®

magicolor 2300W

User’s Guide

1800708-001A

Thank You

Thank you for purchasing a MINOLTA-QMS printer.

Trademarks

The following are registered trademarks of MINOLTA-QMS , Inc.: QMS, the

MINOLTA-QMS logo, and magicolor.

Minolta is a trademark of Minolta Co., Ltd. Other prod uct names mentione d in t his

guide may a lso be t rade marks or registered trade marks of their respective owners.

Proprietary Statement

The dig itally encoded software included with your printer is Copyrighted

© 200 3 by M INOLTA-QMS, Inc. All Rights Re served. This software may not be

reproduced, modified, displaye d, transferred, or copied in any form or in any manner

or on any media, in whole or in part, without the express written permi ssion of

MINOLTA-QMS, Inc.

Copyright Notice

This g uide is C opyr ighted © 2003 by MINOLTA-QMS, Inc., One Magnum Pass,

Mobile, AL 36618 . All R ights Re served. This documen t may not be copied, i n whole or

part, nor transfer red to any o ther media or l anguag e, without written permission of

MINOLTA-QMS, Inc.

Notice

MINOLTA-QMS, Inc. reserves the right to mak e changes to this guide and to the

equipment described herein without notice. Cons iderable effort has be en made to

ensure that this gu ide is fr ee of inaccuracies and omission s. However,

MINOLTA-QMS, Inc. makes no warranty of a ny kind including, but not limited to, an y

implied warranties of m erchan tability and fitness for a particular pu rpose with regard

to this guide. MINOLTA-QMS, Inc. assumes no r esponsibility for, or liability for, errors

contained in this guide or for incidental, special, or consequential damages arising

out of the furnishin g of this g uide, or the u se of this guide in operating the equipment ,

or in connecti on with the performance of the equipment when so operated.

Registering the Printer

Mail— (Americas only) Fill out an d send in the regis tration card enclosed in your

shipment.

Internet—Follow the instructions on www.onlineregister.com/minolta-qms/

or

CD-ROM —Follow the instru ctions on the CD-ROM.

Contents

1 Software Installation ............................................................................1

Utilities and Documentation CD-ROM .................................................................2

Drivers and Utilities .......................................................................................2

Installing the Printer Drivers and Software ..........................................................3

System Requirements ...................................................................................3

For a Local Connection ................................................................................. 3

For a Shared Network Printer ........................................................................5

Selecting Driver Options/Defaults .......................................................................6

Uninstalling the Printer Driver ............................................................................. 8

2 Using Media .......................................................................................... 9

Introduction .......................................................................................................10

Media Specifications .........................................................................................11

Media Types ...................................................................................................... 12

Plain Paper .................................................................................................12

Thick Stock ..................................................................................................13

Envelopes ....................................................................................................14

Labels .......................................................................................................... 15

Letterhead and Memo Media .....................................................................16

Postcards .................................................................................................... 16

Transparencies ...........................................................................................17

What Is the Guaranteed Imageable(Printable) Area? .................................18

Page Margins ..............................................................................................19

Loading Media ...................................................................................................20

Tray 1 (Multipurpose Tray) .........................................................................20

Duplexing ..........................................................................................................23

Output Tray .......................................................................................................24

Media Storage ...................................................................................................24

Additional Assistance ........................................................................................24

3 Working with the Printer ....................................................................25

About the Control Panel ....................................................................................26

Control Panel Key ........................................................................................26

Indicator Lights ............................................................................................27

4 Working with the Printer Driver ........................................................29

Introduction ........................................................................................................30

Displaying Printer Driver Settings ......................................................................30

Displaying Settings in Windows 2000/XP ....................................................30

Displaying Settings in Windows Me/98 ........................................................30

Common Settings on All Tabs .....................................................................31

Common Buttons .........................................................................................32

Setup Tab ..........................................................................................................33

Paper Tab ..........................................................................................................34

Quality Tab ........................................................................................................35

Color Matching .............................................................................................36

Device Options Setting Tab ...............................................................................38

5 Working with the Status Display ......................................................39

Working with the Status Display ........................................................................40

Environment .................................................................................................40

Opening the Status Display and Showing Supplies Status . ........................40

Using the Status Display ...................................................................................41

Working with the Display Menu ...................................................................41

Working with the Printer Menu .....................................................................42

Closing the Status Display ................................................................................43

6 Replacing Consumables ...................................................................45

Consumable Life Expectancies .........................................................................46

Plain Paper ..................................................................................................46

Special Media ..............................................................................................47

Auto-Image Density Control (AIDC) .............................................................47

Toner Cartridge Life .....................................................................................48

Contentsii

Replacing Consumables ...................................................................................48

Refilled Toner Cartridges ............................................................................ 49

Replacing a Toner Cartridge ......................................................................49

Replacing the Waste Toner Bottle ..............................................................53

Replacing the OPC Drum Cartridge ...........................................................54

Ordering Consumables .....................................................................................57

7 Maintaining the Printer ......................................................................5 9

Maintaining the Printer ...................................................................................... 60

Cleaning the Printer ..........................................................................................62

Exterior ...................................................................................................... 62

Interior .........................................................................................................63

Media Rollers .............................................................................................. 63

Printer Interior and Laser Lens Cover ........................................................ 65

8 Troubleshooting ................................................................................. 69

Introduction .......................................................................................................70

Preventing Media Jams .....................................................................................71

Understanding the Media Path ..........................................................................72

Tray 1 (Multipurpose Tray) .......................................................................... 72

Duplex Option ..............................................................................................72

Clearing Media Jams ....................................................................................... 73

Handling Media Jams by Location .............................................................. 73

Tray 1 (Multipurpose Tray) .........................................................................74

Inside the Printer ........................................................................................75

Duplex Option .............................................................................................77

Output Tray .................................................................................................78

Solving Problems with Media Jams ..................................................................79

Solving Other Problems ...................................................................................81

Solving Problems with Printing Quality .............................................................87

Status, Error, and Service Messages ................................................................ 94

Standard Status Messages .........................................................................94

Error Messages ...........................................................................................94

Service Messages .......................................................................................97

Additional Assistance ........................................................................................ 98

9 Installing Accessories ....................................................................... 99

Introduction .....................................................................................................100

Duplex Option ................................................................................................100

10 Repacking the Printer ...................................................................... 105

Storing the Printer ...........................................................................................106

Relocating Your Printer ...................................................................................106

Contents iii

Repacking the Printer ......................................................................................107

A. Turn off t he Printer, Unplug the Power Cord,

and Remove the Interface Cables ............................................................108

B. Remove the Media and the Tray 1 Media Support ................................109

C. Remove the Options (if Attached) .........................................................109

D. Remove the Waste Toner Bottle, Plug the Openings,

and Dispose of It According to Your Local Regulations .............................110

E. Remove the OPC Drum Cartridge .........................................................111

F. Remove the Transfer Belt ......................................................................112

G. Repack the Printer for Shipment ...........................................................113

H. Repack the OPC Drum and Transfer Belt Unit for Shipment ................114

Reinstalling the Printer ....................................................................................115

Reinstalling a Transfer Belt Unit ................................................................116

A Technical Specifications .................................................................117

Requirements ..................................................................................................118

Space Requirements .................................................................................118

Location Requirements ..............................................................................120

Interface Panel ...............................................................................................121

Power Requirements .................................................................................122

ENERGY STAR Compliance .....................................................................123

Engine and Controller Specifications ...............................................................124

Engine ........................................................................................................124

Print Speed—Simplex ................................................................................ 124

Print Speed—Autoduplex ..........................................................................124

General ......................................................................................................125

Controller .................................................................................................125

Electrical ....................................................................................................126

Hazardous Chemical Substance Reporting ..............................................128

Physical ....................................................................................................128

Consumable Life Expectancies ......................................................................129

Plain Paper ...............................................................................................129

Special Media ............................................................................................130

Regulatory Compliance ...................................................................................131

Safety Information ...........................................................................................133

Warning and Precaution Symbols .............................................................136

Meaning of Symbols .................................................................................. 136

Working Safely with Your Laser Printer ...........................................................139

Index .................................................................................................. 141

Contentsiv

Software

Installation

1

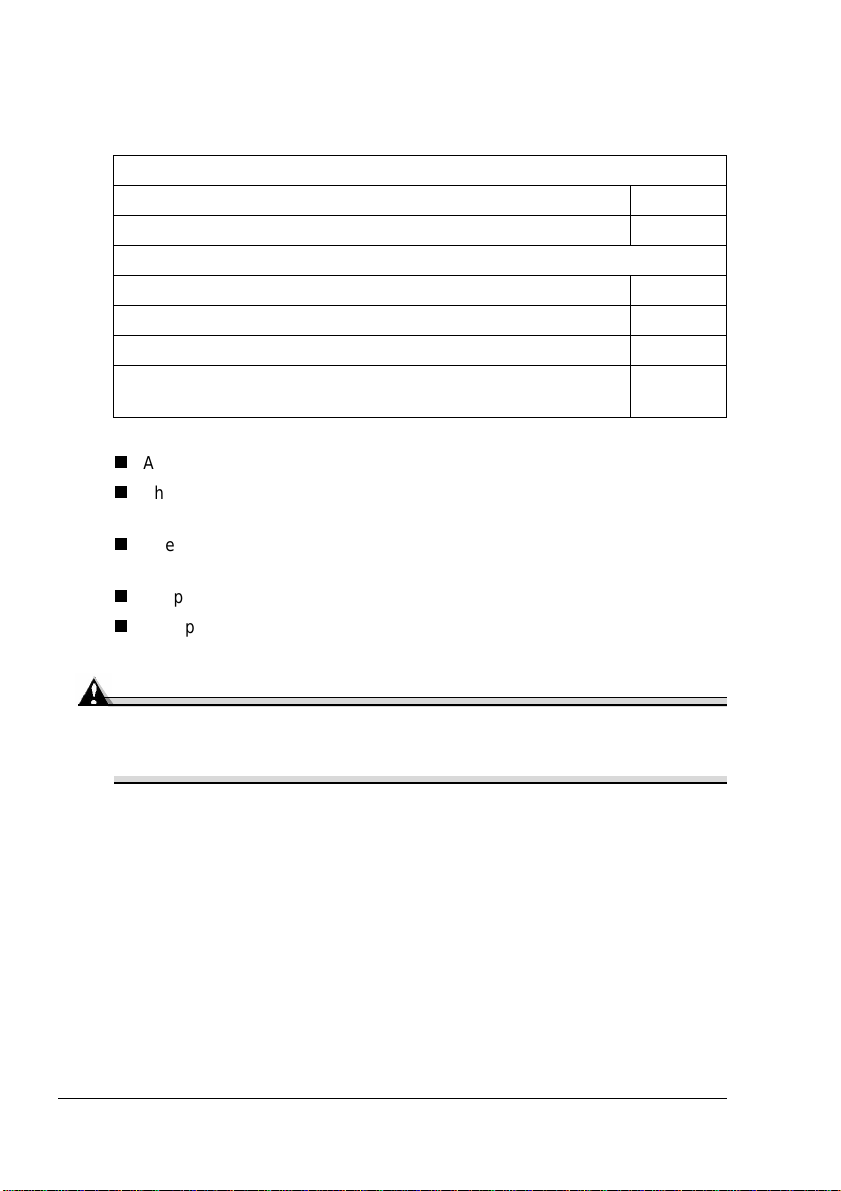

Utilities and Documentation CD-ROM

Drivers and Utilities

Drivers

Drivers/OperatingSystem Use/Benefit

Printer Driver for Windows Me/98 These driversgiveyouaccess to allof

Printer Driver for Windows XP/2000

Utilities

Utilities Use/Benefit

Status Display This utility allows you to monitor the

the printerfeatures, includingfinishing

and advanced layout. See also

“Workingwith the Printer Driver” on

page 29.

printer’s status and perform various

printer functions.See “Working with

the Status Display” on page 39.

