Minolta Di181 Service manual

Di181

SERVICE MANUAL

[GENERAL]

Safety Precautions for Inspection and Service

When performing inspection and service procedures, observe the following precautions to

prevent accidents and ensure utmost safety.

✾ Depending on the model, some of the precautions given in the followingdo not apply.

Different markings are used to denotespecific meanings as detailed below.

Indicatesa potentially hazardous situation which,if not avoided,

WARNING

CAUTION

The following graphic symbols are used to give instructions thatneed to be observed.

Used to call the service technician’s atte nt ion to what is graphically represented

inside themarking (includinga warning).

Used to prohibit the service technician’s from doing what is graphically represented inside the marking.

Used to instruct the service technician’s to do what is graphicallyrepresented

inside themarking.

1. Always observeprecautions.

÷ Parts requiringspecial attention in this product will include a labelcontaining the

mark shownon the left plus precautionarynotes. Be sure to observethe precautions.

÷ Be sure to observe the “Safety Information” given in the Operator’sManual.

could result in death or seriousinjury.

Indicatesa potentially hazardous situation which,if not avoided,

may result in minor or moderate injury. It may also be used to

alert againstunsafe practices.

WARNING

2. Before starting the procedures, be sure to unplug the power cord.

÷ This productcontains a high-voltage unitand a circuitwith a largecurrent

capacity that may causean electric shock or burn.

÷ The product also containsparts that canjerk suddenlyand cause injury.

÷ If this product uses a laser,laser beam leakage maycause eyedamage or

blindness.

3. Use the specified parts.

÷ For replacement parts,always use the genuine parts specified in the manufac-

turer’s parts manual. Installing a wrong or unauthorized part could cause

dielectric breakdown, overload, or undermine safety devices resulting in possible electric shock or fire.

÷ Replace a blown electricalfuse or thermal fuse with its corresponding genuine

part specifiedin the manufacturer’s parts manual. Installing a fuse of a different

make or rating could lead to a possible fire. If a thermal fuse blows frequently,

the temperature control system may have a problem and action must be taken

to eliminate the cause of theproblem.

P-1

4. Handle the power cord with care andnever use a multiple outlet.

÷ Do not break,crush or otherwise damage the powercord. Placinga heavy

object on the power cord, or pulling or bending it may damage it, resulting in a

possible fire or electricshock.

÷ Do not use a multiple outlet to whichany other appliance or machine is con-

nected.

÷ Be sure the power outlet meetsor exceeds the specifiedcapacity.

5. Be careful with the high-voltage parts.

÷ A part marked with the symbolshown on the left carries a high voltage. Touch-

ing it could result in an electric shock or burn. Be sure to unplug the powercord

beforeservicing thispart or the parts near it.

6. Do not work with wethands.

÷ Do not unplug or plug in the power cord, or perform anykind of s ervice or

inspection with wet hands. Doing socould resultin an electric shock.

7. Do not touch a high-temperature part.

÷ A part markedwith the symbolshown on the left and other parts such as the

exposurelamp and fusingrollercan bevery hot whilethe machine isenergized.

Touchingthem may result in a burn.

÷ Wait until these parts have cooleddown before replacingthem or any surround-

ing parts.

8. Maintain a grounded connection at all times. (This item maynot apply in the USA.)

÷ Be sure to connect the ground wire to the ground terminal evenwhen perform-

ing an inspection or repair. Without proper grounding, electrical leakagecould

result in an e lec tric shock or fire.

÷ Neverconnect the groundwire to agas pipe,waterpipe, telephone ground wire,

or a lightning conductor.

9. Do not remodel the product.

÷ Modifying thisproduct in a manner not authorized by the manufacturermay

result in a fireor electric s hock. If this product usesa laser, laserbeam leakage

may c ause eye damage or blindness.

10.Restore all parts and harnesses to their originalpositions.

÷ Topromote safety and prevent product damage, make sure the harnesses are

returned to their original positions andproperly secured in their clamps and saddles in order to avoid hot parts, high-voltage parts, sharp edges, or being

crushed.

÷ To promotesafety, make sure that all tubing and other insulatingmaterials are

returnedto theiroriginalpositions.Makesurethat floating componentsmounted

on the circuit boards are at theircorrect distance and position off the boards.

P-2

CAUTION

1. Precautionsfor ServiceJobs

÷ A toothed washer and spring washer,if used originally, mustbe reinstalled.

Omitting them mayresult in contact failure which could causean electricshock

or fire.

÷ When reassembling parts, make sure thatthe correctscrews (size,type) are

used in the correct places. Usingthe wrong screw could lead to stripped

threads, poorly secured par ts, poor insulating or grounding, and result in a malfunction, electric shock o r injury.

÷ Takegreat careto avoid personal injury from possible burrs andsharp edgeson

the parts,frames and chassis of the product.

÷ When moving the product or removing an option, use care not to injureyour

back or allow yourhands to be caught in mechanisms.

2. Precautionsfor Servicingwith Covers and Parts Removed

÷ Whereverfeasible, keep all parts and covers mounted when energizing the

product.

÷ If energizing the product with a cover removed is absolutelyunavoidable,do not

touch any exposed live parts and use care notto allow your clothing to be

caught in the moving parts. Neverleave a product in this condition unattended.

÷ Never place disassembled parts or a container of liquid onthe product.Parts

falling in to, or the liqu id spilling inside, the mecha nism could result in an electric

shock or fire.

÷ Never use a flammablespray near the product. This could result in a fire.

÷ Make sure the power cord is unplugged beforeremoving or installing circuit

boards orplugging in or unplugging connectors.

÷ Alwaysuse the interlock switch actuating jig to actuate an interlock switchwhen

a coveris opened or removed. The use of folded paper or some other object

may damage the interlock switch mechanism,possibly resulting in an electric

shock, injury or blindness.

3. Precautionsfor the Working Environment

÷ The product must be placedon a flat, level surface that is stable and secure.

÷ Never place this product or its parts on an unsteady or tilting workbenchwhen

servicing.

÷ Provide goodventilationat regular intervals if a service job must be done in a

confined space for a long period of time.

÷ Avoiddusty locationsand places exposed to oil or steam.

÷ Avoidworking positions thatmay block theventilation ports ofthe product.

4. Precautionsfor Handling Batteries

÷ Replace a rundown battery with the same type as specified in the manufac-

turer’sparts manual.

÷ Before installing a new battery, make sure of the correc t polarity of the installa-

tion or the battery could burst.

÷ Dispose of used batteries according to thelocal regulations. Never dispose of

them at the user’spremises or attempt to try to discharge one.

