Page 1

magicolor 3300

®

User’s Guide

1800712-001A

Page 2

Trademarks

The following are registere d trademarks of MINOLTA-QMS, Inc.: Q MS, the M INOLTAQMS logo, Crown, Crow nNet, and magic olor.

Minolta is a trade mark of Mi nolta Co., Ltd. Other product n ames mentio ned in this

guide may also be trademark s or registered tra d emarks of their respec tive owner s.

Proprietary Statement

The digitally encoded software included with your printer is Copyrighted © 2003 by

MINOLTA-QMS, Inc. All Rights Reserved. This software may not be reproduced, modified, displayed, transferr ed, or copied in any form or in any manner or on any media,

in w h o l e or in p a rt, w i t h o ut the e x p res s w r itten pe rmis s ion of MI N OLTA-Q M S , I n c .

Copyright Notice

This guide is Cop yrighted © 2003 by MINOLTA-QMS, Inc., On e Magnum P ass,

Mobile, AL 36618. All Righ ts Reserv ed. This document may not be copied, in whol e or

part, nor transfer red to any oth er media or lang uage, without written permission of

MINOLTA-QMS, Inc.

Notice

MINOLTA-QMS, Inc. reser ves the ri ght to mak e changes to this guid e and to th e

equipment describe d herein without notice. Con siderable effort has been m ade to

ensure that this guide is free of inaccuracies and omissions. However, MINOLTAQMS, Inc. makes no wa rranty of any kind including, bu t not limited to, any implied

warranties of merchanta bility and fitness for a particular purpo se with r egard to this

guide. MINOLTA-QMS, Inc. assumes no res ponsibility for, or liability for, errors

contained in th is guide or for incidental, spec ial, or consequential damages arising

out of the furnishing of this guide, or the use of this guide in operating the equipment,

or in connectio n with the p erforma nce of the equi pment when so operated .

Registering the Printer

Mail (Americas only)—Fill out and send in the r egistration card e nclos ed in your

shipment.

Internet—Go to www.minolta-qms.com/register and follow the instructions

given there.

Software Utilities CD-ROM—Follow the instruction s on the CD- ROM.

Page 3

Contents

1 Software Installation

Software Utilities CD-ROM ......... ..................................... .. ................. 2

Automatic Sy ste m Software Update 2

Drivers and Utilities 2

Installing Printer Drivers and Utilities, Windows Environments ...........5

Installing Printer Drivers and Utilities, Macintosh Environments ......... 5

Some Notes to Consider 5

Macintosh OS 9—PPDs and Utilities Installation 6

Macintosh OS X—PPDs and Utilities Installation 9

UNIX, NDPS, NetWare ... .................................................................11

Linux .................................................................................................11

2 Using Media

Introduction ....................................................................................... 14

Media Storage and Handling ............................................................ 15

General Notes about Media 18

Media Trays 18

Media Sizes and Print Area .............................................................. 19

Page Margins 20

Contents

Page 4

Image Alignment 21

Output Tray 21

Media ................................................................................................21

Plain Paper 22

Special Note about Custom (and Oversized) Media 25

Thick Stock 25

Envelopes 26

Glossy Media 27

Label Stock 27

Postcards (Japanese size) 28

Transparencies (Uncoated Only) 29

Loading Media .................................................................................. 31

Preparing the Media 31

Loading and Printing Media 31

Using Media Other Than Plain Paper 36

System Memory (RAM) Requirements ............................................. 41

Basic Functionality 41

Maximum Performance 41

Duplexing .......................................................................................... 41

3 Color Printing

Introduction .......................................................................................46

Color Registration .............................................................................46

PRISMLASER™ Technology ............................................................49

Color Management and Control ........................................................49

MINOLTA-QMS QCOLOR Technology ......................... ............ ....... .49

Further Information 52

4 Replacing Consumables

Introduction ......................................................................................52

Consumable Life Expectancie s.........................................................52

Starter Toner Cartridges 54

Replacement Toner Cartridges 54

Transfer Unit 55

Imaging Unit 56

Fuser Unit and Media Feed Roller(s) 56

Replacing a Toner Cartridge ............................................................57

Replacing the Transfer Unit ..............................................................61

Replacing the Imaging Unit ..............................................................63

Replacing the Fuser Unit ...................................................................67

Contentsii

Page 5

5 Maintaining the Printer

Introduction .......................................................................................74

Handling the Printer ..........................................................................74

Cleaning the Printer ..........................................................................75

6 Troubleshooting

Introduction .......................................................................................82

Printing a Status Page ........................................................................ 82

Direct PDF File Printing ....................................................................82

Adjusting Memory Clients for PDF Printing 82

Printing Preformatted Files Using CrownView 83

Troubleshooting PDF Direct Printing from CrownView 83

Preventing Media Jams ....................................................................84

Automatic Jam Recovery .................................................................... 85

Understanding the Media Path ......................................................... 85

Understanding Medi a J am Status Messages ...................................86

Clearing Media Jams .......................................................................86

Media Jam Duplex 87

Media Jam Feed 88

Media Jam Fuser 92

Media Jam Registration and Mismatch Jams 94

Solving Prob l em s ..............................................................................96

General Problems 96

Media Jams and Media Transport Problems 98

Other Problems 101

Printing Quality 107

Status, Error, and Service Messages .............................................1 13

Status and Error Messages 113

Service Messages 122

HP-GL Error Codes and PCL Error Codes 123

PostScript Errors 124

Additional Assistance ......................................................................124

7 Installing Accessories

Introduction .....................................................................................126

Antistatic Protection .......................................................................127

BuzzBox (Americas Only) ...............................................................128

What's in the Kit? 128

Installing BuzzBox 128

Usi ng the Buzz B ox 129

Dual In-Line Memory Modules (DIMMs) ................. .. ..... .. ..... ..... .. ..129

Contents

iii

Page 6

Basic Functionality 131

Maximum Performance 131

Installation 131

Duplex Kit (Americas Only) .............................................................134

Emulations , Fonts, and Other Software .......... ................................134

Emulations 134

Fonts, Forms, and Sig nat ures 136

High-capacity Input Feeder (HCIF) ................................................1 38

What’s in the Kit? 138

Installation 139

Internal IDE Har d Disk ................. ...................................................143

What's in the Kit? 143

Installation 143

Media Trays ...................................................................................145

SC-215 Color Convenience Copier .................................................145

Time-of-Day Clock .........................................................................145

Installation 145

Tray Cover .......................................................................................... 147

Installation 147

A Technical Specif icat ion s

Requirements ..................................................................................150

Space Requirements 150

Location Requirements 150

Power Requirements 152

ENERGY STAR Complianc e153

Engine and Contro l le r Spec i fications ................... ...........................154

Print Speed 154

Engine 155

Controller 156

Electrical 157

Physical 159

Consumable Life Expectancies ......................................................159

Starter Toner Cartridges 159

Replacement Toner Cartridges 160

Transfer Unit 161

Imaging Unit 161

Fuser Unit and Media Feed Roller(s) 161

IPP ..................................................................................................162

Document Option Commands .........................................................163

Header/Trailer Page Command s 164

HP-GL Emulation Commands 164

Contentsiv

Page 7

HP PCL 5e Emulation Commands 164

Lineprinter Emulation Commands 165

Document Formatting 165

Job and Subjob Boundary Commands 165

PJL Command ................................................................................166

Menus ............................................................................................. 166

Configuration Chart Conventions 166

Security Menu 166

Operator Control Menu 16 7

Administration Menu 168

Administration/Communications/Resident NIC/CrownNet Menu . 169

TCP/IP Menu .................................................................................. 173

Regulatory Compliance ...................................................................1 74

FCC Compliance Statement 174

Canadian Users Notice 175

CE Marking (Declation of Conformity) 175

Laser Safety 175

International Notices 176

Warranty Considerations ................................................................... 176

Index

Contents

v

Page 8

Page 9

Software

Installation

1

Page 10

Software Utilities CD-ROM

If you followed all the steps in the Installation Guide that came with your

printe r, then the printer is properly set up, connected to your computer,

plugged in, turned on, and ready to receive the system software, drivers, and

utilities on the Software Utilities CD-ROM.

Put the CD-ROM in your computer’s CD-ROM drive and the MINOLTA-QMS

AutoInstaller begins the installation process.

Automatic System Software Update

The AutoInstaller locates the file containing the system software on the

Software Utilities CD-ROM and, if it is a newe r version th an th e one that is

currently on the printer, automatically downloads it to the pr i nter.

Attention

Operator intervention is required to prevent the system software

update.

If y ou attempt to download a previous version of system software, an error

page prints stating “Low Release Level.” This prevents an older version of

system software from being downloaded over a newer version.

The system software update aborts without operator intervention if the

system software on the CD-ROM is the same as, or older than, the one

currently installed on the printer controller.

If you are installing new system software, you may have to wa it up to

10 mi nu tes for the update. Do not interrupt the proces s .

Drivers and Utilities

The printer driver and additi onal s oftwar e on the Software Utilities CD-ROM

can b e installed on P C , M acintosh, and othe r co m puters using any of the

following:

Windows Me

Windows 98

Windows 95 (B minimum)

Windows XP

Windows 2000

Windows NT4

Macintosh OS 9 (version 9.2.1 or

higher) or X (version 10.1.4 or

higher)

UNIX/Linux

NetWare (Versions 5 and 6)