Utilities and Documentation CD-ROM2

Installing the Printer Drivers and Software

System Requirements

PC with a clock speed of 300 MHz or more Intel Pentium/Celeron series,

AMD K6/Athlon/Duron family, or compatible processor

Microsoft Windows 98 SE, Windows Me, Windows 2000 Professional,

Windows XP Home Edition/Professional

Free hard disk space

– Approximately 128 MB of free hard disk space for printer driver and

Status Display

– Approximately 128 MB of free hard disk space for image processing

Memory capacity

– Windows 98 SE:

Atleast16MBofRAM

– Windows Me:

Atleast32MBofRAM

– Windows 2000 Professional:

Atleast64MBofRAM

– Windows XP Home Edition/Professional:

At least 128 M B of RAM

CD-ROM drive

IEEE 1284 compliant type B parallel port, or USB Revision 1.1 compliant

port

For a Local Connection

1 Insert the magicolor2300WUtilities and Documentation CD-ROM in your

PC’s CD-ROM drive. The CD- ROM installer program starts automatically

(if not, browse with the Windows Explorer to the CD -ROM location and

double-clickon setup.exe).

2 Select the language, and click OK.

3 Click .

4 Click Printer Setup.

5 Click Accept.

6 Click OK.

7 Select Local Printer, and then click OK.

Installing the Printer D rivers and Software

3

8 If the computer onto which you are installing the driver is a print server,

check the Server Install checkbox, and then type in a name for Share

Name.

9 Click OK.

10 From the Select Port list, select the port to which the printerisconnected.

11 If the printer is to be used as the default printer,select the Set as default

printer? check box.

12 Click OK.

13 Check and, if desired, change the description that appears in the Pr inter

Name box, and t hen click OK.

14 After the message “Congratulations,installation complete.”appears,click

OK.

The printer icon is added to the Printers folder and “magicolor 2300W

Utilities” is added to Programs in the Start menu.

15 Click to quit the installer program.

16 Remove the magicolor2300WUtilities and Documentation CD-ROM from

your PC’s CD-ROM drive and store it in a safe place.

Installing the Printer Drivers and Software4

For a Shared N etwork Printer

1 Insert the magicolor2300WUtilities and Documentation CD-ROM in your

PC’s CD-ROM drive. The CD- ROM installer program starts automatically

(if not, browse with the Windows Explorer to the CD -ROM location and

double-clickon setup.exe).

2 Select the language, and click OK.

3 Click .

4 Click Printer Setup.

5 Click Accept.

6 Click OK.

7 Select Network Printer, and then click OK.

8 Type \\server_name\shared_printer_name where

server_nameis the name of the shared server and shared_printer_name

is the name of the printer you are s haring.

In Windows 2000 and XP, you can click Browse, and then select the

shared printer.

9 Click OK.

10 If the printer is to be used as the default printer, select Yes. Otherwise,

select No.

11 Click OK.

12 After the message “Congratulations,installation complete.”appears, click

OK.

The printer icon is added to the Printers folder.

13 Click to quit the installer program.

14 Remove the magicolor2300WUtilities and Documentation CD-ROM from

your PC’s CD-ROM drive and store it in a safe place.

Installing the Printer D rivers and Software

5

Selecting Driver Options/Defaults

Before you start working with your printer, you are advised to verify and, if

necessary, change the default driver settings. Also, if you have any options

installedon the printer, you should configure the driver for these options.

1 Choose the driver’s properties as follows:

– (WindowsMe/98)

From the Start menu, choose Settings and then Pr inters to display

the Printers dialog box. Right-click the magicolor 2300W printer icon

and choose Properties. Choose the Printer Properties tab.

– (Windows 2000/XP)

From the Start menu, choose Settings and then Pr inters to display

the Printers dialog box. Right-click the magicolor 2300W printer icon

and choose Printing Preferences...

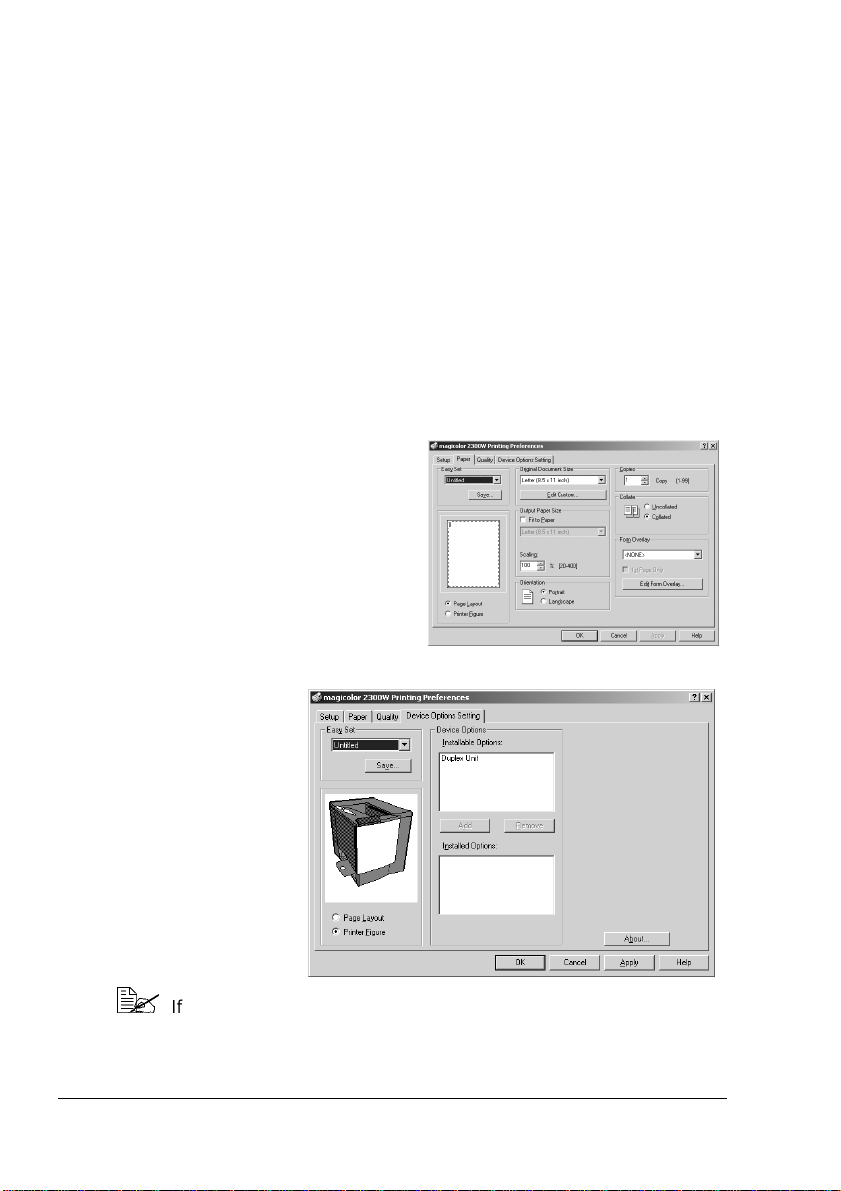

2 Choose the Papertab.Select the

default settings for your printer,

such as the default media f ormat

you use.

3 Click Apply.

4 If you have installed any options

on the printer, proceed with the

next step. Otherwise, skip to

step 8.

5 Select the

Device Options

Setting tab.

6 Select an option

(one at a t ime)

and click Add.

The option

moves to the

Installed

Options list.

If you accidentally add an option that is not installed on the printer,

selecttheoptionintheInstalled Options list and then click Remove.

Selecting Driver Options/Defaults6

7 Click Apply.

Depending on the version of the operating system, Apply may not

appear.If this is the case, continue with the next step.

8 Click OK to save your changes and exit from the Printing Preferences

dialog box.

Selecting Driver Options/Defaults

7

Uninstalling the Printer Driver

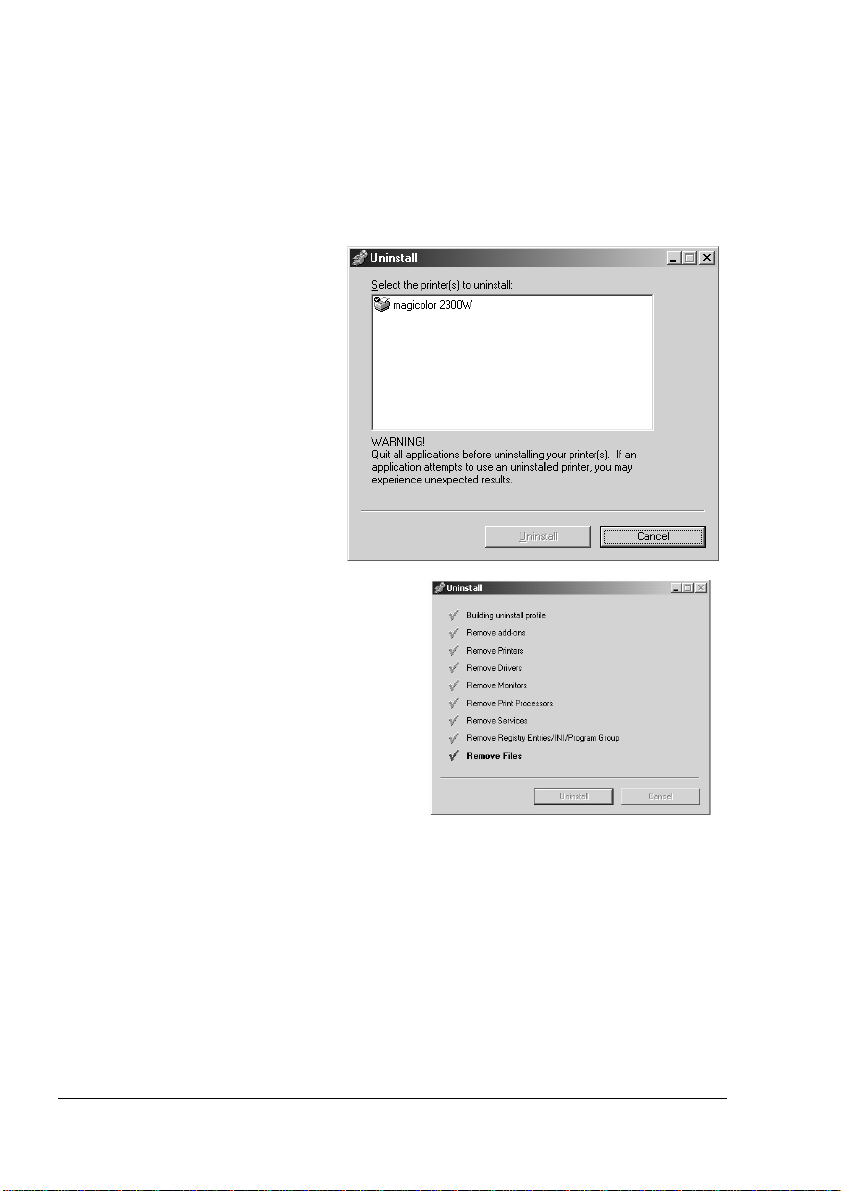

This section describes how to uninstall the magicolor 2300W printer driver if

necessary.

