Page 1

FrameMaker Ver.5.5E(PC) Di152/Di183 TROUBLESHOOTING

01.09.04

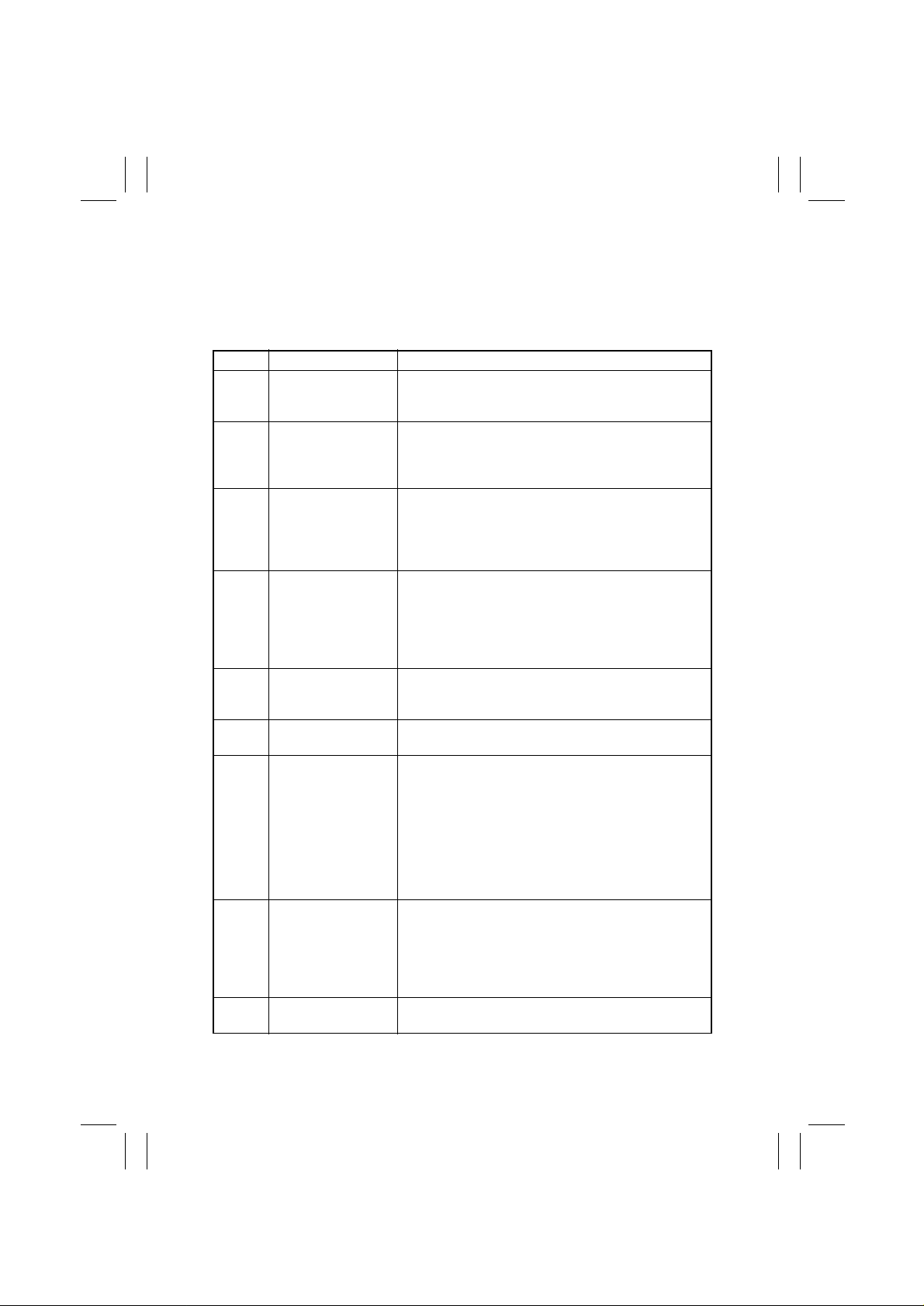

4. MALFUNCTION

The copier’s CPU is equipped with a self-diagnostics function that, on detecting a malfunction, gives the corresponding malfunction code on the Display.

4-1. Detection Timing by Malfunction Code

Code Description Detection Timing

C0000 Main Motor malfunc-

tion

C0045 Fusing Cooling Fan

Motor malfunction

C004E Power Supply Cool-

ing Fan Motor malfunction

C0070 Toner Replenishing

Motor malfunction

C0210 Abnormal image

transfer voltage

C03FF Improperly set Adjust

Mode 11

C0500 Warm-up failure • It takes the surface temperature of the Left Fusing

C0510 Abnormally low fus-

ing temperature

C0520 Abnormally high fus-

ing temperature

• The Main Motor (M1) Lock signal remains HIGH for a

continuous 1-sec. period at any time 1 sec. after the

Main Motor has started turning.

