Page 1

magicolor® 3100 Series

1750051-001B

Service Manual

The essentials of imaging

www.minolta-qms.com

Page 2

ii

Page 3

Introduction

Page 4

Page 5

1. Trademarks

The following are trademarks or registered trademarks of their respective owners. Other product names

mentioned in this manual may also be trademarks or registered trademarks of their respective owners.

Registered trademarks are registered in the United States Patent and Trademark Office; some trademarks

may also be registered in other countries. QMS, magicolor, and the MINOLTA-QMS logo are registered

trademarks of MINOLTA-QMS, Inc. Minolta is a trade-mark of Minolta Co., Ltd.

2. Copyright Notice

This manual is Copyrighted © 2001 by MINOLTA-QMS, Inc., One Magnum Pass, Mobile, AL 36618. All

Rights Reserved. This manual may not be copied in whole or in part, nor transferred to any other media or

language, without the express written permission of MINOLTA-QMS, Inc.

Introduction

v

Page 6

Cautions for operation

1. Marks giving caution

Maintenance operations requiring special cautions or additional information to descriptions of this manual

are presented as "Warning", "Caution", or "Note", according to their nature.

If instructions are not observed, death or serious injury may be caused.

If instructions are not observed, injuries of workers or physical damages to assets

(including this laser printer) may result.

Particularly important essentials for procedures, steps, rules, and others.

Reference Incidental information to descriptions.

2. Related documents

▼ Instruction manuals (standard user manuals)

Describe operation and handling of this laser printer.

▼ Performance specifications

Describe in detail various specifications of this laser printer.

(In the event of discrepancy between this manual and the performance specifications, the performance

specifications shall take preference.)

▼ Spare parts list

Information on maintenance parts (spare parts) for this laser printer

3. Safety

To prevent possible accidents during maintenance operation, you should observe strictly the "Warning" and

"Caution" information in this manual.

Dangerous operations and operations out of range of this manual should be absolutely avoided.

Generally various processes not covered by this manual may be required in actual operation, which should

be performed carefully always giving attention to safety.

3.1 Power source

Keep the power supply off during maintenance operation to prevent electric shock, burns and other

damages. Keep the power plug disconnected during the maintenance operation.

If the power supply should be kept connected for measurement of voltage or other similar reasons,

sufficient care should be given to prevent electric shock, by following the procedures of this manual.

vi

Page 7

Introduction

While the printer is ON, never touch live parts if not required absolutely.

Power is supplied to the power switch / inlet (LVPS ASSY) even while the printer is off.

Never touch its live components.

Do not touch live parts unless otherwise specified.

vii

Page 8

3.2 Driving units

When servicing gears or other driving units, be sure to turn them OFF and plug off. Drive them manually

when required.

Never touch the gears or other driving units while the printer is running.

3.3 High-temperature units

When servicing high-temperature units (securing unit, etc.), be sure to turn them OFF to prevent burns,

injuries and other troubles, remove the power plug and start service processes after they have cooled down

enough.

Immediately after completion of operation, they are still hot. Start services after more

than 40 minutes.

3.4 Laser beams

•If your eyes are exposed to laser beams, you may lose your eyesight.

•Never open the cover if warning label for laser beams is attached there.

•Before disassembling and reassembling this laser printer, be sure to turn it OFF.

•When servicing this laser printer while it is running, be sure to follow the

procedures specified in this manual.

•You should understand the features of the laser beams which are capable of

having an injurious action on the human body, not to extend the danger over the

workers as well as other people around the printer.

Laser beams have features as follows:

•Frequencies are smaller in width than other beams (sun and electric bulbs) and

phases are uniform so that high monochromatic and convergence performance

can be obtained and thin beams of light can reach places at a long distance.

•Due to the high convergence, beams are concentrated in high density and high

temperature, which is dangerous to human body.

Reference: Laser beams of this laser printer is invisible rays which you cannot see.

viii

Page 9

Introduction

3.5 Warning/caution labels

Warning labels and caution labels are attached to this laser printer to prevent accidents Check those labels

for their peeling or stain when servicing the printer.

3.5.1 Caution label for high-temperature units

ix

Page 10

4. List of Abbreviations

ADC Automatic Density Control MPT Multipurpose Tray

AG Analog Ground MSI Multi Sheet Inserter

AUX Auxiliary N/F Normal Force

B/W Blank and White NP No Paper

BCR Bias Charge Roller NVM Non Volatile Memory

BTR Bias Transfer Roller (Image Transfer Roller) OPC Organic Photo Conductor

BUR Back Up Roller P/H Paper Handling

C Cyan PCDC Pixel Count Dispense Control

CART Cartridge PHD Printer Head (Imaging Cartridge)

CCW Counterclockwise Pixel Picture Cell (Picture Element)

CL Clutch PPM Prints per Minute

CLN Cleaning (or Cleaner) PV Print Volume

CLK Clock PWB Printed Wiring Board

CR Charge Roller R/H Right Hand

CRU Customer Replaceable Unit REGI Registration

CRUM CRU Monitor ROS Raster Output Scanner

CW Clockwise RTN Return

DB Developing Bias SEF Short Edge Feed

DTS Detack Saw SG Signal Ground

EP Electrophotography SNR Sensor

FDR Feeder SOL Solenoid

FG Frame Ground SOS Start of Scan

FRU Field Replaceable Unit SPI Scans per Inch

Hex Hexadecimal SYNC Synchronous

I/F Interface T/A Take Away

IDT Intermediate Drum Transfer TC Toner Concentration

ID Image Density (or Identification) TEMP Temperature

KBlackTRTransfer

L/H Left Hand TRANS Transport

L/P Low Paper WDD Wide Range Dynamic Damper

LD Laser Diode XERO Xerographic

LEF Long Edge Feed Y Yellow

M Magenta

x

Page 11

Unpacking the Printer

The printer must be carried horizontally with two or more persons.

Extreme care must be taken to avoid personal injuries

Check visually the printer for evidence of any damages.

Peel all tapes off the printer.

Remove protection parts (2 pieces) from the paper tray.

Introduction

xi

Page 12

xii

Page 13

Contents

Page 14

Page 15

CONTENTS

Introduction ..................................................................................................... iii

1. Trademarks ...................................................................................................................... v

2. Copyright Notice............................................................................................................... v

1. Marks giving caution........................................................................................................ vi

2. Related documents.......................................................................................................... vi

3. Safety .............................................................................................................................. vi

3.1 Power source .........................................................................................................................................vi

3.2 Driving units ......................................................................................................................................... viii

3.3 High-temperature units ........................................................................................................................ viii

3.4 Laser beams ........................................................................................................................................ viii

3.5 Warning/caution labels...........................................................................................................................ix

4. List of Abbreviations......................................................................................................... x

Contents........................................................................................................ 13

Chapter 1 Troubleshooting ........................................................................ 1-23

1. Progressing with the Troubleshooting .........................................................................1-25

1.1 Flow of Troubleshooting.................................................................................................................... 1-25

1.2 Preparatory Requirements................................................................................................................ 1-26

1.3 Cautions for Service Operations ....................................................................................................... 1-27

1.4 Cautions for FIP Use......................................................................................................................... 1-28

2. Level 1 FIP ..................................................................................................................1-30

2.1 Level 1 FIP ........................................................................................................................................ 1-30

2.2 Flow of Level 1 FIP ........................................................................................................................... 1-30

3. Level 2 FIP ..................................................................................................................1-31

3.1 Level 2 FIP ........................................................................................................................................ 1-31

3.2 Error / Status Code List..................................................................................................................... 1-31

3.3 Operating / Clearing the Error........................................................................................................... 1-34

3.4 Error Code FIP .................................................................................................................................. 1-37

3.5 Image Trouble FIP ............................................................................................................................ 1-81

