Page 1

Service Manual

[General]

Di850

Page 2

Dual references may be used on the following:

Official O pti ons name : Popular Op ti ons name

EDH-5 : RADF

C-403/C-40 4 : LT and LCT

FN-115 : FNS

FN-7 : FNS

Cove r I nserte Cr : PI

PK-3 : PU

TMG-2 TU

ZK-2 : PZ

In-System Writer : ISW

Page 3

Page 4

CONTENTS

CONTENTS

SAFETYANDIMPORTANTW ARNINGITEMS

. . . . S-1

IMPORTANTNOTICE . . . . . . . . . . . . . . . . . S-1

DANGER,WA RN ING,AND CAUTION

SYMBOLSANDEXPRESSIONS . .S-1

SAFETYWARNINGS . . . . . . . . . . . . . . . . . . S-2

SAFETYINFORMATION

. . . . . . . . . . . . . . . . . S-9

IMPORTANTINFORMATION . . . . . . . . . . . S-9

SAFETYCIRCUITS . . . . . . . . . . . . . . . . . . .S-10

INDICATIONOFWARNINGONTHE

MACHINE

. . .S-12

1.OUTLINE

OUTLINE OF SYSTEM ...... ..... ................................ ..1-1

PRODUCT SPECIFICATIONS..................................1-2

CENTER CROSS-SECTIONAL VIEW......................1-4

DRIVE SYSTEM DIAGRAM.................................... ..1-5

[1] Main Drive Section .....................................1-5

[2] Drum Drive Section......................... ..... ......1-6

[3] Developing Drive Section...........................1-7

[4] Paper Feed Drive Section..........................1-7

[5] Tray 1 and 2 Pape r Feed Drive Secti on .....1-8

[6] Tray 3 Paper Feed Drive Section ...............1-9

[7] Vertical Conveyance Drive Section..........1-10

[8] By-pass Paper Feed Drive Section..........1-11

[9] Conveyance/Transfer and Separation

Wire Cleaning Drive Section ....................1-12

[10] ADU Conveyance Drive Section ..............1-13

[11] Paper Exit Drive Section ..........................1-14

[12] Toner Supply Drive section......................1-14

[13] Optics Drive Section.................................1-15

[14] Web Drive Section....................................1-16

2.UNIT EXPLANATION

EXTERNAL SECTION...........................................2-A-1

[1] Composition ...........................................2-A-1

DRIVE SECTION....................................... ..... .......2-B-1

[1] Composition ...........................................2-B-1

[2] Mechanisms ...........................................2-B-1

[3] M1 (Main) Control...................................2-B-2

[4] M2 (Drum) Control..................................2-B-2

READ SECTION....................................................2-C-1

[1] Composition ...........................................2-C-1

[2] Mechanisms ...........................................2-C-1

[3] M13 (Scanner Drive) Control..................2-C-2

[4] Exposure control ....................................2-C-4

[5] Original Read Control.............................2-C-5

[6] APS Control............................................2-C-5

[7] AE Control..............................................2-C-7

WRITE UNIT..........................................................2-D-1

[1] Composition ...........................................2-D-1

[2] Mechanisms ...........................................2-D-1

[3] M17 (Polygon) Control ...........................2-D-2

[4] Image Write Control ...............................2-D-4

DRUM UNIT............................. .... ..........................2-E-1

[1] Composition ...........................................2-E-1

[2] Mechanisms ...........................................2-E-1

[3] Separation Claw Control ................. ..... ..2-E-2

[4] Paper Guide Plate Control .....................2-E-2

[5] Drum Potential Control...........................2-E-3

CORONA UNIT SECTION......................... ..... ..... ..2-F-1

[1] Composition ...........................................2-F-1

[2] Mechanisms ...........................................2-F-1

[3] Charging Control ....................................2-F-2

[4] Transfer/Separation Control...................2-F-3

[5] M23 (Charger Cleaning) Control............2-F-4

[6] M18 (Transfer/Separation Cleaning)

Control....................................................2-F-5

3 DIS./ASSEMBLY1 OUTLINE2 UNIT EXPLANATION

Page 5

CONTENTS

[7] PCL/TSL Control ....................................2-F-6

DEVELOPING UNIT .............................................2-G-1

3 DIS./ASSEMBLY1 OUTLINE3 DIS./ASSEMBLY2 UNIT EXPLANATION

[1] Composition........................................... 2-G-1

[2] Mechanisms.......................................... 2-G-1

[3] M3 (Developing Unit Drive) Control....... 2-G-2

[4] Developing Bias Control........................2-G-2

[5] Toner Density Control............................2-G-3

[6] Dmax Control......................................... 2-G-4

[7] Gradation Correction Control................. 2-G-6

[8] Dot Diameter Correction Control........... 2-G-7

[9] FM2 (Developing Suction) Control........ 2-G-8

TONER SUPPLY UNIT..........................................2-H-1

[1] Composition............................................2-H-1

[2] Mechanisms ...........................................2-H-1

[3] Toner Level Detection Control................2-H-2

[4] M11 (Toner Supply 1) Control................2-H-3

CLEANING/TONER RECYCLE UNIT....................2-I-1

[1] Composition.............................................2-I-1

[2] Mechanisms ............................................2-I-1

[3] M14 (Blade) Control ................................2-I-2

TRAY 1/2 PAPER FEED UNIT..............................2-J-1

[1] Composition............................................ 2-J-1

[2] Mechanisms ...........................................2-J-1

[3] First Paper Feed Control........................2-J-3

[4] Paper Up Drive Control .......................... 2-J-5

[5] Paper Size Detection Control.................2-J-7

[6] No paper detection control..................... 2-J-8

TRAY 3 PAPER FEED UNIT.................................2-K-1

[1] Composition............................................2-K-1

[2] Mechanisms ...........................................2-K-1

[3] First Paper Feed Control........................2-K-3

[4] Paper Up Drive Control ..........................2-K-4

[5] Paper Size Detection Control.................2-K-5

[6] No paper detection control.....................2-K-5

BY-PASS TRAY.....................................................2-L-1

[1] Composition............................................2-L-1

[2] Mechanisms ...........................................2-L-1

[3] First Paper Feed Control........................2-L-2

[4] Paper Up/down Control..........................2-L-3

[5] Paper Size Detection Control.................2-L-4

[6] No paper detection control.....................2-L-4

VERTICAL PAPER CONVEYANCE SECTION.... 2-M-1

[1] Composition........................................... 2-M-1

[2] Mechanisms..........................................2-M-1

[3] Vertical Paper Conveyance Control...... 2-M-2

ADU.......................................................................2-N-1

[1] Composition............................................2-N-1

[2] Mechanisms ...........................................2-N-2

[3] Loop/Second Paper Feed Control..........2-N-9

[4] Paper Conveyance Control ..................2-N-10

[5] Paper Reverse and Exit Control...........2-N-11

[6] ADU Paper Feed/Reversal Control......2-N-13

[7] ADU Paper Conveyance/Feed

Control..................................................2-N-15

FIXING UNIT.........................................................2-O-1

[1] Composition ...........................................2-O-1

[2] Mechanisms ...........................................2-O-2

[3] M16 (Web Drive) Control .......................2-O-5

[4] Fixing Temperature Control ...................2-O-6

[5] SD3 (Fixing Guide) Control....................2-O-8

OTHER KINDS OF CONTROL ...... .... ...................2-P-1

[1] Parts Energized when the Main

Switch is OFF.........................................2-P-1

[2] Parts that Operate when the SW1

(Main) is Turned ON...............................2-P-2

[3] Cooling Fan Control ...............................2-P-3

[4] Operation Panel Control.........................2-P-6

[5] Counter Control......................................2-P-8

[6] Option Control........................................2-P-9

Page 6

SAFETY AND IMPORT ANT WARNING ITEMS

SAFETY AND IMPORTANT WARNING ITEMS

Read carefully the Safety and Important Warning Items described below to understand them before doing service work.

IMPORTANT NOTICE

Because of possible hazards to an inexperienced person servicing this copier as well as the risk of damage to

the copier, Minolta Corporation s tron gly re comm ends that all se rvicing be performed only by Minolta-trained service technicians.

Changes may have been made to this copier to improve its performance after this Service Manual was printed.

Accordingly, Minolta Corporation does not warrant, either explicitly or implicitly, that the information contained in

this Service Manual is complete and accurate.

The user of this Service Manual must assume all risks of personal injury and/or damage to the copier while servicing the copier for which this Service Manual is intended.

Therefore, this Service Manual must be carefully read before doing service work both in the course of technical

training and even after that, for performing maintenance and control of the copier properly.

Keep this Service Manual also for future service.

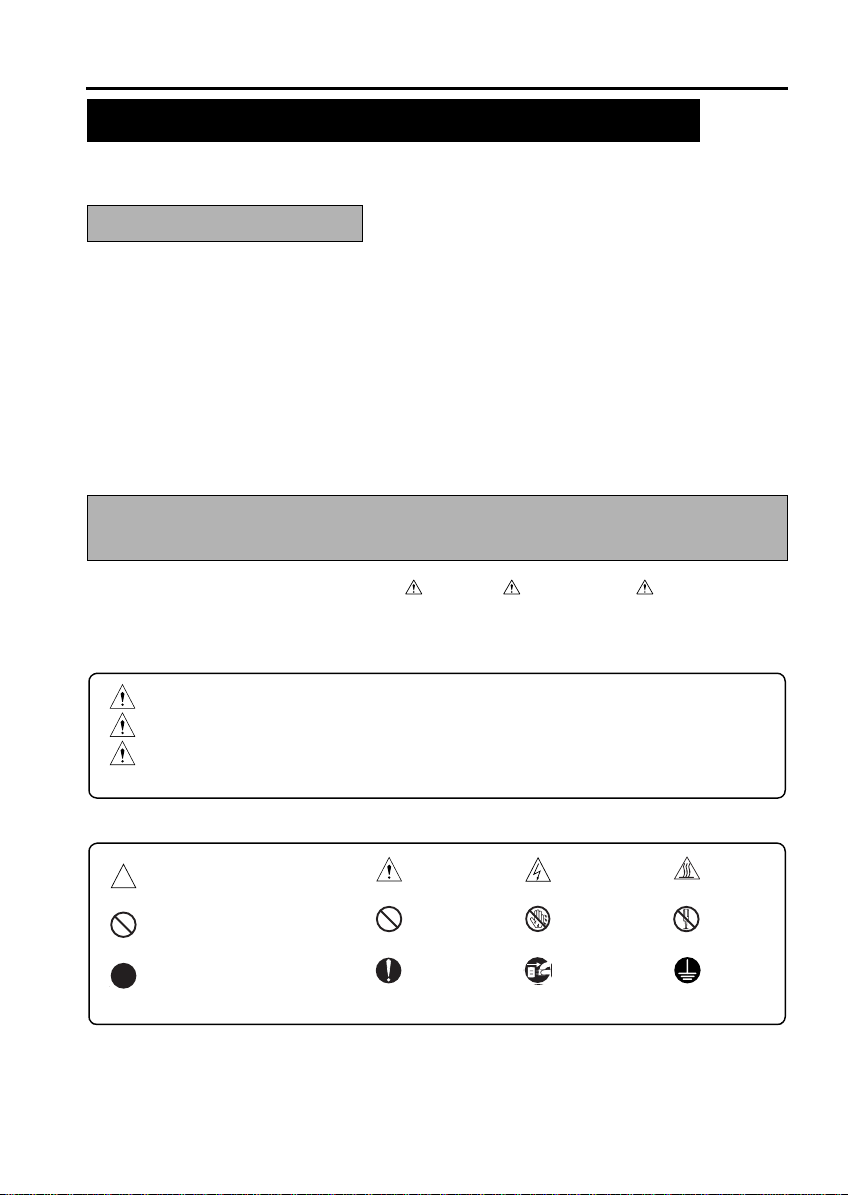

DANGER, WARNING, AND CAUTION SYMBOLS AND

EXPRESSIONS

In this Service Manual, each of three expressions " DANGER," " WARNING," and " CAUTION" is defined

as follows together with a symbol mark to be used in a limited meaning.

When servicing the copier, the relevant works (disassembling, reassembling, adjustment, repair, maintenance,

etc.) need to be conducted with utmost care.

DANGER :Action having a high possibility of suffering death or serious injury

WARNING:Action having a possibility of suffering death or serious injury

CAUTION :Action having a possibility of suffering a slight wound, medium trouble, and property

damage

Symbols used for important warning items are defined as follows:

:Precaution

:Prohibition

:Direction

General precaution Electric shock Heated surface

General prohibition Do not touch with wet hand Do not disassemble

General instruction Unplug Ground/Earth

S-1

Page 7

SAFETY AND IMPORTANT WARNING ITEMS

SAFETY WARNING S

[1] MODIFICATIONS NOT AUTHORIZED BY MINOLTA

Minolta copiers are renowned for their high reliability. This reliability is achieved through high-quality design and

a solid service network.

