Page 1

FrameMaker Ver.5.5E(PC) COVER [FIELD SERVICE] FOR Di350

98.12.09

Di350 SERVICE MANUAL

[

FIELD SERV ICE

FrameMaker Ver.5.5E(PC) COVER [FIELD SERVICE] FOR Di350

98.12.09

Di350

SERVICE MANUAL

Copyright

1999 MINOLTA Co., Ltd.

Printed in Japan

Use of this manual should

be strictly supervised to

avoid disclosure of

confidential information.

]

FIELD SERVICE

[

]

MINOLTA Co., Ltd.

1171-7991-11 99022300

Page 2

FrameMaker Ver.5.5E(PC) PL Standard Document Ver.03

99.01.27

Safety Precautions for Inspection and Service

When performing inspection and service procedures, observe the following precautions to

prevent accidents and ensure utmost safety.

✽

Depending on the model, some of the precautions given in the following do not apply.

Different markings are used to denote specific meanings as detailed below.

Indicates a potentially hazardous situation which, if not avoided,

WARNING

CAUTION

The following graphic symbols are used to give instructions that need to be observed.

Used to call the service technician’s attention to what is graphically represented

inside the marking (including a warning).

Used to prohibit the service technician’s from doing what is graphically represented inside the marking.

could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. It may also be used to

alert against unsafe practices.

Used to instruct the service technician’s to do what is graphically represented

inside the marking.

WARNING

1. Always observe precautions.

•

Parts requiring special attention in this product will include a label containing the

mark shown on the left plus precautionary notes. Be sure to observe the precautions.

•

Be sure to observe the “Safety Infor mation” given in the Operator’s Manual.

2. Before starting the procedures, be sure to unplug the power cord.

•

This product contains a high-voltage unit and a circuit with a large current

capacity that may cause an electric shock or burn.

•

The product also contains parts that can jerk suddenly and cause injury.

•

If this product uses a laser, laser beam leakage may cause eye damage or

blindness.

3. Use the specified parts.

•

For replacement parts, always use the genuine parts specified in the manufacturer’s parts manual. Installing a wrong or unauthor ized part could cause

dielectric breakdown, overload, or undermine safety devices resulting in possible electric shock or fire.

•

Replace a blown electrical fuse or thermal fuse with its corresponding genuine

part specified in the manufacturer’s parts manual. Installing a fuse of a different

make or rating could lead to a possible fire. If a thermal fuse blows frequently,

the temperature control system may have a problem and action must be taken

to eliminate the cause of the problem.

P-1

Page 3

FrameMaker Ver.5.5E(PC) PL Standard Document Ver.03

99.01.27

4. Handle the power cord with care and never use a multiple outlet.

•

Do not break, crush or otherwise damage the power cord. Placing a heavy

object on the power cord, or pulling or bending it may damage it, resulting in a

possible fire or electric shock.

•

Do not use a multiple outlet to which any other appliance or machine is connected.

•

Be sure the power outlet meets or exceeds the specified capacity.

5. Be careful with the high-voltage parts.

•

A part marked with the symbol shown on the left carries a high voltage. Touching it could result in an electric shock or burn. Be sure to unplug the power cord

before servicing this part or the parts near it.

6. Do not work with wet hands.

•

Do not unplug or plug in the power cord, or perform any kind of service or

inspection with wet hands. Doing so could result in an electric shock.

7. Do not touch a high-temperature part.

•

A part marked with the symbol shown on the left and other parts such as the

exposure lamp and fusing roller can be very hot while the machine is energized.

Touching them may result in a burn.

•

Wait until these parts have cooled down before replacing them or any surrounding parts.

8. Maintain a grounded connection at all times. (This item may not apply in the USA.)

•

Be sure to connect the ground wire to the ground terminal even when performing an inspection or repair. Without proper grounding, electrical leakage could

result in an electric shock or fire.

•

Never connect the ground wire to a gas pipe, water pipe, telephone ground wire,

or a lightning conductor.

9. Do not remodel the product.

•

Modifying this product in a manner not authorized by the manufacturer may

result in a fire or electric shock. If this product uses a laser, laser beam leakage

may cause eye damage or blindness.

10. Restore all parts and harnesses to their original positions.

•

To promote safety and prevent product damage, make sure the harnesses are

returned to their original positions and properly secured in their clamps and saddles in order to avoid hot parts, high-voltage parts, sharp edges, or being

crushed.

•

To promote safety, make sure that all tubing and other insulating materials are

returned to their original positions. Make sure that floating components mounted

on the circuit boards are at their correct distance and position off the boards.

P-2

Page 4

FrameMaker Ver.5.5E(PC) PL Standard Document Ver.03

99.01.27

CAUTION

1. Precautions for Service Jobs

•

A toothed washer and spring washer, if used originally, must be reinstalled.

Omitting them may result in contact failure which could cause an electric shock

or fire.

•

When reassembling parts, make sure that the correct screws (size, type) are

used in the correct places. Using the wrong screw could lead to stripped

threads, poorly secured parts, poor insulating or grounding, and result in a malfunction, electric shock or injury.

•

Take great care to avoid personal injury from possible burrs and sharp edges on

the parts, frames and chassis of the product.

•

When moving the product or removing an option, use care not to injure your

back or allow your hands to be caught in mechanisms.

2. Precautions for Servicing with Covers and Parts Removed

•

Wherever feasible, keep all parts and covers mounted when energizing the

product.

•

If energizing the product with a cover removed is absolutely unavoidable, do not

touch any exposed live parts and use care not to allow your clothing to be

caught in the moving parts. Never leave a product in this condition unattended.

•

Never place disassembled parts or a container of liquid on the product. Parts

falling into, or the liquid spilling inside, the mechanism could result in an electric

shock or fire.

•

Never use a flammable spray near the product. This could result in a fire.

•

Make sure the power cord is unplugged before removing or installing circuit

boards or plugging in or unplugging connectors.

•

Always use the interlock switch actuating jig to actuate an interlock switch when

a cover is opened or removed. The use of folded paper or some other object

may damage the interlock switch mechanism, possibly resulting in an electric

shock, injury or blindness.

3. Precautions for the Working Environment

•

The product must be placed on a flat, level surface that is stable and secure.

•

Never place this product or its parts on an unsteady or tilting workbench when

servicing.

•

Provide good ventilation at regular intervals if a service job must be done in a

confined space for a long period of time.

•

Avoid dusty locations and places exposed to oil or steam.

•

Avoid working positions that may block the ventilation ports of the product.

4. Precautions for Handling Batteries

•

Replace a rundown battery with the same type as specified in the manufacturer’s parts manual.

•

Before installing a new battery, make sure of the correct polarity of the installation or the battery could burst.

•

Dispose of used batteries according to the local regulations. Nev er dispose of

them at the user’s premises or attempt to try to discharge one.

P-3

Page 5

FrameMaker Ver.5.5E(PC) PL Standard Document Ver.03

99.01.27

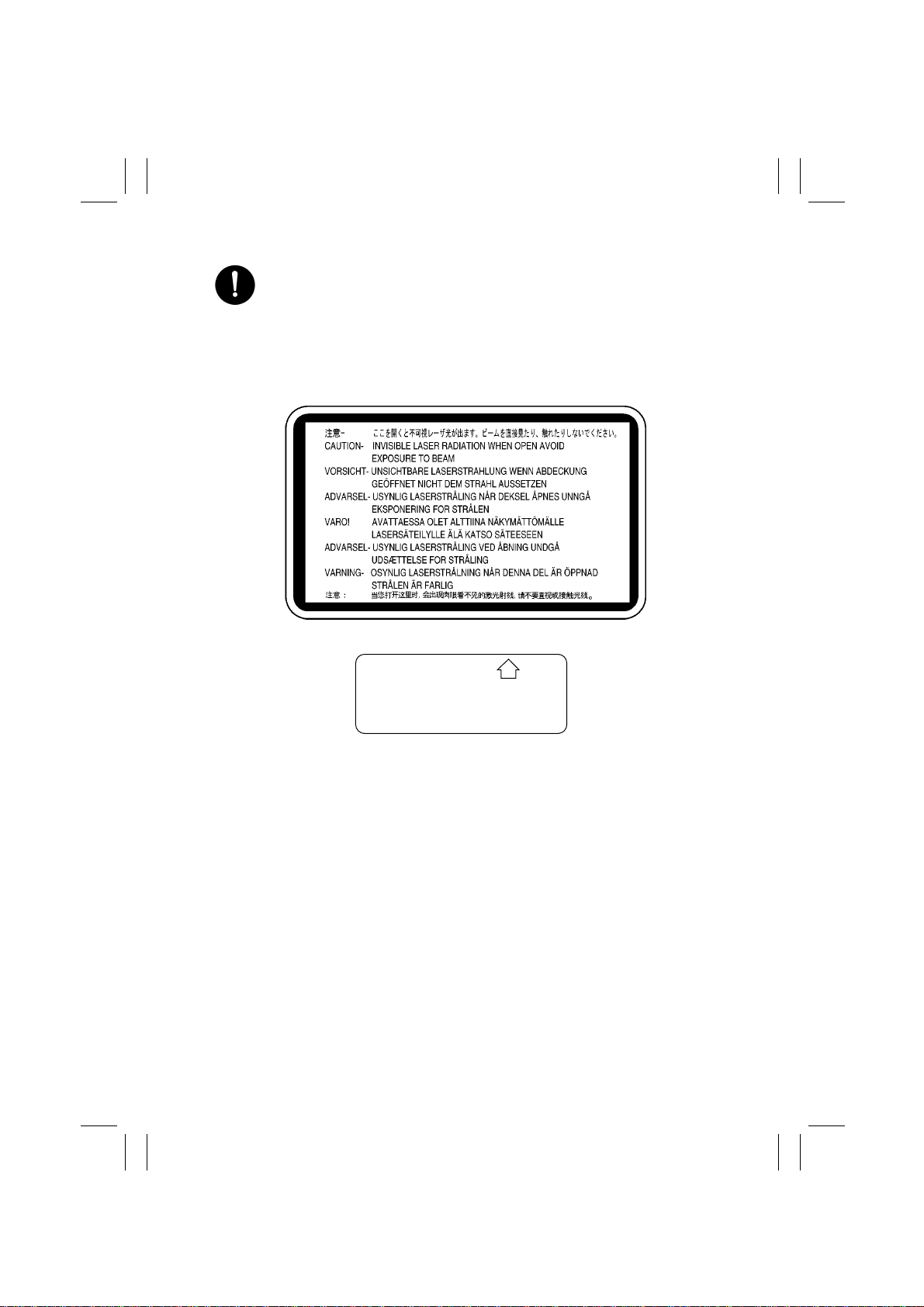

5. Precautions for the Laser Beam (Only for Products Employing a Laser)

•

Removing the cover marked with the follo wing caution label could lead to possible exposure to the laser beam, resulting in eye damage or blindness. Be sure

to unplug the power cord before removing this cover.

•

If removing this cover while the power is ON is una voidable, be sure to wear protective laser goggles that meet specifications.

•

Make sure that no one enters the room when the machine is in this condition.

•

When handling the laser unit, observe the “Precautions for Handling Laser

Equipment.”

.

DANGER

Invisible laser radiation when open.

AVOID DIRECT EXPOSURE

TO BEAM

0947-7127-01

1144D270AA

1167P001AA

P-4

Page 6

FrameMaker Ver.5.5E(PC) PL Standard Document Ver.03

99.01.27

Other Precautions

•

To reassemble the product, reverse the order of disassembly unless otherwise specified.

•

While the product is energized, do not unplug or plug connectors into the circuit boards

or harnesses.

•

The magnet roller generates a strong magnetic field. Do not bring it near a watch, floppy

disk, magnetic card, or CRT tube.

•

An air gun and vacuum cleaner generates a strong electrostatic charge that can destroy

the ATDC sensor and other sensors. Before cleaning a component with one of these

devices, be sure to remove all the sensors. Otherwise, use a blower brush and cloth

when cleaning parts.

•

When handling circuit boards with MOS ICs, observe the “INSTRUCTIONS FOR HANDLING THE PWBs WITH MOS ICs” (applicable only to the products using MOS ICs).

•

The PC Drum is a very delicate component. Observe the precautions given in “HANDLING OF THE PC DRUM” because mishandling may result in serious image problems.

•

Note that replacement of a circuit board may call for readjustments or resetting of particular items, or software installation.

•

After completing a service job, perfor m a safety check. Make sure that all parts, wiring

and screws are returned to their original positions.

•

Check the area surrounding the service site for any signs of damage, wear or need of

repair.

•

Do not pull out the toner hopper while the toner bottle is turning. This could result in a

damaged hopper motor or locking mechanism.

•

If the product is to be run with the front door open, make sure that the toner hopper is in

the locked position.

P-5

Page 7

FrameMaker Ver.5.5E(PC) PL Standard Document Ver.03

99.01.27

Used Batteries Precautions

ALL Areas

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by the manufacturer.

Dispose of used batteries according to the manufacturer’s instructions.

Germany

Explosionsgefahr bei unsachgemäßem Austausch der Batterie.

Ersatz nur durch denselben oder einen vom Hersteller empfohlenen ähnlichen Typ.

Entsorgung gebrauchter Batterien nach Angaben des Herstellers.

France

Ily a danger d’explosion s’ily a remplacement incorrec de la batterie.

Remplacer uniquement avec une batterie du meme type ou d’un type équivalent recommande par le constructueur.

Mettre au rebut les batteries usageés conformément aux instructions du fabricant.

Denmark

Lithiumbatteri - Eksplosionsfare ved fejlagtig håndtering Udskiftning må kun ske med batteri af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

Norway

Eksplosjonsfare ved feilaktig skifte av batteri.

Benytt samme batteritype eller en tilsvarende type anbefalt av apparatfabrikanten.

Brukte batterier kasseres i henhold til fabrikantens instruksjoner.

CAUTION

VORSICHT!

ATTENTION

ADVARSEL!

ADVARSEL

Sweden

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en ekvivalent typ som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt fabrikantens instruktion.

Finland

Paristo voi räjähtää, los se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan tyyppiin. Hävitä Käytetty paristo

valmistajan ohjeiden mukaisesti.

