Page 1

FrameMaker Ver5.5E(PC) P F-120 OPTION FOR Di152/Di183

01.08.27

PF-120

SERVICE MANUAL

10794

Page 2

FrameMaker Ver.5.5(PC) PF-120 OPTION FOR Di183/Di152

01.08.27

CONTENTS

GENERAL, MECHANICAL/ELECTRICAL

1. SPECIFICATIONS ...........................................................................................M-1

2. COMPONENT IDENTIFICATION .............................................. ......................M-1

3. CROSS-SECTIONAL VIEW ............................................................................M-2

4. DRIVE SYSTEM COMPONENT LAYOUT ......................................................M-2

5. ELECTRICAL PARTS LAYOUT ...................................................................... M-3

6. PAPER TAKE-UP/FEEDING SECTION ..........................................................M-4

6-1. Edge Guide and Trailing Edge Stop ........................................................M-4

6-2. Paper Lifting Plate ...................................................................................M-4

6-3. Tray-in-Position Detection ........................ ...............................................M-5

6-4. Paper Empty Detection . ...........................................................................M-5

6-5. Paper Size Detecting Mechanism ............................................................M-6

6-6. Paper Separating Mechanism .................................................................M-7

6-7. Paper Take-Up Control . ...........................................................................M-8

6-8. Paper Take-Up Retry Control ..................................................................M-9

DIS/REASSEMBLY, ADJUSTMENT

1. DISASSEMBLY ...............................................................................................D-1

1-1. Maintenance Schedule ..................................................................... .. .... .D-1

1-2. Removal of the Paper Take-Up Rollers ...................................................D-2

1-3. Cleaning of the Paper Take-Up Roller/Rolls ............................................D-2

1-4. Cleaning of the Vert ical Transport Roller/Rolls ....................................... .D-3

2. ADJUSTMENT .................................................................................................D-4

2-1. Adjust Mode Setting Procedure ............................................................ .. .D-4

2-2. CD Registration Adjus tment ............... ........................... ..........................D-4

MISFEED DETECTION

1. MISFEED DETECTION ............................................ .......................................T-1

1-1. Location of Misfeed Detecting Sensors ...................................................T-1

1-2. Misfeed Detection Timing ........................................................................T-2

i

Page 3

FrameMaker Ver5.5E(PC) P F-120 OPTION FOR Di152/Di183

01.08.27

GENERAL,

MECHANICAL/ELECTRICAL

Page 4

FrameMaker Ver.5.5E(PC) PF-120 OPTION FOR Di152/Di183

01.08.27

1. SPECIFICATIONS

Type : Paper Feed Cabinet

Installation : Installs in the bottom of the Main Unit.

Type of Copy Paper :

Paper Sizes : Metric Areas: A5C, B5L/C, A4L/C, FLS, B4L, A3L

Registration : Center

Capacity : 250 sheets

Power Requirements : DC24 V, DC5 V (supplied from copier)

Max. Power Consumption : 9 W or less

Dimensions : Width: 590 mm or 23-1/4

Weight : 5.5 kg or 12-1/4 lbs.

(Fixed to the Main Unit by plates and screws.)

2

Plain paper, Recycled paper (60 to 90 g/m

Inch Areas: 8-1/2 × 5-1/2C, 11 × 8-1/2C, 8-1/2 × 11L,

8-1/2 × 14L, 11 × 14, 11 × 17

(L: Lengthwise, C: Crosswise)

Depth: 558 mm or 22

Height: 108 mm or 4-1/4

or 16 to 24 lbs.)