1 From theStart menu choose Programs, magicolor 2300W Utilities, and

then magicolor 2300W Uninstall.

2 In the Uninstall

window,select the

magicolor 2300W.

Then click Uninstall.

The magicolor 2300W

driver is uninstalledfrom your

computer.

3 Restart your computer.

Uninstalling the Printer Driver8

Using Media

2

Introduction

This chapter providesinformation on handling,selecting, loading, and storing

media.

Getting Started

What types and sizes of media can I load? page 11

What Is the guaranteed imageable (printable) area? page 18

Other Information

How do I load media? page 20

How do I duplex? page 23

How do I store media? page 24

Where can I order MINOLTA-QMS-approved media or getmore

information?

All media is fed short edge first, face up.

There is a 0.157" (4 mm) non-print border for all edges on all media

types. Refer to page 18 for paper longer than 11.7" (297 mm).

See your application documentation for specific information on formatting

data and printing.

Try printingyour data on a plain sheet of paper first to check placement.

Only plain paper, 16–24 lb (60–90 g/m2) can be autoduplexed. See

“Media Specifications” for supported sizes.

page 24

Attention

Use only MINOLTA-QMS-approved media. Using unsupported media

such as inkjet paper will result in damaging the printer and i n voiding

your warranty.

Introduction10

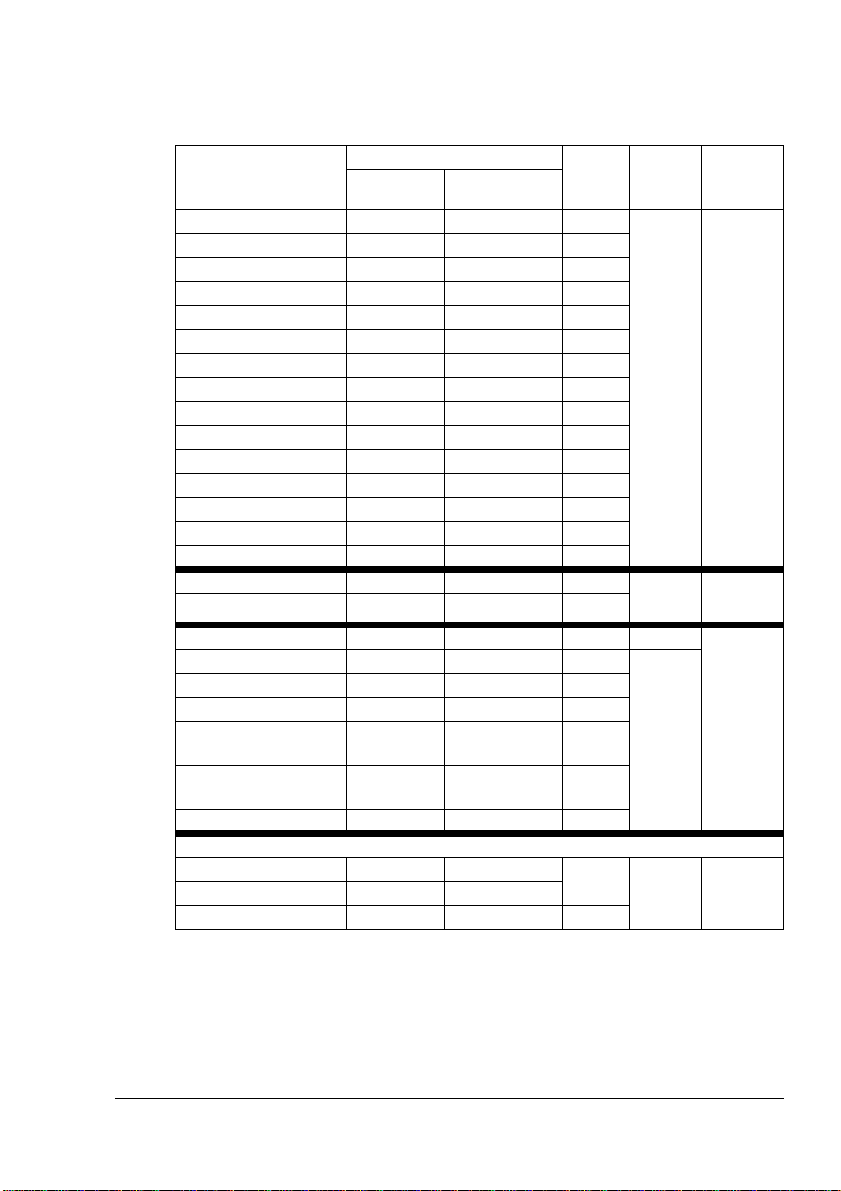

Media Specifications

What types and sizes of media can I load?

Media MediaSize Duplex Driver

Inches Millimeters

A4 8.2 × 11.7 210.0 × 297.0 Yes Plain

A5 5.9 × 8.3 148.0 × 210.0 No

B5 (JIS) 7.2 × 10.1 182.0 × 257.0 No

Custom, Minimum 3.6 × 8.3 92.0 × 148.0 No

Custom, Maximum 8.5 × 14.0 216.0 × 356.0 No

Executive 7.25 ×10.5 184.0 × 267.0 No

Folio 8.3 × 13.0 210.0 × 330.0 Yes

Foolscap 8.0 × 13.0 203.2 × 330.2 Yes

Government Legal 8.5 × 13.0 216.0 × 330.0 Yes

Kai 16 7.3 × 10.2 185.0 × 260.0 No

Legal 8.5 × 14.0 215.9 × 355.6 Yes

Letter 8.5 × 11.0 215.9 × 279.4 Yes

Letter Plus 8.5 × 12.7 215.9 × 322.3 Yes

Statement 5.5 × 8.5 140.0 × 216.0 No

UK Quarto 8.0 × 10.0 203.2 × 254.0 No

A4 Transparency 8.2 × 11.7 210.0 × 297.0 No TransLetterTransparency 8.5 × 11.0 215.9 × 279.4 No

Japanese Postcard 3.9 × 5.8 100.0 × 148.0 No

EnvelopeB5 (ISO) 6.9 × 9.8 176.0 × 250.0 No

Envelope C5 6.4 × 9.0 162.0 × 229.0 No

Envelope C6 4.5 × 6.4 114.0 × 162.0 No

EnvelopeCommercial

#10

Envelope

International DL

EnvelopeMonarch 3.9 × 7.5 99.0× 1 90.5 No

ThickStock—Only supported for letter, A4, or smaller media.

Custom, Minimum 3.6 × 5.8 92.0 × 148.0 No Thick

Custom, Maximum 8.5 × 11.7 216.0 × 297.0

Kai 32 5.1 × 7.3 130.0 × 185.0 No

4.1 × 9.5 104.1 × 241.3 No

4.3 × 8.7 110.0 × 220.0 No

media

Type

Paper

parency

Postcard

Envelope

Stock

Weight

16–24 lb

bond

(60–90

g/m²)

Use only

approved

media

Use only

approved

media

25–90lbs

(91–163

g/m²)

Media Specifications

11

Media Types

Before purchasing a large quantity of special media, do a trial printing

with the same media and check print quality.Check our web site

www.minolta-qms.com for a list of currently approved media.

Keep media on a flat, level surface in its original wrapper until it is time to

load it.

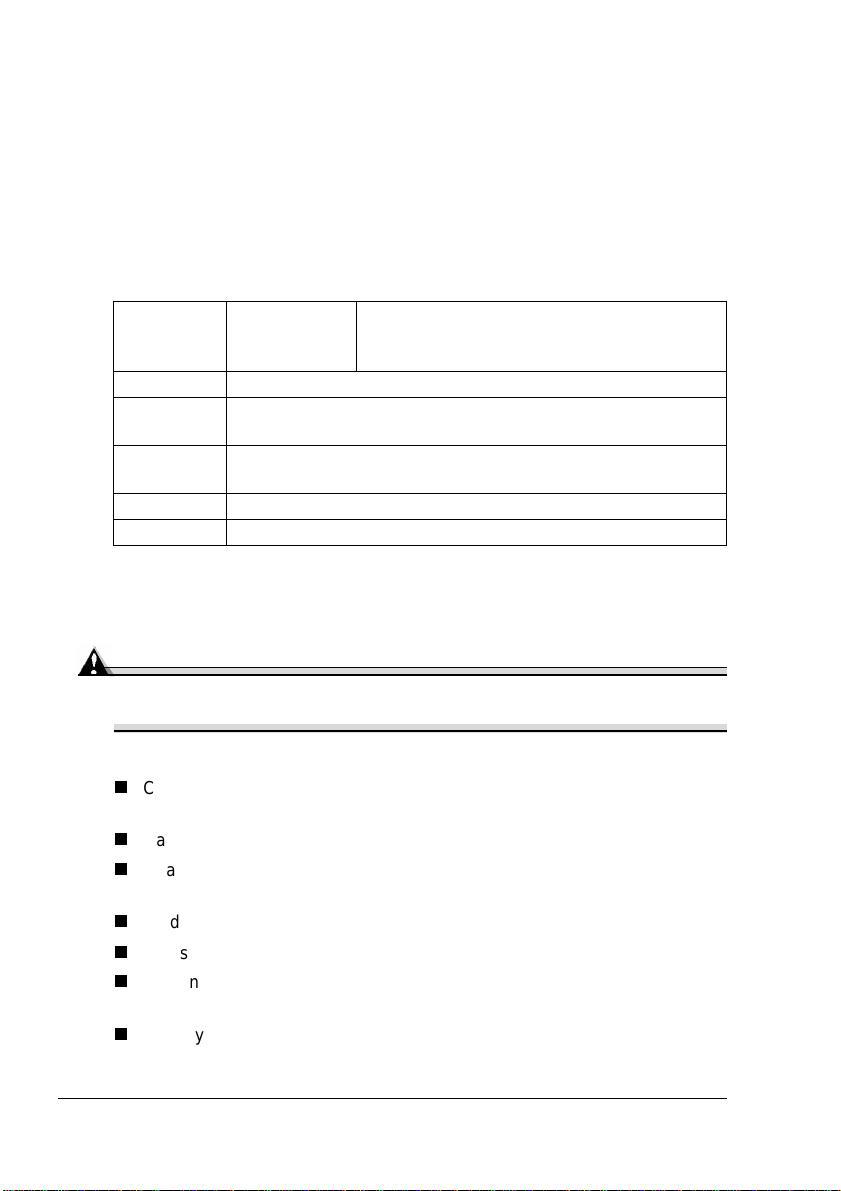

Plain Paper

Capacity Tray 1

(multipurpose

tray)

Orientation Face up

Type Check www.minolta-qms.com/support (click on "Answer

Base") for currently approved media.

Driver

Media Type

Weight 16–24 lb bond (60–90 g/m²)

Duplexing See page 11 for supported sizes.

Use media that is

Suitable for plain-paperlaser printers, such as standard or recycled office

paper.