VARNING

VAROlTUS

P-6

Page 8

FrameMaker Ver.5.5(PC) Di350/Di350f

98.12.09

INDEX (FIELD SERVICE)

DIS/REASSEMBLY,

ADJUSTMENT

SWITCHES ON PWBs,

TECH. REP. SETTINGS

TROUBLESHOOTING

Page 9

Page 10

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

Di350

DIS/REASSEMBLY,

ADJUSTMENT

18605

Page 11

Page 12

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

CONTENTS

1. SERVICE INSTRUCTIONS .............................................................................D-1

1-1. IDENTIFICATION OF FUSES AND CIRCUIT BREAKER S ....................D-1

1-2. PRECAUTIONS FOR HANDLING THE LASER EQUIPMENT ...............D-1

1-3. INSTRUCTIONS FOR HANDLING THE PWBs WITH MOS ICs ............. D-2

1-4. HANDLING OF THE IMAGING CARTRIDGE ............................ .............D-2

1-5. PARTS WHICH MUST NOT BE TOUCHED ...........................................D-3

(1) Red painted Screws ........................................................................D-3

(2) Variable Resistors on Board ............................................................D-3

(3) Other Screws ...................................................................................D-3

2. DISASSEMBLY/REASSEMBLY ...................................................................... D-4

2-1. DOORS, COVERS, AND EXTERIOR PARTS: IDENTIFICATION AND

REMOVAL PROCEDURES .....................................................................D-4

2-2. REMOVAL OF CIRCUIT BOARDS AND OTHER ELECTRICAL

COMPOMENTS .......................................................................................D-7

2-3. PAPER TAKE-UP/TRANSPORT SECTION ............................................D-10

(1) Replacement of the Paper Take-Up Roll ......................................... D-10

(2) Replacement of the Paper Dust Remover .......................................D-10

(3) Cleaning of the Paper Dust Remover ..............................................D-11

(4) Cleaning of the Side Cover ..............................................................D-11

(5) Cleaning of the Duplex Unit Cover ..................................................D-11

2-4. OPTICAL SECTION ............................. ...................................................D-12

(1) Removal of the IR Unit ....................................................................D-12

(2) Removal of the PH Unit ...................................................................D-13

(3) Removal of the CCD Unit ................................................................D-15

(4) Cleaning of the Scanner Rails/Bushings ...................................... ...D-15

(5) Cleaning of the Mirrors ....................................................................D-16

(6) Cleaning of the Lens ........................................................................D-16

(7) Cleaning of the Original Glass .......................................... ...............D-16

(8) Removal of the Scanner ..................................................................D-16

(9) Removal of the Scanner Drive Cables ............................................D-18

(10) Winding of the Scanner Drive Cables ..............................................D-19

2-5. IMAGE TRANSFER SECTION ................................................................D-23

(1) Removal of the Image Transfer Roller .............................................D-23

(2) Cleaning of the Comb Electrode ......................................................D-23

(3) Cleaning of the Pre-Image Transfer Guide Plate ........................... .D-24

(4) Replacement of the Ozone Filter .....................................................D-24

2-6. DEVELOPING SECTION ............................. ...........................................D-25

(1) Removal of the Imaging Cartridge ...................................................D-25

2-7. FUSING SECTION ..................................................................................D-26

(1) Removal of the Fusing Unit ............................................................. D-26

(2) Removal of the Fusing Roller Heater Lamp, Fusing Right Roller,

Fusing Left Roller, Fusing Roller Thermistor, Fusing Roller

Thermostat, and Fusing Roller Heater Lamp Fuse .................. .......D-26

3. ADJUSTMENT .................................................................................................D-29

3-1. ADJUSTMENT JIGS AND TOOLS USED ...............................................D-29

3-2. ADJUSTMENT REQUIREMENT LIST ....................................................D-29

i

Page 13

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

3-3. ADJUSTMENT OF BELT TENSION ........................................................D-30

3-4. TEST PRINT .................... ................................................................. .......D-31

3-5. ELECTRICAL/IMAGE ADJUST MENT .......................................... ...........D-32

(1) Touch Panel Adj. .............................. ...............................................D-32

(2) Original Size Detecting Sensor Adjustment (F7-1) ..........................D-33

(3) Loop Adjustment ................................................................. .............D-34

(4) Edge Erase ......................................................................................D-35

(5) Registration (CD) (Printer) ...............................................................D-38

(6) Registration (FD) (Printer) ........ ......................... ......................... .....D-40

(7) Registration (IR) ............ ....................... ...........................................D-42

(8) Zoom Adjust (IR) .............................................................................D-46

(9) IR-Erasure Width .............................................................................D-50

3-6. OTHER ADJUSTMENTS .........................................................................D-51

4. MISCELLANEOUS ..........................................................................................D-53

4-1. INSTALLATION OF THE KEY COUNTER SOCKET (OPTION) ............. D-53

4-2. REMOUNTING THE EEPROM (IC3A) ......... ...........................................D-54

ii

Page 14

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

1 SERVICE INSTRUCTIONS

1-1. IDENTIFICATION OF FUSES AND CIRCUIT BREAKERS

125V 3.15A

125V 5A

Master Board

PWB-A125V 3A (F1)

125V 3A (F2)

250V 1A (F3)

250V 1A (F4)

Power Supply Unit 1

PU1 125V 10A (F1)

125V 15A (F2)

250V 3.15A (F3)

250V 3.15A (F4)

Power Supply Unit 2

PU2 125V 5A

Fusing Roller

Heater Lamp Fuse

TF1 125V 15A

Fusing Roller

Thermostat

TS1 250V 10A

1171D016AC

1-2. PRECAUTIONS FOR HANDLING THE LASER EQUIPMENT

•

The laser used in this copier is a semiconductor laser having the following specifications.

Max. power: 5mW

Output wavelength: 770~810nm

•

When laser protective goggles are to be used, select ones with a lens conforming to the

above specifications.

•

When a disassembly job needs to be performed in the laser beam path, such as when

working around the printerhead and PC Drum, be sure first to turn the copier OFF.

•

If the job requires that the copier be left ON, take off your watch and ring and wear laser

protective goggles.

•

A highly reflective tool can be dangerous if it is brought into the laser beam path. Use

utmost care when handling tools on the user’s premises.

•

The printerhead is not maintainable in the field. It is to be replaced as an assembly

including the control board. Never, therefore, attempt to remove the laser diode or adjust

trimmers on the control board.

D-1

Page 15

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

1-3. INSTRUCTIONS FOR HANDLING THE PWBs WITH MOS ICs

The following precautions must be observed when handling P.W. Boards with MOS

(Metal Oxide Semiconductor) ICs.

During Transportation/Storage:

•

During transportation or when in storage, new P.W. Boards must not be indiscriminately

removed from their protective conductive bags.

•

Do not store or place P.W. Boards in a location exposed to direct sunlight.

•

When it becomes absolutely necessary to remove a Board from its conductive bag or

case, always place it on its conductive mat in an area as free as possible from static electricity.

•

Do not touch the pins of the ICs with your bare hands.

During Replacement:

•

Before unplugging connectors from the P.W. Boards, make sure that the power cord has

been unplugged from the outlet.

•

When removing a Board from its conductive bag or conductive case, do not touch the

pins of the ICs or the printed pattern. Place it in position by holding only the edges of the

Board.

•

Before plugging connectors into the Board, make sure that the power cord has been

unplugged from the power outlet.

During Inspection:

•

Avoid checking the IC directly with a multimeter; use connectors on the Board.

•

Never create a closed circuit across IC pins with a metal tool.

•

When it is absolutely necessary to touch the ICs and other electrical components on the

PW Board, be sure to ground your body.

1-4. HANDLING OF THE IMAGING CARTRIDGE

During Transportation/Storage:

•

Use the specified carton whenever moving or storing the Imaging Cartridge.

•

The storage temperature is in the range between –20°C and +40°C.

•

In summer, avoid leaving the Imaging Cartridge in a car for a long time.

Handling:

•

Ensure that the correct Imaging Cartridge is used.

•

Store the Imaging Cartridge in a site that is not exposed to direct sunlight.

Precautionary Information on the PC Drum Inside the Imaging Cartridge:

•

The PC Drum exhibits greatest light fatigue after being exposed to strong light over an

extended period of time. Never, therefore, expose it to direct sunlight.

•

Use care not to contaminate the surface of the PC Drum with oil-base solvent, fingerprints, and other foreign matter.

•

Do not scratch the surface of the PC Drum.

•

Do not apply chemicals to the surface of the PC Drum.

•

Do not attempt to wipe clean the surface of the PC Drum.

D-2

Page 16

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

1-5. PARTS WHICH MUST NOT BE TOUCHED

(1) Red painted Screws

Purpose of Application of Red Paint

Red painted screws show that the assembly or unit secured can only be adjusted or set at

the factory and should not be readjusted, set, or removed in the field.

Note that when two or more screws are used on the part in questions, only one representative screw may be marked with red paint.

(2) Variable Resistors on Board

Do not turn the variable resistors on boards for which no adjusting instructions are given in

“ADJUSTMENT.”

(3) Other Screws

Although not marked with red paint, the following screws must not be loosened or readjusted.