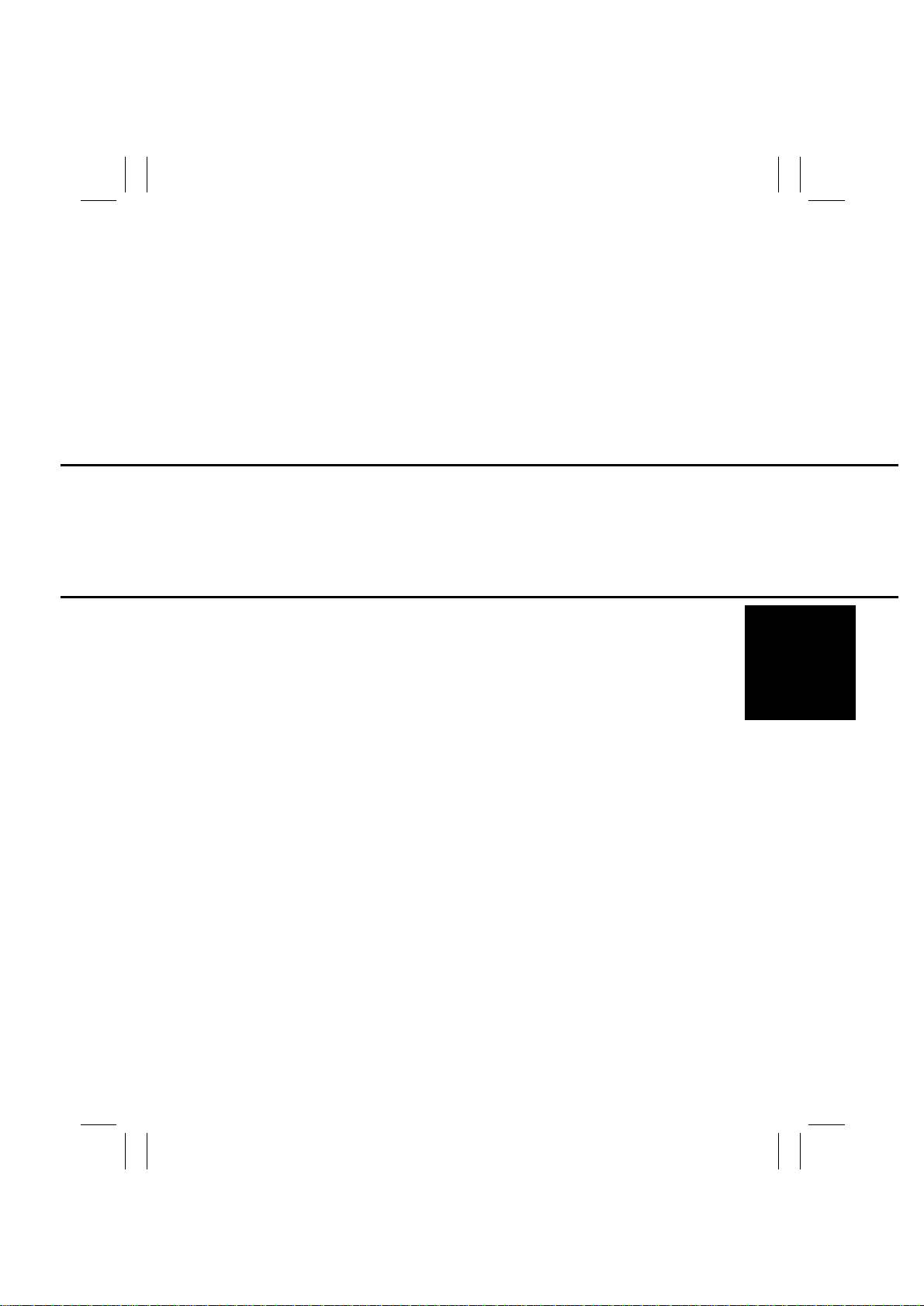

2. COMPONENT IDENTIFICATION

1

1. Trailing Edge Stop 3. Paper Lifting Plate

2. Side Door 4. Edge Guide

2

34

4686M004AA

M-1

Page 5

FrameMaker Ver.5.5E(PC) PF-120 OPTION FOR Di152/Di183

01.08.27

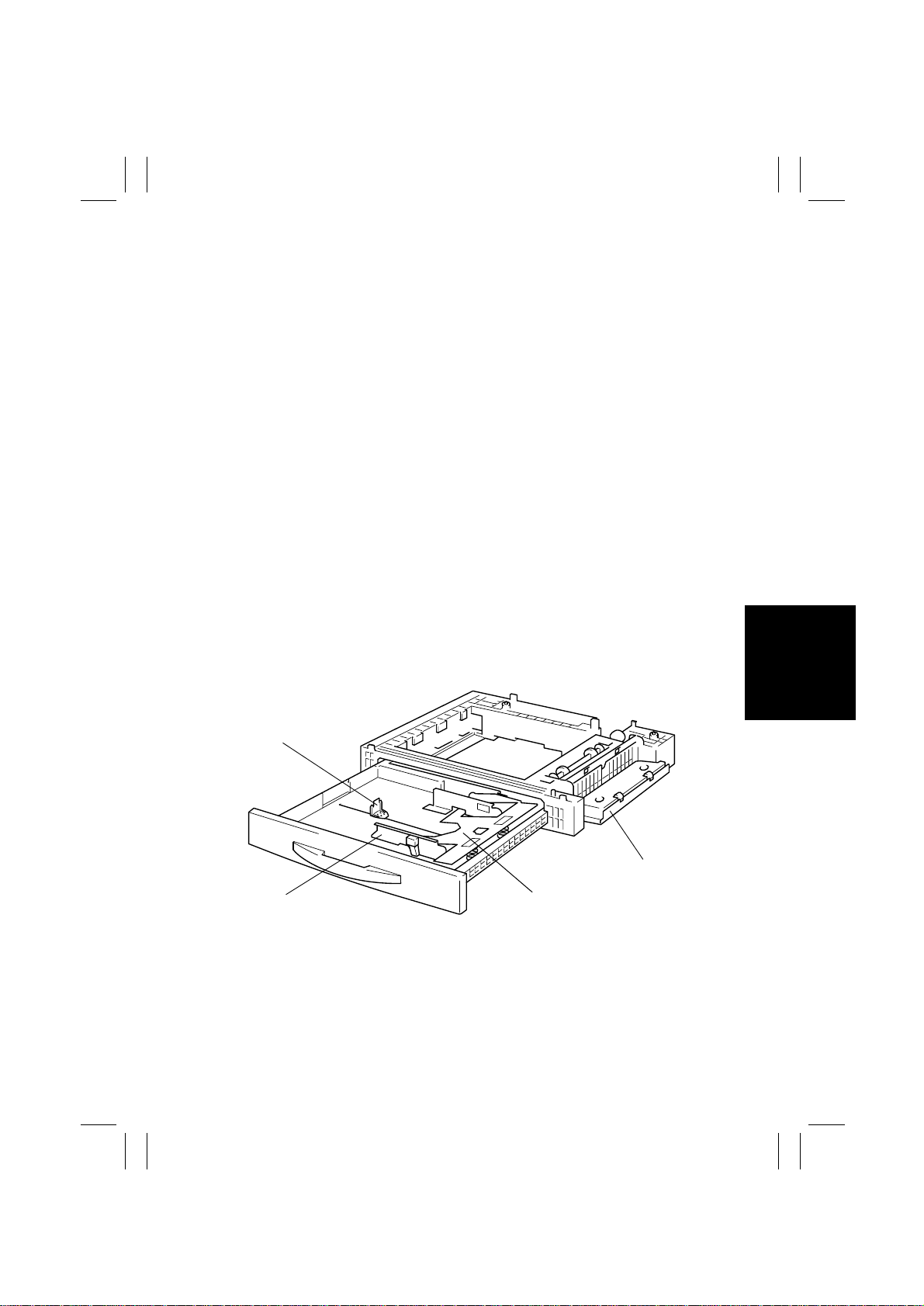

3. CROSS-SECTIONAL VIEW

1. Paper Take-Up Roll 5. Paper Lifting Spring

2. Paper Take-Up Roller 6. Paper Lifting Plate

3. Vertical T ransport Roller 7. Edge Guide

4. Vertical Transport Roll 8. Trailing Edge Stop

234

1

5678

4686M001AC

4. DRIVE SYSTEM COMPONENT LAYOUT

Vertical Transpor t Roller

Paper Take-Up

Drive Mechanism

Paper Take-Up Roller

M-2

4686M003AA

Page 6

FrameMaker Ver.5.5E(PC) PF-120 OPTION FOR Di152/Di183

01.08.27

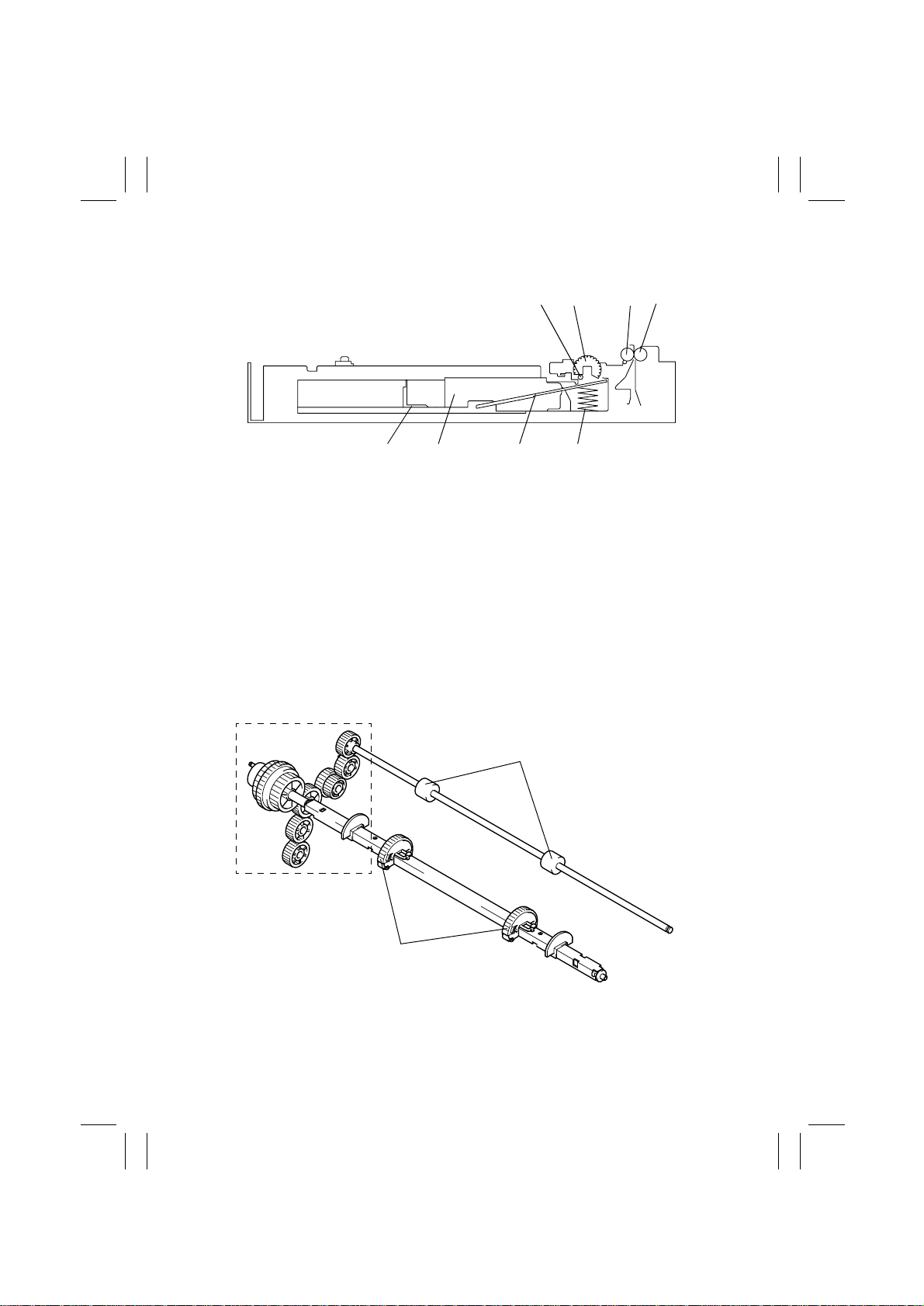

5. ELECTRICAL PARTS LAYOUT

SL11

PWB-A

PC13

PWB-I

Symbol Name Symbol Name

PWB-A

PWB-I

S11

SL11

Control Board

Paper Size (FD) Detection Board