P-3

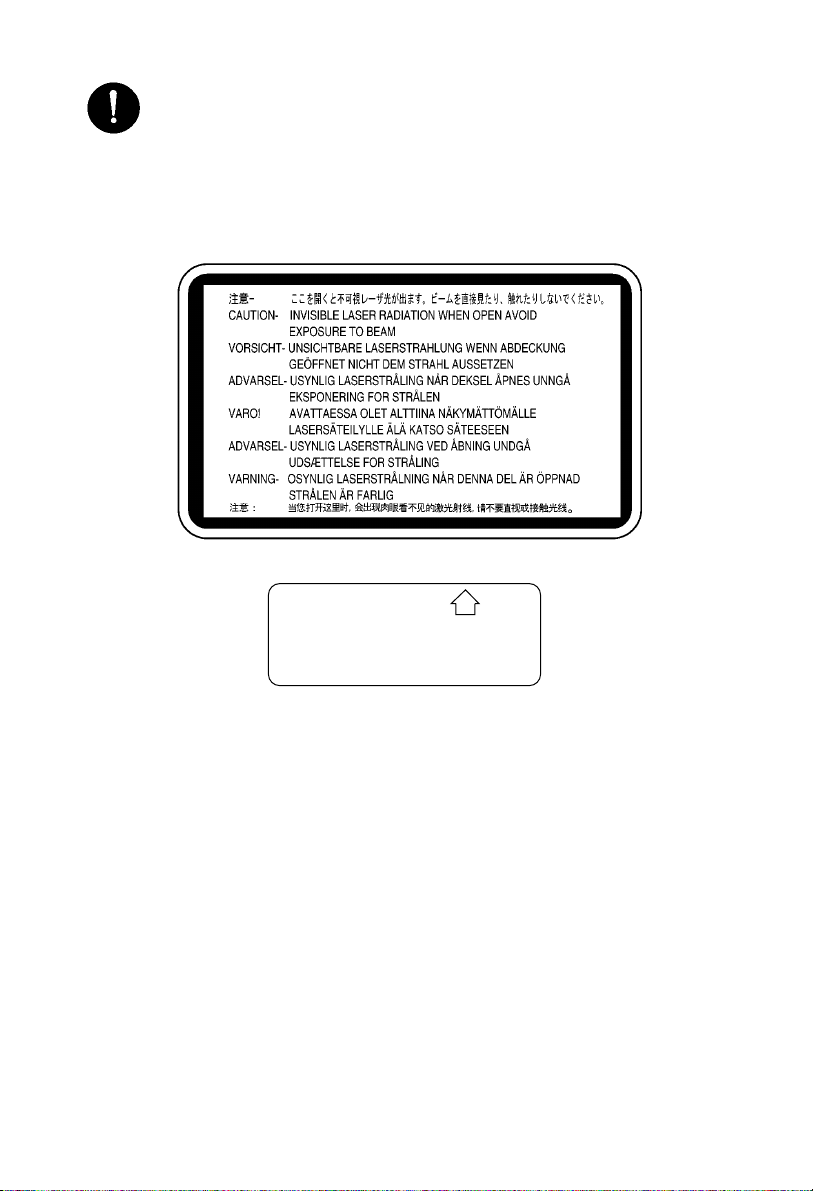

5. Precautionsfor the Laser Beam (Only for ProductsEmploying a Laser)

÷ Removing thecover marked with the following caution label couldlead to possi-

ble exposure to t he laser beam, resulting in eye damageor blindness. Be sure

to unplug the power cord before removing thiscover.

÷ If removing thiscoverwhile thepower is ON is unavoidable,be sure to wear pro-

tectivelaser goggles that meet specifications.

÷ Make sure that no one enters the roomwhen the machine is in this condition.

÷ When handlingthe laser unit, observe the“Precautions for HandlingLaser

Equipment.”

1167P001AA

DANGER

Invisible laser radiation when open.

AVOID DIRECT EXPOSURE

TO BEAM

0947-7127-01

1144D270AA

P-4

Other Precautions

÷ To reassemble theproduct, reverse the order of disassembly unlessotherwise specified.

÷ While the product is energized, do not unplug or plug connectors into the circuit boards

or harnesses.

÷ The magnetroller generates a strong magnetic field. Do not bring it near a watch, floppy

disk, magnetic card, or CRT tube.

÷ An air gun and vacuumcleaner generates a strong electrostatic chargethat can destroy

the ATDC sensor andother sensors. Before cleaning a component with one of these

devices, be sure to remove all the sensors. Otherwise, use a blower brush and cloth

when cleaning parts.

÷ When handling circuit boards with MOS ICs, observe the “INSTRUCTIONS FORHAN-

DLING THEPWBs WITH MOS ICs” (applicableonly to the products using MOS ICs).

÷ The PC Drum is a very delicate component. Observe theprecautions given in “HAN-

DLING OF THE PCDRUM” because mishandling may result in serious image problems.

÷ Note that replacement of a circuit board may callfor readjustments or resetting of partic-

ular items, or s oftware installation.

÷ After completing a serv ice job, perform a safety check. Make sure that all parts,wiring

and screws are returned to their original positions.

÷ Check the area surroundingthe service site for any signs of damage, wear or need of

repair.

÷ Do not pull out the toner hopper while the tonerbottle is turning.This couldresult in a

damaged hopper motor or locking mechanism.

÷ If the product is to be run with the front door open, make sure that the toner hopper is in

thelockedposition.

P-5

Used Batteries Precautions

ALL Areas

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent typerecommended by the manufacturer.

Dispose of used batteries according to the manuf acturer’s instructions.

CAUTION

Germany

Explosionsgefahrbei unsachgemäßemAustausch der Batterie.

Ersatz nur durch denselben oder einenvom Hersteller empfohlenen ähnlichen Typ.

Entsorgunggebrauchter B atterien nach Angabendes Herstellers.

France

Ily a danger d’explosion s’ily a remplacement incorrec de la batterie.

Remplacer uniquement avec une batterie du meme type ou d’un type équivalent recommande parle constructueur.

Mettre au rebut les batteries usageés conformément aux instructions du fabricant.

Denmark

Lithiumbatteri- Eksplosionsfare ved fejlagtighåndtering Udskiftning må kun ske med batteri af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

Norway

Eksplosjonsfare ved feilaktig skifte avbatteri.

Benyttsamme batteritype eller en tilsvarende type anbefalt avapparatfabrikanten.

Brukte batterier kasseres i henhold tilfabrikantens instruksjoner.

Sweden

Explosionsfaravid felaktigt batteribyte.

Använd samma batterityp eller en ekvivalent typ som rekommenderas av apparattillverkaren.

Kasseraanvänt batterienligt fabrikantens instruktion.

VORSICHT!

ATTENTION

ADVARSEL!

ADVARSEL

VARNING

Finland

Paristo voi räjähtää, los se on virheellisesti asennettu.

Vaihda paristo ainoastaanlaitevalmistajan suosittelemaan tyyppiin. Hävitä Käytettyparisto

valmistajan ohjeiden mukaisesti.

VAROlTUS

P-6

GENERAL

14413

CONTENTS

1. SAFETY INFORMATION .................................................................................G-1

2. SPECIFICATIONS ...........................................................................................G-7

3. PRECAUTIONS FOR INSTALLATION ............................................................G-10

3-1. Installation Site ........................................................................................G-10

3-2. Power Source ..........................................................................................G-10

3-3. Grounding ................................................................................................G-10

4. PRECAUTIONS FOR USE ..............................................................................G-11

4-1. To Ensure Optimum Conditions ...............................................................G-11

4-2. Operating Environment ............................................................................G-11

4-3. Power Requirements ...............................................................................G-11

4-4. Prohibitions ..............................................................................................G-11

5. HANDLING OF CONSUMABLES ....................................................................G-12

6. OTHER PRECAUTIONS .................................................................................G-13

7. SYSTEM OPTIONS .........................................................................................G-14

iii

1 SAFETY INFORMATION

Laser Safety

This is a digitalmachine which prints by means of a laser. There is no possibilityof danger

from the laser ,provided the machine is operated according to the instructions in this

manual.

Since radiation emittedby the laseris completelyconfined within protective housing, the

laser beam cannot escape from the machine during any phase of user operation.

This machine is certified as a Class 1 product. This means the machine does not produce

hazardouslaser radiation.

CAUTION: The use of controls, adjustments or performance of procedures

other than those s pecified in this m anual may result in hazardous radiation

exposure. Because of this,Minolta strongly recommends that you operate

your copy machine only as desc ribed in this documentation.

Internal Laser Radiation

Maximum Average Radiation Power: 15.6νW at laser aperture of the print head unit

Wavelength: 770-795nm

This product employs a Class IIIbLaser Diode that emits an invisible laser beam.

The Laser Diode and Scanning Polygon Mirror are incorporated in the print head unit.

The print head unit is NOT A FIELDSERVICE ITEM.

Therefore,the print head unit shouldnot be opened underany circumstances.