NDPS

Software Utilities CD-ROM2

Page 11

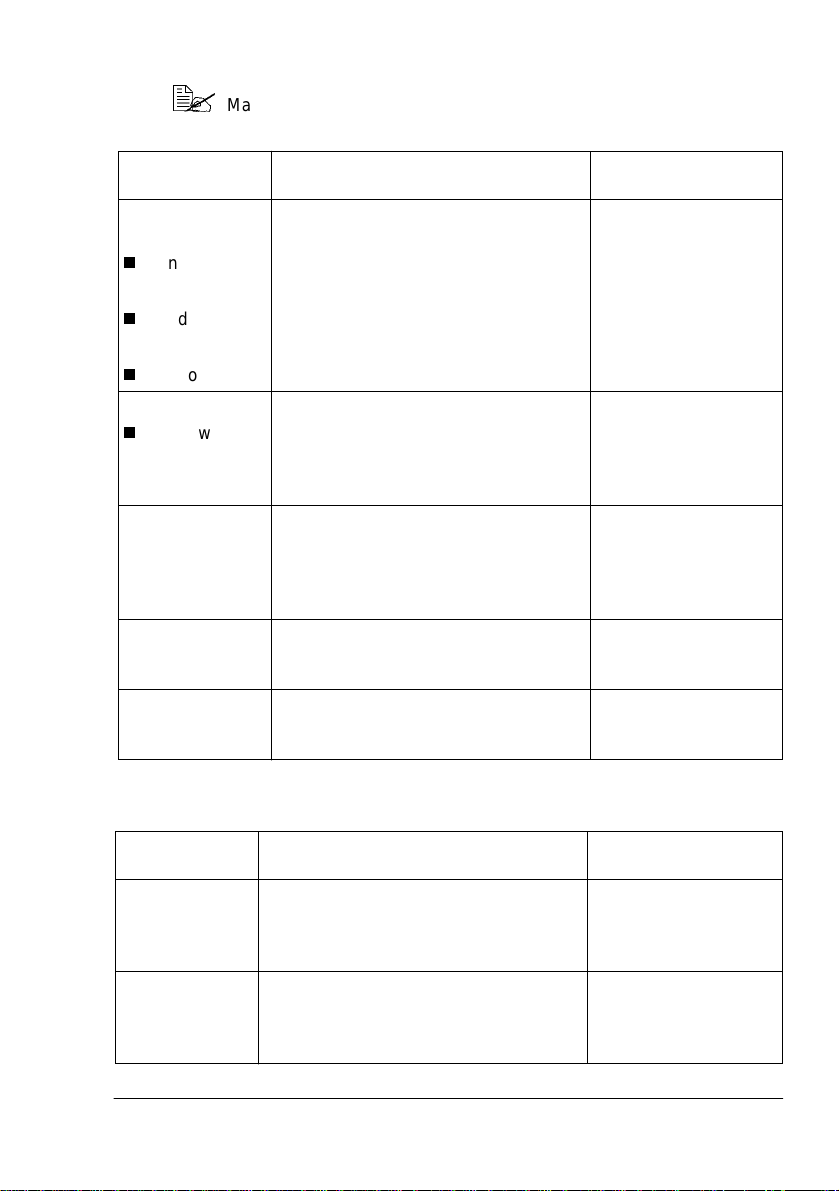

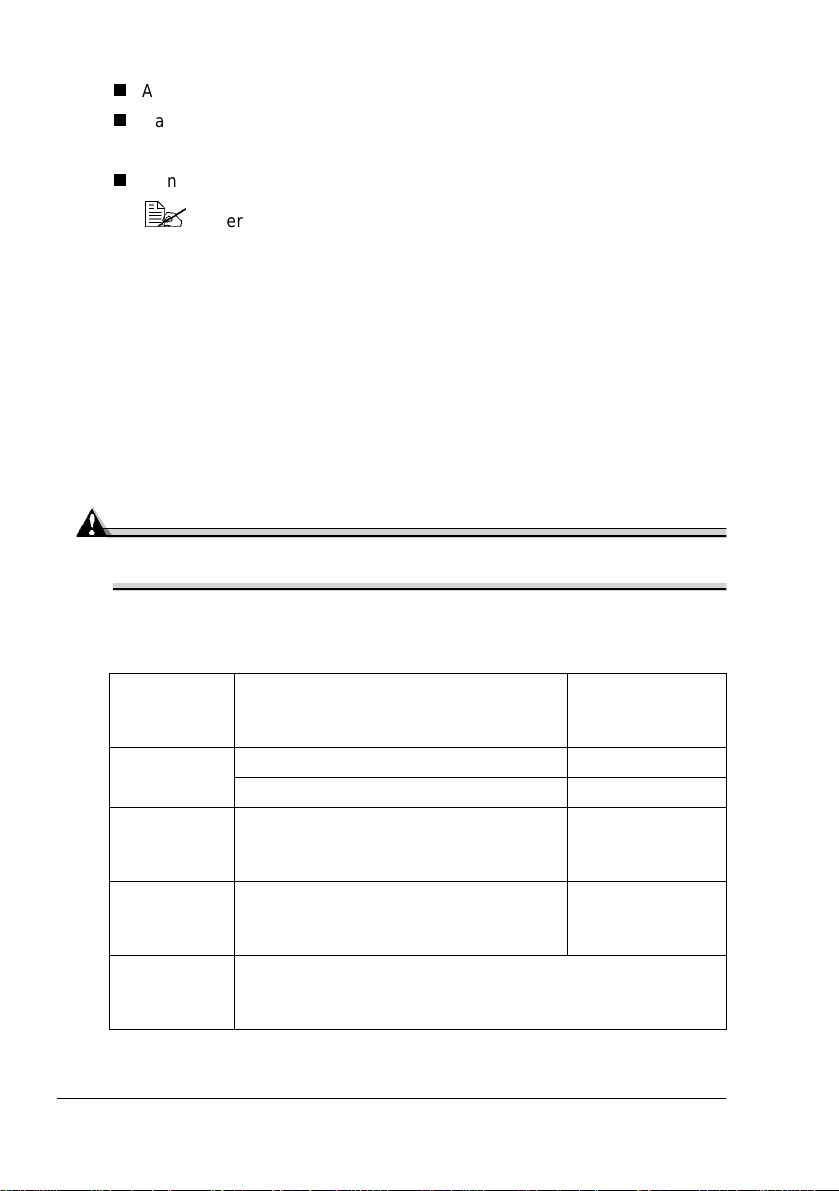

Drivers and PPDs

Manual installat io n instructio ns are prov ided in the rea dme files on the

Software Utilities CD-ROM in case you need them.

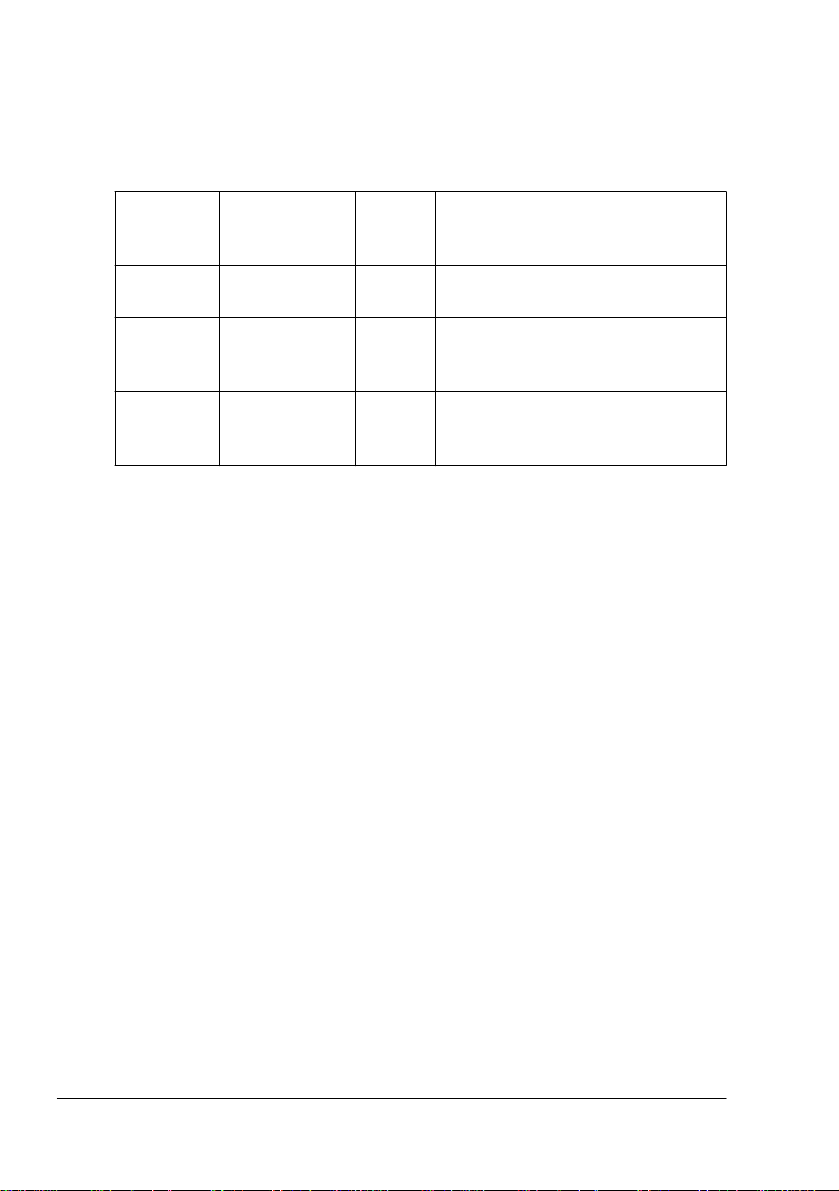

Drivers Use/Benefit Installation

Instructions

PostScript 2/3

Drivers

Windows

XP/2000

Windows

Me/98

Windows NT4

PCL 6 Driver

Windows

XP/2000

Macintosh PPDs PostScript Printer Descripti on (PPD)

Windows PPDs These PPD files allow you to install the

Linux PPDs These PPDs can be used with

These drivers give you access to all of

the printer’s features, including

finishing and advanced layout

This driver gives you access to all of

the printer’s features, including

finishing and advanced layout. It also

includes support for Arabic, Greek, and

Hebrew fonts and font sets.

files allow you to configure options

such as memory and informs the

computer what options and features

are available.

printer for a variety of platforms,

drivers, a nd a pplications.

third-party Linux print filters that use

PPDs.

“Insta lli n g Printer

Drivers and Utilities,

Windows

Environments” on page

7

“Insta lli n g Printer

Drivers and Utilities,

Windows

Environments” on page

7

Readme on the

Software Utilities

CD-ROM

Readme on the

Software Utilities

CD-ROM

Readme on the

Software Utilities

CD-ROM

Utilities

Utilities Use/Benefit Installation

Instruc tions

Crown Print

Monitor + for

Windows

MINOLTA-QMS

Download

Manager

This Windows utility provides an efficient

method for transporting print jobs

directly to a MINOLTA-QMS printer via

the TCP/IP protocol.

This util ity pr ovides the ability to

download fonts and overlays to the

printer’s hard disk. It also allows you to

download fonts to printer memory.

Readme on the

Software Utilities

CD-ROM

Readme on the

Software Utilities

CD-ROM

Software Utilities CD-ROM

3

Page 12

Utilities Use/Benefit Installation

Instructions

PANTONE

Tables

ICC/ICM

Profiles

Macintosh

Installer

PageScope

Net Care

UNIX Host

Software

MINOLTA-QMS

NDPS Gateway

PageScope

Network Setup

Utility

These tables allow you to match printed

colors to scr een color s. Provided f or use

with PostScript High resolution printing

(1200x1200 dpi).

These color profiles provide support for

host-based color management systems

including Microsoft ICM 2 for Windows,

Apple ColorSync, CorelDRAW, Kodak

KCMS, Adobe Photoshop 5 and others.

This installer automatically places all

needed print-related components, such

as a PostScript Printer Description

(PPD) file, color profiles, screen fonts,

and registration information, in the

correct loc ations on your system and

allows you to use your printer with

Macintosh OS 9 (version 9.2. 1 or higher )

or X (version 10.1.4 or higher).

This uti lity, designed with administrator s

in mind, is a powerful tool, allowing

centralized management of network

printers. It is available for Windows and

UNIX platforms. Refer to the

PageScope Net Care Manual in PDF

format on the Documentation CD-ROM.

UNIX Host Software, com patible with a

variety of UNIX platforms, all ows for the

customization of UNIX-based queues

and filters for the specific features of the

Crown printer.

The NetWare interface allows NetWare

users to manage printers from a central

location.

This utility provides basic configuration

functions for network printers using

TCP/IP and IPX protocols.

Readme on the

Softw a re Utilities

CD-ROM

Readme on the

Softw a re Utilities

CD-ROM

Readme on the

Softw a re Utilities

CD-ROM

Readme on the

Softw a re Utilities

CD-ROM

Readme on the

Softw a re Utilities

CD-ROM

Readme on the

Softw a re Utilities

CD-ROM

Readme on the

Softw a re Utilities

CD-ROM

Software Utilities CD-ROM4

Page 13

Installing Printer D rivers and Utilities, Windows Environments

Arabic and Hebrew versions of the drivers and utilities must be

installed manually. For manual installation instructions refer to the

readme file on the Software Utilities CD-ROM.

Insert the Software Utilitie s CD-ROM in your CD-ROM dr ive.

1

If the CD-ROM does not start automatically, double-click setup.exe

in the root directory.

In the first window, click Next.

2

In the next window, click Printer Setup.

3

Choose the method by which the PC and printer are connected.

4

Follow the instructions on the screen.

5

On the Printer Options screen, use the check boxes to print a test page,

6

make the new printer your default, set printer properties and printing

preferences, or update printer firmware (also called printer system

software).

Be sure the check t he Up date Print er Firmware box. It’ s very i mportant

to update the printer firmware the first time you install the printer.

On the last screen, choose Finish.

7

This returns you to the Main Menu screen, where you can register your

printer , r eview dr iver o r util ity documentati on, or purch ase suppl ies onlin e.

When you are finished, exit fr o m the Installer.

When the system software installation is complete, remove the CD-ROM

8

from your CD-ROM drive and store it in a safe place.

Installing Printer D rivers and Utilities, Macintosh Enviro nm e nts

Some Notes to Consider

In the following sections, we assume that you are installing the software

for the first time.

The current version of Macintosh OS X has limited support for PPD

(PostScript Printer Description) files. Although MINOLTA-QMS printers

can be used with Macintosh OS X, not all advanced printing features are

available. Advanced printing features are still available under Macintosh

OS 9.

Installing Printer Drivers and Utilities, Windows

5

Page 14

You can connect to your printer by

A USB cable

A crossover Ethernet cable

Ethernet patch cables and an Ethernet hub

Macintosh—PPDs

MINOLTA-QMS developed a PostScript Printer Description (PPD) file for the

magicolor 3300. This PPD works with the Macintosh Operating System’s

PostScript printe r dr iv e r (L a serWriter) to prov ide s uppor t fo r the features on

the magicolor 3300, such as print resolution and media sizes.

