Page 1

Service Manual

[General]

Di152/Di183

Page 2

INDEX (GENERAL)

GENERAL

MECHANICAL/ELECTRICAL

Page 3

GENERAL

14413

Page 4

CONTENTS

1. SPECIFICATION .............................................................................................G-1

2. PRECAUTIONS FOR INSTALLATION .................................... ........................G-5

2-1. Installation Site ........................................................................................G-5

2-2. Power Source ..........................................................................................G-5

2-3. Grounding ................................................................................................G-5

3. PRECAUTIONS FOR USE ....................... ........................... ........................... .G-6

3-1. To ensure that the copier is used in an optimum condition .....................G-6

3-2. Operating Environment ............................................................................G-6

3-3. Power Requirements ............................................................................... G- 6

3-4. Note ......................................................................................................... G-6

4. HANDLING OF CONSUMABLES ............................. ............... ........................G-7

5. OTHER PRECAUTIONS ................. ............................ ........................... .........G-8

6. SYSTEM OPTIONS .........................................................................................G-9

i

Page 5

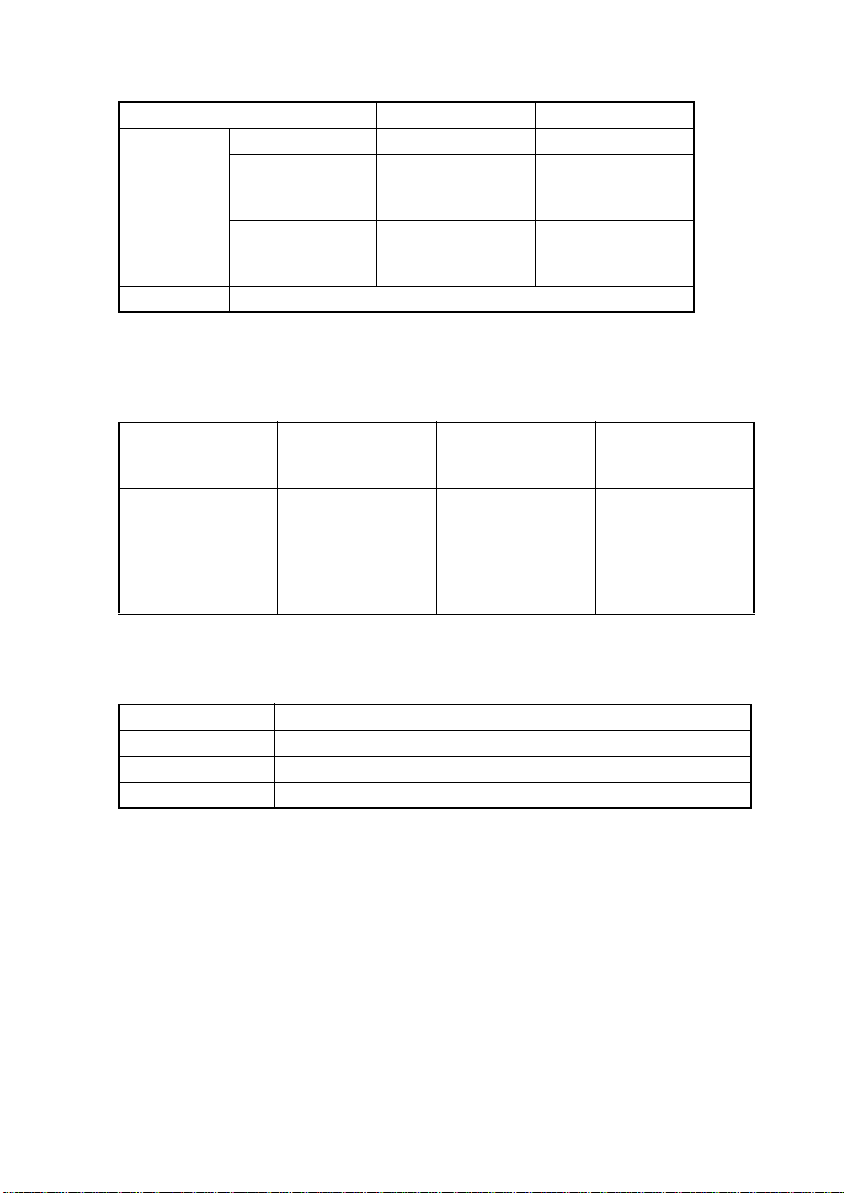

1. SPECIFICATION

TYPE

ORIGINAL SCANNING SYSTEM

PHOTOCONDUCTOR

COPYING SYSTEM

RESOLUTION

PAPER FEEDING SYSTEM

EXPOSURE SYS TEM

DEVELOPING SYSTEM

CHARGING SYSTEM

IMAGE TRANSFER SYSTEM

PAPER SEPARATING SYSTEM

FUSING SYSTEM

PAPER DISCHARGING SYSTEM

MAX. ORIGINAL SIZE

COPY MEDIUM

Paper Source Drawer Manual Bypass

Plain Paper (60 to 90 g/m

Transparencies

Type

Dimensions

MULTIPLE COPIES

WARMING-UP TIME

FIRST COPY TIME

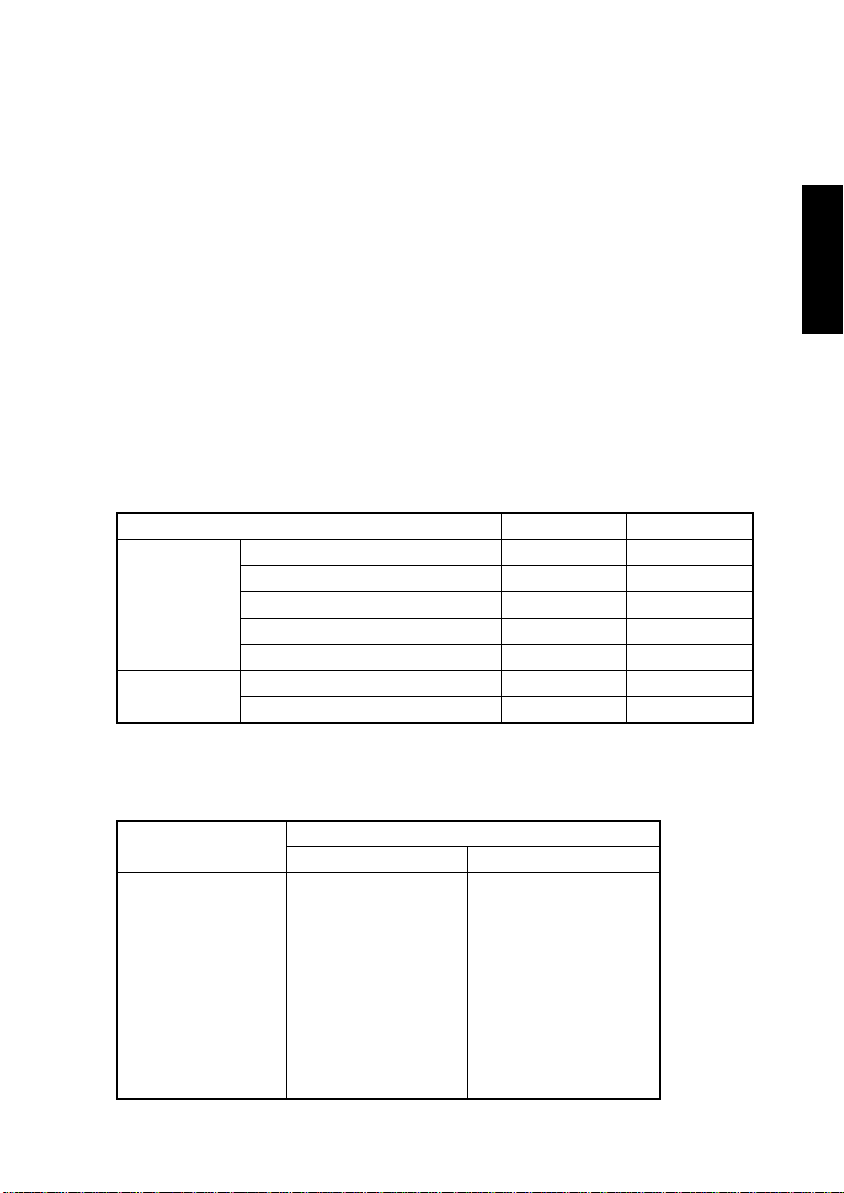

CONTINUOUS COPY SPEED (copies/min)

Size

A4C

A4L

A3L

B4L

B5C

B5L

8-1/2 × 11C

8-1/2 × 11L

11 × 17L

8-1/2 × 14L

11 × 14

Thick Paper (91 to 157 g/m

Recycled Paper (60 to 90 g/m

Maximum (Width × Length) 297 × 432 mm 297 × 432 mm

Minimum (Width × Length) 90 × 140 mm 90 × 140 mm

:

Console/Desktop Type

:

CCD Line Sensor

:

Organic Photoconductor

:

Electrostatic Dry Powdered Image T r ansfer to Plain

Paper with a Laser

:

600 × 600 dpi

:

2-way system

Manual Bypass...Single

Drawer................250 Sheets

:

Mirror Scanning

:

MT-HG System

:

Comb Electrode (1) DC Negative Corona with

Scorotron System

:

Roller Image Transfer

:

Paper Separator Fingers and Charge Neutralizing

Plate

:

Heat Roller

:

Charge Neutralizing Brush

:

A3L, 11 × 17

Postcards

:

1 to 99

:

30 sec. or less (23, Rated Voltage)

:

7 sec. or less (A4C, Drawer, full size mode)

Di152 Di183

15

12

9

10

16

13

15

12

9

10

10

2

)

2

)

2

)