For United St ates

CDRH regulation

This copier is certified as a Class 1 Laser product under the Radiation Performance

Standardaccording to the Food, Drugand Cosmetic Act of 1990. Compliance is mandatory

for Laser productsmarketed in the United States and is reported to the Centerfor Devices

and Radiological Hea lth (CDRH) of the U.S. Foodand Drug Administration of the U.S.

Departmentof Health and Human Services (DHHS). This means that the device does not

producehazardous laser radiation.

G-1

The label shown on page G-3 indicates compliance with the CDRH regulations and must

be attached to laser productsmarketed inthe United States.

CAUTION: Useof controls,adjustmentsor performance ofprocedures other than those

specified in this manualmay result in hazardous radiation exposure.

This is a semiconductor laser. The maximum power of the laserdiode is 5mW and the

wavelengthis 770-795nm.

For Europe

CAUTION: Useof controls,adjustmentsor performance ofprocedures other than those

specified in this manualmay result in hazardous radiation exposure.

This is a semiconductorlaser.The maximum power of the laser diode is 5mW and the

wavelength is 770-795nm.

For Denmark

ADVARSEL

Usynlig laserstråling ved åbning, nårsikkerhedsafbrydere er ude af funktion.

Undgå udsættelse for stråling.

Klasse 1 laser produkt der opfylder IEC60825 sikkerheds kravene.

For Finland

LUOKAN 1 LASERLAITE

VAROITUS

Laitteen käyttäminen muulla kuin tässä käyttöohjee ssa mainitulla tavalla saattaa altistaa

käyttäjän turvallisuusluokan 1 ylittävälle näkymättömälle lasersäteilylle.

VARO

Avattaessa ja suojalukitus ohitettaessa olet alttiina näkymättomälle lase rsäteilylle. Älä

katso säteeseen.

For Sweden

KLASS 1 LASER APPARAT

VARNING

Om apparaten används på annat sätt än i denna bruksanvisning specificerats, kan

användarenutsättasför osynliglaserstrålning,som överskrider gränsen förlaserklass 1.

VARNING

Osynlig laserstråining när denna del är öppnad och spärren är urkopplad. Betrakta ej

stråien.

G-2

For Norway

ADVERSEL

Dersom apparatet brukes på annen måte enn spesifisert i denne bruksanvisning,kan

brukeren utsettes för unsynlig laserstrålning, som overskrider grensen for laser klass 1.

Dette en halveder laser. Maksimal effekttill laserdiode er 5mW og bγlgelengde er 770795nm.

Laser Safety Label

A lasersafety labelis attachedto the outside of the copy machineas shown below.

Laser safety label

For Europe

CLASS 1 LASER PRODUCT

C1177O080CA

Manufacturer’s

Name Plate

LASER KLASSE

For United States

2, Higashiakatsuchi, Yawata-cho, Toyokawa-shi

Aichi-ken 442-8585, Japan

MANUFACTURED:

THIS PRODUCT COMPLIES WITH 21 CFR

CHAPTER I, SUBCHAPTER J.

1 PRODUKT

MINOLTA CO., LTD

0946-7101-14

1166O248AA

The Manufacturer’s Name Plate is affixed at the position illustrated above.

Please write down the Model Name and Serial No. of your copier here.

Model:

Serial No.:

G-3

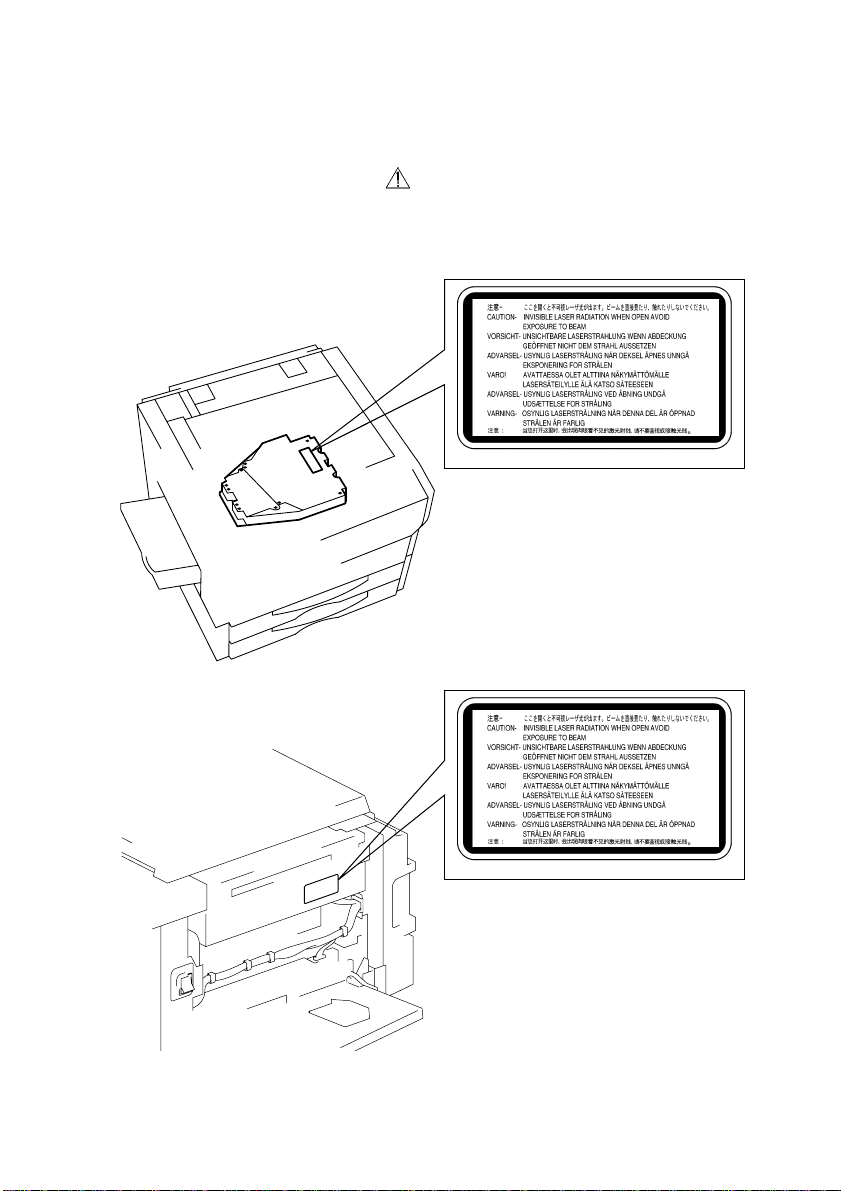

Label inside copy machine

The following laser safety label will be attached inside the copy machine as shown below.

Please read the following for your own protection.

Caution

Openingthe cover indicated by theCaution label may exposeyou to harmfullaser radiation

which could cause damageor loss of eyesight. Do not open thecover when the power is

on.

1167P001AA

1177M052AA

1177M062AA

1167P001AA

G-4

ALL Areas

Germany only

Denmark only

Norway only

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

recommended by the manufacturer.

Dispose of used batteries according

to themanufacturer’s instructions.

VORSICHT!

Explosinsgefahr bei unsachgemäßen austausch der

batterie.Ersatz nur durch denselben oder einen vom hersteller

empfohlenenähnlichen typ.Entsorgung gebrauchter batterien

nach angaben des herstellers.

ADVARSEL!

Lithiumbatteri- Eksplosionsfare ved fejlagtig håndtering

Udskiftningmåkunskemedbatteri

af samme fabrikat og type.

Levér det brugte batteri tilbagetil leverandøren.

ADVARSEL

Eksplosjonsfare ved feilaktig skifte av batteri.

Benytt samme batteritype eller en tilsvarende

type anbefalt av apparatfabrikanten.

Brukte batterier kasseresi henhold til fabrikantens

instruksjoner.

Sweden only

Finland only

VARNING

Explosionsfara vidfelaktigt batteribyte.