Macintosh O S 9—PPDs and Util ities Inst allat ion

OS 9 Step 1. So ftware Installatio n

a

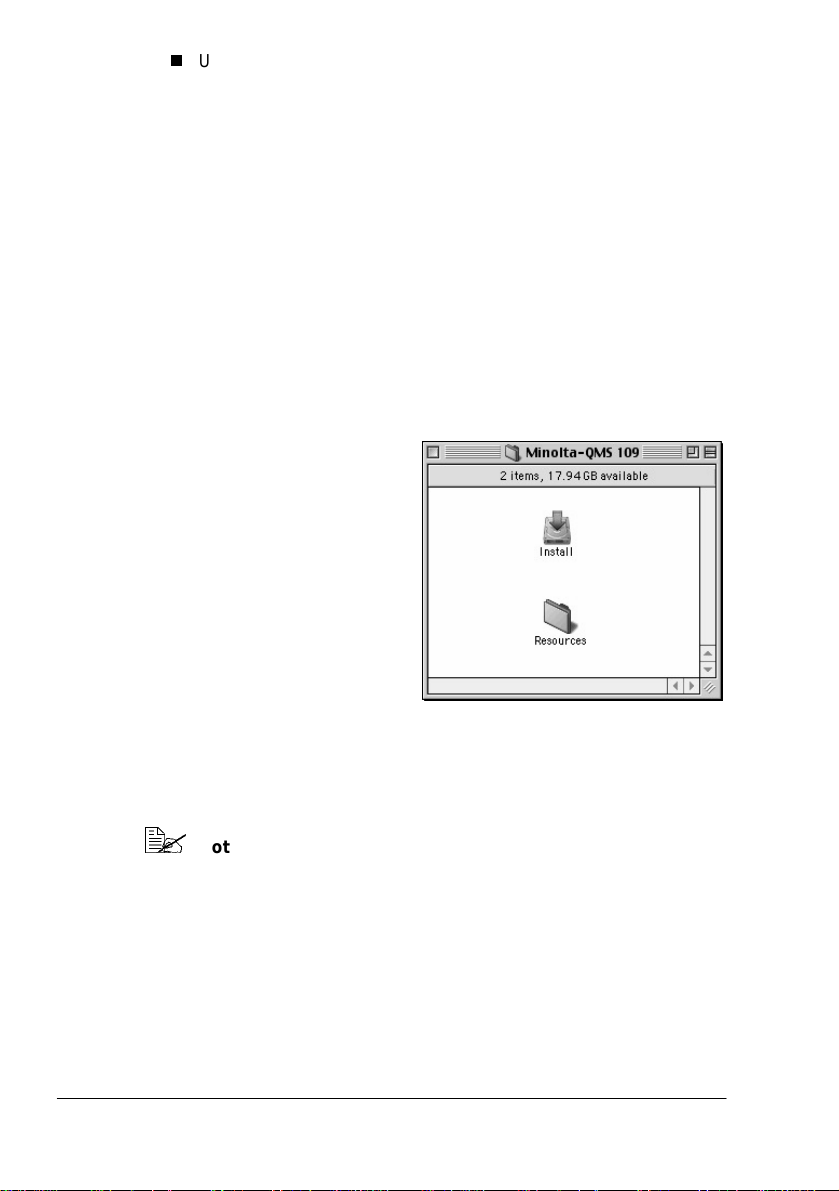

Insert the Software Utilitie s

CD-ROM in your Macin-

tosh’s CD-ROM drive.

If this screen does not

appear , double-clic k the

MINOLTA-QMS CD-ROM

icon on your Macintosh

desktop.

b

Double-click the Install icon.

c

Follow the instructions on

the screen to install the

magicolor 3300 PPD and

utilities.

d

After the PPD and utilities installation is comple te , choose Quit.

e

When the system software installation is complete, remove the

CD-ROM from your CD-ROM drive and store it in a safe place.

OS 9 Step 2. C r eating a Desktop Pri n ter

USB Connection

a

Plug one end of the USB cable into the Macintosh and the other into

the printer’s USB port.

Installing Printer Drivers and Utilities, Macintosh6

Page 15

b

Locate the Desktop Printer Utility.

If you cannot locate it on your Macintosh hard disk, it can be found on

your Macintosh’s system CD-ROM.

c

Double-click the Desktop Printer Utility icon to open the application.

The first window prompts you to select the type of desktop printer you

would like to create.

d

Select Printer (USB), and select OK.

e

Choose the Change button in the PostScript Printer Description section. In the resulting window, select the magicolor 3300 PPD, and

choose Select.

f

Choose the Change but ton i n the USB Pr in ter Selecti on sect ion. I n the

resulting window, select the magicolor 3300, and click

OK

.

EtherTalk Connection

a

You can connect via Ethernet in either of two ways:

Plug one end of a crosso ver Etherne t cable into the Mac intosh and

the other into the printer’s Ethernet port.

Use Ethe r n et p a tc h c a b les a n d an Ethe rn e t hub. P lu g one end of

each patch cable i n to th e hub, then plug the other end of one into

the Macintosh and the other end of the second into the printer’s

Ethe rnet port.

b

Open the Chooser and select LaserWriter.

c

When your printer boots up, it fin ds a defaul t zo ne. If your ne twork has

more than one zone and you want to use a different zone, use the

Interface/Ethernet/Ethertalk/Name and Zone menus on the printer

control panel to specify the new zone.

The Name and Zone menus allow you to identify 1 zone with a

name up to 32 characters long. (Up to 16 characters can be

entered in each of the two menus). You cannot use these two

menus to identify two zones. Trailing spaces are not considered

part of t he zone name. All stan dard printabl e ASCII character s are

valid except the @ and ' symbols. The names are case sensitive.

d

Choose Create and then Set-Up.

LPR Connection

a

You can connect via Ethernet in either of two ways:

Plug one end of a crosso ver Etherne t cable into the Mac intosh and

the other into the printer’s Ethernet port.

Installing Printer Drivers and Utilities, Macintosh

7

Page 16

Use Et hernet patch ca bl e s a nd an E th ernet hub. Plug one end of

eac h patch cabl e into the hub, then plug the other end of one into

the Macintosh and the other end of the second into the printer’s

Ethernet port.

b

Locate the Desktop Printer Utility.

If you cannot locate it on your Macintosh hard disk, it can be found on

your Macintosh’s system CD-ROM.

c

Select Printer (LPR), and select OK.

d

Type in the IP Address and use the same address for the Queue

name. Click OK.

e

Choose Create.

f

Name the printer with the IP Address or a descriptive name.

OS 9 Step 3. System Software

a

Insert the Software Utilitie s

CD-ROM in your Macintos h’s

CD-ROM drive.

b

If this screen does not

appear , double-clic k the

MINOLTA-QMS CD-ROM

icon on your Macintosh

desktop.

c

Double-click the Resources

icon.

d

Double-click the

System_Code folder, and

then locate the system software file (system.ps where system is the

filename).

e

Drag the system. ps icon and dr op it o n the magi color 3 300 pr inte r icon

on your desktop to perform the system software upgrade.

Note: If your p ri nter’s system software version is later than the

version on the CD-ROM that you are downloading, an error page

will print on the printer. In this case, go to step f. You do not need

to upgrade the printer’s system softwar e.

f

When the system software installation is complete, remove the

CD-ROM from your CD-ROM drive and store it in a safe place.

Installing Printer Drivers and Utilities, Macintosh8

Page 17

Macintosh O S X—PPDs and Utilit ies Installation

OS X Step 1. Software Installation—Automatic

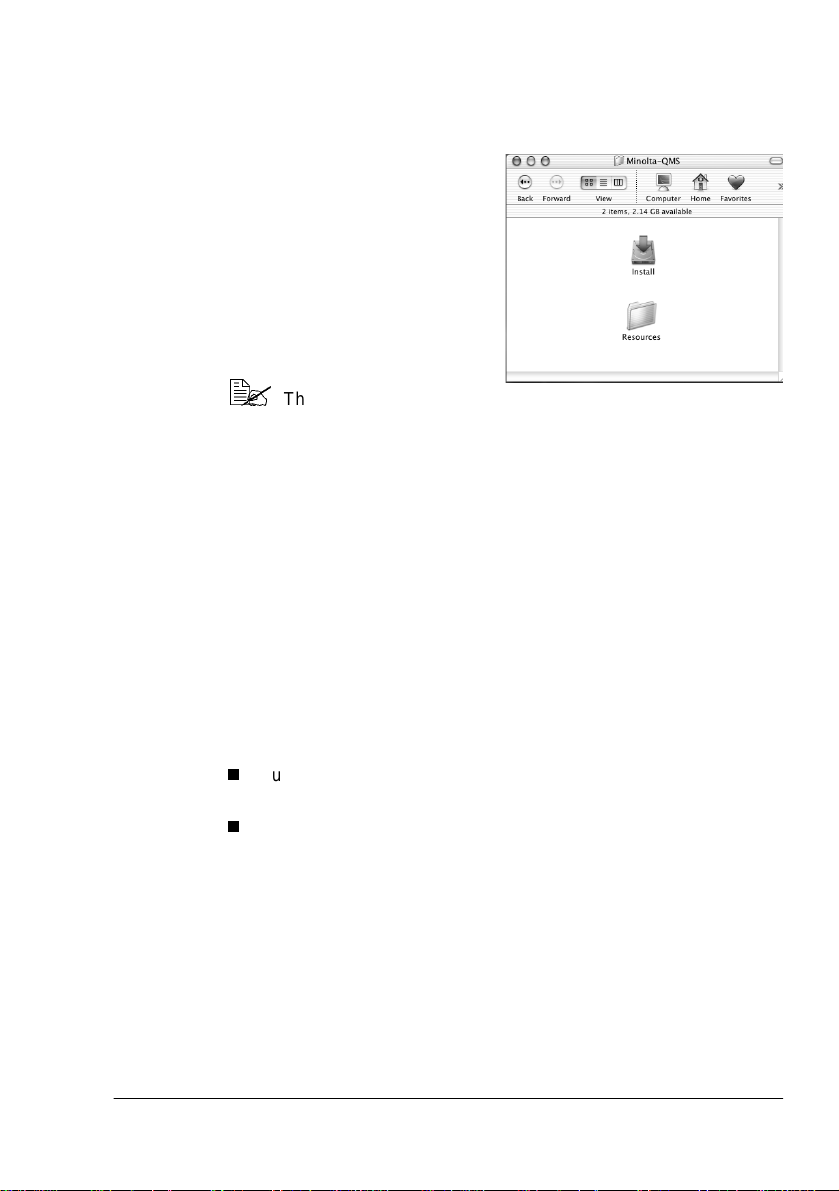

a

Insert the Software Uti lities

CD-ROM in your Macintosh’s

CD-ROM drive.

If this screen does not appear,

double-click the MINOLTA-QMS

CD-ROM icon on your

Macintosh desktop.

b

Double-click the Install icon.

The installer uses the

path Hard Disk Name/Library/Printers/PPDs/Contents/

Resources/ for PPDs and the path: Hard Disk

Name/Library/Fonts/ for fonts.

c

Follow the instructions on the screen to install the magicolor 3300

PPD and utilities.

d

After the PPD and utilities installation is complete, choose Quit.

OS X Step 2. Creating a Printer Queue

a

Connect the printer to the computer using a USB or Ethernet

connection.

For USB, plug one end of the USB cabl e into t he PC and t he other into

the matching printer port.

For Ethernet, you can connect in either of two ways:

Plug one end of a crosso ver Etherne t cable into the Mac intosh and

the other into the printer’s Ethernet port.

Use Ethe r n et p a tc h c a b les a n d an Ethe rn e t hub. P lu g one end of

each patch cable i n to th e hub, then plug the other end of one into

the Macintosh and the other end of the second into the printer’s

Ethe rnet port.

b

Locate and double-click the Print Center utility to open it.

c

In the Printer List window, choose Add Printer.

Installing Printer Drivers and Utilities, Macintosh

9

Page 18

d

In the resulting window, select from USB, AppleTalk, or LPR to match

your printer connection.

USB—The magicolor 3300 appears in the window.