8 screws on the PH Unit Cover

1167D002AB

D-3

Page 17

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

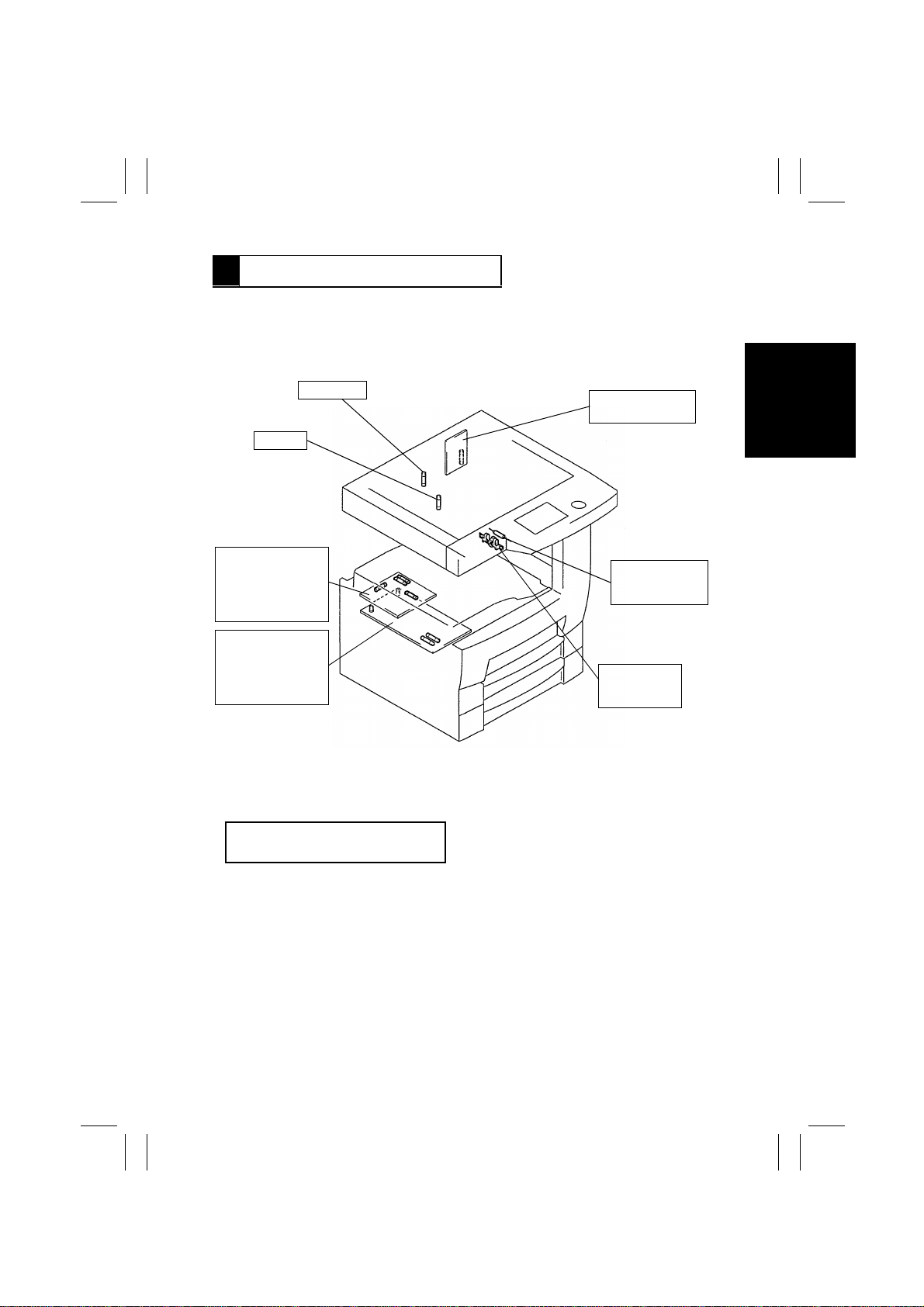

2 DISASSEMBLY/REASSEMBLY

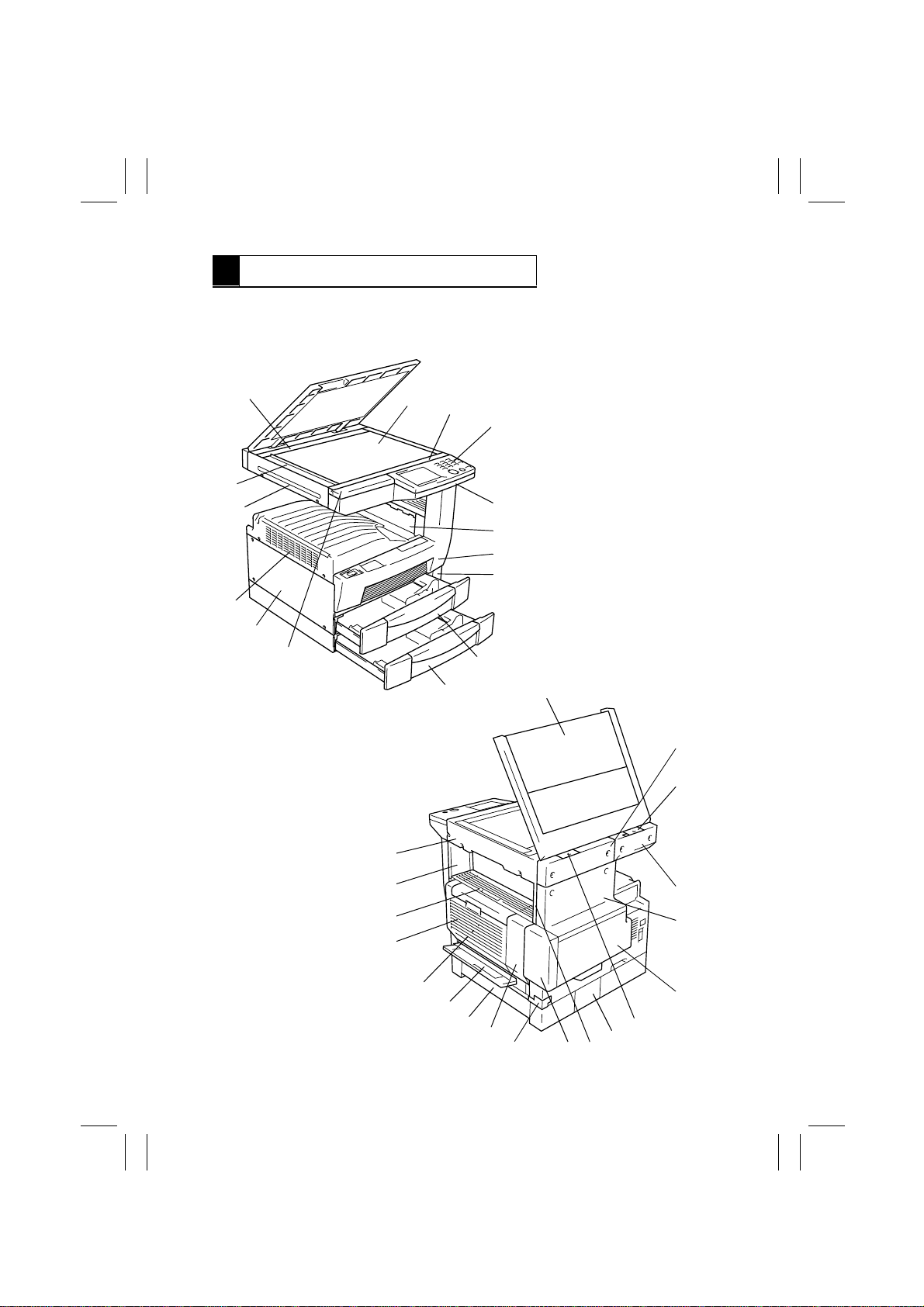

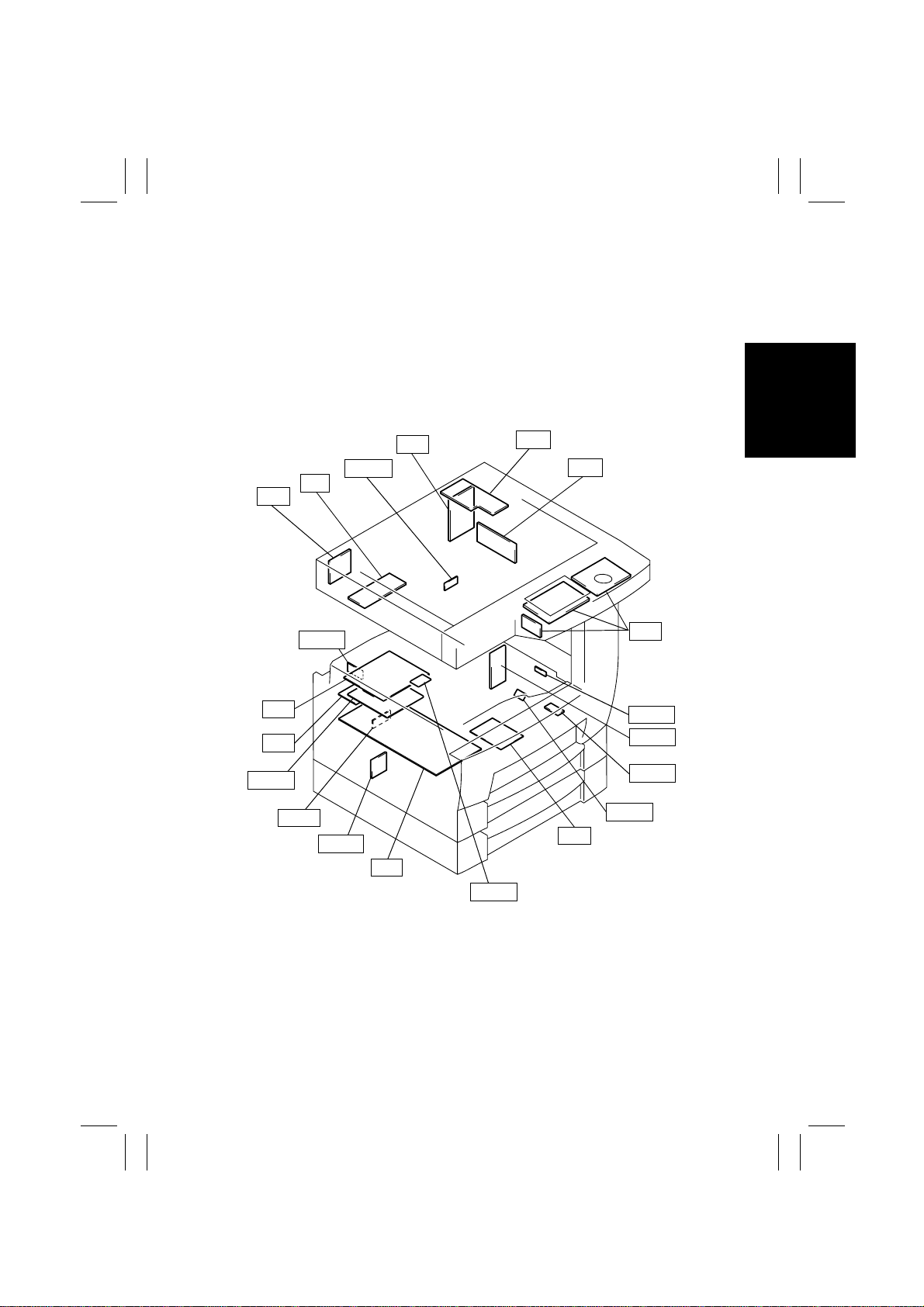

2-1. DOORS, COVERS, AND EXTERIOR PARTS: IDENTIFICATION

AND REMOVAL PROCEDURES

14

1

15

2

13

12

3

4

5

6

7

8

9

1171D017AA

10

11

16

17

18

34

33

32

31

30

29

D-4

28

27

26

19

20

21

22

23

2425

1171D018AB

Page 18

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

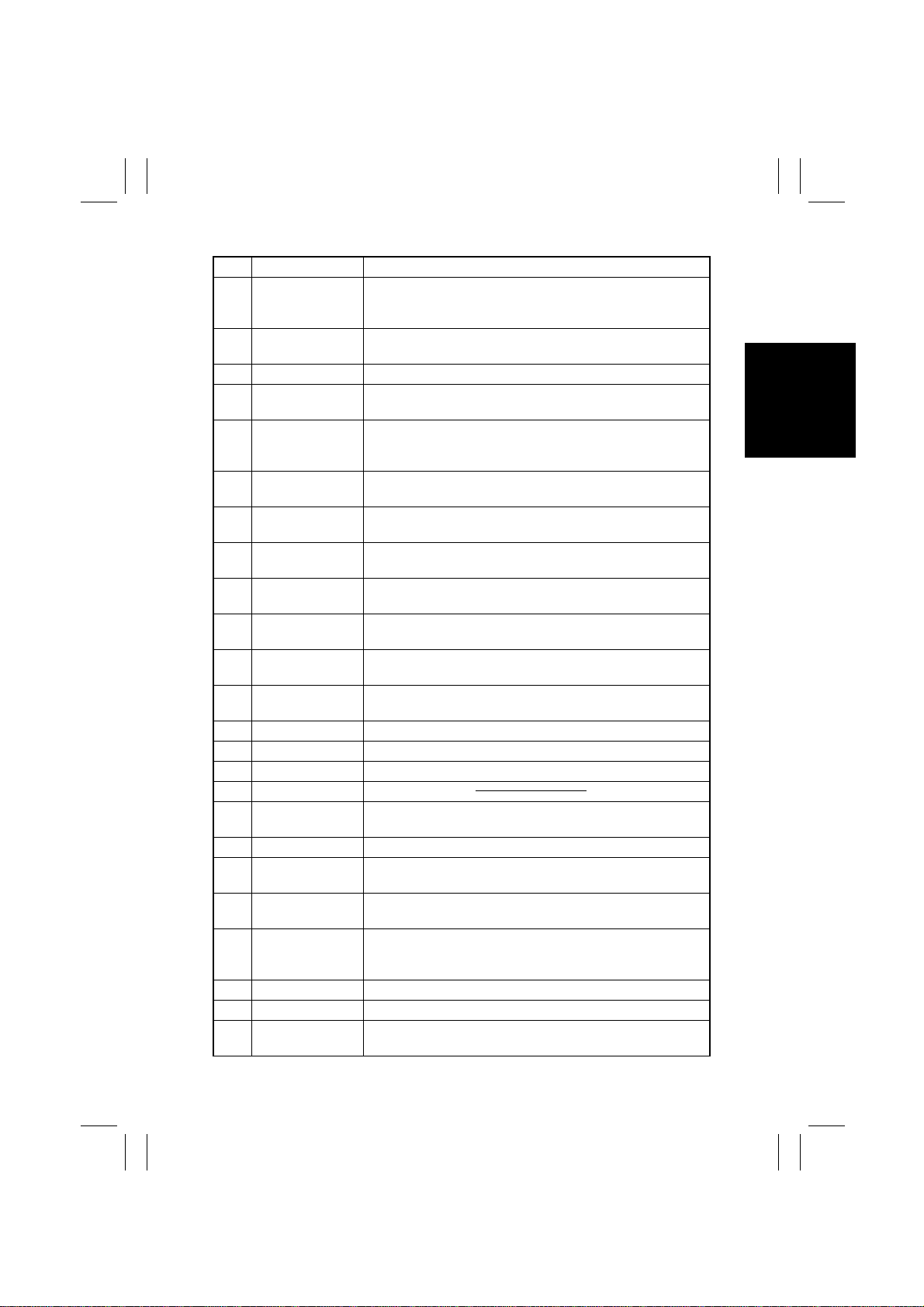

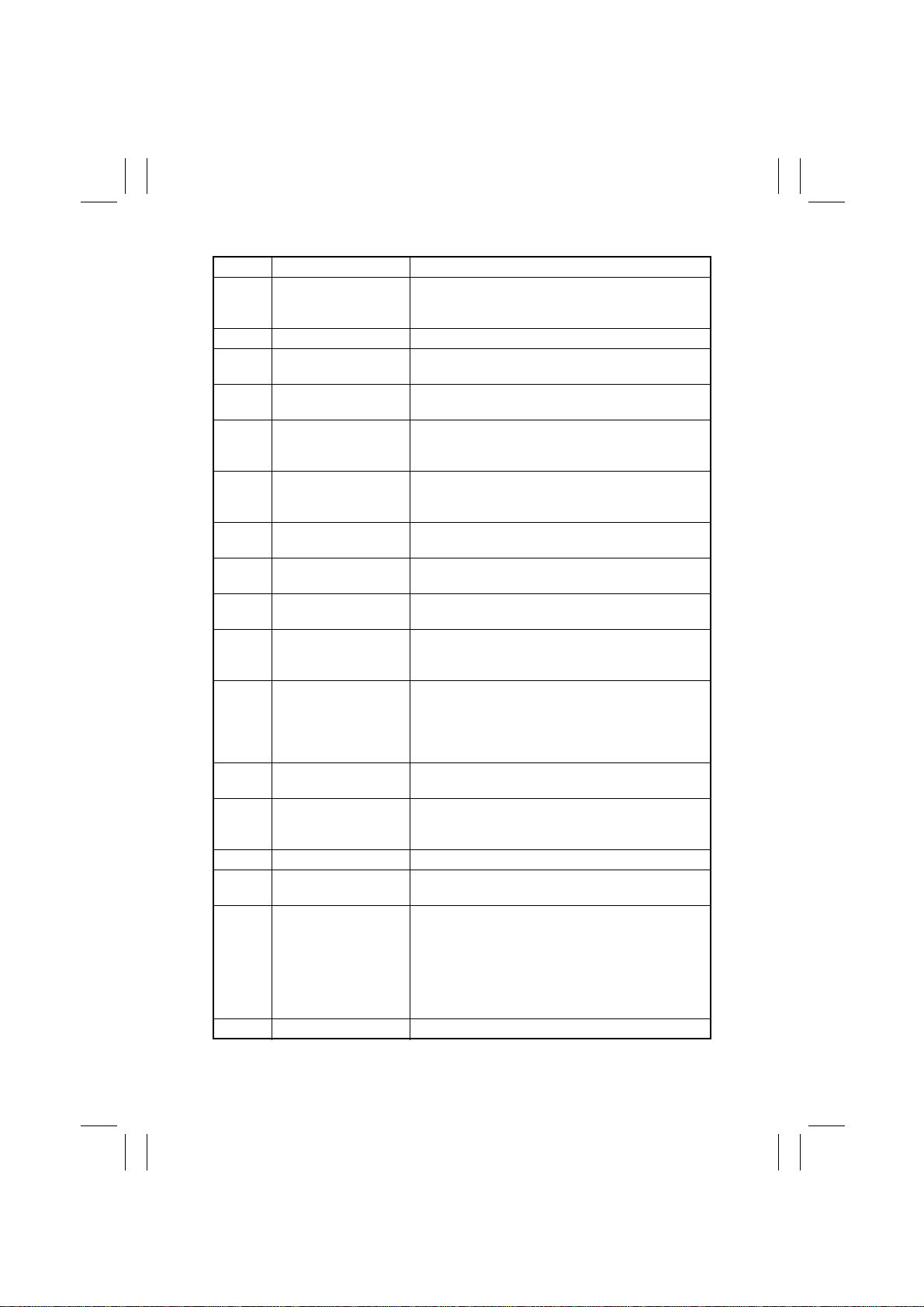

No. Part Name Removal Procedure

1 ADF Glass Assy. Remove No. 2, 4. → Remove two holding brackets. →

2 Rear Holding

Bracket

3 Original Glass Remove No. 4. → Remove two holding brackets.

4 Front Holding

Bracket

5 Control Panel Remove No. 8. → Remove No. 6. → Remove No. 4. →

6 Front Upper Cover Remove No. 8. → Remove No. 12. → Remove six screws that

7 Exit Lower Cover Remove No. 32. → Remove No. 24. → Unhook the two tabs of

8 Front Cover Slide out No. 10. → Open No. 25. → Remove three screws

9 LED Cover Slide out No. 10. → Remove one screw that secure the LED

10 MP Cassette Slide out the MP Cassette. → Pushing the tab on the right rail,

11 500-Sheet

Cassette

12 Upper Front Left

Cover

13 Left Cover Remove six screws that secure the Left Cover.

14 Upper Cover Remove two screws that secure the Upper Cover.

15 Left IR Cover Remove two screws that secure the Left IR Cover.

16 Original Cover

17 Rear Right IR

Cover

18 Left Hinge Cover Remove one screw that secure the Left Hinge Cover.

19 Rear Left IR Cover Remove No. 17. → Remove two screws that secure the Rear

20 Rear Upper Cover Remove No. 21. → Remove No. 17. → Remove No. 19. →

21 Rear Lower Cover Remove No. 26. → Remove No. 25. → Open No. 30. → Open

22 Right Hinge Cover Remove one screw that secure the Right Hinge Cover.

23 Connector Cover Remove one screw that secure the Connector Cover.

24 Rear Inside Cover Remove No. 22. → Remove three screws that secure the Rear

Remove two screw caps. → Remove two screws that secure

the ADF Glass Assy.

Remove No. 17, 18. → Remove two screw caps. → Remove

two screws that secure the Rear Holding Bracket.

Remove two screw caps. → Remove two screws that secure

the Front Holding Bracket.

Remove No. 12. → Remove five screws that secure the control

panel and unplug one connector.

secure the Front Upper Cover.

the Exit Lower Cover and remove the Exit Lower Cover.

that secure the Front Cover.

Cover.

pull out the cassette.

Slide out the 500-Sheet Cassette. → Pushing the tabs on both

the right and left rails, pull out the cassette.

Remove No . 4. → Remove two screws that secure the Upper

Front Left Cover.

Remove No . 22. → Remove No. 19. → Remove two screws

that secure the Rear Right IR Cover.

Left IR Cover.

Remove four screws that secure Rear Upper Cover.

No. 32. → Remove five screws that secure the Rear Lower

Cover.

Inside Cover.