Paper Size (CD) Detection Sensor

Paper Take-Up Solenoid

S11

PC14

PC11

PC12

PC13

PC14

PC11

PC12

Paper Empty Sensor

Paper Take-Up Sensor

Drawer Set Sensor

Side Door Sensor

4686M002AA

M-3

Page 7

FrameMaker Ver.5.5E(PC) PF-120 OPTION FOR Di152/Di183

01.08.27

6. PAPER TAKE-UP/FEEDING SECTION

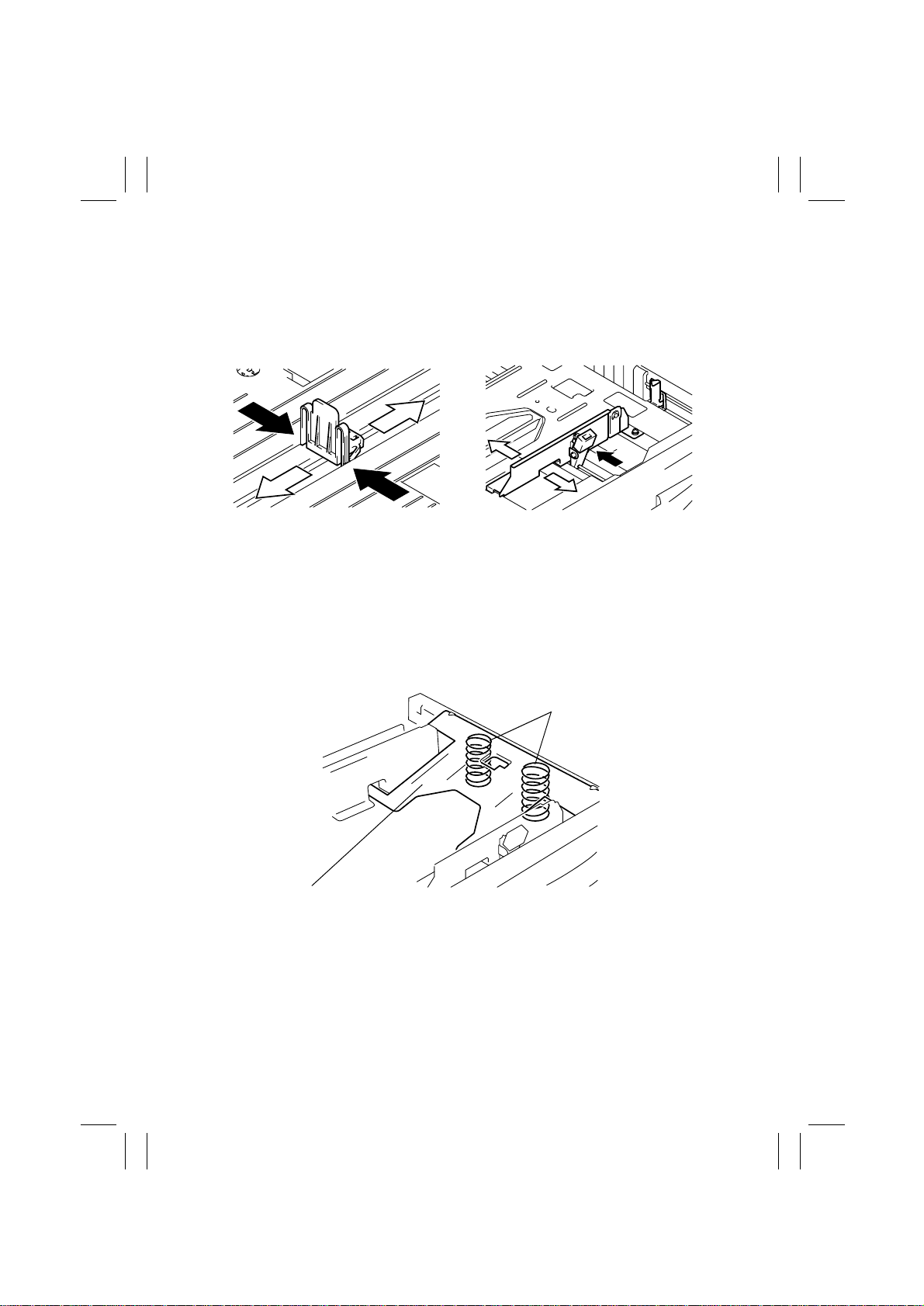

6-1. Edge Guide and Trailing Edge Stop

• The Edge Guide and Trailing Edge Stop can be slid into any desired position.

Trailing Edge Stop Edge Guide

4686M005AA

4686M009AA

6-2. Paper Lifting Plate

• The Paper Lifting Plate is locked into position when it is pressed down. It is unlocked

when the tray is slid into the unit.

• The Paper Lifting Plate is pushed upward by the Paper Lifting Springs at all times.

Paper Lifting Spring

Paper Lifting Plate

4686M006AA

M-4

Page 8

FrameMaker Ver.5.5E(PC) PF-120 OPTION FOR Di152/Di183

01.08.27

6-3. Tray-in-Position Detection