Copier design is a highly complicated and delicate process where numerous mechanical, physical, and electrical

aspects have to be taken into consideration, with the aim of arriving at proper tolerances and safety factors. For

this reason, unauthorized modifications involve a high risk of degradation in performance and safety. Such modifications are therefore strictly prohibited. the points listed below are not exhaustive, but they illustrate the reasoning behind this policy.

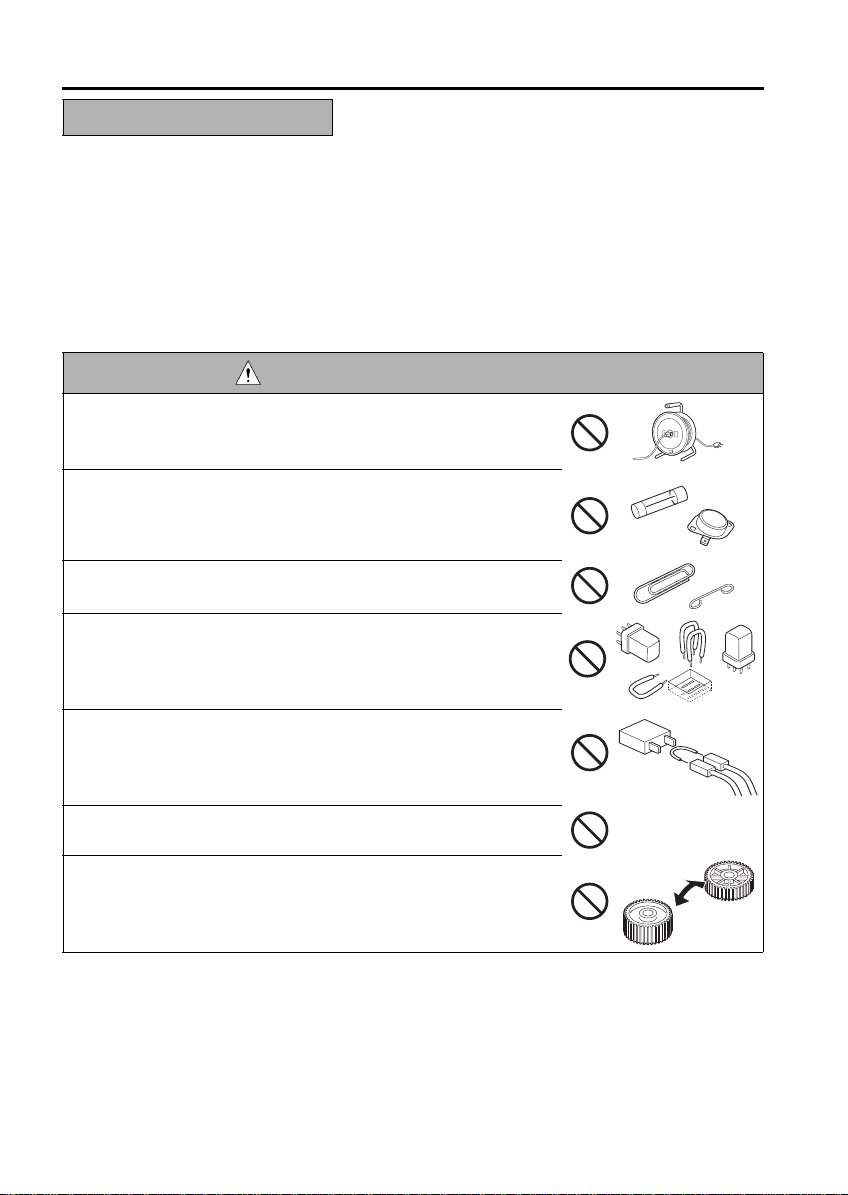

PROHIBITED ACTIONS:

• Using any cables or power cord not specified by Minolta.

• Using any fuse or thermostat not specified by Minolta. Safety will not be

assured, leading to a risk of fire and injury.

• Disabling fuse functions or bridging fuse terminals with wire, metal clips, solder or similar object.

• Disabling relay functions (such as wedging paper between relay contacts)

• Disabling safety functions (interlocks, safety circuits, etc.) Safety will not be

assured, leading to a risk of fire and injury.

• Making any modification to the copier unless instructed by Minolta

• Using parts not specified by Minolta

S-2

Page 8

SAFETY AND IMPORT ANT WARNING ITEMS

[2] CHECKPOINTS WHEN PERFORMING ON-SITE SERVICE

Minolta copiers are extensively tested before shipping, to ensure that all applicable safety standards are met, in

order to protect the customer and customer engineer (hereaf ter called the CE) from the risk of injury. However, in

daily use, any electrical equipment may be subject to parts wear and eventual failure. In order to maintain safety

and reliability , the CE must perform regular safety checks.

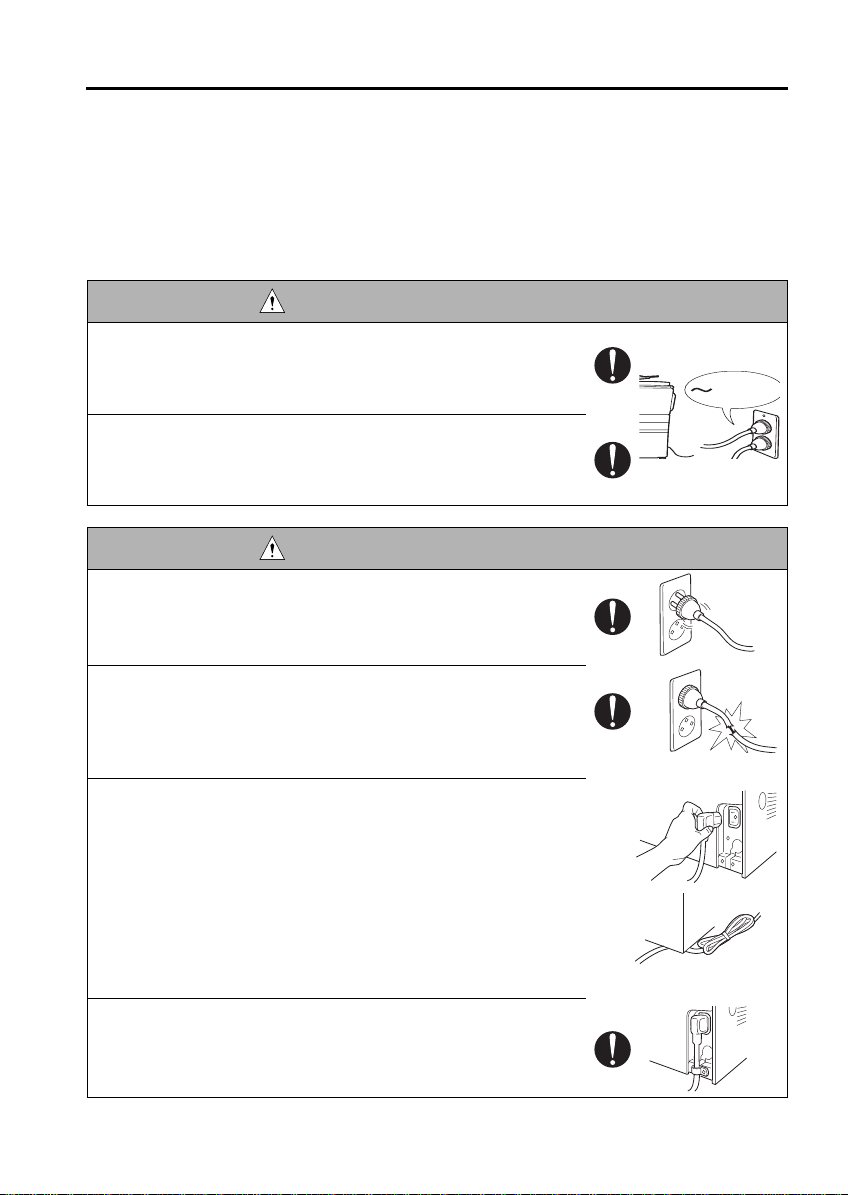

1.Power Supply

WARNING: Wall Outlet

• Check that mains voltage is as specified. Plug the power cord into the dedicated wall outlet with a capacity greater than the maximum power consumption.

If excessive current flows in the wall outlet, fire may result.

• If two or more power cords can be plugged into the wall outlet, the total load

must not exceed the rating of the wall outlet.

If excessive current flows in the wall outlet, fire may result.

kw

WARNING: Power Plug and Cord

• Make sure the power cord is plugged in the wall outlet securely.

Contact problems may lead to increased resistance, overheating, and the

risk of fire .

• Check whether the power cord is damaged. Check whether the sheath is

damaged.

If the power plug, cord, or sheath is damaged, replace with a new power

cord (with plugs on both ends) specified by Minolta. Using the damaged

power cord may result in fire or electric shock.

• When using the power cord (inlet type) that came with this copier, be sure to

observe the following precautions:

a. Make sure the copier-side power plug is securely inserted in the socket

on the rear panel of the copier.

Secure the cord with a fixture properly.

b. If the power cord or sheath is damaged, replace with a new power cord

(with plugs on both ends) specified by Minolta.

If the power cord (inlet type) is not connected to the copier securely, a

contact problem may lead to increased resistance, overheating, and risk

of fire.

• Check whether the power cord is not stepped on or pinched by a table and

so on.

Overheating may occur there, leading to a risk of fire.

S-3

Page 9

SAFETY AND IMPORTANT WARNING ITEMS

WARNING: Power Plug and Cord

• Do not bundle or tie the power cord.

Overheating may occur there , leading to a risk of fire.

• Check whether dust is collected around the power plug and wall outlet.

Using the power plug and wall outlet without removing dust may result in

fire.

• Do not insert the power plug into the wall outlet with a wet hand.

The risk of electric shock exists.

• When unplugging the power cord, grasp the plug, not the cable.

The cable may be broken, leading to a risk of fire and electric shock.

WARNING: Wiring

• Never use multi-plug adapters to plug multiple power cords in the same out-

let.

If used, the risk of fire exists.

• When an extension cord is required, use a specified one.

Current that can flow in the extension cord is limited, so using a too long

extension cord may result in fire.

Do not use an extension cable reel with the cable taken up. Fire may

result.

WARNING: Ground Lead

• Check whether the copier is grounded properly.

If current leakage occurs in an ungrounded copier, you may suffer electric

shock while operating the copier. Connect the ground lead to one of the

following points:

a. Ground terminal of wall outlet

b. Ground terminal for which Class D work has been done

S-4

Page 10

SAFETY AND IMPORTANT WARNING ITEMS

WARNING: Ground Lead

• Pay attention to the point to which the ground lead is connected.

Connecting the ground lead to an improper point such as the points listed

below results in a risk of explosion and electric shock:

a. Gas pipe (A risk of explosion or fire exists.)

b. Lightning rod (A risk of electric shock or fire exists.)

c. Telephone line ground (A risk of electric shock or fire exists in the case

of lightning.)

d. Water pipe or faucet (It may include a plastic portion.)

2.Installation Requirements

WARNING: Prohibited Installation Place

• Do not place the copier near flammable materials such as curtains or volatile

materials that may catch fire.

A risk of fire exists.

• Do not place the copier in a place exposed to water such as rain water.

A risk of fire and electric shock exists.

WARNING: Nonoperational Handling

• When the copier is not used over an extended period of time (holidays, etc.),

switch it off and unplug the power cord.

Dust collected around the power plug and outlet may cause fire.

CAUTION: Temperature and Humidity

• Do not place the copier in a place exposed to direct sunlight or near a heat

source such as a heater.

A risk of degradation in copier performance or deformation exists.

Do not place the copier in a place exposed to cool wind.

Recommended temperature and humidity are as follows:

Temperature: 10

Humidity: 10% to 80% (no dew condensation)

Avoid other environments as much as possible.

°C to 30°C 50 °F to 86°F

CAUTION: Ventilation

• Do not place the copier in a place where there is much dust, cigarette smoke,

or ammonia gas.

Place the copier in a well ventilated place to prevent machine problems

and image faults.

S-5

Page 11

SAFETY AND IMPORTANT WARNING ITEMS

CAUTION: Ventilation

• The copier generates ozone gas during operation, but it is not sufficient to b e

harmful to the human body.

If a bad smell of ozone is present in the f ollowing c ases , ve ntilate t he room.

a. When the copier is used in a poorly ventilated room

b. When taking a lot of copies

c. When using multiple copiers at the same time

CAUTION: Vibration

• When installing the copier, read the Installation Guide thoroughly. Be sure to

install the copier in a level and sturdy place.

Constant vibration will cause problems.

• Be sure to lock the caster stoppers.

In the case of an earthquake and so on, the copier may slide, leading to a

injury.