Speed

❍❍

❍❍

❍❍

❍❍

❍❍

18

14

10

12

20

15

18

14

10

12

12

G-1

Page 6

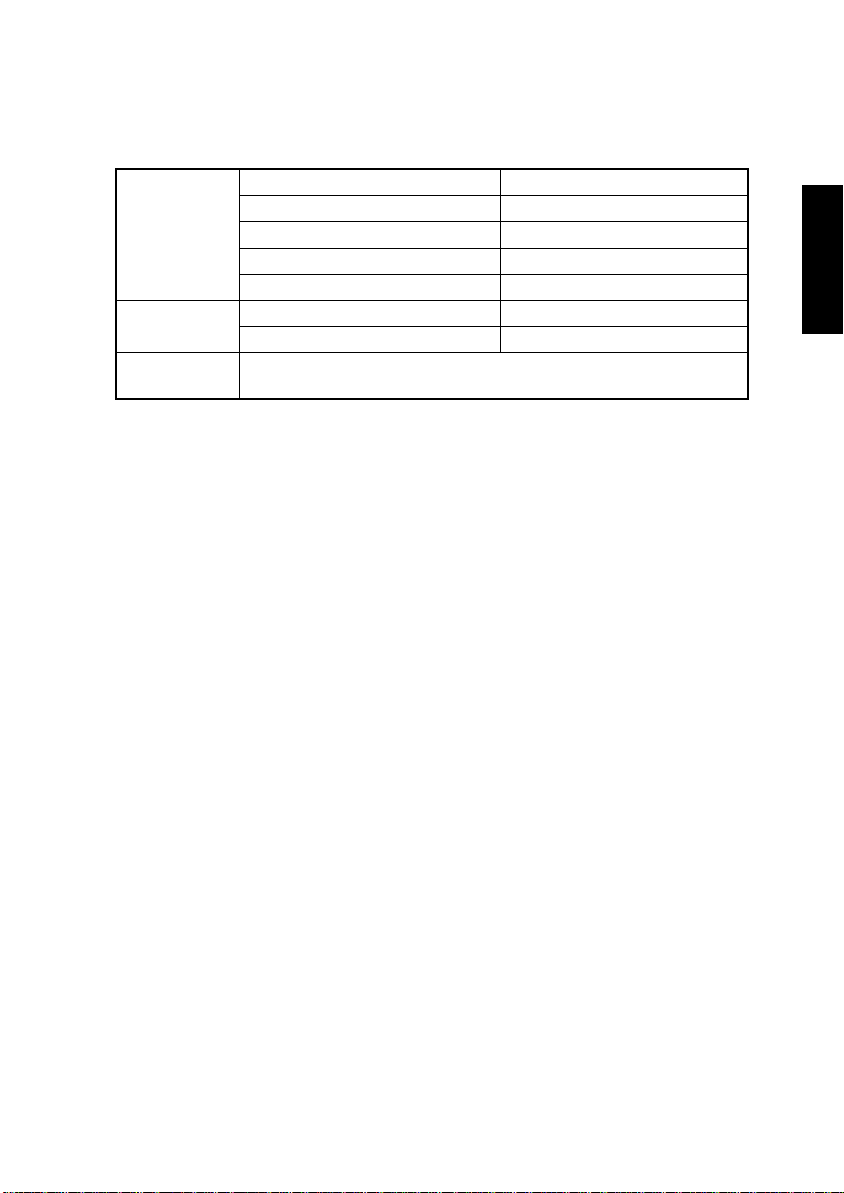

ZOOM RATIOS

Metric Inch

Full Size 100 % 100 %

200 %

Fixed

Enlargement

Reduction

Variable 50 % to 200 % (in 1 % increments)

141 %

115 %

81 %

70 %

50 %

200 %

129 %

121 %

78 %

64 %

50 %

LENS

EXPOSURE LAMP

POWER/CURRENT CONSUMPTION (copier only)

Exposure Lamp

(Rating)

24 V

14.4 W

POWER REQUIREMENTS : 110 V, 120 V, 127 V, 220 V to 240 V, 50/60 Hz

ENVIRONMENTAL CONDITIONS

Temperature 10 to 30 °C with a fluctuation of 10 °C or less per hour

Humidity 15 to 85 % RH with a fluctuation of 10 % RH or less per hour

Ambient Illumination 3,000 lux or less

Levelness 1° (1.75 mm/100 mm)

COPIER DIMENSION

COPIER WEIGHT

Fusing Roller

Heater Lamp

::Through Lens

Fluorescent Lamp

(Rating)

900 W

::W ...590 mm (23-1/4)

D....611 mm (24)

H....487 mm (19-1/4)

39 kg (86 lb)

Max. Power

Consumption

(full system)

110 V: 970 W

120 V: 1090 W

127 V: 1180 W

220 V: 990 W

230 V: 1050 W

240 V: 1120 W

Max. Current

Consumption

(full system)

110 V: 8.9 A

120 V: 9.1 A

127 V: 9.3 A

220 V: 4.5 A

230 V: 4.6 A

240 V: 4.7 A

G-2

Page 7

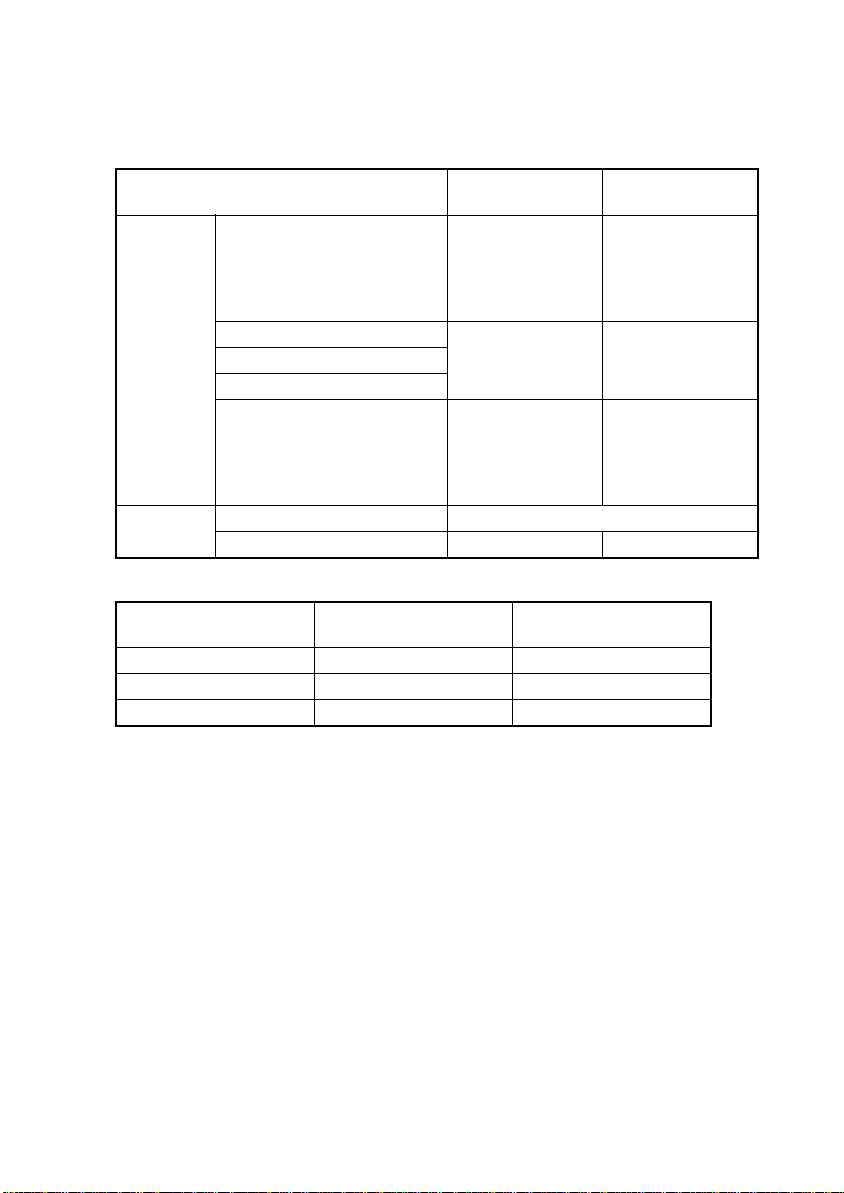

Multiple Bypass (MB-5): option

TYPE

INSTALLATION

COPY PAPER TYPE

Plain Paper (60 to 90 g/m

Transparencies 20 sheets

Type

Thick Paper (91 to 157 g/m

Recycled Paper (60 to 90 g/m

Dimensions

Size

Maximum (Width × Length) 297 × 432 mm

Minimum (Width × Length) 90 × 140 mm

A3L, B4L, FLS, A4L, A4C, B5L, B5C, A5C ,11 × 17, 11 × 14, 8-1/2 × 14,

8-1/2 × 11L, 8-1/2 × 11C, 8-1/2 × 5-1/2

DOCUMENT ALIGNMENT

CAPACITY

POWER REQUIREMENTS

MAX. POWER CONSUMPTION

DIMENSIONS

WEIGHT

OPERATING ENVIRONMENT

::Multiple Bypass

Mounted on the copier

2

)

2

)

50 sheets

20 sheets

Postcards 20 sheets

2

)

Center

:

:

50 sheets (80 g/m

:

DC24 V, DC5 V (supplied from copier)

:

9 W or less

:

W...245 mm (9-3/4)

2

)

50 sheets

D....435 mm (17-1/4)

H....137 mm (5-1/2)

:

2.7 kg (6 lb)

:

Same as copier

G-3

Page 8

Job Tray (JS-202): option

TYPE

INSTALLATION

::Multiple Bypass

Mounted on the copier

CAPACITY

Exit Tray

of the machine

1Stacking height up

Plain Paper (60 to 90 g/m

150 sheets (A4C/L)

2

75 sheets

)

(except A4C/L)

to 22 mm

100 sheets (A4C/L)

50 sheets

(except A4C/L)

Transparencies

Type

Thick Paper (91 to 157 g/m

2

)

20 sheets 10 sheets

Postcards

Stacking height up to

Recycled Paper (60 to 90 g/m

150 sheets (A4C/L)

2

75 sheets

)

(except A4C/L)

22 mm

100 sheets (A4C/L)

50 sheets

(except A4C/L)

Dimensions

Maximum (Width × Length) 297 × 432 mm

Minimum (Width × Length) 90 × 140 mm 140 × 140 mm

Exit Tray by Application Mode

Application Mode

Exit Tray

of the machine

Job Tray

Fax and Copier Copier Fax

Printer and Copier Copier Printer

Fax, Copier and Printer Copier Fax and Printer

Job Tray

POWER REQUIREMENTS : DC24 V, DC5 V (supplied from copier)

Shifting Unit (OT-103): option

TYPE

INSTALLATION

POWER REQUIREMENTS

:

Multiple Bypass

:

Mounted on the copier

:

DC24 V, DC5 V (supplied from copier)

G-4

Page 9

2. PRECAUTIONS FOR INSTALLATION

2-1. Installation Site

To ensure safety and utmost performance of the copier, the copier should NOT be used in a

place:

• Where it will be subjected to extremely high or low temperature or humidity.

• Where it will be subjected to sudden fluctuations in either temperature or humidity.

• Which is exposed to direct sunlight.

• Which is in the direct air stream of an air conditioner, heater, or ventilator.

• Which has poor ventilation or is dusty.

• Which does not have a stable, level floor or where it will receive undue vibration.

• Which is near any kind of heating device.

• Which is near volatile flammables (thinner, gasoline, etc.).

• Where it may be splashed with water.

• Which puts the operator in the direct stream of exhaust from the copier.

• Where ammonia gas might be generated.

2-2. Power Source

• If any other electrical equipment is sourced from the same power outlet, make sure that

the capacity of the outlet is not exceeded.

• Use a power source with little voltage fluctuation.

• Never connect by means of a multiple socket any other appliances or machines to the

outlet being used for the copier.

• Ensure that the copier does not ride on the power cord or communication cable of other

electrical equipment, and that it does not become wedged into or underneath the mechanism.

• Make the following checks at frequent intervals:

✽

Is the power plug abnormally hot?

✽

Are there any cracks or scrapes in the cord?

✽

Has the power plug been inserted fully into the outlet?

✽

Does something, including the copier itself, ride on the power cord?

Use an outlet with a capacity of 110 to 127 V, 15 A or more. 220 to 240 V, 10 A or more.

2-3. Grounding

• Always ground the copier to prevent receiving electrical shocks in the case of electrical

leakage.

• Connect the ground wire to the ground terminal of the outlet or a grounding contact which

complies with the local electrical standards.

• Never connect the ground wire to a gas pipe, the ground wire for a telephone, lightning

arrester, or a water pipe for fear of fire and electrical shock.