Använd samma batterityp eller en ekvivalent

typ som reko mmenderas av apparattillverkaren.

Kassera använt batteri enligt fabrikantens

instruktion.

VAROlTUS

Paristo voi räjähtää, los se on virheellisesti asennettu.

Vaihda paristo ainoastaan laitevalmistajan suosittelemaan

tyyppiin. Hävitä Käytettyparisto valmistajan ohjeiden

mukaisesti.

G-5

ALL Areas

“Replace only with the same or equivalent type recommended by the manufacturer.

Dispose of used IC Package according to the manufacturer’sinstructions.”

CAUTION

Germany only

⇓

”Austauschnur durch denselben oder einen vom Hersteller empfohlenen,

gleichwertigen typ.Entsorgung gebrauchter Batterien nachAngaben des H erstellers.

VORSICHT!

G-6

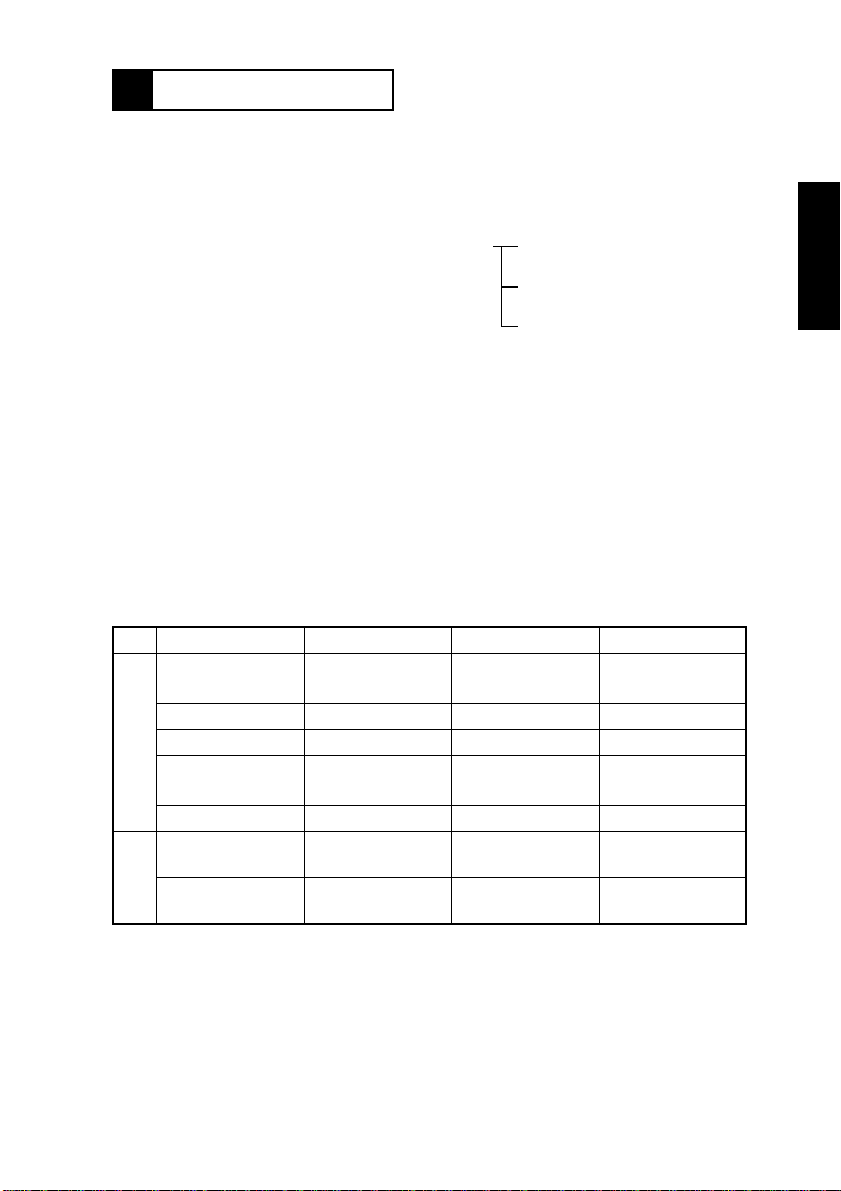

2 SPECIFICATIONS

TYPE

PHOTOCONDUCTOR

COPYING SYSTEM

RESOLUTION

PAPERFEEDING SYSTEM

EXPOSURESYSTEM

DEVELOPING SYSTEM

CHARGING SYSTEM

IMAGE TRANSFER SYSTEM

PAPERSEPARATING SYSTEM

FUSING SYSTEM

PAPER DISCHARGING SYSTEM

MAXIMUM ORIGINAL S IZ E

COPY MEDIUM

Plain paper

(60to90g/m

Translucent paper — — ■

Transparencies — — ■

Medium

Thickpaper

(91to157g/m

Recycled paper ■■■

Maximum

(Width× Length)

Minimum

(Width× Length)

Dimensions

■

: Permissible —: Not permissible

2

)

2

)

:

Desktop (with Stationary Platen)

:

Organic Photoconductor

:

ElectrostaticDry PowderedImage Transferto Plain

Paper

:

600dpi

3-Way system 1st D rawer: Holds up to 250

:

Mirror Scanning, Slit Exposure

:

New Micro-Toning System

:

Comb Electrode DC Negative Coronawith

Scorotron System

:

Visible Image Transfer by means of a Single-Wire

DC Positive Corona with Corotron System

:

Single-WireACCorona with CorotronSystem,plus

PaperSeparator Finger

:

Heat Roller

:

Charge Neutralizing Brush

:

Metric-A3L; Inch-11” × 17”L

1st Drawer 2nd Drawer Multi Bypass Table

■■

——■

297 × 432 mm 297 × 432 mm 297 × 432 mm

140 × 182 mm 140 × 182 mm 100 × 140 mm

sheets of paper

2ndDrawer:Holdsupto250

sheets of paper

Multi B ypass Table:50 sheets of

paper

G-7

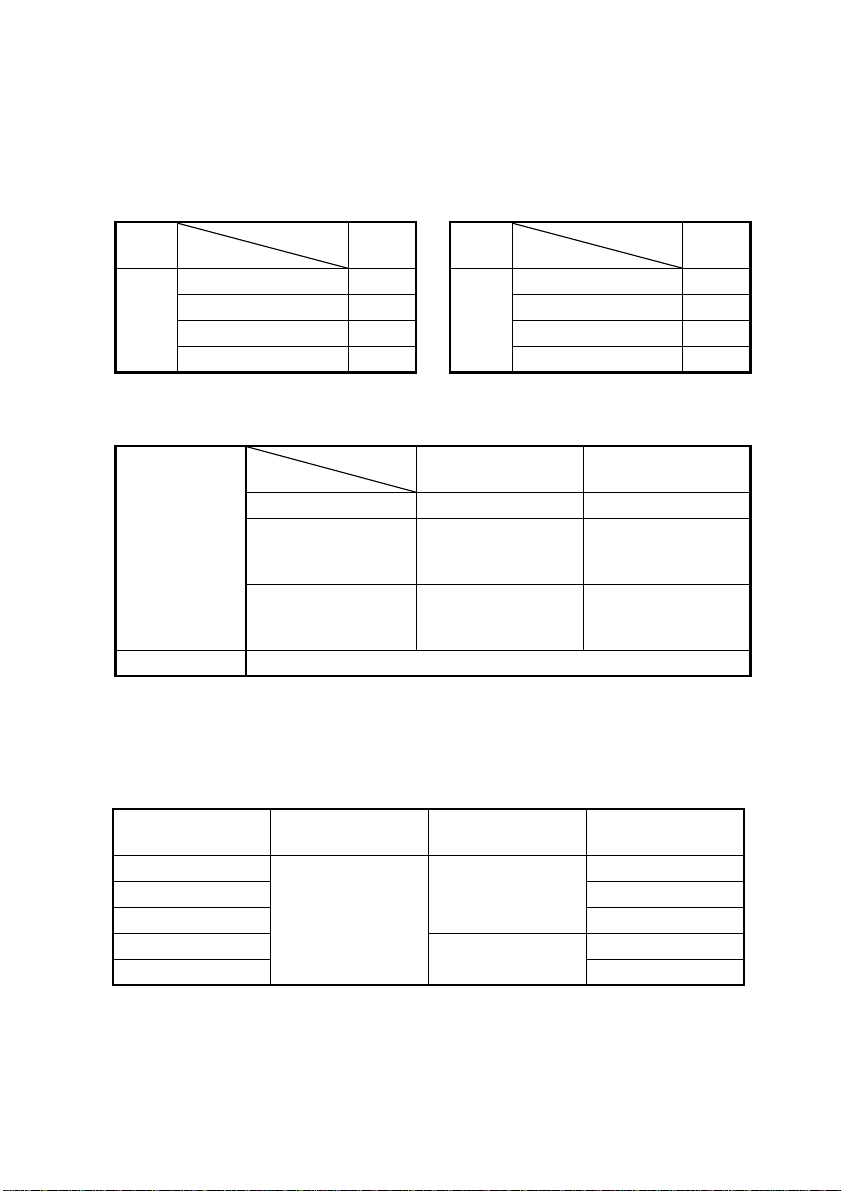

MULTIPLE COPIES

WARMING-UP TIME

FIRST COPY TIME

CONTINUOUS COPY SPEED (copies/min.)

Area

Size

Metric

L: Lengthwise; C: Crosswise

ZOOM RATIOS

Fixed

Variable 50% to 200% (in 0.1% increments)

Zoom Ratio

A3L 13

A4L 17

A4C 18

B4L 13

Mode

Full Size × 1.000 × 1.000

Reduction

Enlargement

:

1to99

:

30 sec. or less with room temperature of 23 °C and

rated power voltage

A4C or 8-1/2” × 11”C: 9.0 sec. or less

:

(inFullSizeModeusing1stDrawer)

× 1.000

Area

Area

Size

Inch

Metric Inch

× 0.816

× 0.707

× 0.500

× 1.154

× 1.414

× 2.000

Zoom Ratio

11” × 17”(L) 13

8-1/2” × 11”(L) 17

8-1/2” × 11”(C) 18

8-1/2” × 14”(L) 13

×1.000

×0.785

×0.647

×0.500

×1.214

×1.294

×2.000

Through Lens (F = 5.0,f = 55mm)

(Rating)

24 V

18 W

:

Fluorescent Lamp

:

185 °C

:

FusingHeater Lamp

(Rating)

115/120 V

900 W

220/240 V

900 W

Max. Power

Consumption

1180 W

1195 W

LENS

EXPOSURE LAMP

Fusing Temperature

POWER/CURRENT CONSUMPTION (Co pier Only)

Voltage

115 V

120 V 1220 W

127 V 1290 W

220 V

240 V 1270 W

POWER REQUIREMENTS : 115 V, 120 V, 127 V, 220-240V; 50/60Hz

Exposure Lamp

G-8

ENVIRONMENTAL CONDITIONS

Temperature 10 to 30 °C with a fluctuation of10 °C or less per hour

Humidity 15 to 85% RH with a fluctuation of 10% RH or less hour

Ambient Illumination 3,000 lux or less

Levelness 1° (1.75 mm/100 mm)

DIMENSIONS

(Copier Only)

WEIGHT

::Width....650 mm (25-1/2”)

Depth....705 mm (27-3/4”)

Height....530 mm (20-3/4”)

69 kg (152 lbs)

G-9

3 PRECAUTIONS FOR INSTALLATION

3-1. Installation Site

To ensure safety and utmostperformanceof the copier,the copier shouldNOTbe usedin a

place:

÷ Where it will besubjected to extremely high or low temperature or humidity.

÷ Where it will besubjected to sudden fluctuations in either temperature or humidity.

÷ Which is exposed to direct sunlight.

÷ Which is in the directair stream of an air conditioner, heater, or ventilator.

÷ Which has poor ventilation or is dusty.

÷ Which doesnot havea stable,level floor or whereit will receive undue vibration.

÷ Which is near any kind of heating device.

÷ Which is near volatileflammables (thinner, gasoline, etc.).

÷ Where it may be splashed with water.

÷ Which putsthe operatorin the directstream of exhaust from the copier.

÷ Where ammoniagas might be generated.

3-2. Power Source

÷ If any other electricalequipment is sourced from thesame power outlet, make sure that

the capacity of the outlet is not exceeded.

÷ Use a power source with little voltage fluctuation.

÷ Neverconnect by means of a multiple socket anyother appliancesor machinesto the

outletbeingusedforthecopier.

÷ Ensure that the copier does not ride on the power cord or communication cable of other

electricalequipment, and that it does notbecome wedgedinto or underneath the mechanism.

÷ Make the following checks at frequent intervals:

✾ Is the power plug abnormally hot?

✾ Are there any cracks or scrapes in the cord?

✾ Has the power plug been inserted fully into the outlet?

✾ Does something, including the copier itself, ride on the power cord?

Use an outlet with a capacity of 115/120/127V or 220-240V.

3-3. Grounding

÷ Alwaysground the copier to prevent receiving electrical shocksin the case of electrical

leakage.

÷ Connectthe ground wire tothe ground terminal ofthe outlet ora grounding contact which

complies with the local electrical standards.

÷ Neverconnect the ground wire to a gas pipe, the ground wire for a telephone, lightning

arrester, or a water pipe for fearof fire andelectrical shock.

G-10

4 PRECAUTIONS FOR USE

4-1. To Ensure Optimum Conditions

÷ Neverplace a heavy object on the copier or subject the copier to shocks.

÷ Insert the power plug all the way into the outlet.

÷ Do not attempt toremove any panel or coverwhich is secured whilethe copieris making

copies.

÷ Do not turn OFF the copier whileit is making copies.

÷ Provide good ventilationwhen making a large numberof copies continuously.

÷ Never use flammable sprays near the copier .

÷ If the copier becomes inordinately hot or produces abnormal noise, turn it OFF and

unplug it.

÷ Do notturn ON the powerswitch at the same timewhen youplug thepowercord intothe

outlet.

÷ When unplugging the power cord, do not pull on the cord; hold the plugand pull it out.

÷ Do not bring any magnetized objectnear the copier.

÷ Do not place a vaseor vesselcontaining water on thecopier.

÷ Be sure to turn OFF thepower switch at the end of the workday or upon powerfailure.

÷ Use care not to drop paper clips,staples, or other smallpieces of metal into the copier.

4-2. Operating Environment

The operating environmental requirements of the copier are as follows.

÷ Temperature:10 to 30 °C

÷ Humidity:15to85%RH

÷ Rate of temperature change:10 °C/h

÷ Rate of humidity change: 10% RH/h

4-3. Power Requirements

The power source voltage requirements are as follows.

÷ Voltage fluctuation: AC115/120/127/220-240

±10% (copying performance assured)

+10%

(paper feeding performance assured)

-15%

÷ Frequency fluctuation: 50/60 Hz ±0.3%

4-4. Prohibitions

÷ It is prohibited to copy paper and hard currencies, government securities, and municipal

bonds (even when they are stamped as “Sample”).

÷ For fear of infringement of copyright, it is also prohibitedto copy copyrighted works,

including books,music, works of art, maps, drawings, motion pictures, and photos except

when the copy is to be for personal use only.

G-11

5 HANDLING OF CONSUMABLES

Before using any consumables, always read the label on its container carefully.

÷ Paper can be easily damaged by dampness. To preventabsorption of moisture, store

paper, which hasbeen removed from itswrapperbutnot loaded in thedrawer, in asealed

plasticbag in a cool, dark place.