3.6 Roller Circumferences ...................................................................................................................... 1-81

3.7 Other FIPs......................................................................................................................................... 1-92

4. Preventive Maintenance.............................................................................................. 1-94

Chapter 2 Operation of Diagnostics........................................................... 2-95

1. Diagnostics for a Standalone Printer ...........................................................................2-97

1.1 General ............................................................................................................................................. 2-97

1.2 Printing Method ................................................................................................................................. 2-97

Page 16

1.3 Test Print Pattern .............................................................................................................................. 2-98

2. Diagnostics Using the MINOLTA- QMS magicolor 3100 Diagnostics

(Hanabi Service Commander) .........................................................................................2-99

2.1 General ............................................................................................................................................. 2-99

2.2 Preparation ..................................................................................................................................... 2-100

2.3 Operation of magicolor 3100 Diagnostics ....................................................................................... 2-101

2.4 Test Print......................................................................................................................................... 2-103

2.5 Input Test ........................................................................................................................................ 2-104

2.6 Output Test ..................................................................................................................................... 2-107

2.7 Operation of EEPROM.................................................................................................................... 2-110

Chapter 3 Removal and Replacement Procedures ................................. 3-119

1. Removal and Replacement Procedures.................................................................... 3-121

1.1 Before starting service work............................................................................................................ 3-121

1.2 Description of procedures ............................................................................................................... 3-122

RRP1. COVERS............................................................................................................3-123

RRP1.1 CONSOLE PANEL HANABI (PL1.1.1) .................................................................................... 3-123

RRP1.2 COVER ASSY FRONT HEAD (PL1.1.2) ................................................................................. 3-124

RRP1.3 FAN FUSER (PL1.1.7) ............................................................................................................ 3-126

RRP1.4 COVER TOP MAIN (PL1.1.9) .................................................................................................3-128

RRP1.5 COVER ASSY TOP PHD (PL1.1.10) ...................................................................................... 3-129

RRP1.6 COVER REAR (PL1.1.20)....................................................................................................... 3-130

RRP1.7 LINK:L (PL1.1.23).................................................................................................................... 3-131

RRP1.8 LINK:R (PL1.1.23) ................................................................................................................... 3-132

RRP1.9 COVER SIDE R (PL1.1.24)..................................................................................................... 3-133

RRP1.10 COVER ASSY FRONT IN (PL1.1.25) ................................................................................... 3-134

RRP1.11 COVER MSI (PL1.1.26) ........................................................................................................ 3-136

RRP1.12 TRAY ASSY MSI (PL1.1.28) ................................................................................................. 3-137

RRP1.13 COVER ASSY FRONT (PL1.1.29) ........................................................................................ 3-138

RRP1.14 COVER SIDE L (PL1.1.30) ................................................................................................... 3-140

RRP2. PAPER CASSETTE...........................................................................................3-141

RRP2.1 ROLL ASSY (PL2.1.1)............................................................................................................. 3-141

RRP2.2 HOLDER RETARD (PL2.1.3)..................................................................................................3-142

RRP2.3 CASSETTE ASSY FRONT (REFERENCE ONLY) ................................................................. 3-144

RRP3. PAPER FEEDER ...............................................................................................3-146

RRP3.1 CHUTE ASSY TURN (PL3.1.2)............................................................................................... 3-146

RRP3.2 COVER CASSETTE REAR (PL3.1.3)..................................................................................... 3-148

RRP3.3 FEEDER ASSY UNIT (REFERENCE ONLY) ......................................................................... 3-150

RRP3.4 HOUSING ASSY FEEDER L (REFERENCE ONLY) .............................................................. 3-152

RRP3.5 HOUSING ASSY FEEDER R (REFERENCE ONLY) ............................................................. 3-154

RRP3.6 SENSOR HUM TEMP (PL3.2.2) ............................................................................................. 3-156

RRP3.7 HARNESS ASSY OPFREC (PL3.2.3)..................................................................................... 3-157

16

Page 17

Table of Contents

RRP3.8 SWITCH ASSY SIZE (PL3.2.4)...............................................................................................3-158

RRP3.9 LEVER LOW PAPER (PL3.2.7) .............................................................................................. 3-160

RRP3.10 INDICATOR (PL3.2.8) ........................................................................................................... 3-162

RRP3.11 GUIDE INDICATOR (PL3.2.10) ............................................................................................ 3-164

RRP3.12 PICKUP ASSY (PL3.3.1)....................................................................................................... 3-166

RRP3.13 ROLL ASSY FEED (PL3.3.2) ................................................................................................3-168

RRP3.14 SENSOR PHOTO:NO PAPER (PL3.3.3) .............................................................................. 3-170

RRP3.15 SENSOR PHOTO:LOW PAPER (PL3.3.3) ........................................................................... 3-171

RRP3.16 ACTUATOR NO PAPER (PL3.3.4) ....................................................................................... 3-172

RRP3.17 LINK ACTUATOR (PL3.3.5).................................................................................................. 3-173

RRP3.18 SOLENOID FEED (PL3.3.16) ............................................................................................... 3-174

RRP3.19 CLUTCH ASSY TURN (PL3.3.17) ........................................................................................ 3-175

RRP3.20 ROLL ASSY TURN (PL3.3.19).............................................................................................. 3-176

RRP3.21 ROLL ASSY (PL3.3.22)......................................................................................................... 3-177

RRP4. HOUSING ASSY RETARD................................................................................3-178

RRP4.1 HOUSING ASSY RETARD (PL4.1.1) ..................................................................................... 3-178

RRP4.2 ROLL TURN (PL4.1.2) ............................................................................................................ 3-179

RRP4.3 ROLL ASSY RETARD (PL4.1.5) ............................................................................................. 3-180

RRP4.4 CLUTCH TURN (PL4.1.9) ....................................................................................................... 3-182

RRP4.5 STUD RTD (PL4.1.10) ............................................................................................................ 3-183

RRP5. FRONT ASSY IN ...............................................................................................3-184

RRP5.1 FRONT ASSY IN (PL5.1.1) ..................................................................................................... 3-184

RRP5.2 SENSOR ADC ASSY (PL5.1.11) ............................................................................................ 3-187

RRP5.3 SENSOR TNR FULL (PL5.1.13) ............................................................................................. 3-188

RRP5.4 FUSER DRIVE ASSY (PL5.1.18)............................................................................................ 3-190

RRP5.5 LATCH R (PL5.1.21) ............................................................................................................... 3-192

RRP5.6 LATCH L (PL5.1.30) ................................................................................................................ 3-193

RRP6. CHUTE ASSY OUT ........................................................................................... 3-194

RRP6.1 CHUTE ASSY OUT (PL6.1.1) .................................................................................................3-194

RRP6.2 SENSOR PHOTO:FULL STACK (PL6.1.4) ............................................................................. 3-197

RRP6.3 ACTUATOR FULL (PL6.1.5) ................................................................................................... 3-198

RRP6.4 SENSOR PHOTO:DUP (PL6.1.4) ........................................................................................... 3-199

RRP6.5 SENSOR PHOTO:MSI (PL6.1.4) ............................................................................................ 3-200

RRP6.6 ELIMINATOR ASSY (PL6.1.9) ................................................................................................3-201

RRP6.7 ROLL DUP (PL6.1.12)............................................................................................................. 3-202

RRP6.8 ACTUATOR DUP (PL6.1.13) ..................................................................................................3-204

RRP6.9 LATCH OUT (PL6.1.18) .......................................................................................................... 3-206

RRP6.10 ROLL ASSY FEED (PL6.1.27) .............................................................................................. 3-207

RRP6.11 ACTUATOR MSI (PL6.1.37) .................................................................................................3-208

RRP6.12 SOLENOID FEED MSI (PL6.1.40) ........................................................................................ 3-209