G-5

Page 10

3. PRECAUTIONS FOR USE

3-1. To ensure that the copier is used in an optimum condition

• Never place a heavy object on the copier or subject the copier to shocks.

• Insert the power plug all the way into the outlet.

• Do not attempt to remove any panel or cover which is secured while the copier is making

copies.

• Do not turn OFF the copier while it is making copies.

• Provide good ventilation when making a large number of copies continuously.

• Never use flammable sprays near the copier.

• If the copier becomes inordinately hot or produces abnormal noise, turn it OFF and

unplug it.

• Do not turn ON the power switch at the same time when you plug the power cord into the

outlet.

• When unplugging the power cord, do not pull on the cord; hold the plug and pull it out.

• Do not bring any magnetized object near the copier.

• Do not place a vase or vessel containing water on the copier.

• Be sure to turn OFF the power switch at the end of the workday or upon power failure.

• Use care not to drop paper clips, staples, or other small pieces of metal into the copier.

3-2. Operating Environment

The operating environmental requirements of the copier are as follows.

• Temperature: 10 to 30 °C

• Humidity: 15 to 85 % RH

• Rate of temperature change: 10 °C/h

• Rate of humidity change: 10 % RH/h

3-3. Power Requirements

The power source voltage requirements are as follows.

• Voltage fluctuation: AC110 to 127 V/220 to 240 V ± 10 %

(copying performance assured)

• Frequency fluctuation: 50/60 Hz ± 0.3 %

+10 %/-15 % (paper feeding performance assured)

3-4. Note

• It is prohibited to copy paper and hard currencies, government securities, and municipal

bonds (even when they are stamped as “Sample”).

• For fear of infringement of copyright, it is also prohibited to copy copyrighted works,

including books, music, works of art, maps, drawings, motion pictures, and photos except

when the copy is to be used only personally.

G-6

Page 11

4. HANDLING OF CONSUMABLES

Before using any consumables, always read the label on its container carefully.

• Paper can be easily damaged by dampness. To prevent absorption of moisture, store

paper, which has been removed from its wrapper but not loaded in the drawer, in a

sealed plastic bag in a cool, dark place.

• Keep consumables out of the reach of children.

• Do not touch the PC Drum with bare hands.

• The same sized paper is of two kinds, short grain and long grain. Short grain paper

should only be fed through the copier crosswise, long grain paper should only be fed

lengthwise.

• If your hands become soiled with toner, wash them with soap and water.

• Do not throw away any used consumables (PC Drum, starter, toner, etc.). They are to be

collected.

• Do not burn, bury in the ground, or throw into the water any consumables (PC Drum,

starter, toner, etc.).

• Do not store consumables in a place which:

✽

Is hot and humid.

✽

Is subject to direct sunlight.

✽

Has an open flame nearby.

G-7

Page 12

5. OTHER PRECAUTIONS

Use the following precautions when performing service jobs for a copier that uses a laser.

• When a service job needs to be performed in the laser beam path, such as when working

around the printerhead or PC Drum, be sure first to unplug the power cord of the copier

from the outlet.

• If the job requires that the power cord be left plugged in, observe the following precautions.

1. Take off your watch, ring and any other reflective object and wear laser protective gog-

gles.

2. Keep users away from the job site.

3. Do not bring a highly reflective tool into the laser beam path during the service job.

G-8

Page 13

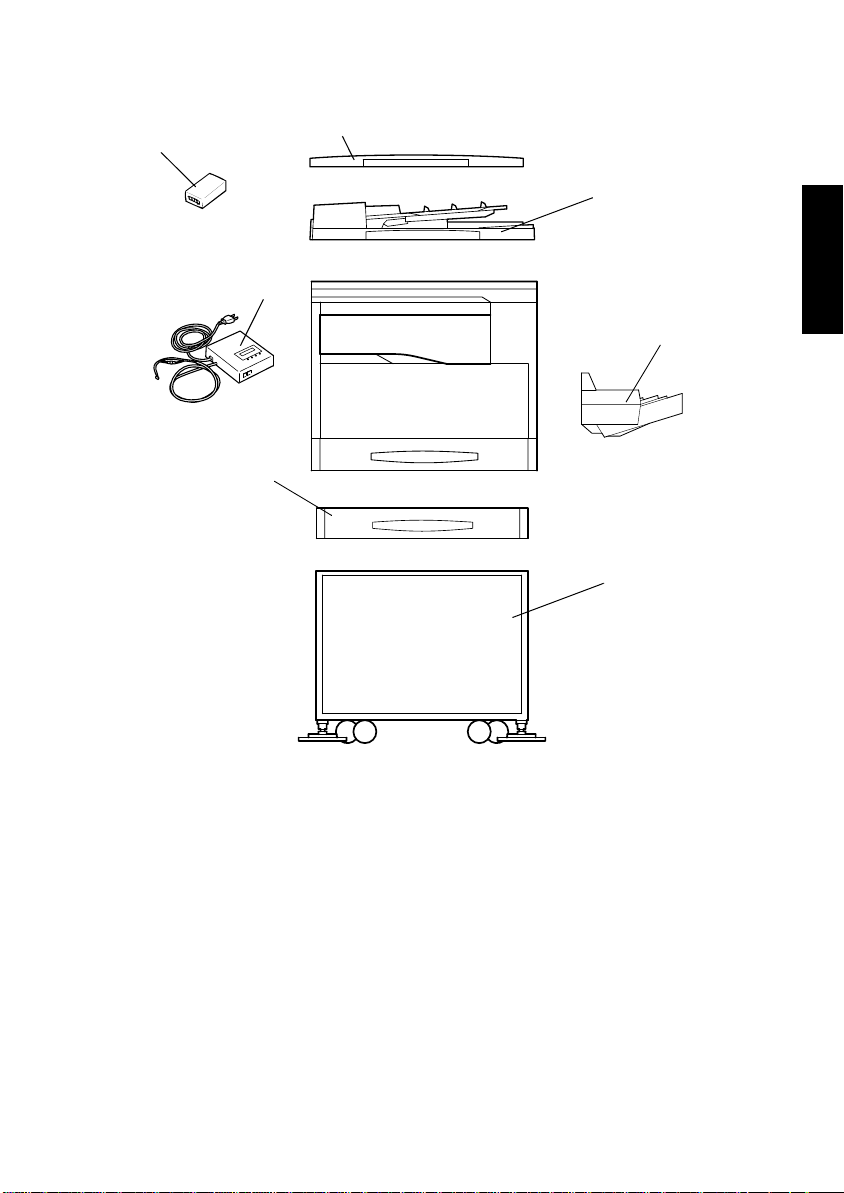

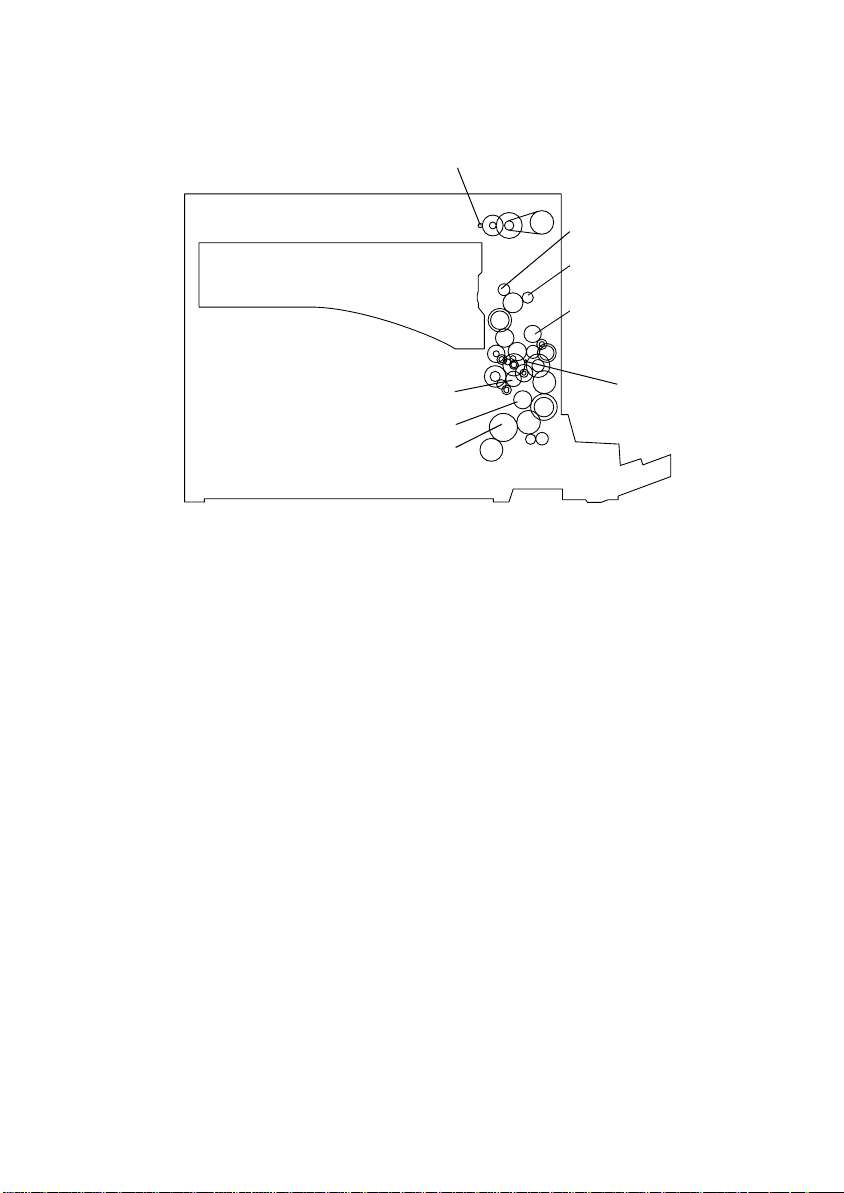

6. SYSTEM OPTIONS

1

2

4021O009AA

3

1144M172AC

4021O010AA

7

4

4695U011AA

4021O013AB

6

4021O063AA

4021O012AA

5

1. Plug-In Counter

2. Original Cover OC-5

3. Automatic Document Feeder AF-10

4. Multiple Bypass MB-5

5. Copy Desk

6. Paper Feed Cabinet PF-120

7. Data Terminal DT- 201

8. Job Tray JS-202

(Illustration none)

4021O014AA

9. Sifting Unit OT-103

(Illustration none)

10. Memory M16-4, M32-3

(Illustration none)

11. Mechanical Counter CNT1

(Illustration none)

G-9

Page 14

MECHANICAL/

ELECTRICAL

14413

Page 15

CONTENTS

1. CROSS SECTIONAL VIEW ............................................................................M-1

2. COPY PROCESS ............................................................................................M-2

3. DRIVE SYSTEM ..............................................................................................M-4

4. SEQUENTIAL EXPLANATION ................. ........................... ............................M-5

5. WATCHDOG FUNCTION (CPU OVERRUN MONITOR) ................................M-6

5-1. Watchdog Function Post-Processing . ......................................................M-6

6. IMAGE STABILIZATION SYSTEM ..................................................................M-7

7. IMAGING UNIT (I/U) ........................................................................................M-8

7-1. Imaging Unit (IU) Drive Mechanism .........................................................M-9