D-5

Page 19

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

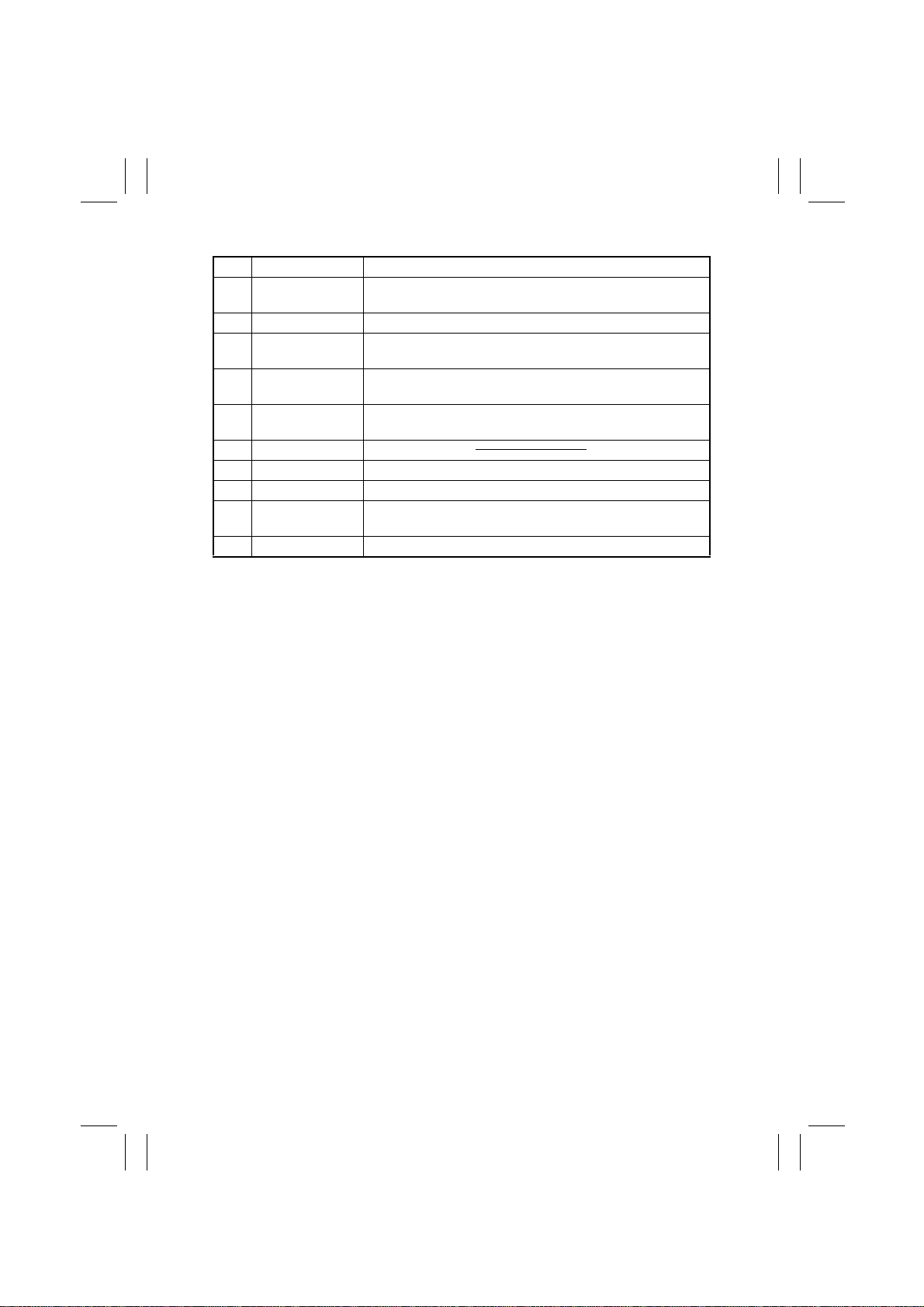

No. Part Name Removal Procedure

25 Toner Bottle Cover Open the Toner Bottle Cover. → Unhook the dowels at four

26 Harness Cover Remove one screw that secure the Harness Cover.

27 Duplex Unit Rear

Cover

28 500-Sheet Cas-

sette Side Cover

29 Manual Bypass

Tray

30 Side Cover

31 Duplex Unit Remove two screws that secure the Duplex Unit.

32 Fusing Unit See D-26.

33 Front Inside Cover Remove No. 8. → Remove No. 32. → Remove two screws that

34 Right IR Cover Remove three screws that secure the Right IR Cover.

places of the Toner Bottle Cover.

Remove No . 31. → Remove two screws that secure the

Duplex Unit Rear Cover.

Open the Side Cover . → Slide the Side Cover to the front and,

at the same time, pull the rear side out of the frame.

Remove No . 26. → Unplug one connector. → Remove three

screws that secure the Manual Bypass Tray.

secure the Front Inside Cover.

D-6

Page 20

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

2-2. REMOVAL OF CIRCUIT BOARDS AND OTHER ELECTRICAL

COMPOMENTS

•

When removing a circuit board or other electrical component, refer to “PRECAUTIONS

FOR HANDLING THE PWBs” contained in SWITCHES ON PWBs and follow the corresponding removal procedures.

•

The removal procedures given in the following omit the removal of connectors and

screws securing the circuit board support or circuit board.

•

Where it is absolutely necessary to touch the ICs and other electrical components on the

board, be sure to ground your body.

BCR

UN2

UN3

PWB-A

PWB-I

INV

PWB-L

PWB-A

PWB-R

PU1

PU2

HGB

CCD

UN1

PWB-R

PWB-A

PWB-R

PWB-H

HV1

1171D020AE

PWB-N

D-7

Page 21

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

Symbol P art Name Removal Procedure

PWB-A Master Board Remo ve the Upper Cover. → Remove nine screws

PWB-A Cassette Main Board Remove the Connector Cover. → PWB-A

PWB-A Duplex Main Board Remove the Duplex Unit. → Remove the Duplex Unit

PWB-H Double Feed Detecting

Board

PWB-I Paper Size Detecting

Board

PWB-L PPM Switching Board Remove the Harness Cover. → Remove the Rear

PWB-N RAM Board Remove the Upper Cover. → Remove nine screws

PWB-R Fuser Frame Register

Board

PWB-R Pre-Transfer Guide

Plate Register Board 1

PWB-R Pre-Transfer Guide

Plate Register Board 2

PU1 Power Supply Board 1 Remove the Ha rness Cover. → Remove the Rear

PU2 Power Supply Board 2 Remove the Ha rness Cover. → Remove the Rear

HV1 High Voltage Unit Open the Side Cover. → Remove the Imaging Car-

INV Inverter Board Remove the Original Glass. → INV

BCR BCR Board Remove the Rear Left IR Cover. → Remove three

HGB HGB Board Remove the Original Glass.

CCD CCD Board See D-15.

and the MFB Box Cover. → Remove two screws and

the MFB Box Assy. → PWB-A

Rear Cover. → PWB-A

Slide out the MP Cassette. → Remove one screw and

the PWB-H Mounting Bracket Assy. → PWB-H

Remove the Harness Cover. → Remove the Rear

Cover. → Remove two screws and the PW Board

Cover. → PWB-I

Cover. → Remove one screw and the PWB-L Mounting Bracket Assy. → PWB-L

and the MFB Box Cover. → PWB-N

Remove the Fusing Unit. → Remove the rear lamp

cover. → PWB-R

Remove the Vertical Transport Unit. → Remove two

screws and two ground plates. → PWB-R

Open the Side Cover. → Remove the Imaging Car-

tridge. → Remove one screw and the PW Board

Cover. → PWB-R

Cover. → Remove the Left Cover. → Remove five

screws and the Reinforcement Bracket. → Remove

three screws and the PU1 Mounting Bracket Assy. →

PU1

Cover. → PU2

tridge. → Remove two screws and the HV1 Cover. →

HV1

screws and the Harness Cover. → BCR

→

→

Cover.

Rear Lower Cover.

→

only)

→

and the HGB Mounting Bracket Assy.

Remove the Optical Cover.

→

Remove the Shielding Plate. (U.S.A. and Canada

→

Remove one screw and the Harness Cover.

Unplug nine connectors. → Remove five screws

Remove the Rear Upper Co ver.