Plain paper

200 sheets of 22 lb bond (80 g/m

capacityfor other weights varies accordingly.

2

) paper;

Attention

Do not use the media types listed below. These could cause poor print

quality, media jams, or damage to the printer.

Do not use media that is

Coated with a processed surface (such as carbon paper, digitally glosscoated media, colored paper that has been treated)

Carbon backed

Unapproved iron-on transfer media (heat-sensitive paper,heat-pressure

paper, heat-press transfer paper)

Cold-water-transfer paper

Pressure sensitive

Designed specifically for inkjet printers (superfinepaper, glossy paper,

glossy film, postcards, etc.)

Already been printed on by another printer, copier, or fax machine

Media Types12

Dusty

Wet (or damp)

Keep media between 35% to 85% relative humidity.Toner does

not adhere well to moist or wet paper .

Layered

Adhesive

Folded, creased, curled, embossed, warped,or wrinkled

Perforated, three-hole punched, or torn

Tooslick,toocoarse,tootextured

Differentin texture (roughness)on the front and back

Too thin or too thick

Stuck together with static electricity

Composed of foil or gilt; too luminous

Heat sensitive or cannot withstand the fusing temperature (356°F/180°C)

Irregularlyshaped(not rectangular or not cut at right angles)

Attached with glue, tape, paper clips, staples,ribbons, hooks, or but tons

Acidic

Any other media that is not approved

Thick Stock

Paper thicker than 24 lb (90 g/m2) bond is r eferred to as thick stock. Test all

thick stock to ensure acceptable performanceand to ensure that the image

does not shift.

Capacity Tray 1 Up to 50 thick stock sheets, depending on their

thickness.Thick stock is supported only in letter,

A4, or smaller media sizes.

Orientation Face up

Type Check www.minolta-qms.com/support(click on "Answer

Base") for currently approved media.

Driver

Media Type

Weight 25–43 lb bond (91–163 g/m²)

Duplexing Not supported

Notes 43 lb (163 g/m²) bond is also referred to as 90 lb index stock.

Thick stock

Media Types

13

Do not use thick stock that is

Mixed with any other media in the media trays (as this will cause media

jams)

Envelopes

Print on the front (address) side only. Some parts of the envelope consist of

three layers of paper—the front, back, and flap. Anything printed in these

layered regions may be lost or faded.

Capacity Tray 1 Up to 50 envelopes, depending on their thickness

Orientation Face up

Type Check www.minolta-qms.com/support (click on "Answer

Base") for currently approved media.

Driver

Media Type

Weight 25–43 lb bond (91–163 g/m²)

Duplexing Not supported

Use envelopes that are

Common officeenvelopes approved for laser printingwith diagonaljoints,

sharp folds and edges, and ordinary gummed flaps

Dry

Printed on the front address side only

Do not use envelopes that have

Self-sticking flaps

Tape seals, metal clasps, paperclips,fasteners, or peel-off strips for

sealing

Transparent windows

Too rough of a surface

Material that will melt, vaporize, offset discolor, or emit dangerous fumes

Been presealed

Envelope

Because the envelopes pass through heated rollers, the gummed

area on the flaps may seal. Using envelopes with emulsion-based

glue avoids this problem.

Media Types14

Labels

A sheet oflabels consistsofaface sheet (the printing surface),adhesive, and

a carrier sheet:

The face sheet must follow the plain paper specification.

The face sheet surface must cover the entire carrier sheet, and no

adhesive should come through on the surface.

You can print continuouslywith label paper. However, this could affect the

media feed, depending on the media quality and printing environment. If

problems occur, stop the continuous printing and print one sheet at a time.

Format label data within your application. Try printing your data on a plain

sheet of paper first to check placement. Check your application

documentation for other information on printing labels.

Capacity Tray 1 Up to 50 label sheets, depending on their thickness

Orientation Face up

Type Check www.minolta-qms.com/support(click on "Answer

Base") for currently approved media.

Driver

Media Type

Weight 16–90 lb (60–163 g/m²)

Duplexing Not supported

Use label sheets that are

Recommended for laser printers

Letter or A4 size (adhesive label stock)

Do not use label sheets that

Have labels that easily peel off

Have backing sheets that have peeled away or have exposed adhesive

Labels

Attention

Labels that easily peel off their backing sheetsand labels with

exposed adhesive may stick to the fuser and cause medi a jams.

Media Types

15

Are precut or perforated

Do not use

Shiny backed paper

OK to use

Full-page labels

(uncut)

Letterhead and Memo Media

Format letterhead or memo data within your application. Try printing your

data on a plain sheet of paper first to check placement.

Capacity Tray 1 Up to 200 sheets, depending on their size and

thickness

Orientation Face up

Type Check www.minolta-qms.com/support (click on "Answer

Base") for currently approved media.

Driver

Media Type

Weight 16–24 lb bond (60–90 g/m²)

Duplexing See page 11 for supported sizes (face up—top of page first).

Plain paper

Postcards

Format postcarddata within your application. Try printing your data on a plain

sheet of paper first to check placement.

Capacity Tray 1 Up to 50 postcards, depending on their thickness

Orientation Face up

Type Check www.minolta-qms.com/support (click on "Answer

Base") for currently approved media.

Driver

Media Type

Weight 16–90 lb (60–163 g/m²)

Duplexing Not supported

Postcard

Media Types16

Use postcards that are

Recommended for laser printers

Do not use postcards that are

Coated

Designed for inkjet printers

Precut or perforated

Warped

If postcards are warped, press on the warped

area before putting them in Tray 1. Preprinted

or multicolored postcards may cause media

jams.

Transparencies

Attention

Use only the MINOLTA-QMS-approved media. U sing unsupported

transparencies will result in damaging your printer and in voiding your

warranty. Check www.minolta-qms.com for currently approved media.

To order approved transparency media, go to www.q-shop.com.

Do not fan t ransparencies before loading them. Resulting static

electricitymay cause printingerrors.

Do not handle transparencies too much. If you touch the face of the

transparencies with your bare hands, print quality may be affected.

Keep the media pathclean. Transparencies areespecially sensitiveto

a dirty mediapath. If thereareshadows on eitherthetoporthe bottom

of the sheets, see chapter 7, “Maintaining the Printer”.

Remove transparencies as soon as possible from t he output tray to

avoid static buildup.

You can print continuously with transparencies. However,this could affectthe

media feed, depending on the media quality, static buildup, and printing

environment.

Format the information to be printed on the transparencieswithin your

application.Try printing your data on a plain sheet of paper first to check

placement.

Media Types

17

If you have problems feeding 50 sheets, try loading only 1–10 sheets

at a time. Loading a large number of transparencies at a time may

cause static buildup, thus causing feeding problems.

Capacity Tray 1 Up to 50 transparencies, depending on their

thickness

Orientation Face up

Type Check www.minolta-qms.com/support (click on "Answer

Base") for currently approved media. To order approved

transparency media, go to www.q-shop.com.

Driver

Media Type

Duplexing Not supported

Use transparencies that are

Approved by MINOLTA-QMS

Do not use transparencies that

Have static electricity that will cause them to stick together

Transparency

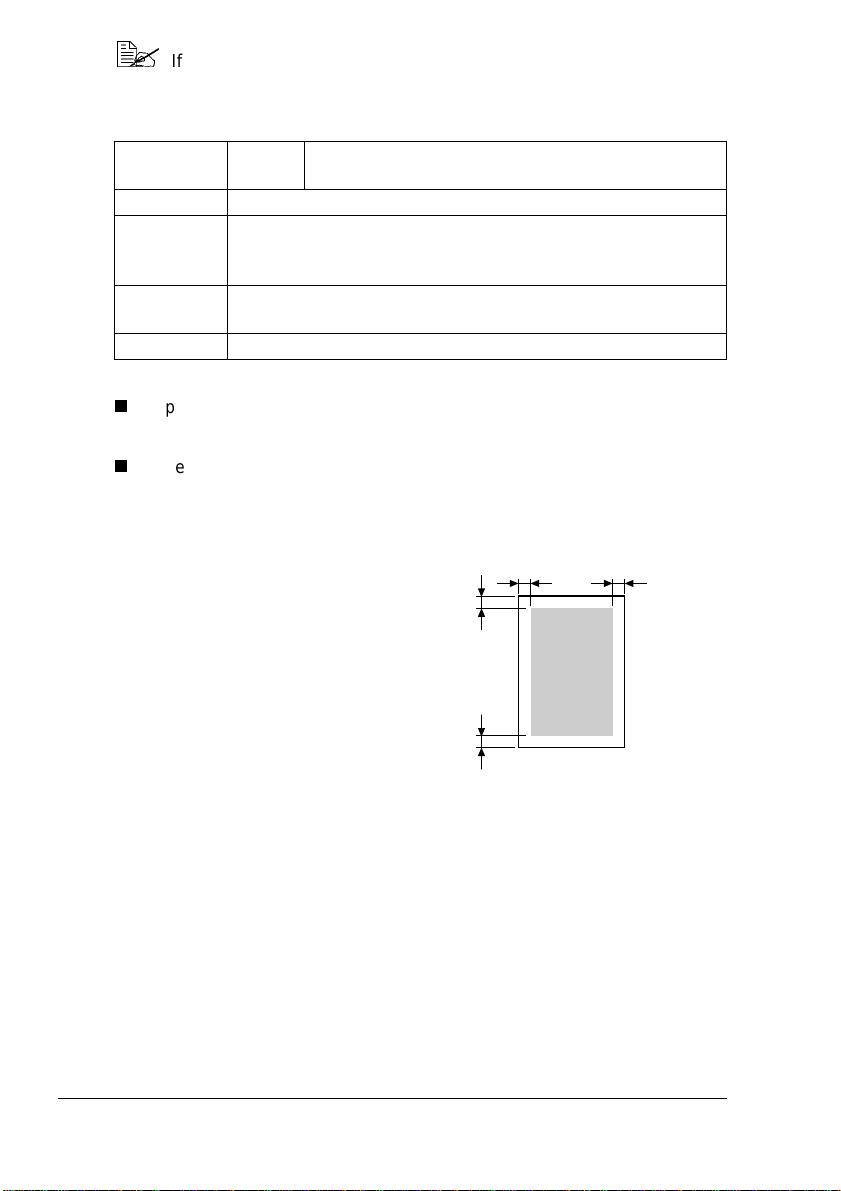

What Is the Guaranteed Imageable ( Printable) Area?

Theprintableareaonallmediasizesis

up to 0.157" (4 mm) from the edges of

the media.

Each media size has a specific

imageable area, the maximum area on

which the printer can print clearly and

without distortion.

