Page 1

®

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

magicolor 2210

User’s Guide

1800669-001B

Page 2

Trademarks

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

The following are registered trademarks of MINOLTA-QMS, Inc.: QMS, the MINOLTAQMS logo, Crown, CrownNet, and magicolor.

Minolta is a trademark of Minolta Co., Ltd. Other product names mentioned in this

guide may also be trademarks or registered trademarks of their respective owners.

Proprietary Statement

The digitally encoded software included with your printer is Copyrighted © 2001 by

MINOLTA-QMS, Inc. All Rights Reserved. This software may not be reproduced, modified, displayed, transferred, or copied in any form or in any manner or on any media,

in whole or in part, without the express written permission of MINOLTA-QMS, Inc.

Copyright Notice

This guide is Copyrighted © 2001 by MINOLTA-QMS, Inc., One Magnum Pass,

Mobile, AL 36618. All Rights Reserved. This document may not be copied, in whole or

part, nor transferred to any other media or language, without written permission of

MINOLTA-QMS, Inc.

Notice

MINOLTA-QMS, Inc. reserves the right to make changes to this guide and to the

equipment described herein without notice. Considerable effort has been made to

ensure that this guide is free of inaccuracies and omissions. However, MINOLTAQMS, Inc. makes no warranty of any kind including, but not limited to, any implied

warranties of merchantability and fitness for a particular purpose with regard to this

guide. MINOLTA-QMS, Inc. assumes no responsibility for, or liability for, errors

contained in this guide or for incidental, special, or consequential damages arising

out of the furnishing of this guide, or the use of this guide in operating the equipment,

or in connection with the performance of the equipment when so operated.

Registering the Printer

—Fill out and send in the

Mail

registration card enclosed in

your shipment or downloaded

from www.onlineregister.com/

minolta-qms/

Internet

instructions on

www.onlineregister.com/minoltaqms/

or

Software Utilities

Follow the instructions on the

CD-ROM.

—Follow the

CD-ROM

—

Page 3

Contents

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

4 5HSODFLQJ&RQVXPDEOHV11111111111111111111111111111111111111111111111111111111111111111111111111111111118

&RQVXPDEOH/LIH([SHFWDQFLHV 9

5HSODFLQJ&RQVXPDEOHV9

2UGHULQJ&RQVXPDEOHV ;

5HSODFLQJ7RQHU&DUWULGJHV ;

7RQHU&DUWULGJH/LIH ;

7RQHU&DUWULGJH+DQGOLQJ <

7RQHU&DUWULGJH5HSODFHPHQW 43

5HILOOHG7RQHU&DUWULGJHV 45

5HSODFLQJWKH23&'UXP.LW 46

:DVWH7RQHU3DFN/23&'UXP&DUWULGJH/DQG/DVHU/HQV&RYHU 46

5HPRYLQJWKH8VHG:DVWH7RQHU3DFN 46

5HPRYLQJWKH8VHG23&'UXP&DUWULGJH 48

5HSODFLQJWKH/DVHU/HQV&RYHU 49

,QVWDOOLQJWKH1HZ23&'UXP&DUWULGJH 4:

,QVWDOOLQJWKH1HZ:DVWH7RQHU3DFN 4<

5HSODFLQJWKH)XVHU8QLWDQG7UDQVIHU5ROOHU.LW 4<

5HSODFLQJWKH)XVHU8QLW 53

5HSODFLQJWKH7UDQVIHU5ROOHU8QLW 57

5HSODFLQJWKH)XVHU2LO5ROOHU 59

5HSODFLQJWKH7UDQVIHU%HOW 5;

Page 4

2 Using Media ............................... ... ................................................... .. ... ...........33

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Introduction 34

Media Handling 34

Media Types 35

Plain Paper 35

Letterhead and Memo Media 35

Thick Stock 36

Envelopes 37

Labels 37

Postcards 38

Transparencies 38

Loading Media 40

Autoduplexing 40

Upper and Optional Media Trays 41

Multipurpose Tray 43

Printing Envelopes from the Multipurpose Tray 45

Printing Area 46

Media Storage 46

3 Maintaining the Printer ....................................................................................47

Maintaining the Printer 48

Cleaning 50

Outside the Printer 50

Inside the Printer 50

4 Troubleshooting ..............................................................................................51

Introduction 52

Printing a Status Page 52

Preventing Media Jams 52

Automatic Jam Recovery 53

Understanding the Media Path 54

Media Tray (Standard Upper Tray and Optional Tray) 55

Lower Feed Unit (LFU) Tray(s) 55

Multipurpose Tray 55

Duplex Unit (Optional) 55

5-bin Mailbox (Optional) 55

Clearing Media Jams 55

Handling Media Jams by Location 56

Clearing Misfeed (Upper or Optional Tray) Jams 57

Clearing Misfeed (Multipurpose Tray) Jams 58

Clearing Inner Jams, Outer Jams, and Drum Jams 58

Media Jams in the Output Tray 66

Solving Problems with Media Jams 66

Make sure that you are using only plain paper (or recycled plain paper). 66

Make sure that you are using only letter/A4 plain paper. 66

Solving Other Problems 69

Contents2

Page 5

Solving Problems with Printing Quality 74

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Status, Error, and Service Messages 85

Status and Error Messages 85

Service Messages 94

HP-GL, HPXL, and PCL Error Codes 97

PostScript Errors 98

Additional Assistance 98

5 Installing Other Accessories ................... .......................................................99

Introduction 100

Accessories 101

Antistatic Protection 101

BuzzBox 101

What's in the Kit? 102

Installing BuzzBox 102

Using BuzzBox 103

Dual In-Line Memory Modules 103

How Much Memory Do You Need? 104

Minimum System Memory Requirements (in MB) 104

Installing a Duplex Unit 107

Emulations, Fonts, and Other Software 112

Emulations 112

Fonts 114

Kanji Font Internal IDE Hard Disk 115

5-bin Mailbox 117

QFORM 122

PlanetPress 122

Interfaces and Daughterboards 123

Interfaces 123

SCSI Interface 125

Internal IDE Hard Disk Drive 127

Lower Feeder Unit 130

Installing a Lower Feeder Unit (LFU) 130

Media Trays 134

Installation 134

Printer Stand/Cabinet 135

SC-210 Convenience Copier 135

Time-of-Day Clock 135

6 Color Printing ................................................................................................139

Introduction 140

Color Management and Control 140

MINOLTA-QMS QCOLOR Technology 140

Further Information 141

Contents

3

Page 6

7 Repacking the Printer ...................................................................................143

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Storing the Printer 144

Relocating Your Printer 144

Repacking the Printer 145

What's Involved? 145

Remove the Cables 146

Remove the Fuser Oil Roller 146

Remove the Toner Cartridges 146

Remove the Waste Toner Pack 147

Remove OPC Drum Cartridge 147

Remove Transfer Belt 147

Remove the Duplex Unit 147

Remove the 5-bin Mailbox 148

Remove the Lower Feeder Unit 148

Repack the Printer 149

Strapping/Buckling Kit Contents 150

A Technical Specifications .................................................................................153

Requirements 154

Space Requirements 154

Power Requirements 155

Location Requirements 155

Engine and Controller Specifications 157

Engine 157

Print Speed—Simplex 157

Print Speed—Autoduplex 158

General 158

Controller 159

Electrical 160

Physical 162

Print Media 162

Document Option Commands 163

Supported DOCs 163

Header/Trailer Page Commands 163

HP-GL Emulation Commands 163

HP PCL 5e Emulation Commands 164

Lineprinter Emulation Commands 164

CCITT Groups 3 and 4 Commands 164

Document Formatting 165

Job and Subjob Boundary Commands 165

LN03 Plus Commands 166

Index......................................................................................................................167

Contents4

Page 7

Replacing

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Consumables

1

Page 8

Consumable Life Expectancies

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

The stated life expectancy of each consumable is based on printing under

specific operating conditions, such as media type, number of color planes,

page size, and page coverage (@ normal 5% coverage of letter/A4-size

media). The actual life expectancy will vary depending on these and other

printing variables, including continuous or intermittent printing, ambient tem-

perature, and humidity. For further information about the consumables statis-

tics page and replacement menus, refer to the

CrownBook

.

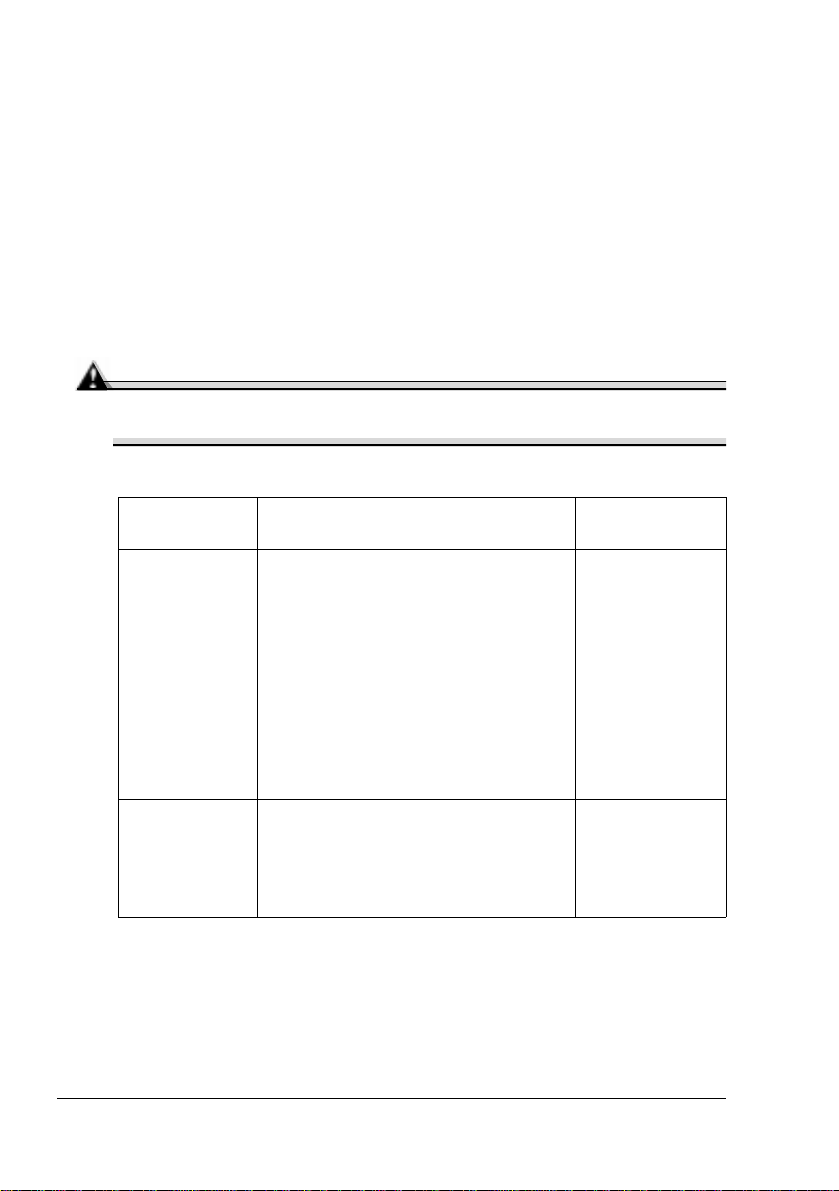

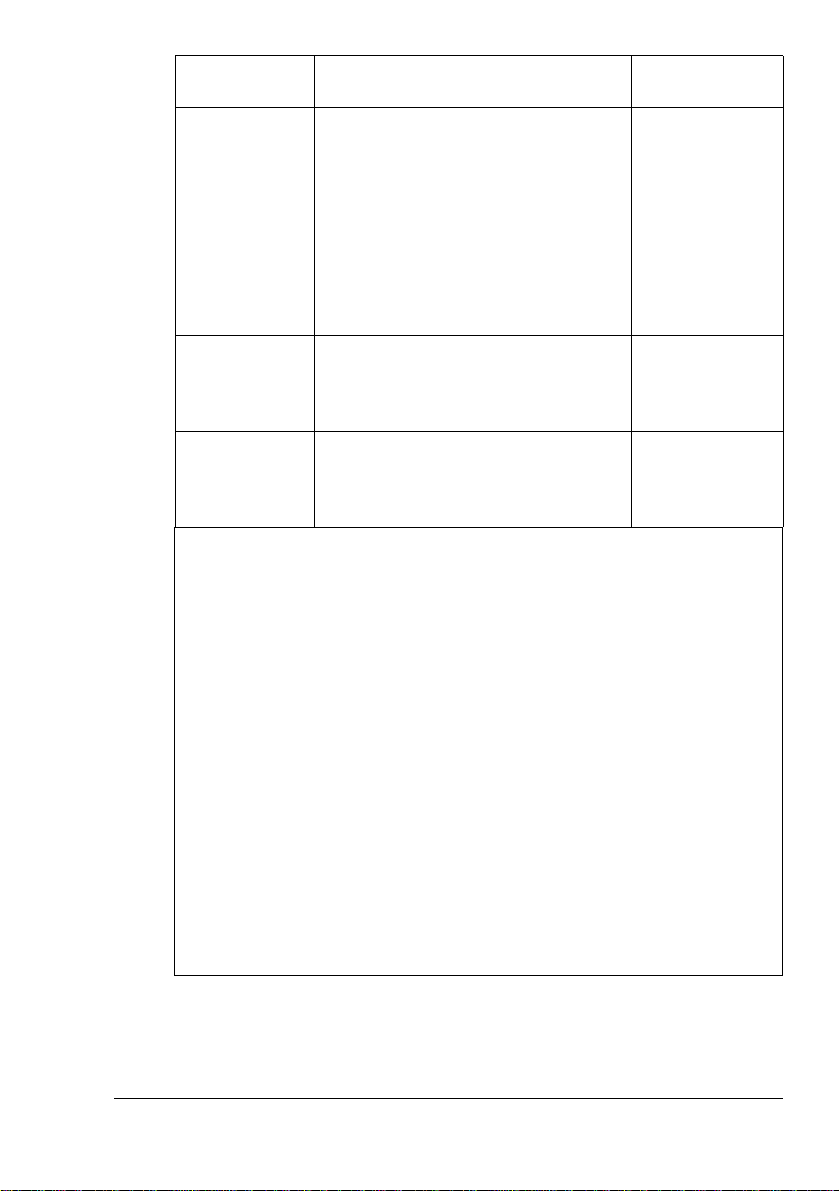

Replacing Consumables

Attention

Failure to follow instructions as outlined in this manual could result in

voiding your warranty.

The following messages indicate that a consumable needs to be replaced.

Item/Message

Display

Fuser oil roller

REPLACE

OIL

ROLLER

Fuser unit/transfer roller kit

REPLACE

FUSER

UNIT

This item needs replacing by user

after...

FUSER OIL LOW, FUSER OIL

EMPTY, or REPLACE OIL ROLLER

displays in the message window (after

up to 21,000 single- sided continuous

monochrome or 7,500 continuous

color pages*, or 7,000 intermittent

monochrome or 5,000 intermittent

color pages). Heavy coverage, intermittent printing, and different media

types can use up oil at an accelerated

rate, reducing fuser oil roller life.

100,000 single-sided pages maximum

at an equal mix of black and 4-color

pages, all with 5% coverage of each

color; however, fuser unit life is coverage and media dependent).

Page Reference

“Replacing the

Fuser Oil Roller”

on page 26

“Replacing the

Fuser Unit and

Transfer Roller

Kit” on page 19

Consumable Life Expectancies6

Page 9

Item/Message

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Display

OPC drum kit**

REPLACE

OPC DRUM

REPLACE

WASTE

TONER

WASTE

TONER

NEAR

FULL

Toner

<COLOR>

TONER

EMPTY

Transfer belt

REPLACE

TRANSFER

BELT

*A plane (also called an image) is a single pass of the OPC drum (one

toner color). For example, a black-only, single-sided (simplex) print job

makes one pass per page. A single-sided color page (also called a face)

consists of up to four passes of the OPC drum, since most color print jobs

use all four toner colors. A two-sided color page may consist of up to eight

passes of the OPC drum, since most color print jobs use all four toner colors. Stated consumable life is expressed at 5% in simplex letter/A4 pages.