Remove the Right IR

→

Remove the

→

HGB

D-8

Page 22

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

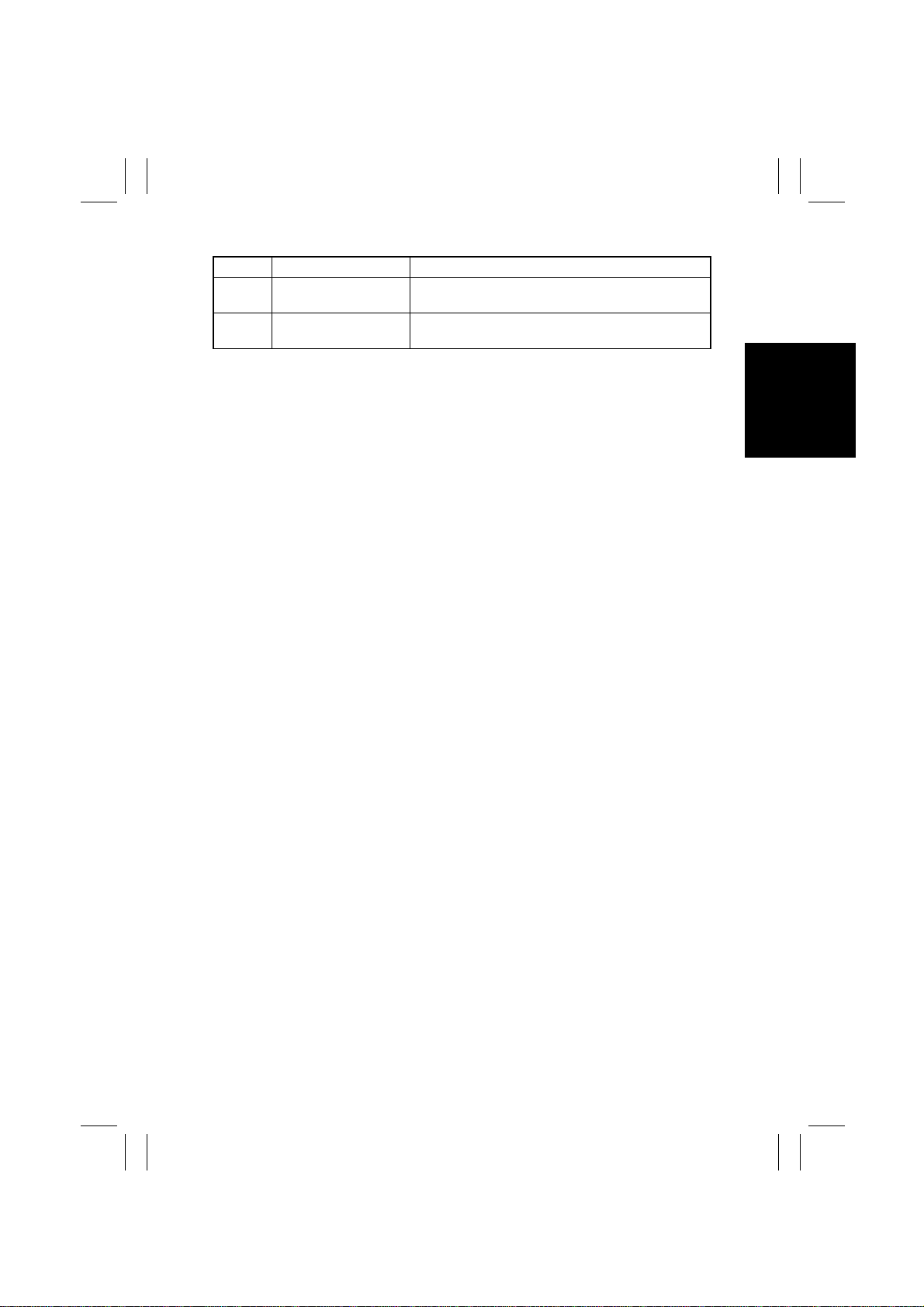

Symbol P art Name Removal Procedure

UN2 MFB Board Remove the Upper Cover. → Remove nine screws

UN3 Polygon Motor Drive

Board

and the MFB Box Cover. → UN2

Remove the PH Unit. → UN3

D-9

Page 23

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

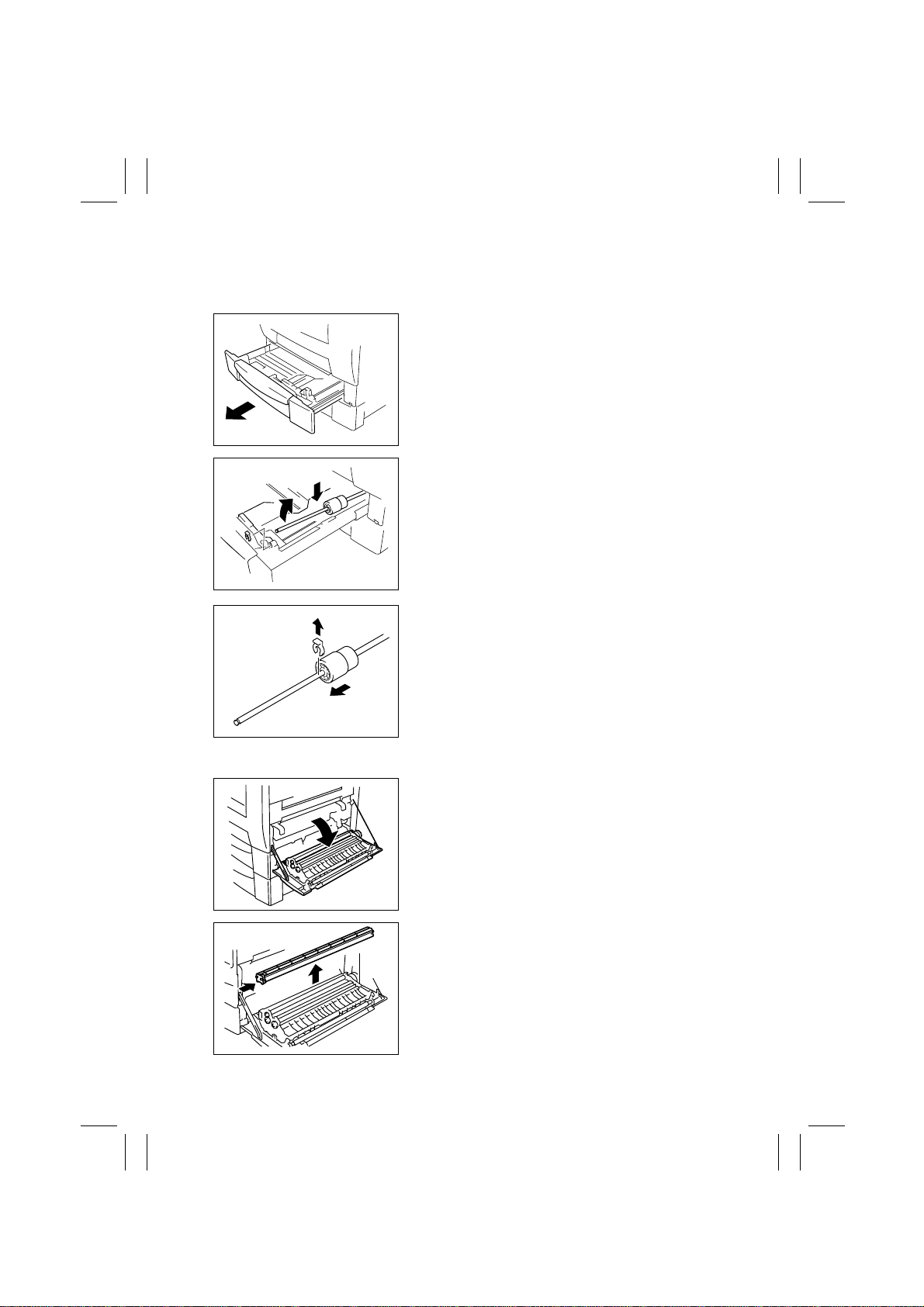

2-3. PAPER TAKE-UP/TRANSPORT SECTION

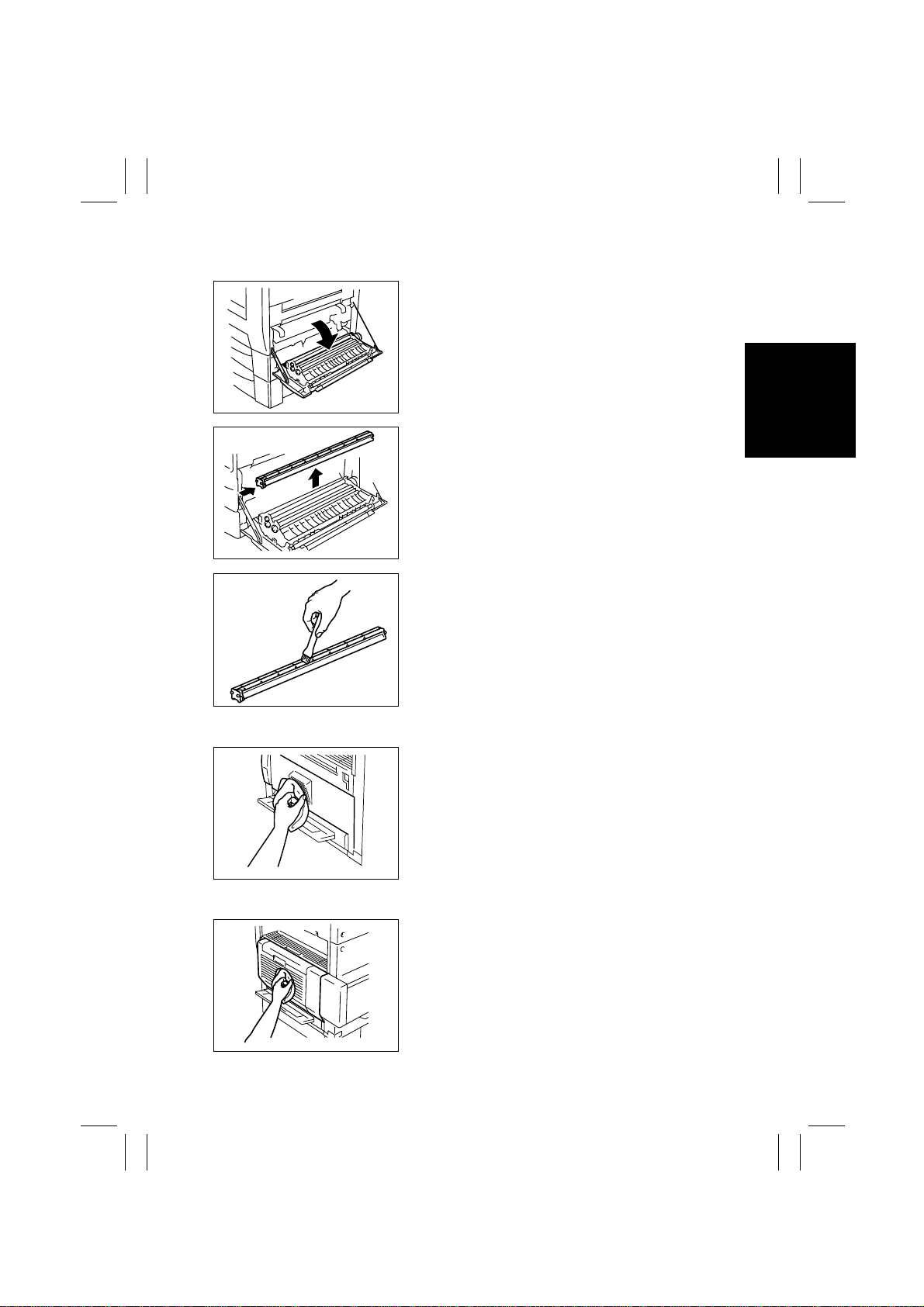

(1) Replacement of the Paper Take-Up Roll

1. Slide out the MP Cassette.

4108D033AA

2. Lock the Paper Lifting Plate.

3. Snap off one C-clip of the Paper Take-Up Roll

Assy.

4. Slide the Paper Take-Up Roll Assy to the rear so

that it can be pulled off the bushing at the front.

1167D140AA

5. Snap off one C-clip and remove and replace the

Paper Take-Up Roll.

4108D035AA

(2) Replacement of the Paper Dust Remover

1. Open the Side Cover.

1171D021AA

2. Remove the Paper Dust Remover and replace it.

1167D007AB

D-10

Page 24

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

(3) Cleaning of the Paper Dust Remover

1. Open the Side Cover.

1171D021AA

2. Remove the Paper Dust Remover.

1167D007AB

3. Using a brush, whisk dust and dirt off the Paper

Dust Remover.

1167D008AB

(4) Cleaning of the Side Cover

Using a soft cloth dampened with alcohol, wipe the

Side Cover.

1171D052AB

(5) Cleaning of the Duplex Unit Cover

Using a soft cloth dampened with alcohol, wipe the

Duplex Unit Cover.

1171D051AA

D-11

Page 25

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

2-4. OPTICAL SECTION

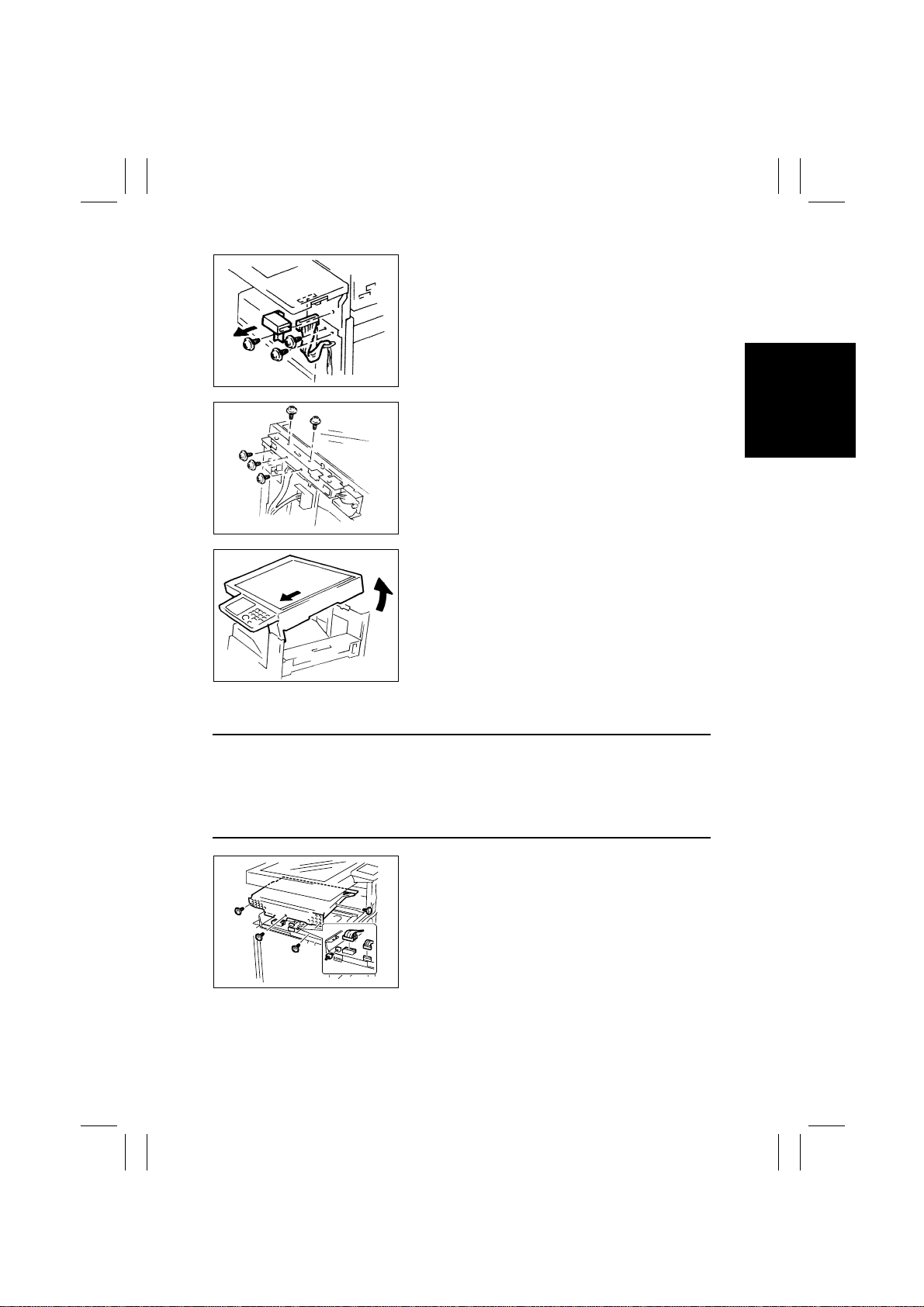

(1) Removal of the IR Unit

1. Remove the Original Cover, Front Holding Brack et, Upper F ront Left Co v er , Front Cover,

Front Upper Cover, Rear Right IR Cover, Rear Left IR Cover, Rear Lower Cover, Rear

Upper Cover, and Front Inside Cover.

2. Remove one screw and the Motor Cover.

1171D054AA

3. Remove the Shielding Plate. (U.S.A. and Canada

only)

4. Remove one screw and the Harness Cover.

1167D149DA

1167D027AC

1167D032AC

5. Unplug eight connectors of the HGB Board.

6. Remove three screws and the Harness Cover.

7. Unplug one connector of the BCR Board.

D-12

Page 26

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

8. Remove one screw and the Total Counter Mounting Bracket Assy.

9. Unplug one connector of the Control Panel.

10. Remove two screws that secure the front end of

the frame.

1167D033AC

11. Remove five scre ws that secure the rear end of the

frame.

1167D059AC

12. Raise the rear end of the IR Unit and pull the unit

out toward front.

1171D053AA

(2) Removal of the PH Unit

NOTES

•

Do not place the PH Unit upside down or subject it to excessive shock.

•

Replace the PH Unit as one unit.

•

NEVER attempt to disassemble or adjust the PH Unit.

•

Whenever the PH Unit has been removed, make the following adjustments:

Edge Erase, Registration (CD, FD) (Printer), Registration (IR).

1. Remove the Upper Cover, Front Cover, Left Cover,

and Rear Cover.

2. Remove four screws and the MFB Box Cover.

3. Unplug five connectors of the MFB Board.

1167D058AE

D-13

Page 27

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

4. Remove two screws and the MFB Box Assy.

1167D028AA

5. Remove five screws and the Reinforcement

Bracket.

6. Remove four screws and the handle.

1167D062AC

7. Unplug all connectors (13) from Master Board

PWB-A.

1167D029AC

1167D030AB

1167D012AA

8. Remove the harness from all cord clamps (12) on

the PH Base Plate.

9. Remove four screws and the PH Unit.

D-14

Page 28

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

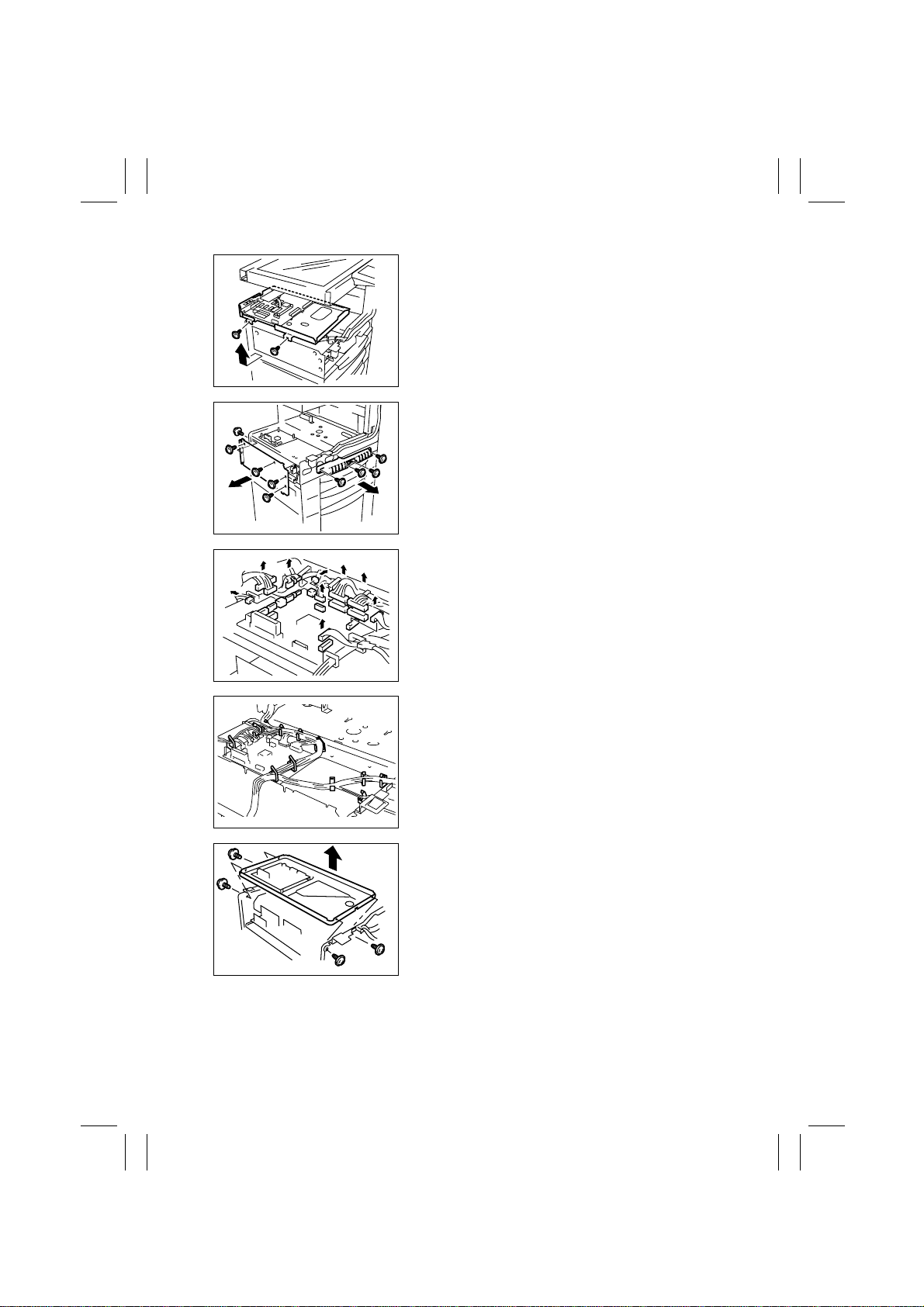

(3) Removal of the CCD Unit

1. Remove the Original Glass.

2. Remove four screws and the Cover.

1167D014AB

3. Unplug two connectors of the CCD Unit.

4. Remove two screws and the CCD Unit.

1171D055AA

NOTES

1. When removing the CCD Unit, remove only those screws and parts that are specified.

(Remove the CCD Unit as one unit.)