This area is subject to both hardware

limits (the physical media size and the

margins required by the printer) and

software constraints (the amount of

memory available for the full-page frame buffer).The guaranteed imageable

(printable) area for all media sizes is the page size minus 0.157" (4 mm) from

all edges of the media.

a

a

Printable

a

a = 0.157" (4 mm)

a

Area

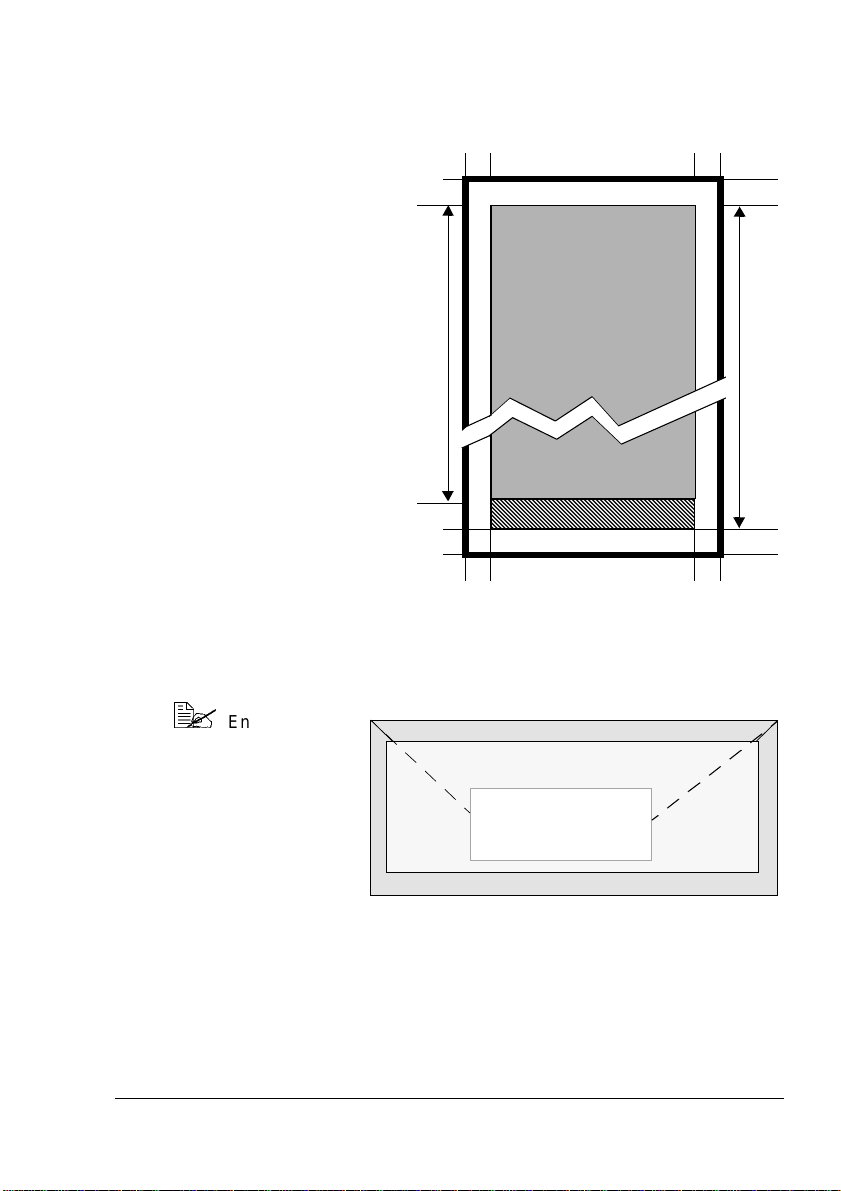

Nonguaranteed Are a—Me dia Longer Tha n 1 1.7" (297 m m )

Any media longerthan 11.7"(297mm) has an additionalnonguaranteed area

of 0.236" (6 mm) on the bottom of each page.

Media Types18

Color printing starts 0.157" (4 mm) from the t op of the page and extends as

far as 13.4" (341.6 mm). Monochrome printing starts 0.157" (4 mm) from the

top of the page and extends as far as 13.7" (347.6 mm).

a = nonprintable area

(0.157"/4 mm)

b = color guaranteed

printable area =

up to 13.4"/

341.6 mm

c = monochrome

guaranteed

printable area =

up to 13.7"/

347.6 mm

aa

aa

m

m

6

.

1

4

3

/

"

4

.

3

1

=

b

aa

aa

Imageable Area—Envelopes

Envelopes have a nonguaranteed flap area that varies with envelope type.

Envelope print

orientationis

determined

by your

application.

Nonimageable area 0.157" (4 mm)

Nonguaranteed area

Guaranteed

area

m

m

6

.

7

4

3

/

"

7

.

3

1

=

c

Page Margins

Margins are set through your application. Some applications allow you to set

custom page sizes and margins while others have only standard page sizes

and margins fromwhichto choose. If you choose a standardformat, you may

lose part of your image (due t o imageable area constraints). If you can

custom-sizeyour page in your application, use those sizes given for the

imageable area for optimum results.

Media Types

19

Loading Media

How do I load media?

Take off the top and bottom sheets of a

ream of paper.Holding a stack of

approximately 200 sheets at a time, fan

the stacktoprevent staticbuildupfor the

paper before inserting it in a tray.

Do not fan t ransparencies.

Attention

Although this printer was designed for printing on a wide range of

media types, it is not intended to print exclusively on a single media

type except plain paper. Continuous printingon media other than plain

paper (such as envelopes, labels, thick stock, or transparencies) may

adversely affect print quality or reduce engine life.

When refilling media, first remove any

media remainingin thetray. Stack it with

the new media, even the edges, then

reload it.

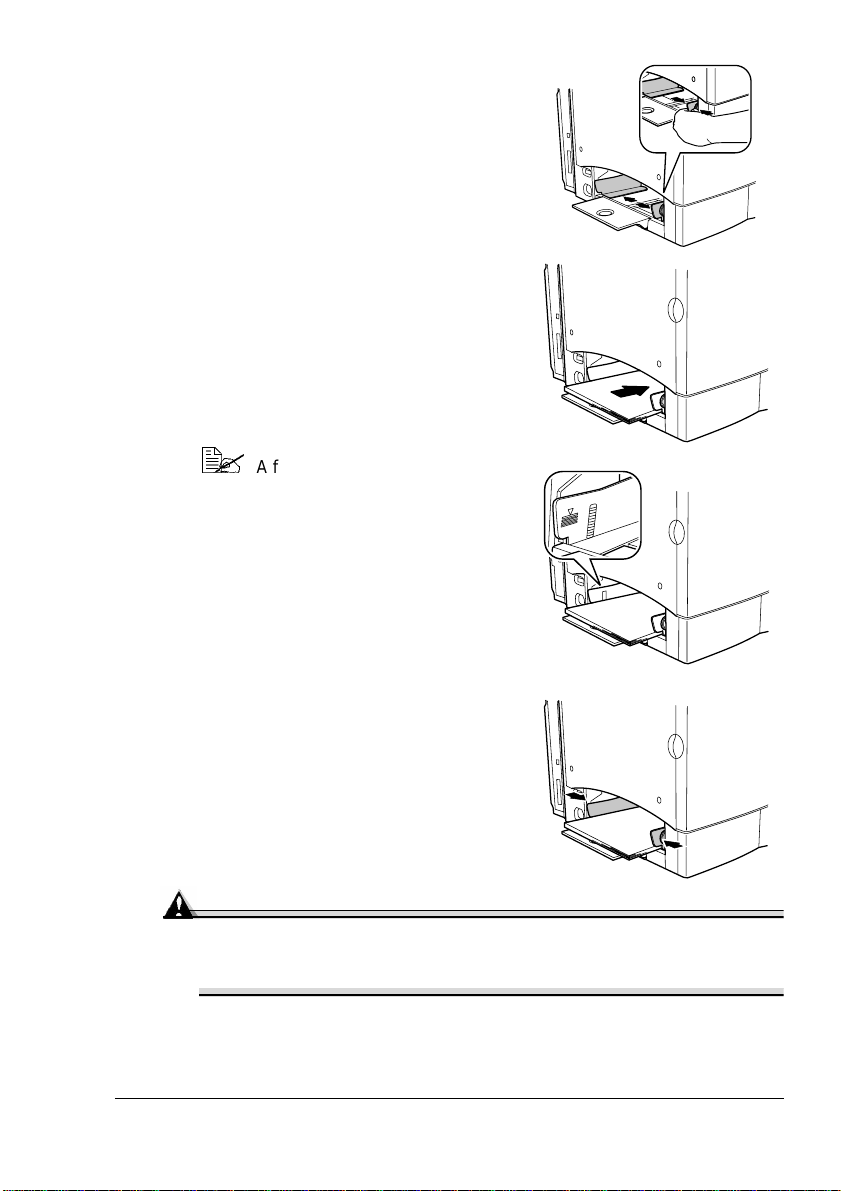

Tray 1 (Multipurpose Tray)

All supported media sizes and types can be printed from Tray 1.

See “Media Specifications” on page 11 for more information about media.

Plain Paper

1 If you already have media i n Tray 1 and want to change i t, remove the

media from Tray 1.

Loading Media20

2 Adjust the media guides to fit the

appropriate media sizes.

3 Load the media face up, short edge (or

letterhead) first.

Often, an arrow on the paper package

label indicates the face-up (printing)

side of the paper.

A fill limitmark is provided on the

inside of the media guides on

Tray 1 (the multipurpose tray).

Tray 1 holds 200 sheets of 22 lb

bond (80 g/m²) paper.

4 Slide the media guides up against the

edge of the media.

Attention

Always adjust the media guides after inserting the media. Media

guides that arenot properlyadjustedcanresult in poor print quality,

media jams, or printer damage.

5 In the printer driver, select the appropriate media mode. Then print

the job.

Loading Media

21

Other Media

When loading media other than plain paper, set the media mode (for

example, Envelope, Label,Thick Stock, or Transparency) in the driver.

For optimum printing resultsit’s important to specify the type of media

loaded into Tray1.

Envelopes

1 Flex the envelope stack (including the edges) to remove any stiffness.

2 Place t he envelopes on a flat surface, and flatten them by pressing down

the corners.

3 Correct any bent corners, and then tap the envelopes on a flat surface to

align them.