• When a tray is slid into the cabinet, the Drawer Set Sensor is blocked and the copier

determines that the tray has been slid in position.

Light Blocking Plate

Drawer Set Sensor PC13

4686M007AA

6-4. Paper Empty Detection

• The Paper Empty Sensor detects a paper-empty condition in the tray.

Paper Empty Sensor PC11

4686M008AA

M-5

Page 9

FrameMaker Ver.5.5E(PC) PF-120 OPTION FOR Di152/Di183

01.08.27

6-5. Paper Size Detecting Mechanism

• Both the width (in the crosswise direction) and length (in the feeding direction) of the

paper are detected and the copier CPU determines the paper size based on the combination of the two readings.

• The width (CD) of the paper is detected when the lever that is operatively connected to

the Edge Guide activates or deactivates the Paper Size (CD) Detection Sensor.

• The length (FD) of the paper is detected when the lever that is operatively connected to

the Trailing Edge Stop actuates or deactuates the switches on the Paper Size (FD)

Detection Board.

Paper Size (FD) Detection Board

PWB-I

SW4 SW3 SW2 SW1

Paper Size (CD) Detection Sensor

S11

Trailing Edge Stop

Paper Size (FD) Detection Board

Paper Size

SW4 SW3 SW2 SW1

A3L, LedgerL ON — — — ON

11 × 14 — — — — ON

B4L, LegalL — — — — —

FLS — — — ON —

A4L — ON ON ON —

B5L, LetterL ON ON ON ON —

A4C, LetterC ON ON — — ON

B5C ON — — ON —

A5C, InvoiceC — — ON — —

Edge Guide

PWB-I

Paper Size (CD) Detection Sensor

M-6

4686M511AA

4686M511AA

S11

Page 10

FrameMaker Ver.5.5E(PC) PF-120 OPTION FOR Di152/Di183

01.08.27

6-6. Paper Separating Mecha nism

• A loop is formed in the paper between the Separator Fingers and the Paper Take-Up

Roller. The turning force of the P aper Take-Up Roller overcomes the block of the Separator Fingers, causing the top sheet of paper to ride over the fingers and be fed out of the

tray into the copier.

