known as software reset. This is a safe

operational state where only the bootloader firmware present on NextMove PCI is running.

Hardware and software reset states should not be confused with the Mint keyword RESET which is

used to clear axis errors.

Communications

Hardware Guide

MN1277 04.2001

25

At power up the CAN controllers will be held in reset and will have no effect on the CAN buses. If a

reset occurs during the transmission of a message CAN errors are likely to occur.

Dual port RAM will contain no information at power up but will be accessible by the PC. A reset

during operation will cause the DPR to stay in its current state.

Digital Outputs

All of the digital outputs are inactive on power up regardless of their polarity. They will return to the

inactive state whenever reset occurs.

Analog Outputs

All analog outputs are set to 0V by hardware during power-up and will return to 0V on a reset.

Stepper/Encoder ASICs

The stepper/encoder ASICs will not generate stepper pulses or register any encoder input during

reset. Position will be set to zero, i.e. if the unit goes into reset all position data will be lost.

3.10 LEDs

There are four bicolour LED’s on NextMove PCI. Two LEDs, S1 and S2, are status indicators and

two, C1 and C2, are CAN traffic indicators. The LED’s can be

red

or

green

and may be

steady

or

flashing

. These states are shown in the following table for the status LED’s:

Figure 3-15: Status and CAN indicator LEDs

State LED Status

No power. All off

In hardware reset. All red

In software reset with no errors. Cycling green

In software reset with POST1 errors. Cycling red

Application running successfully. S1 flashing green (slow)

Application running with initialization error. S1 flashing red (slow)

Asynchronous error (for example: limit switch tripped). S2 flashing red (fast)

Miscellaneous error (for example: output driver not powered). S2 flashing green (fast)

Reception of CAN message on CAN2 C2 flashing

1

POST = power on self test

NextMove PCI Installation Manual

26

MN1277 04.2001

Updating controller firmware All flashing green (slow)

POST executing (after reset command) All red, go off sequentially

(C1,S1,S2,C2)

There are two bicolour LED’s on the NextMove PCI Expansion card. The LED’s can be

red

or

green

and may be

steady

or

flashing

. These states are shown in the following table:

S1

S2

S1

S2

Figure 3-16: Status and CAN indicator LEDs

Expansion LED Status State

All off No power or not used. Check main card LEDs.

All red In hardware reset.

Alternately flashing green In software reset with no errors.

Alternately flashing red In software reset with POST2 errors.

S1 flashing green (slow) Application running successfully.

S1 flashing red (slow) Application running with initialization error.

S2 flashing red (fast) Asynchronous error (for example: limit switch tripped).

S2 flashing green (fast) Miscellaneous error (for example: output driver not powered).

3.11 NextMove PCI Expansion Card

A 64-pin socket on the top edge of NextMove PCI provides a 16-bit expansion bus. The Expansion

Card has the same set of I/O as the main board (except for CAN) and uses the same Breakout Unit

and cabling. NextMove PCI can directly support one or two Expansion Cards. Connection to the

cards is made through a bridging PCB (the

Expansion Interconnect

) that plugs across the top of the

main and Expansion Cards.

2

POST = power on self test

Hardware Guide

MN1277 04.2001

27

Figure 3-17: NextMove PCI Expansion Card

Notes:

The Expansion Interconnect is polarized to prevent mis-insertion. If two Expansion Cards are used

then the Dual Interconnect board is needed. It highly advisable to exert a retaining force on the

interconnect board, for example with a metal bracket and non-conductive padding. See section 5.2

for details on Expansion Card accessories.

The NextMove PCI Expansion card is available in 4 or 8 axis variants, providing an additional 4 or 8

servo / stepper axes. Each expansion card also adds 20 digital inputs, 12 digital outputs, 4 analog

inputs, 4 analog outputs (drive command) and a relay.