A duplex page is equivalent to two simplex pages.

This item needs replacing by user

after...

Up to 30,000 continuous monochrome

or 7,500 continuous four-color pages,

or 10,000 intermittent [one-page jobs]

monochrome or 5,000 intermittent

[one-page jobs] color pages). Other

factors also affect consumables life.

Approximately 6,000 single-sided

pages per cartridge—black, yellow,

magenta, cyan at 5% coverage of

each color.

107,000 single-sided images (1:1

color/monochrome printing)

Page Reference

“Replacing the

OPC Drum Kit”

on page 13

“Replacing Toner

Cartridges” on

page 8

“Replacing the

Transfer Belt” on

page 28

The number of sheets/faces printed shown on the startup page differs from

the number of sheets/faces printed statistics in CrownView and on the consumables statistics page (Operator Control/Consumables/Print Statistics).

The numbers on the startup page refer to number of sheets/faces printed

during the lifetime of the printer. The numbers in CrownView and on the

consumables statistics page refer to the number of sheets/faces printed to

date during the current consumables tracking period (Administration/Consumables/Start Period menu).

**Three items (OPC drum, laser lens cover, waste toner pack) are included

in the OPC drum kit. If one needs replacing, replace all three items.

Replacing Consumables

7

Page 10

Ordering Consumables

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Choosing the right consumables for your magicolor 2210 printer not only

increases its reliability and performance, but also minimizes the risk of

damage. For example, only MINOLTA-QMS toner cartridges are designed to

meet the exact specifications of your MINOLT A-QMS printer , giving maximum

performance, efficiency, and long life.

Toner cartridges and other consumables for the magicolor

from your local vendor or Q-SHOP (www.q-shop.com). See the

Support Guide

you for information on ordering.

for the telephone number of the MINOLTA-QMS office nearest

2210 are available

Replacing Toner Cartridges

Characters and images are created in your laser printer through a process

that applies toner to the photosensitive (OPC) drum (which functions like pho-

tographic film). Your printer uses four toner cartridges: black, yellow,

magenta, and cyan. Handle the toner cartridges carefully to avoid spilling

toner inside the printer or on yourself.

The carbon-particle toner is nontoxic. If you get toner on your hands,

5"

wash them in cool water or a neutral detergent. If you get toner on

your clothes, lightly dust them off as much as possible. If some toner

remains on your clothes, use cool, not hot water, to rinse the toner off,

provided your clothing is washable.

Service &

WARNING!

If you get toner in your eyes, wash it out immediately and consult a

doctor. Material Safety Data Sheets (MSDS) information can be found at

www.minolta-qms.com (click on the Answer Base).

ACHTUNG! Sollte Toner in Ihre Augen gelangen, die Augen unbedingt

sofort mit kaltem Wasser ausspülen und einen Artzt aufsuchen.

MSDS-Informationen (Material Safety Data Sheets; Datenblätter zur

Materialsicherheit) finden Sie im Internet unter www.minolta-qms.com

(klicken Sie auf “Answer Base”).

Toner Cartridge Life

A toner cartridge contains enough toner (yellow, magenta, cyan, or black) to

print a maximum of 6,000 (at normal 5% page coverage) simplex letter/

A4-size pages. With heavier coverages, the approximate maximum

Replacing Toner Cartridges8

Page 11

capacities will decrease. The approximate maximum simplex letter/A4 pages

c#d

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

for heavier coverages are below:

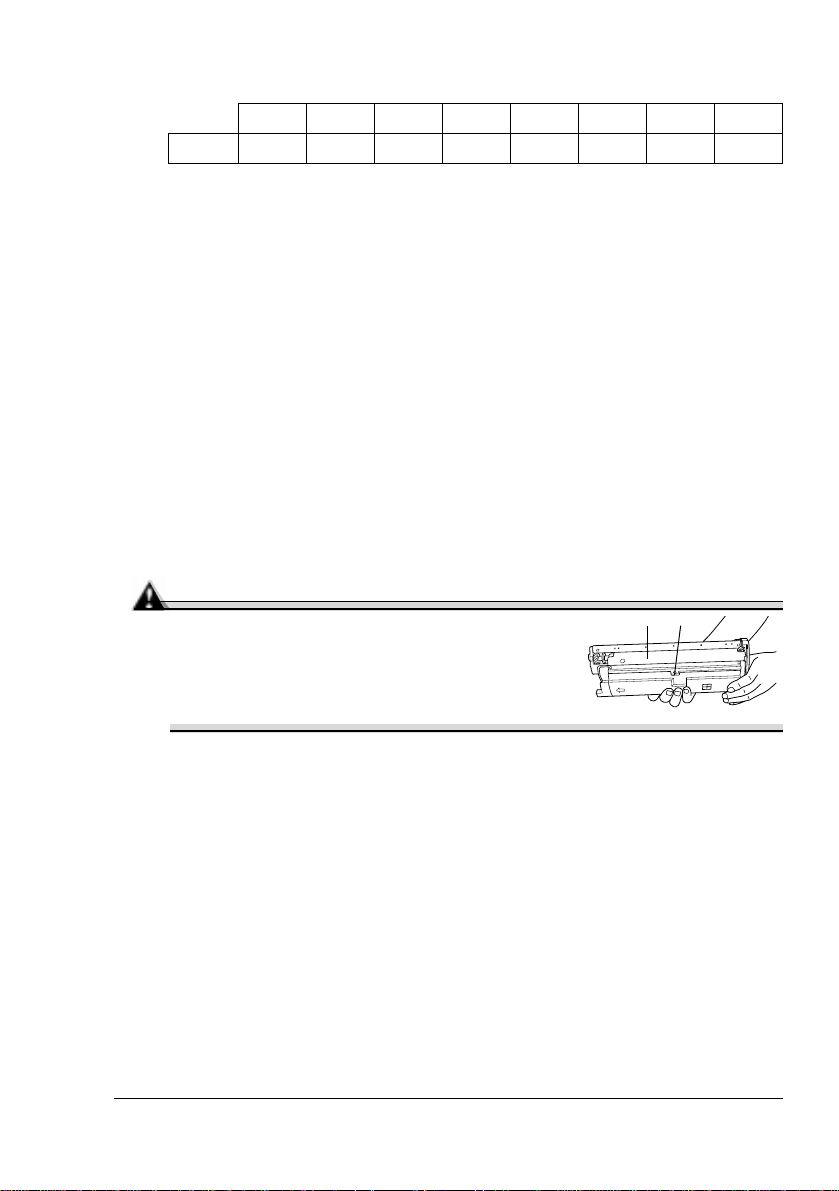

5% 10% 15% 20% 25% 30% 35% 40%

Pages 6,000 3,000 2,000 1,500 1,200 1,000 857 750

To determine your average percent coverage, print a consumables

5"

statistics page (Operator Control/Consumables/Print Statistics).

When toner runs low in a cartridge, XTONER LOW displays in the message

X

window (

printing; usually, parts of the page print lighter.

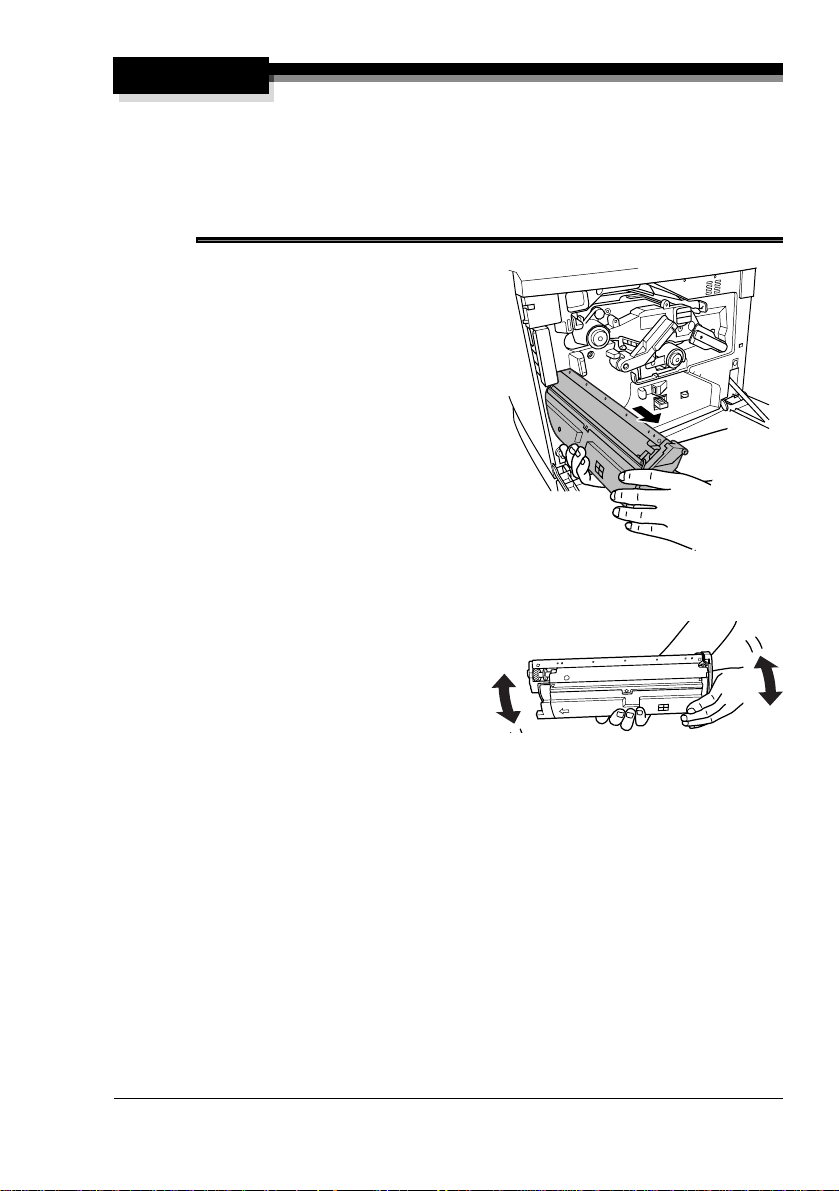

When toner is low, it’s sometimes helpful to take the cartridge out of the

printer and redistribute the toner by gently rocking the cartridge horizontally

side to side (as you do for a new cartridge) five or six times. Then reinstall the

cartridge.

The printer, approximately 100 pages after detecting that toner in a cartridge

is low, displays

toner color). Printing continues even though the out-of-toner warning

appears. However, the color gradually fades, so replace the toner cartridge

as soon as possible.

indicates the toner color). It’s your option whether to continue

X

TONER EMPTY in the message window (X indicates the

Toner Cartridge Handling

Attention

Do not hold a toner cartridge vertically. Do not

touch the toner roller surface c or the

protective shutter d. This could lower image

quality.

Keep toner cartridges:

In their packaging until you’re ready to install them.

„

In a cool, dry location away from sunlight (due to heat).

„

The maximum storage temperature is 95° F (35° C) and the maximum

storage humidity is 80% without condensation.

Level during storage.

„

Do not stand or store cartridges on their ends or turn them upside

down; the toner inside the cartridges may become caked or unequally

distributed.

Away from salty air and corrosive gases such as aerosols.

„

Away from disk drives and floppy disks.

„

The magnets in the cartridges can damage stored data.

Replacing Toner Cartridges

9

Page 12

Toner Cartridge Replacement

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

1

Check the message display to see what toner color is out.

2

Open the printer’s front cover.

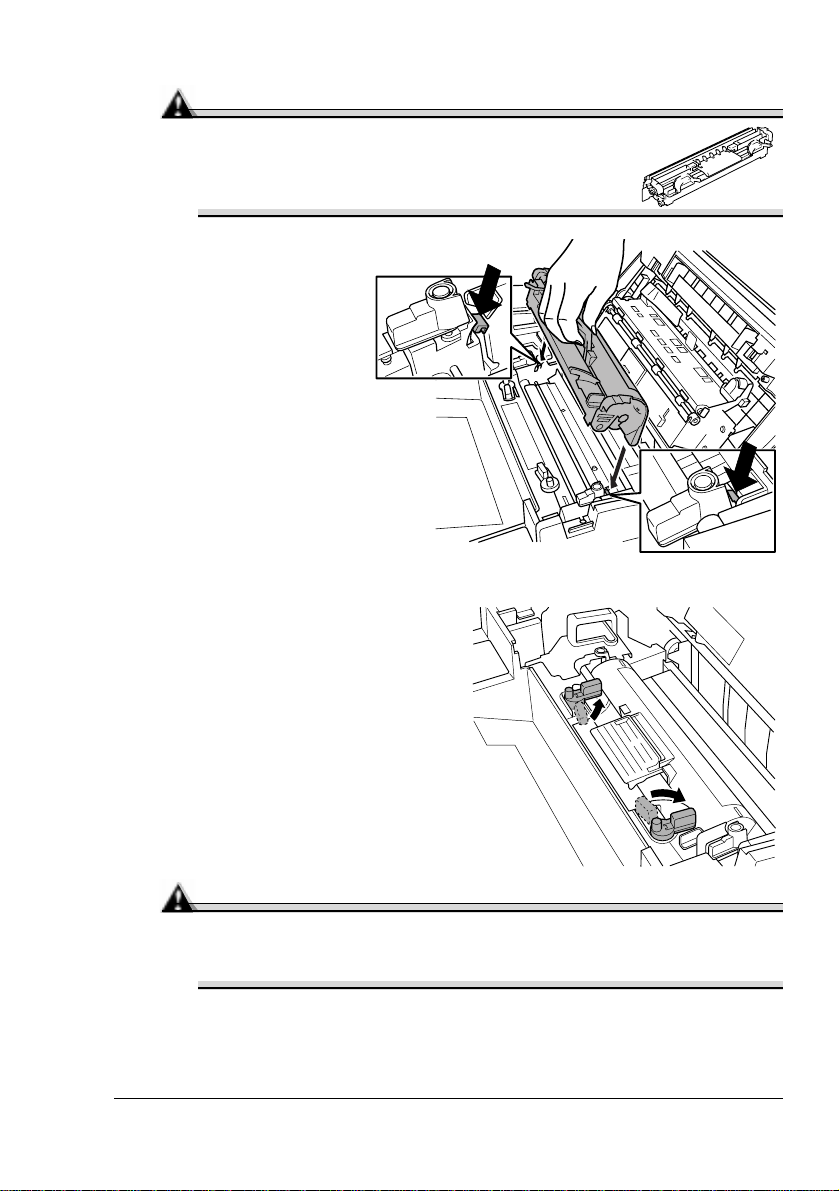

Attention

Be careful not to spill toner on the inside of the printer’s front cover .

Toner will fall from there into the upper media tray. If toner does fall

onto the open cover, immediately wipe it with a dry, lint-free soft

cotton cloth or swabs.

If the toner cartridge you want to replace is the one showing, go to step 5.

If not, go to step 3.