2. Whenever the CCD Unit has been replaced, make the following adjustment:

FD of Zoom Adjust (IR).

(4) Cleaning of the Scanner Rails/Bushings

1. Remove the Original Glass.

2. Using a soft cloth, wipe clean the Scanner Rails

and Bushings.

1167D016AB

D-15

Page 29

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

(5) Cleaning of the Mirrors

1. Remove the Original Glass.

2. Wipe clean the Mirrors with a soft cloth.

1167D017AC

(6) Cleaning of the Lens

1. Remove the CCD Unit.

2. Wipe clean the Lens with a soft cloth.

1167D018AB

(7) Cleaning of the Original Glass

Wipe clean the Original Glass with a soft cloth.

1171D050AA

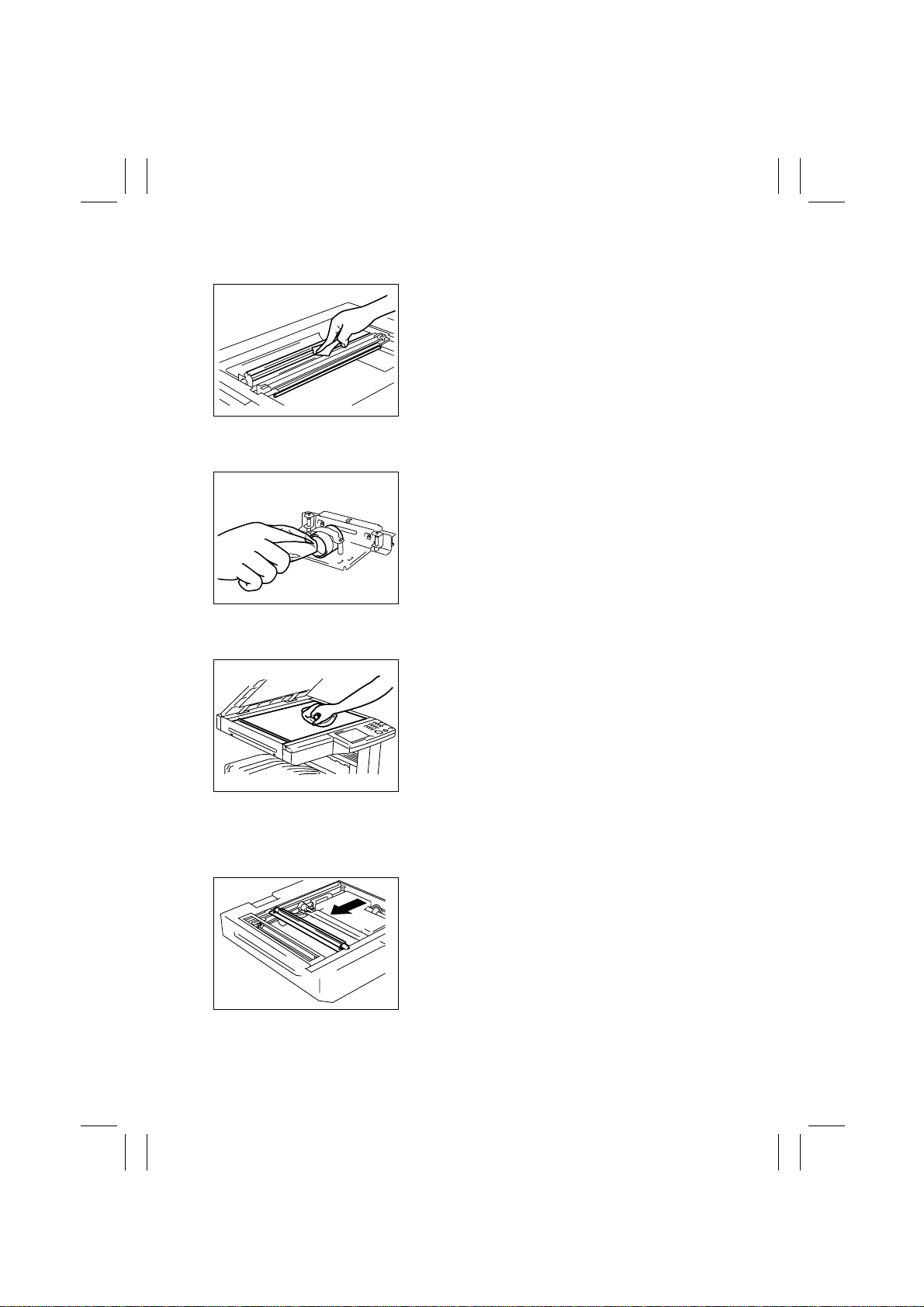

(8) Removal of the Scanner

1. Remove the Original Glass.

2. Remove the Rear Holding Bracket.

3. Slide the Scanner to the position shown.

1167D039AC

D-16

Page 30

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

4. Remove one screw and unplug the connector of

the Exposure Lamp.

5. Remove the flat cable of the Exposure Lamp.

1167D037AC

6. Remove one screw and the Lamp Fixing Bracket.

1167D035AD

Rear

7. Slide the Exposure Lamp to the front and remove

it.

Front

1167D036AA

8. Remove two screws and the Scanner.

1167D049AB

D-17

Page 31

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

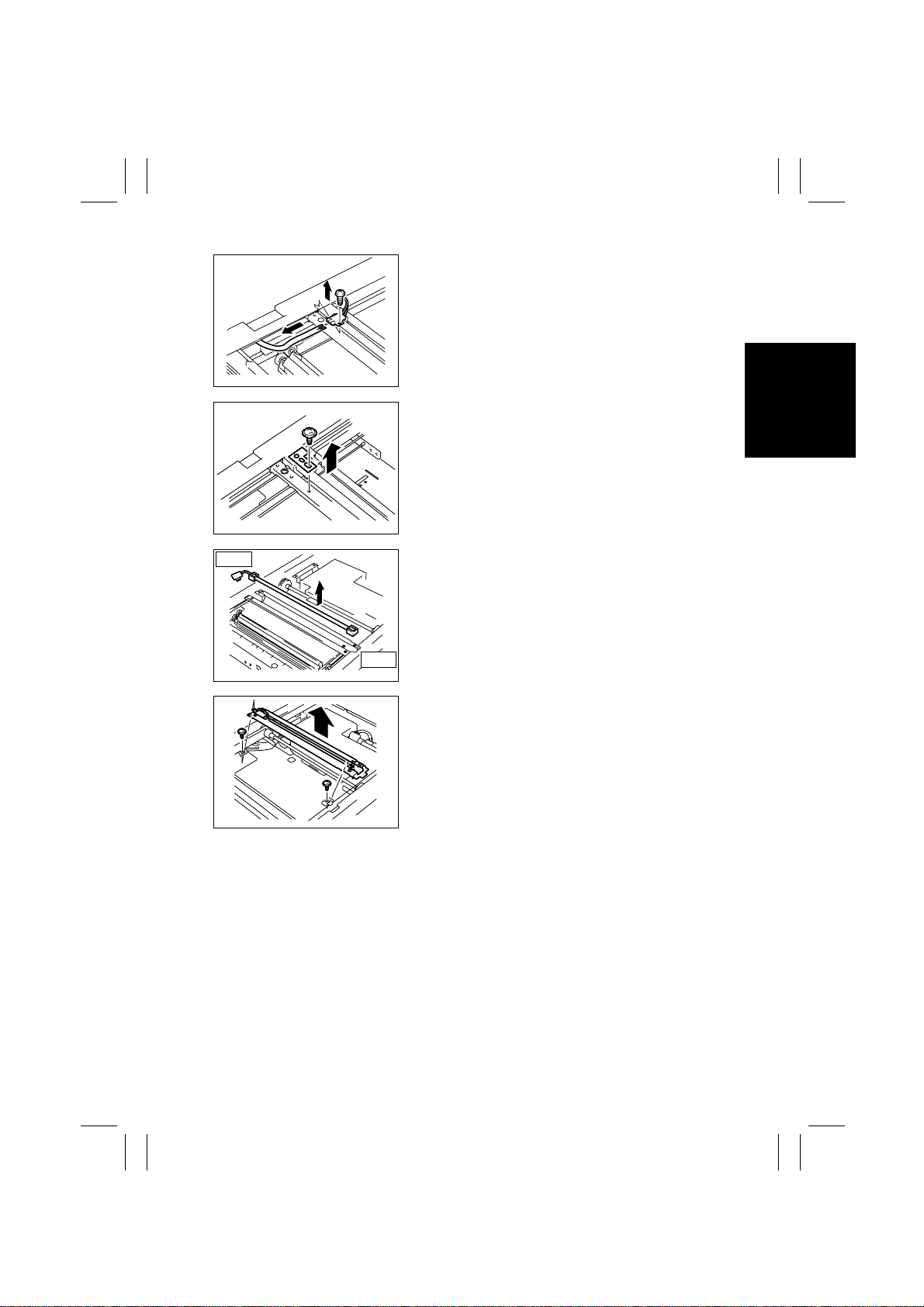

(9) Removal of the Scanner Drive Cables

1. Remove the Original Glass and ADF Glass Assy.

2. Remove the Left IR Cover.

3. Remove the Scanner.

4. Unhook the spring of the cable on the hook side,

one each at the front and in the rear.

1167D044AB

5. Remove one screw and the Original Size Detection

Sensor.

✽

Inch Areas Option.

1167D070AA

6. Snap off one E-ring and remove one mounting

screw from the front pulley and slide the pulley to

the rear.

1167D071AA

7. Snap off one E-ring and remove one mounting

screw from the rear pulley and slide the pulley to

the front.

1167D072AA

8. Remove the Scanner Drive Cable, hook end first.

D-18

Page 32

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

(10) Winding of the Scanner Drive Cables

Pulley H

Pulley F

Pulley E

Pulley G

Pulley B

Pulley C

Pulley A

Front

1. Position the round bead of the Scanner Dr ive

Cable in the pulley as shown.

Pulley D

1167D047AB

Cable on Hook End

1167D051AC

1167D052AD

Cable on

Bead End

1167D053AD

2. Wind the hook end of the Scanner Drive Cable two

turns counterclockwise from the rear side to the

front.

3. Wind the bead end of the cable four turns clockwise from the front to the rear. Then, secure the

cable with tape.

NOTE

Make sure that no part of the cable rides on the other.

D-19

Page 33

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

4. Slide the pulley to the front and install one mounting screw and one E-ring.

1167D073AA

5. Wind the bead end of the cable around pulley D

and pulley C, then hook the bead onto the Adjust-

Pulley D

able Anchor.

Pulley C

Pulley A

Pulley B

Cable Guide

1167D056AC

6. Wind the hook end of the cable around pulley A

and pulley B.

1167D057AC

7. Fit the hook end of the cable into the groove in the

Cable Guide and hook the spring.

1167D074AA

Rear

8. Position the round bead of the Scanner Dr ive

Cable in the pulley as shown.

1167D051AC

D-20

Page 34

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

9. Wind the hook end of the cable two turns counterclockwise from the front to the rear.

Cable on Hook End

Pulley G

1167D054AD

Cable on

Bead End

1167D055AD

1167D075AA

Pulley H

1167D076AA

10. Wind the bead end of the cable four turns clockwise from the rear to the front. Then, secure the

cable with tape.

NOTE

Make sure that no part of the cable rides on the other.

11. Slide the pulley toward the rear and install one

mounting screw and one E-ring.

12. Wind the bead end of the cable around pulley H

and pulley G and hook the bead onto the Adjustable Anchor.

Pulley E

13. Wind the hook end of the cable around pulley E

and pulley F.

Pulley F

1167D078AA

D-21

Page 35

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

14. Fit the hook end of the cable into the groove in the

Cable Guide and hook the spring.

Cable Guide

15. Peel off the tape from the pulleys at the front and rear.

16. Mount the Scanner.

17. Mount the Original Size Detection Sensor.

18. Reinstall the Left IR Cover.

19. Reinstall the Original Glass and ADF Glass Assy.

20. Perform the Focus-Positioning of the Scanner and 2nd/3rd Mirrors Carriage.

(For details, see ADJUSTMENT.)

1167D077AA

NOTE

Whenever the Scanner Drive Cables have been removed, be sure to make the following

adjustment: CD of Zoom Adjust (IR).

D-22

Page 36

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

2-5. IMAGE TRANSFER SECTION

(1) Removal of the Image Transfer Roller

1. Open the Side Cover.

1167D006AD

2. Raise the Image Transfer Guide Plate.

1167D061AA

3. Remove the Image Transfer Roller and replace it.

NOTE

Do not touch the surface of the Image Transfer Roller

directly with bare hands.

4108D027AA

(2) Cleaning of the Comb Electrode

1. Open the Side Cover.

1171D021AA

D-23

Page 37

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

2. Using a soft cloth dampened with alcohol, wipe the

Comb Electrode.

NOTES

•

Make sure the alcohol does not touch the surface of

the Image Transfer Roller.

•

When wiping the Comb Electrode, make sure the

1167D009AA

cloth is not caught by the ends of the combs.

(3) Cleaning of the Pre-Image Transfer Guide Plate

1. Open the Side Cover.

1171D021AA

2. Using a soft cloth dampened with alcohol, wipe the

NOTE

Make sure the alcohol does not touch the surface of

the Image Transfer Roller.

1167D010AA

(4) Replacement of the Ozone Filter

1. Remove the Rear Lower Cover.

2. Pull out the Ozone Filter and replace it.

1171D022AC

Pre-Image Transfer Guide Plate.

D-24

Page 38

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

2-6. DEVELOPING SECTION

(1) Removal of the Imaging Cartridge

1. Open the Side Cover.

1171D021AA

2. Holding onto the green handles, slide the Imaging

Cartridge part of the way out.

3. Then grasp the handle on top of the cartridge and

pull the cartridge out.

NOTE

When installing the Imaging Cartridge, push it all the

1171D023AA

way into the machine.

If the cartridge is not properly installed, the PC Drum

protective shutter of the cartridge may not be opened

or may even be damaged.