÷ Keep consumables out of the reach of children.

÷ Do not touch the PC Drum with bare hands.

÷ The same sized paper is of two kinds, short grainand long grain. Shor t grain paper

should only be fed through the copier crosswise, longgrain papershould only be fed

lengthwise.

÷ If yourhands become soiled with toner, washthem with soap and water.

÷ Do not throw away any used consumables (PC Drum, starter, toner,etc.). Theyare tobe

collected.

÷ Do not burn, bury in the ground, or throw into the water any consumables (PC Drum,

starter, toner, etc.).

÷ Do not store consumables in a place which:

✾ Is hot and humid.

✾ Is subjectto direct sunlight.

✾ Hasanopenflamenearby.

G-12

6 OTHER PRECAUTIONS

Use thefollowingprecautions when performing ser vice jobs fora copier that uses a laser.

÷ When a service job needsto be performedin the laserbeam path, suchas whenworking

around the printerhead or PC Drum, be sure first to unplugthe powercord of the copier

from the outlet.

÷ If the job requires that the power cord be left plugged in, observe the followingprecau-

tions.

1. Takeoff yourwatch, ringand any other reflectiveobject andwear laser protective goggles.

2. Keepusers away fromthe job site.

3. Do not bring a highlyreflective tool into thelaser beam path during the service job.

G-13

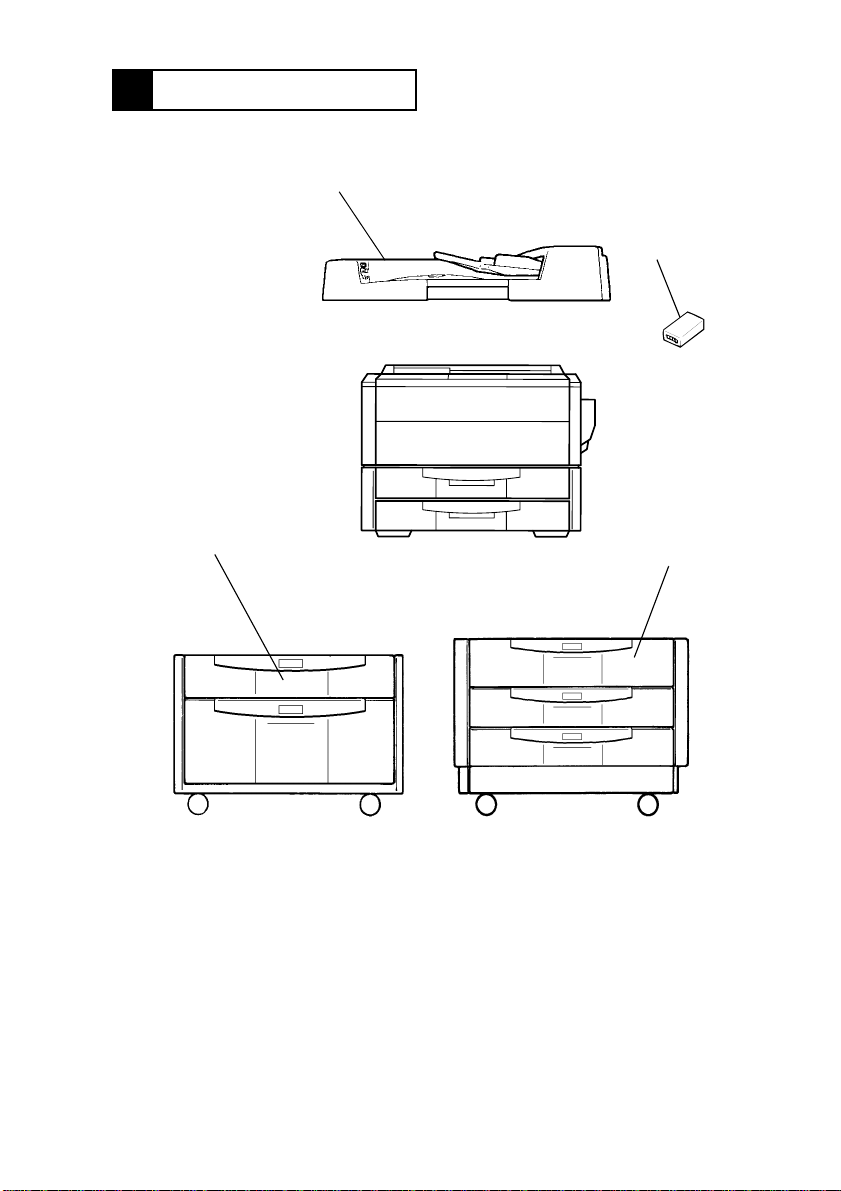

7 SYSTEM OPTIONS

1

2

1151O007AA

1145M035AA

4

1174G004AA

1. AutomaticDocument FeederAF-5

2. Plug-in C ounter

1177M066AA

1174G003AA

3. Paper Feed Cabinet PF-207

4. Paper Feed Cabinet PF-114

3

G-14

MECHANICAL/

ELECTRICAL

14413

CONTENTS

1. CROSS SECTIONAL VIEW ............................................................................M-1

2. COPY PROCESS ............................................................................................M-2

3. DRIVE SYSTEM ..............................................................................................M-4

4. SEQUENTIAL EXPLANATION ........................................................................M-5

5. PC DRUM SECTION .......................................................................................M-6

5-1. PC Drum Drive Mechanism .....................................................................M-6

5-2. Grounding of the PC Drum ......................................................................M-7

6. PC DRUM CHARGING SECTIO N ...................................................................M-8

7. IR SECTION ....................................................................................................M-9

7-1. Exposure Components Section ...............................................................M-10

7-2. Exposure Lamp Control ...........................................................................M-11

7-3. Image Processing Process ......................................................................M-12

7-4. Scanner and Mirrors Carriage Movement Mechanism ............................M-14

(1) Scanner Movement Mechanism ......................................................M-14

(2) 2nd/3rd Mirrors Carriage Movement Mechanism ............................M-14

7-5. Scanner Motor Drive Control ................................................................... M-15

8. Original Size Detecting Section .......................................................................M- 16

8-1. Original Size Detecting Operation ...........................................................M-16

8-2. Original Size Detecting Sensors Locations ..............................................M-17

8-3. Original Size Detection ............................................................................M-18

8-4. Original Size Detection Timing ................................................................M-19

9. PH SECTION ...................................................................................................M-20

9-1. PH Image Processing Process ................................................................M-21

9-2. Laser Exposure Process ..........................................................................M-23

10. DEVELOPING UNIT SECTION .......................................................................M-24

10-1.Developing Unit Drive Mechanism ..........................................................M-25

10-2.Sleeve/Magnet Roller ..............................................................................M-25

10-3.Doctor Blade ............................................................................................M-26

10-4.Developing Bias .......................................................................................M-26

10-5.ATDC Sensor ..........................................................................................M-27

(1) ATDC Sensor Automatic Adjustment ..............................................M-28

10-6.Toner Replenishing Mechani sm ..............................................................M-29

10-7.Toner Replenishing Control .....................................................................M-30

10-8.Toner Supply Hole Covering/Uncovering Mechanism .............................M-31

10-9.Toner Bottle Home Position Detection Mechanism .................................M-31

10-10.Toner Bottle Vibration Mechanism ........................................................M-32

10-11.Toner Empty Detection ..........................................................................M-32

11. PAPER TAKE-UP/FEED SECTION ................................................................M-33

11-1.Drawer In Position Detection ...................................................................M-34

11-2.Paper Empty Detection Mechanism ........................................................M-35

11-3.Universal Tray Paper Size Detection Mechanism ...................................M-36

11-4.Paper Take-Up Mechanism .....................................................................M-38

(1) Paper Separating Mechanism .........................................................M-38

