Manual No. 679A

MINSTER®

8952-574

SCRB-68

EDDY CURRENT COUPLING CONTROLS

DESCRIPTION

OPERATION

MAINTENANCE

REPAIR PARTS

MINSTER SOLID STATE CONTROLS

$5.00

Manual No. 679A

MINSTER®

8952-574

SCRB-68

EDDY CURRENT COUPLING CONTROLS

DESCRIPTION

OPERATION

MAINTENANCE

REPAIR PARTS

MINSTER SOLID STATE CONTROLS

$5.00

—2—

SERVICE

This manual has been prepared to furnish the user with

sufficient detailed information to operate and maintain

the MINSTER SCRB-68 Eddy Current Coupling Controls.

The SCR control described herein has been engineered to provide automatic speed and torque regulation of drives equipped with eddy current couplings.

This design offers a simplified method of adjustment

and includes the reliability of long life solid state components. Inherent construction provides an uncomplicated approach to troubleshooting, should the need

occur. Through the use of extra, known-good, plug-in

modules and reference to the troubleshooting section

of this manual, most technicians should have little difficulty maintaining the controls.

Individual Eddy Current Coupling Control modules, or

the complete control, may be returned to the factory for

checkout and repair. The SCR controls will be repaired

promptly at a reasonable cost.

If technical assistance is desired, please contact the

Minster Service Department.

DESIGN CHANGES

Manufacturing methods, state of the art, and availability of certain components may change. Suppliers may

discontinue production of certain devices whenever

improved types become available to replace them. As

a result of these changes, some components furnished

in MINSTER controls may vary slightly from those illustrated in the manual. Troubleshooting procedures

should not change. If questions should arise concerning the replacement of component parts, please contact the Minster Service Department.

Copyright © 2008, 2011

THE MINSTER MACHINE COMPANY

Minster, Ohio 45865

Printed in the United States of America

Reproduction or use, without express permission, of editorial

or pictorial content, in any manner, is prohibited.

REGARDING WARRANTY

TERMS OF THE WARRANTY ARE FULLY DOCUMENTED IN THE MINSTER WARRANTY.

A COPY OF THAT WARRANTY IS INCLUDED IN THE COMPOSITE SERVICE

MANUAL; ADDITIONAL COPIES ARE AVAILABLE UPON REQUEST.

—3—

CONTENTS

Page

COMPONENT IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Explanation Of Eddy Current Coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Eddy Current Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Function of the Speed Sensitive Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

CHASSIS AND PANEL MOUNTED COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Indicator Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Circuit Breaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Control Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Maximum Speed Potentiometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

To Adjust the Maximum Speed Potentiometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

To Adjust the Torque Limit Potentiometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

To Adjust Operating Point of Speed Sense Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

To set Relay Operating Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

To Adjust the Strokes Per Minute Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Reference Out (PLC analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

CONTROL REPLACEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Option A: Conversion from a SCRB 52/58 to a SCRB 68 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Option B: Conversion from a SCRB 42/48 to a SCRB 68 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Option C: Conversion from a SCR 22/28 to a SCRB 68 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

INSTALLATION NOTE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

TROUBLESHOOTING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

VOLTAGE GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

FACTORY CHECKOUT AND REPAIR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

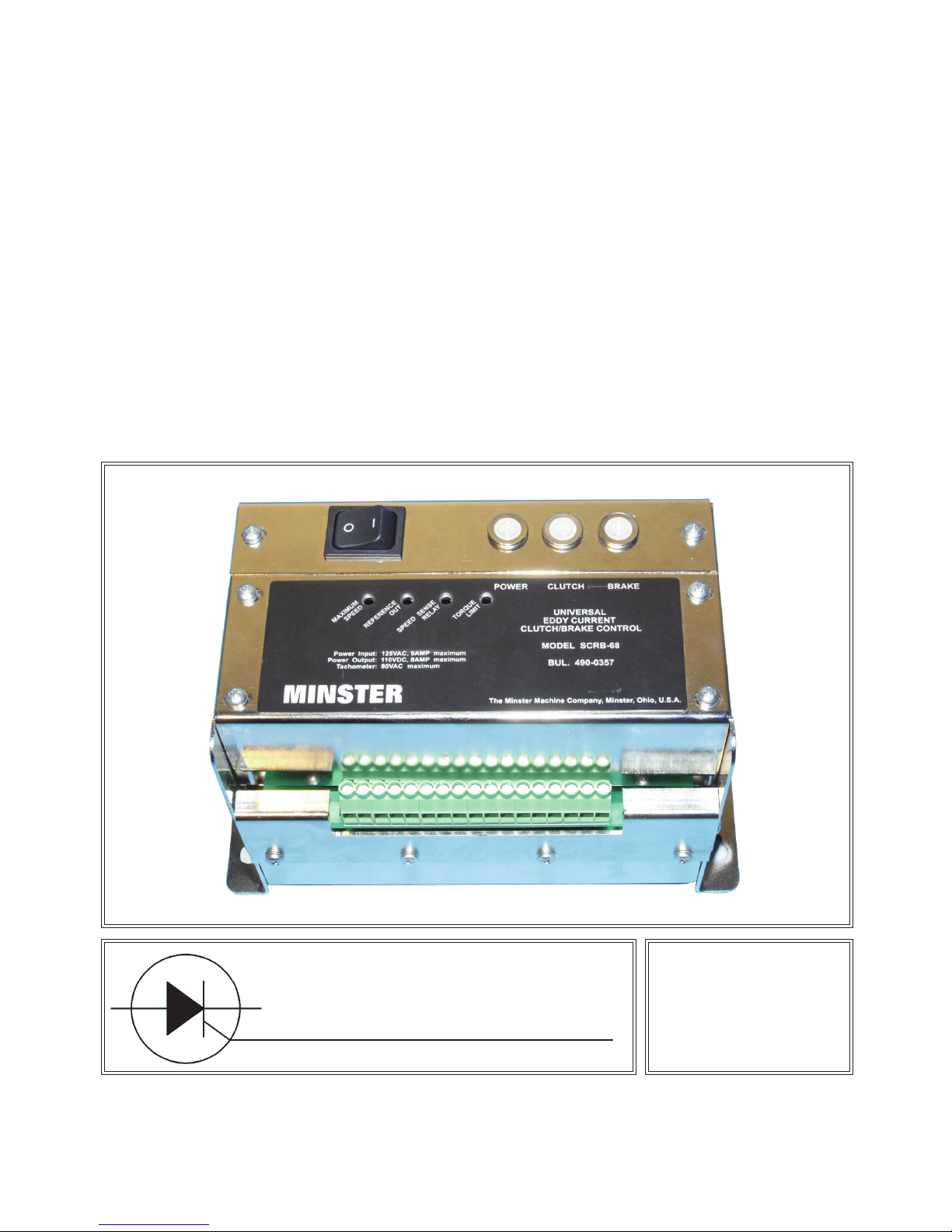

Figure 1. SCRB-68 with cover removed.