• The Fusing Cooling Fan Motor (M3) Lock signal

remains HIGH for a continuous 1-sec. period while the

Fusing Cooling Fan Motor is turning at full speed or

decelerated speed.

• The Power Supply Cooling Fan Motor (M4) Lock signal remains HIGH for a continuous 1-sec. period while

the Pow er Supply Cooling Fan Motor Remote signal

remains ON (for full-speed rotation) or OFF (for decelerated-speed rotation).

• The Toner Bottle Home P osition Sensor (PC7) outputs

a HIGH signal for a continuous 3.5-sec. period while

the Toner Bottle is turning.

• The Toner Bottle Home P osition Sensor (PC7) outputs

a LOW signal f or a continuous 2-sec. period while the

Toner Bottle is turning.

• The image transfer voltage remains more than 100 V

for a continuous given period of time while the PC

Drum remains stationary.

• An incorrect setting is made of Adjust 11.

Roller more than 35 sec. to reach 100 °C since the

start of a warm-up cycle.

• It takes the surface temperature of the Left Fusing

Roller more than 25 sec. to reach 140 °C after it has

reached 100 °C.

• It takes more than 20 sec. for the warm-up cycle to be

completed after the surface temperature of the Left

Fusing Roller has reached 140 °C.

• The surface temperature of the Left Fusing Roller

remains lower than 120 °C for a given period of time

while the copier is in a standby state.

• The surface temperature of the Left Fusing Roller

remains lower than 120 °C for a given period of time

during a print cycle.

The surface temperature of the Left Fusing Roller

remains higher than 240 °C for a given period of time.