11-5.Paper Take-Up Roll .................................................................................M-39

11-6.Paper Take Up Control ............................................................................M-39

(1) Paper Take Up Retry Control ..........................................................M-40

xvi

11-7.Vertical Transport Drive Mechanism .......................................................M-41

12. MANUAL FEED SECTION ..............................................................................M-42

12-1.Manual Feed Paper Take Up Drive Mechanism ......................................M-43

12-2.Manual Bypass Take Up RollPressure Mechanism ...............................M-44

12-3.Manual Feed Paper Separating Mechanism ...........................................M-45

12-4.Manual Feed Paper Empty Detection Mechanism ..................................M-46

12-5.Manual Feed TakeUp Control ................................................................M-46

13. TRANSPORT/SYNCHRONIZING ROLLERS ..................................................M-47

13-1.Paper Dust Remover ...............................................................................M-47

13-2.Transport Roller Drive Mechanism ..........................................................M-48

13-3.Synchr onizing Roller Drive Mechanism ...................................................M-48

13-4.Transport Drive Control ...........................................................................M-49

14. IMAGE TRANSFER AND PAPER SEPARATION ...........................................M-50

14-1.PC Drum Paper Separator Fingers Section ............................................M-51

(1) Finger Back and Forth Detection Mechanism .................................M-51

15. PC DRUM CLEANING SECTION ....................................................................M-52

15-1.Cleaning Blade Moving Mechanism ........................................................M-52

16. MAIN ERASE SECTION ..................................................................................M-53

17. TRANSPORT SECTION ..................................................................................M-54

18. FUSING UNIT SECTION .................................................................................M-55

18-1.Fusing Uni tDrive Mechanism ..................................................................M-56

18-2.Fusing Rol lers Pressure Mechanism .......................................................M-56

18-3.Fusing Rol ler Cleaning Mechanism .........................................................M-57

18-4.Fusing Temperature Control ....................................................................M-58

19. OTHER MECHANISMS ...................................................................................M-60

19-1.Memory Backup .......................................................................................M-60

19-2.Dehumidifying Mechanism ......................................................................M-61

(1) PC Drum Dehumidifying ..................................................................M-61

(2) Paper Dehumidifying Mechanism ....................................................M-61

19-3.Cooling Mechanism .................................................................................M-62

(1) Optical Section Cooling Mechanism ................................................M-62

(2) Power Supply Section Cooling Mechanism .....................................M-62

19-4.Ozone Filter .............................................................................................M-63