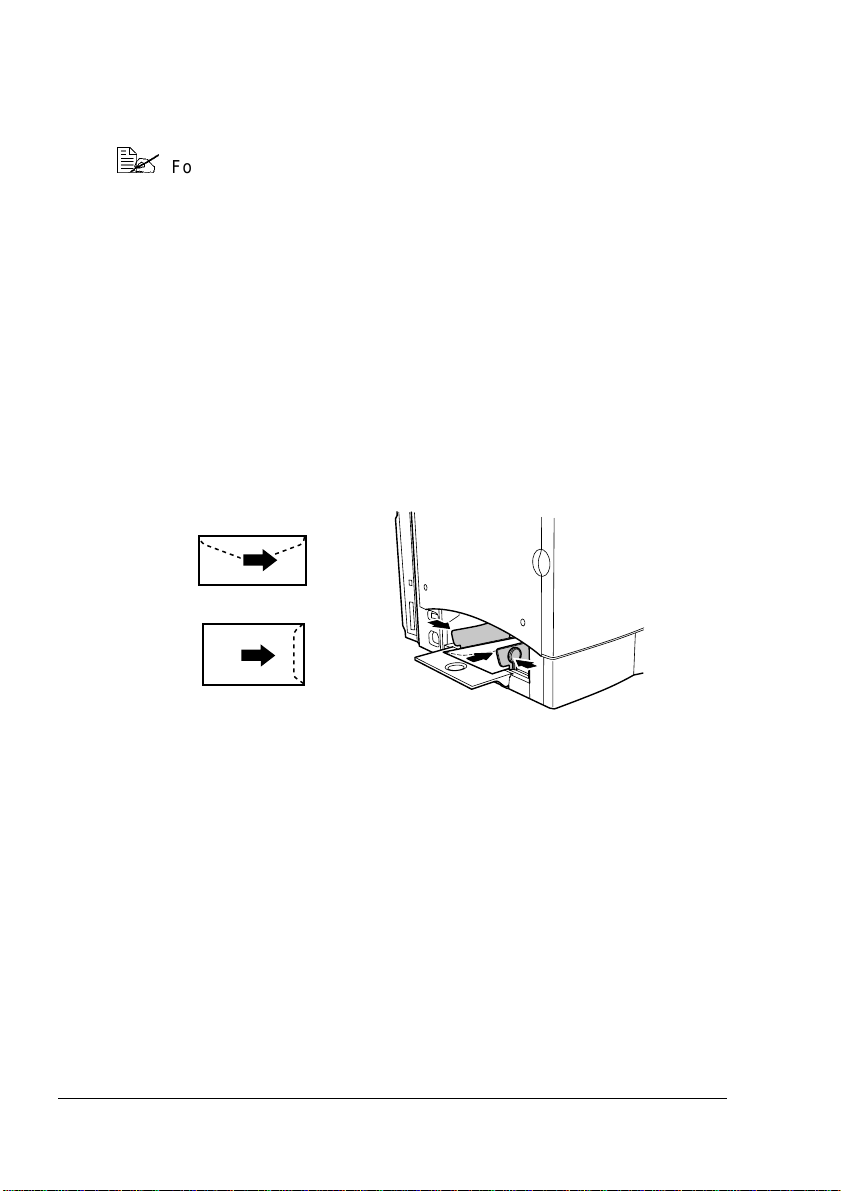

4 Place t he envelope stack into Tray 1 with the flap-side underneath. If the

flap is on the short end of the envelope, insert it into the printer first.

Print a single envelope to check t he orientation before printing

multiple copies.

5 Adjust the media guides to the width of the envelopes.

Make sure the guides are snug enough to keep the envelopes straight,

but not so tight t hat they buckle the envelopes.

6 In the printer driver, select Envelope mode. Then print the job.

7 Open the flap of each envelope immediately(before it cools) after the

envelope is delivered to the output tray.

Loading Media22

Duplexing

How do I print back-to-back (duplex)?

Select paper with high opacity for duplex (2-sided) printing. Opacityrefers to

how effectivelypaper blocks out what is written on the opposite side of the

page. If the paper has low opacity (high translucency), then the printed data

from one side of the page will show through to the other side. Check your

application for margin information. For best results, print a small quantity to

make sure the opacity is acceptable.

Duplex (2-sided)printing can be done manually or can be done automatically

with the duplex option installed and selected.

Attention

Only plain paper, 16–24 lb (60–90 g/m2) can be autoduplexed. See

“Media Specifications” for supported sizes.

Duplexing custom-sized media, envelopes, labels, postcards, thick

stock, or transparencies is not supported.

How do I autoduplex?

Verify that the duplex option is installed on the printer, and check your

application to determine how to set your m argins for duplex

printing.

1 To print duplex (both sides of the sheet), load the media printing-side up

with the top of the media toward the back of the tray.

In autoduplexing,the back side is printed first and the front side is

printed last.

2 Set the driver for the duplex layout you prefer.

Long Edge creates a document that flipshorizontally as in a loose-leaf

notebook; Short Edge creates a document that flips vertically, as on a

clipboard.

3 Click OK.

Duplexing

23

Output Tray

All media is output to the output tray on top of the printer. The face-down

output tray has a capacity of 200 sheets of 22 lb (80 g/m

If the media is stacked too high, your printer may experience media

jams, excessive media curl, or static buildup.

Remove transparencies as soon as possible from the output tray to

avoid static buildup.

Media Storage

How do I store media?

Keep media on a flat, level surface in its original wrapper until it is time to

load it.

Media that has been stored for a long time outside of i ts packagingmay

dry up too much and cause jamming.

If media has been removed from its wrapper, place it in its original

packaging and store in a cool, dark place on a level surface.

Avoid moisture, excess humidity, direct sunlight,excessheat (above

95°F/35°C), and dust

Avoid leaning against other objects or placed in an upright position

Before using stored media, do a trial printing and check print quality.

2

) bond paper.

Additional Assistance

Where can I order MINOLTA-QMS-approved media or get

more information?

Check www.minolta-qms.com/support (click on "Answer Base") for currently

approved media. To order approved transparency media, go to

www.q-shop.com.

See the Service & Support Guide for a list of sources of service and support

for many areas of the world. The most current worldwide information can be

found at www.minolta-qms.com.

Output Tray24

Working with the

Printer

3

About the Control Panel

The control panel, located on the top of the printer, allows you to direct the

printer’s operation.In addition, it displays the current status of the printer,

including any condition that needs your attention.

One key allows you to control the printer configuration through access to

frequently used printer functions.

Four indicator lights (LEDs) provide printer status information.

Control Panel Key

Key Function

Cancels printing when held down for at least 5 seconds.

Overrides a media size/type mismatch when held down for

less than 5 seconds.

Resets the printer to factory defaults when held down for at

least 20 seconds while the printer’s front door is open.

About the Control Panel26

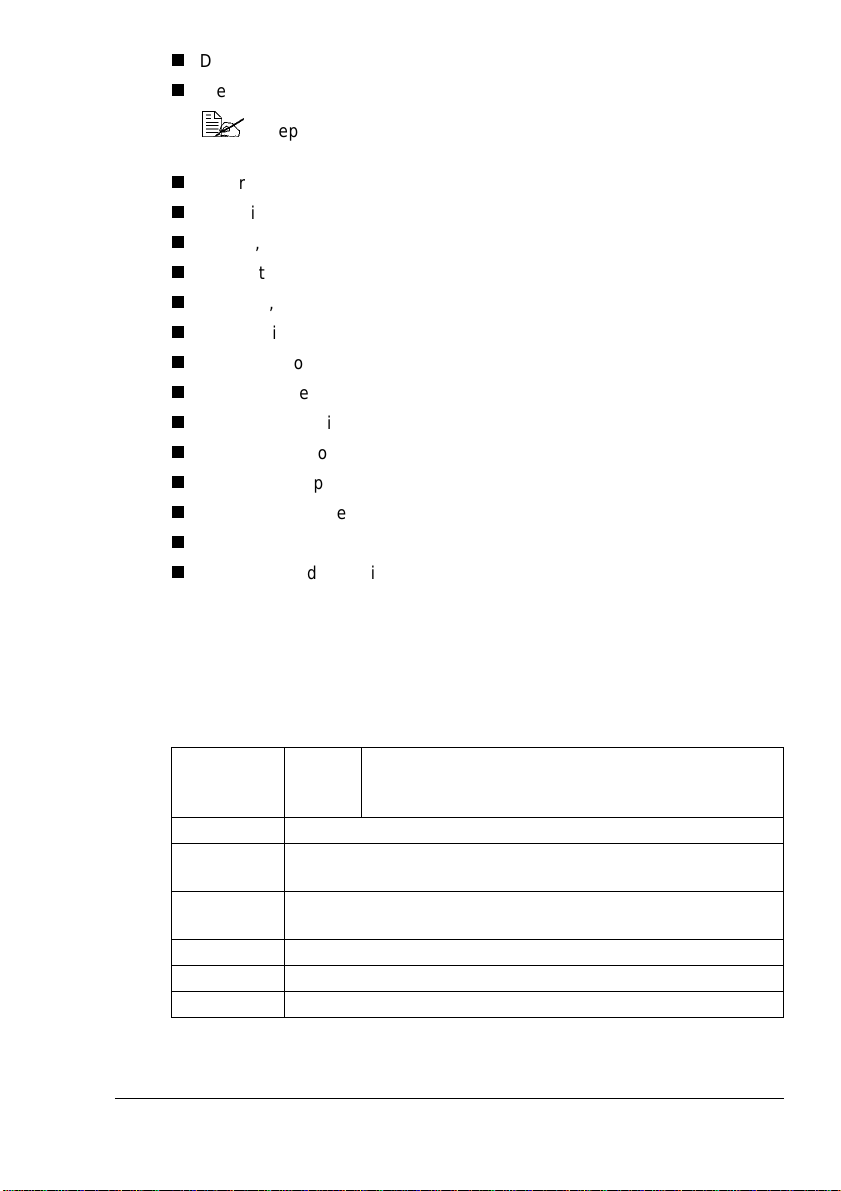

Indicator Lights

Green LED Orange LED

Off Off Power off

On On Power-on initialization

Canceling a job

On Off Printer ready (idle)

Blinking

rapidly***

Blinking

normally**

Blinking slowly* Off Energy Saver mode

On Blinking slowly* Waste toner bottle is nearly full

On Blinking

Off Blinking

Off Blinking

Off On Cover open

Blinking rapidly*** Insert media

Blinking normally** Print overrun

*Blinking slowly 1 blink per every 2 seconds

**Blinkingnormally 1 blink per second

***Blinking rapidly 2 blinks per second

Off Warming up

Calibrating

Off Receiving data

Processing data

Printing

Drum cartridge life has nearly expired

OPC drum cartridge life has expired

normally**

Media jam

normally**

rapidly***

Waste toner bottle is full

No paper in Tray 1

No unit is installed.

Fatal error

Mediasizemismatch

Communication error

Printer Status****

****For details,check the StatusDisplay utility.

Refer to “Working with the Status Display” on page 40.

About the Control Panel

27

Black Toner

Orange LED

Blinking slowly* Black toner low

On Black toner empty

Blinking rapidly*** Ready to change black toner cartridge

Refer to “Replacing a Toner Cartridge”on page 49.

*Blinking slowly 1 blink per every 2 seconds

***Blinking rapidly 2 blinks per second

Condition

Color Toner

Orange LED

Blinking slowly* Color toner low

On Color toner empty

Blinking rapidly*** Ready to change color toner cartridge

Refer to “Replacing a Toner Cartridge”on page 49.

*Blinking slowly 1 blink per every 2 seconds

***Blinking rapidly 2 blinks per second

Condition

About the Control Panel28

Working with the

Printer Driver

4

Introduction

The printer driver functions are summarized in this chapter.

For informationon connecting the printer to the computer, refer to “Connect

the InterfaceCable”intheInstallation Guide.Forinformation on installing the

printer driver, refer to chapter 1, “Software Installation”, in this manual.

Displaying Printer Driver Sett ing s

In addition to the printer driver tabs described in this section, the

Windows operating system also uses tabs. The General and Details

tabs are automatically determined by the operating system and are

therefore not described in this manual.

Refer to the printer driver’s online help for complete information on all driver

features.

Displaying Settings in Windows 2000/XP

1 From the Start menu, choose Settings and then Pr inters to display the

Printers dialog box.

2 Right-click the magicolor 2300W printer icon and choose Printing

Preferences....

Displaying Settings in Windows Me/98

1 From the Start menu, choose Settings and then Pr inters to display the

Printers dialog box.

2 Right-click the magicolor 2300W printer icon and choose Properties.

3 Choose the Printer Properties tab.

Introduction30

Common Settings on All Tabs

Save [Easy Set]

1 To save the current settings, click Save....

Multiple settings can be saved. Select your preferred settings,and

type a title in the dropdown list box. The saved settings can later

be selected from the dropdown list.

2 Select Default from the dropdown list to reset the functions of the tab to

their original values.