CAUTION: Inspection before Servicing

• Before conducting an inspection, read all relevant documentation (Service

Manual, technical notices, etc.) and proceed with the in spec tion following the

prescribed procedure, using only the prescribed tools. Do not make any

adjustment not described in the documentation.

If the prescribed procedure or tool is not used, the copier may break and a

risk of injury or fire exists.

• Before conducting an inspection, be su re to disconnect the power plugs from

the copier and options.

When the power plug is inserted in the wall outlet, some units are still powered even if the POWER switch is turned OFF. A risk of electric shock

exists.

• The area around the fixing unit is hot.

Yo u may get burnt.

DANGER: Work Performed with the Copier Powered

• Take every care when making adjustments or performing an operation check

with the copier powered.

If you make adjustments or perform an operation check with the external

cover detached, you may touch live or high-voltage parts or you may be

caught in moving gears or the timing belt, leading to a risk of injury.

S-6

Page 12

SAFETY AND IMPORT ANT WARNING ITEMS

DANGER: Work Performed with the Copier Powered

• Take every care when servicing with the external cover detached.

High-voltage exists around the drum unit. A risk of electric shock exists.

WARNING: Safety Checkpoints

• Check the exterior and frame for edges, burrs, and other damages.

Personal injuries may result.

• Do not allow any metal parts such as clips, staples, and screw s to f all into the

copier.

They can short internal circuits and cause electric shock or fire.

• Check wiring for squeezing and any other dam age.

Current can leak, leading to a risk of electric shock or fire.

• When disconnecting connectors, grasp the connector, not the cable.

(Specifically, connectors of the AC line and high-voltage parts)

Current can leak, leading to a risk of electric shock or fire.

• Carefully remove all toner remnants and dust from electrical parts and elec-

trode units such as a charging corona unit.

Current can leak, leading to a risk of copier trouble or fire.

• Check high-voltage cables and sheaths for any damage.

Current can leak, leading to a risk of electric shock or fire.

• Check electrode units such as a charging corona unit for deterioration and

sign of leakage.

Current can leak, leading to a risk of trouble or fire.

• Before disassembling or adjusting the write unit incorporating a laser, make

sure that the power cord has been disconnected.

The laser light can enter your eye, leading to a risk of loss of eyes ight.

• Do not remove the cover of the write unit. Do not supply power with the write

unit shifted from the specified mounting position.

The laser light can enter your eye, leading to a risk of loss of eyes ight.

• When replacing a lithium battery, replace it with a new lithium battery speci-

fied in the Parts Guide Manual. Dis pose of the used lithium battery using the

method specified by local authority.

Improper replacement can cause explosion.

S-7

Page 13

SAFETY AND IMPORTANT WARNING ITEMS

WARNING: Safety Checkpoints

• After replacing a part to which AC voltage is applied (e.g., optical lamp and

fixing lamp), be sure to check the installation state.

A risk of fire exi sts.

• Check the interlock switch and actuator for loosening and check whether the

interlock functions properly.

If the interlock does not function, you may receive an electric shock or be

injured when you insert your hand in the copier (e.g., for clearing paper

jam).

• Make sure the wiring cannot come into contact with sharp edges, burrs, or

other pointed parts.

Current can leak, leading to a risk of electric shock or fire.

• Make sure that all screws, components, wiring, connectors, etc. that were

removed for safety check and maintenance have been reinstalled in the original location. (Pay special attention to forgotten connectors, pinched cables,

forgotten screws , etc.)

A risk of copier trouble, electric shock, and fire exists.

HANDLING OF MATERIALS FOR SERVICING

• Unplug the power cord from the wall outlet.

Drum cleaner (isopropyl alcohol) and roller cleaner (acetone-based) are

highly flammable and must be handled with care. A risk of fire exists.

• Do not replace the cover or turn the copier ON before any solvent remnants

on the cleaned parts have fully evaporated.

A risk of fire exi sts.

• Use only a small amount of cleaner at a time and take care not to spill any

liquid. If this happens, immediately wipe it off.

A risk of fire exi sts.

• When using any solvent, ventilate the room well.

Breathing large quantities of organic solvents can lead to discomfort.

S-8

Page 14

SAFETY INFORMATION

DANGER: HANDLING OF MATERIALS FOR SERVICING

• Toner and developer are not harmful substances, but care must be taken not

to breathe excessive amounts or let the substances come into contact with

eyes, etc. It may be stimulative .

If the substances get in the eye, rinse with plenty of water immediately.

When symptoms are noticeable, consult a physician.

• Never throw the used cartridge and toner into fire.

You may be burned due to dust explosion.

[3] CONCLUSION

1. Safety of users and customer engineers depends highly on accurate maintenance and administration.

Therefore, safety can be maintained by the appropriate daily service work conducted by the customer

engineer.

2. When performing service, each copier on the site must be tested for safety. The customer engineer must

verify the safety of parts and ensure appropriate management of the equipment.

SAFETY INFORMATION

IMPORTANT INFORMATION

The Center for Devices and Radiological Health (CDRH) of the U.S. Food and Drug Administration implemented

regulations for laser products manufactured since August 1, 1976. Compliance is mandatory for products marketed in the United States.

This copier is certified as a “Class 1” laser product under the U.S.

Department of Health and Human Services (DHHS) R adiat ion Performance Standard according to the Radiation

Control for Health and Safety Act of 1968. Since radiatio n emitt ed ins i de t his c opier is completely confined within

protective housings and ex ter nal covers, the laser beam cannot escape during any phase of normal user operation.

S-9

Page 15

SAFETY INFORMATION

SAFETY CIRCUITS

This machine is provided with the following safety circuits to prevent machine faults from resulting in serious accidents.

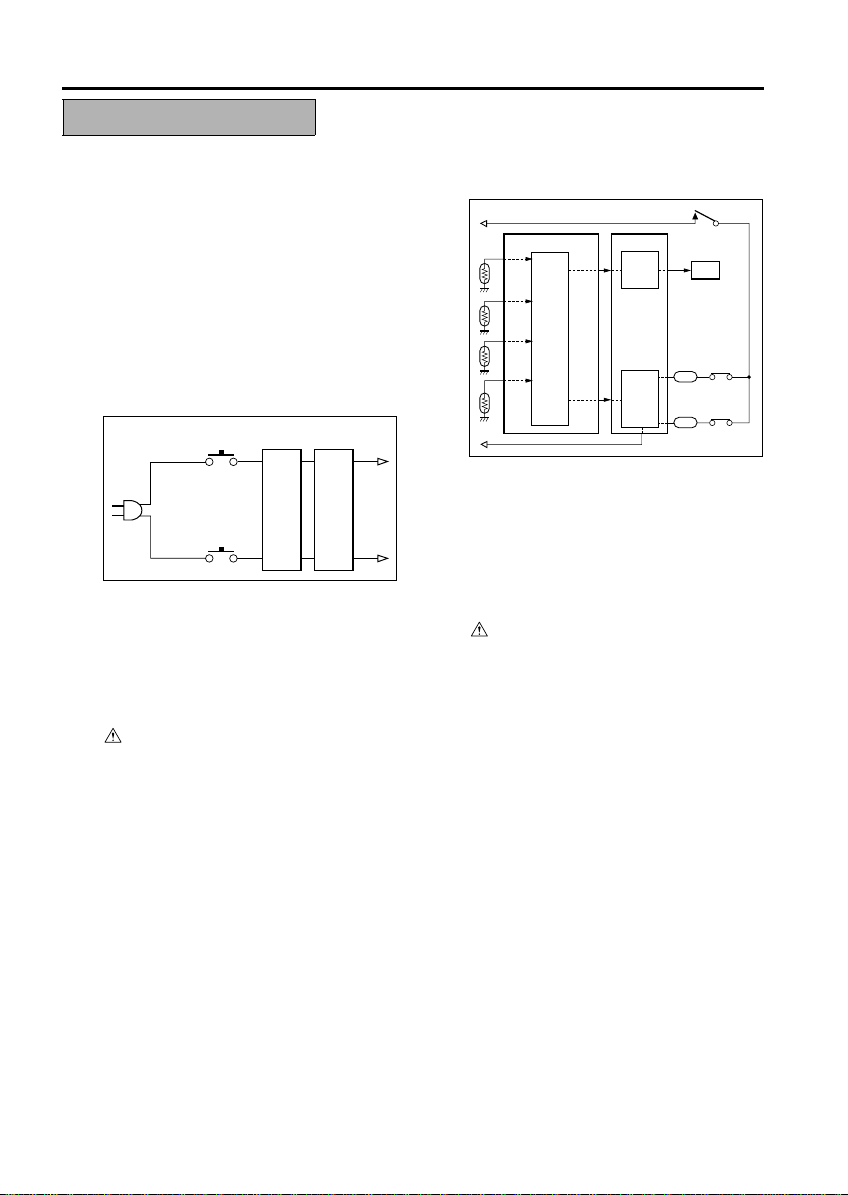

[1] Overall protection circuit

[2] L2 and L4 (fixing heater lamps) overheating

prevention circuit

These safety circuits are described below to provide

the service engineer with a renewed awareness of

them in order to prevent servicing errors that may

impair their functions.

[1] Overall Protection Circuit

CBR1

NF NF2

1. Protection by CBR1 and CBR2 (circuit

breakers)

CBR1 interrupt the AC line instantaneously

when an excessive c urrent flows due to a short

in the AC line.

CAUTION:

The CBR1 and CBR2 functions must not

be deactivated under any circumstances.

[2] Protection by L2 and L4 (fixi ng heater

lamps) overheating prevention circuit

ACDB

RL

driver

section

AC

driver

section

TH4

TH3

TH2

TH1

CB

Control

section

1. Protection by software

The output voltage from TH1 (fixing temperature sensor 1) is read by the CPU. If this voltage is abnormal, L2 (fixing heater lamp 1), and

L4 (fixing heater lamp 3), and RL1 (main relay)

are turned OFF.

CAUTION:

Do not change the gap between the roller

and TH1. When repl-acing TH1, check the

specified mounting dimensions.

The RL1 function must not be deactivated

under any circum-stances.

RL1

RL1

TS1

L2

L4

S-10

Page 16

2. Protection by the hardware circuit

The output voltages from TH1 and TH2 (fixing

temperature sensor 2), TH3 (fixing temperature sensor 3), and TH4 (fixing temperature

sensor 4) are compared with the abnormality

judgement reference value in the comparator

circuit. If the output voltage from TH1, TH2,

TH3, or TH4 exceeds the reference value, L2,

L4, and RL1 are turned off in hardware means.

CAUTION:

Periodically check t he TH2 and TH4 face s

contacting the roller, and replace TH2

and/or TH4 if any abnormality is detected.

Do not change the gap between the roller

and each sensor TH2 and TH4. When

replacing TH2 or TH4, check the specified

mounting dimensions.

The RL1 function must not be deactivated

under any circum-stances.

3. Protection by TS1 (thermostat (upper)) and

TS2 (thermostat (lower))

TS1 is turned off when the temperature of the

fixing roller (upper) exceeds the specified

value, and TS2 is turned off when the temperature of the heating (upper) roller exceeds the

specified value, thus interrupting the power to

L2 and L4 directly .

CAUTION:

Do not use any other electrical conductor

in place of TS1 and TS2.