8. PC DRUM SECTION .......................................................................................M-10

8-1. PC Drum Drive Mechanism ..................................................................... M-10

8-2. Grounding of the PC Drum ................. .... .... .. .... ......... .... .. .... ......... .... .... .. .M-11

9. PC DRUM CHARGING SECTION ...................................................................M-12

10. IMAGE READING SECTION ...........................................................................M-13

10-1.Image Processi ng Pr o cess ............. ....................................... ..................M-14

10-2.Exposure Components Section ...............................................................M-15

10-3.Scanner and Mirrors Carriage Movement Mechanism ............................ M-16

(1) Scanner Movement Mechanism ......................................................M-16

(2) 2nd/3rd Mirrors Carriage Movement Mechanism ............................M-16

10-4.Scanner Motor Drive Control ...................................................................M-17

11. MEMORY STORAGE IMAGE PROCESSING SYST EM .................................M-18

11-1.Laser Exposure Process .........................................................................M-19

12. DEVELOPING UNIT SECTION .............................. ............................ .............M-20

12-1.Developing Unit Drive Mechanism ..........................................................M-21

12-2.Sleeve/Magnet Roller ..............................................................................M-22

12-3.Developing Bi a s ..................... ........................................ ..........................M-22

12-4.ATDC Sensor ................................... ........................... ............... .............M-23

(1) ATDC Sensor Automatic Adjustment ..............................................M-23

12-5.Toner Replenishing Mechanism ..............................................................M-24

12-6.Toner Replenishing Control .....................................................................M-25

12-7.T/C Recovery Mode .................................................................................M-26

12-8.Toner Bottle Home Position Detection Mechanism .................................M-27

13. PAPER TAKE UP/FEED SECTION .................................................................M-28

13-1.Drawer In Position Detection ...................................................................M-29

13-2.Paper Empty Detection Mechanism ........................................................M-29

13-3.Paper Lifting Plate ...................................................................................M-30

13-4.Universal Tray Paper Size Detection Mechanism ...................................M-30

13-5.Paper Take Up Mechanism .....................................................................M-32

(1) Paper Separating Mechanism ......................................................... M-32

13-6.Paper Take Up Control ............................................................................M-33

(1) Paper Take Up Retry Control ..........................................................M-33

14. MANUAL BYPASS SECTION .........................................................................M-34

14-1.Paper Take Up Drive Mechanism ............................................................M-34

14-2.Paper Detection Mechanism ...................................................................M-34

14-3.Manual Feed Take Up Control ........................................................... .... .M-35

15. MULTIPLE BYPASS SECTION .......................................................................M-36

i

Page 16

15-1.Paper Take Up Drive Mechanism ............................................................M-36

15-2.Paper Take-Up Mechanism .....................................................................M-37

15-3.Paper Empty Detection Mechanism ........................................................M-38

15-4.Paper Take Up Control ............................................................................M-38

15-5.Paper Take Up Retry Control ..................................................................M-39

16. IMAGE TRANSFER AND PAPER SEPARATION SECTION ..........................M-40

17. PC DRUM CLEANING SECTION ....................................................................M-41

18. MAIN ERASE SECTION .................................................................................. M-42

19. FUSING UNIT SECTION .................................................................................M-43

19-1.Fusing Unit Drive Mechanism ..................................................................M-44

19-2.Fusing Rollers Pressure Mechanism .......................................................M-44

19-3.Fusing Temperature Control ....................................................................M-45

19-4.CPM Control ............................................................................................M-45

20. JOB TRAY (JS-202): Option ............................................................................M-46

20-1.Tray Selecting Mechanism ......................................................................M-47

20-2.Tray-Full Detecting Mechanism ...............................................................M-48

20-3.Job Tray Paper Detecting Mechanism ....................................................M-48

21. SHIFTING UNIT (OT-103): Option ..................................................................M-49

21-1.Exit Position Shifting Mechanism ............................................................M-50

22. OTHER MECHANISM ................................ ........................... ..........................M-52

22-1.Cooling Mechanism . . ...............................................................................M-52

(1) Power Supply Section Cooling Mechanism .....................................M-52

(2) Fusing Section Cooling Mechanism ................................................M-53

ii

Page 17

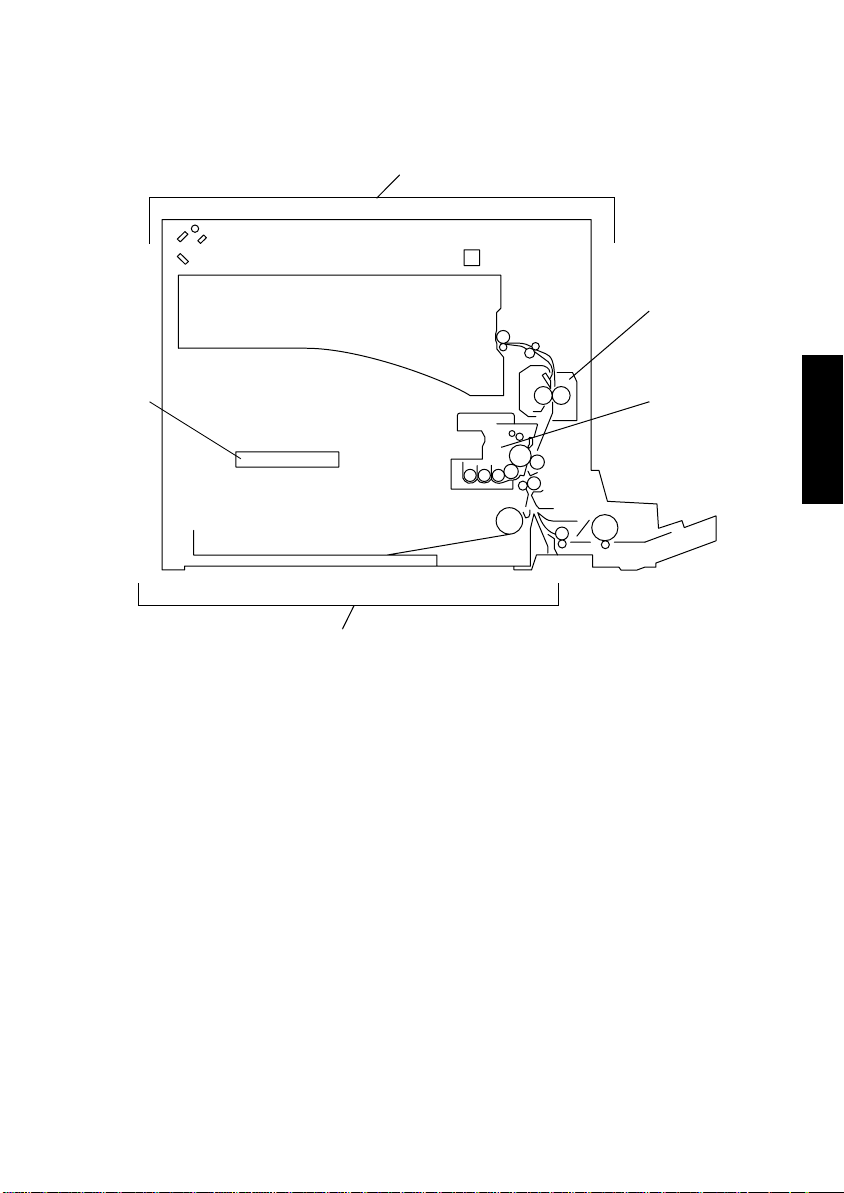

1. CROSS SECTIONAL VIEW

1

2

5

1. IR Section

2. Fusing Unit

3. Imaging Unit

3

4

4. Paper Take-Up/Feed Section

5. PH Section

4021M001AA

M-1

Page 18

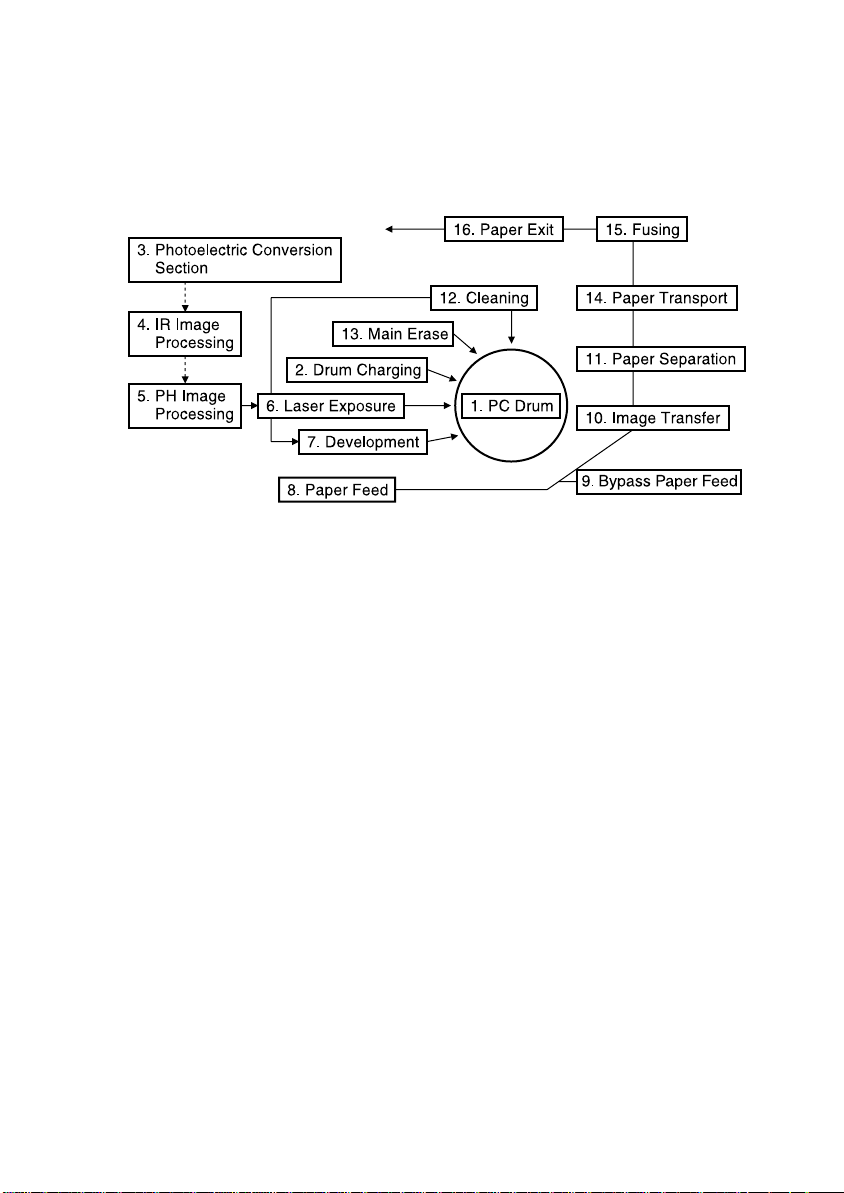

2. COPY PROCESS

4021M065CB

1. PC Drum

• Used as the medium on which a visible developed image of the original is formed.

2. Drum Charging

• A uniform negative DC charge is deposited across the entire surface of the PC Drum.

3. Photoelectric Conversion

• CCD converts the image data represented by light reflected off the original to a corresponding electrical signal which, in turn, is output to IR image-processing section.