AppleTalk (for Ethernet connection)—Select the zone and scroll

through pri nter c hoices. The magi color 3300 appe ars in the c hoice l ist .

LPR—Enter the IP Address. If the “Use Default Queue on Server” box

is checked, click it to unselect it. Type in the IP Address again for the

Queue name.

e

Choose the Printer Model popup menu to select the magicolor 3300

PPD, and choose Other.

f

Browse to Library/Printers/PPDs/Contents/Resources/en.lproj.

The first two letters of the folder name are an abbreviation for

the language. If you prefer another language instead of

English, you can pick a different .lproj folder.

g

Select the magicolor 3300 PPD. Click Choose and then click Add.

The Printer List opens again.

h

Double-click on the printer you just created to open the Print Queue

window.

OS X Step 3. System Software

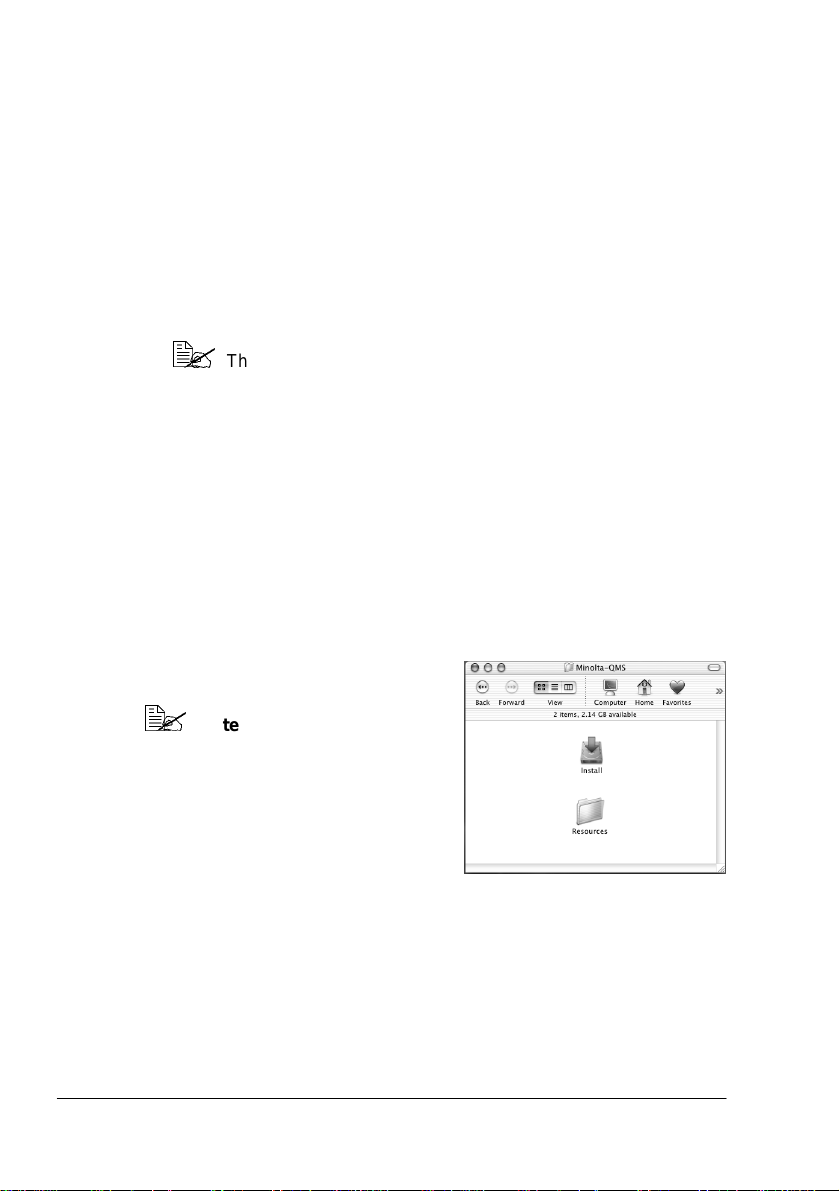

a

If it’s not already there, insert the Software Utilities CD-ROM in your

Macintosh’s CD-ROM drive.

b

Double-click the CD-ROM icon to

display its contents.

Note: Unlike Macintosh OS 9,

it is not necessar y to inst all the

magicolor 3300 PPD and

utilities before upgrading the

printer system software in

Macintosh OS X.

c

Double-click the Resources icon.

d

Double-click the System_Code folder, and then locate the system

softw are file (system.ps where system is the filename).

e

Drag the system.ps icon and drop it into the Print Queue window you

opened in Step 2, Letter H. This performs the system software

upgrade.

f

When the system software installation is complete, remove the

CD-ROM from your CD-ROM drive and store it in a safe place.

Installing Printer Drivers and Utilities, Macintosh10

Page 19

UNIX, NDPS, NetWare

For UNIX and NDPS installation, refer to the readme files on the Software

Utilities CD-ROM. For NetWare installation, check the Answer Base at

www.minolta-qms.com.

Linux

For Linux PPD and PDQ installati on, refer to the read me file s o n the Software

Utilities CD-ROM. This readme includes basic information about PDQ,

XPDQ, CUPS, and XPP connections and instructions for installing them.

UNIX, NDPS, NetWare

11

Page 20

Page 21

Using Media

2

Page 22

Introduction

This chapter provides information on handling, selecting, and storing media.

Getting Started

“How do I take care of media?” page 17

“What should I watch out for when handling media?” page 19

“What sizes of media can I use?” page 21

“What Is the imageable (printable) area” page 22

“What is the differenc e between a nonprintable

and nonguaranteed area?”

Print Quality

“Why have different print qualities?” page 24

“Which print quality is the best?” page 24

“How do I select the print quality?” page 26

Med ia Types

“What are the media types supported?” page 25

“What is the difference betwee n ‘glossy plain’ paper and ‘coated

stock’?”

“How do I select the media type?” page 26

Other In formation

“How do I prepare and load the media?” page 33

“How do I manually duplex?” page 44

“How do I autoduplex?” page 44

“Where can I order MINOLTA-QMS-app roved media o r get

more information?”

page 22

page 26

page 45

Attention

Using unsupported me dia such a s ink jet pa per or coated color

transparencies will result in damaging the printer and voiding your

warranty.

Introduction14

Page 23

Media Storage and Handling

How do I take care of media?

Keep media on a flat, level surface in its original wrapper until it is time to

load it.

If media has been removed from its wrapper, place it in its original packaging

and store in a cool, dark place.

When storing media, avoid

Moisture, excess humidity

Keep media between 30% to 65% relative humidity. Toner does not

adhere well to paper where it has become wet.

On the other hand, media that has been stored for a long time without

staying in its packaging may dry up too much and also cause jamming.

Direct sunlight

Excess heat (up to 86° F/30° C)

Dust

Leaning media against other objects or placed in an upright position

Before purchasing a large quantity or special media, do a trial printing with

the same media and check print quality.

What should I watch out for when handling media?

Attention

Do not use the media types listed below. These could cause poor print

quality, media jams, or damage to the printer.

Do not use media that is

Coated with a processed surface (such as carbon paper, digitally

glos s-coate d m e d i a , hea t-sensit i v e paper, heat-pressure paper,

heat-press transfer paper); colored paper that has been treated

Special media designed specifically for inkjet printers

Media that has already been printed on

–

An inkjet printer

–

A monochrome or color laser printer or copier

–

A heat-transfer printer

–

Another printer or fax machine

Wet or damp

Media Storage and Handling

15

Page 24

Layered

Adhesive

Folded, creased, em bossed, warped, or wrinkled

Perforated, three-hole prepunched, or torn

Too slick, too coarse, too textured

Different in texture (roughness) on the front and back

Too thin or too thi c k

Stuck together with static electricity

Composed of foil or gilt; too luminous

Cold water transfer paper

Heat sensitive or cannot withstand the fusing temperature (between

316° F/158° C and 356° F/180° C, depending on the media)

Irregularly shaped (not rectangular or not cut at right angles); not uniform

in size

Attached with glue, tape, paper clips, stapl es, ribb ons, hook s, or but ton s

Acidic

Any other media that is not approved

Use media that is

Suitable fo r plain- paper l aser printers, such as standard or recycl ed o ffice

paper

What should I watch out for when loading envelopes?

Do not use envelopes that have

Sticky flaps

Tape seals, metal clasps, paper clips, fasteners, or peel-off strips for

sealing

Transparent windows

Too rough of a surface

Material that will melt, vaporize, of fset discolor, or emit dangerous fumes

Been presealed

Use envelopes that are

Common office envelopes with diagonal joints, sharp folds and edges,

and ordinary gummed flaps

Approved for laser printing

Dry

Printed on the front address side only

Media Storage and Handling16

Page 25

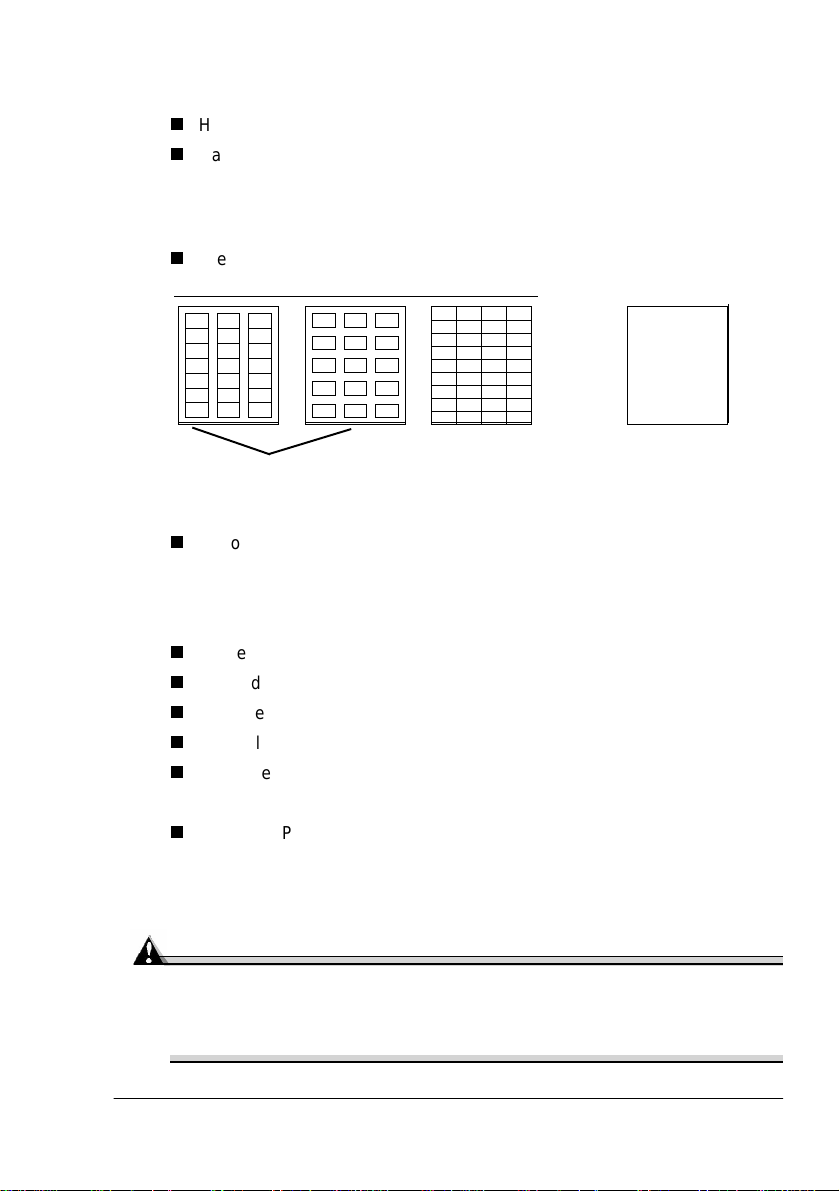

What should I watch out for when loading labels?

Do not use label sheets that

Have labels that easily peel off

Have the ba cki ng sheets that have peeled away or have exposed

adhesive

Labels may stick to the fuser, causing them to peel off and media jams to

occur.

Are precut

Do not use

OK to use

Shiny backed paper

Use label sheets that are

Recommended for laser printers

Paper cut into labels Full page labels

(uncut)

What should I watch out for when loading postcards?