RRP6.13 SHAFT ASSY ROLL FEED (REFERENCE ONLY)............................................................... 3-210

RRP6.14 PLATE ASSY BOTTOM MSI (PL6.1.42) ............................................................................... 3-212

RRP7. CHUTE ASSY EXIT...........................................................................................3-213

RRP7.1 CHUTE ASSY EXIT (PL7.1.1)................................................................................................. 3-213

17

Page 18

RRP7.2 ROLL EXIT (PL7.1.4) ............................................................................................................. 3-214

RRP7.3 ROLL MID (PL7.1.5)................................................................................................................ 3-215

RRP7.4 MOTOR ASSY DUP (PL7.1.8) ................................................................................................ 3-216

RRP8. BTR ASSY & FUSER.........................................................................................3-217

RRP8.1 FUSER ASSY (PL8.1.1).......................................................................................................... 3-217

RRP8.2 ROLL ASSY EXIT (PL8.1.3).................................................................................................... 3-218

RRP8.3 ACTUATOR EXIT (PL8.1.7).................................................................................................... 3-220

RRP8.4 BTR UNIT ASSY (PL8.1.12) ................................................................................................... 3-221

RRP8.5 STRAP (PL8.1.13)................................................................................................................... 3-222

RRP9. XEROGRAPHICS..............................................................................................3-224

RRP9.1 ROS ASSY (PL9.1.1) .............................................................................................................. 3-224

RRP9.2 HSG ASSY BIAS (PL9.1.4) ..................................................................................................... 3-226

RRP9.3 CHUTE ASSY REGI (PL9.1.6)................................................................................................3-228

RRP9.4 SENSOR PHOTO:REGI (PL9.1.8).......................................................................................... 3-230

RRP9.5 ACTUATOR REGI (PL9.1.9) ................................................................................................... 3-231

RRP9.6 OHP SENSOR ASSY (PL9.1.12) ............................................................................................ 3-232

RRP10. TCRU ASSY ....................................................................................................3-236

RRP10.1 HOLDER TCRU ASSY UNIT (REFERENCE ONLY) ............................................................ 3-236

RRP10.2 HOLDER TCRU ASSY (1) (PL10.1.1)................................................................................... 3-239

RRP10.3 HOLDER TCRU ASSY (2) (PL10.1.2)................................................................................... 3-240

RRP10.4 HOLDER TCRU ASSY (3) (PL10.1.3)................................................................................... 3-241

RRP10.5 HOLDER TCRU ASSY (4) (PL10.1.4)................................................................................... 3-242

RRP10.6 SWITCH TCRU ASSY (PL10.1.18)....................................................................................... 3-243

RRP10.7 SENSOR TONER LOW (PL10.1.8)....................................................................................... 3-244

RRP10.8 PWBA EEPROM STD (PL10.1.16) ....................................................................................... 3-245

RRP10.9 S-HVPS (PL10.1.17) ............................................................................................................. 3-246

RRP11. FRAME & DRIVE.............................................................................................3-247

RRP11.1 LEVER DRUM:L (PL11.1.4) .................................................................................................. 3-247

RRP11.2 LEVER DRUM:R (PL11.1.4) .................................................................................................3-250

RRP11.3 ACTUATOR I/R (PL11.1.8) ................................................................................................... 3-253

RRP11.4 DEVE DRIVE ASSY (PL11.1.13) .......................................................................................... 3-254

RRP11.5 MAIN DRIVE ASSY (PL11.1.14) ........................................................................................... 3-255

RRP11.6 PWBA ASSY EARTH (PL11.1.16) ........................................................................................ 3-256

RRP12. ELECTRICAL...................................................................................................3-258

RRP12.1 PWBA HNB MCU (PL12.1.1) ................................................................................................ 3-258

RRP12.2 FAN REAR (PL12.1.2) .......................................................................................................... 3-260

RRP12.3 CONTROLLER BOARD (PL12.1.4)(TBD)............................................................................. 3-261

RRP12.4 LVPS (PL12.1.10) ................................................................................................................. 3-262

RRP12.5 HARNESS ASSY AC SW (PL12.1.11) .................................................................................. 3-264

RRP12.6 PWBA HNB DRV (PL12.1.12) ............................................................................................... 3-265

RRP12.7 BOX ASSY MCU/ESS (REFERENCE ONLY) ...................................................................... 3-266

RRP12.8 HOUSING ASSY CONTACT (PL12.1.14) ............................................................................. 3-268

18

Page 19

Table of Contents

Chapter 4 Plug/Jack (P/J) Connector Locations...................................... 4-271

1. Connector [P (plug) / J (jack)]....................................................................................4-273

1.1 List of P/J ........................................................................................................................................ 4-273

1.2 P/J layout diagram .......................................................................................................................... 4-275

Chapter 5 Parts List ................................................................................. 5-279

1. Parts List....................................................................................................................5-281

1.1 Caution for use of parts list ............................................................................................................. 5-281

Chapter 6 Principles of Operation............................................................ 6-313

1. Printing Process ........................................................................................................6-315

1.1 Summary of Printing Process ......................................................................................................... 6-315

1.2 Schematic Diagram for Printing Processes ....................................................................................6-316

1.3 Description of Printing Process Techniques ................................................................................... 6-317

2. Flow of Print Data...................................................................................................... 6-330

2.1 Data Flow........................................................................................................................................ 6-330

3. Drive Transmission Route .........................................................................................6-331

3.1 MAIN DRIVE ASSY ........................................................................................................................ 6-331

3.2 DEVE DRIVE ASSY........................................................................................................................ 6-332

3.3 HOLDER TCRU ASSY (Y, M, C, K)................................................................................................ 6-332

3.4 FUSER DRIVE ASSY ..................................................................................................................... 6-333

3.5 MOTOR ASSY DUP ....................................................................................................................... 6-333

3.6 Gear • Layout .................................................................................................................................. 6-334

4. Paper Transport.........................................................................................................6-335

4.1 Paper Transport Route (without option).......................................................................................... 6-335

4.2 Layout of Paper Transport Route.................................................................................................... 6-336

5. Functions of Major Functional Components ..............................................................6-337

5.1 Paper Cassette ............................................................................................................................... 6-338

5.2 Paper Feeder .................................................................................................................................. 6-340

5.3 Housing Assy Retard ...................................................................................................................... 6-342

5.4 Front Assy In ................................................................................................................................... 6-344

5.5 Chute Assy Out ............................................................................................................................... 6-346

5.6 Chute Assy Exit............................................................................................................................... 6-348

5.7 BTR Assy & Fuser .......................................................................................................................... 6-350

5.8 Xerographics ................................................................................................................................... 6-352

5.9 TCRU Assy ..................................................................................................................................... 6-354

5.10 Frame & Drive ............................................................................................................................... 6-356

5.11 Electrical ....................................................................................................................................... 6-358

6. MODES .....................................................................................................................6-360

6.1 Print Mode....................................................................................................................................... 6-360

19

Page 20

6.2 Operation Modes ............................................................................................................................ 6-360

7. Control.......................................................................................................................6-361

7.1 Control of Paper Size ...................................................................................................................... 6-361

7.2 Selective Control on Paper Pick-up Unit ......................................................................................... 6-361

7.3 ROS Light Quantity Control ............................................................................................................ 6-361

7.4 Process Control .............................................................................................................................. 6-362

7.5 Color Registration Control............................................................................................................... 6-365

7.6 BTR UNIT ASSY Control ................................................................................................................ 6-366

7.7 Toner Control .................................................................................................................................. 6-367

7.8 Fuser Control .................................................................................................................................. 6-368

Chapter 7 Wiring Diagrams and Signal Information................................. 7-369

1. General Wiring Diagram............................................................................................7-371

1. Wiring Diagram between Parts................................................................................. 7-373

1.1 Configuration................................................................................................................................... 7-373