xvii

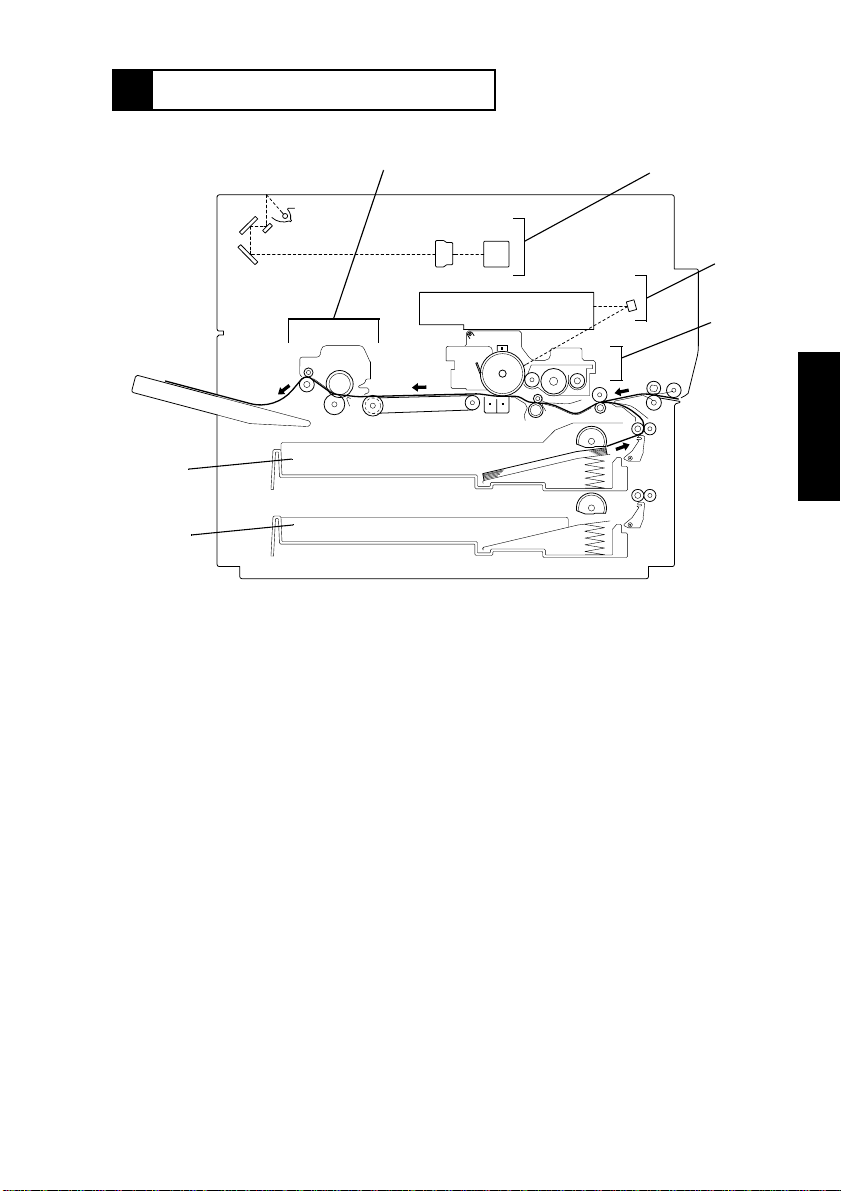

8 CROSS SECTIONAL VIEW

6

5

1. Fusing Unit

2. IR Section

3. PH Section

1

2

3

4

1177M001AB

4. Imaging Unit

5. 2nd Drawer

6. 1st Drawer

M-18

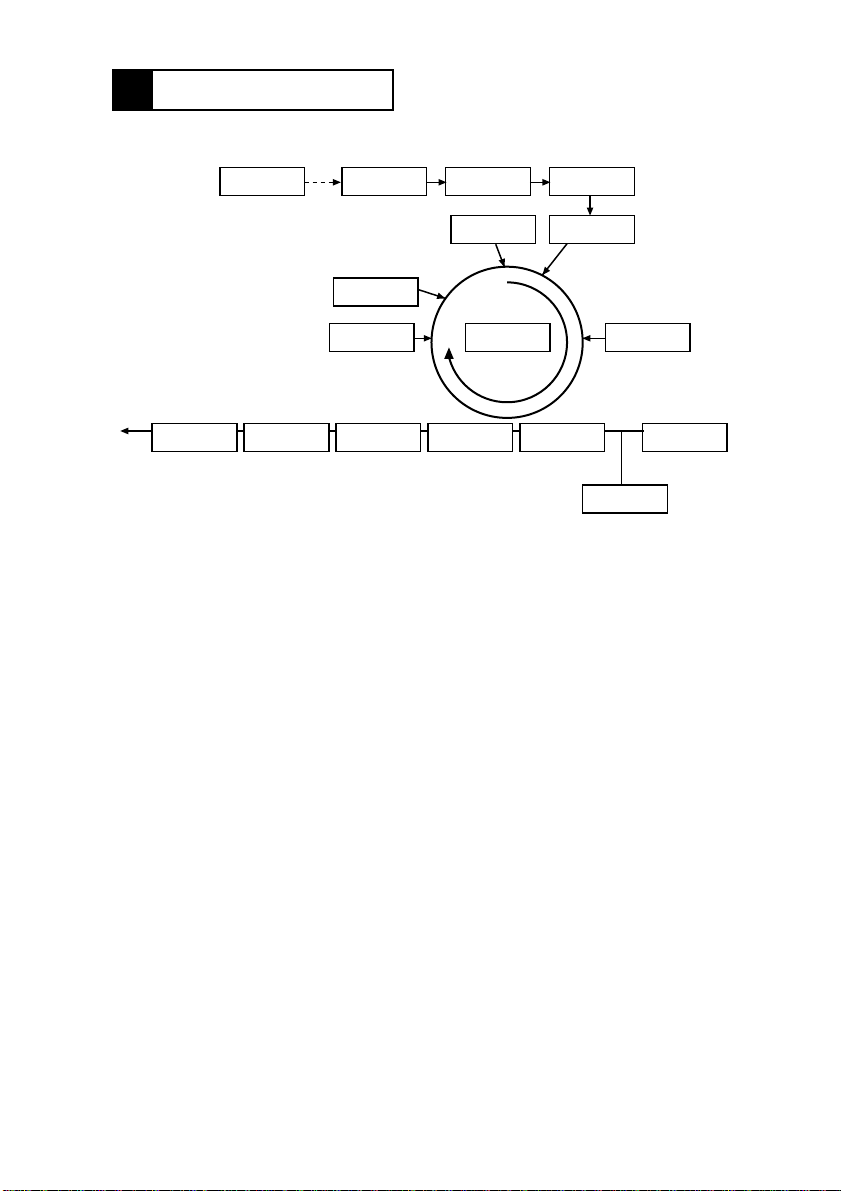

9 COPY PROCESS

6543

2 7

14

13

1617

1. PC Drum

÷ Used as the medium on which a visible developed image of the original is formed.

2. Drum Charging

÷ A uniformnegative DC charge is deposited across the entire surface ofthe PC Drum.

3. Photoelectric Conversion

÷ A CCD converts the image data represented by light reflectedoff the originalto a corre-

sponding electrical signalwhich, in turn, is output to the IR image-processing section.

4. IR Image-Processing

÷ The electricalsignal is converted to an 8-bit digital imagesignal (A/D conversion)which,

in turn, goes through appropriate correctionbefore being outputto the memory.

5. Memory

÷ The digitalimage signal is compressed and stored in memory. It is then output to the PH

image-processing section.

6. PH Image Processing

÷ After goingthrough corrections, the digital image signal is converted to a corresponding

electricalsignal (D/A conversion) that controls the intensity of the light from the laser

diode.

7. Laser Exposure

÷ The laser beamstrikes the surfaceof thePC Drum,forming an electrostaticlatent image.

8. Developing

÷ Toner negatively charged in the Developer Mixing Chamber is attracted onto the electro-

static latent image chan ging it to a visible, developed image.

÷ An AC/DC negative bias voltage is applied to theSleeve/Magnet Roller to prevent toner

from being attracted onto those areasof the PC Drum which correspond to the background areas of the original.

111215

81

10

9

1177M028AC

M-19

9. PaperFeeding

÷ Paper is fed from the drawer.

10.Bypass PaperFeeding

÷ Paper is fed from the BypassTable.

11. Image Transfer

÷ A DCpositivecorona emissionis applied to the backside ofthe paper, thereby attracting

toner onto the surface of the paper.

12.Paper Separation

÷ An ACcorona and DC negative corona emission is applied to the backside of thepaper

to neutralize the paper,while the PC Drum Paper Separator Fingersmechanically

remove the paper from the surface of the PC Drum.

13. Cleaning

÷ Residual toner on the surface of the PC Drum is scraped off.

14. Main Erase

÷ Light is directed to the surface of the PC Drum to neutralize any surface potential remain-

ing thereafter cleaning.

15. Transport

÷ ThepaperisfedtotheFusingUnit.

16. Fusing

÷ The developed image is permanentlyfused to the paper bya combination of heat and

pressure applied by the Upper and Lower Fusing Rollers.

17. Exit

÷ The paper is fed out onto the Exit Tray.

M-20

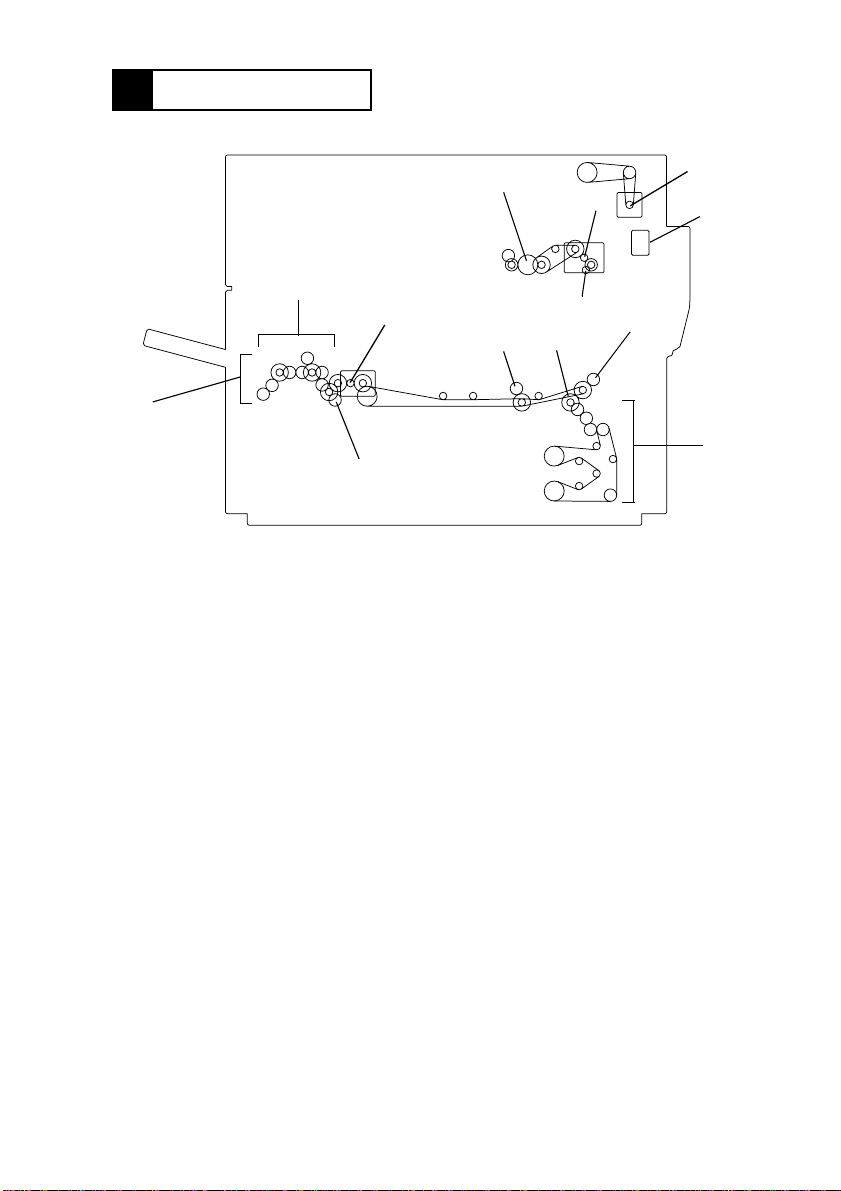

10 DRIVE SYSTEM

12

11

1. PC Drum Drive

2. Upper Drive Motor M1

3. Scanner Motor

4. Toner Replenishing Motor

5. Developing Section Drive

6. Synchronizing Roller Drive

7. Paper Transport Drive

10

1

13

6

7

8. Manual Feed PaperTake-Up Drive

9. PaperTake-Up Drive

10.Suction Belt Drive

11.Exit Section Drive

12.Fusing Unit Section

13. Lower Drive Motor M2

3

2

5

8

4

9

1177M002AB

M-21

Loading...

Loading...