• When there are only two sheets of left in the tray and if the friction force of the Paper Lifting Plate is low, the bottom sheet of paper is taken up and fed into the copier with the top

sheet of paper. To prevent this situation from occurring, there is a Friction Plate provided

on top of the Paper Lifting Plate.

• Before the Paper Take-Up Roller contacts the paper, the Paper Take-Up Roll holds the

paper down so that the paper remains stationary before its being taken up by the Paper

Take-Up Roller.

Paper Take-Up Roller

Paper

Roll

Friction Plate

Separator Finger

4686M010AA

Paper Lifting Plate

M-7

Page 11

FrameMaker Ver.5.5E(PC) PF-120 OPTION FOR Di152/Di183

01.08.27

6-7. Paper Take-Up Control

• The operation of the Paper Take-Up Solenoid is controlled by the signal output from

PJ3A-1 and 2 of the Control Board.

✽

For the 2nd Tray

(A4 crosswise, two sheets)

Start Key ON

Main Motor M1

Paper Take-Up

Solenoid SL11

Synchronizing Roller

Sensor PC1

✽

For the 3rd Tray to 5th Tray

(A4 crosswise, two sheets)

Main Motor M1

Paper Take-Up

Solenoid SL11

Paper Take-Up

Sensor PC12

ON

OFF

ON

OFF

H

L

4686M512CA

Start Key ON

ON

OFF

ON

OFF

H

L

4686M513CA

M-8

Page 12

FrameMaker Ver.5.5E(PC) PF-120 OPTION FOR Di152/Di183

01.08.27

6-8. Paper Take-Up Retry Control

• To minimize the occurrence of paper misfeed, the Paper Take-Up Solenoid is energized a

second time to carry out a paper take-up retry sequence if a sheet of paper fails to reach

the Synchronizing Roller Sensor (for the 2nd Tray) or the Paper Take-Up Sensor (for the

3rd to 5th Tra y) within a giv en period of time after a paper tak e-up sequence has been initiated. This sequence is repeated a predetermined number of times.