1.2 Notes on Using the Wiring Diagram between Parts........................................................................ 7-375

Chapter 8 Printer Specifications .............................................................. 8-401

1. Configuration of Printer..............................................................................................8-403

1.1 Basic Configuration ......................................................................................................................... 8-403

1.2 Functional Configuration ................................................................................................................. 8-403

2. Electrical Properties...................................................................................................8-404

2.1 Power Source ................................................................................................................................. 8-404

2.2 Power Consumption........................................................................................................................ 8-404

3. Mechanical Properties............................................................................................... 8-404

3.1 Dimensions/Mass of Printer ............................................................................................................ 8-404

3.2 Dimensions/Mass of Universal Paper Tray (standard paper supply - 500 sheets) ......................... 8-405

3.3 Dimensions/Mass of Consumables (CRU) ..................................................................................... 8-405

3.4 Installation Space (min. installation space) ..................................................................................... 8-406

4. Functions...................................................................................................................8-407

4.1 Recording System........................................................................................................................... 8-407

4.2 Exposure System ............................................................................................................................ 8-407

4.3 Development System ...................................................................................................................... 8-407

4.4 Fixing System ................................................................................................................................. 8-407

4.5 Resolution ....................................................................................................................................... 8-407

4.6 Operation Mode .............................................................................................................................. 8-407

4.7 Speed Mode.................................................................................................................................... 8-408

4.8 Print Mode....................................................................................................................................... 8-408

4.9 Paper Mode .................................................................................................................................... 8-408

4.10 Warm-up Time .............................................................................................................................. 8-409

4.11 FPOT (First Print Output Time)..................................................................................................... 8-409

20

Page 21

Table of Contents

4.12 Continuous Printing Speed ........................................................................................................... 8-409

4.13 Printing Area ................................................................................................................................. 8-410

4.14 Input Properties............................................................................................................................. 8-411

4.15 Output Properties.......................................................................................................................... 8-412

4.16 Paper ............................................................................................................................................ 8-412

5. Consumables.............................................................................................................8-413

5.1 Items of Consumables .................................................................................................................... 8-413

5.2 Consumable Life ............................................................................................................................. 8-413

5.3 Parts Requiring Periodical Replacement ........................................................................................ 8-414

6. Operating Environment.............................................................................................. 8-414

6.1 Installation Temperature / Humidity ................................................................................................ 8-414

6.2 Installation Altitude.......................................................................................................................... 8-414

6.3 Installation Horizontality .................................................................................................................. 8-414

6.4 Ambient Lighting ............................................................................................................................. 8-414

7. Safety / Environment Conditions ...............................................................................8-414

7.1 Safety Standard .............................................................................................................................. 8-414

7.2 Laser Safety Standard .................................................................................................................... 8-414

7.3 EMI.................................................................................................................................................. 8-414

7.4 Noise............................................................................................................................................... 8-415

8. Print image Quality .................................................................................................... 8-415

8.1 Image Quality Guarantee Conditions .............................................................................................. 8-415

9. Option........................................................................................................................8-415

9.1 Options to be Installed by Users ..................................................................................................... 8-416

Index ......................................................................................................... I-417

21

Page 22

22

Page 23

Chapter 1 Troubleshooting

Page 24

Page 25

Chapter 1 Troubleshooting

Troubleshooting in this manual assumes use of Diag. tools (maintenance tools).

However, the troubleshooting allows for the case where the Diag tools are not used.

You can correct troubles according to these troubleshooting procedures after

understanding them well.

1. Progressing with the Troubleshooting

After making sure of actual condition of a trouble, proceed with the troubleshooting process making use of

the Fault Isolation Procedure (FIP), “Operation of Diagostics” (Chapter 2), “Plug/Jack (P/J) Connector

Locations” (Chapter 7), and “Principles of Operation” (Chapter 6).

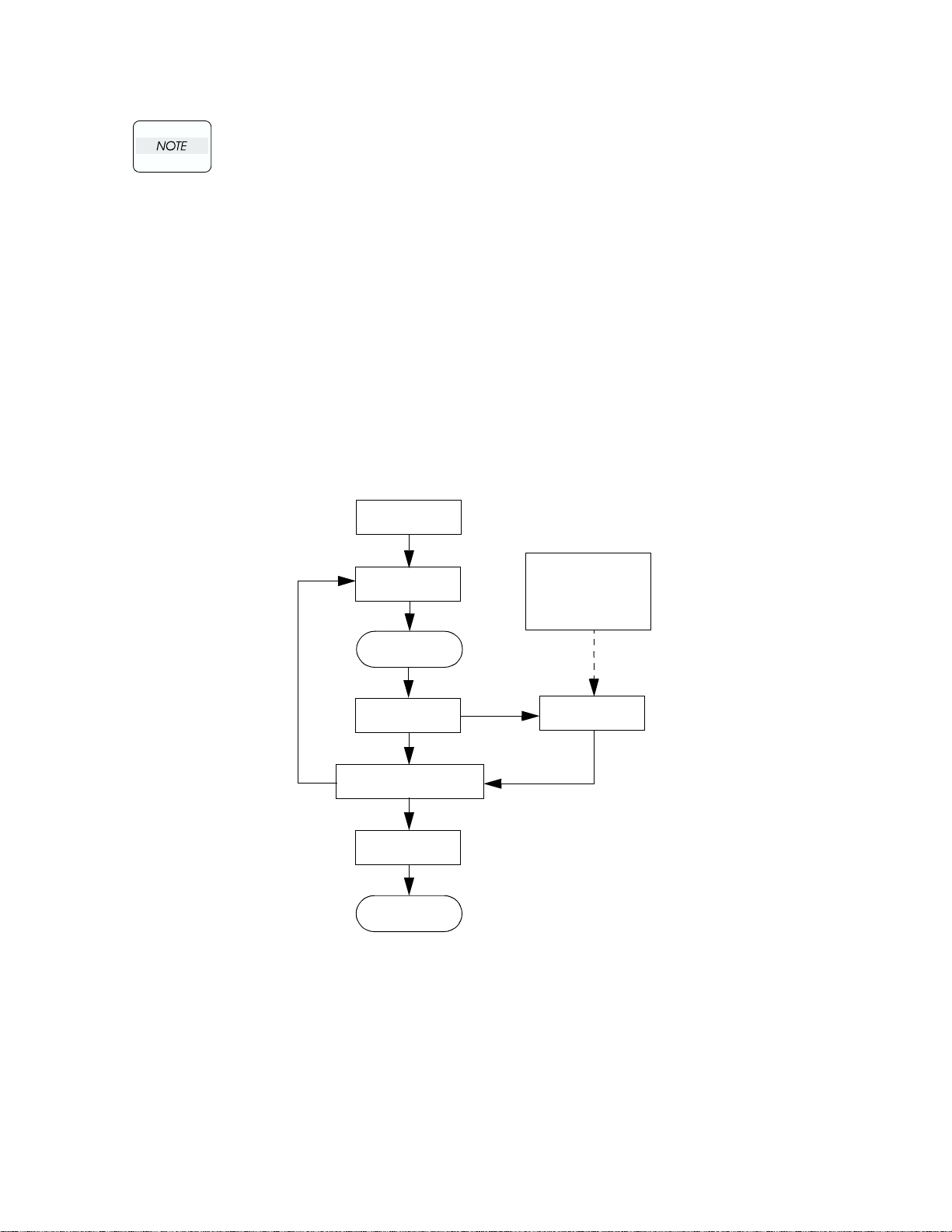

1.1 Flow of Troubleshooting

Flow of the troubleshooting is as follows:

Prior check

Condition check

Start

Level 1 FIP

Trouble recovery check

Preventive

maintenance

End

Diagnostic operation

Operational principle

Wiring connection

diagram

Level 2 FIP

1-25

Page 26

1.2 Preparatory Requirements

Be sure to check the following items before starting any troubleshooting procedures:

1) Voltage of the power supply is within the specifications (measure the voltage at the electric outlet).