The following sections of the Hardware Guide chapter are applicable to the expansion card as well

as the main card:

3.2 Connection to the PCB

3.3 Digital I/O

3.4 Analog I/O

3.5 Encoder Interface

3.6 Relay

3.7 Stepper Drive Outputs

3.13 NextMove PCI Breakout Unit

NextMove PCI Installation Manual

28

MN1277 04.2001

3.12 Miscellaneous

3.12.1 Emulator Connection

An 11-pin footprint on the rear of the card marked ‘ICE’ provides access to the processor for

boundary scan emulation. To connect the Texas Instruments emulator pod, a two row 12 pin 0.1”

pitch surface mount pin header with pin 8 missing must be fitted. The connections are those

specified by Texas Instruments. See the ‘Mint v4 Embedded Programming Guide’ for details on

emulator based system debugging.

3.12.2 System Watchdog

The system watchdog is a hardware protection method so that in the event of a firmware or ‘C’

program malfunction, the controller is put into software reset. It may be disabled during low level

code development and debugging. After reset it is possible to determine that the reset was caused by

the system watchdog and take different action from normal. See the ‘Mint v4 Embedded

Programming Guide’ and the ‘Mint v4 PC Programming Guide’ for details.

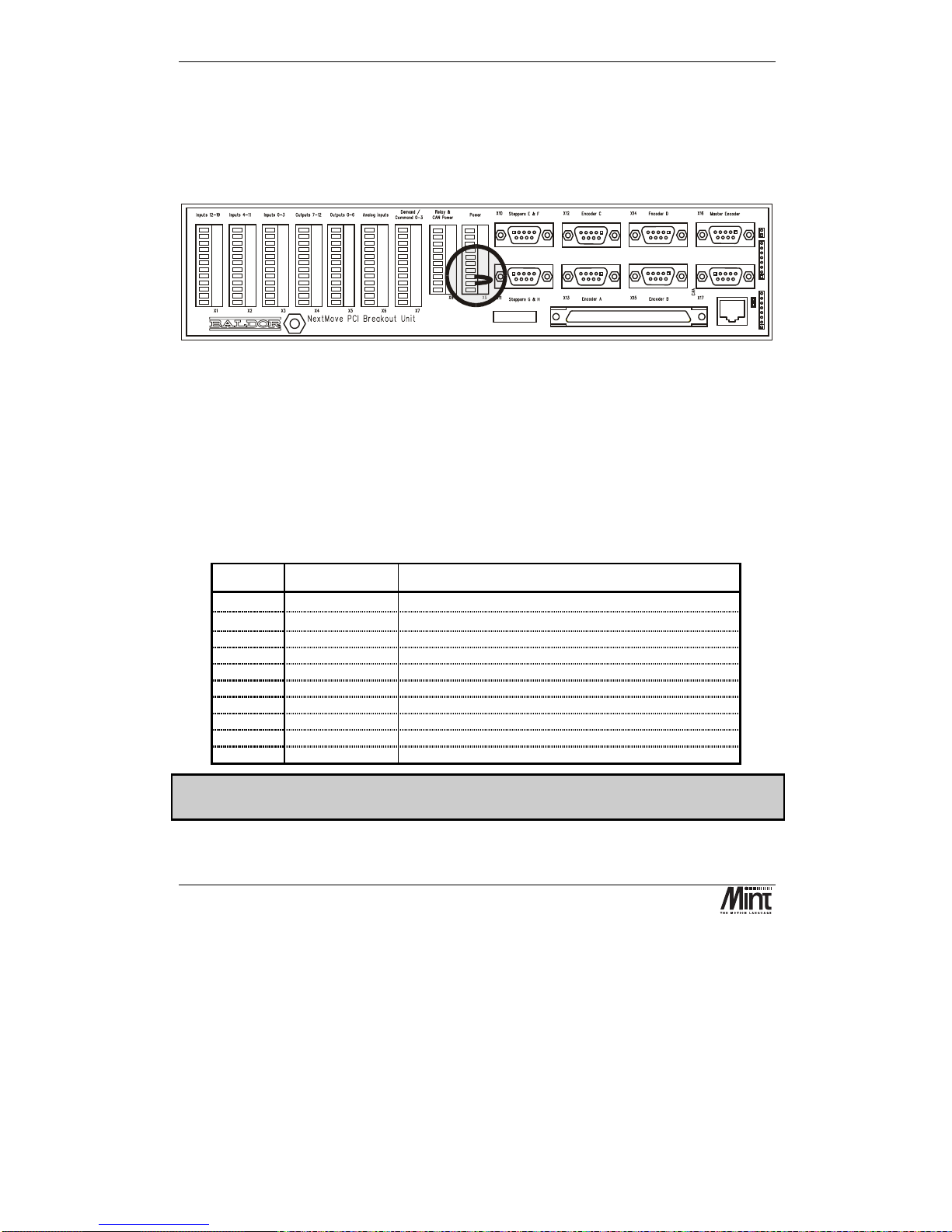

3.13 NextMove PCI Breakout Unit

Two Breakout Units are available for use with the NextMove PCI Expansion Card, one with single

part screw down terminals and the other with two part screw down terminals. The Breakout Unit is

approximately 292mm (11.50 inches) long by 70mm (2.76 inches) wide by 62 mm (2.45 inches)

