Page 1

FrameMaker Ver.5.5E(PC) Di152/Di183 TROUBLESHOOTING

01.09.04

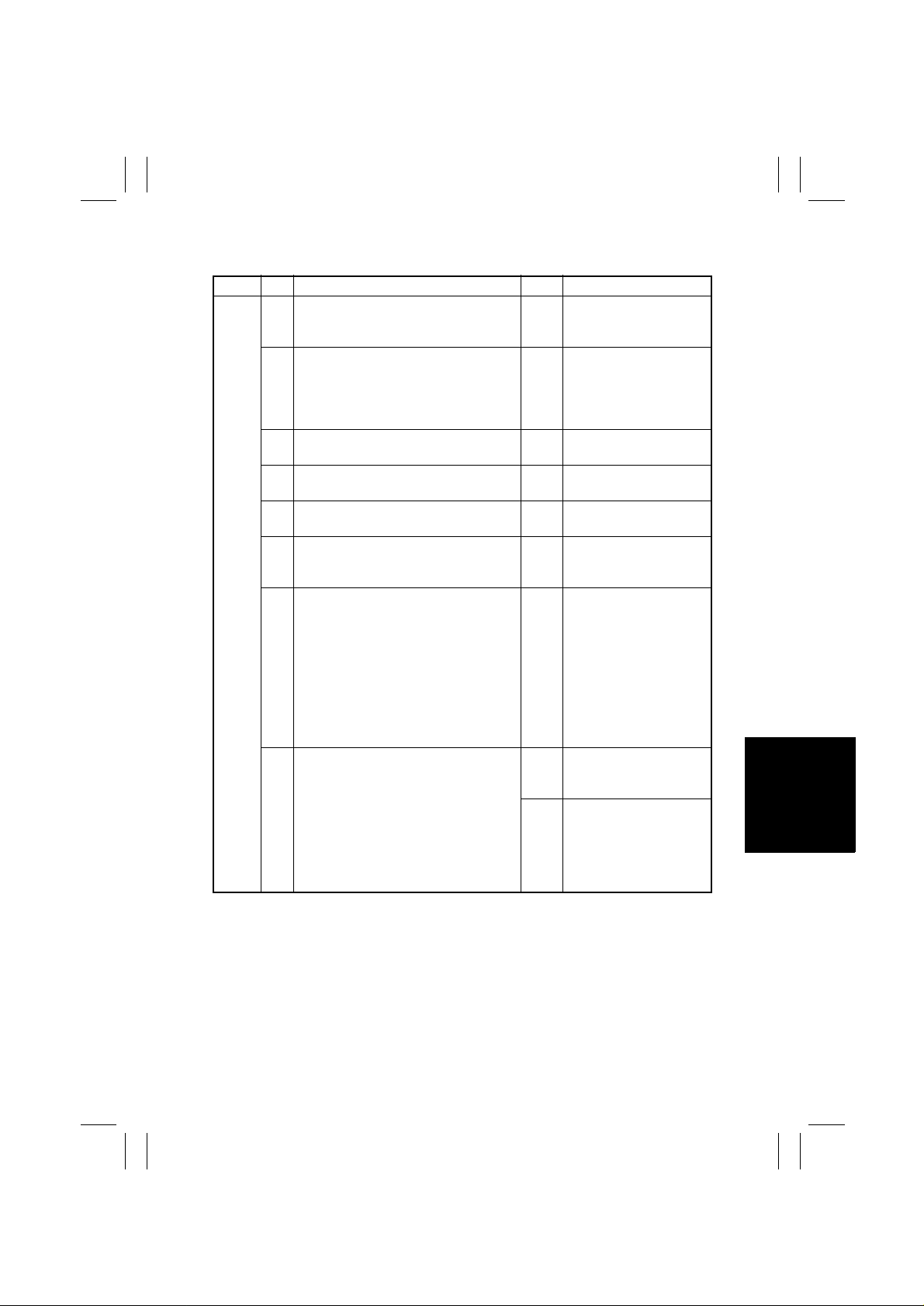

(3) Low image density

Section Step Check Result Action

Output

system

1 Image density changes after “Toner

Replenisher” has been run.

• “Toner Replenisher” of Utility

2 Image density changes after “ID Adjust-

ment” and “VG Adjustment” have been

made.

3 Image transfer current contact is dirty,

folded, or bent.

4 Developing bias contact is dirty, folded,

or bent.

5 High Voltage Unit (HV1) connectors

CN1HV1 and CN2HV1 are loose.

6 ATDC Sensor (UN1) is dirty with foreign

matter (such as paper dust) other than

developer.

7 The following voltages develop from the

ATDC Sensor (UN1).

<Check Procedure>

Check voltage across a Master Board

pin and GND when the Power Switch is

turned ON.

• DC5. 39 V to 8.15 V across PJ7A-8

and GND

• DC1. 41 V to 4.98 V across PJ7A-10

and GND

8 The following voltage is supplied from

the Master Board (copier: PWB-A).

<Check Procedure>

Check voltage across a Master Board

pin and GND when the Start key is

pressed.