2) Power cord is free from breakage, short-circuit, disconnected wire, or incorrect connection in the power

cord.

3) The laser printer is properly grounded.

4) The laser printer is not installed at a place subjected to too high temperature, too high humidity, too low

temperature, too low humidity or rapid change of temperature.

5) The laser printer is not installed close to water service, humidifier, heat generating unit, or fire, in very

dusty place, or a place exposed to air flow from the air conditioning system.

6) The laser printer is not installed in a place where volatile gas or inflammable gas is generated.

7) The laser printer is not installed under direct sunbeams.

8) The laser printer is installed in a well-ventilated place.

9) The laser printer is installed on a stout and stable plane.

10) Paper used meets specifications (standard paper is recommendable).

11) The laser printer is handled properly.

12) Parts which should be periodically replaced are replaced each time when specified number of sheets

have been printed.

1-26

Page 27

Chapter 1 Troubleshooting

1.3 Cautions for Service Operations

1) Be sure to remove the power cord except when it is specifically required.

If the printer is kept ON, never touch the conductive parts while it is not specifically

required.

The power switch/inlet of LVPS is live even while the power supply is cut off. Never

touch the live parts.

2) When checking some parts with covers removed and with the interlock and safety and power switches

ON, remove the connector (P/J151) on the ROS ASSY except when it is specifically required.

When checking some parts with covers removed and with the interlock and safety and

power switches ON, laser beams may be irradiated from the ROS ASSY. Since it is

dangerous, be sure to remove the connector (P/J151) while it is not required.

3) When checking some parts with the left cover removed and power ON, be sure to remove the

connector (P/J5011) on the HVPS while it is not required.

When checking some parts with the left cover removed and power ON, high voltage

may be applied by the HVPS. Be sure to remove the connector (P/J5011) on the HVPS.

When connecting the connector (P/J5011) on the HVPS according to the instructions

of the FIP, never touch the HVPS and parts of high voltage.

4) When using Diag. tools or other tools of high voltage, be sure to keep them covered except when

otherwise specified.

When using Diag.Tool or other tools of high voltage, never touch parts of high voltage.

When using Diag.Tool or other tools of high voltage, be sure to follow the procedure of

this manual.

5)When operating the driving units using the Diag or other tools, be sure to keep them

covered unless otherwise specified.

When operating the driving units using the Diag or other tools, never touch the driving

units. When operating the driving units using Diag or other tools, be sure to observe

the procedures in this manual.

6) When touching hot parts, be careful not to get burnt.

7) Workers should wear a wrist band or the like to remove static electricity from their body, grounding

their body while working.

1-27

Page 28

1.4 Cautions for FIP Use

1) It is assumed in the FIP that the printer controller (CONTROLLER PWB) is normally functioning. If the

trouble cannot be corrected by troubleshooting, replace the printer controller with a normal one and

check for proper operation again.

If the trouble is still not corrected, replace the major parts and then related parts in succession and

confirm according to the procedure of the "Initial check" and "Major check parts".

2) When troubleshooting according to the FIP, normal HNB MCU PWB, Imaging Unit (PHD) or other

parts may be necessary for isolation of failed parts. Prepare them in advance.

3) In the initial check according to the FIP, check only items which can be simply checked.

4) In the initial check according to the FIP, check the constitutive parts of the major check parts and

related parts, as well as major check parts.

5) When working with the printer, Be sure to remove the power cord except when required specifically.

Never touch live parts if not required, while the power cord is connected.

6) Connector condition is denoted as follows:

[P/J12] → Connector (P/J12) is connected.

[P12] → Plug side with the connector (P/J12) removed (except when attached directly to the board).

[J12] → Jack side with the connector (P/J12) removed (except when attached directly to the board).

7) [P/J1-2PIN <=> P/J3-4PIN] in the FIP means measurement with the plus side of the measuring instru-

ment connected to [P/J1] and the minus side to [4PIN] of [P/J3].

8) [P/J<=>P/12] in the FIP means measurement for all terminals corresponding between [P/J1] and [P/J2]

referring to "Wire connecting diagram".

9) In [P/J1-2PIN <=> P/J3-4PIN] in the FIP where voltage is measured, [P/J3-4PIN] on the rear minus

side is always at the AG (analog ground), SG (signal ground), or RTN (return).

Therefore, after checking of proper continuity between AGs, SGs, or RTNs respectively, the rear minus

side can be connected to the PIN of AG, SG or RTN instead of [P/J3-4PIN].

However, care should be taken not to mistake since [AG], [SG], and [RTN] are not on the same level.

10) Measure the voltage of small connectors with the special tool. Handle the tool with care, as the leading

edge of the tool is pointed.

11) When measuring the voltage, set the PDH ASSY, FUSER ASSY, BRT ASSY and paper tray, close the

FRONT COVER ASSY and power ON if not required specifically.

12) Numerical values in the FIP are only for standard. If numerical values are approximate, they should be

considered permissible.

1-28

Page 29

Chapter 1 Troubleshooting

13) Parts which are always removed to check as indicated in the FIP and procedures for that purpose are

not specifically referred to here. They should be handled carefully.

14) "Replacement" in the FIP indicates replacement of parts which are considered to be the source of trou-

ble to be checked after replacing those parts, assemblies containing them, or parts (HIGH ASSY).

15) In the FIP, the paper pick-up unit by means of the paper tray at the lower part of the printer is referred

to as "try 1", the first level of the paper pick-up unit feeder unit as "try 2", and the second level as the

"tray3".

16) In the FIP, existence and non-existence of Diag tools (maintenance tools,) are distinguished in some

cases. Correct troubles according to the instructions in the FIP.

17) In the FIP, procedures are differentiated depending on specifications. Correct troubles according to the

instructions in the FIP.

18) For optional parts, some troubleshooting procedure may follow the manual for those options, of which

you should take note.

Keep those manuals for the optional parts when required.

1-29

Page 30

2. Level 1 FIP

2.1 Level 1 FIP

The level 1 FIP is the first step for trouble diagnosis. The level 1 FIP isolates the presence of various

troubles including error codes, and the level 2 FIP provides a guide for proceeding of the troubleshooting.

2.2 Flow of Level 1 FIP

Ask the operator about trouble status

Is operator’s operating method correct?

Is error code displayed?

Y

Image quality FIP

N

Is trouble related to

image quality?

Y

Y

N

Print in the mode where the trouble

occurred to check if error or jam

occurs

N

Instruct how to operate

1-30

Level 2 FIP

Y

Level 2 FIP Other FIP

N

Page 31

Chapter 1 Troubleshooting

3. Level 2 FIP

3.1 Level 2 FIP

The Level 2 FIP is the trouble diagnostic procedure to sort various troubles in addition to the error codes. In

the troubleshooting, executing the steps given in the FIP or checking procedure allows you to find out a

cause of trouble in a short time.

3.2 Error / Status Code List

This error / status cord list is based on the interface specifications.

Since the error / status codes are represented by the printer controller on the printer,

display on the printer is shown in parentheses below.

Reference FIP

1

2

3

4

5

6

7

8

9

10

11

12

13

Name of error

Contents of error

Yellow Toner Cartridge Detached (Yellow Toner Cartridge Missing)

Cartridge sensor detected no-toner cartridge.

Magenta Toner Cartridge Detached (Magenta Toner Cartridge

Missing)

Cartridge sensor detected no-toner cartridge.

Cyan Toner Cartridge Detached (Cyan Toner Cartridge Missing)

Cartridge sensor detected no-toner cartridge.