D-25

Page 39

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

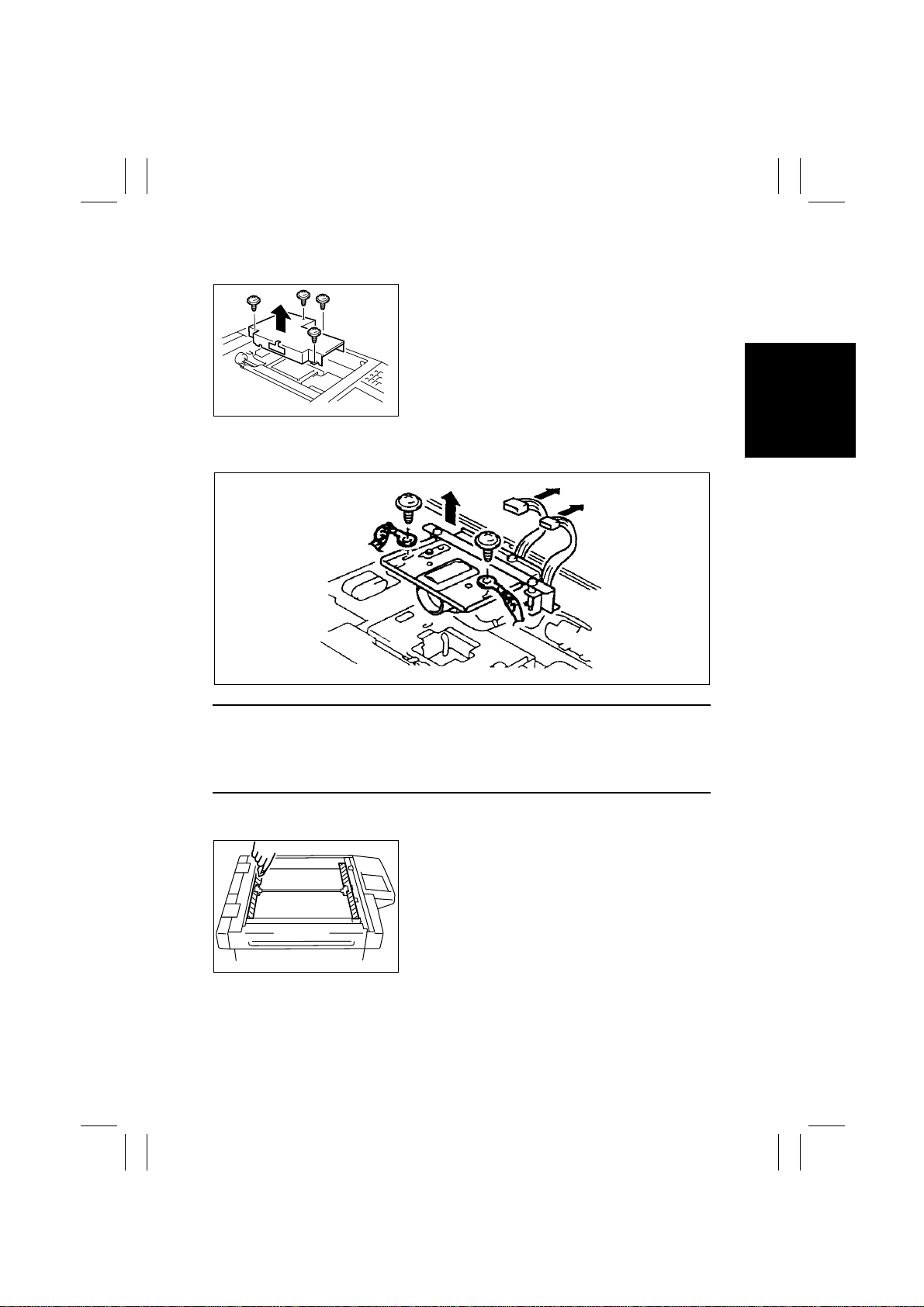

2-7. FUSING SECTION

(1) Removal of the Fusing Unit

1. Open the Side Cover.

1171D021AA

2. Remove the Front Cover.

3. Unplug one connector at the front.

1167D020AB

4. Open the Exit Cover and unplug two connectors in

the rear.

5. Close the Exit Cover and remove two screws and

the Fusing Unit.

1167D021AB

(2) Removal of the Fusing Roller Heater Lamp, Fusing Right Roller, Fusing Left

Roller , Fusing Roller Thermistor, Fusing Roller Thermostat, and Fusing Roller

Heater Lamp Fuse

1. Open the Exit Cover.

2. Remove one screw and the Fusing Front Cover.

1171D036AA

D-26

Page 40

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

3. Snap off one E-ring and remove the Exit Cover.

1171D037AA

4. Unhook one spring to free the Idle Lever.

5. Remove two harnesses.

6. Remove two screws and the Rear Cover.

1171D038AA

7. Remove three screws and the rear Lamp Holder.

1171D039AA

1171D041AA

1171D043AA

8. Remove one screw and the front Lamp Holder.

9. Remove one screw and the Fusing Roller Heater

Lamp.

10. Remove two screws and the Fusing Rear Guide

Assy.

11. Remove two pressure springs.

D-27

Page 41

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

12. Snap off one E-ring and remove the front Misfeed

Clearing Lever Assy and bearing.

13. Remove the Fusing Right Roller.

1171D044AA

14. Snap off two retaining rings.

15. Remove one gear and two bushings.

16. Remove the Fusing Left Roller.

1171D045AA

NOTE

When the Fusing Left Roller is removed, it can cause

the spring to come off the Separator Finger. After the

Fusing Left Roller has later been reinstalled, be sure to

hook the spring onto the Separator Finger.

1171D046AA

1171D047AA

17. Remove one screw and the Fusing Roller Thermistor.

18. Remove two screws and the Fusing Roller Heater

Lamp Fuse.

19. Remove two screws and the Fusing Roller Thermostat.

D-28

Page 42

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

3 ADJUSTMENT

3-1. ADJUSTMENT JIGS AND TOOLS USED

1. Scanner/Mirrors Carriage Positioning Jigs

1167D108AA

3-2. ADJUSTMENT REQUIREMENT LIST

Adjustment Item Requirements Adjustment Point Ref. Page

Touch Panel Adj. Automatically adjusted Control Panel D-32

Original Size Detecting Sensor

Adjustmen t

Loop Adjustment —

Edge Erase

Leading —

Trailing —

Right/Left —

Registration (CD) (Printer) 10 ± 2.0 mm

Registration (FD) (Printer)

Registration (IR)

CD

FD

Zoom Adjust (IR)

CD 200 ±1.0 mm

FD 300 ±1.5 mm

IR-Erasure Width —

↑↑

↑

↑

↑

↑

↑

↑↑

↑↑

↑↑

↑

↑

↑

D-33

D-34

D-35

D-36

D-37

D-38

D-40

D-42

D-44

D-46

D-48

D-50

D-29

Page 43

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

3-3. ADJUSTMENT OF BELT TENSION

•

Adjustment of the Scanner Motor Timing Belt

1. Remove the Original Glass.

2. Remove four screws and the Cover.

1167D014AB

3. Loosen the two screws that secure the Scanner

Motor. Using a bar tension gage, pull the motor to

the right with a tension of 1000 g ±50 g and, at the

same time, tighten the mounting screws.

NOTE

After the adjustment, turn the timing belt to check that

1167D109AB

the belt teeth are in mesh with the pulley grooves.

D-30

Page 44

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

3-4. TEST PRINT

NOTES

This function is used to make the following electrical and image adjustments:

•

Registration (CD) (Printer)

•

Registration (FD) (Printer)

•

Registration (IR)

•

Zoom Adjust (IR)

Adjustment Procedure

1. Check that “Copy Track Mode” of “Copy Track”

under “Admin. Management” available from “Utili ty”

is “OFF.”

1171D026CA

2. Select the paper source for the test print.

1171D027CA

3. Press the Utility key on the control panel and touch

[User Management].

1171D028CA

1171D029CA

4. Touch [Test Print] to produce a test pattern.

D-31

Page 45

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

3-5. ELECTRICAL/IMAGE ADJUSTMENT

(1) T ouch P anel Adj.

NOTE

Make this adjustment after either of the following procedures have been perform ed:

•

Memory Clear

•

Control Panel replacement

Adjustment Procedure

1. Call the Initial mode to the screen. (For details, see SWITCHES ON PWBs, TECH.

REP. SETTINGS.)

2. Touch [Touch Panel Adj.].

12

1171D056CA

4

“Initial” Screen

3. Touch + on screen 1.

NOTE

At this time, ensure that the very center of “+

similar device.

4. Touch + on screen 2.

5. Touch + on screen 3.

6. Touch + on screen 4.

D-32

1171D057CA

3

1171D058CA1171D059CA

is touched using the tip of a ballpoint pen or

”

Page 46

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

(2) Original Size Detecting Sensor Adjustment (F7-1)

NOTE

Make this adjustment after any of the following procedures have been perfor med:

•

Memory Clear

•

A faulty original size detection occurs

•

Replacement of the CCD Unit and Scanner parts (including the Exposure Lamp)

•

RAM Board replacement

Adjustment Procedure

1167D110AB

2. Call the Tech. Rep. mode to the screen.

3. Touch [Function] to call the Function menu.

4. Touch F7-1 Original Size Detecting Sensor Adjustment.

5. Press the Start key to run the Original Size Detecting Sensor Adjustment function.

1. Stack five sheets of blank A3 or 11” × 17” paper on

the Original Glass and lower the Original Cover.

NOTE

The Start key remains lit up orange while this function is being run and lights up green as

soon as the sequence is completed.

D-33

Page 47

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

(3) Loop Adjustment

Requirement

Adjust so that a correct loop is formed before the Synchronizing Rollers when paper is fed

through.

Adjust Mode Setting Value

Loop Adjustment -5 to +5

NOTE

This adjustment is to be made when any of the following symptoms occurs: variations in the

amount of print leading edge void, paper skew, and misfeed.

Adjustment Procedure

1. Call the Tech. Rep. mode to the screen.

2. Touch [Tech. Rep. Choice], then [Printer].

3. Touch [Loop Adjustment] to enter the Loop Adjustment mode.

4. Select the paper source for which the adjustment is to be made.

5. Press the Clear key to clear the current setting.

6. Enter the new setting value from the 10-Key Pad.

Setting Instructions

Change the setting value as necessary until there are no variations in the amount of void

image along the leading edge, skewed feeding, dog-ear, or misfeed.

Use to change the + or - sign.

1171D030CA

Setting Value

Use to change the + or - sign.

Use to clear setting value.

Use to enter setting value.

1171D061CA

7. Touch the [END] key to validate the setting value.

Caution

Be sure to touch the END key before returning to normal operation mode. If the Panel

Reset Key is used, the previous setting remains valid.

8. Perfor m the same step s to adjust for the other paper sources.

D-34

Page 48

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

(4) Edge Erase

1. Leading

Requirement

A

Adjust so that the erase width on the leading edge falls

within the range of 0 to 5 mm.

Adjust Mode Setting Range

Edge Erase/Leading 0 to 5

1171D003AA

NOTE

This adjustment must be made when the PH Unit has been replaced and after Registration

(CD/FD) (Printer) has been made.

Adjustment Procedure

1. Call the Tech. Rep. mode to the screen.

2. Touch [Tech. Rep. Choice], then [Printer].

3. Touch [Edge Erase] and then [Leading] to enter the Leading Edge Erase adjustment

mode.

4. Press the Clear key to clear the current setting.

5. Enter the new setting value from the 10-Key Pad.

Setting Instructions

To make the edge erase width smaller, decrease the setting value.

To make the edge erase width greater, increase the setting value.

Use to clear setting value.

Setting Value

1171D031CA

Use to enter setting value.

1167D069AA

6. Touch the [END] key to validate the setting value.

Caution

Be sure to touch the END key before returning to normal operation mode. If the Panel

Reset Key is used, the previous setting remains valid.

D-35

Page 49

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

2. Trailing

Requirement

Adjust so that the erase width on the trailing edge falls

A

within the range of 0 to 5 mm.

Adjust Mode Setting Range

Edge Erase/Trailing 0 to 5

1171D004AA

NOTE

This adjustment must be made when the PH Unit has been replaced and after Registration

(CD/FD) (Printer) has been made.

Adjustment Procedure

1. Call the Tech. Rep. mode to the screen.

2. Touch [Tech. Rep. Choice], then [Printer].

3. Touch [Edge Erase] and then [Trailing] to enter the Trailing Edge Erase adjustment

mode.

4. Press the Clear key to clear the current setting.

5. Enter the new setting value from the 10-Key Pad.

Setting Instructions

To make the edge erase width smaller, decrease the setting value.

To make the edge erase width greater, increase the setting value.

Use to clear setting value.

1171D031CA

Setting Value

Use to enter setting value.

1167D069AA

6. Touch the [END] key to validate the setting value.

Caution

Be sure to touch the END key before returning to normal operation mode. If the Panel

Reset Key is used, the previous setting remains valid.

D-36

Page 50

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

3. Right/Left

Requirement

Adjust so that the erase width on the right/left edge

falls within the range of 0 to 5 mm.

A

Adjust Mode Setting Range

Edge Erase/Right/Left 0 to 5

A

1171D005AA

NOTE

This adjustment must be made when the PH Unit has been replaced and after Registration

(CD) (Printer) have been made.

Adjustment Procedure

1. Call the Tech. Rep. mode to the screen.

2. Touch [Tech. Rep. Choice], then [Printer].

3. Touch [Edge Erase] and then [Right/Left] to enter the Right/Left Edge Erase adjustment

mode.

4. Press the Clear key to clear the current setting.

5. Enter the new setting value from the 10-Key Pad.

Setting Instructions

To make the edge erase width smaller, decrease the setting value.

To make the edge erase width greater, increase the setting value.

Use to clear setting value.

1171D031CA

Setting Value

Use to enter setting value.

1167D069AA

6. Touch the [END] key to validate the setting value.

Caution

Be sure to touch the END key before returning to normal operation mode. If the Panel

Reset Key is used, the previous setting remains valid.

D-37

Page 51

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

(5) Registration (CD) (Printer)

Requirement

A

1171D006AA

Specification Adjust Mode Setting Range

1-Sided: 10 ±2.0 mm

2-Sided: 10 ±3.0 mm

NOTE

This adjustment must be made when the PH Unit has been replaced and, for 2-sided, af ter

Registration (CD) (Printer) for each paper source for 1-sided and Registration (FD) (Printer)

have been made.

Adjustment Procedure

1. Produce a test pattern. (For details, see 3-4. TEST PRINT.)

2. 1-Sided: Check to see if width A on the test pattern meets the specifications.

2-Sided: Using the test pattern output as the original, make an ordinary 2-sided copy .

Check to see if width A on the second side of the 2-sided copy meets the

specifications.

If width A falls outside the specified range, perform these steps to make the adjustment.

Adjust so that width A on the test pattern output falls

within the following range.

Registration (CD) -4.0 to +4.0

D-38

Page 52

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

3. Call the Adjust mode to the screen.

4. Touch [Printer] and [Registration (CD)], in that order.

5. Select the paper source for which the adjustment is to be made.

6. Press the Clear key to clear the current setting.

7. Enter the new setting value from the 10-Key Pad.

Setting Instructions

If width A is wider than specifications, make the setting value smaller than the current one.

If width A is narrower than specifications, make the setting value greater than the current

one.