Do not use postcards that are

Coated

Warped

Designed for inkjet printers

Multicolored

Preprinted or m ulticolored (may result in printer jamming)

Use postcards that are

Jap an e se Po st Off ice sta n da rd postcards (3.9x5.8" [100x148 mm]) recommended for laser printers

What should I watch out for when loading transparencies?

Attention

Use only the MINOLTA-QMS-approved transparencies. Check

www.minolta-qms.com/support (click on Answer Base) for currently

approved media. To order approved transparencies, go to

www.q-shop.com.

Media Storage and Handling

17

Page 26

Do not use transparencies that

Are coated, such as transparencies designed for m ost color printers

Have static electricity that will cause them to stick together

Use transparencies that are

Monochrome, uncoated transparencies (also known as OHP film)

Refer t o p age 31 for in fo rmation about t he recommended

Q-Media.

General Notes about Media

If you’re printing simplex pages, load the media printing-side down in the multipurpose tray, but printing-side up in the other trays. Th e top of t he sheets of

media should be toward the back of the printer.

Often, an arrow on the media package label indicates the printing side of the

media. If you can’t determine which side of the media to print on, remove the

media from the tray, rotate the stack 180°, turn the stack over, and then place

it back in the tray.

Attention

Do not allow media to go above the fill limit mark inside the tray or the

media may not be fed correctly.

Media Trays

Tray

Location

Printer Upper (standard) tray 500

High-Capacity

Input Feeder

(1x500)

High-Capacity

Input Feeder

(2x500)

Notes You may rename these trays for your convenience. See the

Media Tray Sheet Capacity

for Le tter/A 4 sized Media

Multipurpose 100

Optional Tray (1x500) 50 0

Optional Tray 1 (2x500)

Optional Tray 2 (2x500)

CrownBooks in PDF on the Software Utilitie s CD-ROM for

more information.

1,000

(500 sheets each)

Media Storage and Handling18

Page 27

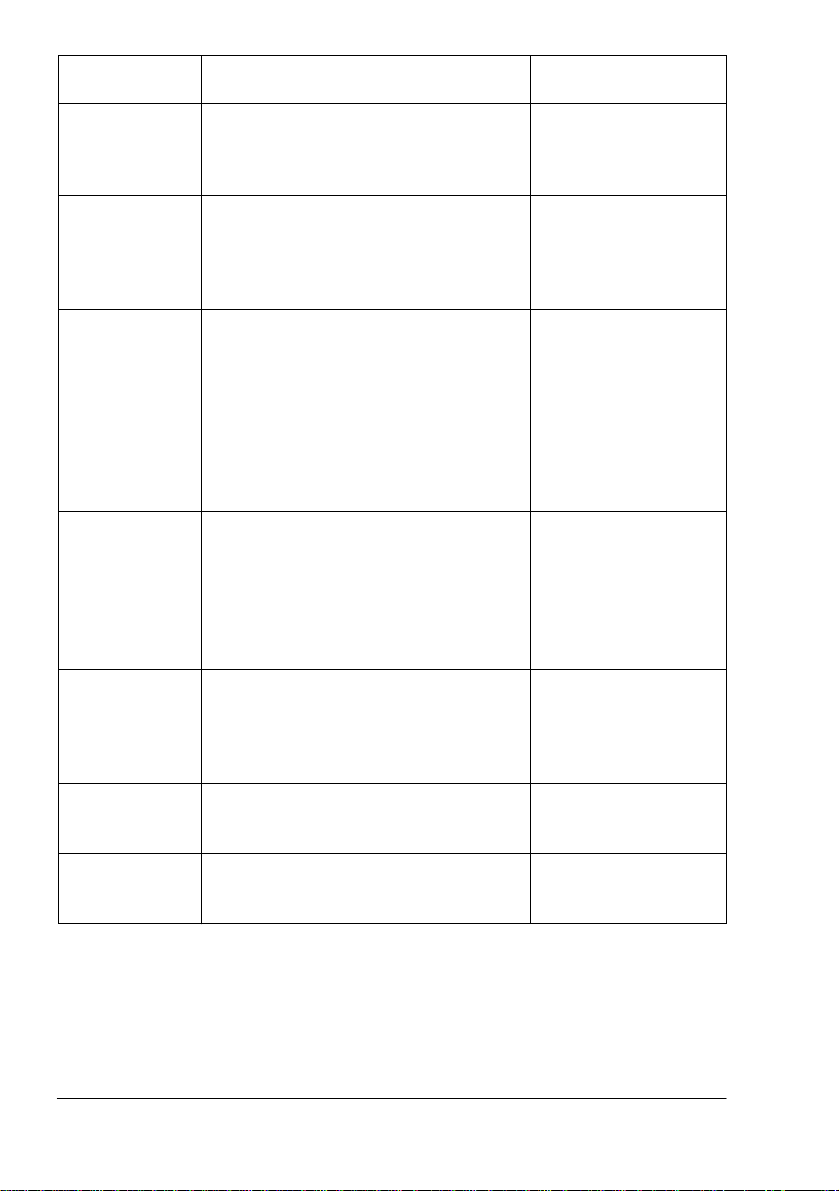

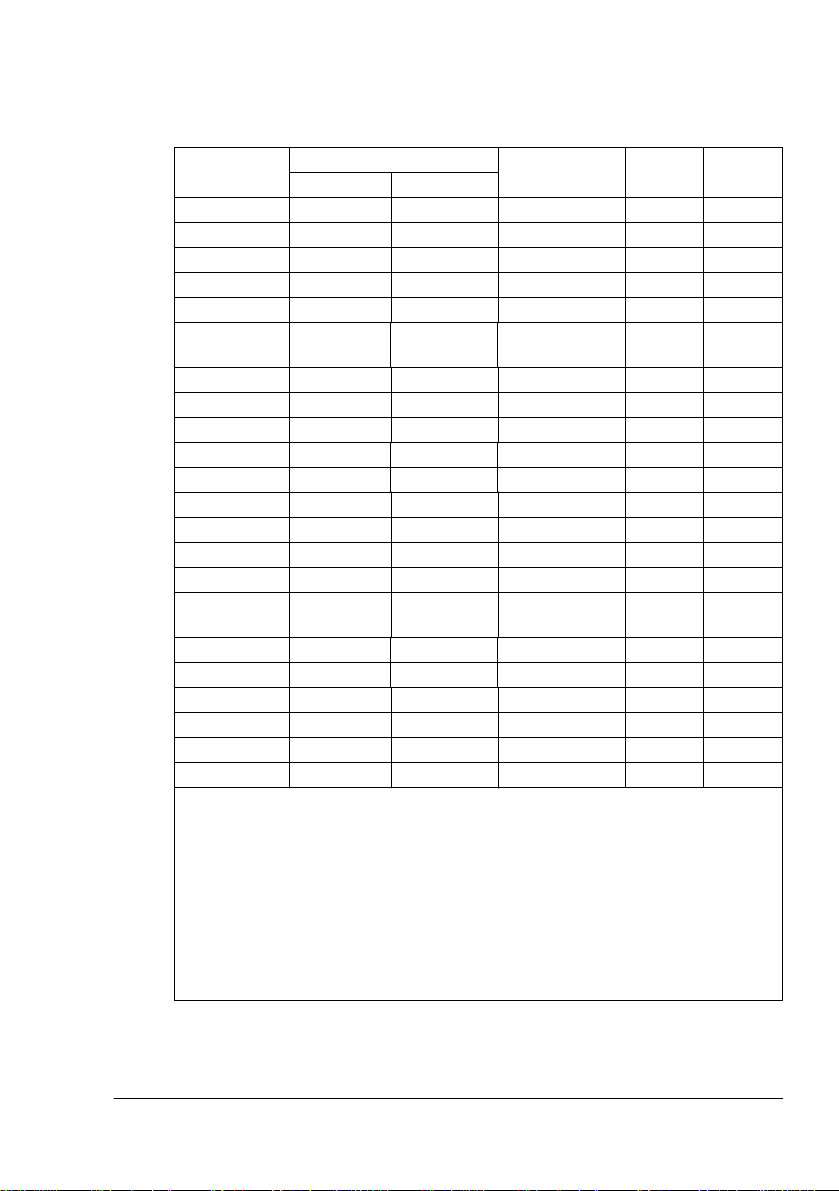

Media Sizes and Print Area

What si z es of medi a can I use?

Your printer supports full-color printing on all approved media sizes.

Media Media Size Media Type in

Inches Millimeters

A4 8.27x11.70 210.0x297.0 **** U/M/H Yes

A4 Transp. 8.27x11.70 210.0x297.0 Transparency U/M/H No

A5 5.93x8.28 148.0x210.0 **** U/M/H Yes

B5 (ISO) 6.93x9.84 176.0x250.0 Envelope M No

B5 (JIS) 7.16x10.11 182.0x257.0 **** U/M/H Yes

Custom

Paper Sizes

Env #10 4.13x9.50 105.0x241.0 Envelope M No

Env C5 6.37x9.01 162.0x229.0 Envelope M No

Env C6 4.49x6.38 114.0x162.0 Envelope M No

Env Chou #3 4.72x9.25 120.0x235.0 Envelope M No

Env Chou #4 3.54x8.07 90.0x205.0 Envelope M No

Env DL 4.33x8.66 110.0x220.0 Envelope M No

Env Monarch 3.88x7.50 98.0x191.0 Envelope M No

Executive 7.25x10.51 184.0x267.0 **** U/M/H Yes

Folio 8.50x13.00 216.0x330.0 **** U/M/H Yes

Japanese

Postcard

Kai 16 7.28x10.24 185.0x260.0 **** M Yes

Kai 32 5.12x7.28 130.0x185.0 **** M Yes

Legal 8.5x14.0 216.0x356.0 **** U/M/H Yes

Letter 8.5x11.0 216.0x279.0 **** U/M/H Yes

Letter Transp. 8.5x11.0 216.0x279.0 Transparency U/M/H No

Statement 5.5x8.5 140.0x216.0 **** M Yes

* The multip urpose tray media typ e set in the printer dr iver overrides the media type

set in the printer’s conf iguratio n menu.

** U=Upper (standard) media tray (500 sheets)

M=Multipurpose media tray (100 sheets)

H=High-capacity input feeder media trays (1x500 and 2x500 sheets)

*** Autodup l ex is avail abl e only on a magicol or 330 0 DN or on a magicol or 3300 wit h

an optional duplex kit installed.

****Choices are Plain Paper, Glossy Plain, Thick 2, or Thick 3. See “What media types

are supported?” on page 25. Thick 3 can be printed only from the multipurpose tray.