Black Toner Cartridge Detached (Black Toner Cartridge Missing)

Cartridge sensor detected no-toner cartridge.

PHD Detached (Imaging Unit Missing)

Machine detected no-Imaging Unit (PHD).

BTR Detached (Transfer Unit Missing)

Machine detected no-Transfer Unit (BTR).

Fuser Detached (Fuser Unit Missing)

Machine detected no-FUSER ASSY.

CRUM ID Error (Call for Service CRUM ID Error)

ID of Imaging Unit (PHD) is different from the recorded ID.

CRUM ID Error (Invalid Imaging Unit)

ID of Imaging Unit (PHD) is different from the recorded ID.

Media Type Mismatch (Media Type Mismatch)

1. Plain paper was detected in the printing by selecting OHP.

2. OHP was detected in the printing by selecting plain paper.

Feed Jam (Media Feed Jam)

Regi sensor cannot detect paper within specified time.

Regi Jam (Media Jam Registration)

Regi sensor cannot detect passage of paper within specified time.

Fuser Jam (Media Jam Fuser)

Exit sensor cannot detect passage of paper within specified time.

Reference

FIP page #

37

38

39

40

41

42

43

44

45

46

47

50

51

1-31

Page 32

Reference FIP

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

Name of error

Contents of error

Duplex Jam (Media Jam Duplex)

Duplex jam sensor cannot detect passage of paper within specified

time.

ROS Failure (Call for Service ROS Motor)

1. Laser power down.

2. SOS signal not detected.

Fuser Failure (Call for Service Fuser Failure)

1. Temperature exceeding 235°C detected consecutively 4 times.

2. Temperature below 120°C detected consecutively 4 times.

3. Resistance value of STS sensor over 2437KW detected

consecutively 4 times.

4. Target temperature is not reached more than 60 seconds after

the fuser lamp lighted up.

5. After the target temperature is reached, the fuser lamp was kept

ON for more than specified time.

6. Value of the STS sensor does not change after the lamp lights up.

7. Temperature exceeding 230°C detected during printing process

consecutively twice.

NV-RAM Error (Call for Service NV-RAM Error)

Error of NV-RAM

ADC Sensor Error (ADC Sensor Dustiness Warning)

Power down of ADC sensor

Fan Motor Failure (Call for Service Fan Motor Error)

Failure of Fan Motor

Low Density Error (Call for Service Low Density)

Toner density is low.

Firmware Error (Call for Service Firmware Error)

Error of software

Environment Sensor Error (Call for Service ENV Sensor Error)

1. The temperature over +100°C or below -20°C was detected.

2. The humidity over 100% was detected.

Yellow Toner Empty (Yellow Toner Low)

Yellow toner emptied.

Magenta Toner Empty (Magenta Toner Low)

Magenta toner emptied.

Cyan Toner Empty (Cyan Toner Low)

Cyan toner emptied.

Black Toner Empty (Black Toner Low)

Black toner emptied.

PHD Life Over (Replace Imaging Unit)

Imaging Unit (PHD) life expired.

BTR Life Over (Replace Transfer Unit)

Transfer Unit (BTR) life expired.

Fuser Life Over (Replace Fuser Unit)

FUSER ASSY life expired.

Reference

FIP page #

52

54

55

56

57

58

60

61

62

63

64

65

66

67

68

69

1-32

Page 33

Chapter 1 Troubleshooting

Reference FIP

30

31

32

33

34

35

36

37

38

39

40

Name of error

Contents of error

ADC Sensor Dustiness (ADC Sensor Dustiness Error)

ADC sensor signal level below specified value.

Front Cover (Front Cover Open)

Front cover open.

BTR Life Warning (Transfer Unit Life Low)

Transfer Unit (BTR) life running out.

Fuser Life Warning (Fuser Life Low)

Fuser life running out.

Paper Empty (Put %s in %s Bin)

Paper in the paper cassette exhausted.

Upper Cassette Detached (Adjust Input Bin)

Paper cassette dislocated.

Full Stack (Output Bin Full)

Delivery tray full of paper

Yellow Toner Empty 2 (Yellow Toner Empty)

Yellow toner emptied.

Magenta Toner Empty 2 (Magenta Toner Empty)

Magenta toner emptied.

Cyan Toner Empty 2 (Cyan Toner Empty)

Cyan toner emptied.

Black Toner Empty 2 (Black Toner Empty)

Black toner emptied.

Reference

FIP page #

70

71

72

73

74

75

76

77

78

79

80

1-33

Page 34

3.3 Operating / Clearing the Error

In the table below, "shutdown" means that control over motors, ROS ASSY, FUSER

ASSY and so on is stopped after a certain time.

In the table below, "print" means that printing is continued even if error message is

generated.

Diag Error Message

(Display Error Mes-

sage)

Yel low To ne r

Cartridge Detached

(Yellow Toner

Cartridge Missing)

Magenta Toner

Cartridge Detached

(Magenta Toner

Cartridge Missing)

Cyan Toner Cartridge

Detached (Cyan

Toner Cartridge

Missing)

Black Toner Cartridge

Detached (Black

Toner Cartridge

Missing)

PHD Detached

(Imaging Unit

Missing)

BTR Detached

(Transfer Unit

Missing)

Fuser Detached

(Fuser Unit Missing)

CRUM ID Error (Call

for Service CRUM ID

Error) or (Invalid

Imaging Unit)

Media Type Mismatch

(Media Type

Mismatch)

Feed Jam (Media

Feed Jam)

Regi Jam (Media Jam

Registration)

Fuser Jam (Media

Jam Fuser)

Operation

Method of clearing

Shutdown

Toner cartridge replacement

Shutdown

Toner cartridge replacement

Shutdown

Toner cartridge replacement

Shutdown

Toner cartridge replacement

Shutdown

Imaging Unit (PHD) replacement

Shutdown

Transfer Unit (BTR) replacement

Shutdown

Power OFF/ON after replacing the FUSER ASSY

Shutdown

Imaging Unit (PHD) replacement

Shutdown

Power OFF/ON after removing the jam paper

Next paper is not picked up after a sheet of paper is delivered during operation

Open and close the front cover after removing the jammed paper

Shutdown

Open and close the front cover after removing the jammed paper

Shutdown

Open and close the front cover after removing the jammed paper

1-34

Page 35

Chapter 1 Troubleshooting

Diag Error Message

(Display Error Mes-

sage)

Duplex Jam (Media

Jam Duplex)

ROS Failure (Call for

Service ROS Motor)

Fuser Failure (Call for

Service Fuser Failure)

NV-RAM Error (Call

for Service NV-RAM

Error)

ADC Sensor Error

(ADC Sensor

Dustiness Warning)

Fan Motor Failure

(Call for Service Fan

Motor Error)

Low Density Error

(Call for Service Low

Density)

Firmware Error (Call

for Service)

Environment Sensor

Error (Call for Service

Sensor Error)

Yellow Toner Empty

(Yellow Toner Low)

Magenta Toner Empty

(Magenta Toner Low)

Cyan Toner Empty

(Cyan Toner Low)

Black Toner Empty

(Black Toner Low)

PHD Life Over

(Replace Imaging

Unit)

BTR Life Over

(Replace Transfer

Unit)

Fuser Life Over

(Replace Fuser Unit)

ADC Sensor

Dustiness (ADC

Warning)

Front Cover (Front

Cover Open)