✽

If a single adjustment procedure does not successfully bring width A into the specified

range, try another setting value.

Use to change the + or - sign.

1171D032CA

Setting Value

Use to change the + or - sign.

Use to clear setting value.

Use to enter setting value.

1171D061CA

8. Touch the [END] key to validate the setting value.

Caution

Be sure to touch the END key before returning to normal operation mode. If the Panel

Reset Key is used, the previous setting remains valid.

9. Perfor m the same step s to adjust for the other paper sources.

D-39

Page 53

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

(6) Registration (FD) (Printer)

Requirement

Adjust so that width A on the test pattern output falls

within the following range.

A

1171D007AA

Specification Adjust Mode Setting Range

10 ±2.0 mm Registration (FD) -19 to +19

NOTE

This adjustment must be made when the PH Unit has been replaced and after Registration

(CD) (Printer) has been made.

Adjustment Procedure

1. Produce a test pattern. (For details, see 3-4. TEST PRINT.)

2. Check to see if width A on the test pattern meets the specifications.

If width A falls outside the specified range, perform these steps to make the adjustment.

D-40

Page 54

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

3. Call the Adjust mode to the screen.

4. Touch [Printer] and [Registration (FD)], in that order.

5. Select the paper source for which the adjustment is to be made.

6. Press the Clear key to clear the current setting.

7. Enter the new setting value from the 10-Key Pad.

Setting Instructions

If width A is wider than specifications, make the setting value smaller than the current one.

If width A is narrower than specifications, make the setting value greater than the current

one.

✽

If a single adjustment procedure does not successfully bring width A into the specified

range, try another setting value.

Use to change the + or - sign.

Setting Value

1171D033CA

Use to change the + or - sign.

Use to clear setting value.

Use to enter setting value.

1171D061CA

8. Touch the [END] key to validate the setting value.

Caution

Be sure to touch the END key before returning to normal operation mode. If the Panel

Reset Key is used, the previous setting remains valid.

D-41

Page 55

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

(7) Registration (IR)

1. CD

Requirement

A

1171D009AA

Specification Adjust Mode Setting Range

10 ±2.0 mm Registration (CD) -127 to +127

NOTE

This adjustment must be made when the PH Unit has been replaced and after the adjustments of Registration (CD and FD) (Printer) and CD of Zoom Adjust (IR) have been made.

Adjustment Procedure

1. After the adjustments of Registration (CD and FD) (Printer) and CD of Zoom Adjust (IR)

have been completed, produce a test pattern. (For details, see 3-4. TEST PRINT.)

2. Place the test pattern output on the Original Glass and make a copy of it.

3. Check to see if width A on the test pattern copy meets the specifications.

If width A falls outside the specified range, perform these steps to make the adjustment.

Place the test pattern output after the adjustments of

Registration (CD and FD) (Printer) have been completed on the Original Glass and make a copy of it.

Adjust so that width A on the test pattern copy falls

within the following range.

D-42

Page 56

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

4. Call the Adjust mode to the screen.

5. Touch [IR], [Registration], and [CD], in that order.

6. Press the Clear key to clear the current setting.

7. Enter the new setting value from the 10-Key Pad.

Setting Instructions

If width A is wider than specifications, make the setting value smaller than the current one.

If width A is narrower than specifications, make the setting value greater than the current

one.

✽

If a single adjustment procedure does not successfully bring width A into the specified

range, try another setting value.

Use to change the + or - sign.

Setting Value

1171D034CA

Use to change the + or - sign.

Use to clear setting value.

Use to enter setting value.

1171D061CA

8. Touch the [END] key to validate the setting value.

Caution

Be sure to touch the END key before returning to normal operation mode. If the Panel

Reset Key is used, the previous setting remains valid.

D-43

Page 57

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

2. FD

Requirement

1171D007AA

Specification Adjust Mode Setting Range

10 ±2.0 mm Registration (FD) -127 to +127

NOTE

This adjustment must be made when the PH Unit has been replaced and after the adjustments of Registration (CD and FD) (Printer) and FD of Zoom Adjust (IR) have been made.

Adjustment Procedure

1. After the adjustments of Registration (CD and FD) (Printer) and FD of Zoom Adjust (IR)

have been completed, produce a test pattern. (For details, see 3-4. TEST PRINT.)

2. Place the test pattern output on the Original Glass and make a copy of it.

3. Check to see if width A on the test pattern copy meets the specifications.

If width A falls outside the specified range, perform these steps to make the adjustment.

Place the test pattern output after the adjustments of

Registration (CD and FD) (Printer) have been completed on the Original Glass and make a copy of it.

A

Adjust so that width A on the test pattern copy falls

within the following range.

D-44

Page 58

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

4. Call the Adjust mode to the screen.

5. Touch [IR], [Registration], and [FD], in that order.

6. Press the Clear key to clear the current setting.

7. Enter the new setting value from the 10-Key Pad.

Setting Instructions

If width A is wider than specifications, make the setting value smaller than the current one.

If width A is narrower than specifications, make the setting value greater than the current

one.

✽

If a single adjustment procedure does not successfully bring width A into the specified

range, try another setting value.

Use to change the + or - sign.

1171D034CA

Setting Value

Use to change the + or - sign.

Use to clear setting value.

Use to enter setting value.

1171D061CA

8. Touch the [END] key to validate the setting value.

Caution

Be sure to touch the END key before returning to normal operation mode. If the Panel

Reset Key is used, the previous setting remains valid.

D-45

Page 59

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

(8) Zoom Adjust (IR)

1. CD

Requirement

1. The difference should be within ±1.0% of the actual length.

2. Adjust so that the following specifications are satisfied with a scale length of 300 mm.

Zoom Ratio Specification Adjust Mode Setting Range

Full size (×1.000) 300 ±3.0 mm Zoom Adjust (CD) 0.990 to 1.010

NOTE

This adjustment must be made when the Scanner Drive Cables have been replaced and

after the adjustments of Registration (CD and FD) (Printer) have been made.

Adjustment Procedure

1167D111AA

1138D154AA

1. Place a scale in parallel with the Original Width

Scale and make a copy. (Note that the scale is perpendicular to the Original Length Scale.)

✽

Use the full size (×1.000) mode and A3 or 11” × 17”

paper.

✽

If the scale is of plastic and transparent, place a

blank sheet of paper over it.

2. Measure the length of the scale on the copy to find

the difference.

✽

If the difference is outside the specification, adjust

by following the procedure shown below.

D-46

Page 60

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

3. Call the Adjust mode to the screen.

4. Touch [IR], [Zoom Adjust], and [CD], in that order.

5. Press the Clear key to clear the current setting.

6. Enter the new setting value from the 10-Key Pad.

Setting Instructions

If the scale on the copy is longer than the actual scale, decrease the setting value.

If the scale on the copy is shorter than the actual scale, increase the setting value.

✽

If the measurement does not fall within the specifications through one setting, try another

setting.

Use to clear setting value.

1171D035CA

Setting Value

Use to enter setting value.

1167D069AA

7. Touch the [END] key to validate the setting value.

Caution

Be sure to touch the END key before returning to normal operation mode. If the Panel

Reset Key is used, the previous setting remains valid.

D-47

Page 61

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

2. FD

Requirement

1. The difference should be within ±1.0% of the actual length.

2. Adjust so that the following specifications are satisfied with a scale length of 200 mm.

Zoom Ratio Specification Adjust Mode Setting Range

Full size (×1.000) 200 ±2.0 mm Zoom Adjust (FD) 0.990 to 1.010

NOTE

This adjustment must be made when the CCD Unit has been replaced and after the adjustments of Registration (CD and FD) (Printer) have been made.

Adjustment Procedure

1167D112AA

1134D124AA

1. Place a scale in parallel with the Original Length

Scale and make a copy.

✽

Use the full size (X1.000) mode and paper with a

width of 200 mm or more.

✽

If the scale is of plastic and transparent, place a

blank sheet of paper over it.

2. Measure the length of the scale on the copy to find

the difference.

✽

If the difference is outside the specification, adjust

by following the procedure shown below.

D-48

Page 62

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

3. Call the Adjust mode to the screen.

4. Touch [IR], [Zoom Adjust], and [FD], in that order.

5. Press the Clear key to clear the current setting.

6. Enter the new setting value from the 10-Key Pad.

Setting Instructions

If the scale on the copy is longer than the actual scale, decrease the setting value.

If the scale on the copy is shorter than the actual scale, increase the setting value.

✽

If the measurement does not fall within the specifications through one setting, try another

setting.

Use to clear setting value.

1171D035CA

Setting Value

Use to enter setting value.

1167D069AA

7. Touch the [END] key to validate the setting value.

Caution

Be sure to touch the END key before returning to normal operating mode. If the Panel

Reset Key is used, the previous setting remains valid.

D-49

Page 63

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

(9) IR-Erasure Width

Requirement

A

Set so that the erase width along four edges of the

paper falls within the range of 0 to 3 mm.

A

Adjust Mode Setting Range

IR-Erasure Width 0 to 3

A

A

1171D062AA

NOTE

This adjustment must be made when a shadow is produced from the Original Scale.

Adjustment Procedure

1. Call the Tech. Rep. mode to the screen.

2. Touch [Tech. Rep. Choice].

3. Touch [IR-Erasure Width] to enter the IR-Erasure Width mode.

4. Press the Clear key to clear the current setting.

5. Enter the new setting value from the 10-Key Pad.

Setting Instructions

To make the erase width along four edges of the paper smaller, decrease the setting value.

To make the erase width along four edges of the paper greater, increase the setting value.

Use to clear setting value.

Setting Value

1171D064CA

Use to enter setting value.

1167D069AA

6. Touch the [END] key to validate the setting value.

Caution

Be sure to touch the END key before returning to normal operation mode. If the Panel

Reset Key is used, the previous setting remains valid.

D-50

Page 64

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

3-6. OTHER ADJUSTMENTS

•

Focus-Positioning of the Scanner and 2nd/3rd Mirrors Carriage

NOTE

Make this adjustment after any of the following procedures has been performed:

•

After the Scanner Drive Cable has been replaced.

•

When the Scanner Fixing Bracket has been removed from the Scanner Drive Cable.

•

When the Scanner Drive Cable comes unwound.

Requirement

With the Scanner fixed to the Scanner Drive Cables, there should be no gap between the

Scanner/Mirrors Carriage Positioning Jig and the Scanner and also between the Scanner/

Mirrors Carriage Positioning Jig and the 2nd/3rd Mirrors Carriage.

Adjustment Procedure

1167D113AA

1167D114AA

Scanner/Mirrors Carriage Positioning Jig

2nd/3rd

Mirrors

Carriage

Scanner

1167D115AC

1. Remove the Exposure Lamp. (For details, see

steps 1 through 7, (8) Removal of the Scanner, 2-4

OPTICAL SECTION.)

2. Temporarily loosen the set screws of the cable

holding plate of the Scanner Drive Cable.

3. Fit the Scanner/Mirrors Carriage Positioning Jigs in

the space between the Scanner and 2nd/3rd Mirrors Carriage.

4. Press the Scanner up against the jig and 2nd/3rd

Mirrors Carriage and, at the same time, tighten the

set screws of the cable holding plate.

D-51

Page 65

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

Adjusting Screw

NOTE

If the Scanner does not run parallel with the 2nd/3rd

Mirrors Carriage when the Scanner/Mirrors Carriage

Positioning Jigs are in position, turn the adjusting

screw for the rear Scanner Drive Cable as necessary.

1167D116AB

✽

If the Scanner/Mirrors Carriage Positioning Jigs are not available, follow these steps to

make the adjustment.

1. Temporarily loosen the set screws of the cable

holding plate of the Scanner Drive Cable.

1167D113AA

2. Obtain a distance of 13 mm between the 2nd/3rd

Mirrors Carriage and rail.

13 mm

1167D117AC

Adjusting Screw

3. Secure the Scanner where it is located at a position 21 mm from the right side face.

4. Tighten the set screws of the cable holding plate.

21 mm

1167D118AC

NOTE

If the Scanner does not run parallel with the 2nd/3rd

Mirrors Carriage, turn the adjusting screw for the rear

Scanner Drive Cable as necessary.

1167D116AB

D-52

Page 66

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

4 MISCELLANEOUS

4-1. INSTALLATION OF THE KEY COUNTER SOCKET (OPTION)

1. Remove the Front Cover.

2. Remove the knockout from the Front Upper Cover.

3. Using two screws, secure the Counter Mounting

Bracket.

1167D022AB

4. Route the harness of the Key Counter as shown.

1167D025AB

1167D023AB

1167D024AB

5. Connect the Key Counter Socket connector.

6. Using one screw and one screw and nut, secure

the counter socket.

7. Using two screws, secure the Key Counter Cover.

NOTE

When the Key Counter Socket is mounted, set to “ON

the “Key Counter” available from the Security mode.

”

D-53

Page 67

FrameMaker Ver.5.5E(PC) Di350 DIS/REASSEMBLY, ADJUSTMENT

98.12.09

4-2. REMOUNTING THE EEPROM (IC3A)

NOTES

•

If the Imaging Cartridge is not to be replaced after the Master Board has been replaced

with a new one, be sure to remount the EEPROM (IC3A) from the old to new Master

Board.

•

If the Master Board has been replaced with a new one and the EEPROM (IC3A) has not

been remounted, be sure to replace the Imaging Cartridge with a new one. Because the

EEPROM contains no data in this case, make settings and readjustments as necessar y.

1. Remove the Master Board. (For details, see 2-2. REMOVAL OF CIRCUIT BOARDS

AND OTHER ELECTRICAL COMPONENTS.)

2. Demount the EEPROM (IC3A) from the new Master Board.

3. Demount the EEPROM (IC3A) from the old Master Board and remount it onto the new

Master Board.

New Master Board

New EEPROM

A

A

1171D049AA

Old EEPROM

Old Master Board

1171D048AA

NOTE

Note the alignment notch on the EEPROM (IC3A)

when mounting the IC.

D-54

Page 68

FrameMaker Ver.5.5(PC) Di350 SWITCHES ON PWBs/TECH. REP. SETTINGS

98.11.25

Di350

SWITCHES ON PWBs,

TECH. REP. SETTINGS

17196

Page 69

Page 70

FrameMaker Ver.5.5E(PC) Di350 SWITCHES ON PWBs/TECH. REP. SETTINGS

98.11.25

CONTENTS

1. PRECAUTIONS FOR HANDLING THE PWBs ................................................S-1

1-1. Precautions for Transportation and Storage .................... ........................S-1

1-2. Precautions for Replacement and Inspection ..........................................S-1

2. CONTROL PANEL KEYS AND TOUCH PANEL ............................................. S-2

2-1. Control Panel Keys ..................................................................................S-2

2-2. Explanation of the Touch Panel .............................................................. .S-3

(1) Basic Screen ...................................................................................S-3

(2) Warning Screens ........................ ....................... ..............................S-4

3. FUNCTION OF SWITCHES AND OTHER PARTS ON PWBs ........................S-5

3-1. PWB Location ..........................................................................................S-5

3-2. PWB-A (Master Board) ............................................................................S-5

3-3. UN1 (Control Panel) .................... .......................... ..................................S-6