3.5 to 8.5 x

5.5 to 35.4

3.94x5.83 100.0x148.0 Postcard M No

88.9 to 215.9

x 139.7 to 900

Printer Driver*

Plain Paper M No

Input

Source**

Autoduplex***

Media Sizes and Print Area

19

Page 28

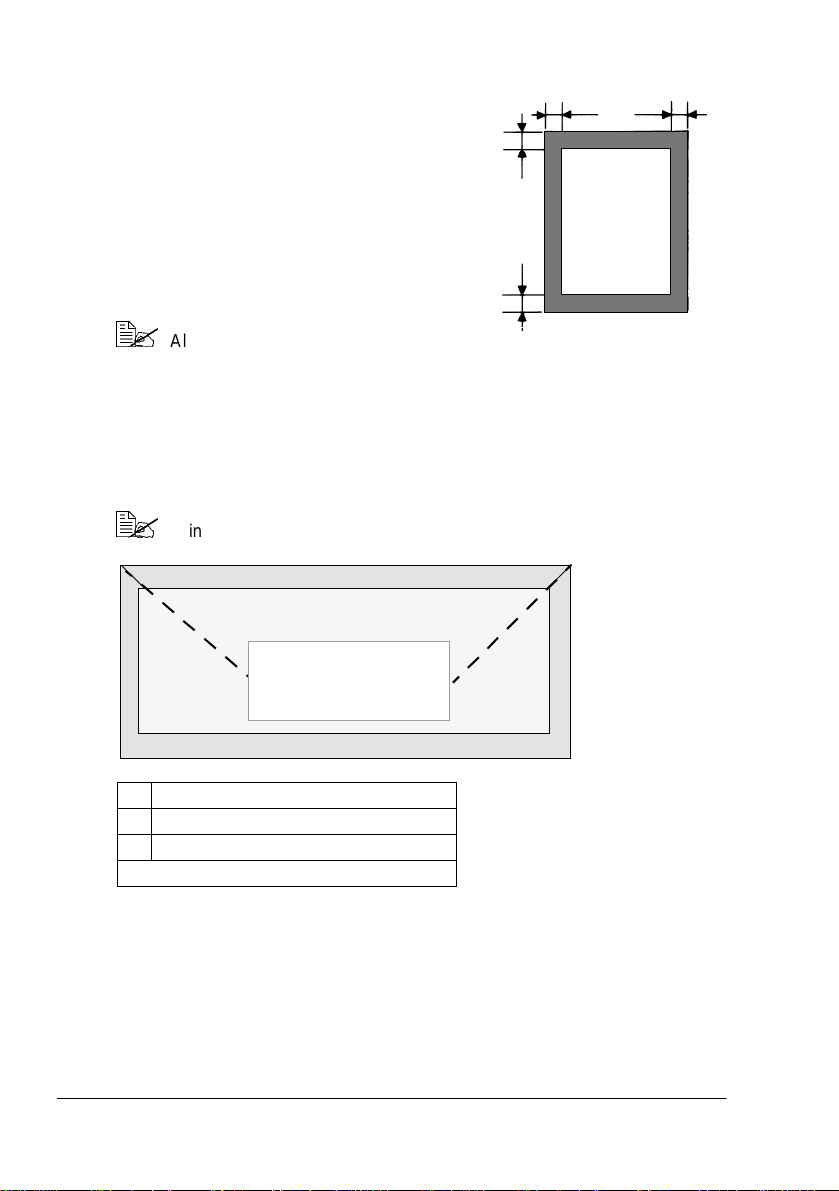

What is the image able (printab l e) area

Each media size has a specific imageable area,

the maximum area on which the printer can print

clearly and without distortion.

This area is subject to both hardware limits (the

physical media si ze and the margins required by

the print er) and so ftware constrai nts ( th e amoun t

of memory available for the full-page frame

buffer). The imageable (printable) area for all

media sizes is the page size minus 0.157"/4 mm

from all edges of the media.

All media is fed in por trai t (short edge f irst ) ori entat ion, and all media i s

output to the 250-sheet output tray on top of the printer.

What is the difference between a nonprintable and a

nonguaranteed area?

There is a 0.157"/4 mm nonprintable border for all edges on all media sizes

and types. Only envelopes have a nonguaranteed area.

Print orientation is determined by your application.

A

B

C

A Non pr in ta ble area 0.157"/4 mm

B Nonguaranteed area*

C Guaranteed area*

* Varies with envelope type

Page Margins

Margins are set through your application. Some applications allow you to set

custom page sizes and margins while others have only standard page sizes

and margins from which to choose. If you choose a standard format, you

may lose part of your image (due to imageable area constraints). If you can

custom-size your page, use those sizes given for the imageable area for

optimum results.

Media Sizes and Print Area20

Page 29

Image Alignment

If for any reason, you need to change the image alignment, you can do so in

several different ways:

Adjust the margins or page size through your app lication (recommended

method).

Use the printer’s control panel (Administrat ion/Engine/Image Alignment

menu).

Use the PostScript translate and scale operators to reduce image size

and change its placement on the page (requires PostScript programming

knowledge).

Outp ut Tray

The single face-down output tray has a capacity of 250 sheets of 2 0lb

(75 g/m

printer (with an optional 1x500 HCIF installed) or 1,600 sheets of media (with

an optional 2x500 HCIF installed), but don’t forget the output tray has a limit.

2

) bond paper. It is possible to load up to 1,100 sheets of media in the

Media

Try printing your data on a plain sheet of paper first to check placement.

All media is fed on the short edge.

Test a n y sto ck thic ker than 2 8 l b b ond (105 g/m²) to ensure that its

performance is acceptable. You should test the number of sheets of thick

stock a media tray can hold to ensure that its performance is acceptable.

Select Single User Mode or Network Mode (job modes) to specify

how media type requests are handled. For more information, refer to

the CrownBooks in PDF format on the Software Utilities CD-ROM.

–

In Single User Mode, you can select the media type and size from

the drivers. The driver will overwrite any settings on the printer.

–

In Network Mode, if special media is not selected in both the driver

and from the printer’s control panel, the printer uses plain paper

settings.

Select print quality to control the speed of printing, the fuser

temperature, and the amount of toner gloss.

Select the media type.

Media

21

Page 30

Why have different print qualities?

The specific print quality that is best depends upon your parti cular needs.

For example, you can control the the amount of toner gloss.

Which print quality is best?

Print

Quality

Standard 600x600 Full If getting your jobs printed in a

Quality 1200x1200 Full If getting your jobs printed with

Fine 1200x1200 Half If getting your jobs printed with

Resolution:

Dots per Inch

(dpi)

Speed Comment

timely manner is most important.

more g lo ss and bett er quality is

most important.

more gloss and best quality is

most important.

How do I choose print quality?

In the Windows printer driver (Features tab, Resolution [DPI] option), select

Quality.

You have the choice to customize the printing. For example, printing a glossy

(shinier) image on plain paper is less e xp e nsive, a nd you d on’t have to load

two media types in your trays.

Test any stock to ensure that its performance is acceptable.

Media22

Page 31

What media types are supported?

Media Type Selection Duplexing

Supported***

Plain Paper Yes 16–28 lb bond

Glossy Plain (the image is glossy, not the

media)

Thick 2 ** 105–162 g/m²

Thick 3* No 163–216 g/m²

Evelope*† N/A

Label Stock* N/A

Postcard*† N/A

Transparency N/A

N/A Not applicable

* Printed from the multipurpose tray only.

† Cannot be manually selected; automatically selected when an envelope

or postcard media size is selected; identified in the driver as Printer

Default.

** Duplexing is supported only up to 28 lb (105 g/m²) bond.

**

Duplexing is available only on a magicolor 330 0 DN or on a magicolor

3300 EN with an optional duplex kit installed.

Weight

(60–105 g/m²)

Media

23

Page 32

What is the difference between “glossy plain” paper and

“coated stock”?

The “Glossy Plain” media type r ef ers to the amount of glos s the toner has

when it is on the page. The image is glossy, not the media.

Coated stock is media that has a coating (shiny or otherwise) which may

not withstand the fusing temperature (between 316° F/158° C and 356° F/

180° C, depending on the media). Coated stock cannot be printed on the

magicolor 3300.

Since it may be difficult to tell whether media has a coating, check with

www.minolta-qms.com/support (click on Answer Base) for currently

approved media.

Attention

Using unsupported media will result in damaging the printer and

voiding your warranty.

How do I select the media type?

In the Windows printer driver (Paper tab, Media Type option), select Plain

Paper.

Plain Paper

Media Type Plain paper

Glossy plain

Input Tray Upper

Multipurpose

High-capaci ty input feeder (optional t rays)

Capacity Upper: 500 sheets* of 20 lb bond (75g/m²)

paper; capacity for other weights varies accordingly.

Multipurpose: 100 sheets of 20 lb bond

(75 g/m²) paper; capacity for other weights varies

accordingly.

High-capacity input feeder (each tray): 500

sheets* of 20 lb bond (75 g/m²) paper; capacity f or

other weights varies accordingly.

Orientation Upper or

optional

tray

Multipurpose tray

Face up

Face down

Media24

Page 33

Approved

Media

Weight 16–28 lb bond (60–105 g/m²)

Duplexing Supported up to 28 lb bond (105 g/m²).

Warning U sing u nsupported media such as ink jet paper will result in

Notes *For A5-size media, load up to 350 sheets only.

Use only media approved for laser products. Check

www.minolta-qms.com/support (click on Answer Base) for

currently approved media.

damaging the printer and voiding your warranty.

Printing a glossy (shinier) image on plain paper (Glossy

Plain media type) is less expensive.

Special Note about Custom (and Oversized) Media

When printing on media that is longer than 14"/355.6 mm, use the multipur-

pose tray extender and support the media with your hands underneath while

it feeds through the multipurpose tray.

Input Tray Multipurpose tray only

Capacity Up to 5 0 sheets, depending on the thickness of

the media

Orientation Face down

Weight Varies

Print Mode

to Sel ect

Duplexing Not support ed

Notes

Plain Paper

Width: 3.5"/88.9 mm up to 8.5"/215.9 mm

Thick Stock

Media Type Thick 2

Input Tray Thick 2—all input sources

Media

Length: 5.5"/139.7 mm up to 35.4"/900 mm

On media that is longer than 14"/355.6 mm, the printer

pauses for a calibration after every page.

Thick 3

Thick 3—multipurpose tray only

Capacity Up to 50 sheets, depending on the thickness of

the media

25

Page 34

Orientation Upper or

optional

tray

Multipurpose tray

Approved

Media

Weight Thick 2

Duplexing Thick 2 up to 105 g/m² is supported.

Notes

Use only media approved for laser products. Check

www. minolta-qms.com/ support (click on Answer Base) for

currently approved media.

Thick 3

Thick 2 over 105 g/m² and Thick 3 are not supported.

Test all thick stock to ensure acceptable perf o rmance.

43 lb (163 g/m²) bond is also referred to as 90 lb index

stock.

Test any stock such as rigid cardboard (maximum

216 g/m

Do not mix thick stoc k wit h any o ther media in the media

trays, as this will cause printer jamming.

Do not duplex envelopes and postcards.

Face up

Face down

100–159 g/m²

160–216 g/m²

2

) to ensure that the image does not shift.

Envelopes

Media Type Envelope

(Cannot be m anual ly selec ted; auto matical ly s el ected whe n an

envelope media size is selected; identified in the driver as

Printer Default.)

Input Tray Multipurpose tray only

Capacity Up to 100, depending on the thickness of the

envelopes

Orientation Face down

Approved

Media

Duplexing Not supported

Use only media approved for laser products. Check

www. minolta-qms.com/support (clic k on An swer Base) for

currently approved media.

Media26

Page 35

Glossy Media

Glossy Stock

Media Type Glossy Plain Paper—see “Plain Paper” on page 26.

Thick 2 or Thick 3—see “Thick Stock” on page 27.

Approved

Media

Duplexing Not supported over 28 lb (105 g/m²)

Notes See “What is the difference between “glossy pl ain” paper and

Use only media approved for laser products. Check

www.minolta-qms.com/support (click on Answer Base) for

currently approved media.

“coated stock”?” on page 26.

Glossy Toner

For all media types, in the print quality option on the Features Tab in the

printer driver , Quality h as mor e toner glo ss than St andard, and Fine has more

toner gloss than Quality.

Label Stock

Media Type Label stock

Input Tray Multipurpose tray only

Capacity Up to 50 sheets, depending on the thickness of

the labels

Orientation Face down

Approved

Media

Duplexing Not supported

Use only media approved for laser products. Check

www. minolta-qms.com/support (clic k on Answer Base) for

currently approved media.

Media

27

Page 36

Notes

Format label data within your appli cation. Try printing your

data on a plain sheet of paper first to check placement.

Avoid using labels with exposed adhesive; it may stick to

the fuser, causing labels to peel off and media jams to

occur.

Adhesive label stock is supported only in letter or A4

sheets.

A label consists of a face sheet (the printing surface),

adhesive, and a carrier sheet

— The face sheet must follow the plain paper

specification.

— The face sheet surface must cover the entire carrier

sheet, and no adhesive should come through on the

surface.

You can print continuously with label paper. However, this

could affect the media feed, depending on the media

quality and printing environment. If problems occur, stop

the continuous print and print one sheet at a time.

Check your application documentation for other

information on printing labels.

Postcards (Jap ane se size)

Media Type Postcard

(Cannot be manually selected; automatically selected when a

postcard media size is selected; identified in the driver as

Printer Default.)

Input Tray Multipurpose tray only

Capacity Up to 100 sheets, depending on the thickness of

the postcards

Orientation Face down

Approved

Media

Duplexing Not supported

Use only media approved for laser products. Check

www. minolta-qms.com/support (clic k on An swer Base) for

currently approved media.