COMPONENT IDENTIFICATION

—4—

Figure 2. SCRB-68 rear view.

Terminal Strip

Power Switch

Indicators

MINSTER Model SCRB-68 is an electronic control unit

designed to provide controlled excitation for eddy current coupling type variable speed drives. These controls are compatible with Dynamatic, Louis-Allis

Adjusto-Spede and Torspec drives and with WER

drives that are equipped with special 90 volt D.C. coupling coils. The control consists of a rugged metal housing. The SCRB-68 control may be used with drives

requiring up to 900 watts at 90 volts D.C.

To briefly describe operation, a portion of a regulated

voltage supply, selected by a speed adjusting potentiometer, and a rectified feedback voltage from a

tachometer generator connected to the drive output

shaft, are compared. The error signal obtained is used

to control a silicon controlled rectifier to energize the

coupling. If the reference portion is greater than

tachometer feedback, the coupling is turned “ON.” If

the tachometer feedback is greater, the coupling is

turned “OFF” to produce less output torque and the

optional eddy current brake is fired, to allow output

shaft slowdown.

Extremely fast and accurate speed control is realized

— response time being solely a function of load and

coupling time constants.

The SCRB-68 Control consists of two circuit boards

and housing. A power switch is built-in as a convenient

means of disconnecting power. A torque limiter feature

prevents excitation of the eddy current coupling as long

as motor current exceeds the preselected torque limit

point. A speed sensitive relay drive feature is also built

into the control. This feature is used to control energization of a D.C. control relay in relation to output

speed of the drive. A precision speed reference signal

which varies in direct relation to the output speed of the

drive is provided for use with programmable controls

requiring a low voltage D.C. tachometer signal.

Three (3) neon indicator lamps are located on top of the

control housing adjacent to the power switch. The “D.C.

Power” indicator lamp will glow with a steady brilliance

whenever the unit is turned on. The other lamps are

used to indicate excitation of the eddy current coupling

or brake as noted. Since the eddy current coupling and

brake coils are constantly being pulsed “ON” and

“OFF,” it is normal for the lamps to glow with varying

brilliance.

The SCRB-68 control is usually used in conjunction

with an external control in which certain preset speeds

can be programmed. With this arrangement, press

speed will immediately and automatically change to the

rate which has been preset for a certain function whenever that function is selected. For variable speed drives

equipped with eddy current brakes, by adding a time

delay relay to this control, the drive can be used as a

flywheel brake to quickly slow the flywheel when the

press is shut off.

—5—

DESCRIPTION

OPERATION

The press drive motor and speed controller are both

energized with the “Drive Start” push button. Torque is

transmitted from the drive motor output shaft through a

set of belts to the flywheel. Once the motor is started,

the drive will continue to accelerate flywheel rotation

until it reaches the speed which has been set on the

speed control located on the operator's control panel.

The speed meter, calibrated in strokes per minute, will

indicate the approximate number of times the slide will

cycle continuously each minute. This speed will be

shown even though the press clutch is not engaged

and the slide is not moving.

The strokes per minute indicator reading may vary

slightly from the actual press speed. Accuracy of the

reading depends, to a great degree, on how closely the

meter is calibrated. A resistance network consisting of

several fixed resistors and a potentiometer are placed

in series with analog type meters to accomplish this

calibration. The digital S.P.M. meter contains an integral calibration network.

Speed of the press will be controlled from the variable

speed selector on the operator's control panel. After a

particular speed has been selected, the control will hold

that speed constant. An exception to this will exist,

however, if a torque limit control is installed and the

torque requirements are in excess of the preset torque

limit point.

EXPLANATION OF

EDDY CURRENT COUPLING

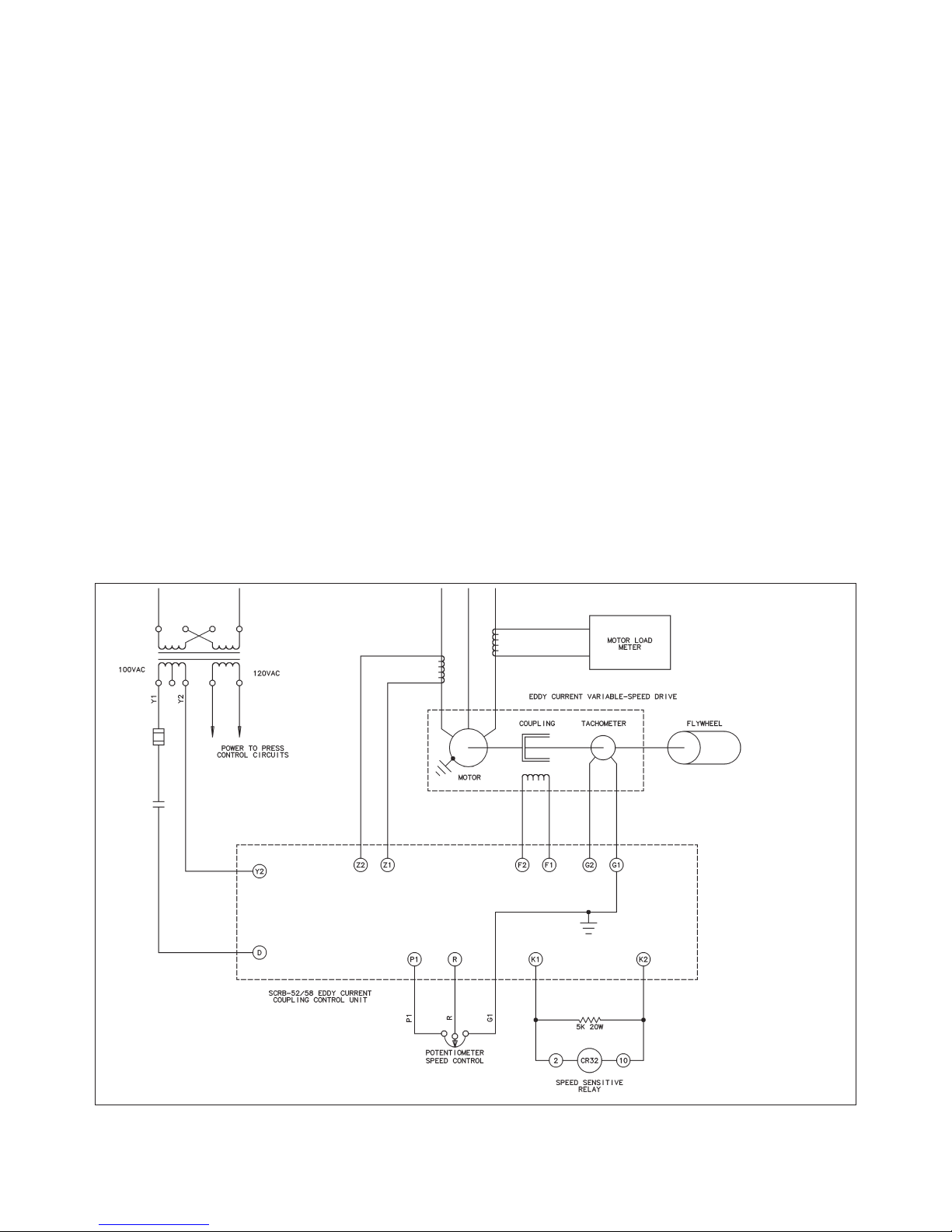

(See Figure 3)