✽

For the 2nd Tray

No. of Paper Take-Up

Retry Sequences

Paper Take-Up Retry 1

1st Paper Take-Up

Retry Sequence

Paper Take-Up

Solenoid SL11

Synchronizing

Roller Sensor PC1

✽

For the 3rd to 5th Tray

Paper Take-Up Retry 2

Paper Take-Up

Solenoid SL11

Paper Take-Up

Sensor PC12

ON

OFF

H

L

ON

OFF

H

L

Successful paper take-up

4686M514CA

No. of Paper Take-Up

Retry Sequences

1st Paper Take-Up

Retry Sequence

2nd Paper Take-Up

Retry Sequence

Successful paper take-up

4686M515CA

M-9

Page 13

FrameMaker Ver5.5E(PC) P F-120 OPTION FOR Di152/Di183

01.08.27

DIS/REASSEMBLY,

ADJUSTMENT

Page 14

FrameMaker Ver.5.5E(PC) PF-120 OPTION FOR Di152/Di183

01.08.27

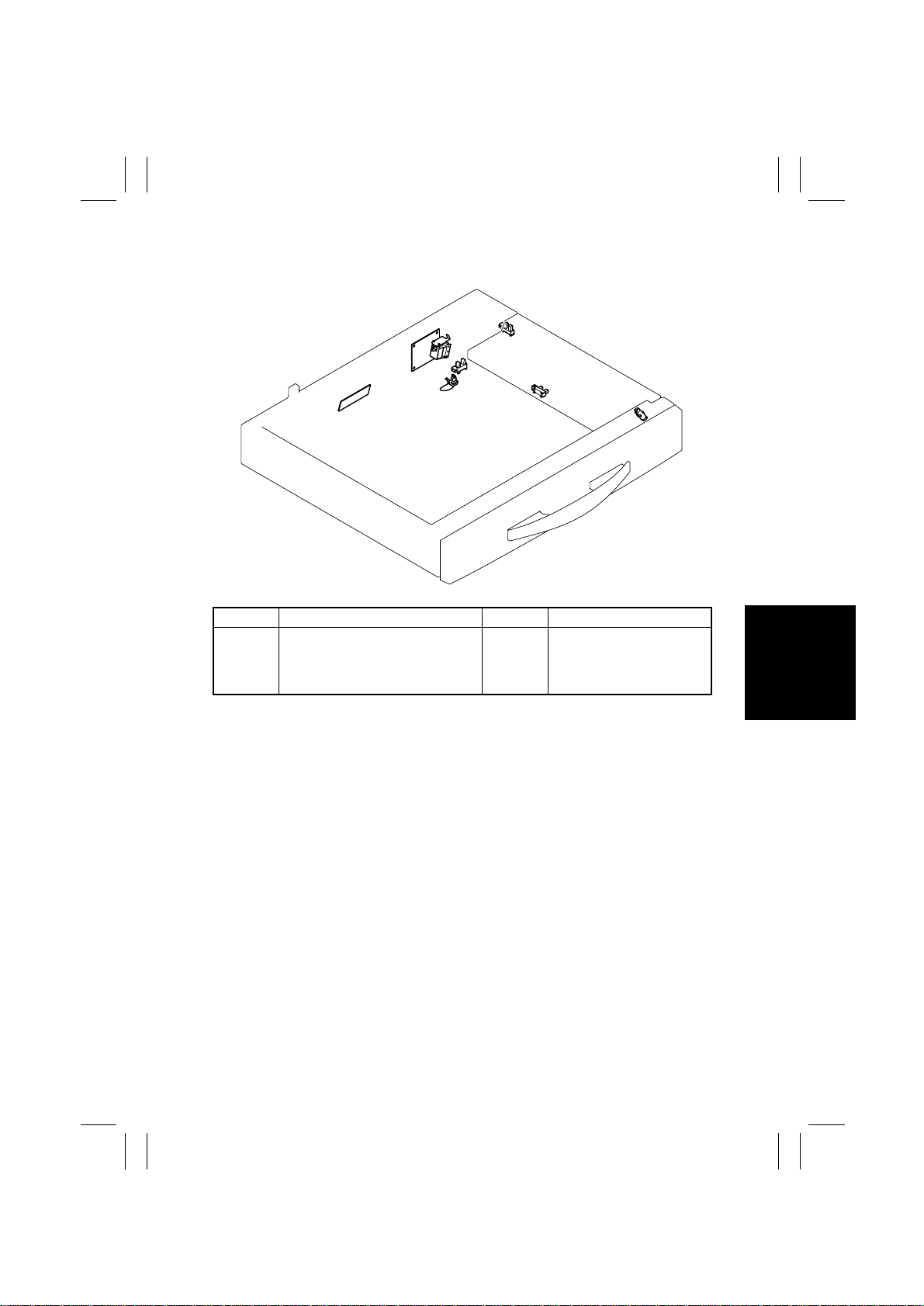

1. DISASSEMBLY

1-1. Maintenance Schedule

Maintenance

PM Parts

Paper Take-Up

Roller/Rolls

Vertical

Transport Rollers

Vertical

Transport Rolls

NOTE

• k=1,000 sheets

• The above maintenance schedule is to be based on the value of PM Counter.

(For how to show the PM Counter on the Display, see “SWITCHES ON PWBs, TECH.

REP. SETTINGS” of the Service Manual for the copier.)

• Cleaning should be performed when a paper take-up failure occurs for “ ❍” marked with

*1 and when a paper transport failure occurs for “ ❍” marked with *2.

• The parts should be replaced for each tray.

• See the Parts Manual and Parts Modification Notice for the part number.

• The above information is subject to change without notice.

Schedule Cycle

Clean Replace

*1

❍

❍

❍

150 k

*2

*2

Tools

Used for

Cleaning

Cloth,

——2☞ D-3

alcohol

——2☞ D-3

Parts No. QTY

4686-3311-XX 2

PM

Counter

2nd Tray

3rd Tray

4th Tray

5th Tray

Page

☞

D-2

D-1

Page 15

FrameMaker Ver.5.5E(PC) PF-120 OPTION FOR Di152/Di183

01.08.27

1-2. Removal of the Paper Take-Up Rollers

1. Remove two screws, two brackets, and the tray

immediately above the one for which the Paper

Take-Up Roller is to be replaced.

4686D003AA

2. Unlock the Paper Take-Up Roller and slide it off

its shaft.

4686D506AA

NOTE

• When installing the roll, make sure it securely locks

into place as illustrated.

lock point

4686D502AA

1-3. Cleaning of the Paper Take-Up Roller/Rolls

1. Remove the Paper Take-Up Roller/Rolls.

2. Wipe the surface of the Paper Take-Up Roller/

Rolls clean with a soft cloth dampened with alcohol.