• Voltage across PJ8A-8 and GND

DC14 V in standby state

DC0 V when Start key is pressed

YES • Replenish the supply of

toner using “Toner

Replenisher.”

YES • Readjust.

For more details, see

SWITCHES ON PWBs/

TECH. REP. SETTINGS.

YES • Clean, correct, or

change.

YES • Clean, correct, or

change.

YES • Reconnect.

YES • Clean.

NO • Change ATDC Sensor

(UN1) and then change

developer.

YES • Change IU.

• Change High Voltage

Unit (HV1).

NO • Change Mas ter Board

(copier: PWB-A).

T-47

Page 2

FrameMaker Ver.5.5E(PC) Di152/Di183 TROUBLESHOOTING

01.09.04

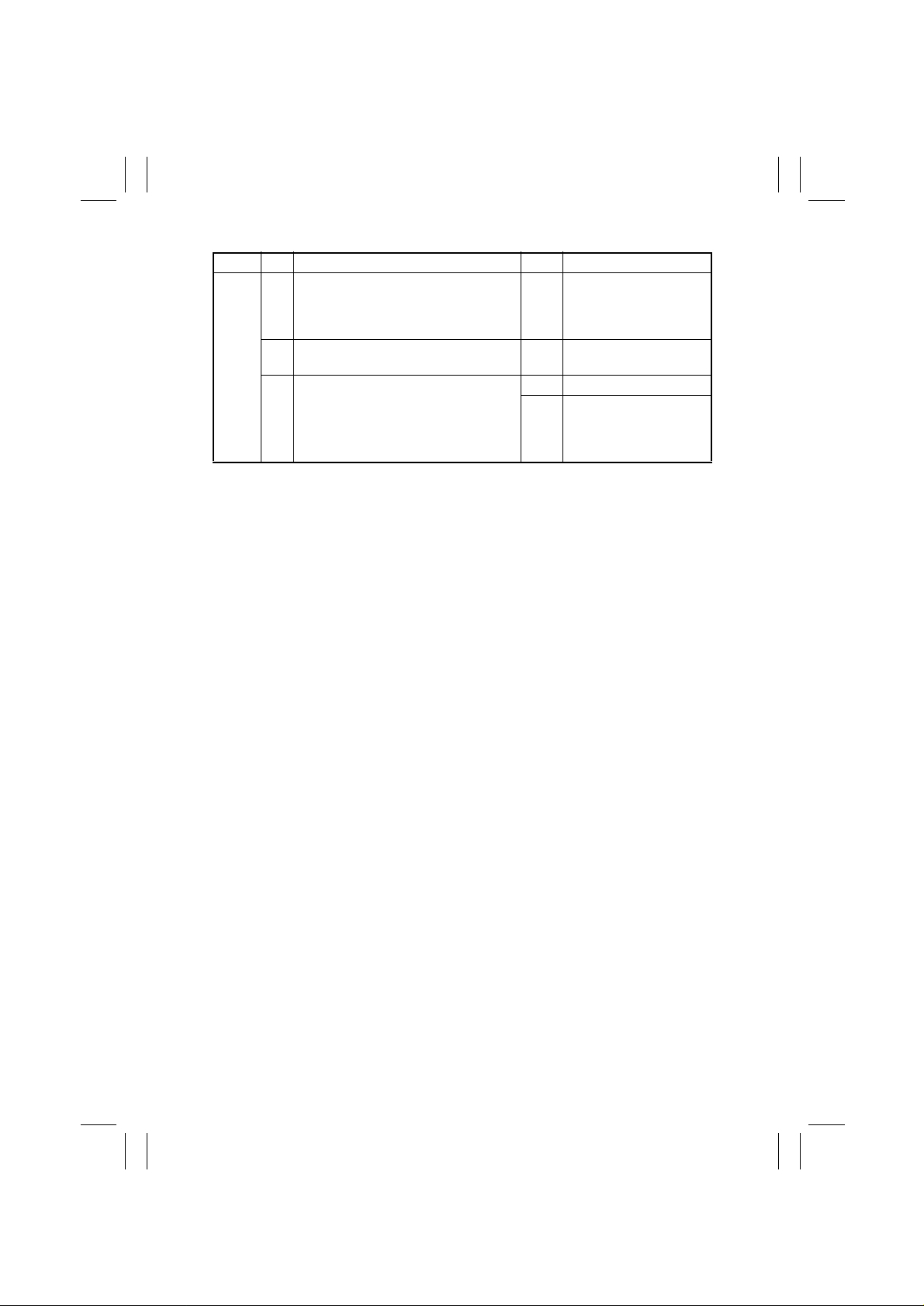

Section Step Check Result Action

Input

system

1 Shading sheet reading portion (the por-

tion on the backside of the Original

Glass to which Original Width Scale is

affixed) is dirty .

2 CCD Board (copier: PWB-J) connector

is loose.

3 Control Board (copier: PWB-C) connec-

tor PJ1A is loose.

YES • Clean.

YES • Reconnect.

YES • Reconnect.

NO • Change Control Board

(copier: PWB-C).

• Change Mas ter Board

(copier: PWB-A).

T-48

Loading...

Loading...