Before entering into a circuit description of the Eddy

Current Coupling Control, a few preliminary remarks

regarding the principle of eddy current coupling will be

noted. This brief description is offered merely to establish a common background for describing the control

application.

The principle of eddy current coupling makes it possible to obtain a wide range of stepless, adjustable

speeds directly from industrial A.C. power lines at standard frequencies. The drive unit consists of a constant

speed induction motor and an integral magnetic clutch,

or eddy current coupling, assembled in a common

housing. The variable speed output shaft is rotated by

the constant speed A.C. motor through the eddy current coupling.

The eddy current coupling usually consists of three

basic members: the driving member or drum assembly,

the driven member or rotor assembly, and a stationary

member which is the field coil assembly. These basic

components are illustrated schematically in Figures 3

and 4.

A high strength iron drum is connected to the driveshaft

of the constant speed motor and rotates at the speed of

the motor. This drum is the driving member and, in principle, serves as a series of conductor loops as well as

a magnetic flux carrier. The position of the drum is such

that its inner surface surrounds and partially encloses

both field coil and rotor.

The variable speed output shaft is a part of the rotor

assembly and rotates at speeds determined by the

control setting. The cylindrical portion of the rotor lies

between the drum and field coil assemblies and is

divided into magnetically isolated sections by a nonmagnetic metal ring called a magnetic barrier. Poles,

cast into each rotor section, project alternately across

the outer surface of the rotor and are isolated from the

inner surface of the drum by an air gap. As the field coil

is excited, each rotor section assumes a polarity opposite to that of the other section and becomes alternate

north and south magnetic poles.

The field coil assembly is a stationary toroidal coil located concentrically within the rotor assembly. When the

coil is excited, magnetic lines of force emanate from it,

flowing through the north poles of the rotor into the

drum, through the south poles of the rotor and back to

the field assembly. As the drum rotates, the direction of

—6—

Figure 3. SCRB-52/58 Coupling control.

magnetic flux changes at any given point between

these eddy currents and the magnetic field produces a

drag, or relative torque, to be transmitted from the drum

to the rotor and the output shaft connected directly to it.

With no current flowing through the coupling coil, the

rotor and drum assemblies are free to rotate independently of each other. Under this no current condition,

the drum assembly will rotate at full motor speed with

little or no rotation of the output shaft. As current is

applied to the coil, the output shaft accelerates. Output

shaft speed will continue to increase, as long as the coil

remains energized, until it is rotating at a speed slightly less than the speed of the input member. Speed of

the output shaft will never exactly match that of the

motor since some slip is required to transmit torque.

Slip, in this case, refers to speed difference between

the two rotating members. With the control automatically varying the amount of coupling coil excitation, output shaft speed can be held to the preselected rate.

A tachometer generator is attached to the output shaft.

This is an alternating current device whose output frequency varies in direct proportion to the speed of the

output shaft. This voltage is fed into the SCRB-68 control where it is converted from a frequency signal to a

voltage. This voltage is compared with a reference volt-

age so that speed control can be constantly maintained. A portion of the tachometer voltage is also used

to operate the strokes per minute indicator.