4686D006AA

D-2

Page 16

FrameMaker Ver.5.5E(PC) PF-120 OPTION FOR Di152/Di183

01.08.27

1-4. Cleaning of the Vertical Transport Roller/Rolls

1. Open the Side Door.

2. Wipe the surface of the Vertical Transport Roller/

Rolls clean with a soft cloth dampened with alcohol.

4686D002AA

D-3

Page 17

FrameMaker Ver.5.5E(PC) PF-120 OPTION FOR Di152/Di183

01.08.27

2. ADJUSTMENT

2-1. Adjust Mode Setting Procedure

1. Press the Meter Count key.

2. Press the following keys in this order: Stop → 0 → 0 → Stop → 0 → 1.

3. Press the Stop key and then the Start key.

2-2. CD Registration Adjustment

Requirement:

A

4686D504AA

Adjustment Procedure

1. Set the copier into the Adjust mode.

2. With “AJ-” shown on the Display, enter the code number “12” from the 10-Key Pad.

3. Press the Paper key and select the tray.

4. Press the Start key to let the copier produce a test print.

5. Check that dimension A on the test print meets the specifications.

✽

Perf orm the following steps if dimension A falls outside the specified range.

Dimension A on the test print produced should meet

the following specifications.

✽

Specifications

A4C: 20 ± 2.0 mm

LetterC: 11.2 ± 2.0 mm

NOTE

• This adjustment should be made whenever the PH

has been replaced with a new one.

• Load the tray with A4C or LetterC paper.

6. Unload the paper stack from the tray. Loosen one

screw shown and adjust the position of the Edge

Guide in the rear.

4686U025AB

4686D505AA

Setting Procedure

• If dimension A on the test print is longer than the

specified range, move the Edge Guide to the rear.

• If dimension A on the test print is shorter than the

specified range, move the Edge Guide to the front.

7. Let the copier produce another test print and

check dimension A once again.

D-4

Page 18

FrameMaker Ver5.5E(PC) P F-120 OPTION FOR Di152/Di183

01.08.27

MISFEED DETECTION

Page 19

FrameMaker Ver.5.5E(PC) PF-120 OPTION FOR Di152/Di183

01.08.27

1. MISFEED DETECTION

1-1. Location of Misfeed Detecting Sensors

Synchronizing Roller Sensor

PC1

2nd Tray Paper Take-Up Sensor

PC12

T-1

3rd Tray Paper Take-Up Sensor

PC12

4th Tray Paper Take-Up Sensor

PC12

5th Tray Paper Take-Up Sensor

PC12

4686T512AA

Page 20

FrameMaker Ver.5.5E(PC) PF-120 OPTION FOR Di152/Di183

01.08.27

1-2. Misfeed Detection Timing

• The following lists the types of misfeed detection and detection timings for different misfeed locations.

• The symbol “L” (for the leading edge) and “T” (for the trailing edge) given in ( ) indicate

the particular edge of the paper detected by the sensor.

Type Detection Start Detection

Paper left

2nd Tra y paper tak e-up

failure

3rd Tray paper take-up

failure

4th Tray paper take-up

failure

5th Tray paper take-up

failure

Misfeed at 3rd Tray vertical

transport section

Misfeed at 4th Tray vertical

transport section

Misfeed at 5th Tray vertical

transport section

2nd Tray size error misfeed Synchronizing Roller Sensor (L)

3rd Tray size error misfeed

4th Tray size error misfeed

5th Tray size error misfeed

Power Switch ON

Misfeed reset

Paper Take-Up Solenoid of the

2nd Tray energized

Paper Take-Up Solenoid of the

3rd Tray energized

Paper Take-Up Solenoid of the

4th Tray energiz ed

Paper Take-Up Solenoid of the

5th Tray energiz ed

3rd Tray Paper Take-Up Sensor

(L)

4th Tray Paper Take-Up Sensor

(L)

5th Tray Paper Take-Up Sensor

(L)

3rd Tray Paper Take-Up Sensor

(L)

4th Tray Paper Take-Up Sensor

(L)

5th Tray Paper Take-Up Sensor

(L)

Paper Take-Up Sensor of

each tray activated

Synchronizing Roller

Sensor (L)

3rd Tray Paper Take-Up

Sensor (L)

4th Tray Paper Take-Up

Sensor (L)

5th Tray Paper Take-Up

Sensor (L)

Synchronizing Roller

Sensor (L)

3rd Tray Paper Take-Up

Sensor (L)

4th Tray Paper Take-Up

Sensor (L)

Synchronizing Roller

Sensor (T)

3rd Tray Paper Take-Up

Sensor (T)

4th Tray Paper Take-Up

Sensor (T)

5th Tray Paper Take-Up

Sensor (T)

T-2

Page 21

Page 22

Loading...

Loading...