T-18

Page 2

FrameMaker Ver.5.5E(PC) Di152/Di183 TROUBLESHOOTING

01.09.04

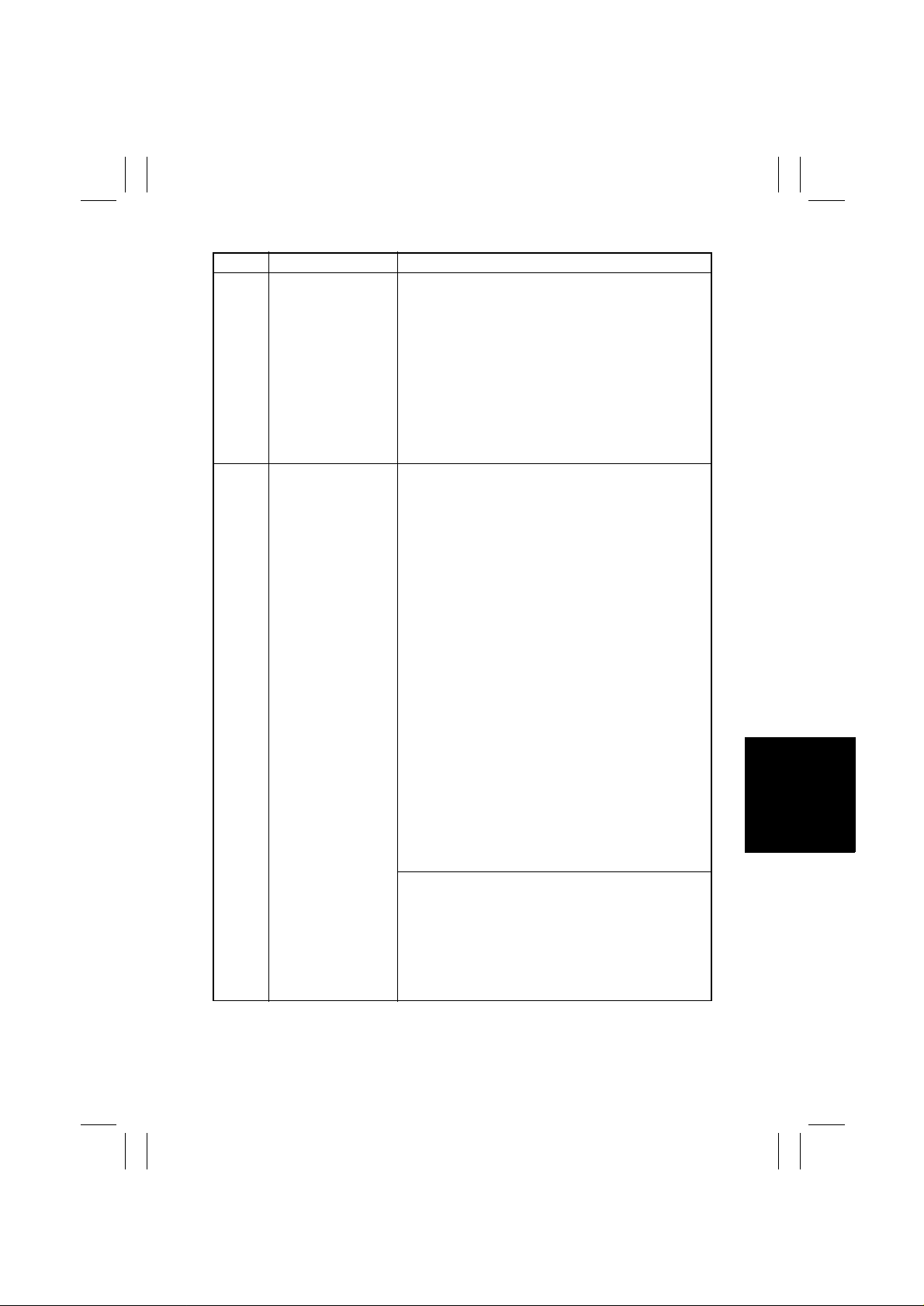

Code Description Detection Timing

C0650 Faulty Scanner Home

Position Sensor

C0B60 Bin Switching Motor

malfunction

• The Scanner Home Position Sensor (PC6) does not

go from HIGH to LOW when the Scanner Motor (M5)

is energized for a given number of steps after the

sequence to bring the Scanner back to its home position has been started at the end of a scan motion and

during re-shading.

• The Scanner Home Position Sensor (PC6) does not

go from LOW to HIGH when the Scanner Motor (M5)

is energized for a given number of steps after a scan

motion has been started at the end of a Scanner

Home Position Sensor home check scan motion and

during re-shading.

If the Upper Home Position Sensor is LOW during an initial operation:

• The Lower Home Position Sensor (PC33) is LOW

when the Bin Switching Motor (M1) starts turning forward.

• If the Lower Home Position Sensor (PC33) does not

go LOW at a time 2.5 sec. after the Bin Switching

Motor (M1) has started turning forward, the Bin

Switching Motor is kept deenergized for a given

period of time and then energized again to turn backward. The Upper Home Position Sensor (PC32) does

not go LOW after the motor has started turning backward.

• The Upper Home Position Sensor (PC32) does not go

HIGH at a time 1 sec. after the Bin Switching Motor

(M1) has started turning forward.

• When the Lower Home Position Sensor (PC33) goes

LOW, the Bin Switching Motor (M1) starts turning

backward. The Upper Home Position Sensor (PC32)

does not go LOW at a time 2.5 sec. after the motor

has started turning backward.

• When the Lower Home Position Sensor (PC33) goes

LOW, the Bin Switching Motor (M1) starts turning

backward. The Lower Home Position Sensor (PC33)

does not go HIGH at a time 1 sec. after the motor has

started turning backward.

If the Lower Home Position Sensor is LOW during an initial operation:

• The Upper Home Position Sensor (PC32) does not go

LOW at a time 2.5 sec. after the Bin Switching Motor

(M1) has started turning backward.

• The Lower Home Position Sensor (PC33) does not go

HIGH at a time 1 sec. after the Bin Switching Motor

(M1) has started turning backward.

T-19

Page 3

FrameMaker Ver.5.5E(PC) Di152/Di183 TROUBLESHOOTING

01.09.04

Code Description Detection Timing

C0B60 Bin Switching Motor

malfunction

C0B80 Shift Motor malfunc-

tion

C0F32 Faulty ATDC Sensor • The measurement taken by the ATDC Sensor (UN1)

C0F33 Improperly adjusted

ATDC Sens or

C1038 Engine connection

failure

If both the Upper Home Position Sensor and the Lower

Home Position Sensor are HIGH during an initial operation:

• If the Lower Home Position Sensor (PC33) does not

go LOW at a time 2.5 sec. after the Bin Switching

Motor (M1) has started turning forward, the Bin

Switching Motor is kept deenergized for a given

period of time and then energized again to turn backward. The Upper Home Position Sensor (PC32) does

not go LOW after the motor has started turning backward.

• When the Lower Home Position Sensor (PC33) goes

LOW, the Bin Switching Motor (M1) starts turning

backward. The Upper Home Position Sensor (PC32)

does not go LOW at a time 2.5 sec. after the motor

has started turning backward.