4. IR Image-Processing

• The electrical signal is converted to an 8-bit digital image signal (A/D conversion) which,

in turn, goes through appropriate correction before being output to the PH Image Processing.

5. PH Image Processing

• After going through corrections, the digital image signal is converted to a corresponding

electrical signal (D/A conversion) that controls the intensity of the light from the laser

diode.

6. Laser Exposure

• The laser beam strikes the surface of the PC Drum, forming an electrostatic latent image.

7. Developing

• Toner negatively charged in the Developer Mixing Chamber is attracted onto the electrostatic latent image changing it to a visible, developed image.

• An AC/DC negative bias voltage is applied to the Sleeve/Magnet Roller to prevent toner

from being attracted onto those areas of the PC Drum which correspond to the background areas of the original.

8. Paper Feed

• Paper is fed from the drawer.

M-2

Page 19

9. Bypass Paper Feed

• Feeds paper from the Manual Bypass Tray, one piece at a time.

• The optional Multiple Bypass T ray (MB-5), when mounted on the machine, permits continuous paper feeding.

10. Image Transfer

• A DC positive charge is applied to the Image Transfer Roller to transfer the visible image

on the surface of the PC Drum onto the paper.Paper Separation.

11. Paper Separation

• The PC Drum Paper Separator Fingers remove paper from the surfa ce of the PC Drum.

• The Charge Neutralizing Plate neutralizes any charge left on the paper.

12. Cleaning

• Residual toner on the surface of the PC Drum is scraped off.

• The toner is then recycled back to the Developing Unit.

13. Main Erase

• Light is directed to the surface of the PC Drum to neutralize any surface potential remaining there after cleaning.

14. Paper Transport

• The paper is fed to the Fusing Unit.

15.Fusing

• The developed image is permanently fused to the paper by a combination of heat and

pressure applied by the Right and Left Fusing Rollers.

16. Paper Exit

• The paper is fed out onto the Exit Tray.

• When the optional Job Tray (JS-202) is mounted, the specific tray into which paper is f ed

is selected according to the application mode.

• The optional Shifting Unit (OT-103), when mounted, permits different finishing functions

set on the machine (Non-Sort, and Sort) .

M-3

Page 20

3. DRIVE SYSTEM

1

Paper Exit Roller Gear

Transport Roller Gear

Fusing Roller Gear

1. Scanner Motor M5

2. Main Motor M1

PC Drum

Synchronizing Roller Clutch

Paper Take-Up Roller Gear

2

4021M003AA

M-4

Page 21

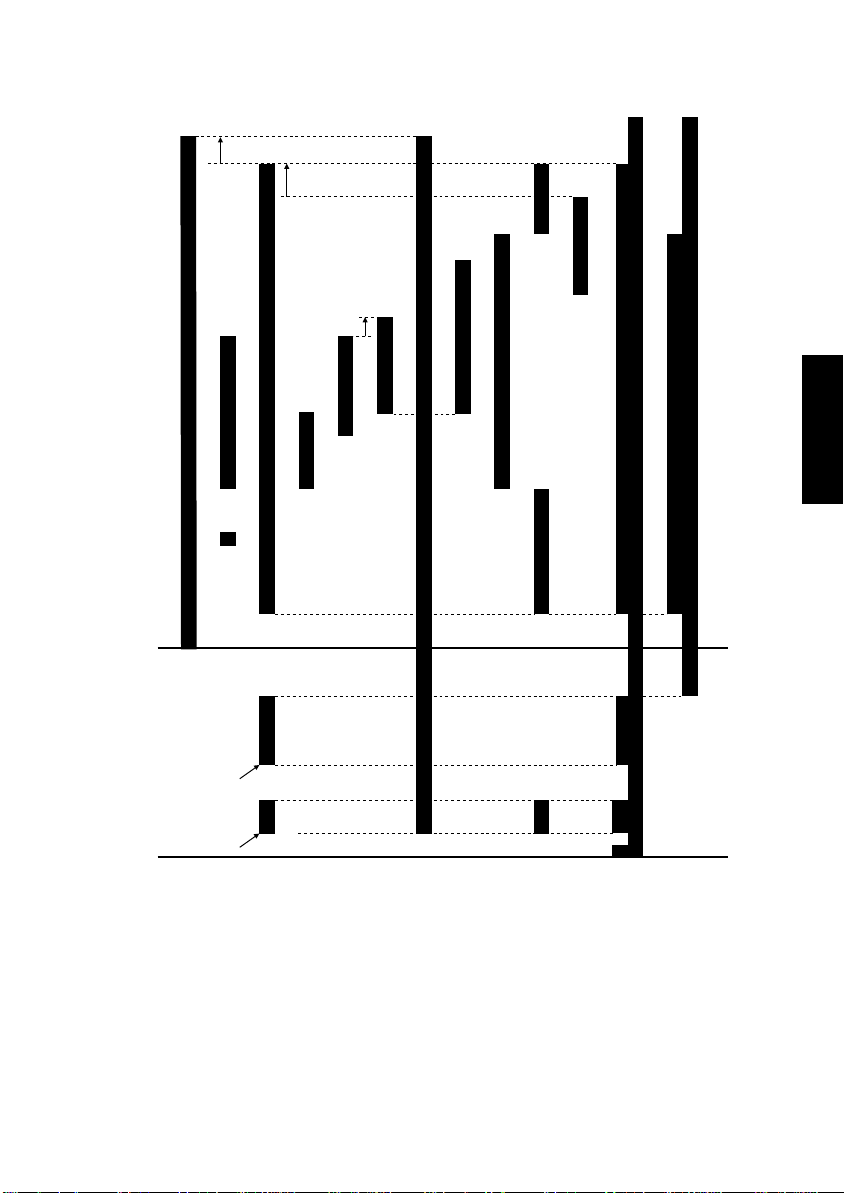

4. SEQUENTIAL EXPLANATION

4021M510CA

Power Switch ON Start Key ON

Polygon Motor M2

Predrive

150 ˚C Warm-up completed

Exposure Lamp LA2

Main Motor M1

Paper Take-Up Solenoid SL1

Synchronizing Roller Sensor PC1

Synchronizing Roller Clutch CL1

Developing Bias (VB) DC

Developing Bias (VB) AC

Image Transfer Bias (+)

Image Transfer Bias (–)

Exit Paper Sensor PC3

M-5

Full speed

Full speed

Speed reduction

Speed reduction

Power Supply Cooling

Fan Motor M4

Fusing Cooling Fan

Motor M3

Page 22

5. WATCHDOG FUNCTION (CPU OVERRUN MONITOR)

• The watchdog function, or CPU overrun monitor function, monitors whether any of the

CPUs mounted in the copier overruns.

• If the function detects that a CPU overruns, the copier automatically resets the CPU,

thereby restarting the logic circuit and mechanism.

5-1. Watchdog Function Post-Processing

The following processing is performed if a faulty condition is detected in the CPU.

When the copier CPU is found faulty:

• All CPUs are reset and the system is restarted.

• If the CPU is found faulty during a copy cycle, the system attempts to feed all sheets of

paper out of the copier before restarting. (If paper is left inside the copier, the copier

detects it as a misfeed as it is restarted.)

M-6

Page 23

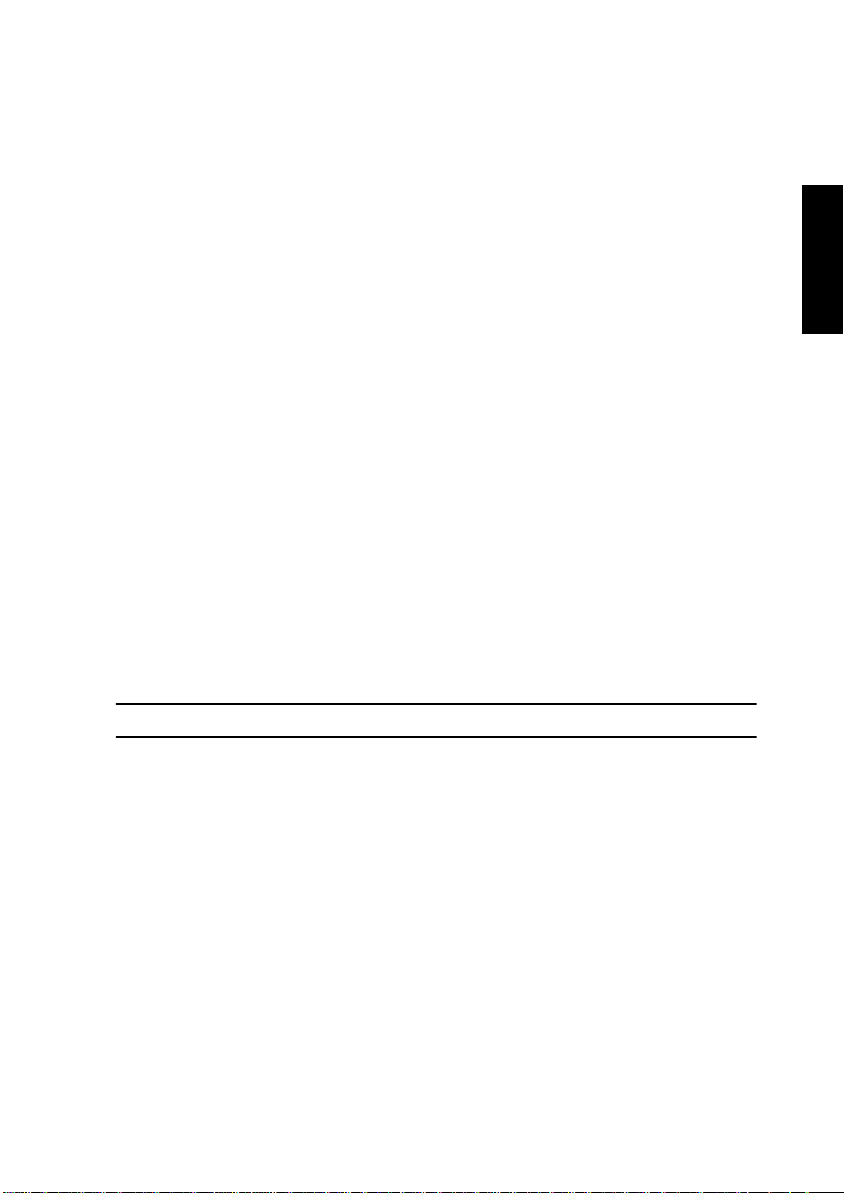

6. IMAGE STABILIZATION SYSTEM

The following image stabilization controls are provided to ensure stabilized copy image.

Purpose Means Control

The Vg/Vb control voltage is varied to bring

Vg/Vb to an appropriate level according to

the following settings.

To stabilize image density. Vg/Vb control

To stabilize image transfer.

Image transfer

output control

• Tech. Rep. Choice: ID Adjustment

• Tech. Rep. Choice: VG Adjustment

• User's Choice: Print Density

• IU Life Counter

• Paper type

The image transfer output is varied to bring

the image transfer current to an appropriate

level according to the following conditions.

• Paper type

• Paper width

• B/W ratio of image

M-7

4021M066CA

Page 24

7. IMAGING UNIT (I/U)

• The IU integrates the PC Drum, Developing Unit, PC Drum Charge Corona, and the PC

Drum Cleaning Mechanism, all in one body.