high. The layout of the board is shown in Figure 3-18. It fits on to either a 35mm symmetric DIN

rail (EN 50 022, DIN 46277-3) or a G-profile rail (EN 50 035, DIN46277-1). The Breakout Unit

connects to NextMove PCI using the 100-Way cable.

Figure 3-18: NextMove PCI Breakout Unit Assembly

This section provides connection details for each connector. For further information, see the earlier

detailed sections on each functional block.

Hardware Guide

MN1277 04.2001

29

3.13.1 X1 - Inputs 12-19

Pin Signal Function

1

Chassis

Shield connection

2

DIG_IN_12

Digital input 12 (referenced to Common8-19)

3

DIG_IN_13

Digital input 13 (referenced to Common8-19)

4

DIG_IN_14

Digital input 14 (referenced to Common8-19)

5

DIG_IN_15

Digital input 15 (referenced to Common8-19)

6

DIG_IN_16

Digital input 16 (referenced to Common8-19)

7

DIG_IN_17

Digital input 17 (referenced to Common8-19)

8

DIG_IN_18

Digital input 18 (referenced to Common8-19)

9

DIG_IN_19

Digital input 19 (referenced to Common8-19)

10

Chassis

Shield connection

11

n/c

Not Connected

12

Common8-19

Common for Inputs 8-19

3.13.2 X2 - Inputs 4-11

Pin Signal Function

1

Chassis

Shield connection

2

DIG_IN_4

Digital input 4 (referenced to Common0-7)

3

DIG_IN_5

Digital input 5 (referenced to Common0-7)

4

DIG_IN_6

Digital input 6 (referenced to Common0-7)

5

DIG_IN_7

Digital input 7 (referenced to Common0-7)

6

DIG_IN_8

Digital input 8 (referenced to Common8-19)

7

DIG_IN_9

Digital input 9 (referenced to Common8-19)

8

DIG_IN_10

Digital input 10 (referenced to Common8-19)

9

DIG_IN_11

Digital input 11 (referenced to Common8-19)