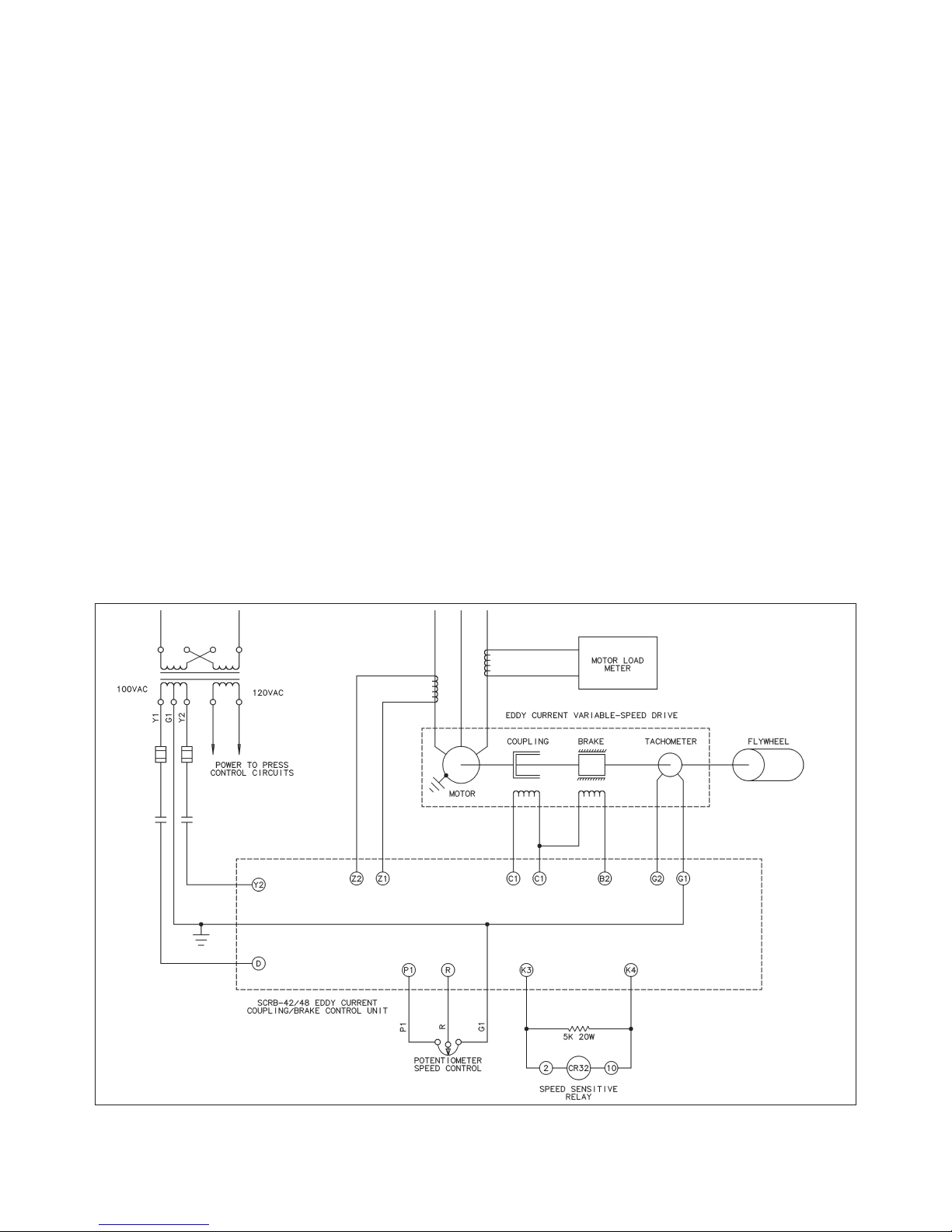

EDDY CURRENT BRAKE

Eddy current drive units may be ordered complete

with eddy current brakes for the purpose of quickly

slowing speed of the output shaft. The eddy current

brake is located within the coupling housing and consists of a brake field coil assembly and the brake

rotor.

The brake field assembly is attached to the coupling

housing and includes a toroidal field coil which is surrounded by two field end rings to form an electromagnet. Poles are cast into the inner surfaces of the end

rings and machined to allow an air gap between the

rings and rotor assembly.

The brake rotor is keyed to the coupling output shaft

and rotates inside the field assembly. If no current is

applied to the brake field coil, no braking torque is

developed. However, as the field coil is excited, eddy

currents are induced in the rotating assembly which

interacts with the stationary field to develop braking

torque. Amount of braking torque may be controlled

by changing excitation of the brake coil.

—7—

Figure 4. SCRB-42/48 coupling/brake control.

FUNCTION OF THE SPEED

SENSE RELAY

Certain types of feeds, tooling, and threading devices

must be started at slow speed. However, once these

parts are in motion, their speed may be increased for

more efficient operation. In order that the press may be

started at speeds commensurate with the tolerable

starting rate of these auxiliary devices, preset controls

may be built-in to automatically reduce speed of the

drive whenever the press is stopped.

The speed sensitive relay is used as a checking device

to make certain speed has been reduced adequately

prior to engagement of the press clutch. If motor output

speed is too fast for an acceptable starting rate, the

relay will open contacts in the control run circuit to prevent press clutch engagement.

The speed range through which the speed sensitive

relay is energized can be changed. Adjustment procedures are explained below.

CHASSIS AND PANEL

MOUNTED COMPONENTS

INDICATOR LIGHTS

A neon indicator light, labeled “POWER,” is connected

across the output terminals of the D.C. power supply

rectifier bridge. Failure of the lamp to glow would indicate failure of power supply bridge or lack of A.C. input

power.

Additional neon indicator lamps (CLUTCH and

BRAKE) are connected across the coupling and brake

coils to serve as an indication of coil excitation. To

accurately measure the amount or presence of a small

excitation voltage on the coupling or brake, a D.C. voltmeter should be used since a rather large “threshold”

voltage is needed to light neon indicators. This excitation voltage can be signal checked between terminals

3 (F2/C2) and 5 (F1/C1 signal) or terminals 4 (B2 signal) and 6 (C1 signal) for the coupling (clutch) or brake

respectively.

POWER OFF/ON

A power switch is mounted on the face of the SCRB-68

Eddy Current Coupling Control and provides a convenient means of disconnecting power from the control

should the need occur.

CONTROL TRANSFORMER

The voltage from the control transformer is dependent

on what the voltage of the motor coils are rated. In

most cases the motor coils are rated at 90 volts so an

isolated 100 volt secondary transformer winding is necessary to supply A.C. power to the control. If the motor

coils were rated at 115 volts then a 125 volts secondary

transformer winding would be required. This winding is

usually auxiliary to the main control transformer. Applications with an eddy current brake require this winding

to have a center tap. This center tap is grounded and

also connected to terminal 7.

FUSES

The supply voltage must be fused in all applications of

the SCRB-68 Eddy Current Coupling Control.

—8—

Figure 5. SCRB-52/58 Coupling control.

MINSTER®

ADJUSTMENTS

Before attempting any adjustments, set the four

potentiometer adjustment screws to their initial values. All four screws are 25 turn potentiometers. You

will hear a click every turn when you reach the clockwise or counter-clockwise end of the potentiometer.

Set ‘MAXIMUM SPEED’ full clockwise.

Set ‘REFERENCE OUT’ full clockwise.

Set ‘SPEED SENSE RELAY’ full clockwise.

Set ‘TORQUE LIMIT’ full counter-clockwise.

MAXIMUM SPEED POTENTIOMETER

An adjustment of the maximum speed potentiometer is

used to match the tachometer generator, located in the

drive, to the control. The potentiometer is located on

the SCRB-68 unit and is labeled “Maximum Speed” and

is located first from the left when viewing the control.

The potentiometer is accessible through an opening on

the front panel. (Refer to Figure 4.)

Once properly adjusted, normally no further attention

need be given this item. Improper adjustment of the

maximum speed potentiometer may result in one of the

following:

1. Drive reaches full speed before operator's speed

control selector is set to maximum. This situation

results in the control running wide open in an attempt

to increase the speed of the drive, but full rated

speed is already being attained, and further speed

increase is not possible. While the control is rated

sufficiently to provide full output continuously, it must

be recognized that this condition is abnormal, and

that control life will be less than it would were proper

operation followed. Normal output voltage of the

control to the coupling will not exceed 60 volts D.C.

at full rated load and speed of drive even though this

output voltage may be 90 volts D.C. during drive

acceleration. It should be noted that this abnormal

condition reflects little, if any, additional load on the

A.C. drive motor itself, due to the nature of the drive.

When the control reacts in the manner just

described, a counterclockwise adjustment of the

maximum speed potentiometer is needed.

2. The drive does not reach full speed even with the

operator's speed control set to maximum. This condition is the result of too much tachometer voltage

being applied and can be corrected by turning the

maximum speed potentiometer adjustment screw in

the clockwise direction. Turning adjustment screw in

this direction will insert additional resistance in the

tachometer circuit.

NOTE: The maximum speed potentiometer will in no

way increase the maximum speed capabilities

of the drive. It will not affect trip out of motor

overload relays, nor will it assist in getting an

inoperative control working. This potentiometer

should not be used as a “Stop” to reduce maximum speed capabilities, since better arrangements are available for this purpose.