Media28

Page 37

Notes

Use o nly Ja panese Post Office stand ard postcards

(3.9"x5.8" [100x148 mm]) recommended for laser printers.

If the postcar d is warpe d, press o n t he w arped area to

flatten it before putting it in the multipurpose tray.

Using preprinted multicolored postcards may result in

printer jamming.

Transparen cies (U nc oated Only)

Media Type Transparency

Input Tray All input sources

Capacity Up to 100 sheets, depending on the thickness of

the transparencies

Orientation Upper or

optional

tray

Multipurpose tray

Approved

Media

Use uncoated transparencies (also known as OHP film). We

recommend

Q-Media T ranspa renc y Media f or the magi colo r 3 300 serie s

(letter and A4 sizes only)

Face up

Face down

Only media recommended for laser products. Check

www.minolta-qms.com/support (click on Answer Base) for

currently approved media. (Often, you can’t tell by looking

at an unprinted transparency or by looking at the outside of

the package which transparencies are acceptable.) To

order approved transparencies, go to www.q-shop.com.

Media Size Only letter and A4 sized transparencies are supported.

Duplexing Not supported

Warning Using unsupported transparency media such as coated color

transparencies will result in damaging the printer and voiding

your warranty.

Media

29

Page 38

Notes

Use uncoated transparencies. You may print colored text

and/or images on monochrome transparencies.

Remove transparency media as soon as possible from the

output tray to avoid builtup static.

Do not handle transparencies too much. Do not fan large

quantities of transparencies before loading. If you touch the

face of transparencies wi th yo ur bare hands, print quality

may be affected.

You can print continuously with transparencies. However,

this could affect the media feed, depending on the media

quality, stati c build up, and printi ng environme nt. If you have

problems loading a large number of transparencies at a

time, try loading only 1–10 sheets. For the 500-sheet media

trays, tr y loading about 100 pages of plain paper first in the

tray to give more height to the transparency stack to reach

the feed rollers.

Media30

Page 39

Loading Media

Check www.minolta-qms.com/support (click on

Answer Base) for currently approved media.

How do I prepare and load the media?

Preparing the Media

Don’t unwrap the paper above the

printer, as thi s m i g h t cau se pape r

particles to fall into the printer. Don’t

fan large quantities of transparency

media.

Take off the top and bo ttom sheets of a ream of paper.

1

Holding a stack of approximately 500 sheets at a time, fan the stack to

2

preve n t s tatic b u ildup i n the paper before inserting it in a tray.

Loading and Printing Media

Refilling an Upper or Optional Media Tray

The illustrations show a standard upper media tray; however,

instr uctio ns are the s ame fo r a h igh-capacity inp ut feeder m edia tray.

Attention

Except for transparencies, do not mix media of different sizes, types, or

weights in the same tray, as this will cause printer jamming.

Loading Media

31

Page 40

Slide open the media tray until it

1

stops.

Using two hands, li ft it slight ly to

2

remove it from the printer and place

it on a flat surface.

Remove any media remaining in

3

the tray.

If necessary, adjust the t wo si de media guides and the en d medi a guide to

4

the proper positions.

Attention

The end media guide must be in dir ect ali gnment with the m edia size

mark in the bottom of the media tray. If the guide is not in the proper

hole, automatic paper size detection will not work.

Loading Media32

Page 41

T o set the tray for A5 paper , use the

5

provided A5 spacer.

a

Lift the A5 spacer from its

storage place in the media tray.

b

Gently lift the end media guide

to position the guide in the

proper media size hole.

A5

c

Insert the s pacer into its slo t and

load the A5 media.

Make sure that both the

end media guide and A5

spacer have clicked into

place.

A5

d

To return to other approved media sizes, remove the A5 spacer from

the slot. and then replace it in the tray.

A5

Load the media (plain or glossy) face-up with its top toward the back of

6

the printer.

Often, an arrow on the media

package label indicates the

printing-side of the media. If you

can’t remember which side of the

media to print on, remove the media

from the tray, rotate the stack 180°,

turn the stack over, and then place it

back in the tray.

A fill limit mark is provided on the

inside of the tray. The upper and

optional media trays hold 500 sheets of 20 lb bond (75 g/m²) paper.

Loading Media

1

2

A5

33

Page 42

If you have removed media from the tray, stack it with the new media,

7

even t he edge s, then reload it.

Attention

Readju s t th e m e d i a g u id e s af t er i n se rting th e m e dia. Improperly

adjusted guides may cause poor print quality, media jams, or printer

damage. The paper should fit easily between the guides. Make sure

the paper corners are not bent. Do not overfill the tray.

Slide the media tray back into the

8

printer.

Check the gauge to make sure the

tray is registering the loaded media.

Use this gauge to determine when the

tray needs to be refilled.

Loading Media34

Page 43

Refilling a Multipurpose Media Tray

Take off the top and bo ttom sheets of a ream of paper. Holding a stack

1

of approximately 100 sheets at a time, fan the stack to prevent static

buildup in the paper before inserting it in a tray. Don’t fan la rge quant it i e s

of transparency media.

Open the multipurpose tray.

2

Do not place heavy objects on the

multipurpose tray.

Adjust the media guides to the width

3

of the media.

The tray extender supports long

media.

Attention

Make sure the media fits easily

between the guides. Improperly

adjusted guides may cause poor

print quality, medi a jams, or

printer damage.

Make sure the guides are snug

enough to keep the media

straight, but not so tight that it

buckles.

Loading Media

35

Page 44

Place the media into the multip urpose

4

tray w i th the p r i n ting -side up.

Using Media Other Than Plain Paper

Attention

For information about media recommended for your printer, go to

www.minolta-qms.com/support, then click on the Answer Base.

Attention

Although your printer was designed for occasional printing on a wide

range of media types, it is not intended to print exclusively on a single

media type except plain p aper . Continuous printing o n media ot her than

plain paper (such as envelopes, labels, thick stock, or transparencies)

may adversely affect print quality or reduce engine life.

How do I load and print envelopes?

Envelope printing is supported only from the multipurpose tray.

In the printer driver ( P aper tab, Media Type option), select Envelope.

1

Select the size of envelope, eithe r

2

a

Pres s the MP S ize key and sc roll to the required envelope size

and select it, or

b

On the control panel, press the Menu key and select Operator

Control/Multi purpose Sz, and scroll to the required envelope size, and

select it.

Place the envelopes on a flat surface, and flatten them by pressing down

4

the corners.

Flex the envelope stack (including the edges) to remove any stiffness.

5

Correct any bent corners, and then tap the envelopes on a flat surface to

6

align them.

Loading Media36

Page 45

Open the multipurpose tr ay and ad just the media guide s to the length and

7

width of the envelopes.

Attention

Improperly adjusted guides may cause poor print quality, media

jams, or printer damage.

Fold th e f laps.

8

Make sure the adhesive

is dry.

Place the envelope stack into the

9

multip u rpo s e tr a y w it h th e p ri nti ngside down.

Print envelopes on the front address

side only. Some parts of the

envelope consist of three layers of

paper—the front, back, and flap.

Anything printed in these layered

regions may be lost or faded.

Check your application documentation to determine if the flap

should be p l a ced on the left or on the right. You can also print a

single envelope to check the orientation before printing multiple

copies.

Recheck the media guides to make sure they are adjusted to the width of

10

the envelopes.

Print the envelopes.

11

Loading Media

37

Page 46

Open the flap of each envelope immediately (before it cools) after the

12

envel op e is deliv ered t o th e output tray.

Because the envelopes pass through heated rollers, the gummed

area on the flaps may seal. Using envelopes with emulsion-based

glue avoids this problem.

How do I load and print glossy stock?

Refer to “Loading and Printing Media” on page 33.

How do I load and print labels?

Label printing is supported only from the multipurpose tray in letter or

A4 media sizes.

In the printer driver ( P aper tab, Media Type option), select Label Stock.

1

Select the size of label.

2

a

Pres s the MP S ize key and sc roll to the required label size

and select it, or

b

On the control panel, press the Menu key and select Operator

Control/Multipurpose Sz. Scroll to the required label size and

select it.

Load the label media face down in the multipurpose tray.

4

Adjust the media guides to the width of the label media.

5

Print the labels.

6

How do I load and print postcards?

Postcard printing is only supported from the multipurpose tra y.

In the printer driver ( P aper tab, Media Type option), select Postcard.

1

Select postcard.

2

a

Pres s the MP Size key and scrol l to Pos tcar d and select it, or

b

On the control panel, press the Menu key and select Operator

Control/Multipurpose Sz. Scroll to Postcard and select it.

Place the postcards on a flat surface, and flatten the corners by pressing

4

down them.

Loading Media38

Page 47

Load the postcard media

5

printing-side down in the

multipurpose tray.

Adjust the media guides to the

6

width of the postcards.

Print t he postcards .

7

How do I load and print thick stock?

Attention

Do not mix thick stock wi th any othe r media in the sam e tray, as this will

cause printer jamming.

Most thick stock printing is supported from any inputbin. However,

media type “Thick 3” can be printed only from the multipurpose tray.

In the printer driver (Paper tab, Media Type option), select Thick 2 (105–

1

162 g/m

Remove any media in the media tray.

2

Load the new media.

3

Slide the media tray back into the printer.

4

Print the thick stock.

5

2

).

How do I load and print transparencies?

Attention

Use only transparency media approved for this printer. Check

www.minolta-qms.com/support (click on Answer Base) for currently

approved media.

In the printer driver (Paper tab, Media Type option), select Tr ans pare n cy

1

and (Paper tab, Paper Size option), select either Letter or A4.

Select the size of transparency in one of the following ways:

2

Multipurpose Tray—Press the MP Size key and scroll to the

required transparency size and select it, or

Loading Media

39

Page 48

All input trays—On the control panel, press the Menu key and

select Operator Control/Multipurpose Sz. Scroll to the required trans-

parency size and select it.

Do not fan transparencies. Fanning transparencies will build up static

electricity.

Load the media tray.

3

Upper and Optional Trays

Put media face side down in the

upper or optional trays.

Multipurpose Tray—Open the multipurpose tray, adjust the media

guide s to the width of the transparencies, and then place the transpar-

encies into the tray with the printing side up.

OHP

Attention

Improperly adjusted guides may cause poor print quality, media

jams, or printer damage.

Print the transpar encies.

4

Immediately remove the printed transparencies from the output tray.

Loading Media40

Page 49

System Memory (RAM) Requ irements

Basic Funct i on alit y

Monochrome Color

Simplex Duplex Simplex Duplex

Size S/Q F S/Q F S/Q F S/Q F

Letter/A4256 MB (Base memory)

Legal

Notes: S = St andard print quality (600x600 dpi, full speed)

Q = Quality print quality (1200x1200 dpi, full speed)

F = Fine print quality (1200x1200 dpi, half speed)

Maximum Performan ce

Monochrome Color

Simplex Duplex Simplex Duplex

Size S/Q F S/Q F S/Q F S/Q F

Letter/A4 256 MB (Base memory)

Legal 288 MB

Notes: S = Standard print quality (600x600 dpi, full speed)

Q = Quality print quality (1200x1200 dpi, full speed)

F = Fine print quality (1200x1200 dpi, half speed)

Duplexing

Select paper with high opacity for duplex (2-sided) printing. Opacity refers to

how effectively paper blocks out what is written on the opposite side of the

page. If the paper has low opacity (high translucency), then the printed data

from one side o f the p age wi ll show thr ough to t he other s ide. F or best results ,

print a small quantity to make sure the opacity is acceptable.

Only up to 28 lb bond (105 g/m²) plain paper can be autoduplexed.

System Memory (RAM) Requ irements

41

Page 50

How do I manually duplex?

Manual duplexing is available on all magicolor 3300 printers.

Media ja ms ma y occur if the printed sheet( s) re inse rted are n o t

entirely flat.

In the printer driver ( P aper tab), sel ect Simplex, then double-click OK.

1

In the Print Document screen, select All.

2

Select and print the Odd-Numbered Pages.

3

Remove the media, flip it over, and select and print the Even-Numbered

4

Pages.

How do I autoduplex?

Autoduplexing is available only on the magicolor 3300 DN or on the magicolor 3300 with an optional duplex kit installed.