SAFETY INFORMATION

S-11

Page 17

SAFETY INFORMATION

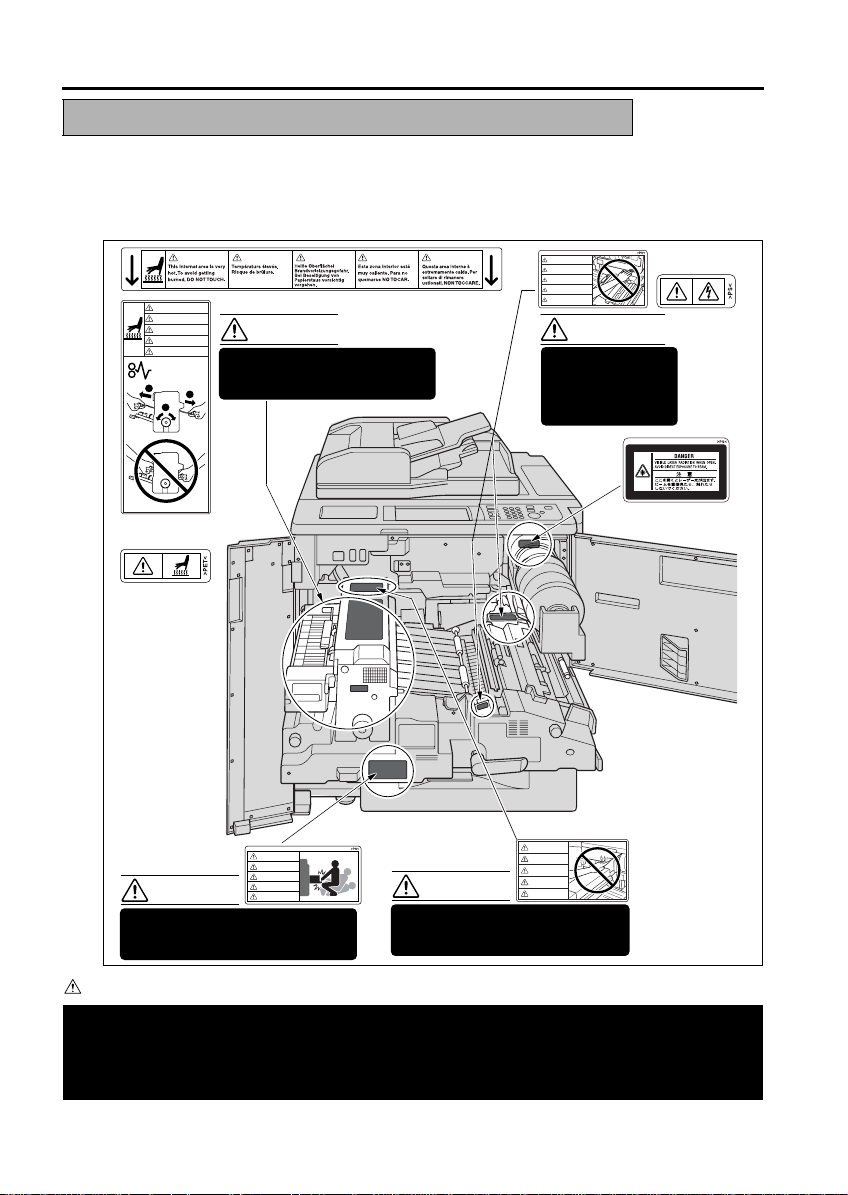

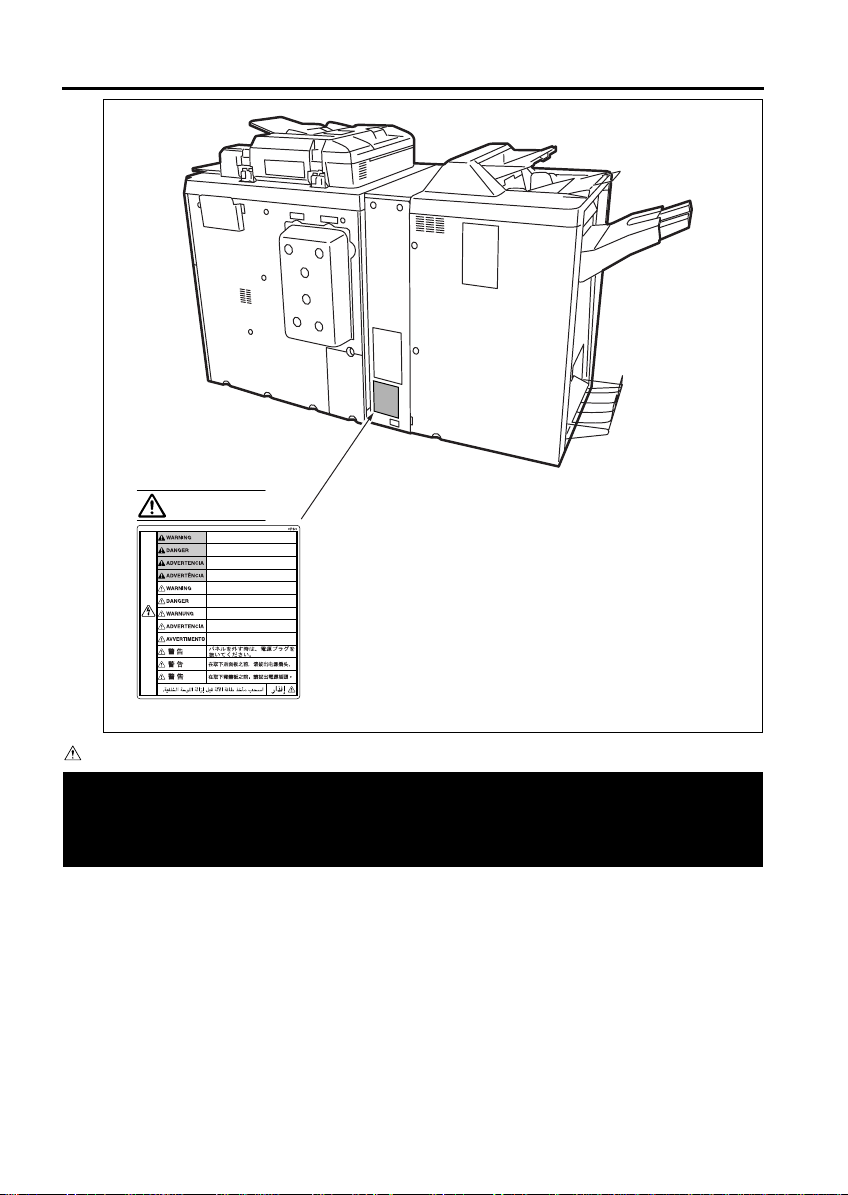

INDICATION OF WARNING ON THE MACHINE

Caution labels shown below are attached in some areas on/in the machine areas.

When accessing these areas for maintenance, repair, or adjustment, special care should be taken to avoid burns

and shock hazards.

CAUTION

CAUTION

ATTENTION

VORSICHT

PRECAUCION

ATTENZIONE

2

2

1

(Top surface of

the fixing unit)

(Inside of

the fixing unit)

(Front side of

the fixing unit)

ATTENTION

VORSICHT

PRECAUCION

(Both sides of the fixing unit)

CAUTION

The fixing unit is very hot.

To avoid getting burned DO NOT

TOUCH.

ATTENZIONE

WARNING

DANGER

WARNUNG

ADVERTENCIA

AVVERTIMENTO

WARNING

This area generates

high voltage. If

touched, electrical

shock may occur. DO

NOT TOUCH!

CAUTION

ATTENTION

VORSICHT

CAUTION

The conveyance fixing unit is heavy.

Use care and draw it out gently;

otherwise you may be injured.

PRECAUCION

ATTENZIONE

CAUTION

DO NOT put your hand between the

main body and developing fixing

unit; otherwise you may be injured.

CAUTION

Please adhere to all caution labels to avoid burns or injury.

S-12

CAUTION

ATTENTION

VORSICHT

PRECAUCION

ATTENZIONE

Page 18

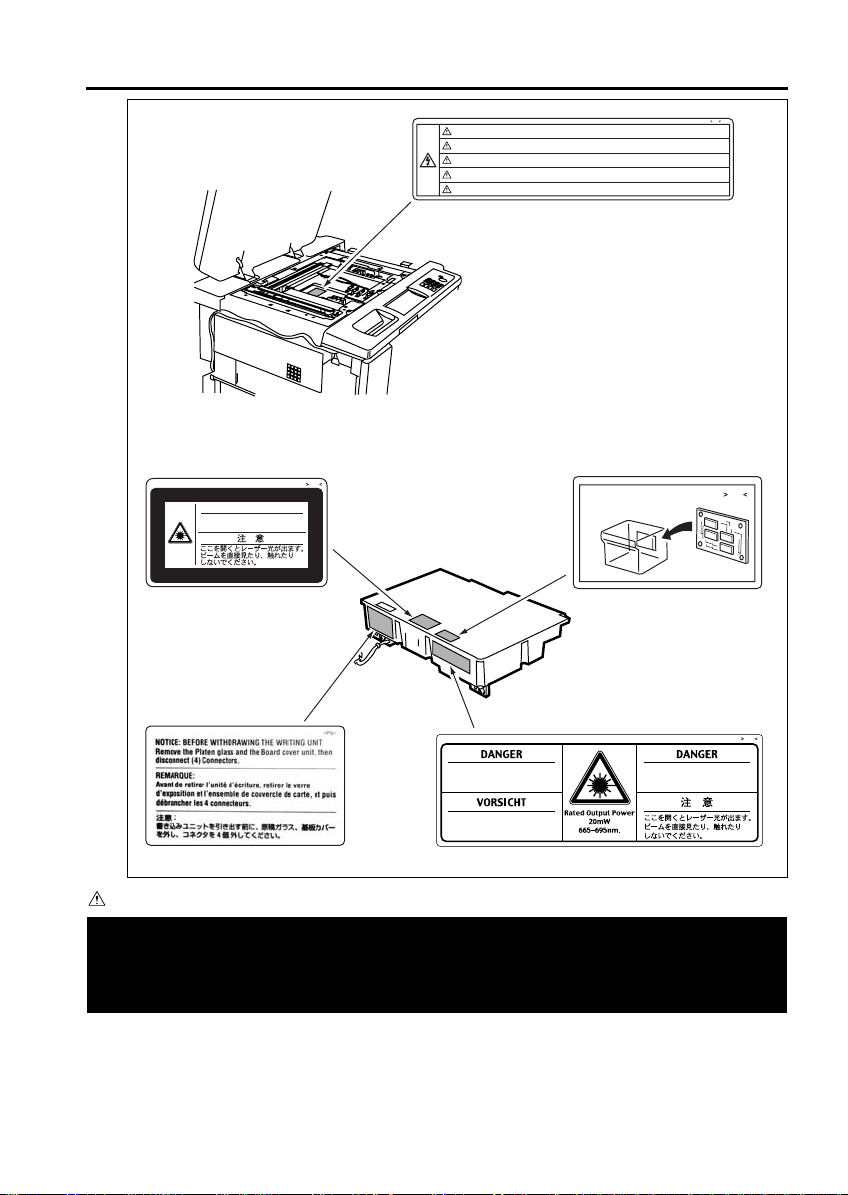

SAFETY INFORMATION

DANGER

VISIBLE LASER RADIATION WHEN OPEN.

AVOID DIRECT EXPOSURE TO BEAM.

Unplug the machine before removing platen glass.

WARNING

Debrancher le copieur avant de retirer la vitre d'exposition.

DANGER

Vor Entfernen des Vorlagenglases Netzstecker ziehen.

WARNUNG

Desenchufe la maquina antes de quitar el vidrio.

ADVERTENCIA

Estrarre la spina dalla presa prima di rimuovere il vetro di esposizione.

AVVERTIMENTO

PS

Elektrische T eile

In dieser Einheit

PS

PS

for BA standard

VISIBLE LASER RADIATION WHEN OPEN.

AVOID DIRECT EXPOSURE TO BEAM

LASERSTRAHLUNG,WENN ABDECKUNG

GEÖFFNET.

NICHT DEM STRAHL AUSSETZEN.

CAUTION

Please adhere to all caution labels to avoid burns or injury.

S-13

RAYON LASER VISIBLE LORS DE

L‘OUVERTURE.

EVITER L‘EXPOSITION DERECTE.

PS

Page 19

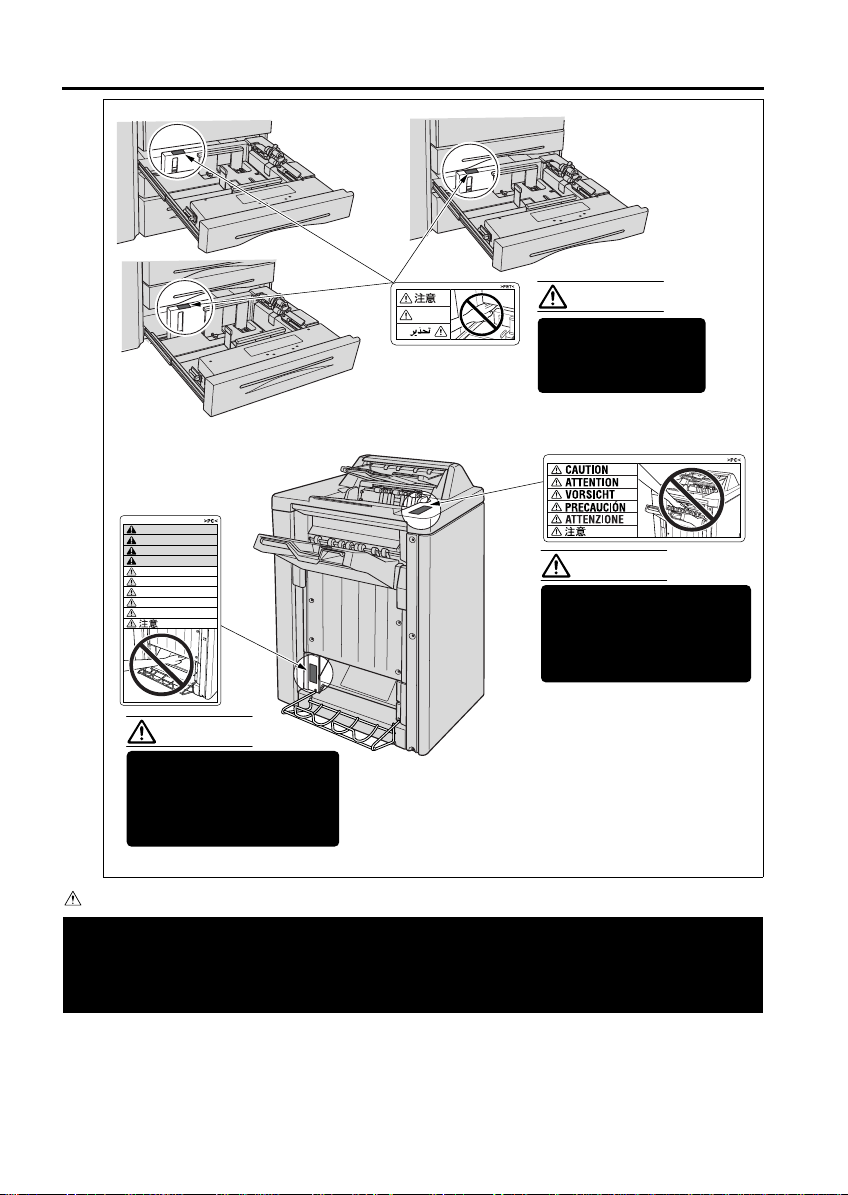

SAFETY INFORMATION

Tray 3

FN-7 Only

CAUTION

ATTENTION

PRECAUCION

CUIDADO

CAUTION

ATTENTION

VORSICHT

PRECAUCION

ATTENZIONE

Tray 1

CAUTION

Tray 2

CAUTION

DO NOT put your hand

between the main body

and tray; otherwise you

may be injured.