Operation

Method of clearing

Shutdown

Open and close the front cover after removing the jammed paper

Shutdown

Power ON/OFF

Shutdown

Power ON/OFF

Shutdown

Power ON/OFF

Shutdown

Power ON/OFF

Shutdown

Power ON/OFF

Shutdown

Power ON/OFF

Shutdown

Power ON/OFF

Shutdown

Power ON/OFF

Shutdown

Toner cartridge replacement

Shutdown

Toner cartridge replacement

Shutdown

Toner cartridge replacement

Shutdown

Toner cartridge replacement

Shutdown

Imaging Unit (PHD) replacement

Shutdown

Transfer Unit (BTR) replacement

Shutdown

Clearing the counter after replacing the FUSER ASSY

Print

Open and close the front cover after cleaning the sensor

Shutdown

Close the front cover

1-35

Page 36

Diag Error Message

(Display Error Mes-

sage)

Yellow Toner Near

Empty (Yellow Toner

Low)

Magenta Toner Near

Empty (Magenta

Ton er Lo w)

Cyan Toner Near

Empty (Cyan Toner

Low)

Black Toner Near

Empty (Black Toner

Low)

PHD Life Warning

(Imaging Unit Life

Low)

BTR Life Warning

(Transfer Unit Life

Low)

Fuser Life Warning

(Fuser Life Low)

ADC Sensor

Dustiness (ADC

Sensor Dustiness

Error)

Paper Empty (Put

Paper in Input Bin)

Upper Cassette

Detached (Adjust

Input Bin)

Full Stack (Output Bin

Full)

Yellow Toner Empty 2

(Yellow Toner Empty)

Magenta Toner Empty

2 (Magenta Toner

Empty)

Cyan Toner Empty 2

(Cyan Toner Empty)

Black Toner Empty 2

(Black Toner Empty)

Operation

Method of clearing

Print

Toner cartridge replacement

Print

Toner cartridge replacement

Print

Toner cartridge replacement

Print

Toner cartridge replacement

Print

Imaging Unit (PHD) replacement

Print

Transfer Unit (BTR) replacement

Print

Replace the FUSER ASSY and clear the counter

Print

Clean the sensor and open and close the front cover

Print (Paper cannot be delivered from the cassette)

Replenish the paper

Print (Paper cannot be delivered from the cassette)

Paper cassette replacement

Print

Take out paper from the delivery tray

Shutdown

Toner cartridge replacement

Shutdown

Toner cartridge replacement

Shutdown

Toner cartridge replacement

Shutdown

Toner cartridge replacement

1-36

Page 37

Chapter 1 Troubleshooting

3.4 Error Code FIP

FIP-1 Yellow Toner Cartridge Detached (Yellow Toner Cartridge Missing)

Step Check

Initial check.

Check the following for damage:

Cartridge condition

1

2

3

4

5

6

7

8

9

SW TCRU ASSY (Y) condition

SW TCRU ASSY (Y) actuator condition

SW TCRU ASSY SW TCRU ASSY (Y) connector

condition

Check SW TCRU ASSY

Using the diagnostic tool, check by Diagnostic Input Test.

Does SW TCRU ASSY (Yellow Cartridge Toner Bottle

Sensor) function normally?

Check PWBA HNB DRV for signal

Is P/J51-11PIN <=> P/J51-12PIN 0VDC?

Check SW TCRU ASSY (Y) for signal

Is P/J431-2PIN<=>P/J431-1PIN 0VDC?

Check SW TCRU ASSY (Y) for continuity

Is P431-2PIN <=> P431-1PIN of SW TCRU ASSY (Y)

check continuous?

Check HARNESS ASSY TNR for continuity

J51 <=> J431 check continuous?

Check PWBA HNB DRV for signal

Is P/J42-4PIN<=>P/J42-14PIN 0VDC?

Check PWBA HNB MCU for signal

Is P/J12-27PIN <=> P/J12-17PIN of PWBA HNB MCU PWB

0VDC?

Check HARNESS ASSY DRV2 for continuity

J12 <=> J42 check continuous?

Yes No

With tool

Replace the parts

concerned

Replace PWBA

HNB MCU

Go to step [7] Go to step [4]

Go to step [6] Go to step [5]

Go to step [6]

Go to step [7]

Go to step [8]

Replace PWBA

HNB MCU

Replace PWBA

HNB MCU

Go to step [2]

Without tool

Go to step [3]

Go to step [3]

Replace SW

TCRU ASSY (Y)

Replace

HARNESS ASSY

TNR

Replace PWB

HNB DRV

Go to step [9]

Replace

HARNESS ASSY

DRV2

1-37

Page 38

FIP-2 Magenta Toner Cartridge Detached (Magenta Toner Cartridge Missing)

Step Check

Initial check

Check the following for damage.

Cartridge condition

1

2

3

4

5

6

7

8

9

SW TCRU ASSY (M) condition

SW TCRU ASSY (M) actuator condition

SW TCRU ASSY SW TCRU ASSY (M) connector

condition

Check SW TCRU ASSY

Using the diagnostic tool, check by Diagnostic Input Test.

Does SW TCRU ASSY (Magenta Cartridge Toner Bottle

Sensor) function normally?

Check PWBA HNB DRV for signal

Is P/J51-13PIN <=> P/J51-14PIN 0VDC?

Check SW TCRU ASSY(M) for signal

Is P/J432-2PIN <=> P/J432-1PIN 0VDC?

Check SW TCRU ASSY (M) for continuity

P432-2PIN <=> P432-1PIN of SW TCRU ASSY (M) check

continuous?

Check HARNESS ASSY TNR for continuity

J51 <=> J432 check continuous?

Check PWBA HNB DRV for signal

Is P/J42-5PIN <=> P/J42-14PIN 0VDC?

Check PWBA HNB MCU for signal

Is P/J11-26PIN <=> P/J11-17PIN of HNB MCU WITHMCU

PWB 0VDC?

Check HARNESS ASSY DRV2 for continuity

J12 <=> J42 check continuous?

Yes No

With tool

Replace the parts

concerned

Replace PWBA

HNB MCU

Go to step [7] Go to step [4]

Go to step [6] Go to step [5]

Go to step [6]

Go to step [7]

Go to step [8]

Replace PWBA

HNB MCU

Replace PWBA

HNB MCU

Go to step [2]

Without tool

Go to step [3]

Go to step [3]

Replace SW

TCRU ASSY (M)

Replace

HARNESS ASSY

TNR

Replace PWB

HNB DRV

Go to step [9]

Replace

HARNESS ASSY

DRV2

1-38

Page 39

FIP-3 Cyan Toner Cartridge Detached (Cyan Toner Cartridge Missing)

Chapter 1 Troubleshooting

Step Check

Initial check

Check the following for damage.

Cartridge condition

1

2

3

4

5

6

7

8

9

SW TCRU ASSY (C) condition

SW TCRU ASSY (C) actuator condition

SW TCRU ASSY SW TCRU ASSY (C) connector

condition

Check SW TCRU ASSY

Using the diagnostic tool, check by Diagnostic Input Test.

Does SW TCRU ASSY (Cyan Cartridge Toner Bottle

Sensor) function normally?

Check PWBA HNB DRV for signal

Is P/J51-29PIN <=> P/J51-30PIN 0VDC?

Check SW TCRU ASSY (C) for signal

Is P/J433-2PIN <=> P/J433-1PIN 0VDC?

Check SW TCRU ASSY (C) for continuity

P433-2PIN <=> P433-1PIN of SW TCRU ASSY (C) check

continuous?

Check HARNESS ASSY TNR for continuity

J51 <=> J433 check continuous?

Check PWBA HNB DRV for signal

Is P/J42-6PIN <=> P/J42-14PIN 0VDC?

Check PWBA HNB MCU for signal

Is P/J12-25PIN <=> P/J12-17PIN of PWBA HNB MCU PWB

0VDC?

Check HARNESS ASSY DRV2 for continuity

J12 <=> J42 check continuous?