3

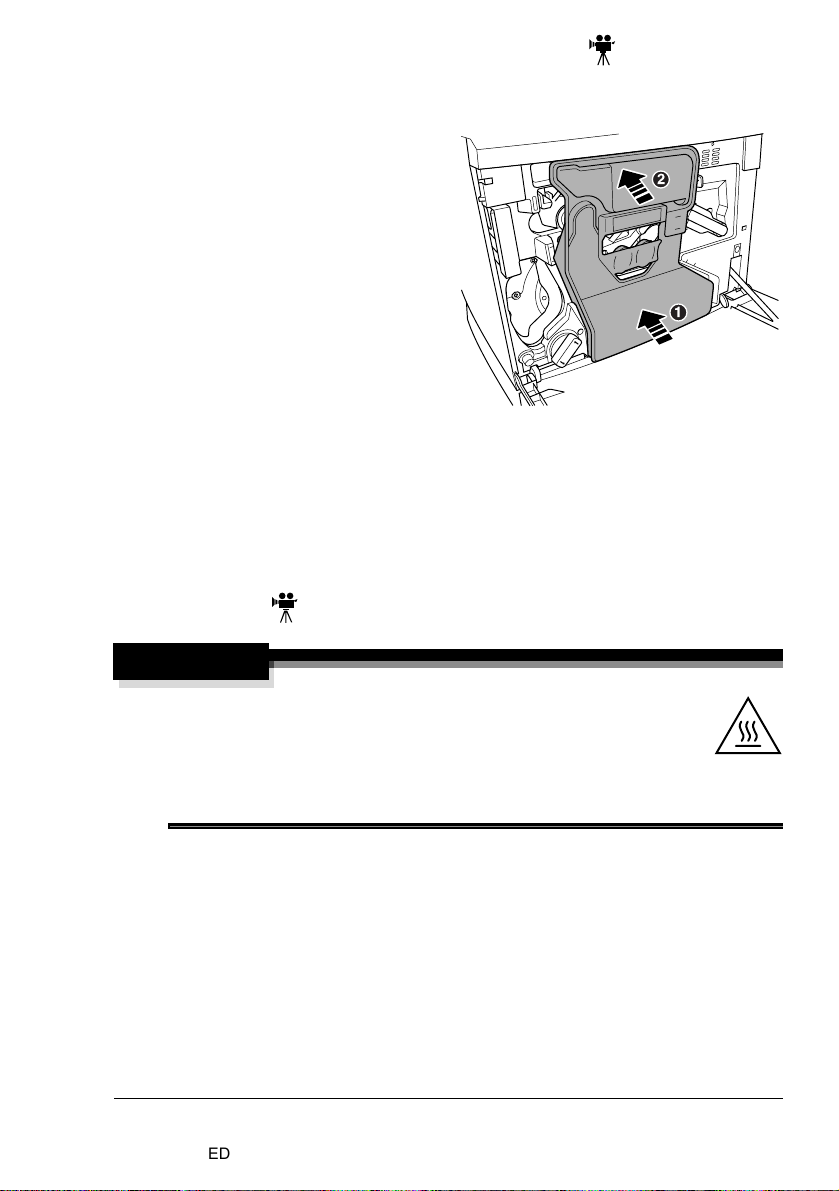

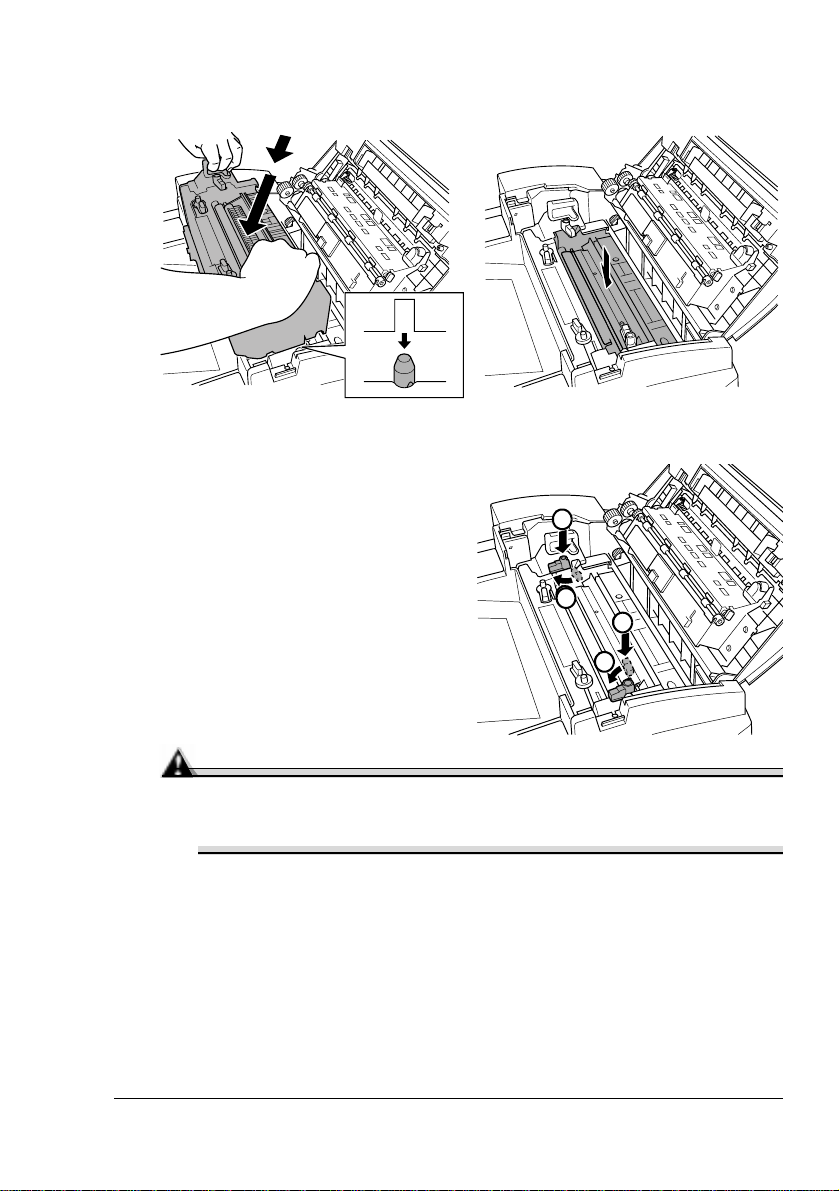

Press the toner cartridge

carrousel button cand

release the button dbefore

turning the carrousel dial

e

counterclockwise until it

stops.

The carrousel rotates 90°

and stops.

The toner cartridge carrousel may start to turn automatically from the weight of

the inserted toner cartridge.

Make sure you have fully

turned to the next slot before

trying to insert another toner cartridge.

4

Repeat step 3 until the color to be replaced is visible.

5

Pull the release lever to eject and

remove the toner cartridge you

are going to replace.

1

2

3

Replacing Toner Cartridges10

Page 13

WARNING!

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Dispose of the used toner cartridge according to your local

regulations. Do not dispose of it by burning.

ACHTUNG! Entsorgen Sie alte Tonerkassetten keinesfalls durch

Verbrennen, sondern ordnungsgemäß entsprechend den lokalen

Bestimmungen.

6

Remove the new toner cartridge

from its shipping carton.

7

Distribute the toner inside the

cartridge.

Holding a cartridge with both

hands, gently shake it five or

six times.

Replacing Toner Cartridges

11

Page 14

8

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

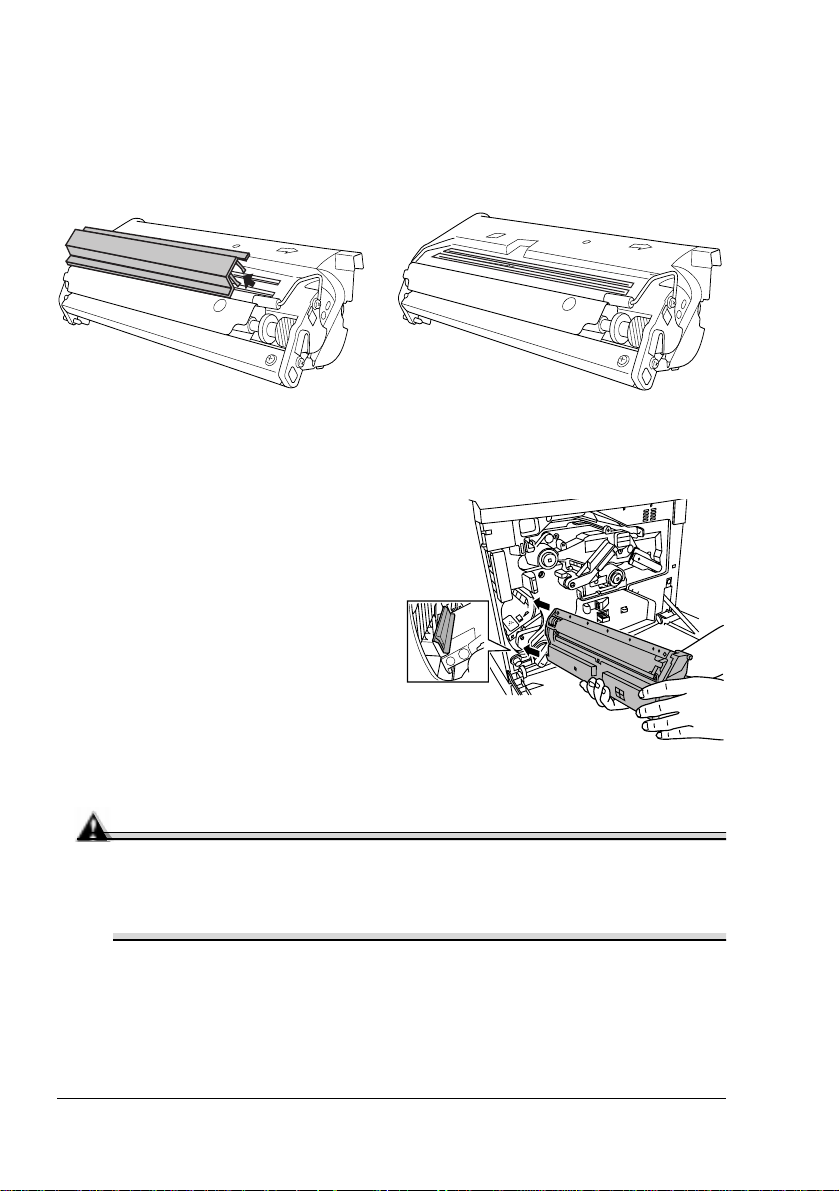

There are two types of toner cartridge available. Look at the following

graphics to determine which type you have.

„ If you have this type of toner cartridge,

remove the protective yellow cover

clearly marked “Remove.” Then go to

step 9.

Each toner cartridge has a colored end that corresponds to a col-

5"

ored label inside the cartridge slots. Always install the toner cartridge in the slot with a label of the same color.

9

Place the front end of the toner

cartridge installation guides

into the cartridge installation

rails on the cartridge carrousel.

10

Gently push the new cartridge

into the printer.

11

Close the printer’s front cover.

„ If you have this type of toner cartridge,

go to step 9.

Refilled Toner Cartridges

Attention

Refilled toner cartridges may produce variations in toner quality and

reliability and can reduce the print quality of your documents. Any

damage to the printer or quality problems caused by a refilled toner

cartridge use will void your warranty.

Replacing Toner Cartridges12

Page 15

Replacing the OPC Drum Kit

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Waste Toner Pack, OPC Drum Cartridge, and Laser Lens Cover

Attention

The OPC drum is extremely sensitive to bright light and direct sunlight.

Always leave it in its protective bag until you’re ready to install it. Any

exposure to light should be avoided, or permanent damage could

result. Any damage resulting from mishandling of the OPC drum will

void the warranty of the OPC drum. Also, handle the cartridge carefully

by its sides so you don’t touch the surface (the green part) of the d rum.

The drum is also extremely sensitive to hand oils and scratches, both of

which reduce print quality.

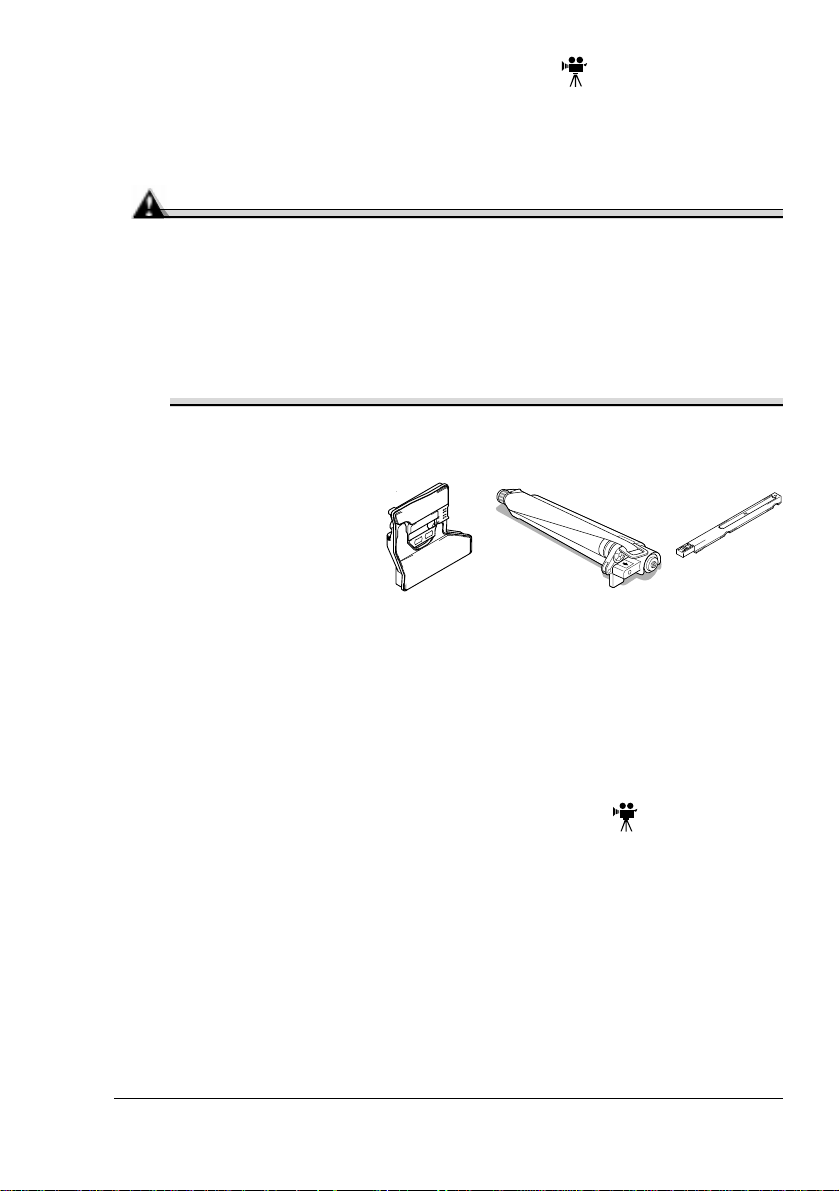

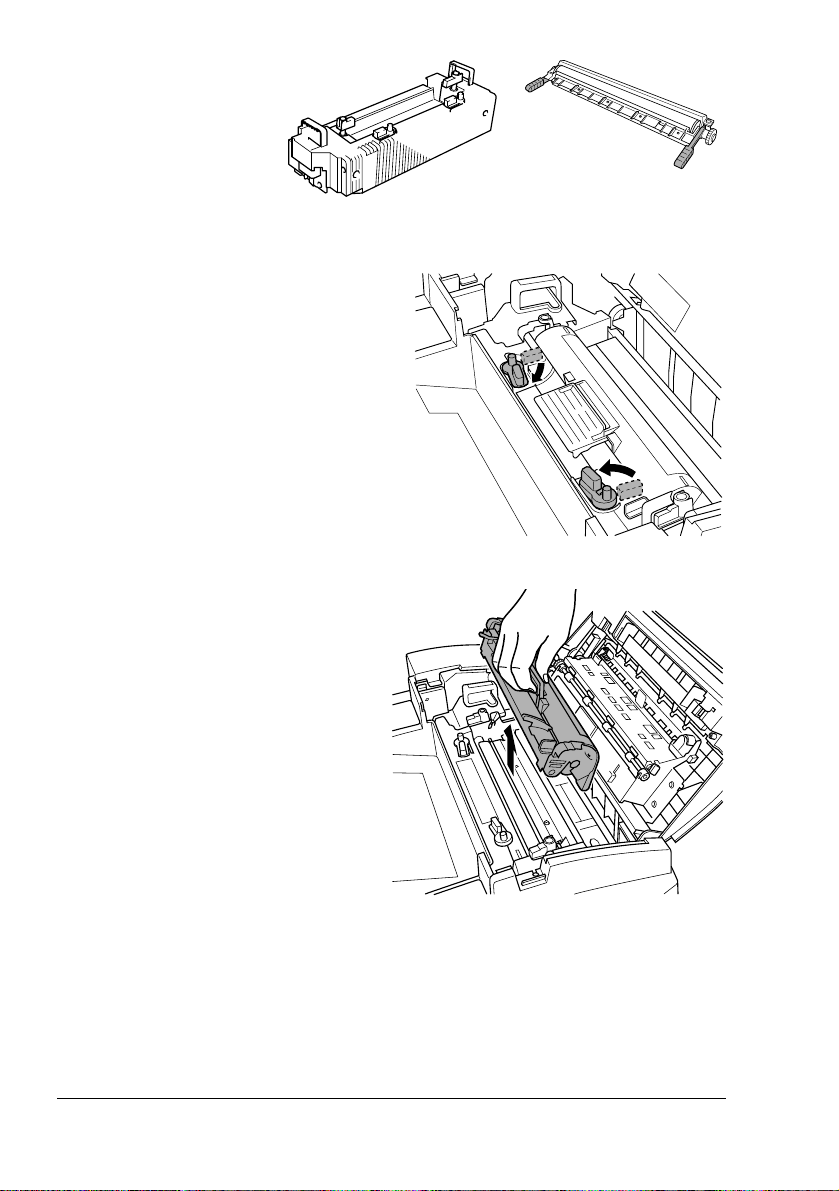

The three items below are included in the OPC drum kit. If one needs

replacing, replace all three items.