CAUTION

Use care after opening the

paper exit outlet. DO NOT

put your hands into the

paper exit outlet as you

may be injured.

CAUTION

Inside the lower paper exit outlet

is the roller drive unit.

DO NOT put your hands into the

paper exit outlet as you may be

injured

CAUTION

Please adhere to all caution labels to avoid burns or injury.

Finisher [FN-7 / FN-115]

S-14

Page 20

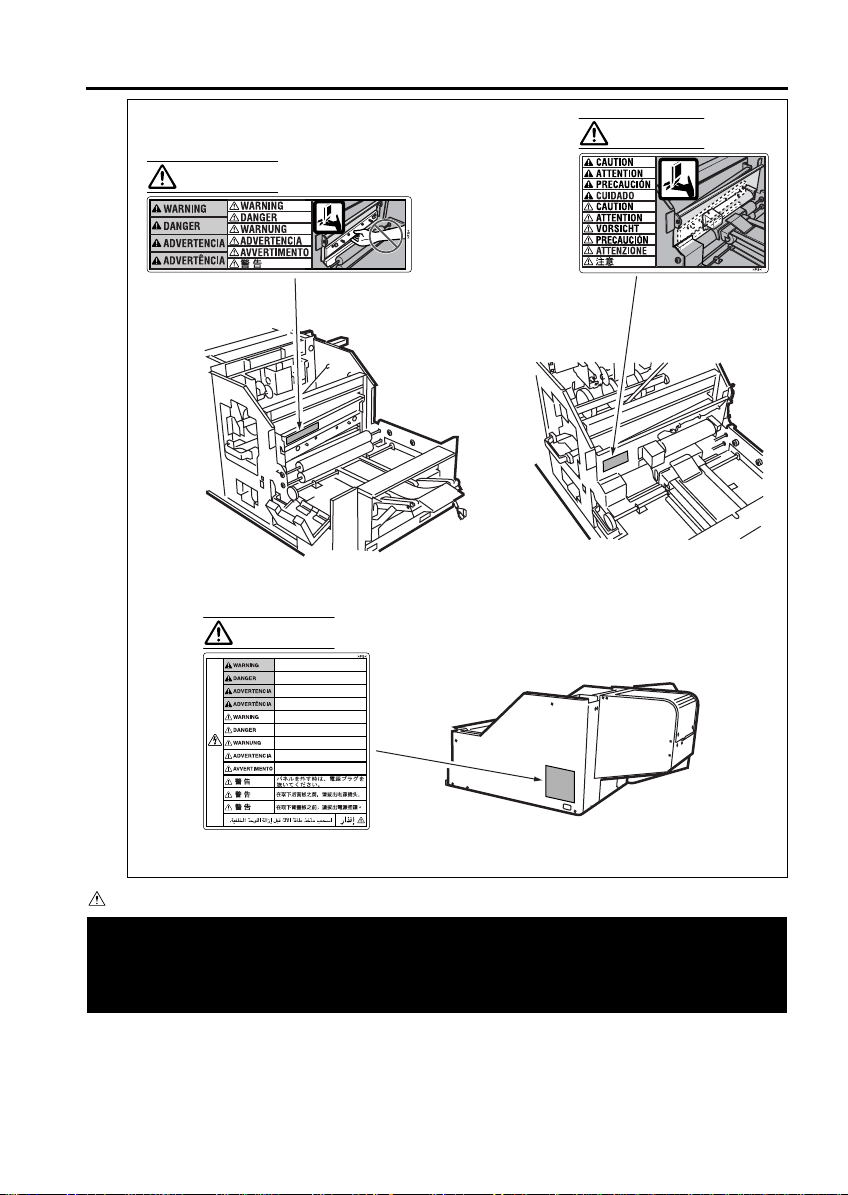

WARNING

WARNING

Unplug the machine before removing

panels.

D brancher lÕappareil avant de

retirer les panneaux arri res.

Desenchufe la m‡quina antes de

quitar los paneles.

Desconecte a unidade da tomada

antes de remover os pain is.

Unplug the machine before removing

panels.

D brancher lÕappareil avant de

retirer les panneaux arri res.

Vor Abnahme der Schutzverkleidung

Netzstecker ziehen.

Desenchufe la m‡quina antes de

quitar los paneles.

Scollegare la macchina prima di

rimuovere i pannelli.

SAFETY INFORMATION

CAUTION

Trimmer [TMG-2]

CAUTION

Please adhere to all caution labels to avoid burns or injury.

S-15

Page 21

SAFETY INFORMATION

WARNING

Unplug the machine before removing

panels.

Débrancher l’appareil avant de retirer

les panneaux arrières.

Desenchufe la máquina antes de

quitar los paneles.

Desconecte a unidade da tomada

antes de remover os painéis.

Unplug the machine before removing

panels.

Débrancher l’appareil avant de retirer

les panneaux arrières.

Vor Abnahme der Schutzverkleidung

Netzstecker ziehen.

Desenchufe la máquina antes de

quitar los paneles.

Scollegare la macchina prima di

rimuovere i pannelli.

<PK-3 Puncher>

<ZK-2 Puncher with Z-folding>

CAUTION

Please adhere to all caution labels to avoid burns or injury.

S-16

Page 22

1

OUTLINE

1 OUTLINE

Page 23

1 OUTLINE

Page 24

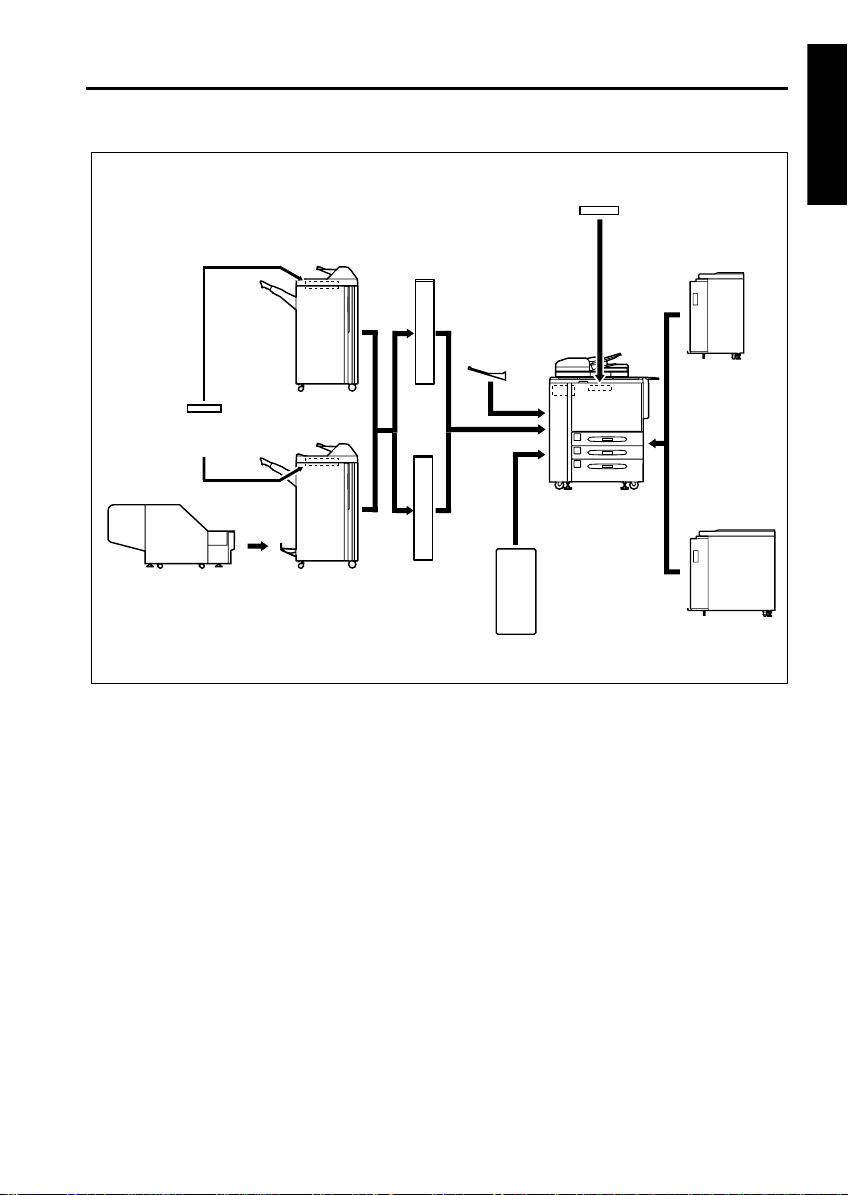

OUTLINE OF SYSTEM

OUTLINE

Cover Inserter

[Cover In serter C]

Trimmer

[TMG-2]

Finisher

[FN-115]

Finisher

[FN-7]

Puncher

[PK-3]

Puncher with

Z-folding

[ZK-2]

Paper

exit tray

Printer Controller

Expansion memory unit

[M64-1 / M128-1]

1 OUTLINE

LCT [C-403]

LCT [C-404]

1-1

Page 25

OUTLINE

PRODUCT SPECIFICATIONS

[1] Type

1 OUTLINE

[2] Functions

Installation Type:

Copying method:

Document tray type:

Photosensitive material:

Sensitizing method:

Paper feed trays:

Applicable document types:

Document size:

Copy paper size:

• Metric area

A3 to A5, 11x17 to 8.5 x11, F4

• Inch Area

11x17 to 8.5 x5.5, A3 to B5R, F4

Wide paper (max. 314x445mm)*2

*2: When using C404

Paper size for ADU paper passage:

Max. 314 x 459 mm to A5 or

8.5 x 5.5 min.

Magnifications

Fixed magnifications:

• Metric area

x1.00, x2.00, x1.41, x1.22, x1.15,

x0.86, x0.82, x0.71, x0.50

• Inch Area

x1.00, x4.00, x2.00, x1.55, x1.29,

x0.77, x0.65, x0.50

Special ratio magnifications:

Console type (floor-mounted type)

Indirect electrostatic method

Fixed

OPC

Laser writing

Three stacked trays (two for 500

sheets of 80 g/m

one for 1000 sheets of 80 g/m

20lbs. paper)

A by-pass tray for various paper

sizes (150 sheets of 80 g/m

lbs. paper)

LCT (4000 sheets of 80 g/m

lbs. paper)*1

*1: Optional

Sheets, book, solid object

A3 (11x17) max.

3 modes

2

or 20lbs. paper;

2

or 20

2

or 20

Zoom magnifications:

Vertical magnifications:

Horizontal magnifications:

Warm-up time:

First copy out time:

2

or

Continuous copy speed (life size, copies/

min):

Continuous copy count:

Copy density selections:

E-RDH memory capacity:

x0.25 to x4.00 (600 dpi, in 1% steps)

x0.25 to x4.00 (600 dpi, in 1% steps)

x0.25 to x4.00 (600 dpi, in 1% steps)

Less than 6 minutes*2

*2: 6 minutes is the machine for the

230VAC specification.

Warm-up time differs depending

on the Power sour ce (voltage).