• When the Lower Home Position Sensor (PC33) goes

LOW, the Bin Switching Motor (M1) starts turning

backward. The Lower Home Position Sensor (PC33)

does not go HIGH at a time 1 sec. after the motor has

started turning backward.

• The Home Sensor (S31) is LOW at a timing immediately before the Shift Motor (M1) starts turning backward.

• The Home Sensor (S31) is LOW after the lapse of a

given period of time after the Shift Motor (M1) has

started turning backward.

at a time 2.5 sec. after the Main Motor (M1) has

started turning is less than 3 % (greater than 4.98 V).

• The measurement taken by the ATDC Sensor (UN1)

at a time 2.5 sec. after the Main Motor (M1) has

started turning is 19 % or more (1.41 V or less).

• The adjustment of the ATDC control voltage is not

completed within 1 sec. after sampling has started of

the ATDC Sensor (UN1) as part of an operation of

ATDC Sensor Automatic Adjustment.

• The ATDC Sensor control voltage falls outside the

range of 5.39 V to 8.15 V during an operation of ATDC

Sensor Automatic Adjustment.

Master Board (PWB-A) to Control Board (PWB-C) connection failure

• There is no acknowledge signal transmitted from the

Master Board (PWB-A) to Control Board (PWB-C) for

1.5 sec. or more.

• An error command signal is transmitted from the Control Board (PWB-C) to Master Board (PWB-A).

• An error status signal is transmitted from the Master

Board (PWB-A) to Control Board (PWB-C).

T-20

Page 4

FrameMaker Ver.5.5E(PC) Di152/Di183 TROUBLESHOOTING

01.09.04

Code Description Detection Timing

C1200 Faulty ASIC/memory ASIC/memory (for image and control) fault

• A write or read error occurs with SRAM on the Control

Board (PWB-C).

C1300 Polygon Motor mal-

function

C13F0 Fault y HSYNC Laser scanning system malfunction

C1468 Faulty EEPROM EEPROM fault

C14A3 IR fluorescent lamp

fault

Startup failure

• A LOW Polygon Motor (M2) Lock signal is not

detected within a given period of time that begins 1

sec. after the Polygon Motor has started turning.

Lock signal fault: Unstable aft er the fi rst Lock signal has

been detected

• For a period of 1 sec. after the first LOW Polygon

Motor (M2) Lock signal (first Lock) has been detected,

the next LOW Polygon Motor Lock signal is not

detected.

Lock signal fault: Lock signal out-of-timing

• A LOW Polygon Motor (M2) Lock signal is not

detected for a continuous given period of time while

the rotation of the Polygon Motor remains stabilized.

Faulty Lock signal

• A LOW Polygon Motor (M2) Lock signal is detected for

a given period of time or more when the Polygon

Motor remains deenergized.

• The SOS Sensor does not detect a rising edge of

SOS within a given period of time after the Polygon

Motor (M2) has started turning and a laser output has

been started.

• The SOS Sensor detects no rising edges of SOS

while VIA (image area control) is ON.

• Data cannot be written in EEPROM.

• Data stored in EEPROM is wrong.

The Exposure Lamp (LA2) of the Scanner fails to turn

ON.

• The intensity of the Exposure Lamp is a predetermined value or less during shading and re-shading.

T-21

Page 5

FrameMaker Ver.5.5E(PC) Di152/Di183 TROUBLESHOOTING

01.09.04

4-2. Resetting Procedure by Malfunction Code

Code Description Resetting Procedure

C0000 Main Motor malfunction • Turn OFF and ON the Power Switch.

C0045 Fusing Cooling Fan Motor mal-

C004E Power Supply Cooling Fan Motor

C0070 Toner Replenishing Motor mal-

C0210 Abnormal image transfer voltage

C03FF Improperly set Adjust Mode 11 • Set Adjust Mode 11 correctly and then

C0500 Warm-up failure • Turn ON the Power Switch with the Stop

C0510 Abnormally low fusing temperature

C0520 Abnormally high fusing tempera-

C0650 Faulty Scanner Home Position

C0B60 Bin Switching Motor malfunction

C0F32 Faulty ATDC Sensor

C0F33 Improperly adjusted ATDC Sensor

C1038 Engine connection failure

C1200 Faulty ASIC/memory

C1300 Polygon Motor malfunction

C13F0 Faulty HSYNC

C1468 Fault y EEPROM

C14A3 IR fluorescent lamp fault

function

malfunction

function

turn OFF and ON the Power Switch.

• For details, see SWITCHES ON PWBs/

TECH. REP. SETTINGS.

key held down.

ture

• Turn OFF and ON the Power Switch.

Sensor

T-22

Loading...

Loading...