10

Chassis

Shield connection

11

Common0-7

Common for Inputs 0-7

12

Common8-19

Common for Inputs 8-19

NextMove PCI Installation Manual

30

MN1277 04.2001

3.13.3 X3 - High Speed Inputs

Pin Signal Function

1

DIG_IN_0

Digital input 0

2

Common0-7

Reference for inputs 0-7

3

Chassis

Shield connection

4

DIG_IN_1

Digital input 1

5

Common0-7

Reference for inputs 0-7

6

Chassis

Shield connection

7

DIG_IN_2

Digital input 2

8

Common0-7

Reference for inputs 0-7

9

Chassis

Shield connection

10

DIG_IN_3

Digital input 3

11

Common0-7

Reference for inputs 0-7

12

Chassis

Shield connection

3.13.4 X4 - Outputs 6-11

Pin Signal Function

1

Chassis

Shield connection

2

DIG_OUT_6

Digital output 6

3

DIG_OUT_7

Digital output 7

4

DIG_OUT_8

Digital output 8

5

DIG_OUT_9

Digital output 9

6

DIG_OUT_10

Digital output 10

7

DIG_OUT_11

Digital output 11

8

n/c

Not connected

9

n/c

Not connected

10

Chassis

Shield connection

11

USR-V+

∗∗∗∗

Output power supply power

12

USR-GND

Output power supply ground

Hardware Guide

MN1277 04.2001

31

3.13.5 X5 - Outputs 0-5

Pin Signal Function

1

Chassis

Shield connection

2

DIG_OUT_0

Digital output 0

3

DIG_OUT_1

Digital output 1

4

DIG_OUT_2

Digital output 2

5

DIG_OUT_3

Digital output 3

6

DIG_OUT_4

Digital output 4

7

DIG_OUT_5

Digital output 5

8

n/c

Not connected

9

n/c

Not connected

10

Chassis

Shield connection

11

USR-V+

∗∗∗∗

Output power supply power

12

USR-GND

Output power supply ground

3.13.6 X6 - Analog Inputs

Pin Signal Function

1

AGND

Analog Ground

2

AIN_0+

Analog input 0 positive input

3

AIN_0-

Analog input 0 negative input

6

Chassis

Shield connection

1

AGND

Analog Ground

4

AIN_1+

Analog input 1 positive input

5

AIN_1-

Analog input 1 negative input

6

Chassis

Shield connection

7

AGND

Analog Ground

8

AIN_2+

Analog input 2 positive input

9

AIN_2-

Analog input 2 negative input

12

Chassis

Shield connection

7

AGND

Analog Ground

10

AIN_3+

Analog input 3 positive input

11

AIN_3-

Analog input 3 negative input

12

Chassis

Shield connection

∗

This power must be supplied externally

NextMove PCI Installation Manual

32

MN1277 04.2001

3.13.7 X7 – Command Signals

Pin Signal Function

1

DEMAND_0

Command signal for axis 0

2

AGND

Analog ground

3

Chassis

Shield connection

4

DEMAND_1

Command signal for axis 1

5

AGND

Analog ground

6

Chassis

Shield connection

7

DEMAND_2

Command signal for axis 2

8

AGND

Analog ground

9

Chassis

Shield connection

10

DEMAND_3

Command signal for axis 3

11

AGND

Analog ground

12

Chassis

Shield connection

3.13.8 X8 - PSU connections

Pin Signal Function

1

CAN-V+ 1

Power input for CAN 1 network (

CAN

open

)

2

CAN-GND 1

Ground for CAN 1 network (

CAN

open

)

3

CAN-V+ 2

Power input for CAN 2 network (Baldor CAN)

4

CAN-GND 2

Ground for CAN 2 network (Baldor CAN)

5

Relay-NC

Normally closed relay connection

6

Relay-NO

Normally open relay connection

7

Relay-COM

Common relay connection

8

USR-V+

2

Output power supply power

9

USR-GND

Output power supply ground

10

Chassis

Shield connection

2

USR-V+ must be supplied externally

Hardware Guide

MN1277 04.2001

33

3.13.9 X9 - Encoder Power

Pin Signal Function

1

Vcc

5V power connection (from the PC)

2

Vcc

5V power connection (from the PC)

3

Encoder V+

1

Power to the encoder connectors (normally +5V)

4

Encoder V+

1

Power to the encoder connectors (normally +5V)

5

GND

Digital ground (from the PC)

6

GND

Digital ground (from the PC)

7

USR-V+

2

Output power supply

8

USR-V+

2

Output power supply

9

USR-GND

Output power supply ground

10

USR-GND

Output power supply ground

3.13.10 X10, X11 - Steppers

Figure 3-19: Stepper D-types Connector

Signal Pin Nos. Function Cabling

Step n

1,5 Step signal true

!Step n

6,9 Step signal complement

Dir n

2,4 Direction signal true

!Dir n

7,8 Direction signal complement

GND

3 Signal ground

chassis

Shell screen

1

Encoder V+ must be connected to VCC or supplied externally

2

USR-V+ must be supplied externally

NextMove PCI Installation Manual

34

MN1277 04.2001

3.13.11 X12, X13, X14, X15, X16 - Encoders

Figure 3-20: Encoder Connector

Pin Signal Function Cabling

1

Encoder V+

∗∗∗∗

Power to the Encoder (not always 5V)