„ Waste toner pack

„ OPC drum cartridge

„ Laser lens cover

The steps are

„ Removing the used waste toner pack

„ Removing the used OPC drum cartridge

„ Replacing the laser lens cover

„ Installing the new OPC drum cartridge

„ Installing the new waste toner pack

Removing the Used Waste Toner Pack

When you replace the OPC drum cartridge, the printer automatically recovers. However, the replaced waste toner pack consumables monitoring system

must be manually reset through control panel (Operator Control/

Consumables/Items Replaced) menu.

1

Open the printer’s front cover.

Replacing the OPC Drum Kit

13

Page 16

2

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

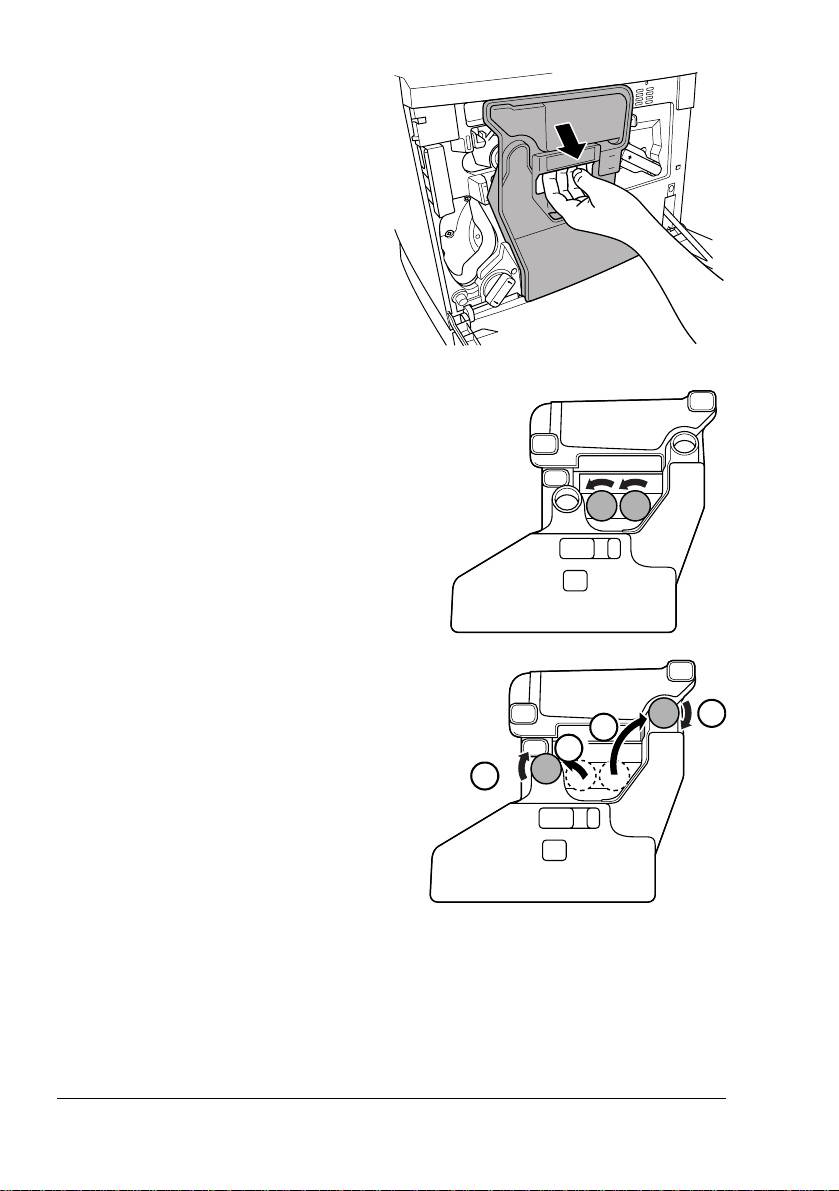

Carefully remove the waste

toner pack using the handle.

Keep the waste toner pack

upright so the toner does

not spill.

3

Turn the two caps labeled “A”

counterclockwise and remove them.

4

Twist the two “A” caps c onto the

two “A” holes d.

T urn the caps clockwise to secure

them.

2

1

1

1

1

2

2

2

Replacing the OPC Drum Kit14

Page 17

5

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Remove waste toner pack cap labeled

“B” and insert it into

hole “B.”

6

Dispose of the used waste toner pack.

WARNING!

Dispose of the used waste toner pack properly according to your local

regulations (do not dispose of it by burning).

Achtung! Entsorgen Sie den Alttonerbehälter kei nesfalls, i ndem Sie ih n

verbrennen, sondern ordnungsgemäß entsprechend den lokalen

Bestimmungen.

7

Continue with replacing the OPC drum cartridge.

You will install the new waste toner pack after replacing the OPC drum.

Removing the Used OPC Drum Cartridge

When the OPC drum is worn out, the message

printer will not print until the drum kit is replaced.

When you replace the OPC drum cartridge after a

message displays in the message window, the printer automatically

DRUM

recovers.

The OPC drum life is directly related to the number of rotations of the

5"

drum. Longest drum life is achieved with continuous printing. Intermittent printing with small job sizes requires cleaning rotations before and

after each job, and subsequently will impact OPC life.

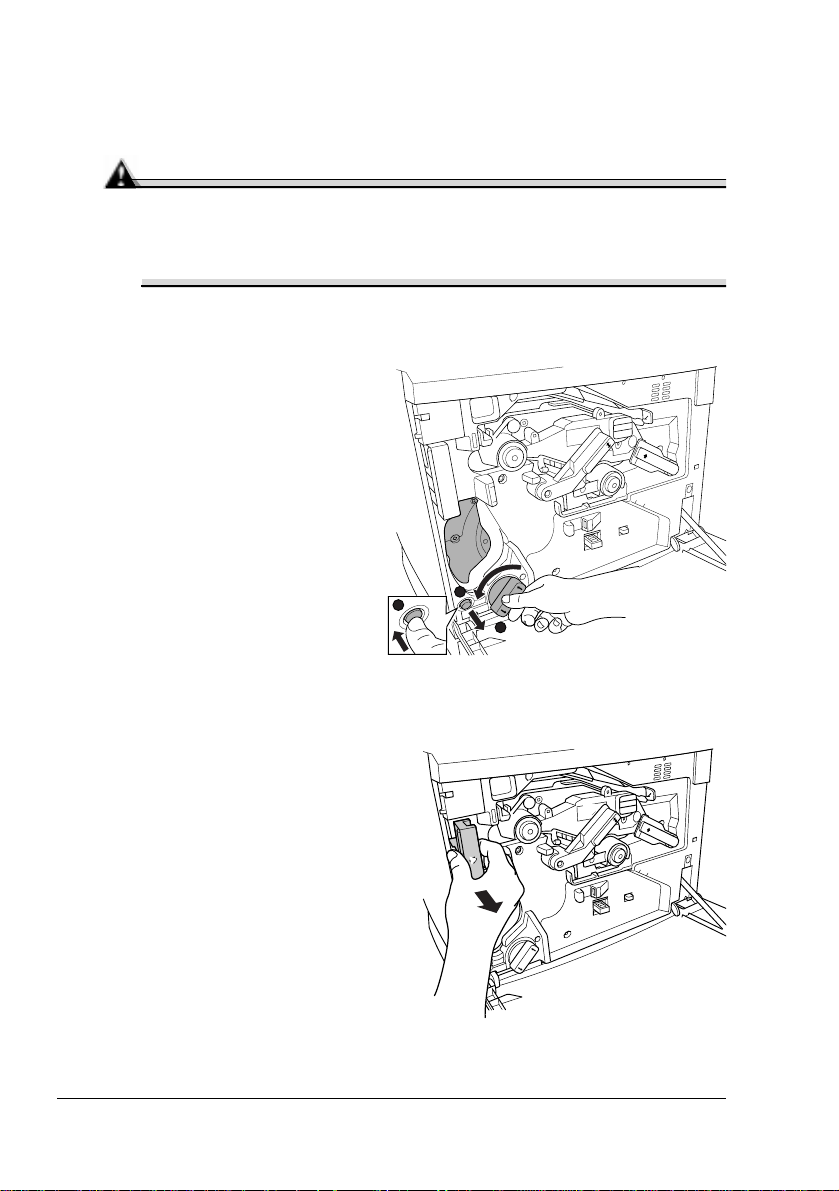

1

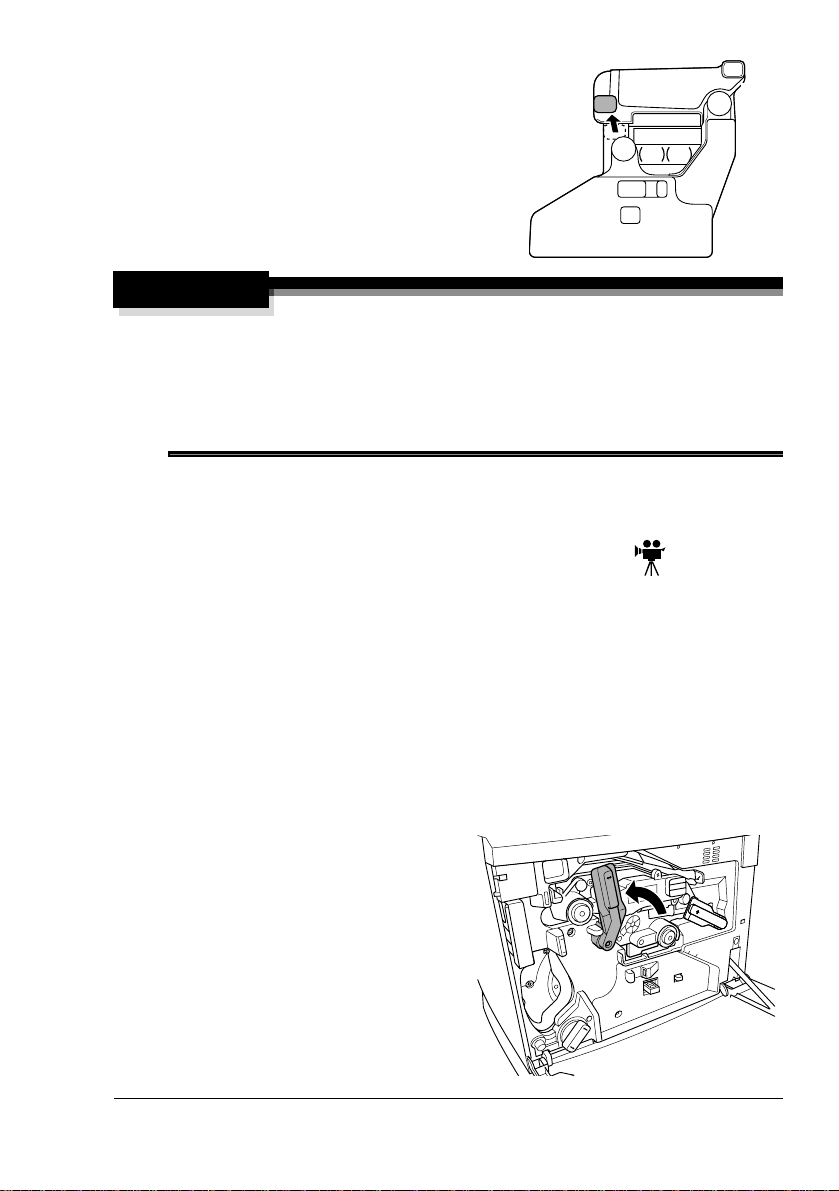

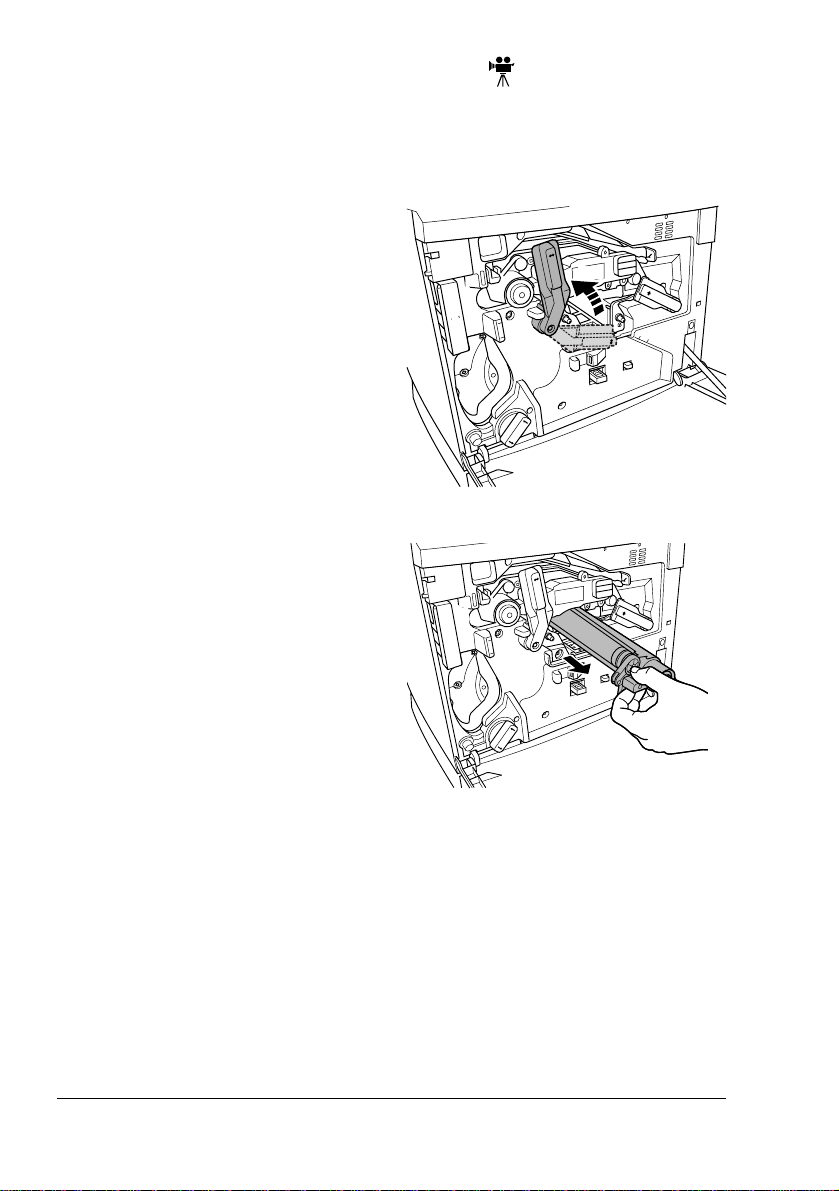

With the front cover open, rotate

the transfer belt unit left release

lever counterclockwise to the

top (12 o’clock) position.

This raises the transfer

belt unit.