Mode A4, 8.5x11

Manual 3.3 seconds or less

*Straight paper ejection with the

copied image facing up, platen

mode, life size, paper f eed from tra y

1

Size cpm

A4, 8.5x11 85

1 to 9999

AE, manual

Arbitrary density (2 modes)

standard 128 MB

maximum 512 MB

1-2

Page 26

OUTLINE

[3] Applicable Copy Paper

Plain paper:

High quality paper 60 to 90 g/m

Special paper:

Bypass feed only:

Tray feed only:

ADU paper passage:

or 17 to 24 lbs

High quality paper

50 to 59 g/m

13 to 16 lbs, 24 to 40 Ibs

Label paper

OHP Film

Blueprint master paper

High quality paper

171 to 200 g/m

High quality paper

60 to 200 g/m

2

, 91 to 170 g/m2 or

2

[4] Options

LCT: C-403 / C-404

Expansion memory unit:

Finisher: FN-115 / FN-7

Post inserter: Cover Inserter C

Trimmer: TMG-2

Puncher: PK-3

Puncher with Z-folding :ZK-2

Paper exit tr ay

Printer Controller:

M64-1: 64MB

M128-1: 128MB

2

or 40 to 45 lbs

or 17 to 45 lbs

[5] Particulars of Machine

2

Power supply:

230 VAC EURO: -14 to 10.6 %

USA : ±10 %

50 Hz/ 60 Hz

208 to 240 VAC 60 Hz

Power consumption:

230 V Machine: 3450 W max.

(Full option)

208 to 240 V Machine: 3840 W max.

(Full option)

Weight: Approx. 280 kg (617 lbs.)

Machine dimensions:

35"

[6] Maintenance and Life

Periodic maintenance:

Machine life:

Every 500,000 copies

30,000,000 copies or 5 years

[7] Consumables

Developer: Exclusively for Minolta Di850

Toner : Exclusively for Minolta Di850

Drum: Exclusively for Minolta Di850 (ø100)

[8] Environmental Conditions

Temperature:

Humidity: 10% to 80% RH

Note: The information herein may subject to

10°C to 30°C (50°F to 86°F)

change for improvement without notice.

1 OUTLINE

45.5"

35.5"

1-3

Page 27

OUTLINE

CENTER CROSS-SECTIONAL VIEW

1 OUTLINE

Image processing

section

Exposure lamp

Fixing

section

Paper exit

section

Paper reverse/

exit section

Cleaning section PCL

Charging corona

section

RADF

Image read

section

Image write

section

Developing

section

Second paper

feed section

By-pass tray

T ransf er corona

section

Vertical conveyance

section

TSL

Tray 1

Tray 2

section

Separation

corona section

1-4

Tray 3

ADUPaper conveyance

Page 28

DRIVE SYSTEM DIAGRAM

OUTLINE

[1] Main Drive Sect io n

To paper conveyance and

transfer/separation cor ona

cleaning section

Fixing unit

Heating roller

1

Fixing unit

upper roller

1 OUTLINE

FRONT

Main motor (M1)

Fixing unit lower roller

1-5

Page 29

OUTLINE

[2] Drum Drive Se ct io n

1 OUTLINE

Drum motor (M2)

Separation claw

solenoid (SD4)

Toner guide brush

Drum

FRONT

Toner guide shaft

Toner conveyance screws

Separation claw unit

Separation claw swing cam

1-6

Page 30

OUTLINE

[3] Developing Drive Section

Agitator screw

Developing motor ( M3)

[4] Paper Feed Drive Section

5

FRONT

Agitator wheel

Developing slee ve

To tray 1 paper feed/ tray up drive section

2

FRONT

1 OUTLINE

6

To vertical conveyance section

To vertical conveyance section

Paper feed motor (M4)

To tray 2 paper feed/ tray up drive section

3

To tray 3 paper feed/tray up drive section

4

1-7

Page 31

OUTLINE

[5] Tray 1 and 2 Paper Feed Drive Section

1 OUTLINE

Pre-feed registration roller

Pre-registration MC1/2

(MC4/MC6)

Tray up motor 1/2 (M19/M20)

FRONT

Feed roller

2

3

From paper feed

drive section

Feed MC1/2 (MC3/MC5)

Paper feed roller

Double feed

prevention roller

1-8

Page 32

OUTLINE

[6] Tray 3 Paper Feed Drive Section

Pre-feed registration roller

Pre-registration MC3

(MC8)

1 OUTLINE

Feed roller

FRONT

4

From paper feed drive

section

Tray up motor 3 (M21)

Paper feed roller

Double feed

prevention roller

Feed MC3 (MC7)

1-9

Page 33

OUTLINE

[7] Vertical Conveyance Drive Section

1 OUTLINE

From bypass

paper feed drive

7

section

FRONT

Vertical conveyance

roller (Upper)

Vertical

conveyance

MC1 (MC9)

Vertical

conveyance

MC2 (MC10)

From paper

feed drive

5

section

From paper

feed drive

6

section

Vertical conveyance

roller (Middle)

Vertical conveyance

roller (Lowe r )

1-10

Page 34

OUTLINE

[8] By-pass Paper Feed Drive Section

Tray up/down motor (by-pass tray: M22)

Paper feed roller

To ADU conveyance

8

drive section

1 OUTLINE

FRONT

Feed roller

Loop roller motor (M6)

To vertical conveyance

7

1-11

Page 35

OUTLINE

[9] Conveyance/Transfer and Separation Wire Cle aning Drive Section

1 OUTLINE

Transfer/separation cleaning motor (M18)

Thick paper conveyance rollers

1

1-12

From main drive section

FRONT

Conveyance belts

Page 36

OUTLINE

[10] ADU Conveyance Drive Sect ion

Registration MC (MC1)

Loop roller

Registration roller

ADU exit roller

8

From by-pass

paper feed

drive section

Registration mo to r

(M12)

ADU pre-registration

MC (MC2)

Transfer motor (M9)

FRONT

1 OUTLINE

ADU conveyance motor (M8)

ADU reverse roller

ADU reverse motor (M7)

Paper reverse/exit

motor (M5)

Pre-registration roller

Pre-transfer roller

Pre-registration loop

roller

ADU horizontal

conveyance roller 2

ADU horizontal

conveyance roller 1

From fixing

unit drive

1-13

Paper rev erse/exit

entrance roller

Paper reverse/

exit roller 1

Paper reverse/

exit roller 2

Paper reverse/exit roller 3

Page 37

OUTLINE

[11] Paper Exit Drive Section

1 OUTLINE

Paper exit motor (M10)

[12] Toner Supply Drive Section

Toner supply motor 1 (M11)

FRONT

Paper exit roller

Toner supply motor 2 (M15)

FRONT

Toner car t ridge

1-14

Page 38

OUTLINE

[13] Optic s Drive Se ction

Slit-glass

1 OUTLINE

Scanner drive motor (M13)

First mirror

Second mirror

Third mirror

Optics wire (Rear)

FRONT

Optics wire (Front)

1-15

Page 39

OUTLINE

[14] Web Drive Section

1 OUTLINE

Web drive motor (M16)

FRONT

Cleaning web

1-16

Page 40

2

UNIT EXPLANATION

2 UNIT EXPLANATION

Page 41

2 UNIT EXPLANATION

Page 42

EXTERNAL SECTION

[1] Composition

EXTERNAL SECTIO N

Main switch

Left side cover

Left front door

Operation panel

Front right door

Bypass tray

Tray 1

Tray 2

Tray 3

Right side cover

(middle)

Right side cover

(upper)

Ver tical

Conveyance

door

RADF(EDH-5)

Cooling

cover

2 UNIT EXPLANATION

Optional cover

Rear cover

Right side cover

(lower)

2-A-1

Page 43

2 UNIT EXPLANATION

Page 44

DRIVE SECTION

[1] Composition

DRIVE SECTION

Drum motor (M2)

Main motor (M1)

Developing motor (M3)

Loop roller motor (M6)

Paper feed motor (M4)

Paper exit motor

(M10)

[2] Mechanisms

Mechanism Driven Parts Method

*1 Drum drive Drum, clearer fur brush Gear drive (dedicated motor)

*1 Developing drive Developing sleeve Gear drive (dedicated motor)

*1 Main drive Fixing upper roller Gear drive (dedicated motor)

*1 Paper feed drive Tray 1/2/3, Vertical conveyance roller

(middle/lower)

*1 By-pass/loop drive By-pass feed roller, loop roller, vertical

conveyance roller (upper)

*1 Paper exit drive Paper exit roller Gear drive (dedicated motor)

*1 Independent drive mechanisms

Drive mechanisms are driven by dedicated motors to ensure high-speed operation and to improve serviceability of the drum unit and developing performance.

In order to improve the fixativeness in copying thick paper, the selection of [Thick paper 3] in the key operation

mode decreases the linear speed of the main motor (M1) to 210mm/s only when the paper passes through

the fixing unit.

The mode of [Thick paper 3] is available only when the length of the paper in the paper feed direction is 216mm

or shorter and the paper is fed from LT.

Gear drive (dedicated motor) + Belt

Gear drive (dedicated motor)

2 UNIT EXPLANATION

2-B-1

Page 45

DRIVE SECTION

[3] M1 (Main) Control

MS2 MS1

24VDC

PGND

DCPS2

M1 CONT

M1 EM

CLK

PRCB

2 UNIT EXPLANATION

M1 (main) is controlled by the PRCB (printer control

board) and the motor drive power is supplied from

DCPS2 (DC power supply unit 2).

1. Operation

M1 is a motor driven by 24V DC. It drives fixing

upper and lower rollers, paper con vey ance belts,

and thick paper conveyance roller. M1 incorporates a speed controller circuit to send a signal

indicating abnormal rotation to PRCB when the

PLL lock has been released for longer than the

specified period of time.

M1 starts rotating when the START PRINT button is pressed and stops when the last copied

paper has been ejected. During the warm-up

operation, M1 rotates to rotate the fixing rollers.

When either one of the front doors of this

machine opens or closes, MS1 (interlock 1) or

MS2 (interlock 2) actuates to stop supplying the

DC power to the motor, causing the M1 to stop.

2. Signals

a. Input signal

(1) M1 EM (M1 to PRCB)

M1 fault detection signal.

[H]:Abnormal rotation (PLL lock has been

released for 2 to 3 seconds or longer.)

[L]: Normal rotation

b. Output signal

(1) M1 CONT (PRCB to M1)

M1 drive control signal.

[H]:M1 ON

[L]: M1 OFF

(2) CLK (PRCB to M1)

Clock signal for M1.

[4] M2 (Dru m) Control

24VDC

PGND

DCPS2

M1

M2CONT

PRCB

M2 F/R

SGND

M2 EN

M2 (drum) is controlled by the PRCB (printer control

board) and the motor drive power is supplied from

DCPS2 (DC power supply unit 2).

1. Operation

M2 is a motor driven by 24V DC. It drives a drum,

toner guide brush, toner guide shaft, toner conveyance screw, and separation claw swing sections. M2 incorporates a speed sensor (encoder)

to send a feedback signal to PRCB. Using this

signal, PRCB detects the rotational speed and

calculates the PWM duty to be given to the

motor, controlling the M2 speed. In addition to

the speed sensor, M2 also has a fly wheel mechanism to ensure accurate and steady rotation.

M2 starts rotating when the STA RT PRINT button is pressed and stops when the last copied

paper has been ejected.

When either one of the front doors of this

machine opens or closes, MS2 (interlock 1) or

MS2 (interlock 2) actuates to stop supplying the

DC power to the motor, causing the M2 to stop.

2. Signals

a. Input signal

(1) M2 EN (M2 to PRCB)

M2 motor encoder signal.

b. Output signals

(1) M2 CONT (PRCB to M2)

M2 drive control signal (PCOM).

[L]: M2 ON

[H]:M2 OFF

(2) M2 F/R (PRC B to M 4 )

M2 rotational direction switchover signal.

[H]:CCW (relative to motor shaft)

[L]: CW (relative to motor shaft)

MS2 MS1

M2

2-B-2

Page 46

READ SECTION

[1] Composition

READ SECTION

Optics rail (R)

Scanner drive wire

Slit glass

Scanner cooling fan (FM7)

A/D converter

board

Exposure unit

CCD unit

[2] Mechanisms

Mechanism Method

Light source Xenon lamp

Exposure Light source shift slit exposure, static exposure

Scanning Platen original scanning: 1st, 2nd, and 3rd mirrors are shifted.

Lamp power supply Lamp cord

Optics cooling Cooling fan

RADF original scanning: Original is moved with light source held stationary.

V-mirror unit

(2nd and 3rd mirrors)

2 UNIT EXPLANATION

2-C-1

Page 47

READ SECTION

[3] M13 (Scanner Drive) Control

M13 CLK

M13 F/R

M13 CSEL

M13 V0

M13 V1

M13 V2

PS5

PS7

PS6

PS4

2 UNIT EXPLANATION

PRCB SCDB DCPS1

M13 (scanner drive) is driven by the SCDB (scanner

drive board) and is controlled by the PRCB (printer

control board).