Refer to the tables in “Sys tem Memory (RAM ) Requireme nts” on page

43 for information on how much memory is required for duplex print-

ing. Very high coverage pages may revert to 600 dpi when duplex

printing if enough memory is not in stalled. With letter media, two

sheets are in the media path; with legal, only one is. Therefore, it

requires more memory to print the two sheets of letter media.

Attention

Duplexing envelopes, glossy stock heavier than 28 lb bond (105 g/m2),

labels, postcards, thick stock heavier than 28 lb bond (105 g/m

transfer media, and transparencies is not supported.

2

),

To print duplex (both sides of the sheet), load the media with the top of

1

the m edia towa rd the back of the tray. When prin ti ng fro m the

Upper or optional trays, load the media printing-side up.

Multipurpose tray, load the media printing-side down.

In autoduplexing, the back side is printed first and the front side is

printed last.

Set the driver—for example: in the Layout tab, Duplex Options, select

2

Long Edge (flipped horizontally as in a loose-leaf notebook), o r Short

Edge (flipped vertically as on a clipboard) as the Duplex option.

Click OK.

3

Duplexing42

Page 51

Where can I order MINOLTA-QMS -approved media or get more

information?

See your application documentation for specific information on formatting

data and printing.

Check www.minolta-qms.com/support (click on Answer Base) for

currently approved media.

See the Service & Support Guide f or a complete listing of support telephone

numbers.

Duplexing

43

Page 52

Page 53

Color Printing

3

Page 54

Introduction

Your printer features advanced color laser technology that produces inexpensive and durable color prints at 1200x1200 dpi on plain paper, envelopes,

labels, thick stock, and transparencies .

Color Registration

Anytime you notice shadowi ng on your pri nted documents and whene ver you

replace the imaging unit, adjust the side (scan direction) color registration

using the following control panel sequence.

The p rint e r automatic a lly adjusts the registration in the top-to-bottom

(feed) direction.

The following illustration shows the options available in the Administration/

Engine/Registration menu.

ADMINISTRATION

ENGINE

REGISTRATION

REGISTRATION PG MAGENTA YELLOW CYAN

YES/NO -7 ... 0 ... +7 -7 ... 0 ... +7 -7 ... 0 ... +7

To verify and/or change the side-to-side color registration, use the following

control panel sequenc e.

Press this ke y . .. (until) the message windows displa y s ...

Online IDLE (and the Online button is off)

Menu CONFIGURATION

OPERATOR CONTROL

Next ( )

Select ADMINISTRATION

Next ( )

Select ENGINE

Next ( )

CONFIGURATION

ADMINISTRATION

COMMUNICATIONS

ADMINISTRATION

ENGINE

ALIGNMENT

ENGINE

REGISTRATION

Introduction46

Page 55

Pre s s t h is key . . . (unt il ) the m essage window s displa y s ...

Select REGISTRATION

REGISTRATION PG

Select REGISTRATION PG

YES

Select REGISTRATION

REGISTRATION PG

When the Side Color Registration Page pri nts, not e the number below each of

the three color swatches that identifies the set of lines that align the straightest.

-3-4-5-6-7 -2 -10+1+2 +3 +4 +5 +6 +7

If the straightest lines are all at the “0” position (as in the illustration

above) for all thre e colors , you do no t need to adj ust th e registration. Press

Online twice to r e turn the printer t o o n line and IDLE.

If the straightest lines are in a position other than “0” (+4 in thi s exampl e),

continue with these instructions.

-3-4-5-6-7 -2 -10+1+2 +3 +4 +5 +6 +7

Next ( )

Press the Next key until the color you want to

adjust is in the message window. For example,

Select Press Select to see the current registration setting

Next ( ) or

Previous ( )

Select 0

Color Registra tion

REGISTRATION

MAGENTA

for this color. For example,

MAGENTA

+4

Press the Next or Previous key until the registration number of the color to be adjusted is set at

the baseline of “0.” For example,

MAGENTA

0

IS SELECTED

and then

REGISTRATION

MAGENTA

47

Page 56

Press this ke y . .. (until) the message windows displa y s ...

Next ( ) or

Previous ( )

Select REGISTRATION PG

Select REGISTRATION

Wait for another Side Color Registration Page to print. Note the number

below each of the three color swatches that identifies the set of lines that

align the straightest.

If the straigh te st lines ar e all at the “0” position for all three colors, you do

not need to adjust the registration. Press Online twice to return the printer

to online and IDLE.

If the straightest lines are in a position other than “0” (+2 in this example),

continue with these instructions.

Next ( )

Select MAGENTA

Next ( ) or

Previous ( )

REGISTRATION

REGISTRATION PG

YES

REGISTRATION PG

-3-4-5-6-7 -2 -10+1+2 +3 +4 +5 +6 +7

Press Next to go back to the color to be a d ju sted.

For example,

REGISTRATION

MAGENTA

0

Press the Next or Previous key until the registration number of the strai ghtest line is displ a yed.

For example, +2 the illustration above.

MAGENTA

+2

Select +2

IS SELECTED

and then

REGISTRATION

MAGENTA

Next ( ) or

Previous ( )

Select REGISTRATION PG

REGISTRATION

REGISTRATION PG

YES

Color Registration48

Page 57

Pre s s t h is key . . . (unt il ) the m essage window s displa y s ...

Select REGISTRATION

REGISTRATION PG

Another Side Color Registration Page prints. Confirm that the color

registration is correct. Repeat the process for the other colors, if necessary.

Online (twice

) IDLE (and the Online button is on).

The printer automatically saves each number as you progress

through the choices using the Next or Previous key. The printer

does not have to be restarted for the changes to take effect.

PRISMLASER™ Technology

How does PRISMLASER work?

PRISM (P

an all-in -one imaging unit technology where all four

color toners may be printed in one pass. The

photo-reactive image goes through an imagesplittin g modu le where th e colors are div id ed.

hoto-Reactive Image Splitting Module) is

Color Management and Control

The magicolor 3300 offers a host of color screening, matching, and calibration tools for both the beginner and professional color user.

MINOLTA-QMS Q

Color management does not mean all devices will match exactly. It does

ensure the closest possible color transformation. MINOLTA-QMS Q

technology offers four methods for color matching across devices:

MINOLTA-QMS Q

Supplied ICC printer profiles

Built-in color rendering dictionaries (CRDs)

Supplied PANTONE®* Color matching tables

MINOLTA-QMS Q

produce professional quality, colorized documents without the use of sophisticated manual optimization techniques.

* Pantone, Inc.’s check-standard trademark for color reproduction and color reproduction materials.

COLOR

COLOR

COLOR

technology automatically optimizes color output to

Technology

COLOR

automatic color correction

PRISMLASER™ Technology

49

Page 58

The following is a summary of MINOLTA-QMS Q

correction features:

Ease of use across applications: With MINOLTA-QMS Q

easy to get great color from a PowerPoint presentation as it is from a

deskt op pu blishing applicatio n , s u ch as QuarkXPr e ss. MIN OLTA-QMS

Q

professional color users to navigate.

Single-button control: Whether accessing through the printer driver, or

from the printer’s front panel, MINOLTA-QMS Q

controls enable automatic correction of uncalibrated RGB or CMYK

color files.

Printer-resident CMS: Because MINOLTA-QMS Q

color correction is built into the printer, it works well in all computing environments and with most design, publishing, and office applications.

Industry-standard profiles: Q

files for compatibility with popular input and output devices.

Supports host-based color management systems: Easily disable

MINOLTA-QMS Q

host-based ColorSync or ICM color matching.

Profiles for common monitors and output devices: MINOLTA-QMS

Q

and printing presses.

Download device profiles: For custom color matching, Q

ports downloaded (to disk only) ICC profiles.

Support for Internet standard: MINOLTA-QMS Q

Internet-standard default color matching.

Individual page element correction: Q

(matches) graphics, text, and images on a single page using printerresident CRDs .

’s color matching methods are simple for both novice and

COLOR

uses industry-standard ICC pro-

COLOR

automatic color correction when using

COLOR

offers default color matching for a variety of common monitors

COLOR

COLOR

automatic color

COLOR

COLOR

’s single-button

COLOR

automatic

COLOR

COLOR

uses sRGB for

COLOR

separately color corrects

, it’s as

sup-

Further Information

For further information about MINOLTA-QMS color management, refer to the

CrownBooks.

MINOLTA-QMS QCOLOR Technology50

Page 59

Replacing

Consumables

4

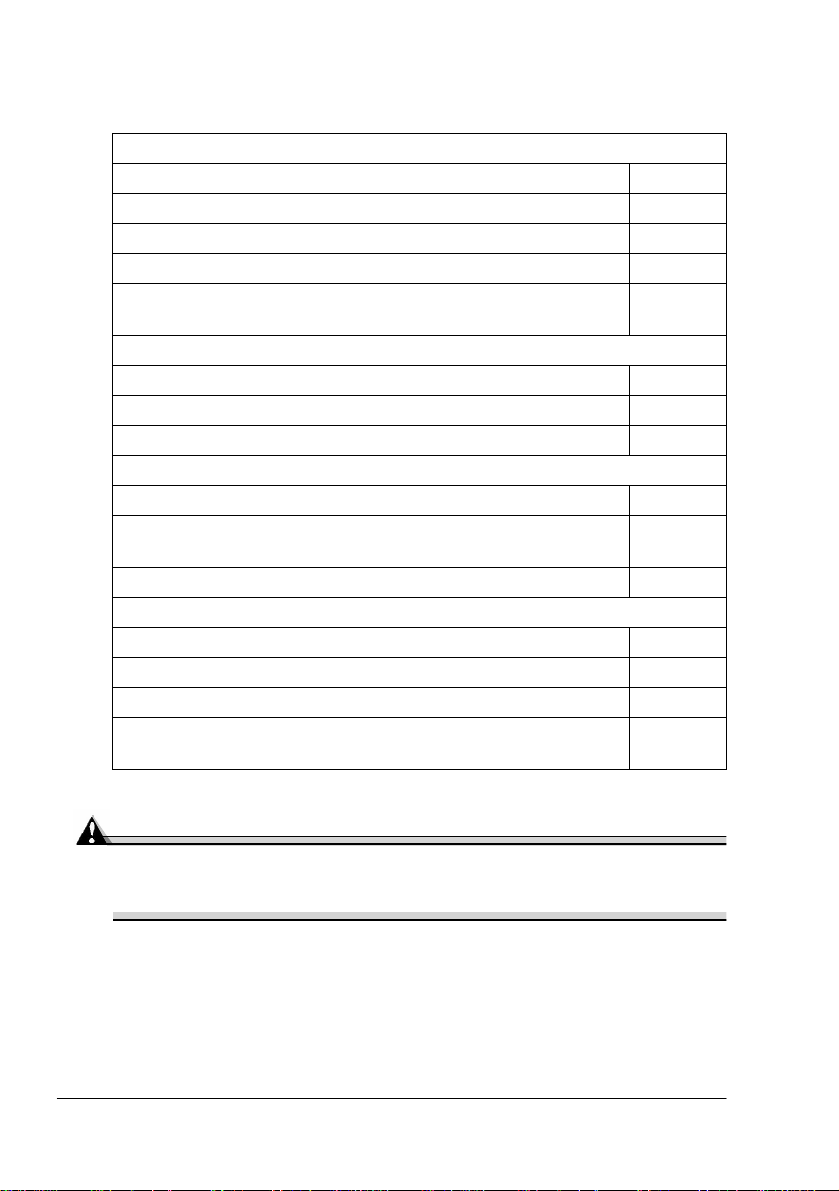

Page 60

Introduction

Item Page

“What is a consumable?” page 52

“What are sheets, faces, and pages?” page 52

“When do consumables have to be replaced?” page 53

“What is the life expectancy of consumables” page 54

“How do I order consumables?” page 56

“Where can I get more information?” page 56

“How do I replace the fuser unit?” page 67

“How do I replace the media feed roller(s)?” page 69

“How do I replace the imaging unit?” page 63

“How should I handle toner cartridges?” page 57

“How do I replace a toner cartridge?” page 58

“How do I replace the transfer unit?” page 57

Consumable Life Expectanc ies

What is a consumable?

A consumable is an item that needs to be replaced at regular intervals. For

the magicolor 3300, consumables include:

Fuser unit

Imag ing un it

Media feed roller