7

gnd

Power and signal ground

5

chA

Channel A true signal

9

!chA

Channel A complement signal

8

chB

Channel B true signal

3

!chB

Channel B complement signal

2

index

Index true signal (channel I or Z or C)

6

!index

Index complement signal (channel I or Z or C)

4

chassis

Chassis connection

Shell

chassis

Screen

∗

This power rail must be connected to VCC or supplied externally

Hardware Guide

MN1277 04.2001

35

3.13.12 X17, X18 - CAN

Figure 3-21: CAN Connectors

Signal Function D-type Pin RJ-45 Pin Cabling

can+

CAN data signal 7 1

can-

CAN data signal 2 2

can V+

Power to the CAN Nodes 9 5

gnd

Signal ground 3 4

chassis

Screen pin 1 -

NC No connection 4,5,6,8 3,6,7,8

chassis

Screen Shell Shell

NextMove PCI Installation Manual

36

MN1277 04.2001

Operation and Setup

MN1277 04.2001

37

4. Operation and Setup

4

This chapter is step by step guide to setting up a NextMove PCI servo and

stepper control system. Basic familiarity with PC’s and the Windows

environment is assumed.

Installing NextMove PCI into the PC.

Introduction to servo systems and tuning. Determining system gains and

fine-tuning.

NextMove PCI Installation Manual

38

MN1277 04.2001

4.1 Installing NextMove PCI

NextMove PCI can be installed into an AT style personal computer that has a free 7 inch PCI card

slot. The Baldor Motion Toolkit CD supports the following operating systems only: Windows 95,

Windows 98 and Windows NT version 4.

4.1.1 Placing the Card In the Computer

Before placing the card in the computer, carry out the following steps:

1. Exit any applications that are running and close all windows.

2. Turn off the power and unplug all power cords.

3. Remove the cover from your computers system unit.

4. Locate an unused PCI slot.

Note that before touching the card, be sure to discharge static electricity from hands by

touching a grounded metal surface, such as the screw on an electrical outlet’s plate cover.

Alternatively, wear an earth strap while handling the card.

5. Remove the cover from the slot, and save the screw for use later.

6. Discharge any static electricity from hands.

7. Remove the card from its protective wrapper. Do not to touch the gold contacts at the bottom of

the card.

8. Align the bottom of the card (gold contacts) with the slot and press the card firmly into the

socket. When correctly installed, the card locks into place.

9. Make sure that the top of the card is level (not slanted) and that the hole on top of the card’s

metal bracket lines up with the screw hole at the back of the slot.

10. Anchor the card in place using the screw removed earlier.

11. Replace the computer cover and screws.

12. Reconnect any cables and power cords that were disconnected or unplugged and turn on the

computer.

4.1.2 Installing Software

NextMove PCI is a plug and play device. Once the card has been inserted into the PC it will be

detected the next time the PC is turned on. This detection process varies depending on the operating

system running on the PC.

Operation and Setup

MN1277 04.2001

39

Windows 95/98/ME:

As Windows 95/98/ME starts it will display a dialog box indicating that it has detected the presence

of a new PCI card, the ‘Update Device Driver Wizard’. This utility will allow a device driver to be

selected for NextMove PCI.

Figure 4-1: Windows 95 ‘Update Device Driver Wizard’

Place the Baldor Motion Toolkit CD into the CDROM of the computer. Select ‘Next’ and then

manually specify the following directory which contains the device driver for NextMove PCI:

DRIVERS\NMPCI\WIN9x

Once the device driver has been selected Windows will continue to load.

Windows NT:

Under Windows NT there will be no indication that a new card has been installed. The device driver

for NextMove PCI will need to be installed from the Baldor Motion Toolkit. Place the Baldor

Motion Toolkit CD into the CDROM of the computer. The CD should auto-run and display the

‘Welcome to the Baldor Motion Toolkit’ page. If auto-run is disabled, browse the CD and double

click the file SETUP.HTM.