Related signals are PS5 (scanner HP), PS6 (original

HP), and PS7 (ADF brake).

1. Operation

a. Operation of M13

M13 is a 3-phase stepping motor driven using

the 3-phase bipolar constant-current drive

method. The motor is turned ON/OFF by supplying/stopping clock pulses.

b. Movement speed of the exposure unit

Scanning speed

Operation mode Movement speed

Scan 400 mm/sec (600 dpi, 1:1)

Forward 615.38 mm/sec

Home position

search

c. Positions of sensors

Paper exit side Paper feed side

M13 DRIVE U

M13 DRIVE V

M13 DRIVE W

5VDC

SGND

5VDC

SGND

205.1 mm/sec

PS5

PS7

PS6

M13

PS5

PS7

PS6

24VDC

PGND

DCPS2

5VDC

SGND

d. Exposure unit home position search

If the exposure unit is not at the home position

when the main switch is turned ON or when the

ST AR T PRINT button is pressed, the home position is searched for in the followin g manner:

(1) When the ex posure unit is on the paper e xit side

with respect to the home position

When the exposure unit is at PS7 (ADF brake)

(PS7 is ON), it moves forward at a low speed.

And it moves until PS5 (scanner HP) turns ON

and OFF again, then stops. It moves backward

until PS5 turns ON again.

When the exposure unit is between PS7 and

PS5, it moves backward until PS7 turns ON

before moving f orward as mentioned above.

(2) When the expos ure unit is on the paper feed side

When the exposure unit is at PS5 (PS5 is ON), it

moves forward at a low speed until PS5 turns

OFF before moving as discussed in (1) above.

When the exposure unit is located on the paper

feed side with respect to PS5, it mov es backward

then stops for a short while after PS5 turns ON.

Then it moves forward and performs operations

as described in (1) above.

e. Read with shading correction

L1 is turned ON, when black correcti on has been

completed after the home position search operation, thus reading the light reflected by the white

reference plate installed underneath the glass

stopper plate and performing the first white correction. Then, the exposure unit moves to the

paper exit side, performs the second white correction while stopping at the preset position, then

returns to the home position to turn OFF L1.

ADF

break

PS7 PS5

Scanner

HP

First white correction

Second white correction

PS7 PS5 PS6

2-C-2

Page 48

READ SECTION

f. ADF copy operation

Scanner

HP

Second white correction

First white correction

Original

read

position

ADF

break

PS7 PS5

g. Platen copy operation

Scanner

ADF

brake

HP

PS5 PS6PS7

Second white correction

First white correction

AE scan

Original area justment

Exposure scan

Home position search

Original HP

2. Signals

a. PRCB input signals

(1) PS5 (PS5 to SCDB to PRCB)

Scanner home position detection signal.

The reference position for the home position of

the exposure unit is detected.

[L]: The exposure unit is detected.

[H]:The exposure unit is not detected.

(2) PS6 (PS6 to SCDB to PRCB)

Original home position detection signal.

In the platen mode, the ref erence position f or the

original’s leading edge is detected.

[L]: The exposure unit is detected.

[H]:The exposure unit is not detected.

(3) PS7 (PS7 to SCDB to PRCB)

ADF brake detection signal.

In the DF mode, the exposure ref erence position

is detected.

[L]: The exposure unit is detected.

[H]:The exposure unit is not detected.

Scanner

return

b. PRCB output signals

(1) M13 CLK (PRCB to SCDB)

Clock signal for M13.

(2) M13 F/R (PRCB to SCDB )

M13 rotational direction switchover signal.

[L]: The exposure unit is moved t oward the paper

exit side.

[H]:The exposure unit is mov ed toward the paper

feed side.

(3) M13 CSEL (PRCB to SC DB)

M13 excitation switchover signal.

[L]: 2-/3-phase excitation

[H]:W2-/3-phase excitation

(4) M13 V0 to V2 (PRCB to SCDB)

M13 excitation current swit chover signal.

c. SCDB output signals

(1) M13 DRIVE, U, V, W (SCD B to M13)

M13 drive control signals.

These signals are used to control rotation of

M13. By supplying and stopping clock pulses,

the motor is turned ON/OFF and the rotational

direction is switched.

2 UNIT EXPLANATION

2-C-3

Page 49

READ SECTION

[4] Exposure co ntrol

L1 CONT

PRCB SCDB

24VDC

L1 CONT

L1 INVB

24VDC

PGND

DCPS2

2 UNIT EXPLANATION

L1 (exposure lamp) is driven by the L1 INVB (L1

inverter) and is controlled by the PRCB (printer control

board) via the SCDB (scanner drive board).

1. Operation

L1 is a xenon lamp driven by the inverter circuit.

The xenon lamp can emit a constant quantity of

light and generates less heat than other lamps,

requiring neither light quantity controller circuit

nor thermal protector circuit that have been used

in the conventional machines . Howe ver , since L1

is held lit when the exposure unit is nonoperational in the DF mode, a FM7 (scanner cooling)

is installed in the read section.

2. Signals

a. Output signals

(1) L1 CONT (PRCB to SCDB to L1 INVB)

L1 ON/OFF control signal.

[L]: L1 ON

[H]:L1 OFF

LV

L1

HV

2-C-4

Page 50

READ SECTION

[5] Original Read Control

CCD

ADB

ICB IFB ICB

Original read control is performed by the ADB (A/D

converter board) and CCD sensor installed in the ADB .

1. Operation

The light reflected by the exposed original is

input to the CCD sensor through the lens. The

analog voltage corresponding to the quantity of

input light is A/D-converted in the ADB, being

output to the ICB (image control board).

a. Original read

The original read timing is as follows:

(1) Platen mode

Specified interval after exposure unit turns PS6

(original HP) ON.

(2) DF mode

After lapse of the specified time after the original’s leading edge turns ON PS308 (Original

conveyance).

[6] APS Control

5VDC

PS62

SGND

PS63

PS64

PS65

PS66

PS67

PS68

PRCB ICB IFB

The APS method used in the platen mode is different

from that used in the DF mode.

The signal read by the APS sensor o r the original siz e

detection sensor of the RADF is proces sed by the I CB

(image control board).

1. Operation

a. APS detection

(1) DF mode

The original size is detected according to the

combination of ON/OFF states of PS302 (original size detection 1) and PS303 (original size

detection 2) and the resistance value of VR301

(original size detection).

PS62

PS63

PS64

PS65

PS66

PS67

PS68

5VDC

SGND

DCPS1

2 UNIT EXPLANATION

2-C-5

Page 51

READ SECTION

(2) Platen mode

2 UNIT EXPLANATION

The paper size is detected according to the co mbination of ON/OFF states of PS62 (APS 1),

PS63 (APS 2), PS64 (APS 3), PS65 (APS 4),

PS66 (APS 5), PS67 (APS 6), and PS68 (APS

7).

The APS sensor consists of LEDs and photosensors. Lights emitted from the LEDs is reflected by

the original and received by photosensors.

PS63 PS62 PS68

PS66

PS64

Paper exit side

PS67

PS65

Photo sensor

LED

Relationships between sensors and original

sizes are as follows:

Sensor

Paper

size

B5R

B5

B4

A4R

A4

A3

8.5 x 11R

8.5 x 11

8.5 x 14

11 x 17

Min. size

PS62 PS63 PS64 PS65 PS66 PS67 PS68

z

zzz

zzzzz

zzz

zzzzz

zzzzzzz

zz

zzzz

zz z z

zzz zzz

z ON

OFF

b. APS detection timing

The APS detection timing differs between the

platen mode and DF mode.

(1) DF mode

When the DF mode is selected or original is set

on the RADF original feed tray, APS detection

takes place using PS302 (original size detection

1), PS303 (original size detection 2), and VR301

(original size detection).

(2) Platen mode

When RADF is closed and PS315 (APS timing)

turns ON, APS detection takes place using PS62

to PS68.

2. Signals

a. Input signals

(1) PS62 (PS62 to ICB IFB)

Paper size detection signal.

[L]: Paper is detected.

[H]:Paper is not detected.

(2) PS63 (PS63 to ICB IFB)

Paper size detection signal.

[L]: Paper is detected.

[H]:Paper is not detected.

(3) PS64 (PS64 to ICB IFB)

Paper size detection signal.

[L]: Paper is detected.

[H]:Paper is not detected.

(4) PS65 (PS65 to ICB IFB)

Paper size detection signal.

[L]: Paper is detected.

[H]:Paper is not detected.

(5) PS66 (PS66 to ICB IFB)

Paper size detection signal.

[L]: Paper is detected.

[H]:Paper is not detected.

(6) PS67 (PS67 to ICB IFB)

Paper size detection signal.

[L]: Paper is detected.

[H]:Paper is not detected.

(7) PS68 (PS68 to ICB IFB)

Paper size detection signal.

[L]: Paper is detected.

[H]:Paper is not detected.

2-C-6

Page 52

READ SECTION

[7] AE Control

CCD

ADB

ICB IFB ICB

The CCD sensor detects the image density on an original during AE scanning to select the optimum copy

gamma correction curve.

AE processing is controlled by the ICB (image cont rol

board).

1. Operation

a. AE detection

(1) Platen mode

The image density on an original is measured

while the exposure unit moves from the home

position to the leading edge of the original after

depression of the START button.

<AE sampling area>

(1) Normal copy

10mm inside perimeter of original size detected

by APS.

(2) Non-image area erasure mode

Entire original area detected by forward scanning.

(3) DF mode

The image at the leading edge of the original is

read when the START button is pressed.

The read data is used to measure the image density on the original.

<AE sampling area>

(1) Main scanning direction

• 10-mm area inside the original detected by

APS

(2) S ub scanning direction

Range between 2mm to 7.3mm from the leading

edge of the original.

2 UNIT EXPLANATION

2-C-7

Page 53

2 UNIT EXPLANATION

Page 54

WRITE UNIT

[1] Composition

Index sensor board

WRITE UNIT

Cylindrical lens 1

Polygon mirror

Cylindrical lens 2

3rd mirror

2 UNIT EXPLANATION

Laser driver board LD2

2nd mirror

fθ lens 2

Collimator lens unit 1

fθ lens 1

Laser driver board LD1

[2] Mechanisms

Mechanism Method

*1 Scan Polygon mirror

Light source Laser diodes (two)

*2 Positioning Index sensor

*3 Laser beam

combining

*1 Path of laser light

The light output from semiconductor laser is radiated onto the OPC drum via the collimator lens,

compression prism, fine adjustment prism, beam

combining prism, cylindrical lens 1, polygon mirror, fθ lens 1, fθ lens 2, second m irror , cylindrical

lens 2, and third mirror.

Rotational speed:

24,803.1 rpm (400 dpi)

37,204.7 rpm (600 dpi)

(Output: Max. 20 mW)

Fine adjustment prism

Beam combining prism

Collimator lens unit 2

Beam combining prism

Semiconductor

laser LD2

CY2 lens

3rd mirror

Polygon

mirror

Glass cover

Index mirror

Index sensor

OPC drum

Compression prism

Semiconductor

laser LD1

Collimator

lens unit

Beam

combining

prism

CY1 lens

2nd mirror

fθ lens 2

fθ lens 1

2-D-1

Polygon Cooling Fan

Page 55

WRITE UNIT

*2 Positioning

Each laser beam is positioned by the compression prism and fine adjustment prism.

*3 Laser beam combining

Two laser beams output at right angle to each

other are redirected in the same direction using

the beam combining prism.

2 UNIT EXPLANATION

Semiconductor l ase r 1

Laser 1 beam passes

Laser 2 beam

reflected

Beam combining prism

Semiconductor

laser 2

[3] M17 (P olygon) Control

M17 EM

M17 CLK

M17 CONT

PRCB

24VDC

PGND

DCPS2 PMDB

M17 (polygon) is driven by the PMDB (polygon driver

board) and is controlled by the PRCB (printer control

board).

1. Operation

a. Explanation of operation

M17 is a 3-phase brushless DC motor which is

driven by the 3-phase bipolar method. The current flowing through the coil is switched according to the position of the rotor detected by the

position sensor (magnetic sensor) in the motor.

This motor rotates the polygon mirror to scan the

laser beams from LDB1 and 2 (laser driver

boards 1 and 2) in the axial direction of the drum.

Its rotation is held constant by PLL control.

b. Rotational speed

36VDC is used to drive M17. The rotation speeds

are as follows:

Resolution Rotational speed (rpm)

400 dpi 24,803.1 rpm

600 dpi 37,204.7 rpm

SGND

24VDC

M17 MAG A’

M17 MAG A

M17 MAG B’

M17 MAG B

M17 MAG C’

M17 MAG C

M17 DRIVE C

M17 DRIVE B

M17 DRIVE A

M17

2. Signals

a. PRCB input signals

(1) M17 EM (PMDB to PRCB)

This signal indicates the clock synchronization

state of M17.