TO ADJUST THE MAXIMUM

SPEED POTENTIOMETER:

Required Equipment: A.C. Voltmeter with 0 - 75 or 0 100 V.A.C. range.

With flywheel only running, set operator's speed control

to the position for maximum speed. Presses with preset starting speeds will not respond to the operator's

speed control under these circumstances, since this

control is not effective until the press clutch is engaged.

In this situation, the preset potentiometer itself may be

temporarily adjusted fully clockwise to run drive to full

speed. More than one preset speed may exist, in which

case it will be necessary to use the proper one depending on selector switch setting. For example, if selector

switch is set on “INCH”, and an “Inch Speed” preset

potentiometer exists, then this one must be used to

obtain temporary full speed. If a low speed maximum

limit exists on the preset speed controls, remove the

wire connected to terminal 9 (R signal) of the SCRB-68

control and temporarily jumper terminals 9 (R signal)

and 8 (P1 signal). This will give the effect of full reference speed applied to the control.

Once full speed is obtained from the drive, with flywheel only running, connect the A.C. voltmeter probes

to terminals 7 (G1 signal) and 12 (G2 signal) (tachometer generator leads). Reading should be at least 40

volts A.C. with a 1700 RPM drive.

NOTE: Allow enough time when adjusting the Maxi-

mum Speed Potentiometer for the drive to

reach a stable speed. This potentiometer

requires 25 turns of the adjustment screw for

full range of adjustment.

The Maximum Speed Potentiometer adjustment screw

should now be turned clockwise until no further

increase in measured voltage occurs. Read this voltage accurately. Multiply the voltage so obtained by .95

and adjust the Maximum Speed Potentiometer counterclockwise until the calculated, or 95% value, is indicated on the voltmeter.

As a further reference, with flywheel only running, the

coupling coil voltage measured between terminals 5

(C2 signal) and 7 (G1 signal) should be about 5 to 10

volts D.C. - (Continue to next page.)

—9—

Remove jumper wires from terminals 9 (R signal) and

8 (P1 signal); then reconnect the appropriate wire

securely to terminals 9 (R signal). Adjustment of the

Maximum Speed Potentiometer is now completed.

TO ADJUST THE TORQUE

LIMIT POTENTIOMETER:

Required Equipment: If press is equipped with a “Per-

cent of Load” meter, no other equipment will be needed. If this meter is not furnished, a snap-around type

ammeter may be used. Range of the ammeter should

cover at least 200% of the motor full load current.

NOTE: If a snap-on ammeter is used, place the meter

tongs around one of the “T” leads going to the

main drive motor.

Adjustment of the Torque Limit Potentiometer is made

to prevent firing of the coupling SCR whenever A.C.

motor current exceeds the preset value. This potentiometer is located on the SCRB-68 unit and is labeled

“Torque Limit” and is located last from the left when

viewing the control. This potentiometer is accessible

through an opening on the front panel. To adjust, start

drive from rest and promptly turn speed control to the

maximum speed position. While flywheel is accelerating from rest to full speed, adjust the Torque Limit

Potentiometer so as to cause the motor current indicator to fluctuate between 100% and 150% of full load.

The operator’s speed control, or one of the preset

potentiometers (as explained under maximum speed

adjustment) should be used to control the speed for this

setting. It is suggested that the slide not be cycled while

making this adjustment.

Care should be taken when making this adjustment

since too tight an adjustment will prevent any excitation

of the coupling, and too little will prevent any torque limiting action.

TO ADJUST OPERATING POINT

OF SPEED SENSE RELAY:

Required Equipment: D.C. Voltmeter with 0 - 150

V.D.C. range. The potentiometer is located on the

SCRB-68 unit and is labeled “Speed Sense Relay” and

is located third from the left when viewing the control.

The operating point of the speed sensitive relay is

adjustable by a potentiometer accessible through an

opening on the front panel. It can be set to operate at

practically any speed falling within the range of the

press.

A D.C. voltmeter may be used as an indicator to show

when the relay is energized. Set meter range to the 0150 volt scale, attach negative probe to control terminal

16 (K2 signal) and positive probe to terminal 15 (K1 sig-

nal). When the relay is energized, meter reading will be

approximately 90 volts D.C. in the de-energized state,

only about 10 V.D.C will be indicated.

To Set Relay Operating Point:

1. Start press drive motor and adjust operator’s speed

control or one of the preset potentiometers (as

explained under maximum speed potentiometer

adjustment) to the speed desire for the operating

point of the relay. Allow sufficient time for the drive

to stabilize at the selected speed.

2. Set voltmeter to 0-150 V.D.C. range and attach

probes to control terminals 15 (+) and 16 (-).

3. If D.C. meter indicates relay is energized, turn

speed sense relay adjustment screw, counterclockwise until relay de-energizes. If relay is de-energized, turn the adjusting screw clockwise until the

relay is energized.

4. Double check adjustment by varying press speed

through the selected speed operating point and

observing relay drop out point. Make further fine

adjustments, if necessary.

5. Adjustment is now complete. Disconnect and

remove D.C. voltmeter.

TO ADJUST THE STROKES

PER MINUTE METER:

Voltage from the tachometer generator (in the eddy

current drive) is used to operate the strokes per minute

meter. That meter is essentially a voltmeter calibrated

in strokes per minute. Because of the variation in

speeds, meters and tachometer generator voltages, a

means of adjusting the meter to the actual press speed

is provided. Some of the meters are A.C. types while

others are D.C. operated; therefore, the type of calibration network furnished will depend upon the meter.

Calibration instructions are included for the most popular arrangements. Follow instructions matching the

arrangement furnished.

When calibrating the S.P.M. meter, determine the actual number of strokes per minute that the press is running by observing the stroke counter (if furnished), by

using a mechanical hand tachometer, or by actual

count.

The Bul. 490-0246 Digital S.P.M. Meter contains an

integral calibration network. Refer to the separate

Technical Bulletin, 193 or 2007, which is included in the

composite Service & Operating Manual, for detailed

calibration instructions on this unit.

— 10 —

— 11 —

REFERENCE OUT (PLC ANALOG INPUTS):

The reference out potentiometer is located on the front

of the SCRB-68 unit.

For PLC analog inputs, the output level is typically set

at 95% of the maximum allowable input voltage. For

example, with an analog input range configured for 010 volts DC, the output voltage would be adjusted so

that 9.5 volts DC is present when the output terminals

(Terminals located on outside edge of the board same

as the adjustment potentiometers) when the drive is at

full speed. Note also that the output voltage must be

something less that 13 volts DC since it is internally limited to that level.

With the flywheel only running set the speed control to

maximum speed. Once full speed is obtained from the

drive, connect a voltmeter to the terminals on the II

board.