PC Drum

PC Drum Cleaning Mechanism

4021M006AB

PC Drum Charge Corona

Developing Unit

4021M007AB

M-8

Page 25

7-1. Imaging Unit (IU) Drive Mechanism

• The IU is driven by the Main Motor.

Main Motor M1

4021M008AB

Elevtrical Component Control Signal

M1

PWB-A PJ7A-5 L L H

PWB-A PJ7A-7 H L H

Forward

Rotation

M-9

Backward

Rotation

OFF Wiring Diagram

17-G

Page 26

8. PC DRUM SECTION

• The PC Drum consists of layers of semiconductive materials placed on an aluminum

alloy base, on which an electrostatic latent image is formed.

PC Drum

(PC Drum Cross-Section)

Charge Transport Layer

Charge Generation Layer

1167M007AA

8-1. PC Drum Drive Mechanism

• The PC Drum is rotated by drive from a motor.

PC Drum

Aluminum Base

1139M007AA

Main Motor M1

Elevtrical Component Control Signal

M1

PWB-A PJ7A- 5 L H

PWB-A PJ7A- 7 H H

Forward

Rotation

M-10

4021M009AA

OFF Wiring Diagram

17-G

Page 27

8-2. Grounding of the PC Drum

• The potential on the surface of the PC Drum exposed to the light is grounded to the

frame.

PC Drum

Frame

Ground Plate

4021M010AA

M-11

Page 28

9. PC DRUM CHARGING SECTION

• The PC Drum Charge Corona has a scorotron grid to deposit a charge evenly across the

surface of the PC Drum.

• The corona unit has a comb electrode that discharges only toward the grid mesh, thus

minimizing the amount of ozone produced.

Comb Electrobe

Grid Mesh

Elevtrical Component Control Signal ON OFF Wiring Diagram

HV1 PWB-A PJ8A-8 L H 5-C

4021M011AA

M-12

Page 29

10. IMAGE READING SECTION

6

5

1. Scanner /Motor M5

2. CCD Board PWB-J

3. Size Reset Switch S10

1

4. Scanner

5. 2nd/3rd Mirrors Carriage

6. Scanner Home Position Sensor PC6

2

3

4

4021M012AB

M-13

Page 30

10-1. Image Processing Process

1. Photoelectric Conversion

• Light reflected off the original is read by the CCD Sensor which converts the data to a

corresponding analog signal.

2. Analog-to-Digital Conversion

• The analog signal output from the CCD Sensor is converted to a corresponding 8-bit digital signal.

3. Shading Correction

• An error is corrected that occurs due to variations in sensitivity of each CCD chip and the

light distribution varying along the length of the Exposure Lamp.

• The data obtained through actually illuminating the shading sheet with the Exposure

Lamp is compared with the shading sheet reading reference value (white = max. data

value) to make the necessary correction.

4. Zoom Processing

• The synchronous timing of the input data (read) and output data (read) is varied to

decrease (reduction) or increase (enlargement) the number of data readings, thereby

reducing or enlarging the image in the main scanning direction.

5. Data is sent to the PH.

M-14

Page 31

10-2. Exposure Components Section

1

2

4021M013AA

3

1. Auxiliary Reflector

When a book or other bound original is copied, the paper in the area near the binding

generally fails to come flush against the glass, so that the copy of these areas is generally too dark. The Auxiliary Reflector reduces this problem by reflecting light from the

Exposure Lamp onto these areas of the original.

2. Exposure Lamp LA2

A fluorescent lamp is used to illuminate the original.

3. 1st Mirror

Directs the light reflected off the original to the 2nd Mirror.

M-15

Page 32

10-3. Scanner and Mirrors Carriage Movement Mechanism

(1) Scanner Movement Mechanism

• The Scanner is driven by the Scanner Motor.

(2) 2nd/3rd Mirrors Carriage Movement Mechanism

• The 2nd/3rd Mirrors Carriage moves at a speed half that of the Scanner, thereby keeping

constant the optical path length between the original and the CCD Board.

Scanner Motor M5

2nd/3rd Mirrors Carriage

CCD Board PWB-J

Scanner

4021M014AB

M-16

Page 33

10-4. Scanner Motor Drive Control

• The speed at which the Scanner is moved is controlled by varying the period of the motor

drive pulse that is timed with the reference clock.

High Speed

Low Speed

Period

• The distance over which the Scanner travels is controlled by the number of motor drive

pulses that correspond to each paper size and zoom ratio.

Elevtrical Component Control Signal ON OFF Wiring Diagram

M5 PWB-C JP5C-1 to 4 Pulse output 11-B

M-17

Page 34

11. MEMORY STORAGE IMAGE PROCESSING SYSTEM

• Based on the image data output from the IR, a laser light is projected onto the surface of

the PC Drum to form a corresponding latent image.

PH Unit

4021M015AA

M-18

Page 35

11-1. Laser Exposure Process

1. The Start key is pressed.

2. The laser diode is forced to turn ON and the laser intensity is automatically adjusted.

3. The SOS Sensor Board is illuminated by the laser beam, which generates an SOS sig-

nal.

4. The SOS signal determines the laser emission timing for each main scanning line.

5. The surface of the PC Drum is illuminated by the laser beam corresponding to the

image data, which forms an electrostatic latent image.

Polygon Motor M2

LD Board PWB-B

SOS Mirror

PC Drum

SOS Board

PC Drum

SOS Mirror

DCBA

SOS

Sensor

4021M016AA

SOS Signal

1171M038AA

A to B: LD activation

B to C: LD OFF

C to D: Laser beam exposure area according to the image data

Elevtrical Component Control Signal ON OFF Wiring Diagram

M2 PWB-A PJ13A-3 L H 8-D

M-19

Page 36

12. DEVELOPING UNIT SECTION

The Developing Unit agitates and triboelectrically charges toner so that it sticks to the electrostatic latent image formed on the surface of the PC Drum, then changing the image to a

visible, developed one.

1

14

13

1. Spent Toner Recycling Coil

2. PC Drum Charge Corona

3. Spent Toner Conveying Screw 2

4. Cleaning Blade

5. Spent Toner Conveying Screw 1

6. PC Drum Paper Separator Finger

7. PC Drum Protective Shutter

12

3

2

11

10

8. PC Drum

9. Sleeve/Magnet Roller

10. 1st Toner Conveying Roller

11. ATDC Sensor UN1

12. 2nd Toner Conveying Roller

13. 3rd Toner Conveying Roller

14. Spent Toner Recycling Duct

4

5

6

7

8

4021M017AA

9

M-20

Page 37

12-1. Developing Unit Drive Mechanism

The rollers are driven through a gear train from the motor.

Sleeve/Magnet Roller

Main Motor M1

1st Toner Conveying Roller

2nd Toner Conveying Roller

4021M008AB

Elevtrical Component Control Signal

M1

PWB-A PJ7A-5 L H

PWB-A PJ7A-7 H H

Forward

Rotation

3rd Toner Conveying Roller

OFF Wiring Diagram

17-G

M-21

Page 38

12-2. Sleeve/Magnet Roller

• The Sleeve/Magnet Roller, which consists of an outer sleeve roller and an inner magnet

roller, conveys developer to the point of development.

• The magnetic force of the magnet roller at the point of development is the strongest so

that the developer brush stands straight up to deliver the greatest amount of toner to the

point of development.

Sleeve/Magnet Roller

PC Drum

Sleeve/Magnet Roller

1171M027AA

4021M062AA

1st Toner Conveying Roller

12-3. Developing Bias

• Vb (-DC, AC) is applied to the Sleeve/Magnet Roller.

• Vb (-DC) is applied to prevent toner from sticking to the background of the image.

• Vb (AC) is applied to enhance good separation of toner from carrier.

• The amount of toner sticking to the surface of the PC Drum is varied according to the difference in potential between the voltage (Vi) on the surface of the PC Drum and

Vb (-DC).

✽

Large difference = A greater amount of toner sticks.

✽

Small difference = A smaller amount of toner sticks.

PC Drum

Sleeve/Magnet Roller

Elevtrical Component Control Signal ON OFF Wiring Diagram

Vb (-DC) PWB-A PJ8A-9 L H

Vb (AC) PWB-A PJ8A-10 L H

Developing Bias Terminal

4021M018AB

6-B

M-22

Page 39

12-4. ATDC Sensor

The ATDC Sensor detects the toner-to-carrier ratio (T/C) of the developer in the Developer

Mixing Chamber.

2nd Toner Conveying Roller

ATDC Sensor UN1

4021M019AA

(1) ATDC Sensor Automatic Adjustment

The reference value for the ATDC Sensor is automatically adjusted as detailed below using

the ATDC Sensor Automatic Adjustment mode.

With the copier set in the ATDC Sensor Automatic Adjustment mode, press the Start key.

The developer is mixed.

The ATDC Sensor converts the reference T/C (14 %) to a corresponding voltage

value and outputs it.

Does the output voltage fall within the range from 2.36 to 2.44 V?

YES NO

The voltage input to the ATDC Sensor from the

Master Board at this time is fixed as the reference

voltage.

The voltage input to the ATDC Sensor from

the Master Board is varied.

2.45 V or more: Decrease the voltage.

2.35 V or less: Increase the voltage.

M-23

Page 40

12-5. Toner Replenishing Mechanism

• Toner is supplied from the Toner Bott le to the Developer Mixing Chamber.

1. The coupling is turned by the motor, which turns the Toner Bottle.

2. To regulate the amount of toner supplied from the Toner Bottle, there is a Metering

Chamber provided in the outer race of the coupling.

3. When the Toner Bottle turns, toner in the Metering Chamber drops.

4. Toner from the metering chamber is conveyed by the Toner Conveying Screw into the

Developer Mixing Chamber.

5. The Toner Conveying Screw is turned by the motor.

coupling

4021M022AA

Toner Bottle

Metering

Chamber

4021M020AB 4021M021AB

Toner Conveying Screw

Developer Mixing Chamber

Elevtrical Component Control Signal ON OFF Wiring Diagram

M6 PWB-A PJ19A-6 L H 4-B

4021M023AA

M-24

Page 41

12-6. Toner Replenishing Control

• Replenishing of the supply of toner is determined based on the T/C ratio and B/W ratio.

• If T/C is 14 % or more, toner replenishing is not carried out regardless of the B/W value.

• If T/C is less than 14 %, toner replenishing is determined according to the B/W value.

• Toner is replenished until T/C becomes 14 %.

T/C ratio (%) B/W ratio toner replenishing

More than 14 — not supply

13.5 to 14 More than 2000 supply

13 to 13.5 More than 1000 supply

12.5 to 13 More than 500 supply

12 to 12.5 More than 500 supply

10 to 12 More than 0 supply

Less than 7 Proceeds to the T/C recovery mode

✽

The greater the value of B/W in the table, the higher the B/W ratio (high image density

original).

M-25

Page 42

12-7. T/C Recovery Mode

The machine enters the T/C recover mode when a T/C of 10 % or less is detected.

Toner is replenished for 90 sec.

T/C is recovered by 1 % or more. T/C is not recovered by 1 % or more, or T/C

Toner is replenished for 60 sec.