[L]: Synchronous (normal)

[H]:Asynchronous (abnormal)

2-D-2

Page 56

b. PRCB output signals

(1) M17 CONT (PRCB to PMDB)

This signal turns ON/OFF M17.

[L]: M17 ON

[H]:M17 OFF

(2) M17 CLK (PRCB to PMDB)

This is a reference clock signal for PLL-controlling M17 in PMDB.

c. PMDB input signals

(1) M17 MAG A/A’ (M17 to PMDB)

(2) M17 MAG B/B’ (M17 to PMDB)

(3) M17 MAG C/C’ (M17 to PMDB)

Output signals from the position sensor (magnetic sensor) incorporated in M17.

The PMDB detects the position of the motor rotator using these signals, switching among outputs, M17 DRIVE A to C.

d. PMDB output signals

(1) DRIVE A to C (PMDB to M17)

M17 drive signals.

M5 DRIVE A to C supplies the corresponding

voltages to M17. Pulses of the voltages applied

to M17 are shown below . The pulse widths of the

PMDB output signals change as shown below

depending on the state of M17 rotation, changing

the effective values of the voltages supplied to

M17. Thus, the M17 speed can be controlled.

WRITE UNIT

2 UNIT EXPLANATION

M5 DRIVE A

M5 DRIVE B

M5 DRIVE C

2-D-3

Page 57

WRITE UNIT

[4] Image Write Control

2 UNIT EXPLANATION

ADB

ICB

DCPS1

DCPS2

5VDC

SGND

24VDC

PGND

M24 PWR A

M24 PWR B

M24 DRIVE A

M24 DRIVE A’

M24 DRIVE B

M24 DRIVE B’

5VDC

SGND

M INDEX 1

SGND

M INDEX 2

SGND

S INDEX1

SGND

S INDEX 2

SGND

HL VL

IPR

SGND

5VDC

SGND

LD1 SH

LD1 ENB

LD1 VIDEO

SGND

LD1 ALM

LD1DCLK

LD1 DI

LD1 LD

LD1 PR

5VDC

SGND

LD2 SH

LD2 ENB

LD2 VIDEO

SGND

LD2 ALM

LD2 DCLK

LD2 LD

LD2 AD

LD2 PR

M24

INDEXSB

LDB1

LDB2ICB IFB

The analog image data from the CCD sensor is A/Dconverted by the ADB (A/D conv erter board), then sent

to the ICB (image control board) for data processing.

The processed image data is converted into a laser

beam according to the control signal received from the

ICB through the ICB IFB (ICB I/F board), then the b eam

is radiated onto the drum surface. Two lasers are pro-

vided to write two lines of image data per scan. The

write start position is detected by the INDXSB (index

sensor board). The ICB has an E-RDH (electronic

RDH processing) function to store digitized data. Various editing functions can be performed based on this

data.

2-D-4

Page 58

WRITE UNIT

1. Operation

a. Image processing

The following processing is performed by the ICB

(image control board):

(1) AOC (Auto Offset Control)

During shading correction, a read operation

takes place while L1 (exposure lamp) is OFF, and

the analog offset voltage of the output from the

CCD sensor is automatically adjusted so t hat the

resulting level is the lower limit of the A/D converter.

(2) AGC (Auto Gain Control)

During shading correction, the white reference

plate is read, and the amplification of the a nalog

output from the CCD sensor is automatically

adjusted so that the resulting level is the up per of

the A/D converter.

(3) Shading correction

<Timing>

• When SW1 (main switch) is turned ON

(4) Brightness/density conver sion

(5) EE processing

(6) Text/dot pattern judgment

(7) Filtering/magnification change processing

(8) Magnification change processing

(9) Copy gamma correction

(10)Skew correction

(11)Error diffusion processing

(12)Data compression

(13)Write density control

b. Write

The ICB (image control board) sends image data

on a pixel basis to LDB1 and LDB2 according to

the control signals from the PRCB (printer control board).

LDB1 and LDB2 cause the lasers to emit for a

period corresponding to the image data. This

laser light is radiated onto the drum surface.

(1) MPC (Maximum Power Control)

ICB informs LDB1 and LDB2 of the maximum

output value and sets that value for the laser

beam emission. LDB1 and LDB2 store this setting value and maintain the quantity of the laser

beam emission using the APC (Auto P ow er Control).

<MPC timing>

• When SW1 (main switch) is turned ON

(2) APC (Auto Power Control)

The ICB outputs an APC start instruction to the

LDB at the following timing, after MPC is set.

<APC timing>

• The LDB1 and LDB2 automatically monitor the

laser drive current one line at a time, and controls it so that the light intensity remains the

MPC value.

(3) Write timing

a) Main scanning direction

Using INDEX signal from INDXSB, determines the laser write reference position for

each scan in the drum rotation direction, and

writes the image to copy paper using the

paper position information derived from the

paper position detection by PS1 (paper miscentering).

INDEX

Laser

output 1

Laser

output 2

ab c d e

Image area

1st scanning

2nd scanning

Symbol Description

a Laser goes ON for first scan.

b Index sensor goes ON.

b-c

c-d

d-e

The timing at the left is controlled

by counting the LD1 IRCLK and

LD2 IRCLK signals. It differs

depending on the document size.

b) Sub scanning direction

Specified interval after PS44 (registration)

detects the tip of the copy paper.

(4) Las er beam position correction

a) Main scanning direction

The index sensor detects the devi ation of the

positions of the two beams. This erro r is c orrected by changing the timing of the light

emission from the laser.

b) Sub scanning direction

The index sensor detects the devi ation of the

positions of two beams in order to change the

angle of the fine adjustment prism of the LD1

laser using M24 (laser correction), thus

adjusting the vertical angle of the beam.

2 UNIT EXPLANATION

2-D-5

Page 59

WRITE UNIT

2. Signals

a. ICB IFB input signals

(1) M INDEX 1, 2 (INDEXSB to ICB IFB)

This is an index signal used to detect deviation of

vertical scanning.

(2) S INDEX 1, 2 (INDEXSB to ICB IFB)

This is an index signal used to detect deviation of

horizontal scanning.

(3) IPR (INDEXSB to ICB IFB)

This signal monitors the INDEXSB power supply .

[H]:Normal

[L]: Abnormal

(4) LD1 ALM (LDB1 to ICB IFB)

2 UNIT EXPLANATION

This signal indicates the state of the LD1 laser

drive current.

[H]:Normal

[L]: Abnormal

(5) LD1 PR (LDB1 to ICB IFB)

LD1 power supply monitor signal.

[H]:Normal

[L]: Abnormal

(6) LD2 ALM (LDB2 to ICB IFB)

This signal indicates the state of the LD2 laser

drive current.

[H]:Normal

[L]: Abnormal

(7) LD2 PR (LDB2 → ICB IFB)

LD2 power supply monitor signal.

[H]:Normal

[L]: Abnormal

b. ICB IFB output signals

(1) M24 PWR A (ICB IFB to M24)

M24 A-phase drive signal.

(2) M24 PWR B (ICB IFB to M24)

M24 B-phase drive signal.

(3) M24 DRIVE A/A’ (ICB IFB to M24)

M24 A-phase drive pulse signal.

(4) M24 DRIVE B/B’ (ICB IFB to M24)

M24 B-phase drive pulse signal.

(5) LD1 SH (ICB IFB to LDB1)

One scan line equivalent APC sampling signal.

(6) LD1 ENB (ICB IFB to LDB1)

Laser APC function ON/OFF control signal.

Laser beam emission stops when it is OFF.

(7) LD2 SH (ICB IFB to LDB2)

One scan line equivalent APC sampling signal.

(8) LD2 ENB (ICB IFB to LDB2)

Laser APC function ON/OFF control signal.

Laser beam emission stops when it is OFF.

(9) LD1 VIDEO (ICB IFB to LDB1)

LD1 laser image signal.

(10)LD2 VIDEO (ICB IFB to LDB2)

LD2 laser image signal.

(11)LD1 DCLK (ICB IFB to LDB1)

LD1 clock signal for MPC value data transmission.

(12)LD1 DI (ICB IFB to LDB1)

LD1 data signal for MPC.

(13)LD1 AD (ICB IFB to LDB1)

LD1 MPC value storage command signal.

(14)LD2 DCLK (ICB IFB to LDB2)

LD2 clock signal for MPC value data transmission.

(15)LD2 DI (ICB IFB to LDB2)

LD2 data signal for MPC.

(16)LD2 AD (ICB IFB to LDB2)

LD2 MPC value storage command signal.

2-D-6

Page 60

DRUM UNIT

[1] Composition

Cleaning/toner

recycle unit

Cleaning/toner recycle unit

Charging corona unit

Developing unit

Charging corona unit

PCL

TSL

DRUM UNIT

Separation claws

2 UNIT EXPLANATION

Separation claw solenoid (SD4)

Developing unit

Transfer and separation corona unit

[2] Mechanisms

Mechanism Method

Carriage support F ixed rail

PCL/TSL LED

Auxiliary separation Separation claws

*1

Conveyance assistance Ratchet wheel

*2

The drum unit is an integral assembly consisting of a

drum, charging corona unit, dev eloping un it, cleaning/

toner recycle unit, PCL, and separation claws.

*1 Auxiliary separation

• To prevent paper jamming, three separation

claws are used to separate paper from the

drum forcibly. These separation claws are

pressed against the drum or detached from it

by turning ON/OFF the separation claw solenoid (SD4).

• To prevent a specific part of image copied

paper from being stained and to prevent the

drum from being scratched, the sw ing mecha-

nism slides the separation claws about 5 mm

back and forth in parallel with the drum surface.

Separation claw solenoid (SD4)

Separation claw

*2 Conveyance assistance

The thick paper conveyance ability has been

improved by the use of ratchets.

2-E-1

Page 61

DRUM UNIT

[3] Separation Claw Control

24VDC

SD4 DRIVE

M2CONT

M2EM

PRCB

MS2 MS1

24VDC

PGND

2 UNIT EXPLANATION

The separation claw is driven by SD4 (separation

claw). The vibration of the separation claw is put in by

M2 (drum). SD4 is controlled directly by PRCB (printer

control board).

1. Operation

a. Separation claw ON/OFF control

SD4 is a pull-type solenoid po wered by 24 VDC .

It turns ON to press separation claws against the

drum to help image copied paper separate.

(1) SD4 operation timing

SD4 turns ON after a lapse of specified time from

turning ON of PS45 (leading edge detection) in

the second paper fe ed section. It turns OFF after

a lapse of the time set by the PRCB timer.

b. Separation claw swing control

Separation claws are swung by M2 (drum) via

the cam mechanism.

2. Signals

a. Output signal

(1) SD4 DRIVE (PRCB to S D4 )

SD4 drive control signal.

[L]: SD4 ON

[H]:SD4 OFF

DCPS2

SD4

M2

[4] Paper Guide P late Control

GP CONT

PRCB

24VDC

PGND

DCPS2

ADUSDB

To prevent toner from adhering to the paper guide

plate, a constant voltage is applied to the paper guide

plate. This voltage is supplied from HV2 (high voltage

unit 2) and is controlled by the serial data sent from the

PRCB (printer control board) via the ADUSDB (ADU

stand drive board). When t he front door of this machine

opens or closes, MS1 (interlock 1) or MS2 (interlock 2)

operates to interrupt the DC power supply to HV2,

stopping the voltage application to the paper guide

plate.

1. Operation

a. ON/OFF timing

Turning ON/OFF in sync with M2 (drum)

b. Applied voltage

-500 VDC

2. Signal

a. Output signal

(1) GP CONT (ADUSDB to HV2)

This signal controls turning ON/OFF the voltage

application to paper guide plate.

[L]: Voltage applied

[H]:Voltage not applied

GP

HV2

2-E-2

Page 62

DRUM UNIT

[5] Drum Potential Control

DPS DRIVE A

DPS DRIVE B

DPS ANG 1

DPS ANG 2

DPSB

PRCB

DCPS2

DPS ANG

SGND

24VDC

PGND

The drum potential is detected by the DPS (drum

potential sensor) and send the PRCB (printer control

board) via the DPSB (drum potential sensor board).

1. Operation

Drum potential control is performed to keep the

drum surface potential constant and maintain

image quality regardless of the usage environment or the number of copies.

(1) Method

The image is created on the drum surface by the

difference in the exposure potential and de veloping bias. A patch is created with laser PWM maximum.

The developing bias is corrected so that the difference between the after exposure potential

(solid black area) and the developing bias is

always kept constant and the charging current

and the grid voltage are corrected so that the difference between the before exposure potential

and developing bias is always kept constant.

(2) Timing

a) When the fixing temperature is lower than

50°C at power ON.

b) At the end of job after every 5,000 copies.

DPS

2. Signals

a. PRCB Input signals