NextMove PCI Installation Manual

40

MN1277 04.2001

Select ‘NextMove PCI’ from the menu and select the ‘NextMove PCI NT Device Driver’ option on

the NextMove PCI page of the Baldor Motion Toolkit. Once the device driver has been installed it

will be necessary to restart your PC. This will load the device driver and enable communication with

NextMove PCI.

If upgrading your device driver from a previous release, you must uninstall the old device

driver first. To do this, select ‘NextMove PCI Device Driver’ from the ‘Add/Remove

Programs’ group in Windows Control Panel.

The driver can also be found in the following directory.

DRIVERS\NMPCI\WINNT

Windows 2000:

The Windows NT device driver can be used under Windows 2000.

After installing the NextMove PCI card, turn the PC on. Enter the BIOS and disable the ‘Plug and

Play’ option or select ‘Operating system is not plug and play compatible’. Exit the BIOS and let

Windows 2000 boot.

Once Windows 2000 has loaded it will enter the Hardware Wizard.

•

Select 'Search for a suitable device driver', hit 'Next'.

•

Un-check all search locations, hit 'Next'.

•

Select the 'Disable the device' option, hit 'Finish'.

Restart the PC, the hardware wizard should not re-appear.

The Windows NT device driver then needs to be installed from the Baldor Motion Toolkit CD.

Place the Baldor Motion Toolkit CD into the CDROM of the computer. The CD should auto-run and

display the ‘Welcome to the Baldor Motion Toolkit’ page. If auto-run is disabled, browse the CD

and double click the file SETUP.HTM. Using the Baldor Motion Toolkit install the NMPCI device

driver, either by using the HTML front end or directly from CD Drive\Mint v4\Installation\NT

NMPCI Device Driver.

The WinNT Device Driver works under Win2000, but the Device Manager may report a conflict and

display the device along with a ! symbol. This is only because the Device Driver is not native to

Win2000, and does not affect functionality.

4.2 Baldor Motion Toolkit CD

Place the Baldor Motion Toolkit CD in the CD drive of the PC. The CD will auto-run and display

the home page. If auto-run is disabled, browse the CD and double click the file ‘SETUP.HTM’.

Operation and Setup

MN1277 04.2001

41

Figure 4-2: Baldor Motion Toolkit - Home Page

Select the NextMove link and then select the ‘NextMove PCI’ option. This opens the page that

allows the various NextMove PCI related applications to be installed.

Figure 4-3: Baldor Motion Toolkit – NextMove PCI page

NextMove PCI Installation Manual

42

MN1277 04.2001

The

Mint WorkBench

is the IDE and user interface for communicating with a Mint controller.

Installing the Mint WorkBench will also install firmware (NMPCI.OUT) for NextMove PCI. The

Mint Configuration Tool

is a rapid getting started and configuration utility designed for use with a

number of Mint v4 controllers. The rest of this chapter makes use of both of these applications and

it is recommended that both of these are installed.

4.3 Configuring your System

This section shows you how to configure your system and check the system wiring. The Mint

Configuration Tool allows easy setup of NextMove PCI and allows operational tests to be performed

on the system.

A typical closed loop positioning system can be broken down into three elements:

1.

Position controller

– performs real time positional control of the motor(s), stores the

application program and communicates with the user and other control equipment.

2.

Servo amplifier

– takes command signals from the position controller to control the torque

or speed of the motor/actuator.

3.

Motor/actuator

– translates electrical power from the servo amplifier into rotary or linear

movement. The motor is fitted with a position sensor that feeds the output position back to

the controller.

The controller works by sampling the position of the motor at regular intervals and comparing this

position with its target position. It then instructs the amplifier to drive the motor to correct any

positional error. This process is repeated typically 1000 times per second to ensure that the motor is

always in the correct position.

4.3.1 Minimum System Wiring Example

The following section is a guide to setting up a minimum system. A minimum system is one where

the controller and drives are configured to work with as little external wiring as possible. It is

recommended that motors are tested and set up ‘on the bench’ and not within the machine.