T/C is recovered by 2 % or more, or is 12 % or more. T/C is not recovered by 2 % or

Toner is replenished for 30 sec. to complete the A toner-empty condition is detected.

T/C recovery mode.

A toner-empty-stop condition results and the initiation

of any new copy cycle is prohibited.

✽

A toner-empty condition is reset when the Front Cover is opened and closed after a T/C

of 10 % or more is detected with the supply of toner replenished.

✽

A toner-empty-stop condition is reset when the Front Cover is opened and closed after a

T/C of 8 % or more is detected with the supply of toner replenished. A toner-empty condition results, howev er, if T/C falls within the range between 8 % and 10 % when the Front

Cover is opened and closed.

is less than 12 %.

more, or T/C is less than 12 %.

T/C is less than 8 %.

M-26

Page 43

12-8. Toner Bottle Home Position Detection Mechanism

• The Toner Bottle is at its home position (where it remains stationary) when its Toner Supply Port faces up. This position is detected by a sensor.

Toner Bottle Home Position Sensor PC7

Toner Supply Port

4021M024AA

Elevtrical Component Control Signal Activated Deactivated Wiring Diagram

PC7 PWB-A PJ19A-10 L H 4-B

M-27

Page 44

13. PAPER TAKE UP/FEED SECTION

1

2

1. Paper Size Detecting Board PWB-I

2. Paper Size Detecting Sensor S11

3. Paper Empty Sensor PC4

3

4

5

6

4021M025AA

4. Paper Take-Up Roll

5. Separator Roll

6. Paper Lifting Plate

M-28

Page 45

13-1. Drawer In Position Detection

• When the drawer is slid into the copier, the light blocking plate blocks the Set Sensor.

The copier then knows that the drawer has been slid in position.

Drawer Set Sensor PC5

Elevtrical Component Control Signal Activated Deactivated Wiring Diagram

PC5 PWB-A PJ15A-10 L H 1-I

4021M026AA

13-2. Paper Empty Detection Mechanism

• The Paper Empty Sensor detects a paper-empty condition in the drawer.

Paper Empty Sensor PC4

1167M073AD

Elevtrical Component Control Signal Activated Deactivated Wiring Diagram

PC4 PWB -A PJ6A-6 L H 1-I

M-29

Page 46

13-3. Paper Lifting Plate

• The Paper Lifting Plate is locked into position when it is pressed down. It is unlocked

when the tray is slid into the unit.

• The Paper Lifting Plate is pushed upward by the Paper Lifting Springs at all times.

Paper Lifting Plate

Spring

4021M063AA

13-4. Universal Tray Paper Size Detection Mechanism

• Both the width (in the crosswise direction) and length (in the feeding direction) of the

paper are detected and the copier CPU determines the paper size based on the combination of the two readings.

• The width (CD) of the paper is detected when the lever that is operatively connected to

the Edge Guide activates or deactivates the Paper Size (CD) Detection Sensor.

• The length (FD) of the paper is detected when the lever that is operatively connected to

the Trailing Edge Stop actuates or deactuates the switches on the Paper Size (FD)

Detection Board.

Paper Size Detecting Board PWB-I

Paper Size Detecting Sensor S11

12 34

4011M009AA

M-30

Page 47

Paper Size Detecting Board

PWB-I

SW1 SW2 SW3 SW4

— — — — — B4L, 8-1/2 × 14

— — — — Activated 11 × 14

— — — ON Activated A3L, 11 × 17

— — ON ON — A5L, 5-1/2 × 8-1/2 L

— — ON ON Activated A4C, 8-1/2 × 11 C

— ON — — — A5C, 5-1/2 × 8-1/2 C

— O N ON ON — A5L, 5-1/2 × 8-1/2 L

— ON ON ON Activated A4C, 8-1/2 × 11 C

ON — — — — FLS

ON ON — — — FLS

ON ON ON ON — A4L, 8-1/2 × 11 L

Elevtrical Component Control Signal ON OFF Wiring Diagram

PWB-I SW1 PWB- A PJ15A-1 L H

PWB-I SW2 PWB- A PJ15A-2 L H

PWB-I SW3 PWB- A PJ15A-3 L H

PWB-I SW4 PWB- A PJ15A-4 L H

Elevtrical Component Control Signal Activated Deactivated Wiring Diagram

S11 PWB-A PJ15A-7 H L 1-H

Paper Size Detecting

Sensor S11

Paper Size

2-H

M-31

Page 48

13-5. Paper Take Up Mechanism

• Drive for the paper take-up sequence is transmitted via t he P aper Take-Up Solenoid from

a motor.

Main Motor M1

Paper Take-Up Roll

Paper Take-Up Solenoid SL1

(1) Paper Separating Mechanism

• The coefficient of friction between the Paper Take-Up Roll and Separator Roll is effectively used to prevent double feed of paper.

When one sheet of paper is taken up:The coefficient of friction on the front side of the

When two or more sheets of paper are taken up:The coefficient of friction between the

Paper Take-Up Roll

sheet of paper taken up and fed through the space

between the Paper Take-Up Roll and Separator Roll

is the same as that on the backside of the sheet of

paper, allowing the paper to be properly fed into the

machine.

paper and the Separator Roll is greater

than that between the sheets of paper,

which allows only the top sheet of paper to

be fed into the machine.

Paper

Separator Roll

4021M060AB

4021M027AA

M-32

Page 49

13-6. Paper Take Up Control

Start Key ON

Main Motor M1

Paper Take-Up

Solenoid SL1

Synchronizing Roller

Sensor PC1

Elevtrical Component Control Signal

M1

Elevtrical Component Control Signal ON OFF Wiring Diagram

SL1 PWB-A PJ5A-2 L H 1-I

Elevtrical Component Control Signal Activated Deactivated Wiring Diagram

PC1 PWB -A PJ6A-3 L H 1-F

(1) Paper Take Up Retry Control

• To minimize the occurrence of a paper misfeed, the paper take-up sequence is temporarily halted if the paper fails to reach the Synchronizing Roller Sensor within a given

period of time after the sequence has been started. The paper take-up sequence is then

performed again. These paper take-up sequences are repeated a given number of times.

ON

OFF

ON

OFF

H

L

Forward

Rotation

PWB-A PJ7A-5 L H

PWB-A PJ7A-7 H H

4021M515CA

OFF Wiring Diagram

17-G

Paper Take-Up Retry 2

Paper Take-Up

Solenoid SL1

Synchronizing Roller

Sensor PC1

ON

OFF

H

L

M-33

No. of Paper Take-Up

Retry Sequences

1st Paper Take-Up

Retry Sequence

Successful paper take-up

4021M514CA

Page 50

14. MANUAL BYPASS SECTION

14-1. Paper Take Up Drive Mechanism

• Drive for paper take-up from the Manual Bypass is transmitted from a motor via the Solenoid.

Main Motor M1

Manual Feed Paper Sensor PC2

Manual Bypass Solenoid SL2

4021M028AA

14-2. Paper Detection Mechanism

• The Sensor detects a sheet of paper on the Manual Bypass.

<When Paper is not Present><When Paper is Present>

Manual Feed Paper Sensor PC2

Paper

M-34

4021M029AA4021M061AA

Page 51

14-3. Manual Feed Take Up Control

Paper Set

Manual Feed

Paper Sensor PC2

Main Motor M1

Manual Bypass

Solenoid SL2

Elevtrical Component Control Signal

M1

Elevtrical Component Control Signal ON OFF Wiring Diagram

SL2 PWB-A PJ4A-2 L H 1-B

Elevtrical Component Control Signal Activated Deactivated Wiring Diagram

PC2 PWB -A PJ4A-5 L H 1-A

H

L

ON

OFF

ON

OFF

Paper drawing-in sequence completed

PWB-A PJ7A-5 L H

PWB-A PJ7A-7 H H

Start Key ON

Forward

Rotation

4021M511CA

OFF Wiring Diagram

17-G

M-35

Page 52

15. MULTIPLE BYPASS SECTION

1

2

4021M031AA

1. Paper Take-Up Roll

2. Multiple Bypass Solenoid SL21

3

3. Multiple Bypass Paper Empty Sensor

PC21

15-1. Paper Take Up Drive Mechanism

• Drive for paper take-up from the Multiple Bypass is transmitted from a motor via the Solenoid.

Main Motor M1

Multiple Bypass Solenoid SL21

Paper Take-Up Roll

4021M032AA

Multiple Bypass Paper Empty Sensor PC21

M-36

Page 53

15-2. Paper Take-Up Mechanism

• The Paper Lifting Plate is raised to press the paper stack on the tray up against the

Paper Take-Up Roll.

• The Paper Lifting Plate is raised and lowered in time with a paper take-up sequence.

• The ascent and descent motion of the P aper Li fting Plate is accomplished when the drive

from the motor is transmitted to the cam through a solenoid to rotate the cam.

Drive from Main Motor

Paper Take-Up Roll

Cam

<Ascent/Descent Motion>

Main Motor (M1) is energized.

Paper Take-Up Roll is turned.

Multiple Bypass Solenoid (SL21): Energized

Cam: Rotates

Tray: Raised

Multiple Bypass Solenoid (SL21): Deenergized

Multiple Bypass Solenoid SL21

4021M033AA

Paper Take-Up Roll

Cam

Paper

Tray

Paper take-up

Multiple Bypass Solenoid (SL21): Energized

Cam: Rotates

Tray: Lower ed

Multiple Bypass Solenoid (SL21): Deenergized

M-37

4021M059AA

Page 54

15-3. Paper Empty Detection Mechanism

• The Paper Empty Sensor detects a sheet of paper on the Multiple Bypass.

<When Paper is not Present><When Paper is Present>

Multiple Bypass Paper Empty Sensor PC21

Paper

4021M034AA

4021M035AA

15-4. Paper Take Up Control

Paper Set Start Key ON

ON

OFF

ON

OFF

H

L

4021M512CA

Forward

Rotation

OFF Wiring Diagram

17-G

Multiple Bypass Paper

Empty Sensor PC21

Main Motor M1

Multiple Bypass Solenoid

SL21

Elevtrical Component Control Signal

M1

Elevtrical Component Control Signal ON OFF Wiring Diagram

SL21 PWB-A PJ4A-2 L H 17-F

Elevtrical Component Control Signal Activated Deactivated Wiring Diagram

PC21 PWB-A PJ4A-5 L H 17-F

PWB-A PJ7A-5 L H

PWB-A PJ7A-7 H H

M-38

Page 55

15-5. Paper Take Up Retry Control

• To minimize the occurrence of a paper misfeed, the paper take-up sequence is temporarily halted if the paper fails to reach the Synchronizing Roller Sensor within a given

period of time after the sequence has been started. The paper take-up sequence is then

performed again. These paper take-up sequences are repeated a given number of times.

No. of Paper Take-Up

Retry Sequences

Paper Take-Up Retry 2

1st Paper Take-Up

Retry Sequence

Multiple Bypass

Solenoid SL21

Synchronizing

Roller Sensor PC1

ON

OFF

H

L

Successful paper take-up

4021M516CA

M-39

Page 56

16. IMAGE TRANSFER AND PAPER SEPARATION SEC-

TION

✽

Image Transfer

• A positive charge is applied to the Image Transfer Roller to transfer the toner image

formed on the surface of the PC Drum onto the paper.