Page Layout

Click this radio button to display a sample of the page layout in the figure

area. This figure shows the following:

Imaging area

Paper size

Orientation

N-up

Watermark

Duplex/Booklet

Refer to the printer driver’s online help for complete information on all of

these features.

Displaying Printer Driver Settings

31

Printer Figure

Click this radio button to display an image of the printer in the figure area.

Common Buttons

OK

Click this button to exit the Properties dialog box, saving any changes made.

Cancel

Click this button to exit the Properties dialog box without saving any changes

made.

Apply

Click this button to save all changes without exiting the Properties dialog box.

Depending on the version of the operating system, Apply may

not appear.

Help

Click this button to view online help.

Help on a Specific Item

Click and then click on a feature in t he driver to see more information

about that feature.

Close

Click to close the Properties dialog box without saving any changes

made.

Displaying Printer Driver Settings32

Setup Tab

This tab allows you to:

Print several pages of a document on the same print page (N-up)

Provide printouts with a watermark

Design and edit custom watermarks

Specify duplex and booklet printing

Specify paper source

Define the type of media

Refer to the printer driver’s online help for complete information on all of

these features.

Setup Tab

33

Paper Tab

This tab allows you to:

Select an original document size

Set up custom paper sizes

Select the output paper size

Scale (enlarge/reduce) documents upon printout

Specify the orientationof the paper

Specify the number of copies

Select/deselect collatation

Print using a form overlay

Add and edit form overlays

Refer to the printer driver’s online help for complete information on all of

these features.

Paper Tab34

Quality Tab

This tab allows you to:

Switch between color and monochrome printing

Specify color matching (Images, Graphics and Text)

Specify the resolution for the printout

Control the tones of an image (Contrast)

Control the darkness of an image (Brightness)

Control the color purity of an image (Saturation)

Control the clarity of an image (Sharpness)

Refer to the printer driver’s online help for complete information on all of

these features.

Quality Tab

35

Color Matching

You can specify whether or not to use the Color Matching function, which

adjuststheprinter’s color tonestoaccurately reproducethecolor tones of the

monitor.

Choices Off Does not use color matching.

With certain applications, such as desktop

publishing applications, data is color-matched to

be the most suitable for the printer. If this type of

output setting is used in the application, Color

Matching should be turned off.

On Uses color matching.

If On is selected, Images (bitmap image data

such as photos), Graphics (graphic data such as

drawings) and Text (text data such as written

documents) can be set to one of the three color

conversionmethods

Perceptual: This method is most suitable for

photographic images.With this method, the

data is smoothly reproduced with minimal

brightness variations.

Saturation: This method is most suitable for

business presentations and other similar applications. With this method, the data is reproduced with more vivid tones.

*

:

Colorimetric:This method can be used for

any typeofapplication. The dataisreproduced

with the tones of the original image. However,

when data is reproduced on the monitor and

the color of some areas cannot be expressed

accurately or with the printer colors, those colors are replaced with the closest printer color,

so that the difference in the color of those

areas is not noticeable.

Quality Tab36

Notes The ICM color profile, which is automatically defined when the

driver isinstalled, isusedand a color conversionis made in the

driver so that sRGB colors can be output. sRGB is a general

Windows color space with the color space international

standard (IEC61966-2-1)definedby the IEC (International

Electrotechnical Commission).

There are also additional ICM profiles available on the Utilities

and DocumentationCD- ROM for specific applications,such as

Photoshop. Refer to the readme on the CD-ROM f or more

information.

* Col ors that can normally be displayed on the monitor

include many vivid or bright colors that cannot be reproduced by with the printer. In this case, the colors are compressed with the perceptual, saturation, or colorimetric

method to convert them to colors that can be reproducedby

the printer.

Quality Tab

37

Device Options Setting Tab

This tab allows you to:

Activate the duplex option

View information about the printer driver

Refer to the printer driver’s online help for information on all of these

functions.

Device Options Setting Tab38

Working with the

Status Display

5

Working with the Status Display

The StatusDisplay displays information about the current status of the

computer’slocal printer.If you used the CD-ROM Installer to installtheprinter

driver, the Status Display was alsoinstalled. However, if you used Add Printer

to manually install the printer driver, Status Display is not installed.

Environment

The StatusDisplayfunctions over paralleland USB connections on all

supported Windows operating systems,but only for the default printer.

Opening the Status Display and Showing Supplies Status

1 Double-clickthe Status Display icon in the taskbar. (If the Status Dis-

play icon does not appear in the taskbar, pointto Programs in the Start

menu, and then point to magicolor 2300W Utilities and click magi color

2300W Status.)

2 From the Display menu, choose Supplies Status to view remaining

consumables life.

Working with the Status Display40

Using the Status Display

When the background of the right-hand printer graphicis green, the

printer is in standby mode or a job is printing normally.

When the background of the right-hand printer graphicis red, there is an

error and the job has been interrupted. The status of the printer and the

error message are shown in the dialog boxes on the left.

The function areas include:

Printer Status—Displays text messages that describe the current

operational status of the printer.

How to Recover—Providesyouwith instructionstocorrect problems and

recover from error conditions.

Warning Status—Displaystext messages that warn you of such

conditions as low toner.

Printer Status Figure—Shows a graphic representation of t he printer

and indicates where there is a problem.

Printing Status—Displays the status of the current print job.

Working with the Display Menu

Select Popup Message—Allows you to choose which message(s) you

want to bring to the foreground when that particular condition occurs on

the printer.

Status (Reduce)—Decreases the size of the Status Display window.

Status (Expand)—Increases the size of the Status Display window.

Using the Status Display

41

Printer Information—Displays the total print count, the list of installed

options and the memory size.

Supplies status—Displays consumablesusage (percentageremaining)

for the toner cartridges and OPC drum cartridge.

Refer to the Status Display’s onlinehelp for information on all of its functions.

WorkingwiththePrinterMenu

Power On Test—Performs an AIDC (Auto Image Density Control)

calibrationcycle. Wait until the test is finished, the Ready indicatoron the

control panel lights up,and the Error indicator goes off (less than 150

seconds).

Maintenance...

Duplex Density

Adjusts the density of the second side of the paper when duplex

printing.

Energy Saver

Sets the length of time until the printer enters Energy Saver mode

after it no longer receives print jobs or is not operated. If a print job is

received while the printer is in Energy Saver mode, the printer warms

up, then returns to normal print mode before starting to print.

Auto Continue

When set to On, causes the printer to continue printing even if the

specified tray is not loaded with paper of the correct size. If the Auto

Continue setting is changed during printing, the setting remains valid

for future print jobs.

Toner Replace...—Allows you to replace a toner cartridge.

1. From the list, select the color of the toner cartridge to be replaced.

2. Select the capacity of the toner cartridge (1500 or 4500).

3. Click OK.

4. Open the front door, and then replace the toner cartridge.

Refer to “Replacing a Toner Cartridge” on page 49 for complete details.

Print Status Sheet

Prints an LED status Sheet, which lists all LED combinations and their

related printer statusand error conditions.

Using the Status Display42

Closing the Status Display

To close the Status Display from the File menu, choose Exit.

If you click the X button in the upper-right corner of the Status Display

window to close the window, the Status Display remains available at

the right end of t he taskbar. Double-click the icon to open it again.

Closing the Status Display

43

Replacing

Consumables

6

Consumable Life Expectancies

Plain Paper

The stated life expectancy of each consumable is based on printing under

specific operating conditions such as media type, number of color planes,

page size, and page coverage (at normal 5% coverage of letter-/A4-size

media). The actual life expectancy will vary depending on these and other

printing variables, including continuous or intermittent printing,ambient

temperature, and humidity. For current information about consumable life

expectancies, refer to www.minolta-qms.com/support, then click on “Answer

Base.”

The following messages in the Status Display’s message window indicate

that a consumable needs to be replaced.

Message This item needs replacing by

user after...

Drum

Cartridge

End of

Life

COLOR

Toner

Empty

Waste

Toner

Box

Full

Up to 45,000 continuous

monochromeor11,250 continuous

four-colorpages, or 10,000

intermittent(one-pagejobs)

monochrome or 7,500 intermittent

color pages.

Standardcapacity:Approximately

1,500 single-sidedpages per

cartridge—yellow, magenta, cyan

at 5% coverage of each color.

High capacity: Approximately

4,500 single-sidedpages per

cartridge—black, yellow, magenta,

cyan at 5% coverage of each color.

Approximately 25,000 continuous

monochromeor 21,600intermittent

(one-page jobs) monochrome, or

6,250 continuous or intermittent

color pages (based on the

standard mode with 5% toner

coverage of letter/A4 media).

Comment

See “Replacing the OPC

Drum Cartridge” on page

54.

See “Replacing a Toner

Cartridge” on page 49.

See “Replacing the Waste

Toner Bottle” on page 53.

Consumable Life Expectancies46

Special Media

The stated life expectancy of each consumable on page 46 i s based on

letter-/A4-size plain paper. If you are using special media such thick stock or

transparencies, the life expectancy will vary depending on those printing

variables and the print speed automatically determined by the thick stock or

transparency selection on the driver’s Setup Tab.

Consumables

(Special Media)

OPC Drum

Cartridge

Toner Cartridge

(pages per

cartridge at 5%

coverage of

each color)

Waste Toner

Box

This item needs replacing by user after...

Up to 15,000 continuous monochrome or 7,500

continuous four-color pages, or 5,000 intermittent

(one-page jobs) monochrome or 4,100 intermittent color

pages.

Standard capacity (black): Approximately1,500

continuous single-sided pages or 1,000 intermittent

single-sidedpages (if monochrome black printingonly).

Standard capacity (yellow, magenta, cyan):

Approximately 1,500 continuous or intermittent

single-sidedpages.

High capacity (black): Approximately4,500 continuous

single-sidedpages or 3,200 intermittentsingle-sided

pages (if monochrome black printing only).

High capacity (yellow, magenta, cyan): Approximately

4,500 continuous or intermittent single-sided pages.

Approximately 25,000 continuous or 14,400 intermittent

(one-page jobs) monochrome pages or 6,250 continuous

or intermittent color pages.

For current information about consumable life expectancies, refer to

www.minolta-qms.com/support, then click on “Answer Base.”

Auto-Image Density Control (AIDC)

The printer periodicallypauses for the color calibration procedure (also

known as the Auto-Image Density Control [AIDC] cycle). This process is

provided to make sure reliable printer operation with optimum output quality.

This 150-secondcalibration cycleautomatically occursafter the installationof

a new toner cartridge or OPC drum cartridge.

If you open the door before the Ready indicator on the control panel

lights up andtheErrorindicator goes off, the printerstops and repeats

the calibration cycle.

Consumable Life Expectancies

47

The printer also pauses to do a 90-second AIDC cycle after 200

1-sidedpagesof a continuous printrun,and a 150-second AIDC cycle

when waking up from ENERGY SAVER with more than 1,000 pages

since the last AIDC cycle or when there has been an environmental

change such as in temperature or humidity.

Toner Cartridge Life

A high-capacity toner cartridge contains enough toner (yellow, magenta,

cyan, or black) to print a maximum of 4,500 (at normal 5% page coverage)

simplex letter/A4-size pages of continuous print. The standard-capacity toner

cartridge contains enough toner to print a maximum of 1,500 (at normal 5%

page coverage) simplex letter/A4-size pages of continuousprint.