Replacing the OPC Drum Kit

REPLACE DRUM

DRUM LOW or REPLACE

appears. The

15

Page 18

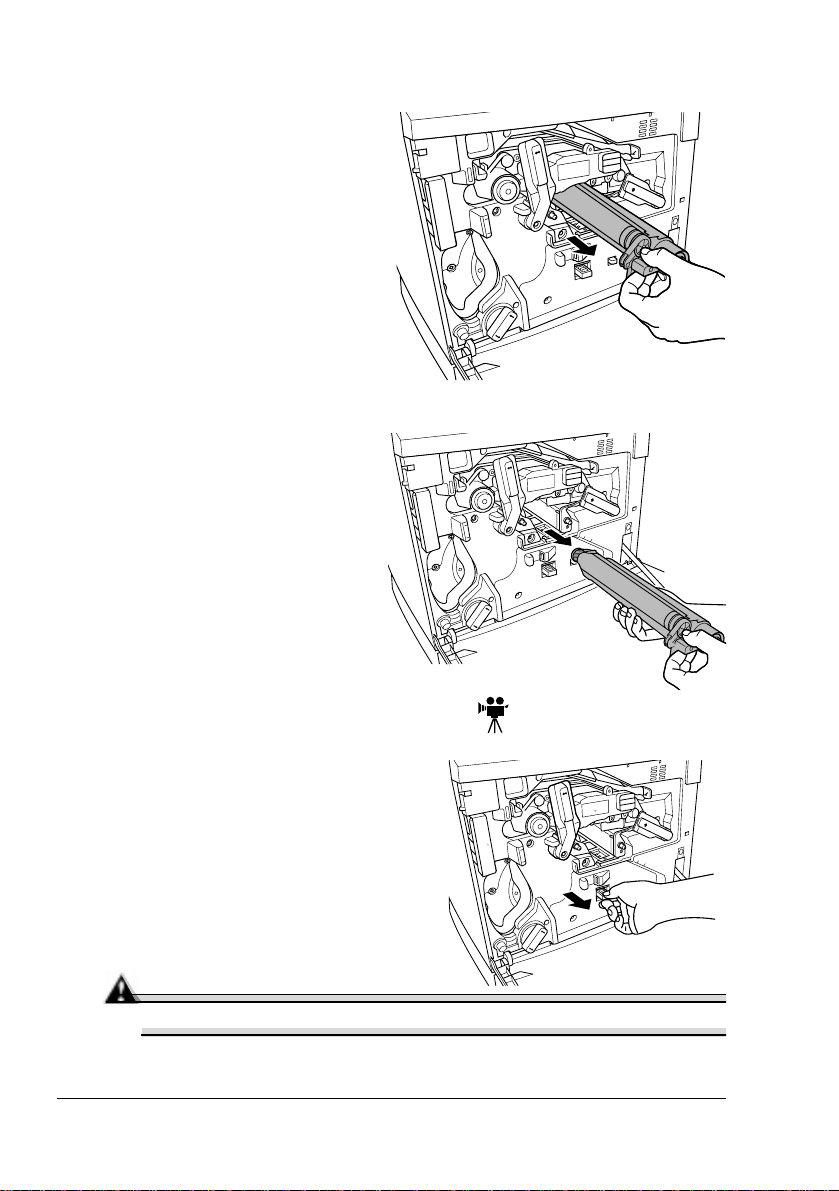

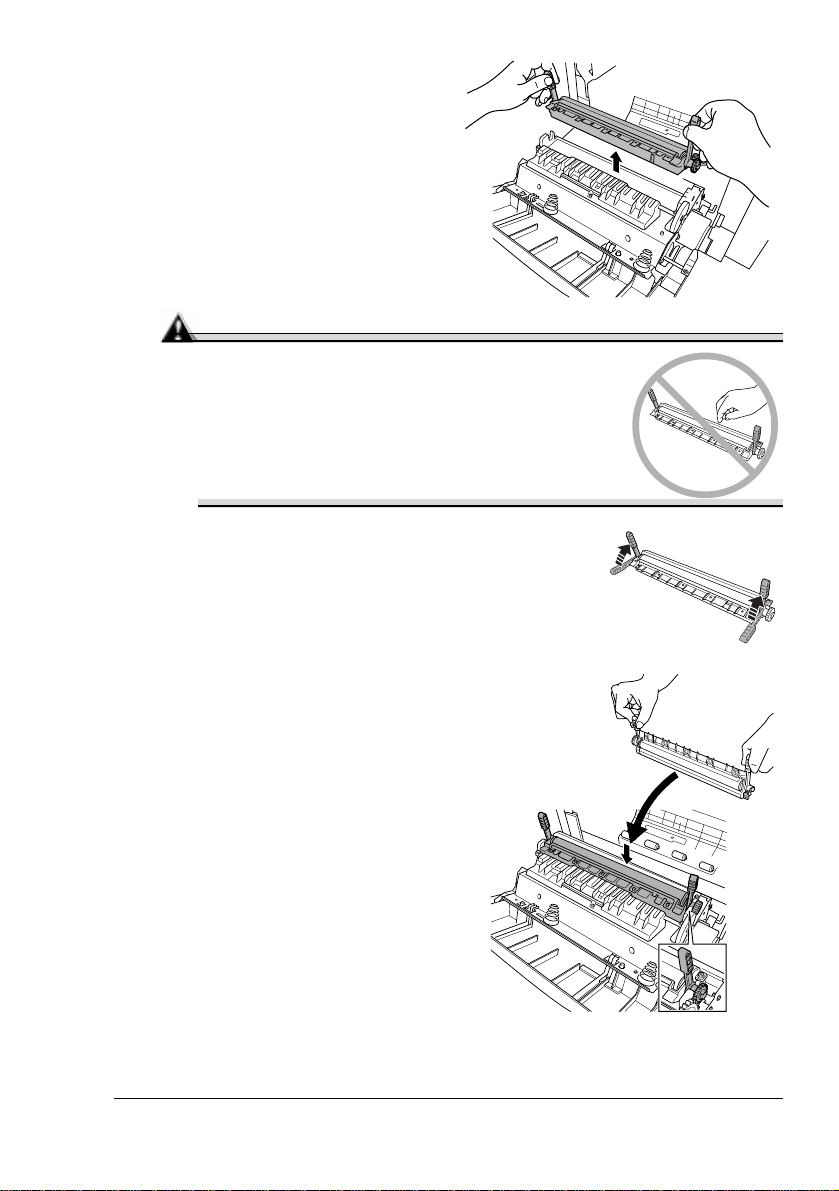

2

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Hold the OPC drum cartridge

handle and carefully pull it out

about 8 inches

(20 cm).

3

Support the bottom of the

drum with your hand, then

carefully pull the cartridge

toward you and remove it.

Dispose of it prop-

5"

erly according to your

local regulations.

4

Continue with replacing the

laser lens cover.

Replacing the Laser Lens Cover

1

Press on the laser lens cover lock

release lever and gently pull the

laser lens cover toward you.

Dispose of it properly accord-

5"

ing to your local regulations.

2

Remove the new laser lens cover

from the OPC drum kit box.

Attention

Do not touch the glass surface of the laser lens.

Replacing the OPC Drum Kit16

Page 19

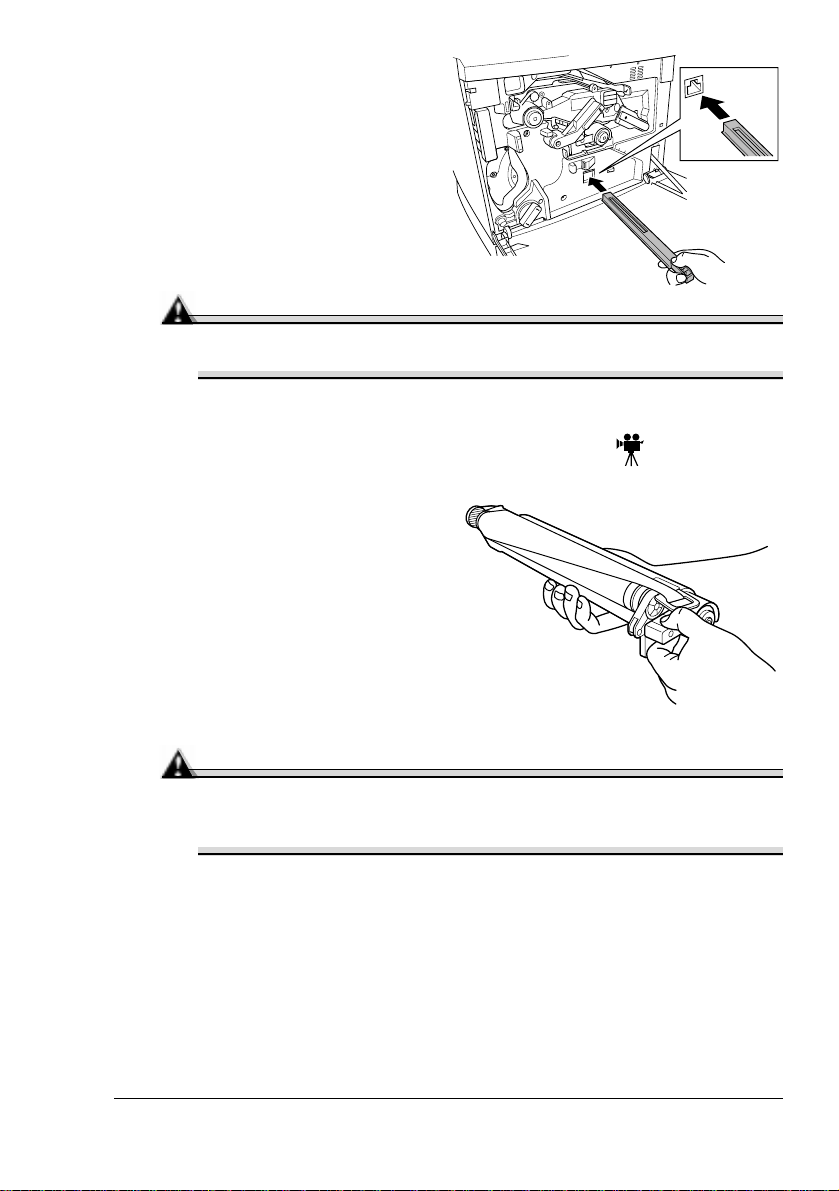

3

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Place the front end of the

laser lens cover into its installation rail.

4

Carefully insert the laser lens

cover and check to make sure

it is fully inserted.

Attention

If the laser lens cover is not properly installed, serious damage to

the printer could result.

5

Continue with replacing the OPC drum cartridge.

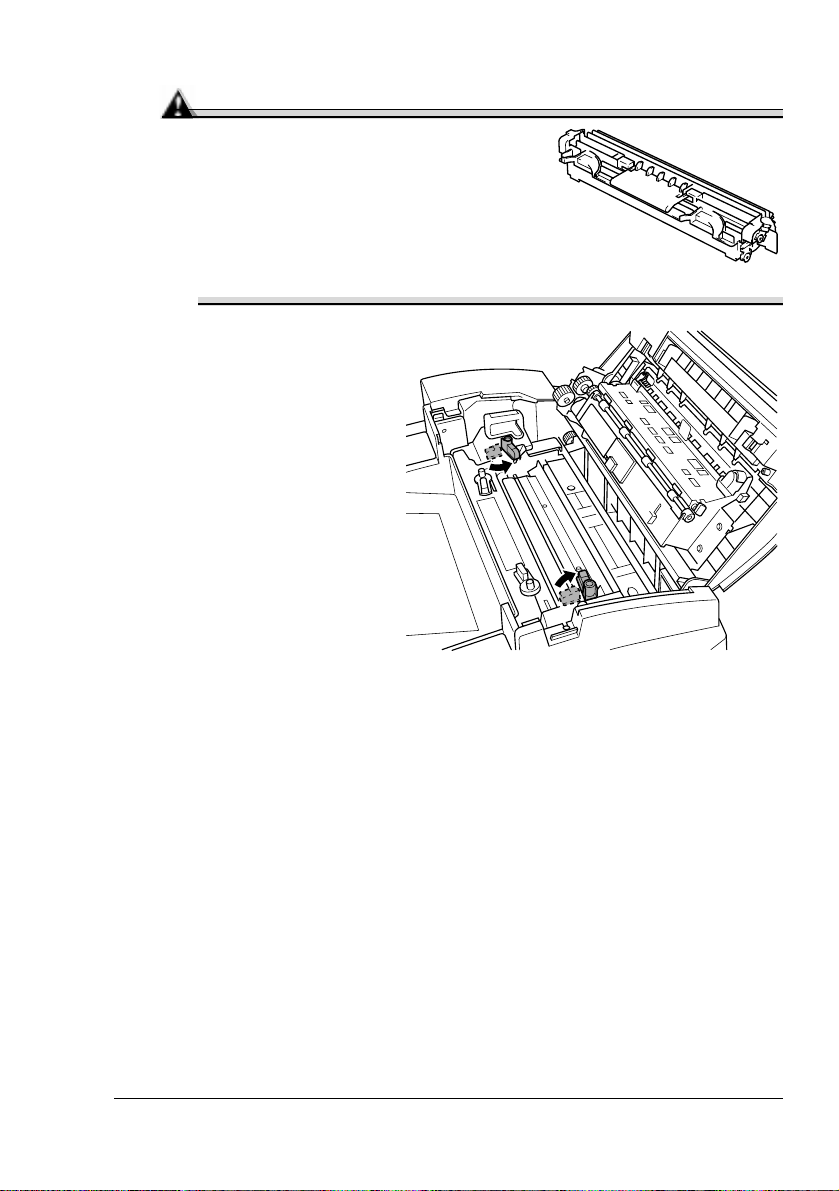

Installing the New OPC Drum Cartridge

1

Remove the new OPC drum

cartridge from its shipping box.

Attention

Keep the protective sheet on the cartridge. Do not touch the

protective sheet on the photosensitive (green) surface or scratch the

surface. This could lower image quality.

Make sure the transfer belt left release lever is still set to its top position

(12 o’clock).

Replacing the OPC Drum Kit

17

Page 20

2

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Hold the OPC drum cartridge level, place the front

end of the OPC drum cartridge installation guide

into the installation rail.

3

Carefully push the OPC

drum cartridge in.

Attention

The cartridge should slide easily into the printer. Don’t force it.

4

Press on the front handle of the

OPC drum cartridge with one hand

and hold the front handle of the

OPC protective cover with the

other hand.

5

Peel the protective cover off

(straight toward you).

Dispose of it properly

5"

according to your local

regulations.

6

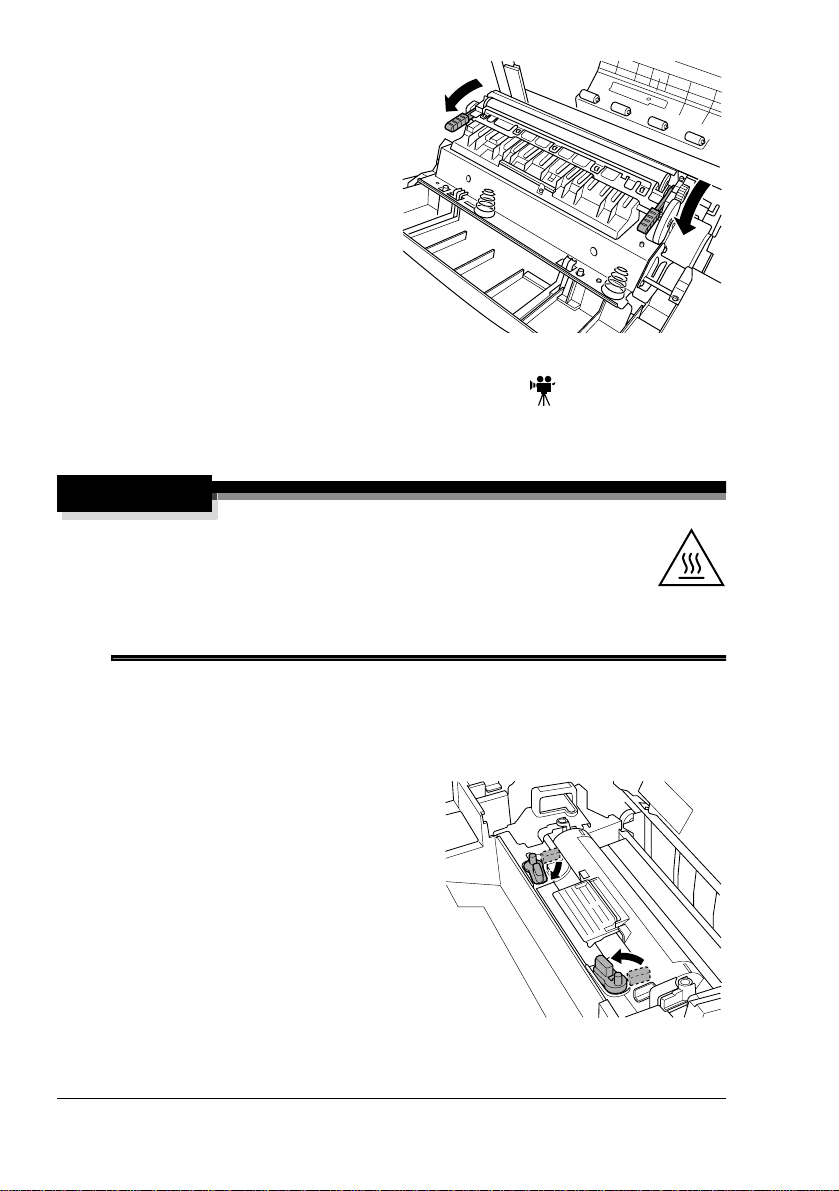

Turn the left release lever of the

transfer belt clockwise to its correct position (2 o’clock).