This step-by-step example covers setting-up a system with one servo axis and one stepper axis.

Connections to the controller are made via the 100-way cable assembly and din rail mounted

Breakout Unit (supplied as an option). Figure 4-4 is a simplified wiring diagram for the two axis

system mentioned above. It should be noted that this is not the only possible configuration. It is

important to read the associated text before attempting the set-up. For detailed wiring information,

see section 3.

Operation and Setup

MN1277 04.2001

43

Figure 4-4: Minimum System Wiring

The following table shows the minimum pin connections:

Breakout

Unit

Connector

Name of

Signal

Function Connection on Drive

X7: 1

Command0

Command signal for axis 0

command+

input

X7: 2

agnd

Reference for analog signals

command-

input

X13

encoder

Position feedback

encoder out

output.

Or direct from motor

X1: 2

dig_in_12

Error input

error

output

X10: 1 & 6

step0

Step output for stepper motor axis 4

step

input

X10: 2 & 7

dir0

Direction output for stepper motor

axis 4

direction

input

X8: 7

relay-com

Common connection of relay

enable

input

X8: 6

relay-no

Normally open connection of relay Amplifier/Digital Ground

4.3.2 Starting with the Mint Configuration Tool

Start the Mint Configuration Tool by clicking the icon of the same name which can be found in the

‘Mint v4’ program group.

NextMove PCI Installation Manual

44

MN1277 04.2001

Figure 4-5: Mint Configuration Tool Start Up Page

Select ‘Next’ and proceed to the ‘Controller Type Select’ page. NextMove PCI should have been

found automatically and will appear in the ‘Controller Select’ dropdown. If you have more than one

NextMove PCI then select the card number from the list. The card numbers are allocated

automatically by the PCI and cannot be changed. If NextMove PCI does not appear in the list then

refer to trouble shooting in section 7.

Figure 4-6: MCT Select Controller Drop-down

Clicking ‘Next’ will download firmware to the controller and bring up the ‘Axes Selection’ page.

From here, you can decide which axes you wish to configure in the Mint Configuration Tool. This

example assumes a 4 axis NextMove PCI. We will configure 2 axes, 1 servo and 1 stepper.

Operation and Setup

MN1277 04.2001

45

Figure 4-7: MCT Axis Configuration

From the list given, axis 0 has been selected as a servo and axis 1 as a stepper.

NextMove PCI is available in a number of axis variants: 1, 2, 3, 4 or 8 axes. For the 1, 2, 3 and 4

axis cards, each axis, labeled 0 to 3, can be configured as a servo axis or a stepper axis. For the 8

axis card, axes 0 to 3 are servo axes and axes 4 to 7 are stepper axes. The axes selection screen will

show the current configuration of each axis and the possible configurations. The Mint keyword

VIEW CONFIG can also be used to show similar information. See the Mint v4 Advanced

Programming Manual for further details on axis variants and mappings.

Click ‘Next’ to move to the ‘Scale Parameters’ page. Here you should set the scale factor for each

axis.

Figure 4-8: MCT Scale Settings

Mint defines all positional and speed related motion keywords in terms of encoder quadrature counts

for servo motors or steps for stepper motors. The scale factor allows the system to be scaled to your

own units to suit your application. The diagram below shows the effect of scaling on positional

information:

NextMove PCI Installation Manual

46

MN1277 04.2001

Figure 4-9: The Effect of Scaling on Positional Information

In an XY application, for example, you may want to define all positions in millimeters or inches.

For each servo axis, either manually enter a scale factor for ‘Counts per user unit’ or select ‘Counts

per revolution’ and select the number of lines on the encoder. For each stepper axis, either manually

enter a scale factor for ‘Steps per user unit’ or select ‘Steps per revolution’ and select the number of

steps per revolution.

4.4 Servo Setup

Clicking ‘Next’ brings up the ‘Test Select’ screen. In order to perform some basic tests on the

system wiring, select ‘Perform Axes Configuration Test’.