Allow sufficient time when adjusting the output scaling

potentiometer for output voltage stabilize. This potentiometer requires 25 turns of the adjustment for full

range of adjustment.

The output scaling potentiometer should now be turned

to obtain desired output voltage at full speed. Turn

adjustment screw clockwise to increase output level or

counterclockwise to decrease the level.

CONTROL REPLACEMENT

The SCRB-68 is the latest in a series of eddy current

adjustable speed drive controls produced by MINSTER. This latest generation unit incorporates the

functions of all of the previous controls. As such it can

replace any of those previous controls. There are three

options to replace the existing eddy current control with

the SCRB-68.

Option A: Conversion from a SCRB-52/58 to a

SCRB-68

Option B: Conversion from a SCRB-42/48 to a

SCRB-68

Option C: Conversion from a SCR-22/28 to a

SCRB-68

WARNING

VOLTAGE THAT COULD BE FATAL TO HUMAN LIFE

IS PRESENT WITHIN THE ELECTRICAL CONTROL

CIRCUITS. ONLY AUTHORIZED, EXPERIENCED

PERSONNEL SHOULD ATTEMPT THE INSTALLATION AND SERVICING OF ELECTRICAL EQUIPMENT.

Option A: Conversion from a SCRB-52/58 to a

SCRB-68

When replacing a SCRB-52 Control Unit with a SCRB68 Control Unit, a 3.2 Amp fuse must be installed in the

100 volt AC power-in circuit and when replacing a

SCRB-58 Control, a 10 Amp fuse must be installed.

— 12 —

!

Figure 6. SCRB-52/58 replacement worksheet.

The fuse is to be installed in series with the terminal 1

of the SCRB-68 control. Follow the procedure outlined

below to replace the SCRB unit and install the fuse.

1. Place the POWER, OFF-ON Selector Switch in the

OFF position and lock the electrical disconnect

switch in the OFF position. Then open the electrical

control panel to obtain access to the SCRB-52/58

unit.

2. Disconnect the wires from the terminals on the

SCRB-52/58 unit. The wires will be re-connected to

the new unit, therefore, make certain the wires are

labeled before disconnecting them. Also the correct

wire number from the wire being taken off of the

SCRB-52/58 should be written into the blanks

above the terminals on Figure 6.

3. Loosen the four (4) mounting screws that secure

the SCRB-52/58 unit to the panel just enough to

permit removal of the unit. Then remove the unit

from the control panel.

4. Install the SCRB-68 unit in the control panel and

tighten the four (4) associated mounting screws

securely.

5. Connect the wires (previously removed in Step 2) to

the terminals on the SCRB-68 unit. Refer to Figure

6 for wiring details.

NOTE: A jumper must be installed between termi-

nals 5 and 7 on the SCRB-68. Failure to

install this jumper will result in an inoperable

SCRB-68.

6. The fuse holder (furnished) should be installed as

close to the 100 Volt transformer as possible. Begin

by drilling and tapping two (2) #10 - 24 holes in the

control panel to anchor the fuse holder. Then mount

and secure the fuse holder to the panel.

CAUTION

WHEN DRILLING AND TAPPING HOLES FOR THE

FUSE HOLDER MAKE SURE THAT NO METAL

SHAVINGS FALL ON ANY CIRCUIT BOARDS OR

ANY OTHER ELECTRIC DEVICES.

7. Remove the wire from terminal “Y1” of the trans-

former and re-label it “1Y1.” (NOTE: Re-label both

ends of the wire.) Then attach the wire to the bottom

side of the fuse.

8. Run a #16 ga. MTW grade wire (or equivalent) from

the top of the fuse to terminal “Y1” of the 100 Volt

transformer. Label this wire “Y1.”

9. After completing Steps 1 through 8, close up the

electrical control panel. Then refer to the Adjustment section of this manual.

WARNING

VOLTAGE THAT COULD BE FATAL TO HUMAN LIFE

IS PRESENT WITHIN THE ELECTRICAL CONTROL

CIRCUITS. ONLY AUTHORIZED, EXPERIENCED

PERSONNEL SHOULD ATTEMPT THE INSTALLATION AND SERVICING OF ELECTRICAL EQUIPMENT.

— 13 —

!

!

— 14 —

Option B: Conversion from a SCRB-42/48 to a

SCRB-68

When replacing a SCRB-42 Control Unit with a SCRB68 Control Unit, (2) 3.2 Amp fuses must be installed in

the 100 volt AC power-in circuit and when replacing a

SCRB-48 Control Unit , (2) 10 Amp fuses. The first fuse

is to be installed in series with the terminal 1; the second fuse is to be installed in series with the terminal 2

of the SCRB-68 control.

Follow the procedure outlined below to replace the

SCRB unit and install the two fuses.

1. Place the POWER, OFF-ON selector switch in the

OFF position and lock the electrical disconnect

switch in the OFF position. Then open the electrical

control panel to obtain access to the SCRB-42/48

unit.

2. Disconnect the wires from the terminals on the

SCRB-42/48 unit. The wires will be re-connected to

the new unit, therefore, make certain the wires are

labeled before disconnecting them. Also the correct

wire number from the wire being taken off of the

SCRB-42/48 should be written into the blanks

above the terminals on Figure 7.

3. Loosen the four (4) mounting screws that secure

the SCRB-42/48 unit to the panel just enough to

permit removal of the unit. Then remove the unit

from the control panel.

4. Install the SCRB-68 unit in the control panel and

tighten the four (4) associated mounting screws

securely.

5. Connect the wires (previously removed in Step 2) to

the terminals on the SCRB-68 unit. Refer to Figure

7 for wiring details.

NOTE: A jumper must be installed between termi-

nals 15 and 17 on the SCRB-68. Failure to

install this jumper will result in an inoperable

SCRB-68.

6. The two (2) fuse holders (furnished) should be

installed as close to the 100 Volt transformer as

Figure 7. SCRB-42/48 replacement worksheet.

— 15 —

possible. Begin by drilling and tapping four (4) #10

- 24 holes in the control panel to anchor the fuse

holders. Then mount and secure the fuse holders to

the panel.

CAUTION

WHEN DRILLING AND TAPPING HOLES FOR THE

FUSE HOLDER MAKE SURE THAT NO METAL

SHAVINGS FALL ON ANY CIRCUIT BOARDS OR

ANY OTHER ELECTRIC DEVICES.

7. Remove the wire from terminal “Y1” of the trans-

former and re-label it “1Y1.” (NOTE: Re-label both

ends of the wire.) Then attach the wire to the bottom

side of the first fuse.

8. Run a #16 ga. MTW grade wire (or equivalent) from

the top of the first fuse to terminal “Y1” of the 100

Volt transformer. Label this wire “Y1.”