This lowers the transfer belt.

Also make sure the transfer belt

right release lever is set to its

correct position (10 o’clock).

Attention

If the transfer belt left release lever is at its top position (12 o’clock),

the waste toner pack cannot be installed.

Replacing the OPC Drum Kit18

Page 21

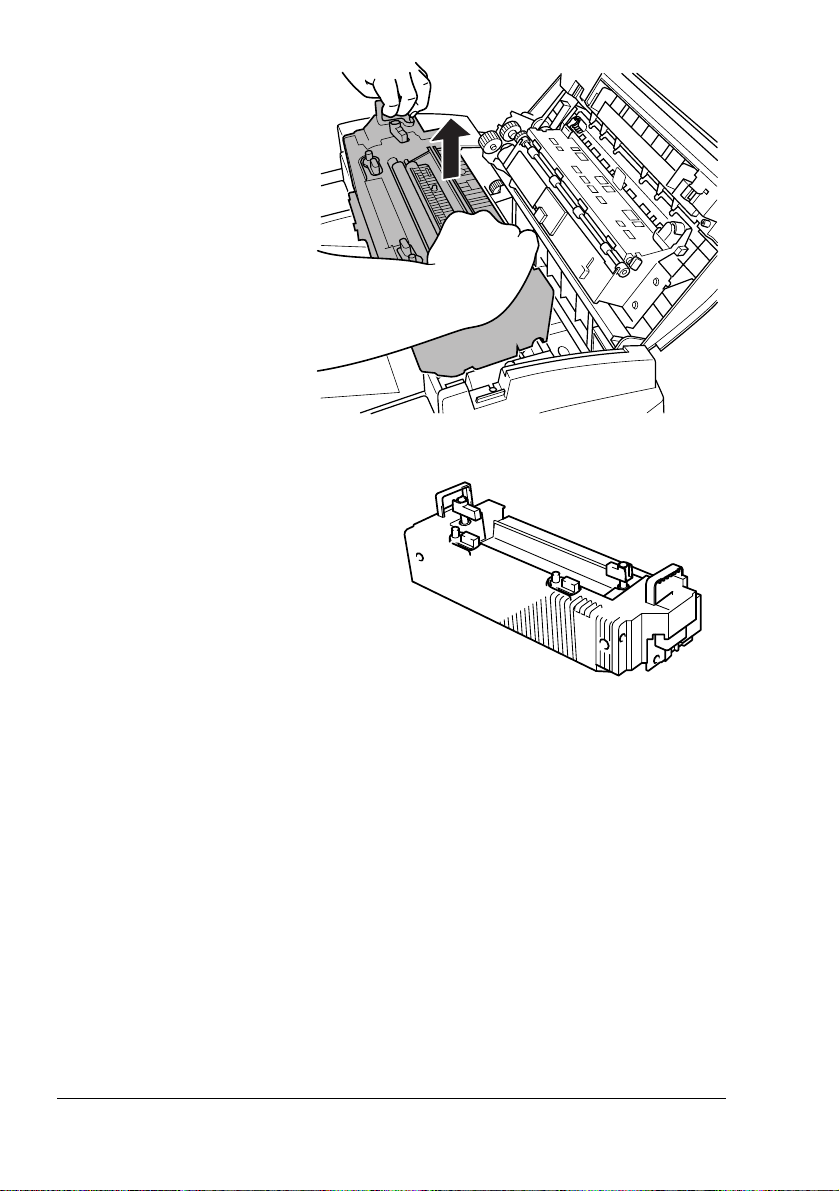

Installing the New Waste Toner Pack

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

1

Remove the new waste toner pack from the drum kit box.

2

Insert the bottom of the waste

toner pack c into its installation position in the printer.

3

Insert the top of the waste

toner pack d into its installation position in the printer until

it is firmly seated.

4

Close the printer’s front cover.

If the waste toner pack is not

correctly installed or the transfer belt right release lever is at

its top position (12 o’clock),

the front cover cannot be

closed.

5

In the Operator Control/Consumables/Items Replaced/Waste Toner

menu, choose Yes to reset the consumables monitoring system.

2

1

Replacing the Fuser Unit and Transfer

Roller Kit

WARNING!

The fuser unit can become extremely hot and cause severe

burns. Make sure the unit is cool before handling it.

ACHTUNG! Die Fixiereinheit kann sehr heiß werden, so daß

Verbrennungsgefahr besteht. Bitte lassen Sie die Fixiereinheit einige

Zeit abühlen, bevor Sie diese berühren.

When the fuser is worn out, the message “

and the printer does not print. Replace the fuser kit. After the new fuser kit is

installed, printing automatically resumes.

The fuser kit includes the two items below. When replacing the fuser unit,

replace the transfer roller as well.

Replacing the Fuser Unit and Transfer Roller Kit

REPLACE FUSER UNIT

” appears

19

Page 22

„ Fuser unit

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

„ Transfer roller

unit

Replacing the Fuser Unit

1

Open the printer’s top cover.

2

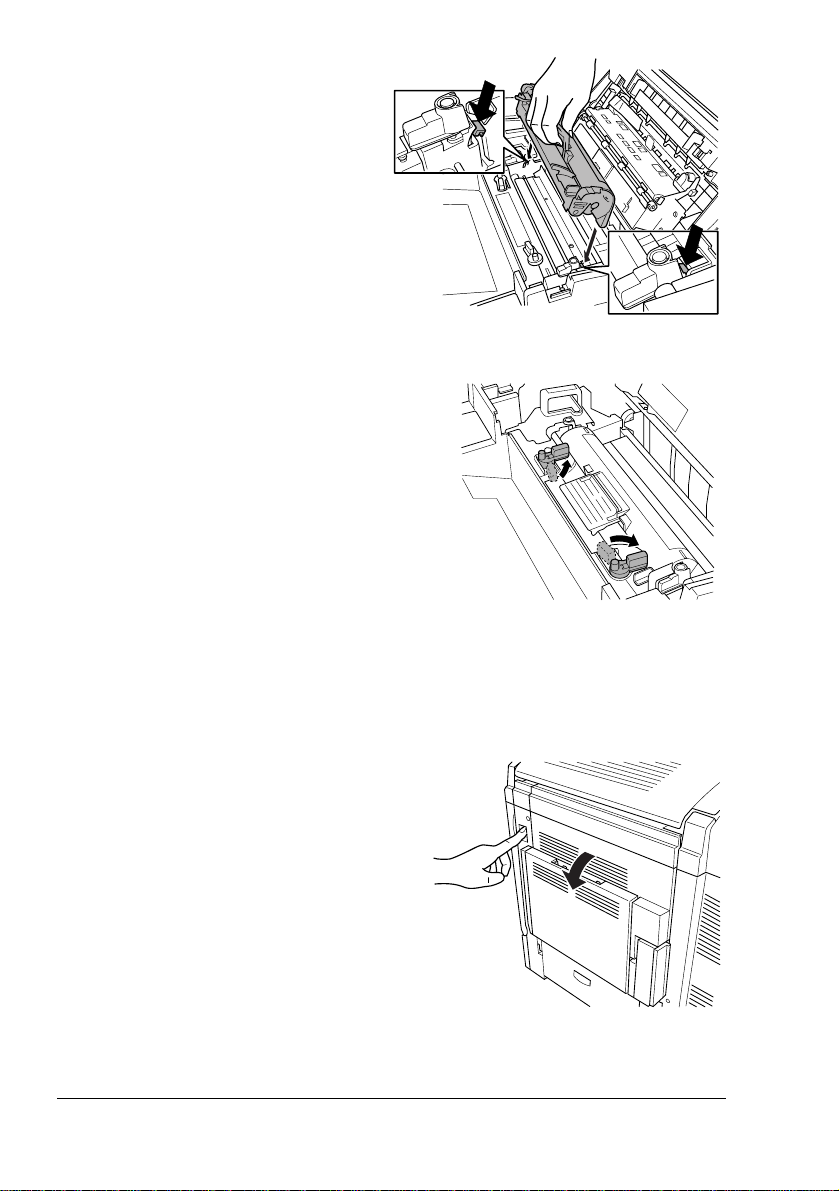

Rotate the two fuser oil roller

lock levers to release the fuser

oil roller.

3

Remove the fuser oil

roller.

Hold it by the green

handle only.

Replacing the Fuser Unit and Transfer Roller Kit20

Page 23

4

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Place the fuser oil roller on a table or level surface.

Attention

Since the fuser oil roller removed here is

to be installed in the new fuser unit,

handle it with care.

If you set the fuser oil roller on the table

do it as shown in the illustration. Do not

allow the roller surface to contact the

table or get dirty. This could lower image quality.

5

Turn the release levers

(front, rear) to release

the fuser unit.

Replacing the Fuser Unit and Transfer Roller Kit

21

Page 24

6

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Holding the fuser

unit handles, lift up

the unit.

Dispose of it

5"

properly

according to

your local

regulations.

7

Remove the new fuser from

its shipping box.

Replacing the Fuser Unit and Transfer Roller Kit22

Page 25

8

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Carefully lower the new fuser unit so that the two pins in the fuser unit

installation section go into the two installation holes in the fuser unit.

9

Press in on the fuser unit

release levers cand rotate

them downward d.

This secures the fuser unit.

1

1

1

2

2

1

1

Attention

If the fuser unit release levers are not set correctly, the fuser oil

roller cannot be installed. Set the fuser unit release levers to the

fixed position.

Replacing the Fuser Unit and Transfer Roller Kit

2

2

23

Page 26

10

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Reinstall the fuser oil roller

(removed in step 4).

11

Rotate the two oil roller

levers to lock the oil roller into place.

12

Close the printer’s top cover.

Check the release button to make

sure the top cover is properly closed.

Replacing the Transfer Roller Unit

If there is media in the multipurpose tray, remove it. Close the multi-

5"

purpose tray.

1

Press the right cover release

button and carefully open the right

cover.

Replacing the Fuser Unit and Transfer Roller Kit24

Page 27

2

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Holding the two transfer roller

unit handles, remove the transfer roller unit.

Dispose of it properly

5"

according to your local

regulations.

3

Remove the new transfer roller

unit from the fuser kit box.

Attention

Do not touch the surface of the transfer roller

unit. This could lower image quality.

4

Place the new transfer roller unit on a

level surface.

5

Lift up the two transfer roller unit handles.

6

Holding the two transfer roller unit

handles, carefully lower it so the

transfer roller unit shaft goes into

the two transfer roller unit installation guides.

Replacing the Fuser Unit and Transfer Roller Kit

25

Page 28

7

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Lower the two transfer roller

unit handles.

8

Carefully close the right

cover.

Check the release button

status to make sure the cover

is properly closed.

9

If necessary, reopen the

multipurpose tray and put the

media back in.

Replacing the Fuser Oil Roller

The fuser oil roller provides a lubricant for the printer via an oil-impregnated

roller. This oil is necessary for the proper functioning of the printer.

WARNING!

The fuser unit can become extremely hot and cause severe

burns. Make sure the unit is cool before handling it.

ACHTUNG! Die Fixiereinheit kann sehr heiß werden, so daß

Verbrennungsgefahr besteht. Bitte lassen Sie die Fixiereinheit einige

Zeit abühlen, bevor Sie diese berühren.

When the fuser oil roller is worn out, the message “

appears and the printer does not print. Replace the fuser oil roller. After the

new roller is installed, printing automatically resumes (if you have not turned

off the printer).

1

Open the printer’s top cover.

2

Rotate the two fuser oil roller lock

levers to release the fuser oil roller.

Dispose of it properly

5"

according to your local regulations.

REPLACE OIL ROLLER

”

Replacing the Fuser Oil Roller26

Page 29

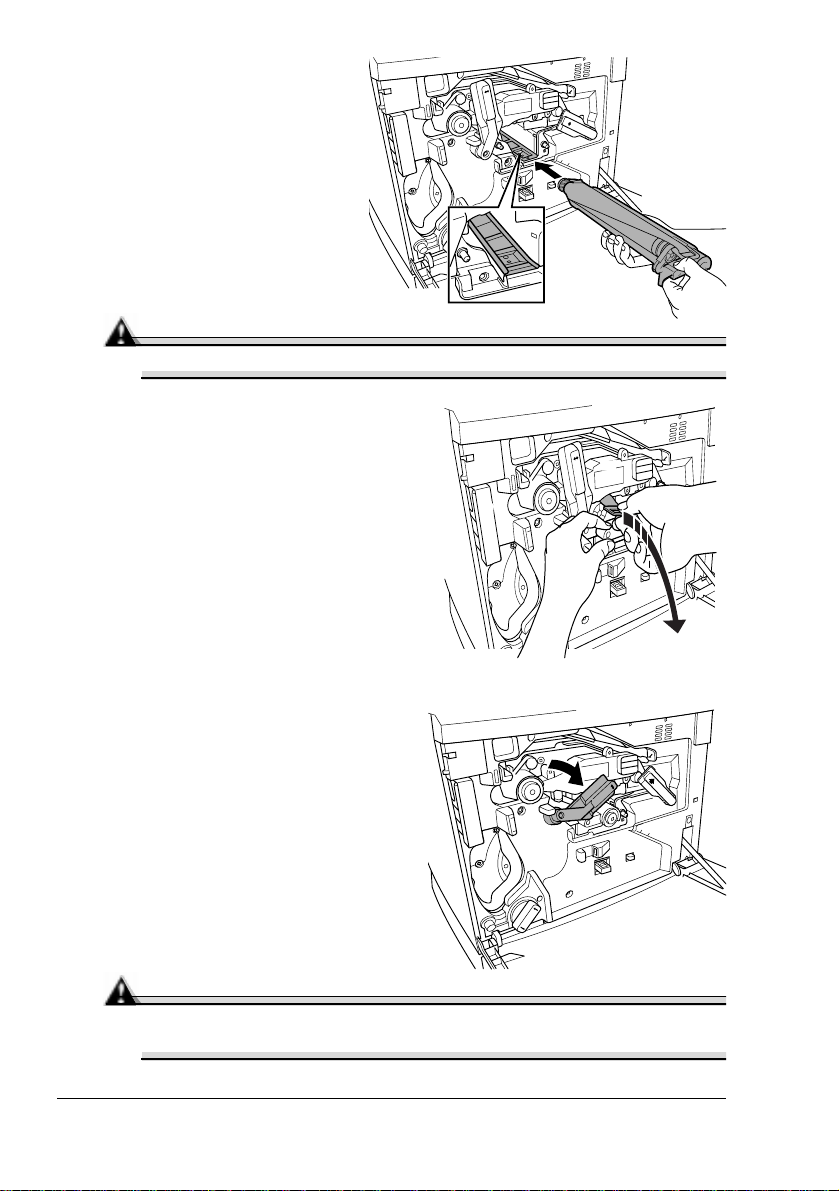

3

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Remove the new fuser oil roller from its shipping box.

Attention

If you set the new fuser oil roller on a table, do it

as shown in the illustration. Do not allow the

roller surface to contact the table or get dirty.