• The charge applied to the Image Transfer Roller is varied according to the following conditions to ensure that image transfer efficiency is stabilized.

Paper Type: The amount of charge is made less for OHP transparencies.

Paper width: The greater the paper width, the more the amount of charge.

B/W ratio of the image: The higher the B/W ratio, the more the amount of charge.

• A negative charge is applied to the Image Transfer Roller to return toner sticking to the

Image Transfer Roller to the PC Drum. It is performed in the following timings:

• A copy cycle is started and completed, The Power Switch is turned ON, A misfeed or a

malfunction is reset.

✽

Paper Separation

• The PC Drum Paper Separator Fingers mechanically separate paper from the surface of

the PC Drum to ensure good and positive paper separation.

• The Charge Neutralizing Plate is used to neutralize any charge left on the paper , to which

image has been transferred, thereby preventing discharge noise that occurs when paper

is separated.

PC Drum Paper Separator Fingers

PC Drum

Charge Neutralizing Plate

4021M037AA

Image Transfer Roller

Elevtrical Component Control Signal ON OFF Wiring Diagram

HV1 PWB-A PJ8A-8 L H 6-C

M-40

Page 57

17. PC DRUM CLEANING SECTION

• The Cleaning Blade is used to scrape residual toner off the surface of the PC Drum.

• The spent toner is conveyed through the Recycling Duct and eventually back to the

Developer Mixing Chamber.

• To prevent paper dust from being compacted on the edge of the Cleaning Blade, the PC

Drum is turned backward (by turning the Main Motor backward) when the cumulative

time through which the PC Drum has turned reaches a predetermined value. When the

PC Drum is turned backward, a backlash in gears prevents drive from being transmitted

to other drive mechanisms.

Cumulative Time Through Which PC Drum

Has Been Driven

Approx. 330 sec 50 ms

PC Drum

4021M039AA

Spent Toner Recycling Coil

Spent Toner Recycling Duct

Cleaning Blade

PC Drum Backward

Rotation Time

Spent Toner Conveying Screw 1

Spent Toner Conveying Screw 2

M-41

4021M038AB

Page 58

18. MAIN ERASE SECTION

• Any potential remaining on the surface of the PC Drum is neutralized by both light from

the Main Erase and a negative voltage applied by the Charge Neutralizing Sheet.

• A negative charge is applied to the Charge Neutralizing Sheet to neutralize a positive

charge on the surface of the PC Drum. The Main Erase then illuminates the surface of

the PC Drum to neutralize the charge left on it.

Main Erase LA1

Charge Neutralizing Sheet

PC Drum

4021M040AA

Elevtrical Component Control Signal ON OFF Wiring Diagram

LA1 PWB-A PJ7A-12 L H 4-A

M-42

Page 59

19. FUSING UNIT SECTION

• The Fusing Unit fixes permanently the developed image to the paper by applying heat

and pressure to the toner and paper.

1

10

9

8

1. Paper Exit Roller

2. Transport Roller

3. Fusing Paper Separator Finger

4. Exit Paper Sensor PC3

5. Right Fusing Roller

2

3

7

6. Pressure Spring

7. Fusing Heater Lamp H1

8. Thermistor TH1

9. Thermoswitch TS1

10. Left Fusing Roller

4

5

4021M041AD

6

M-43

Page 60

19-1. Fusing Unit Drive Mechanism

• The Fusing Unit is driven by a motor.

Left Fusing Roller

Main Motor M1

Right Fusing Roller

4021M042AA

19-2. Fusing Rollers Pressure Mechanism

• To ensure that there is a certain width of area of contact between the Right and Left Fusing Rollers, a pressure spring is used to press the Lower Fusing Roller up against the

Upper Fusing Roller.

Right Fusing Roller

Left Fusing Roller

4021M043AA

Pressure Spring

M-44

Page 61

19-3. Fusing Temperature Control

• The Fusing Roller Heater Lamp is turned ON and OFF to keep a set temperature on the

surface of the Fusing Roller.

• The Fusing Roller surface temperature is detected by using a thermistor that translates

the temperature to a corresponding electrical signal.

• If the Fusing Roller temperature becomes excessively high, the Fusing Roller Heater

Lamp is shut down.

<Temperature Control in Standby State>

(˚C)

200

190

180

Warm-up completed

170

155

30 sec.

or less

Mode 1

5 min

Mode 2

1 min

Mode 3

4021M513CA

Machine Condition or Paper Type Mode 1 Mode 2 Mode 3

Standby 180 °C 180 °C → 170 °C 170 °C

Plain paper (width 251 mm or more) 190 °C 190 °C → 170 °C 170 °C

Plain paper (width 250 mm or less) 160 °C 160 °C 160 °C

Thick paper (width 251 mm or more) 210 °C 210 °C → 190 °C 190 °C

Thick paper (width 250 mm or less) 200 °C 200 °C → 190 °C 190 °C

OHP transparencies (width 251 mm or more) 180 °C 180 °C → 165 °C 165 °C

OHP transparencies (width 250 mm or less) 155 °C 155 °C 155 °C

Elevtrical Component Control Signal ON OFF Wiring Diagram

H1 PWB-A PJ10A-7 L H 1-D

19-4. CPM Control

• If paper of a small size (width of 250 mm or less) or thick paper is used to run a multicopy cycle, the temperature on the edges of the Fusing Rollers tends to run high, meaning that the temperature of the Fusing Rollers varies among different spots of the rollers.

• When the cumulative number of copies made through continuous copy cycles* exceeds

30, the paper take-up interval is made longer, thereby allowing the temperatures of the

Fusing Rollers at different spots to be uniform.

✽

Continuous copy cycle: Continuous copy cycles run with an interval of 2 min. or less

between cycles.

M-45

Page 62

20. JOB TRAY (JS-202): Option

1

1. Job Tray

2. Main Board PWB-A

3. Paper Empty Sensor PC35

4. Full Detecting Sensor PC34

2

5. Upper Home Position Sensor PC32

6. Lower Home Position Sensor PC33

7. Paper Detecting Board PWB-B

8. Bin Switching Motor M1

3

4

6

5

4021M045AC

7

8

M-46

Page 63

20-1. Tray Selecting Mechanism

• Paper is fed into either the Exit Tray of the machine or the Job Tray. Either is selected

according to the application mode (fax, copier, or printer).

• The specific tray in which paper is fed is selected by a motor and a sensor.

<When feeding paper into the Exit Tray: Copier>

Upper Home Sensor PC32: Activated

Paper

(M1: Backward Rotation)

<When feeding paper into the Job Tray: fax/printer>

Lower Home Sensor PC33: Activated

Paper

Bin Switching Motor M1

4021M046AB

Job Tray

4021M047AB

Elevtrical Component Control Signal O N OFF Wiring Diagram

M1 PWB-A PJ2A-1 to 4 Pulse output 16-A

Elevtrical Component Control Signal Activated Deactivated Wiring Diagram

PC32 PWB-A PJ4A-3 L H

PC33 PWB-A PJ4A-6 L H

16-B

M-47

Page 64

20-2. Tray-Full Detecting Mechanism

• Tray-full detection is valid only when paper is fed into the Job Tray (Job Tray in the lowered position).

• A tray-full condition is detected when the sensor is block ed for a continuous given period

of time (approx. 20 sec.).

Paper

Full Detecting Sensor PC34

Exit Roller

Job Tray

4021M049AA

Elevtrical Component Control Signal Activated Deactivated Wiring Diagram

PC34 PWB-A PJ4A-9 L H 16-C

20-3. Job Tray Paper Detecting Mechanism

• If paper is fed into the Job Tray when the machine is in a mode in which paper is fed into

the Exit Tray (Job Tray in the raise position), the indicator lamp on the Paper Detecting

Board lights to warn the user that there is paper in the Job Tray.

• A sensor is provided for detecting paper in the Job Tray.

<When Paper is Present>

Paper Empty Sensor PC35

Paper Detecting

Job Tray

Paper

<When Paper is not Present>

4021M051AA

Board PWB-B

4021M050AA

4021M052AA

Elevtrical Component Control Signal Activated Deactivated Wiring Diagram

PC35 PWB-A PJ3A-3 L H 18-A

M-48

Page 65

21. SHIFTING UNIT (OT-103): Option

1

2

3

4021M053AB

1. Main Board PWB-A

2. Home Sensor S31

3. Shift Motor M1

M-49

Page 66

21-1. Exit Position Shifting Mechanism

• Paper is fed into the Shifting Unit along a straight path or shifted from the reference

straight path position. This exit position shifting mechanism allows different finishing

functions offered by the machine (Non-Sort, Sort, and Group) to be effected.

<Straight Feeding>

• The paper that travels along a straight path is fed straight into the Shifting Unit without

being shifted sideways as the Exit Roller turns.

Exit Roller

Paper

4021M054AA

<Shifted Feeding>

• When the trailing edge of the paper transported to the exit section moves past the Fusing

Roller, the Shift Motor is energized to move the Transport Roller sideways.

• The paper is fed into the Shifting Unit as it is shifted sideways.

• The Exit Roller is moved sideways by turning the motor forward or backward.

• The Exit Roller is detected at its home position by a sensor.

Shift Moto r M1

Paper

4021M055AA

Home Sensor S31

Exit Roller

4021M056AB

M-50

Page 67

Elevtrical

Component

M1 PWB-A PJ2A-1 to 4 Pulse output 16-C

Elevtrical Component Control Signal Activated Deactivated Wiring Diagram

S31 PWB-A PJ3A-3 L H 17-D

Control Signal

Forward

Rotation

Backward

Rotation

OFF Wiring Diagram

M-51

Page 68

22. OTHER MECHANISM

22-1. Cooling Mechanism

(1) Power Supply Section Cooling Mechanism

• A cooling fan motor draws air from the area around the Power Supply Unit to the outside

to prevent the Power Supply Unit temperature from running high.

• The cooling fan motor is turned at full speed when the Main Motor turns and at a speed

reduction during other timings, thereby making the machine quieter without sacrificing

cooling performance.

4021M057AA

Power Supply Cooling F an Motor M4

Elevtrical Component Control Signal ON OFF Wiring Diagram

M4 PWB-A PJ19A-1

analog voltage

output

H 11-I

M-52

Page 69

(2) Fusing Sect ion Cooling Mechanism

• A fan motor draws air from the area around the Fusing Unit to the outside to prevent the

machine interior temperature from running high. In addition, the fan motor pulls paper

being transported up through suction force to help stabilize paper transport.

• Ozone produced from the PC Drum Charge Corona is absorbed by the Ozone Filt er from

the air drawn by a fan motor to the outside.

• The fan motor is turned at full speed during a print cycle and at a speed reduction during

other timings, thereby making the machine quieter without sacrificing cooling performance.

Fusing Cooling Fan Motor M3

Ozone Filter

4021M058AB

Elevtrical Component Control Signal ON OFF Wiring Diagram

M3 PWB-A PJ10A-4

analog voltage

output

H1-C

M-53

Page 70

Service Manual [General]

Di152/Di183

Service Manual

[General]

Di152/Di183

2001 MINOLTA CO., LTD.

Copyright

Printed in Japan

Use of this manual should be strictly supervised to

avoid disclosure of confidential information.

MINOLTA Co.,Ltd.

4021-7990-11 01100500

Loading...

Loading...