9. Remove the wire from terminal “Y2” of the transformer and re-label it “2Y2.” (NOTE: Re-label both

ends of the wire.) Then attach the wire to the bottom

side of the second fuse.

10. Run a #16 ga. MTW grade wire (or equivalent)

from the top of the second fuse to terminal “Y2” of

the 100 Volt transformer. Label this wire “1Y2.”

11. After completing Steps 1 through 10, close up the

electrical control panel. Then refer to the Adjustment section of this manual.

WARNING

VOLTAGE THAT COULD BE FATAL TO HUMAN LIFE

IS PRESENT WITHIN THE ELECTRICAL CONTROL

CIRCUITS. ONLY AUTHORIZED, EXPERIENCED

PERSONNEL SHOULD ATTEMPT THE INSTALLATION AND SERVICING OF ELECTRICAL EQUIPMENT.

!

!

Option C: Conversion from a SCR-22/28 to a

SCRB-68

The MINSTER Model SCRB-68 and Model SCR-22/28

eddy current coupling controls are completely interchangeable, even though their physical appearance is

somewhat different. However, since there is a slight difference in terminal strip designation between the units,

this step-by-step procedure has been prepared to aid

the technician in interchanging the controls.

NOTE: A 3.2 amp fuse must be installed in the 100-120

Volt AC control power circuit. Install the fuse in series

with terminal 1 on the SCRB-68 control.

The terminal strip designation of the late Model SCR22/28 control is different from that of earlier models.

This difference appears in the eddy current field coil

terminology and was the result of the motor manufacturer’s changing the designation of these leads from

“C1-C2” for “clutch” to “F1-F2” for “field.” Late model

controls are arranged for the “F1-F2” designation. The

reverse side of the SCR-22 terminal strip also carries

the old terminology and may be turned over, if desired,

so that the strip terminology will match that of the leads.

Both types are shown in Figure 8.

If an optional torque limiter control is attached to the

SCR-22/28 unit, terminals Z1 and Z2 (located on the

torque limiter) should be connected to the motor current transformer. See Figure 8 for details.

The Model SCRB-68 control has a terminal strip similar to that shown in Figure 8.

— 16 —

Figure 8. SCR-22/28 replacement worksheet.

1. Place the POWER, OFF-ON Selector Switch in the

OFF position and lock the electrical disconnect

switch in the OFF position. Then open the electrical

control panel to obtain access to the SCR-22/28

unit.

2. Disconnect the wires from the terminals on the

SCR-22/28 unit. The wires will be re-connected to

the new unit, therefore, make certain the wires are

labeled before disconnecting them. Also the correct

wire number from the wire being taken off of the

SCR-22/28 should be written into the blanks above

the terminals on Figure 9.

3. Loosen the four (4) mounting screws that secure

the SCR-22/28 unit to the panel just enough to permit removal of the unit. Then remove the unit from

the control panel.

4. Install the SCRB-68 unit in the control panel and

tighten the four (4) associated mounting screws

securely.

5. Connect the wires (previously removed in Step 2) to

the terminals on the SCRB-68 unit. Refer to Figure

8 for wiring details.

NOTE: A jumper must be installed between termi-

nals 5 and 7 on the SCRB-68. Failure to

install this jumper will result in an inoperable

SCRB-68.

6. The fuse holder (furnished) should be installed as

close to the 100 Volt transformer as possible. Begin

by drilling and tapping two (2) #10 - 24 holes in the

control panel to anchor the fuse holder. Then mount

and secure the fuse holder to the panel.

CAUTION

WHEN DRILLING AND TAPPING HOLES FOR THE

FUSE HOLDER MAKE SURE THAT NO METAL

SHAVINGS FALL ON ANY CIRCUIT BOARDS OR

ANY OTHER ELECTRIC DEVICES.

7. Remove the wire from terminal “Y1” of the transformer and re-label it “1Y1”. (NOTE: Re-label both

ends of the wire.) Then attach the wire to the bottom

side of the fuse. (See Figure 8.)

8. Run a #16 gauge MTW grade wire (or equivalent)

from the top of the fuse to terminal “Y1” of the 100

Volt transformer. Label this wire “Y1”.

9. After completing Steps 1 through 8, close up the

electrical control panel. Then refer to the Adjust-

ment section of this manual.

While the SCR-22/28 control uses a 500 ohm speed

control potentiometer, and the SCRB-68 uses a 1000

ohm potentiometer, use of the 500 ohm potentiometer

will not damage the SCRB-68. This control should work

normally except in some instances the 15 Volt DC reference supply may lose its controlled regulation, resulting in slight, speed changes if the plant voltage

changes.

If the SCRB-68 control installation is to be permanent,

it is suggested that the 1000 ohm speed control potentiometer be installed.

INSTALLATION NOTE:

A troubleshooting guide is included as a part of this

manual to aid technicians in restoring normal control

functions, should the need occur. It is recommended

that this unit not be dismantled for repair. Minster does

not stock or supply internal components for this unit.

Return unit to Minster for repair.

As mentioned previously, the unit contains potentiometers which must be adjusted to suit operating conditions

of the control.

During the process of troubleshooting a control malfunction, do not overlook the fact that a problem could

exist within the eddy current coupling or its associated

drive motor. Some of the suggested checks in the troubleshooting guide are included to help determine

whether a problem exists in that area.

If it should become necessary to disassemble the

motor or coupling, follow step-by-step procedure outlined in the motor manufacturer’s instructional manual.

If trouble should develop within the tachometer generator, disassembly of the coupling housing will usually

be required since the generator is normally attached to,

or located just inside, the coupling end bell. Use caution when disassembling this part. The tachometer

generator should never be subjected to sharp blows or

heat.

Air-cooled eddy current coupling rotating equipment

requires ample quantities of clean, cooling air. Exhaust

air must be permitted to flow away from the drive and

not be returned. For most efficient use of the equipment, make certain that air inlets and exhaust outlets

are not obstructed in any way that would tend to reduce

air flow or cause recirculation of the heated exhaust air.

Establish periodic cleaning and lubrication schedules

for the drive. Use dry compressed air of moderate pressure to dislodge and remove foreign matter from air

intake screens or louvers. If dirt or foreign matter accumulates inside, it will then become necessary to disassemble the drive in accordance with manufacturer’s

instructions and clean with an approved cleaning solution. At the same time, inspect condition of windings

and insulation. After cleaning, reassemble per instructions.

— 17 —

!