This could lower image quality.

4

Insert the new

fuser oil roller

installation guides

(front, rear) into

the fuser unit

installation rail.

5

Carefully lower the

roller.

6

Rotate the two oil roller levers

to lock the oil roller into place.

Attention

If the two fuser oil roller release levers are not correctly set, the

top cover cannot be closed. Set the release levers to the roller

fixed position.

7

Carefully close the top cover.

Check the release button to make sure the top cover is properly closed.

Replacing the Fuser Oil Roller

27

Page 30

Replacing the Transfer Belt

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

When the transfer belt is at the end of its life, the message “REPLACE

TRANSFER BELT” appears, and the printer does not print. Replace the trans-

fer belt. After the new transfer belt is installed, printing automatically resumes

(if you have not turned off the printer).

1

Open the printer’s front cover.

2

Remove the waste toner pack.

3

Rotate the left transfer belt

lock lever.

4

Remove the OPC drum cartridge and set it aside.

Replacing the Transfer Belt28

Page 31

Attention

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

The OPC drum is extremely sensitive to bright light and direct

sunlight. Always put it in its protective bag until you’re ready to

reinstall it. Any exposure to light should be avoided, or permanent

damage could result.

Also, handle the cartridge carefully by its sides so you don’t touch

the surface (the green part) of the drum. The drum is also extremely

sensitive to hand oils and scratches, both of which reduce print

quality.

5

Rotate the left lever to its

4 o’clock position.

6

Grasp the handles of the transfer belt and remove it.

Dispose of it properly according to your local regulations.

5"

Replacing the Transfer Belt

29

Page 32

7

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Remove the new transfer belt

from its packaging and insert it

into the printer.

8

Press on the transfer belt front

handle with one hand, take

the handle of the transfer belt

fixture with your other hand,

and pull the fixture straight

toward you.

Dispose of it properly

5"

according to your local

regulations.

9

Rotate the transfer belt lock

lever.

Replacing the Transfer Belt30

Page 33

10

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Reinstall the OPC

drum cartridge.

11

Close the transfer

belt lock lever.

12

Check to make sure the

laser lens cover is firmly

seated.

13

Reinstall the waste

toner pack.

14

Close the front cover.

Replacing the Transfer Belt

2

1

31

Page 34

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Page 35

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Using Media

2

Page 36

Introduction

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

This chapter provides information on handling, selecting, and storing media.

Refer to the

Maintenance Guide

for media specifications.

Media Handling

Before purchasing a large quantity of special media, do a trial printing

with the same media and check print quality. Check our web site

www.minolta-qms.com for a list of current approved media.

Attention

Do not use the media types listed below. These could cause poor print

quality, media jams, or damage to the printer.

Do not use media that is

„ Not approved

„ Meant for ink jet printers

„ Folded, embossed, warped, or wrinkled

„ Perforated or prepunched

„ Too slick, too coarse

„ Composed of foil or gilt

„ Coated with a processed surface (such as carbon paper, heat-sensitive

paper, heat-pressure paper)

„ Irregularly shaped (not rectangular); not uniform in size

„ Bound with glue, tape, or paper clips, or attached to ribbons, hooks, but-

tons, and so forth

Do not use envelopes that have

„ Sticky flaps

„ Metal clasps, fasteners, transparent windows, peel-off strips for sealing

„ Material that will melt, vaporize, offset discolor, or emit dangerous fumes

Do not use labels that have

„ Label(s) already peeled off

„ Labels that peel off easily

„ Glue or sealer that might come off

„ Material that will melt, vaporize, offset discolor, or emit dangerous fumes

Introduction34

Page 37

Media Types

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Plain Paper

Formatting

Input Upper and

Orientation Upper and

Type

Weight

Duplexing

Format data within your application.

500 sheets of 20 lb bond (75 g/m²) paper (letter/

Optional

Trays

Multipurpose

Tray

Optional

Trays

Multipurpose

Tray

Any standard or recycled office paper suitable for plain-paper

laser printers, such as

„ Hammermill Laser Print

„ Georgia-Pacific Microprint Laser 1000

„ Neusiedler Color Copy 90

„ Xerox 4024

16–24 lb bond (60–90 g/m²)

Up to 24 lb bond (90 g/m²)

A4/legal) each; capacity for other weights varies

accordingly.

150 sheets of 20 lb bond (75 g/m²) paper; capacity

for other weights varies accordingly.

Simplex—Face up; Duplex—Face down

Simplex—Face down; Duplex—Face up

Letterhead and Memo Media

Formatting

Input Upper and

Orientation Upper and

Format letterhead or memo data within your application. Try printing your data on a plain sheet of paper first to check placement.

Up to 500 sheets

Optional

Trays

Multipurpose

Tray

Optional

Trays

Multipurpose

Tray

Up to 150 sheets

Face up—top of page toward the right

Face down—top of page toward the printer side

Media Types

35

Page 38

Type

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Weight

Duplexing Upper and

Notes

Any standard or recycled office paper suitable for plain-paper laser

printers, such as

„ Hammermill Laser Print

„ Georgia-Pacific Microprint Laser 1000

„ Neusiedler Color Copy 90

„ Xerox 4024

16–24 lb bond (60–90 g/m²)

Optional

Trays

Multipurpose

Tray

Check your application documentation for other information about

printing on letterhead and memo media.

Thick Stock

Face down—top of page toward the right

Face up—top of page toward the printer side

Formatting

Input Multipurpose

Orientation

Type

Weight

Duplexing

Notes

Format the information to be printed on the thick stock within your

application. Try printing your data on a plain sheet of paper first to

check placement.

Tray Only

Face down

For information about thick stock media recommended for your

printer, go to www.minolta-qms.com/support, then click on Answer

Base, or contact Technical Support. See the

Guide

for a complete listing of support telephone numbers.

Simplex: 24–43 lb bond (90–163 g/m²)

Autoduplex: Up to 28 lb bond (105 g/m²)

Manual Duplex: 24 lb (90 g/m²) to 43 lb (163 g/m²) bond

Autoduplexing thick stock over 28 lbs (105 g/m²) is not supported.

Thicker stock may be manually duplexed.

You should test the number of sheets of thick stock the multipur-

pose tray can hold to ensure that its performance is acceptable.

43 lb (163 g/m²) bond is also referred to as 90 lb index stock.

Up to 50 sheets, depending on the thickness of the

media

Service & Support

Media Types36

Page 39

Envelopes

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Formatting

Input Multipurpose

Orientation

Type

Duplexing

Notes

Your printer receives the instructions to print on envelopes from

your application.

„ Print on the front side only. Some parts of the envelope consist

of three layers of paper—the front, back, and flap. Anything

printed in these layered regions may be lost or faded.

„ See your application documentation for specific information on

printing envelopes.

Tray Only

Face down

Use common office envelopes approved for laser printing with

diagonal joints, sharp folds and edges, and ordinary gummed

flaps, such as

„ Commercial #10: Columbian Recycled COR02

„ International DL: Auto Fil #01914

Not supported

„ You ca n pri n t

„ Envelopes should be dry.

„ Do not preload or preseal envelopes.

Labels

Up to 50, depending on the thickness of the envelopes

only

on the address side of the envelope.

Formatting

Input Multipurpose

Orientation

Type

Weight

Duplexing

Format label data within your application. Try printing your data on

a plain sheet of paper first to check placement.

Up to 50 sheets, depending on the thickness of the

Tray Only

Face down

Use only labels recommended for laser printers, such as Avery

5260

16–90 lb (60–163 g/m²)

Not supported

labels

Media Types

37

Page 40

Notes

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Postcards

„ Avoid using labels with exposed adhesive; it may stick to the

transfer belt or the fuser roller, causing labels to peel off and

media jams to occur.

„ Adhesive label stock is supported only in letter or A4 sheets.

„ A label consists of a face sheet (the printing surface), adhesive,

and a carrier sheet

— The face sheet must follow the plain paper specification.

— The face sheet surface must cover the entire carrier

sheet, and no adhesive should come through on the surface.

„ Y ou can print continuously with label paper . However, this could

affect the media feed, depending on the media quality and printing environment. If problems occur, stop the continuous print

and print one sheet at a time.

„ Check your application documentation for other information on

printing labels.

Formatting

Input Multipurpose

Orientation

Type

Weight

Duplexing

Notes

Format postcard data within your application. Try printing your

data on a plain sheet of paper first to check placement.

Tray Only

Face down

Use only postcards recommended for laser printers

16–90 lb (60–163 g/m²)

Not supported

If the postcard is warped, press on the warped

area before putting in multipurpose tray.

Transparencies

Formatting

Format the information to be printed on the transparencies within

your application. Try printing your data on a plain sheet of paper

first to check placement.

Up to 50 sheets, depending on the thickness of the

postcards

Media Types38

Page 41

Input Location Upper and Optional Trays

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Multipurpose tray

Capacity Up to 50 sheets, depending on the thickness of the

transparencies

If you have problems feeding 50 sheets, try loading only 5–10 sheets at a time. Loading a large

number of transparencies at a time may cause

static buildup, thus causing feeding problems

OrientationUpper and

Optional

Trays

Multipurpose

Tray

Type Use any full-color transparencies (also known as OHP film) that

meet normal photocopier standards. We recommend

„Q-Media Transparency Media for the magicolor 2200 Series for

color printing

„Q-Media Transparency Media for the magicolor 2200 Series for

monochrome printing

„3M PP2500 for monochrome printing

Duplexing Not supported

Notes „If you touch the face of transparencies with your bare hands,

print quality may be affected.

Face up

Face down

.

„Do not handle transparency media too much. Do not fan trans-

parency media before loading it. Resulting static electricity may

cause printing errors.

„Keep the media path clean. Transparencies are especially sen-

sitive to a dirty media path. If there are shadows on either the

top or the bottom of the sheets, see “Cleaning the Printer Interior” in the

„You can print continuously with transparencies. However, this

could affect the media feed, depending on the media quality

and printing environment. If problems occur, stop the continuous print and print one sheet at a time.

„Check your application documentation for other information

about printing on transparencies.

Maintenance Guide.

Media Types

39

Page 42

Loading Media

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Take off the top and bottom

sheets of a ream of paper. Holding a stack of approximately 250

sheets at a time, fan the stack to

prevent static buildup for the

paper before inserting it in a tray.

Do not fan transparency media.

5"

Attention

Always load the media short edge first.

Attention

Do not mix media of different sizes, types, or weights, as this will cause

printer jamming.

When refilling media, first remove any media remaining in the tray. Stack

„

it with the new media, even the edges, then reload it. Although the magicolor 2210 was designed for printing on a wide range of media types, it is

not intended to print exclusively on a single media type except plain

paper. Continuous printing on media other than plain paper (such as

envelopes, labels, thick stock, or transparencies) may adversely affect

print quality or reduce engine life.

For media other than standard plain paper or transparencies, both the

„

driver (Paper tab, Paper Type option) and the MP Size key on the control

panel need to be selected.

It is important to use the MP Size key to set the multipurpose tray to the

appropriate media size in order to obtain optimum printing results.

OHP

Autoduplexing

Duplex (2-sided) printing can be done automatically with the optional duplex

unit installed.

Only up to 24 lb (90g/m²) plain paper can be duplexed.

5"

Loading Media40

Page 43

If you are printing duplex from the upper or optional tray, load the media print-

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

ing-side down with the top of the media (or letterhead or memo information)

toward the right side of the tray. If you are printing duplex from the multipurpose tray, load the media printing-side up with the top of the media toward the

printer.

The options in the driver are Simplex (1-sided pages), or Long Edge

5"

(flipped horizontally as in a loose-leaf notebook), or Short Edge

(flipped vertically as on a clipboard).

Upper and Optional Media Trays

1

Slide the media tray open.

2

Push the media pressure plate

down to lock it in position.

Loading Media

41

Page 44

3

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Adjust the media guides to fit the size paper you’re loading.

Squeeze the retainers, move the guides to the appropriate location

(media sizes are listed on the tray), and release the retainers. The media

should fit easily between the guides.

4

Load the paper face-up, short

edge toward the right of the tray.

Often, an arrow on the media

package label indicates the

printing-side of the media.

Do not overfill the tray.

A fill limit mark is provided on

the inside of the tray. The

media tray holds 500 sheets

of 20 lb bond (75 g/m²) paper.

Loading Media42

Page 45

Make sure that the paper fits

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

easily between the guides and

the paper corners are under the

left and right media-separating

tabs and are not bent.

Attention

Always readjust the media guides after inserting the media.

Improperly adjusted guides may cause poor print quality, media

jams, or printer damage.

5

Slide the tray back into

the printer.

If you have

5"

removed the tray

from the printer,

slightly tilt up the

tray to insert it

into the installation

rails to slide it

back in.

Multipurpose Tray

Page sizes other than letter, A4, and legal can be printed only from the multipurpose tray (also known as tray 1). Use the MP (Multipurpose)

the control panel to set the page size.

Other special types of media (such as thick stock, transparencies, and envelopes) are also fed from the multipurpose tray. See “Media Specifications” in

Maintenance Guide

the

for more information about media.

Loading Media

Size

key on

43

Page 46

1

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Open the multipurpose tray on

the right side of the printer.

2

Open the media support.

Attention

Load only one type/size of media per tray at a time.

3

Load the media face down, short edge toward the printer.

DOWN

FACE

Loading Media44

Page 47

Often, an arrow on the paper

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

package label indicates the

face-up (printing) side of

the paper.

A fill limit mark is provided on the

inside of the media guides on the

multipurpose tray. The multipurpose tray holds 150 sheets of

20 lb bond (75 g/m²) paper.

4

Adjust the media guides to fit the

size media you’re loading.

A5

B5

A4

Attention

Always adjust the media guides after inserting the media. A guide

that is not properly adjusted can cause poor print quality, media

jams, or printer damage.

LTR.

LGL.

EXE.

5

Specify the media size in the multipurpose tray by using the MP Size key

on the control panel.

Printing Envelopes from the Multipurpose Tray

1

Flex the envelope stack (including the edges) to remove any stiffness.

2

Place the envelopes on a flat surface, and flatten them by pressing down

the corners.

3

Correct any bent corners, and then tap the envelopes on a flat surface to

align them.

Loading Media

45

Page 48

4

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Place the envelope stack into the multipurpose tray with the flap-side up.

Check your application documentation to determine if the flap should be

placed on the left or on the right. Print a single envelope to check the orientation before printing multiple copies.

5

Adjust the media guides to the width of the envelopes.

Make sure the guides are snug enough to keep the envelopes straight,

but not so tight that they buckle the envelopes.

6

Open the flap of each envelope immediately (before it cools) after the

envelope is delivered to the output tray.

Because the envelopes pass through heated rollers, the gummed

5"

area on the flaps may seal. Using envelopes with emulsion-based

glue avoids this problem.

Printing Area

The printing area on all media sizes is up to

about 0.157 inch (4 mm) from the edges of the

media.

Media Storage

When storing media, avoid:

Direct sunlight

„

Excess heat and humidity

„

Dust

„

If media has been removed from its wrapper, place it in its original packaging

and store in a cool, dark place on a level surface.

Media Storage46

Page 49

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Maintaining the

Printer

3

Page 50

Maintaining the Printer

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Handle the printer with care to preserve its life. Abuse may cause damage

and void your warranty. If dust and paper scraps remain on the inside or outside of the printer, printer performance and print quality will suffer, so the

printer should be cleaned periodically. Keep the following guidelines in mind:

WARNING!

T urn off the printer, unplug the power cord, and disconnect all interface

cables before cleaning. Do not spill water or detergent into the printer;

otherwise the printer will be damaged and an electric shock may occur.

ACHTUNG! Ziehen Sie den Netzstecker aus der Steckdose bevor Sie

den Drucker reinigen. Verschütten Sie kein Wasser oder andere

Flüssigkeiten auf dem Drucker, da das Gerät sonst beschädigt wird

oder die Gefahr eines elektrischen Schlages besteht.

If you have an optional 5-bin mailbox installed, turn the printer off first,

then turn off the mailbox.

„ Either clean the printer before use, or allow time after unplugging it to

allow the fuser unit to cool down.