Yes No

With tool

Replace the parts

concerned

Replace PWBA

HNB MCU

Go to step [7] Go to step [4]

Go to step [6] Go to step [5]

Go to step [6]

Go to step [7]

Go to step [8]

Replace PWBA

HNB MCU

Replace PWBA

HNB MCU

Go to step [2]

Without tool

Go to step [3]

Go to step [3]

Replace SW

TCRU ASSY (C)

Replace

HARNESS ASSY

TNR

Replace PWB

HNB DRV

Go to step [9]

Replace

HARNESS ASSY

DRV2

1-39

Page 40

FIP-4 Black Toner Cartridge Detached (Black Toner Cartridge Missing)

Step Check

Initial check

Check the following for damage.

Cartridge condition

1

2

3

4

5

6

7

8

9

SW TCRU ASSY (K) condition

SW TCRU ASSY (K) actuator condition

SW TCRU ASSY SW TCRU ASSY (K) connector

condition

Check SW TCRU ASSY

Using the diagnostic tool, check by Diagnostic Input Test.

Does SW TCRU ASSY (Black Cartridge Toner Bottle

Sensor) function normally?

Check PWBA HNB DRV for signal

Is P/J51-31PIN<=>P/J51-32PIN 0VDC?

Check SW TCRU ASSY (K) for signal

Is P/J434-2PIN<=>P/J434-1PIN 0VDC?

Check SW TCRU ASSY (K) for continuity

P434-2PIN <=> P434-1PIN of SW TCRU ASSY (K)

check continuous?

Check HARNESS ASSY TNR for continuity

J51 <=> J434 check continuous?

Check PWBA HNB DRV for signal

Is P/J42-3PIN <=> P/J42-14PIN 0VDC?

Check PWBA HNB MCU for signal

Is P/J12-28PIN <=> P/J12-17PIN of PWBA HNB MCU PWB

0VDC?

Check HARNESS ASSY DRV2 for continuity

J12 <=> J42 check continuous?

Yes No

With tool

Replace the parts

concerned

Replace PWBA

HNB MCU

Go to step [7] Go to step [4]

Go to step [6] Go to step [5]

Go to step [6]

Go to step [7]

Go to step [8]

Replace PWBA

HNB MCU

Replace PWBA

HNB MCU

Go to step [2]

Without tool

Go to step [3]

Go to step [3]

Replace SW

TCRU ASSY (K)

Replace

HARNESS ASSY

TNR

Replace PWB

HNB DRV

Go to step [9]

Replace

HARNESS ASSY

DRV2

1-40

Page 41

FIP-5 PHD Detached (Imaging Unit Missing)

Chapter 1 Troubleshooting

Step Check

Initial check

Check the following for damage.

1

2

3

4

5

Imaging Unit (PHD) condition

PWBA CRUM in Imaging Unit (PHD) condition

Check PWBA CRUM

Is PWBA CRUM connector connected to the

harness connector normally?

Check HARNESS ASSY CRUM for continuity

J170 <=> J71 check continuous?

Check HARNESS ASSY EEPROM for continuity

J17 <=> J140 check continuous?

Check Imaging Unit (PHD)

Replace Imaging Unit (PHD), and check if an error occurs

Yes No

Replace the parts

concerned

Go to step [3]

Go to step [4]

Go to step [5]

Replace PWBA

HNB MCU

Go to step [2]

Replace

HARNESS ASSY

CRUM

Replace

HARNESS ASSY

CRUM

Replace

HARNESS ASSY

EEPROM

End of work

1-41

Page 42

FIP-6 BTR Detached (Transfer Unit Missing)

Step Check

Initial check

Check the following for evidence of fault.

1

2

3

4

5

6

Transfer Unit (BTR) condition

SENSOR ADC ASSY condition

Check HARNESS ASSY ADC for connection

Is HARNESS ASSY ADC connected to the SENSOR ADC

ASSY normally?

Check HARNESS ASSY ADC for continuity

J136 <=> J1361 check continuous?

Check HARNESS ASSY FRONT1A for continuity

J1361 <=> J13 check continuous?

Check HARNESS ASSY FRONT1A for signal

Is P/J136-5PIN <=> P/J136-3PIN 0VDC?

Check Transfer Unit (BTR)

Replace new Transfer Unit (BTR), and check if an error

occurs

Yes No

Replace the parts

concerned

Go to step [3]

Go to step [4]

Go to step [5]

Replace SENSOR

ADC ASSY

Replace PWBA

HNB MCU

Go to step [2]

Replace the parts

concerned

Replace

HARNESS ASSY

ADC

Replace

HARNESS ASSY

FRONT1A

Go to step [6]

End of work

1-42

Page 43

FIP-7 Fuser Detached (Fuser Unit Missing)

Chapter 1 Troubleshooting

Step Check

Initial check

1

2

3

4

Check the following for damage.

FUSER ASSY condition

Check FUSER ASSY

Remove the FUSER and measure resistance value

Is P232-A4PIN <=> P232-A5PIN less than 400KΩ?

Check HARNESS ASSY FSR2 for continuity

J232 <=> J138 check continuous?

Check HARNESS ASSY FRONT 1A for continuity

P138 <=> J13 check continuous?

Yes No

Replace the parts

concerned

Go to step [3]

Go to step [4]

Replace PWBA

HNB MCU

Go to step [2]

Replace FUSER

ASSY

Replace

HARNESS ASSY

FSR2

Replace

HARNESS ASSY

FRONT 1A

1-43

Page 44

FIP-8 CRUM ID Error (Call for Service CRUM ID Error)

Step Check

Verify that the printer has a genuine Minolta-QMS PHD

1

ASSY (Imaging Unit)

Check the following for damage.

2

3

4

5

6

Imaging Unit (PHD) condition

PWBA CRUM in Imaging Unit (PHD) condition

Check PWBA CRUM for connection

Is PWBA CRUM connector connected to the harness

connector normally?

Check HARNESS ASSY CRUM for continuity

J170 <=> J71 check continuous?

Check HARNESS ASSY EEPROM for continuity

J17 <=> J140 check continuous?

Check Imaging Unit (PHD)

Replace new Imaging Unit (PHD), and check if an error

occurs

Yes No

Go to step [2]

Replace the parts

concerned

Go to step [4]

Go to step [5]

Go to step [6]

Replace PWBA

HNB MCU

Replace Imaging

Unit (PHD)

Go to step [3]

Replace

HARNESS ASSY

CRUM

Replace

HARNESS ASSY

CRUM

Replace

HARNESS ASSY

EEPROM

End of work

1-44

Page 45

FIP-9 CRUM ID Error (Invalid Imaging Unit)

Chapter 1 Troubleshooting

Step Check

Verify that the printer has a genuine Minolta-QMS PHD

1

ASSY (Imaging Unit)

Check the following for damage.

2

3

4

5

6

Imaging Unit (PHD) condition

PWBA CRUM in Imaging Unit (PHD) condition

Check PWBA CRUM for connection

Is PWBA CRUM connector connected to the harness

connector normally?

Check HARNESS ASSY CRUM for continuity

J170 <=> J71 check continuous?

Check HARNESS ASSY EEPROM for continuity

J17 <=> J140 check continuous?

Check Imaging Unit (PHD)

Replace new Imaging Unit (PHD), and check if an error

occurs

Yes No

Go to step [2]

Replace the parts

concerned

Go to step [4]

Go to step [5]

Go to step [6]

Replace PWBA

HNB MCU

Replace Imaging

Unit (PHD)

Go to step [3]

Replace

HARNESS ASSY

CRUM

Replace

HARNESS ASSY

CRUM

Replace

HARNESS ASSY

EEPROM

End of work

1-45

Page 46

FIP-10 Media Type Mismatch (Media Type Mismatch)

Step Check

Initial check

Check the following for damage.

1

2

3

4

5

SENSOR OHP condition

CHUTE ASSY REGI condition

Check SENSOR OHP

Feed the paper to the SENSOR.

Does SENSOR OHP (OHP Sensor) function normally?