— 18 —

TROUBLESHOOTING GUIDE

TROUBLE

CHECK

UNIT DOES

NOT RUN

AFTER DRIVE

MOTOR HAS

STARTED

1. Make certain 100 volts A.C. exists between terminals 1 (D signal) and 2 (Y2 signal) with the

power switch on. A voltage of approximately 16 volts D.C. between terminals 8 (P1 signal)

and 7(G1 signal) shows presence of the reference voltage. A voltage or approximately 90

volts D.C. between terminals 15 (K1/K3 signal) and 5 (F1/C1 signal) checks the power rectifier bridge. If no D.C. power, or incorrect reference voltage is indicated, suspect trouble in the

control.

2. Make certain that the operator’s speed potentiometer is giving a reference signal to the control. No excitation of the coupling is possible unless the voltage between terminals 9 (R signal) and 7 (G1 signal) is at least .7 volt D.C. with terminal 9 (R signal) positive. The voltage

between terminals 9 (R signal) and 7 (G1 signal) will vary from 0 to 16 volts D.C. depending

upon the setting of the speed potentiometer.

3. Check for D.C. output voltage on coupling terminals 5 (F1/C1 signal) and 3 (F2/C2 signal).

With full excitation, terminal 3 (F2/C2 signal) will be as much as 90 volts D.C. positive. If excitation is present, unit should be running unless the coupling coil circuit is open. To check for

open coupling coil, disconnect power to press and remove wires from control terminals 5

(F1/C1 signal) and 3 (F2/C2 signal). Connect ohmmeter leads to these two wires and check

resistance. Normal resistance is approximately 50 to 65 ohms. If measurement indicates

“open,” check coil connections inside motor drive conduit box. Also, recheck coil resistance

from this point. If coupling coil is “open,” contact local area motor repair shop for installation

of new coil.

4. Check setting of torque limit control.

UNIT SLOWLY

DRIFTS IN

SPEED

1. Torque Limiter may be set incorrectly. Reset torque limiting point per instructions in manual.

2. Check for worn speed control potentiometer or loose wiring connections between it and the

control terminal strip.

3. Operating drive at relatively low output speeds may cause excessive loading and resultant

slowdown.

4. Check for erratic tachometer feedback voltage, A.C., between terminals 7 (G1 signal) and 12

(G2 signal). Rapidly changing voltage here may be caused by loose connections, broken or

shorted wires, or a defective tachometer generator.

UNIT RUNS

ONLY AT FULL

DRIVE MOTOR

SPEED

1. Make certain problem is electrical. Check coupling excitation on terminals 5 (F1/C1 signal)

and 3 (F2/C2 signal). Use D.C. voltmeter (start with 0-150 V.D.C. scale). Connect positive

probe to terminal 3 (F2/C2 signal) and negative to 5 (F1/C1 signal). No excitation voltage

means unit is not energized electrically and problem could be mechanical within the drive.

2. Check D.C. voltage between terminals 9 (R signal) (+) and 7 (G1 signal) (-) to make certain it

is zero when the speed potentiometer is turned down. If not, external speed potentiometer

may be shorted or incorrectly connected.

3. Check for presence of tachometer feedback voltage, A.C., between terminals 7 (G1 signal)

and 12 (G2 signal). Without this feedback, unit will run at full speed with only a small reference voltage applied to terminal R. The tachometer feedback voltage varies from 30 to 60

volts A.C., depending on motor and drive.

4. Turn power switch off on control unit. If the drive remains running, the drive has failed either

through the center bearing locking up or the air gap in the coupling is closed. If this is the

case the motor will need to be repaired by a motor rebuild shop.

FUSES BLOW

1. If operator’s speed potentiometer is turned down and the fuse instantaneously blows an

internal failure may have occurred. Before replacing the unit, check for a direct short across

terminals 5 (F1/C1 signals) and 3 (F2/C2 signals) or terminals 4 (B2 signal) and 6 (C1 signal). A short indication at this point could be the result of a shorted coupling or brake coil,

lead, or associated component in that circuit.

FACTORY CHECKOUT AND REPAIR

If it is determined that a problem exists within the

SCRB-68, it can be returned to the factory for checkout

and repair. Before returning the unit, contact the Minster Repair Parts Department for a Returned Goods

Authorization number (RGA#). This will ensure the

timely return of the repaired unit.

When returning a unit to the factory for repair, make

certain it is carefully packaged to protect it from damage during shipment. Include, with the unit, the RGA#,

a description of the problem(s) encountered and the

serial number of the press on which it is used. Also

include your purchase order covering the work to be

performed and any special shipping instructions concerning return of the unit.

Ship To: The Minster Machine Company

115 North Ohio Street

Minster, Ohio 45865-0120

ATTN: RGA# ________

SPECIFICATIONS

Supply

• Voltage: 100-125VAC

• Power: 900W

• Frequency: 48 to 62 Hz

Input/Output Characteristics

• Coupling: 90VDC-115VDC, 900W

• Brake: 90VDC-115VDC, 900W

• Tachometer: 30-60VAC, 300-800Hz

• Relay Output: 110VDC, 200mA

Miscellaneous

• Dimensions (L × D × H): 231mm (9.125 in.) × 140mm

(5.5 in.) × 130mm (5.125 in.)

• Temperature Range: 0°C to 60°C (32°F to 140°F)

— 19 —

VOLTAGE GUIDE

TERMINALS FUNCTION VOLTAGE REQUIRED WITH DRIVE RUNNING

1 to 2

(Signals D to Y2)

A.C. Supply Voltage 100 Volts A.C.

5 to 15

(Signals F1/C1 to

K1/K3)

D.C. Supply Voltage 90 Volts D.C., 5 (-) and 15 (+)

5 to 3

(Signals F1/C1 to

F2/C2)

Coupling Coil

Excitation Voltage

Normally 5 to 10 Volts D.C. with flywheel only running. Could

increase to 90 volts D.C. with coupling fully energized. 5 (-) and 3 (+)

7 to 12

(Signals G1 to G2)

Tachometer Voltage Approximately 30 to 60 Volts A.C., depending on speed of drive.

8 to 7

(Signals P1 to G1)

Reference Voltage Approximately 16 Volts D.C., 8 (+) and 7 (-)

7 to 9

(Signals G1 to R)

Selected

Reference Voltage

0 to 16 Volts D.C. depending upon setting of speed potentiometer.

7 (-) and 9 (+).

ADDITIONAL COMMENTS:

— 20 —

MMC0311

MINSTER®

The Minster Machine Company, Minster, Ohio 45865, U.S.A.

Phone: (419) 628-2331 / Fax: (419) 628-3517

Distributors strategically located throughout the world.

MMC0311

MINSTER®

The Minster Machine Company, Minster, Ohio 45865, U.S.A.

Phone: (419) 628-2331 / Fax: (419) 628-3517

Distributors strategically located throughout the world.

Loading...

Loading...