Attention

The fuser unit is hot. When the top cover is opened,

the fuser unit temperature drops gradually (one hour

wait time).

„ Be careful when cleaning the inside or removing paper jams, as the fuser

unit and other internal parts may become very hot.

„ Do not place anything on the top of the printer.

„ Use a soft cloth to clean the printer.

„ Never spray cleaning solution directly on the printer’s surface; the spray

could penetrate through the air vents of the printer and damage the internal circuits. Avoid using abrasive or corrosive solutions or solutions that

contain solvents, (such as alcohol and benzene) to clean the printer.

„ Always test any cleaning solution (such as mild detergent) on a small area

of your printer to check the solution's performance.

„ Never use sharp or rough implements, such as wire or plastic

cleaning pads.

„ Always close the printer covers gently. Never expose the printer

to vibrations.

Maintaining the Printer48

Page 51

„ Do not put a cover on the printer immediately after using it. Turn it off and

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

wait until it cools down.

„ Do not leave the printer’s covers open for any length of time, especially in

well-lit places; light may damage the OPC drum cartridge.

„ Do not open the printer during printing.

„ Do not tap paper stacks on the printer.

„ Do not tilt, lubricate, or disassemble the printer.

„ Do not touch the electrical contacts, gears, or laser beam devices. Doing

so may damage the printer and cause the print quality to deteriorate.

„ Keep media in the output tray at minimum level. If the media stacks too

high, your printer may experience media jams and excessive media curl.

„ Lift the printer from the bottom only, using the carrying grips and the

carrying bars. Make sure two people are available to lift the printer when

moving it.

When moving the printer, keep the printer level to avoid toner spillage.

„ If you get toner on your skin, wash it off with cool water and neutral

detergent.

WARNING!

If you get toner in your eyes, wash it out immediately with cool water

and consult a doctor. Material Safety Data Sheets (MSDS) information

can be found at www.minolta-qms.com (click on the Answer Base).

ACHTUNG! Sollte Toner in Ihre Augen gelangen, die Augen unbedingt

sofort mit kaltem Wasser ausspülen und einen Artzt aufsuchen.

MSDS-Informationen (Material Safety Data Sheets; Datenblätter zur

Materialsicherheit) finden Sie im Internet unter www.minolta-qms.com

(klicken Sie auf “Answer Base”). Read all caution and warning labels

carefully, making sure to follow any instructions contained in them.

These labels are located on the inside of the printer’s covers and the

interior of the printer body.

„ Make sure any parts removed during cleaning are replaced before you

plug in the printer.

“Repacking the Printer” on page 143

See

instructions.

Maintaining the Printer

for printer storing and shipping

49

Page 52

Cleaning

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

You should perform a thorough cleaning every 30,000 single-sided pages,

every 12 months, or as needed, whichever comes earlier.

Always test any cleaning solution (such as a mild detergent) on a small area

of your printer to check the solution’s performance

Outside the Printer

Use Avoid

dry

A soft

control panel

A soft

the printer exterior

Mild detergent to clean the

printer exterior

Inside the Printer

cloth to clean the

damp

cloth to clean

Sharp or rough implements (such as wire or

plastic cleaning pads). Any liquid

Sharp or rough implements (such as wire or

plastic cleaning pads)

Abrasive or corrosive solutions that contain

solvents (such as alcohol or benzine)

This item needs

cleaning...

Laser lens cover Removing the waste toner pack to

Duplex unit paper

guides or rollers

OPC drum cartridge

Paper exit rollers

Printer interior

Registration roller

Transfer roller

After... By...

clean around it or to replace it.

Every 30,000 single-sided pages,

every 12 months, or as needed,

whichever comes earlier.

User

See the

nance Guide.

Mainte-

Cleaning50

Page 53

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Troubleshooting

4

Page 54

Introduction

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

This chapter provides information to aid you in resolving printer problems you

may encounter, or at least guide you to the proper sources for help.

Printing a Status Page

Print a status page to verify the printer is printing correctly.

Press Key (Until) Display Reads

Online IDLE (and online LED is off)

Menu OPERATOR CONTROL

Next ( )

Select ADMINISTRATION–SPECIAL PAGES

Select PRINT STATUS

Select YES

Online IDLE (and online LED is on)

ADMINISTRATION

Preventing Media Jams

Make sure that... Avoid...

Media matches the printer specifications

Media is flat, especially on the leading edge

The printer is on a hard, flat, level

surface

You have the correct media type

selected if you’re printing on envelopes, labels, thick stock, or transparencies.

You store media in a dry location

away from moisture and humidity

Media that is folded, wrinkled, or

excessively curled

Double feeding (

and fan the sheets—they may be

sticking together

Fanning transparencies since this

causes static

Loading more than one type/size/

weight of media in a tray at the

same time

Overfilling the media

remove the media

)

input

trays

Introduction52

Page 55

Make sure that... Avoid...

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

You always adjust the media width

regulation guides in the multipur-

after

pose tray

a guide that is not properly

(

adjusted can cause poor print quality, paper jams, or printer damage)

You remove transparencies from

the output tray immediately to avoid

static buildup.

Y ou load the media (for single-sided

pages) printing-side up in the upper

or optional trays or printing-side

down in the multipurpose tray (m

place an arrow on the end of the

wrapper to indicate the printing

side—if you can’t determine which

side of the media to print on,

remove the media from the tray,

rotate the stack a half-turn, turn the

stack over, and then place it back in

the tray)

inserting the media

any manufacturers

Allowing the

the face-down output tray has a

(

500-sheet capacity—jamming may

occur if you allow media to accumulate more than 500 sheets at a time

output

tray to overfill

)

Automatic Jam Recovery

The magicolor 2210 provides automatic jam recovery (when enabled through

the Administration/Engine/Page Recovery menu). After you remove any

jammed media, printing automatically resumes from the page the printer

stopped at when the jam occurred.

For automatic jam recovery to work, it is necessary to leave the printer

5"

turned on when you remove the jammed media.

Automatic Jam Recovery

53

Page 56

Understanding the Media Path

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Understanding the printer’s media path will help you locate media jams.

cccc

Media exit unit

dddd

Output tray

eeee

Fuser

ffff

Transfer belt

gggg

OPC drum cartridge

hhhh

Duplex unit (optional)

iiii

Multipurpose tray

jjjj

Upper media tray

kkkk

Lower feeder unit (LFU) and optional tray (optional)

llll

5-bin mailbox (optional)

cccc

Model with

LFU

Model with

LFU and

Mailbox

eeee

ffff

gggg

dddd

hhhh

iiii

jjjj

kkkk

llll

Simplex

Duplex

Understanding the Media Path54

Page 57

Media Tray (Standard Upper Tray and Optional Tray)

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

The media tray(s) is (are) located at the bottom front of the printer. The media

is picked from the tray, passed under the OPC drum cartridge and the

transfer belt, passed through the fuser, and delivered via the paper exit unit

to the output tray on top of the printer.

Lower Feed Unit (LFU) Tray(s)

The LFU media tray(s) is (are) located at the bottom front of the printer in the

lower feeder unit(s). The media fed through the LFU is picked and delivered

to the output tray the same way as media from the standard upper tray.

Multipurpose Tray

The multipurpose tray is located at the right of the printer. The media is

picked from the multipurpose tray, passed under the OPC drum cartridge and

the transfer belt, passed through the fuser, and delivered via the paper exit

unit to the output tray on top of the printer.

Duplex Unit (Optional)

The media is picked from a media tray, passed under the transfer belt,

passed through the fuser, fed into the duplex unit where the media undergoes

a change in direction, cycles through the transfer belt and fuser again, and is

delivered via the paper exit unit to the output tray, which is the top of the

printer. Since several sheets cycle through the printer/duplex unit at the

same time, recovering from a media jam may require the removal of more

than one sheet.

To manually duplex, remove the media, flip it over, and reload it.

5-bin Mailbox (Optional)

The 5-bin mailbox is located on the top of the printer. The media is picked

from the tray, passed under the transfer belt, passed through the fuser, and

delivered via the paper exit unit to the 5-bin mailbox, which is on top of the

printer.

Clearing Media Jams

To avoid damage, always remove jammed media gently, without tearing it.

Any pieces of media left in the printer, whether large or small, can obstruct

the paper path and cause further jams. Do not reload media that has jammed.

Clearing Media Jams

55

Page 58

Attention

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

The image is not fixed on the media before the fusing process. If you

touch the printed surface, the toner may stick to your hands, so be

careful not to touch the print face when removing the jammed media.

Make sure not to spill any toner inside the printer. Unfused toner can

dirty your hands, clothes, or anything else it gets on. If you accidentally

get toner on your hands, wash them in cool water. If you accidentally

get toner on your clothes, lightly dust them off as much as possible. If

some toner remains on your clothes, use cool, not hot water, to rinse

the toner off, provided your clothing is washable. If toner gets on your

skin, wash it off with water or a neutral detergent.

WARNING!

If you get toner in your eyes, wash it out immediately and consult a

doctor. Material Safety Data Sheets (MSDS) information can be found at

www.minolta-qms.com (click on the Answer Base).

ACHTUNG! Sollte Toner in Ihre Augen gelangen, die Augen unbedingt

sofort mit kaltem Wasser ausspülen und einen Artzt aufsuchen.

MSDS-Informationen (Material Safety Data Sheets; Datenblätter zur

Materialsicherheit) finden Sie im Internet unter www.minolta-qms.com

(klicken Sie auf “Answer Base”).

If, after clearing the media jam, the jam message in the control panel window

persists, open and close the printer’s covers. This should clear the jam

message.

Handling Media Jams by Location

Location of Jam Page Reference

Tray 1—multipurpose tray Page 58

Tray 2—upper tray

Tray 5—optional tray (lower feeder unit)

Near the OPC drum Page 59

Near the duplex unit Page 62

In the mailbox Page 65

In the output tray Page 66

Page 57

Clearing Media Jams56

Page 59

Clearing Misfeed (Upper or Optional Tray) Jams

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

1

Remove the media tray(s).

2

Carefully remove the jammed

media.

3

Shuffle the media currently in

the tray and even up the front edges.

4

Reinsert the media printing face up.

Make sure the media is lying flat, is under the

media separating tabs, and doesn’t exceed

the media limit mark. Check to see if the

media width guides are correct.

5

Slide the tray(s) back into the

printer.

6

Open the front cover, then

close it.

The media jam message is no

longer displayed in the printer

message window.

Clearing Media Jams

57

Page 60

Clearing Misfeed (Multipurpose Tray) Jams

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

1

Remove the media from in the multipurpose tray.

2

Carefully remove the jammed media.

3

Shuffle the media that was removed in

step 1 and even up the front edges.

4

Reinsert the media printing face down.

Make sure the media is lying flat and doesn’t

exceed the media limit mark. Check to see if

the media width guides are correct.

5

Open the front cover, then close it.

The media jam message is no longer displayed in the printer message

window.

Clearing Inner Jams, Outer Jams, and Drum Jams

Media Jams inside the Lower Right Door (Vertical

Transport Area)

1

Open the lower right door(s).

2

Carefully remove the jammed

media.

3

Close the lower right door(s).

The media jam message is no

longer displayed in the printer

message window.

Clearing Media Jams58

Page 61

Media Jams near the OPC Drum

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

1

If there is any media in the multipurpose

tray, remove it and close the multipur pose

tray.

2

Press the right-side cover release button

and carefully open the cover all the way.

3

Remove the jammed

media by pulling it slowly

from the bottom of the

fuser.

Attention

Do not pull jammed media from the

top of the printer through the fusing

rollers.

This prevents any unfused toner

from dirtying the fuser rollers.

Clearing Media Jams

59

Page 62

4

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Close the right-side cover.

The media jam message is no longer displayed in the printer message

window.

5

Check the release button to make sure the cover is securely closed.

6

If media was removed in step 1, open the multipurpose tray.

7

Shuffle the media that was removed in

step 1 and even up the front edges.

8

Reinsert the media printing face down.

Make sure the media is lying flat and

doesn’t exceed the media limit mark.

Check to see if the media width guides

are correct.

Media Jams near the Duplex Unit (Optional)

1

Open the top cover.

Attention

Do not pull jammed media from

the top of the printer through the

fusing rollers.

This prevents any unfused toner

from dirtying the fuser rollers.

Clearing Media Jams60

Page 63

2

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Carefully remove the jammed

media in the top cover media

reverse area.

3

Open the media jam removal cover

with your left hand and carefully

remove the jammed media in the

duplex media feed area with your

right hand.

4

Close the media jam removal cover

with your left hand and close the

top cover.

5

Check the release button to make

sure the door is securely closed.

6

If the multipurpose tray is

closed, open it.

Clearing Media Jams

61

Page 64

7

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Pressing the duplex unit cover release,

carefully open the cover.

8

Remove the jammed media.

9

Close the duplex unit’s cover.

10

Close the multipurpose tray.

11

If there still is a jam message,

press the right-side cover release

button and carefully open the

cover all the way.

12

Lift the inner paper guide.

13

Remove the jammed media by pulling it toward you.

If the media came out easily, skip ahead to step 15.

If the media did not come out easily or if you cannot reach the media from

this area, keep the duplex unit’s lower cover open.

Clearing Media Jams62

Page 65

14

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Open the duplex unit cover.

15

Remove the jammed media by pulling it slowly from the bottom of the

fuser rollers.

Be careful not to touch the transfer belt while removing jammed media.

16

Close the printer’s top cover.

17

Close the duplex unit’s paper guide, lower cover, and top cover.

The media jam message is no longer displayed in the printer message

window.

Media Jams near the Fuser Unit

1

Open the top cover.

Attention

Do not pull jammed media from

the top of the printer through the

fusing rollers

.

This prevents any unfused toner

from dirtying the fuser rollers.

2

Carefully remove the jammed

media through the

removal cover

3

Open the media jam removal cover

and carefully remove the media that

is jammed there.

4

Close the media jam removal cover.

media jam

.

Clearing Media Jams

63

Page 66

5

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Close the top cover.

Check the release button to make sure the top cover is securely closed..

6

Open the right-side cover.

7

Remove the jammed media by pulling it slowly from the bottom of the

fuser.

Be careful not to touch the transfer

belt while removing jammed media.

8

Close the right-side cover.

Check the release button

to make sure the duplex unit

cover is securely closed.

The media jam message is no

longer displayed in the printer

message window.

Clearing Media Jams64

Page 67

Media Jams in the Optional 5-bin Mailbox

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

1

Carefully remove the jammed

media from the paper eject area

of the mailbox.

2

Open the mailbox door.

3

Lift up the paper jam removal

guide in the mailbox with your left

hand, and use your right hand to

carefully remove the jammed paper.

Clearing Media Jams

65

Page 68

4

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Close the mailbox door.

The media jam message is no

longer displayed in the printer

message window.

Media Jams in the Output Tray

Remove jammed media from the output tray by gently pulling it to the left

away from the media exit area.

Solving Problems with Media Jams

Frequent jams in any area indicate that area should be checked,

5"

repaired, or cleaned. Repeated jams may also happen if you’re using

the wrong weight print media.

Symptom Cause Solution

Several

sheets go

through

the printer

together.

Paper jam

message

stays on.

5-bin mailbox jams.

The front edges of

the media are not

even.

The media is moist

from humidity.

Front cover needs

to be opened and

closed again to

reset the printer.

Some media

remains jammed in

the printer.

The wrong media

is being used.

Remove the havemedia and even up

the front edges, then reload it.

Remove the moist media and replace it

with new, dry media.

Open and close the front cover of the

printer again.

Recheck the paper path and make sure

you have removed all of the media

jams.

Make sure that you are using only plain paper (or recycled plain paper).

Make sure that you are using only letter/A4 plain paper.

Solving Problems with Media Jams66

Page 69

Symptom Cause Solution

EDNord - Istedgade 37A - 9000 Aalborg - telefon 96333500

Duplex

unit jams.

Media is

jamming.

The wrong media

is being used.

Media may still be

jammed.

The media is not

correctly positioned

in the tray.

The number of

sheets in the tray

exceeds the maximum allowed.

The width regulation guides are not

correctly adjusted

to the media size.

The media in upper

or optional tray is