The first test checks that the drive enable is correctly wired. By default NextMove PCI does not

associate any physical output with a drive enable. In this example the relay will be used as the drive

enable channel. Select ‘Relay0’ from the drop down list.

Figure 4-10: MCT Drive Enable Channel Drop-down

The assigned drive enable channel allows NextMove PCI to shut down the drive in the event of an

error. Clicking the ‘Drive Enable’ button should enable the drive and the ‘Drive Disable’ button

should disable the drive. If this is not the case, then the wiring and drive set-up should be checked.

Operation and Setup

MN1277 04.2001

47

Figure 4-11: MCT Drive Enable Test

The next test checks that the command and direction signals to the drive. A positive command

signal should result in a positive encoder change and a negative command signal should result in a

negative encoder change.

Figure 4-12: MCT Command Test

If the encoder runs in the opposite direction when a command voltage is applied then the system may

be re-wired or the ‘Advanced Encoder Settings’ button can be used to modify the encoder settings.

NextMove PCI Installation Manual

48

MN1277 04.2001

Figure 4-13: MCT Advanced Encoder Mode Settings

If the position does not change then check the following:

•

The encoder cable is connected to the correct encoder input.

•

The encoder has power and is correctly wired.

If the motor does not move, check the following:

•

The amplifier is enabled.

•

There is a voltage output from the

command+

output.

4.4.1 Tuning a Servo Drive

At the lowest level of control software, instantaneous axis position demands produced by the

controller software must be translated into motor demands. This is achieved by closed loop control

of the motor. The motor is controlled to minimize the error between demand and actual position

measured with an incremental encoder.

Every 1ms (or optionally 500us or 200us using the

LOOPTIME

keyword) the controller compares

desired and actual positions and calculates the correct demand for the motor. The corrective signal

is calculated by a PIDVFA (Proportional, Integral, Derivative, Velocity Feedback, Velocity Feed

forward and Acceleration Feed forward) algorithm.

Control could be achieved by applying a signal proportional to the error alone, but this is a rather

simplistic approach. Imagine that there is a small error between demanded and actual position. A

proportional controller will simply multiply the error by some constant and apply the result to the

motor via an amplifier. If the gain is too low, then the motor will not hold positional. As the gain is

increased, the motor will present more resistance to positional error, but oscillations will increase in

magnitude until the system becomes unstable.

Operation and Setup

MN1277 04.2001

49

time

velocity

acceleration/deceleration rate

ACCEL

0

axis speed during move

SPEED

units of

measure

set by

SCALE

Ideal trapezoidal velocity profile

time

velocity

0

Typical actual velocity profile

Overshoot

Following error (positional lag)

Underdamped

Good

Ideal

Figure 4-14: Velocity Profiles

To reduce the onset of instability a damping term is incorporated in the servo loop algorithm, called

velocity feedback gain. Velocity feedback acts to resist rapid movement of the motor and hence

allows the proportional gain to be set higher before vibration sets in. (In some applications, the

velocity feedback is handled by the amplifier, called a velocity servo). The effect of too high

proportional gain, or too low velocity feedback gain is illustrated by the "Under damped" line in

Figure 4-14.

In NextMove PCI, an alternative damping method is provided in the form of the derivative of the

error signal. Derivative action has the same effect as velocity feedback if the velocity feedback and

feedforward terms are equal. In torque controlled systems, derivative action is generally the

preferred term.

Below is a description of the servo loop terms and their effect on the response of an axis.

Proportional Gain

: This acts directly on the difference between the actual position of the axis and

the desired position (following error). The larger the proportional gain the faster the axis will

respond, however large values of proportional gain will introduce oscillation and result in a large

settling times or in a worse case instability of the axis. Conversely, a small value of proportional

gain will result in the axes responding slowly and never reaching the desired position.

NextMove PCI Installation Manual

50

MN1277 04.2001

Derivative Gain

: This acts on the rate of change of following error. This term will speed up the

response of an axis to the initial change in demand and reduce overshoot. As this term acts on the

rate of change of following error when the axis is stationary the control effort generated by the

derivative term should be zero. However in reality as servo axes are never truly at rest a large value