With heavier coverages, the approximatemaximum capacities will decrease:

How do I know if I need to replace the toner?

When it’s time to replace the t oner, COLOR Toner Low displays in the

Status Display. Printingcan continue even though the warning appears.

However,the color graduallyf ades out, so replacethetoner cartridgeassoon

as possible.

You can also access t he toner cartridge suppliesstatususingthe Status

Display (refer to “Working with the Status Display” on page 40).

How can I tell if a toner c artridge is standard or

high capacity?

Refer to the label on the toner cartridge.

Replacing Consumables

Attention

Failure to follow instructions as outlined in t his manual could result in

voiding your warranty.

Replacing Consumables48

Refilled Toner Cartridges

Attention

Do not use refilled toner cartridges.Any damage to the printerorquality

problems caused by a refilled toner cartridge will void your warranty.

Replacing a Toner Cartridge

Characters and images are created in your l aser printer through a

photosensitive process that applies toner to the O

(OPC) drum cartridge (which functions like photographic film). Your printer

uses four toner cartridges: black, yellow, magenta, and cyan. Handle the

toner cartridges carefully to avoid spilling toner inside the printer or on

yourself.

The toner is nontoxic. If you get toner on your hands, wash them in

cool water or a neutral detergent. If you get toner on your clothes,

lightly dust them off as much as possible. If some toner remains on

your clothes, use cool, not hot water, to rinse the toner off.

ptical Photo Conductor

WARNING!

If you get toner in your eyes, w ash i t out immediately and consult a

doctor.Material Safety Data Sheets (MSDS) information can be found at

www.minolta-qms.com (click on “Answer Base”).

Attention

Do not hold a toner cartridge vertically.

Do not touch t he toner roller surface. This could

lower image quality.

Keep toner cartridges:

In their packaging until you’re ready to install them.

In a cool, dry location away from sunlight (due to the heat it generates).

The maximum storage temperature is 95°F(35°C) and the maximum

storage humidity is 85% (noncondensing). If the toner cartridge is moved

from a cold place to a warm, humid place, condensation may occur,

degrading print quality. Allow the toner to adapt to the environment for

about one hour before use.

Replacing Consumables

49

Level during storage.

Do not stand or store cartridges on their ends or turn them upside down;

the toner inside the cartridges may become caked or unequally

distributed.

Away from salty air and corrosive gases such as ammonia.

Procedure

You can use this procedure to replace either an empty toner cartridge or one

that is not empty.

You may want to replace a tonercartridge that is not empty if theconsumable

monitor in your printer driver or the Status Display indicates that a particular

colorcartridge is running lowandyouneed to print a lengthy job whennoone

will be available to change the cartridge.

Attention

Be careful not to spill toner while replacing a toner cartridge. If toner

spills, immediately wipe it off with a soft, dry cloth.

1 Open the Status Display, and then check which toner color is empty.

2 From the Printer tab choose Toner Replace...

3 In the Color list box, select the color of the toner cartridge to be replaced

(CYAN, MAGENTA, YELLOW,orBLACK).

4 Select the capacity of the new toner cartridge (1500 or 4500).

5 Click OK.

6 When the toner indicator on the con-

trol panel starts flashing, open t he

printer’s front door.

The carousel is automatically

repositioned so that the appropriate

toner cartridge can be removed.

Replacing Consumables50

7 Insert you thumb and index finger

into the two holes in the front of the

toner cartridge, and then pull the

cartridge straightout about 6"

(15 cm).

8 Support the middle of the cartridge

with your lefthand, and then pullout

the cartridge.

WARNING!

Contacttoner_recycle@minolta-qms.com for tonerrecycling

availability, or dispose of the used toner cartridge according

to your local regulations. Do not dispose of it by burning.

9 Remove the new toner cartridge from its shipping carton.

10 Remove the protectivecoverclearly

marked “Remove.”

Each toner cartridge has a

coloredend thatcorresponds

to a color insidethe cartridge

slots.Alwaysinstallthetoner

cartridge in the slot of the

same color.

Replacing Consumables

51

11 Support the middle of the cartridge

with your left hand, insert the thumb

and index finger of your right hand

into the two holes in the front of the

toner cartridge, and then insert the

cartridge so that the guides on the

cartridge fit into the rails in the

cartridge compartment in the

carousel.

12 Gently push the new toner cartridge

into the printer.

13 Close the printer’s front door.

The printermust complete a 150-secondcalibrationcycle after any

consumable has been replaced. If you open the door before the

Ready indicator on the control panel lights up and the Error indicator turns off, the printer stops and repeats the calibration cycle.

Replacing Consumables52

Replacing the Waste Toner Bottle

When the waste tonerbottle becomes full, the messageWaste Toner Box

Full appearsintheStatus Display. The printer stops and will not startagain

until the waste toner bottle is r eplaced.

Removing the Used Waste Toner Bottle

1 Turn off the printer, then open the printer’s front door.

2 Grasp the waste toner bottle’s

handle and then lift the bottle out

and up to remove it.

Keep the waste toner bottle upright

so the toner does not spill.

3 Remove the two caps by turning

them counterclockwise.

4 Secure t he two caps onto the tw o

holes by turning them clockwise.

5 Dispose of the used waste toner

bottle.

WARNING!

Dispose of the used waste toner bottle properly according to your local

regulations (do not dispose of i t by burning).

Replacing Consumables

53

Installing a N ew Waste Toner Bottle

1 Remove the new waste toner bottle from its carton.

2 Insert the bottom of the waste toner

bottle

into its installation position

in the printer.

3 Push the top of the waste toner

bottle

into position until it is firmly

seated.

4 Close t he printer’s front door.

If the waste toner bottle is not

correctlyinstalled orthetransfer belt

releaselever is at itstop position(11

o’clock), the front door cannot be

closed.

The printermust complete a 150-secondcalibrationcycle after any

consumable has been replaced. If you open the door before the

Ready indicator on the control panel lights up and the Error indicator goes off, the printer stops and repeatsthe calibrationcycle.

Replacing the OPC Drum Cartridge

When the OPC drum cartridge is worn out, the message Drum Cartridge

EndofLifeappearsint he StatusDisplay.Printing can continue evenafter

thismessageappears; however,since print qualityis reduced,the OPC drum

cartridge should be replaced immediately.

The OPC drum cartridge life is directly related to the number of

rotations of the drum. Longest drum l ife is achieved with continuous

printing. Intermittent printing with small job sizes requires cleaning

rotationsbefore and after each job, and subsequently will impact OPC

life.

You can also access t he OPC drum cartridge life status using the Status Dis-

play (refer to “Working with the Status Display”on page 40).

Replacing Consumables54

Removing the Used OPC Drum Cartridge

1 With the front door open and the

used waste toner bottle removed

(see page 53), rotate the transfer

belt unit release lever clockwise to

the top (11 o’clock)position.

This releases the pressure on the

transfer belt unit.

2 Grasp the release lever for the OPC

drum cartridge, and then pull the

cartridgestraight out about 6 inches

(15 cm).

3 Support the bottom of the drum with

your hand, then carefully pull the

cartridge toward you and remove it.

Dispose of the cartridge

properly according to your

local regulations.

Replacing Consumables

55

Installing a New OPC Drum Cartridge

Attention

The OPC drum is extremely sensitive to bright light and direct sunlight.

Always leave it in its protective bag until you’re ready to install it. Any

exposure to light should be avoided, or permanent damage could

result.

Any damage resulting from mishandling of the OPC drum will void the

warranty of the OPC drum cartridge. Handle the cartridge carefully by

its sides so you don’t t ouch the surface (the green part) of the drum.

The drum isalsoextremely sensitivetohand oils and scratches,both of

which reduce print quality.

1 Remove the new O PC drum cartridge from its

carton.

Attention

Keep the protective sheet on the cartridge. Do not touch the

protectivesheet on the photosensitive (green) surfaceorscratch the

surface. This could lower image quality.

Make sure the transfer belt release lever is still set to its top position

(11 o’clock).

2 Holding the OPC drum cartridge level,

place the front end of the OPC drum

cartridge guide into the rail.

3 Carefully push the OPC drum

cartridge in.

When installing the OPC drum cartridge,

be sure not to press on thereleaselever.

If the lever is pressed during installation,

the lock is released, and the cartridge is

not installed correctly.

Attention

The cartridge should slide easily into the printer. Don’t force it.

Replacing Consumables56

4 Press on the front handle of the

OPC drum cartridge with one hand

and hold the handle of the OPC

protectivecover with the other hand.

5 Peel t he protective coverstraight

towardyou.

Dispose of it properly

according to your local

regulations.

6 Rotate thetransfer beltrelease lever

counterclockwise to its correct

position (7 o’clock).

This lowers the transfer belt.

Attention

If the transfer belt release lever is not at its correct position

(7 o’clock), the waste toner bot tle cannot be installed.

7 Reinstall thewastetonerbottle you removed earlieror installa new waste

toner bottle (see page 54).

8 Close t he printer’s front door.

The printermustcomplete a 150-secondcalibrationcycleafter any

consumable has been replaced. If you open the door before the

Ready indicator on the control panel lights up and the Error indicator turns off, the printer stops and repeats the calibrationcycle.

Ordering Consumables

Choosing the right consumables for your printer not only increases its

reliabilityand performance, but also minimizes the risk of damage. For

example, only MINOLTA-QMS toner cartridges are designed to meet the

exact specifications of your MINOLTA-QMS printer, giving maximum

performance,efficiency,andlong life.Toner cartridges and other

consumablesforyour printer areavailable from your local vendororQ-SHOP

(www.q-shop.com).

See the Service & Support Guide for a list of sources of service and support

in many areas of the world. The most current worldwide information can be

found at www.minolta-qms.com.

Ordering Consumables

57

Maintaining the

Printer

7

Maintaining the Printer

Attention

Read all caution and warning labelscarefully, making sure to follow any

instructions contained inthem. These labelsarelocated on the insideof

the printer’s doors and the interior of the printer body.

Handle the printer with care to preserve its life. Abuse may cause damage

and void your warranty.If dust and paper scraps remain on the inside or

outside of the printer,printer performance and print quality will suffer, so the

printer should be cleaned periodically. Keep the following guidelines in mind.

WARNING!

Turn off the printer, unplug the power cord, and disconnect all interface

cables before cleaning. Do not spill water or detergent into the printer;

otherwise the printer will be damaged and an electric shock may occur.

Either clean the printer before use, or allow time after unplugging it to

allow the fuser unit to cool down.

Attention

The fuser unit is hot. When the right door is opened, the

fuser unit temperature drops gradually (one hour wait time).

Be careful when cleaning the inside or removing paper jams, as

the fuser unit and other internal parts m ay become very hot.

Do not place anything on the top of the printer.

Use a soft c loth to clean the printer.

Never spray cleaning solution directly on the printer’s surface; the spray

could penetrate through the air vents of the printer and damage the

internal circuits. Avoid using abrasive or corrosive solutions or solutions

that contain solvents, (such as alcohol and benzene) to clean t he printer.

Alwaystestany cleaning solution(such as mild detergent)on a small area

of your printer to check the solution’sperformance.

Never use sharp or rough implements,suchas wire or plastic cleaning

pads.

Always close the printer doors gently.Never expose the printer to

vibrations.